Printability of Nixtamalized Corn Dough during Screw-Based Three-Dimensional Food Printing

Abstract

:1. Introduction

2. Materials and Methods

2.1. NCF

2.2. Preparation of NCD Samples

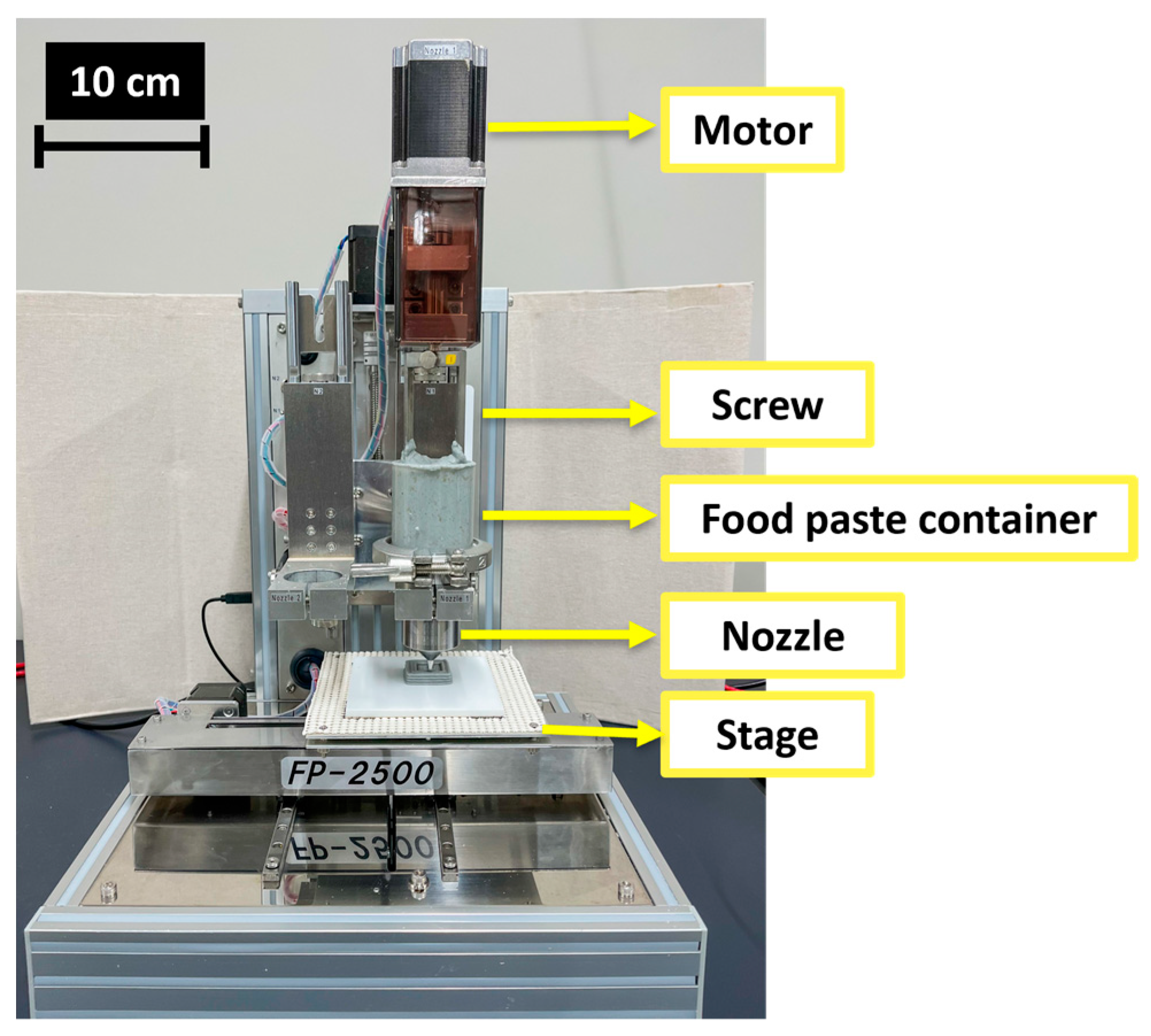

2.3. Screw-Based 3DFP

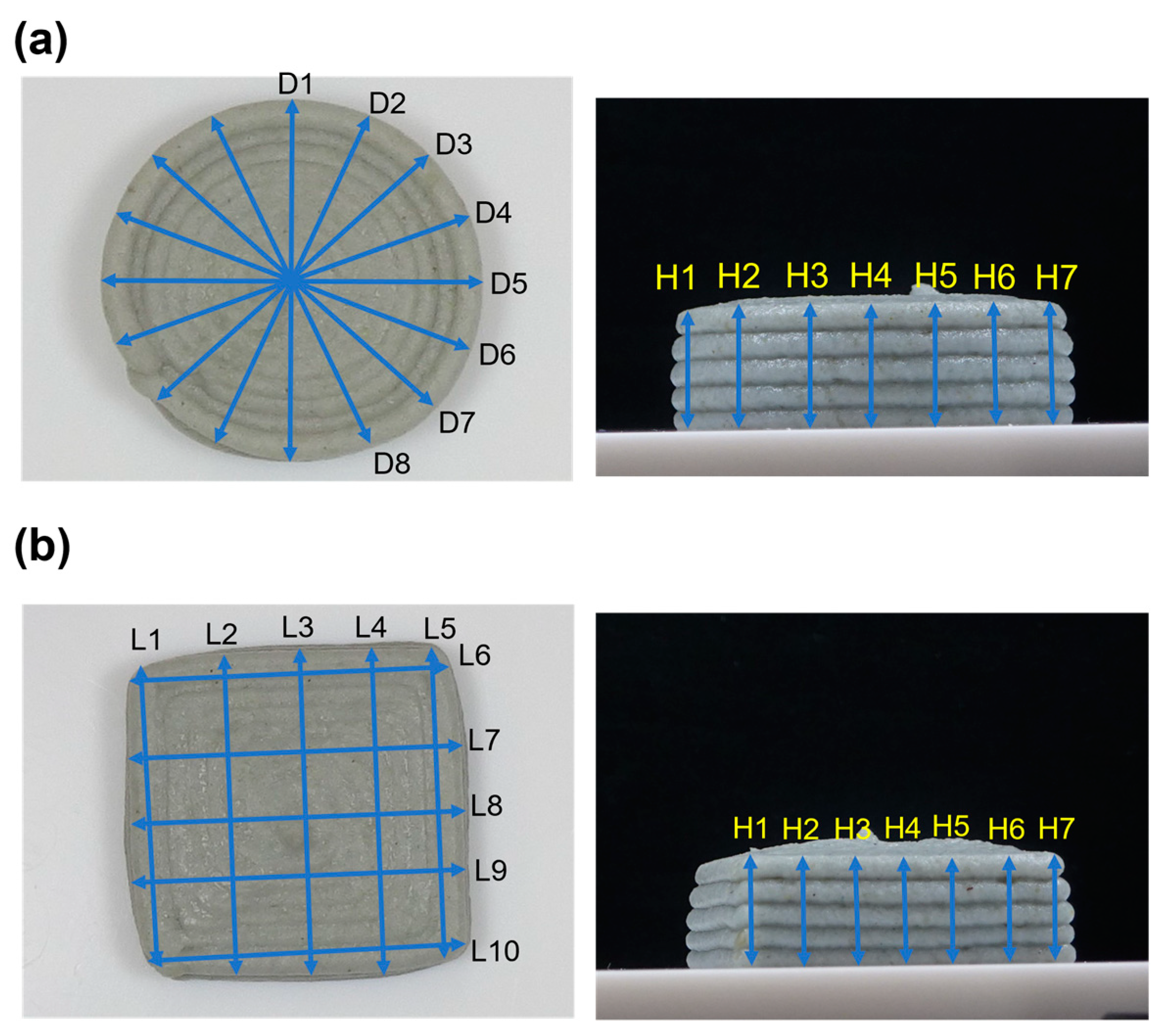

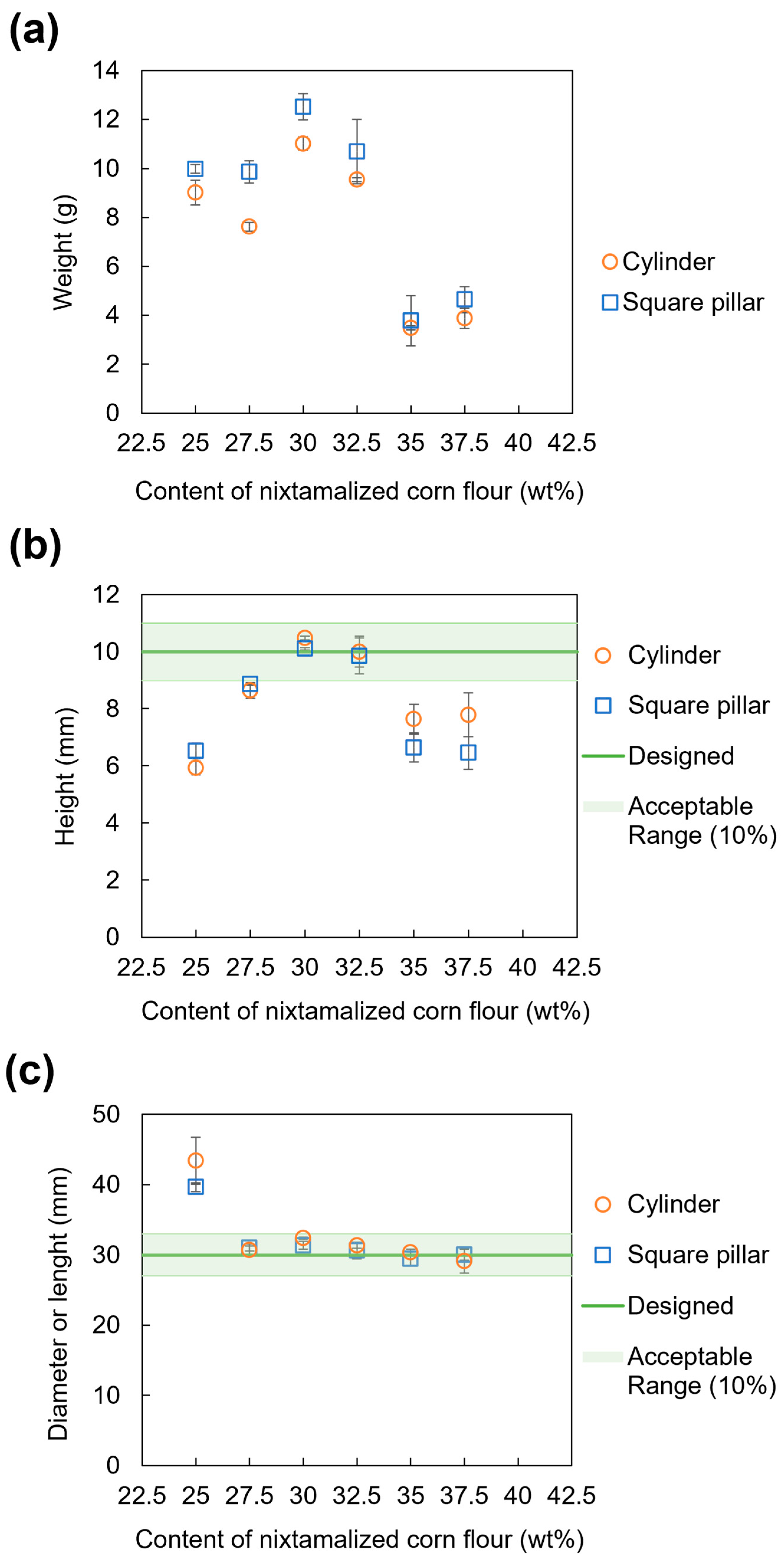

2.4. Weight and Dimensional Analysis

2.5. Rheological Analysis

2.5.1. Rotational Ramp

2.5.2. Oscillation Strain Sweep

2.5.3. Oscillation Stress Sweep

2.6. Analysis of Texture Profiles

3. Results

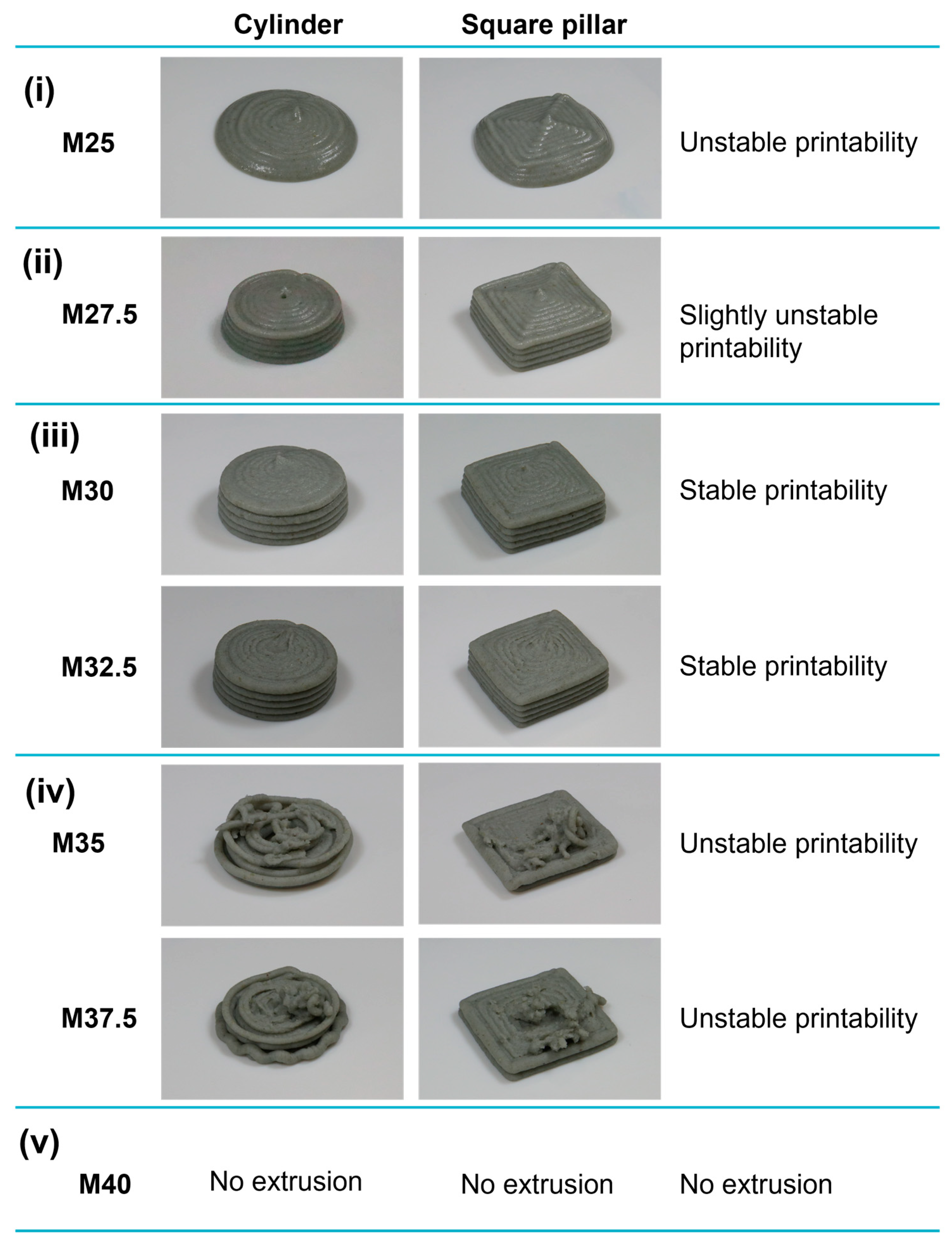

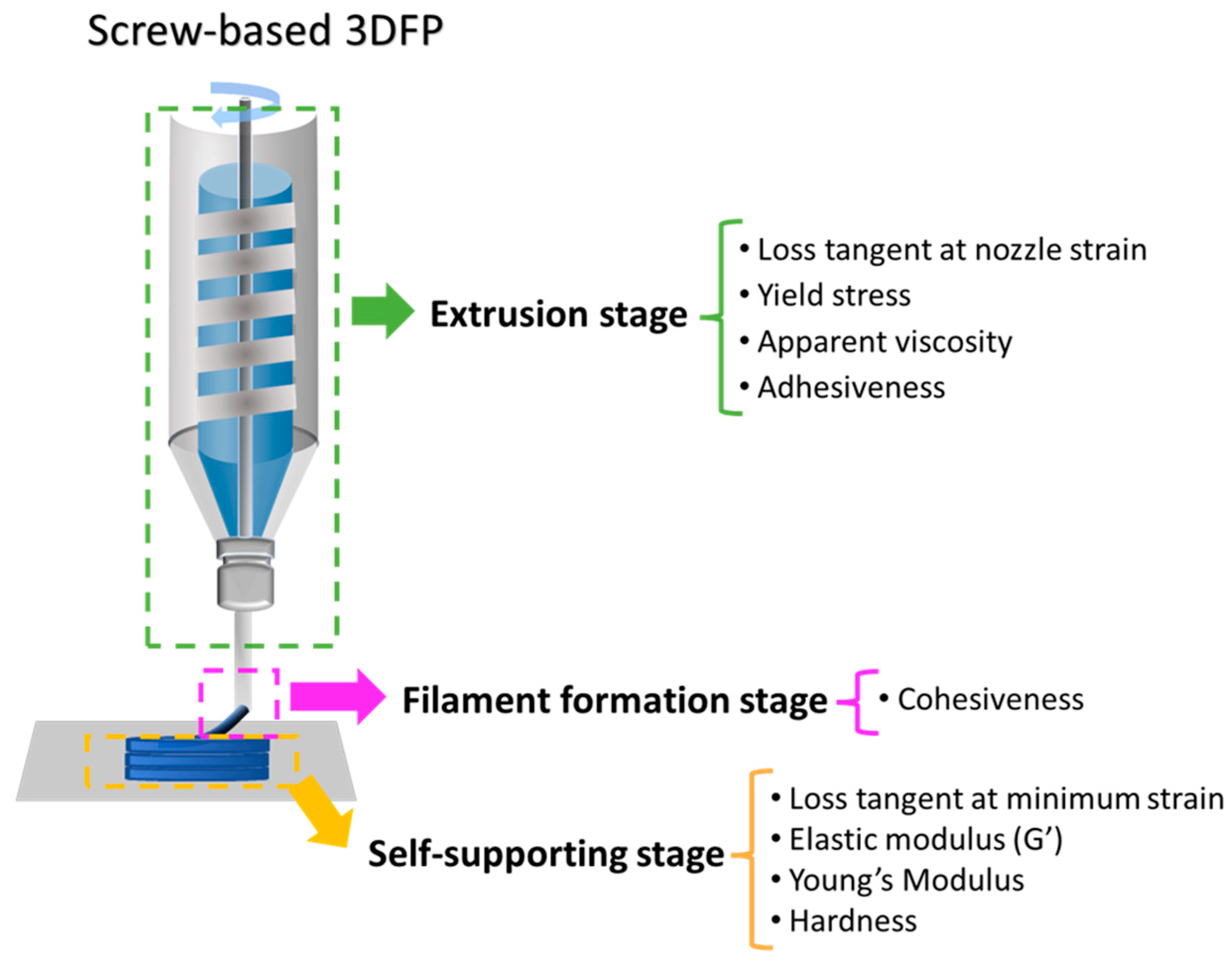

3.1. Screw-Based 3DFP

3.2. Rheological Properties

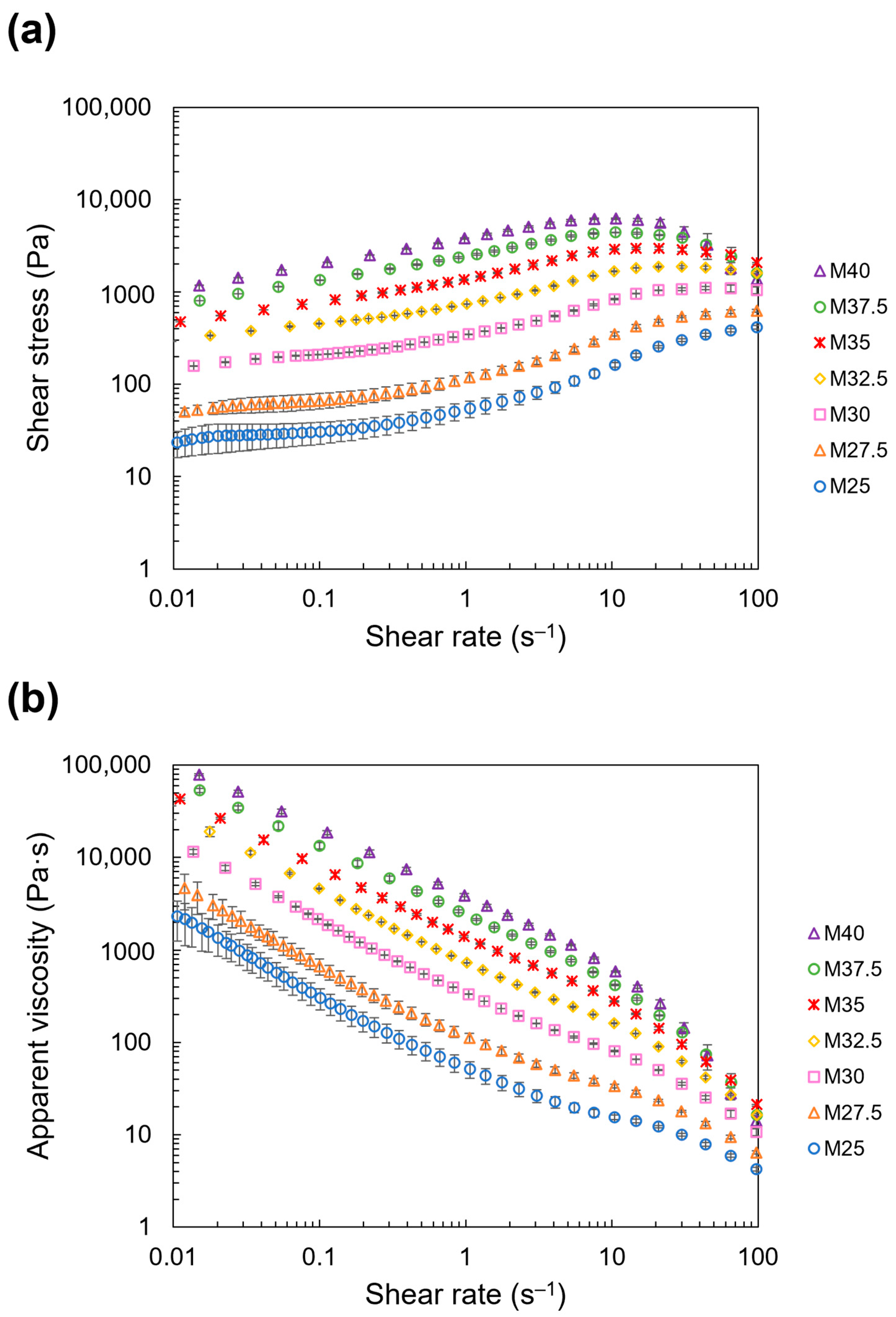

3.2.1. Flow Behavior and Apparent Viscosity

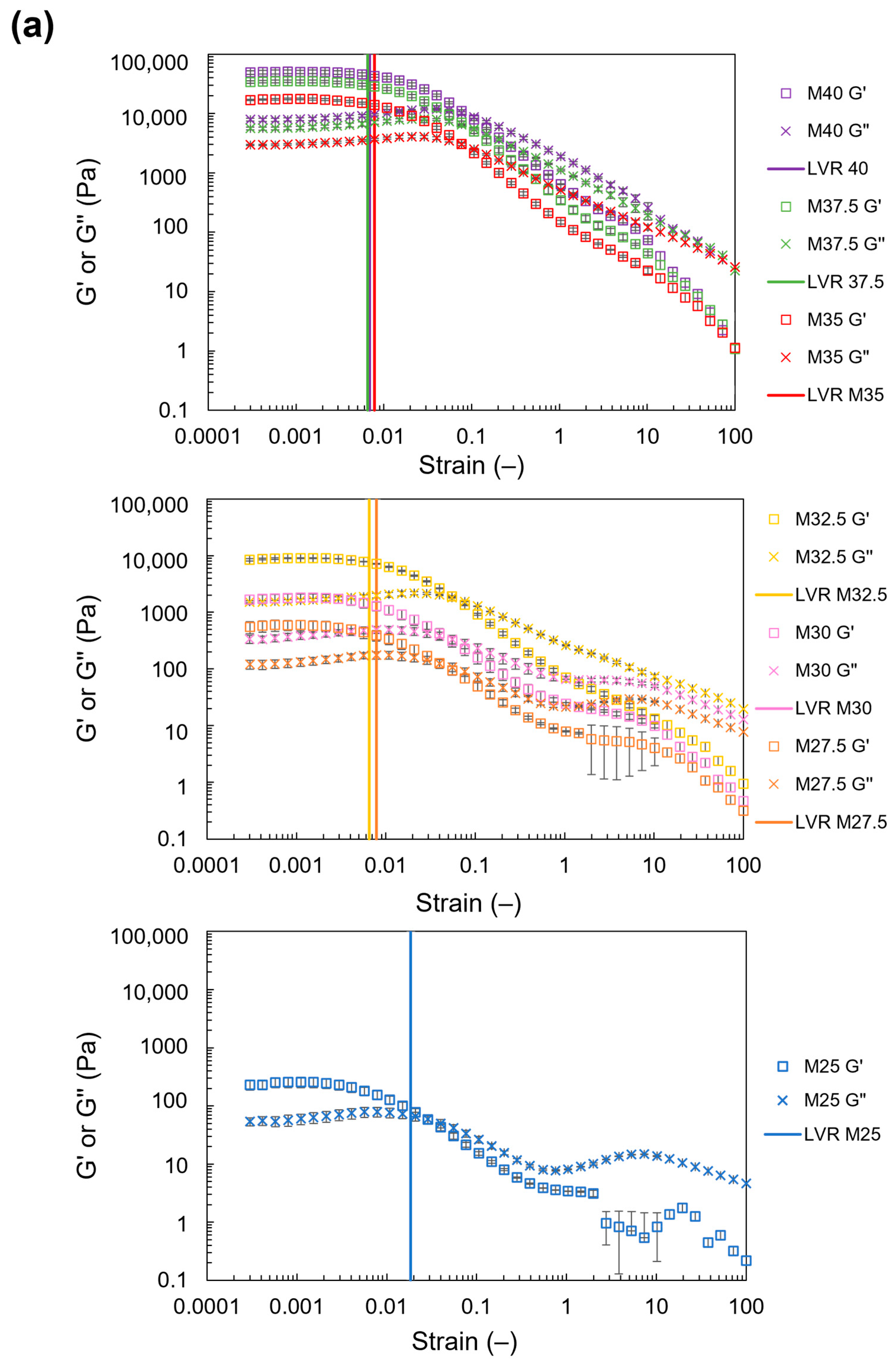

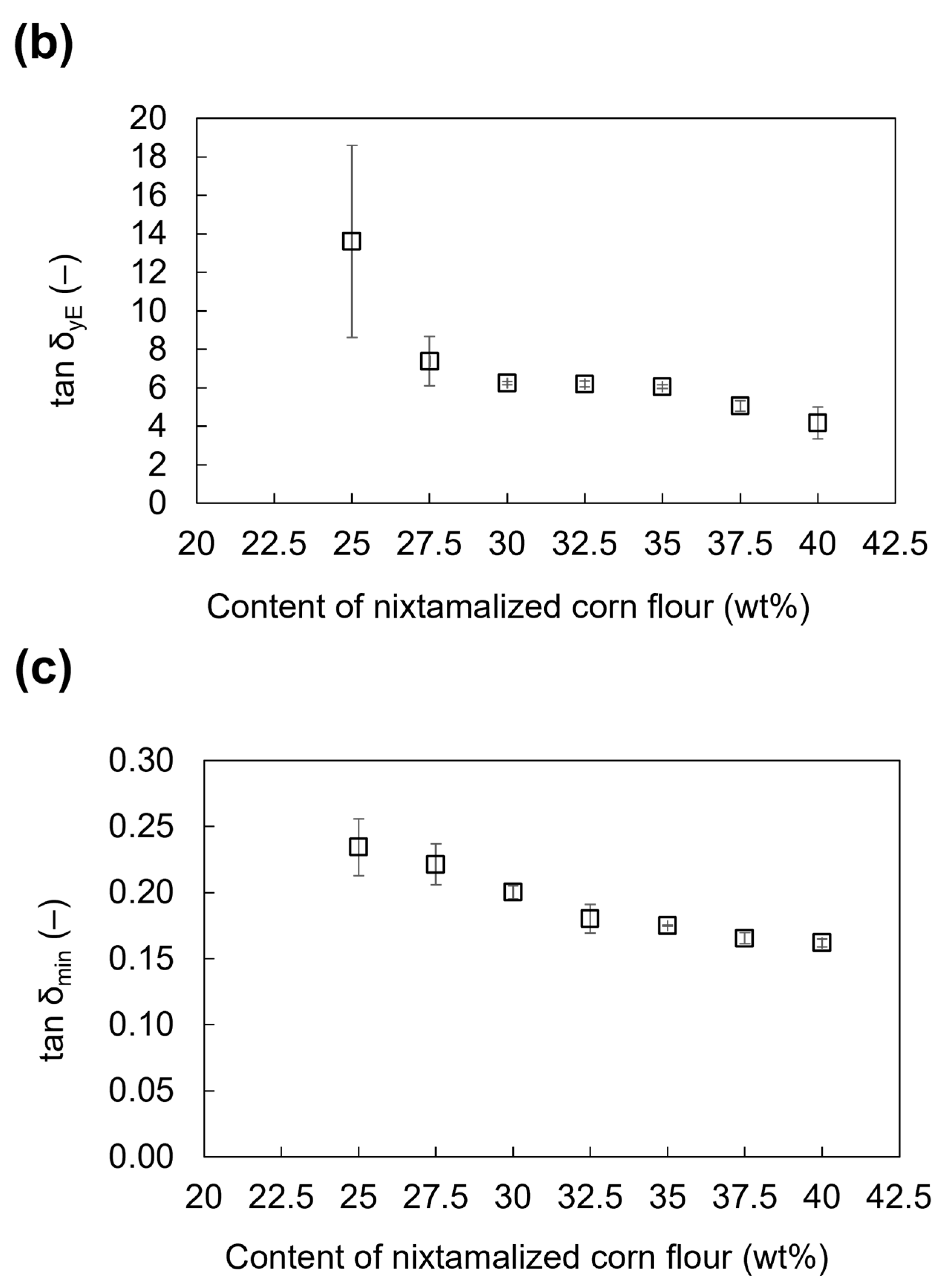

3.2.2. Elastic and Viscous Moduli

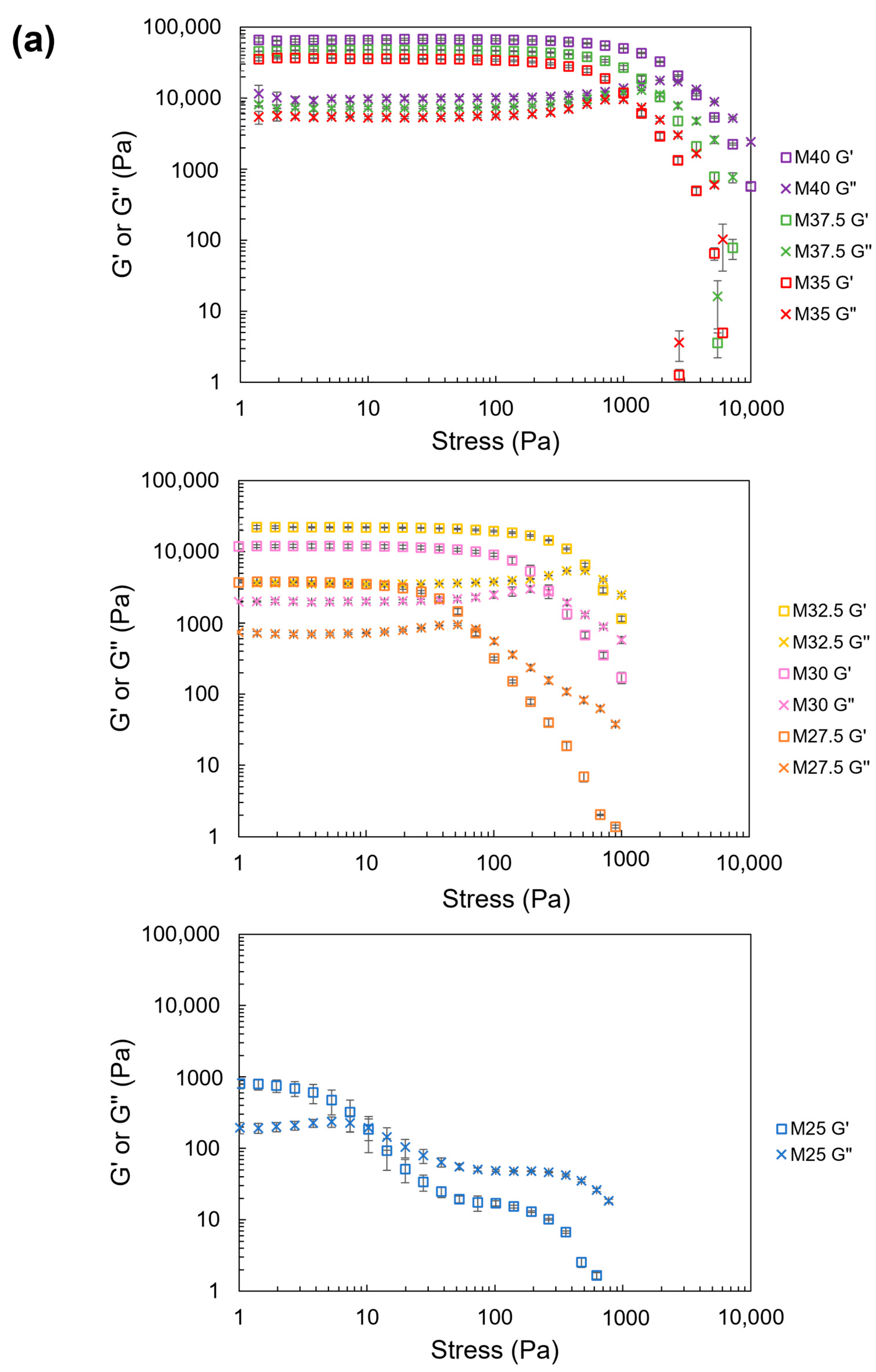

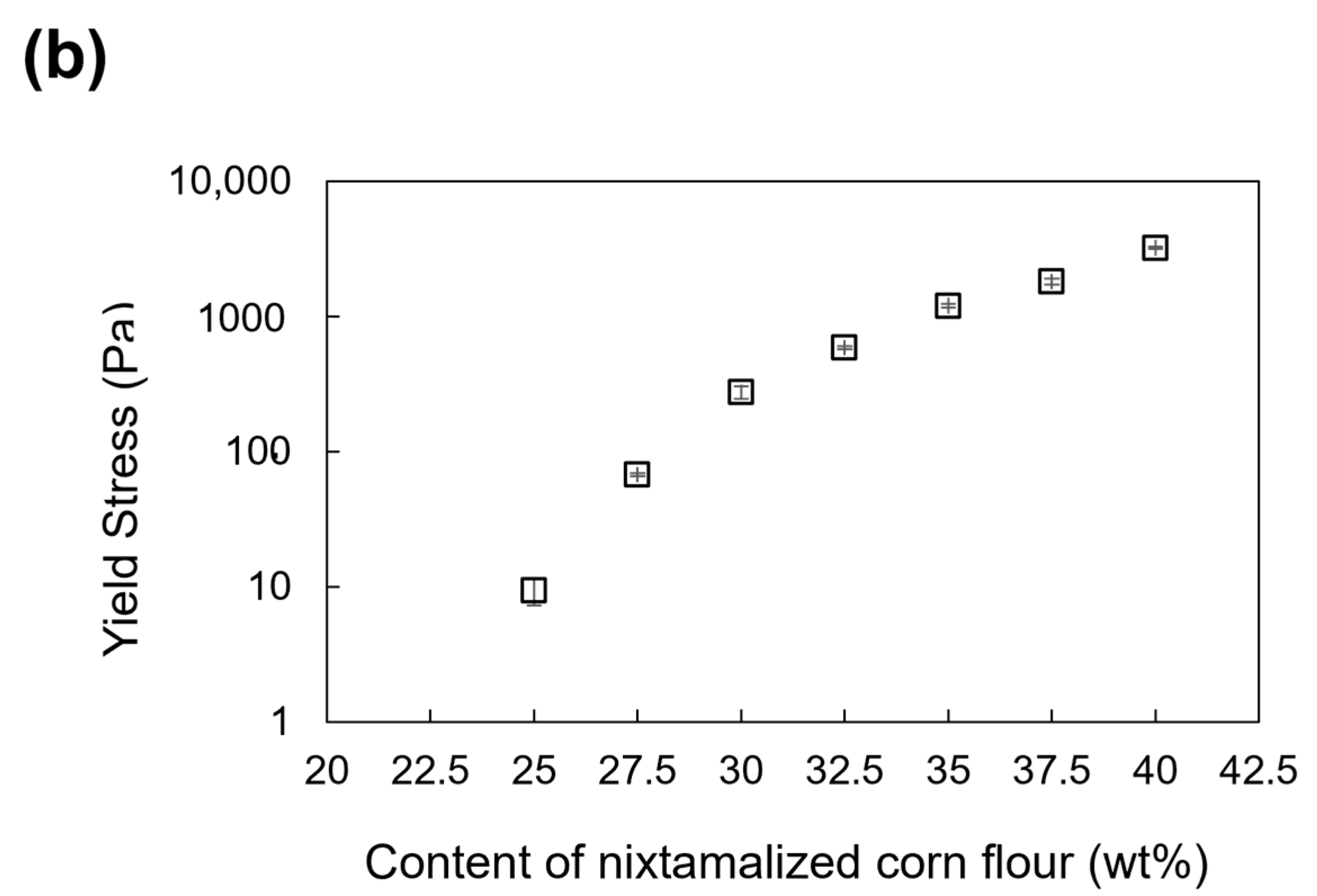

3.2.3. Loss Tangent

3.3. Texture Properties

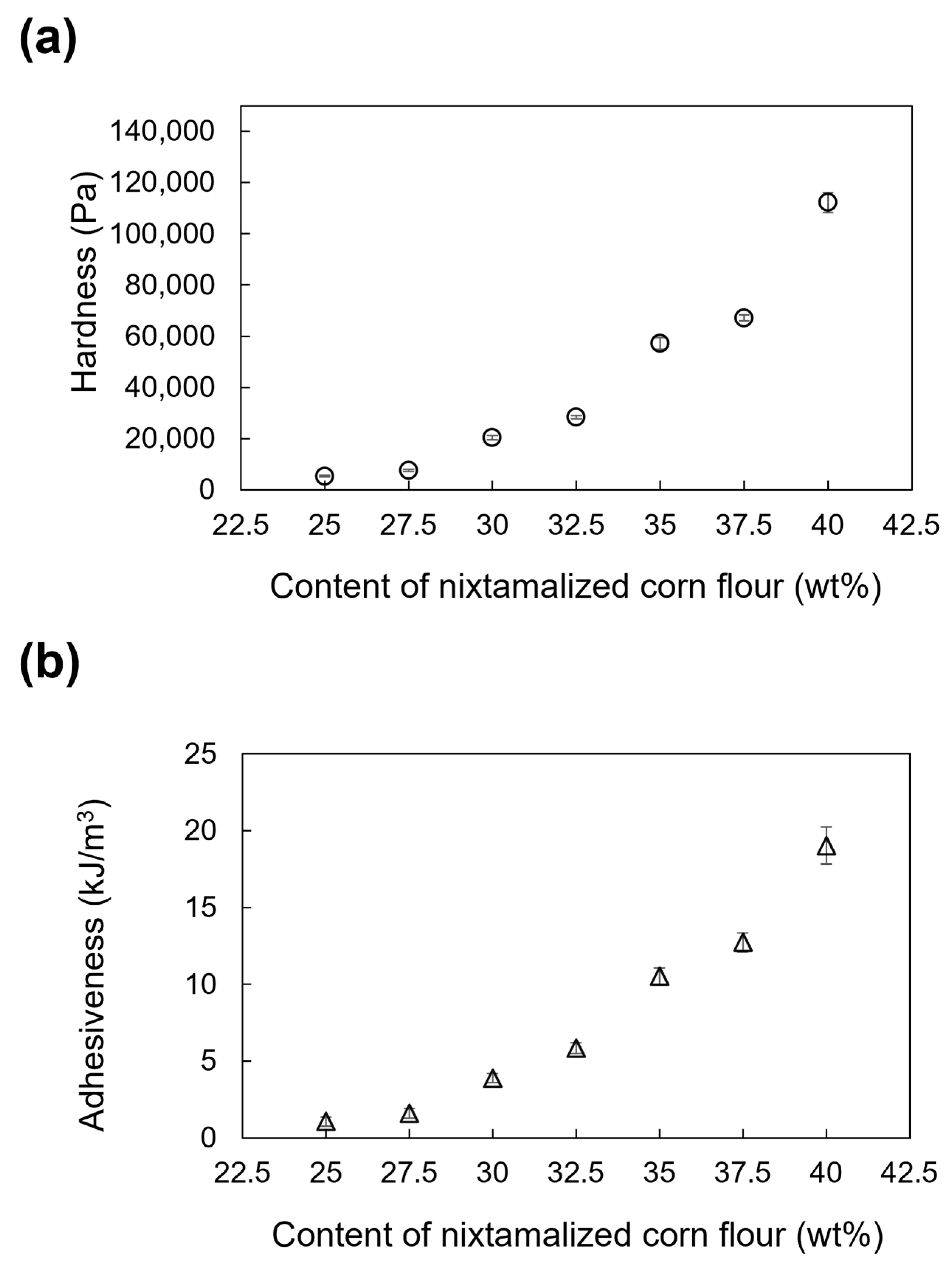

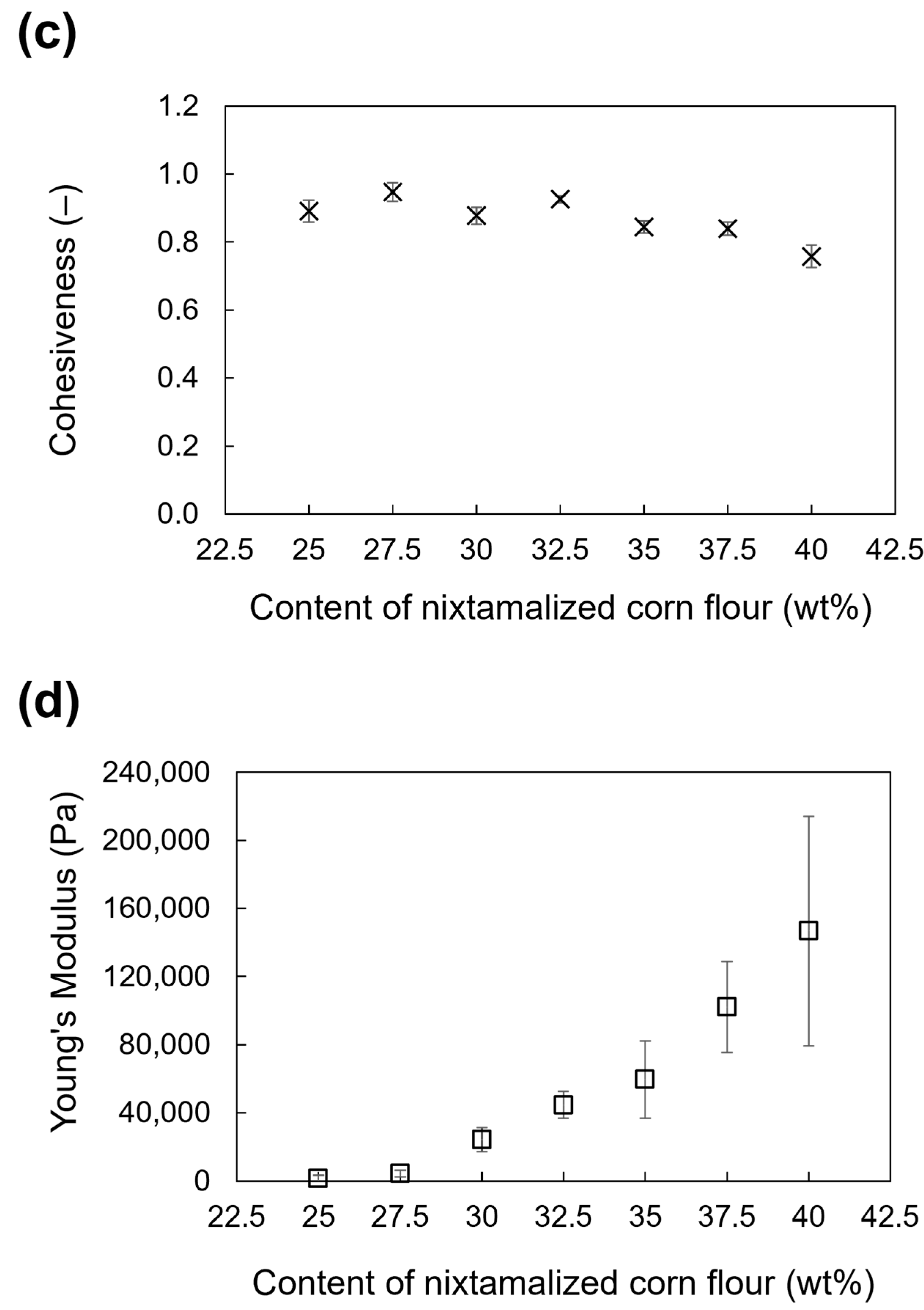

4. Discussion

4.1. Extrusion Stage

4.2. Filament Formation Stage

4.3. Self-Supporting Stage

4.4. General Discussion and Future Prospects

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gholamipour-Shirazi, A.; Kamlow, M.; Norton, I.T.; Mills, T. How to Formulate for Structure and Texture via Medium of Additive Manufacturing—A Review. Foods 2020, 9, 497. [Google Scholar] [CrossRef] [PubMed]

- Pereira, T.; Barroso, S.; Gil, M.M. Food Texture Design by 3D Printing: A Review. Foods 2021, 10, 320. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, Q.; Zhang, W.; Yang, F.; Zhao, K.; Dong, X.; Prakash, S.; Yuan, Y. Advances in the Potential Application of 3D Food Printing to Enhance Elderly Nutritional Dietary Intake. Foods 2023, 12, 1842. [Google Scholar] [CrossRef] [PubMed]

- Derossi, A.; Caporizzi, R.; Azzollini, D.; Severini, C. Application of 3D printing for customized food. A case on the development of a fruit-based snack for children. J. Food Eng. 2018, 220, 65–75. [Google Scholar] [CrossRef]

- Pant, A.; Ni Leam, P.X.; Chua, C.K.; Tan, U. Valorisation of vegetable food waste utilising three-dimensional food printing. Virtual Phys. Prototyp. 2023, 18, e2146593. [Google Scholar] [CrossRef]

- Thakur, R.; Yadav, B.K.; Goyal, N. An Insight into Recent Advancement in Plant- and Algae-Based Functional Ingredients in 3D Food Printing Ink Formulations. Food Bioprocess Technol. 2023, 16, 1919–1942. [Google Scholar] [CrossRef]

- Soares, S.; Forkes, A. Insects au gratin-an investigation into the experiences of developing a 3d printer that uses insect protein based flour as a building medium for the production of sustainable food. In E&PDE14. DS78, Proceedings of the 16th International Conference on Engineering and Product Design Education, University of Twente, Enschede, The Netherlands, 4–5 September 2014 “Design Education & Human Technology Relations”; Bohemia, E., Eger, A., Eggink, W., Kovacevic, A., Parkinson, B., Wits, W., Eds.; The Design Society: Glasgow, UK; Institution of Engineering Designers: Wiltshire, UK, 2014. [Google Scholar]

- Chen, Y.; Zhang, M.; Phuhongsung, P. 3D printing of protein-based composite fruit and vegetable gel system. LWT 2021, 141, 110978. [Google Scholar] [CrossRef]

- Lam, C.X.F.; Mo, X.M.; Teoh, S.H.; Hutmacher, D.W. Scaffold development using 3D printing with a starch-based polymer. Mater. Sci. Eng. C 2002, 20, 49–56. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M. 3D Food Printing Technologies and Factors Affecting Printing Precision. In Fundamentals of 3D Food Printing and Applications; Godoi, F.C., Bhandai, B.R., Prakash, S., Zhang, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 19–40. ISBN 9780-1281-4564-7. [Google Scholar]

- Schwab, A.; Levato, R.; D’Este, M.; Piluso, S.; Eglin, D.; Malda, J. Printability and Shape Fidelity of Bioinks in 3D Bioprinting. Chem. Rev. 2020, 120, 11028–11055. [Google Scholar] [CrossRef]

- Umeda, T.; Kozu, H.; Kobayashi, I. Analysis of Pumpkin Paste Printability for Screw-Based 3D Food Printer. Food Bioprocess Technol. 2023, 17, 188–204. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Prakash, S.; Mantihal, S.; Zhang, M. Linking rheology and printability of a multicomponent gel system of carrageenan-xanthan-starch in extrusion based additive manufacturing. Food Hydrocoll. 2019, 87, 413–424. [Google Scholar] [CrossRef]

- Figura, L.O.; Teixeira, A.A. Rheological Properties. In Food Physics: Physical Properties—Measurement and Applications; Springer: Berlin/Heidelberg, Germany, 2007; pp. 117–206. ISBN 9783-5403-4194-9. [Google Scholar]

- Bourne, M.C. Texture, Viscosity, and Food. In Food Texture and Viscosity; Academic Press: Cambridge, MA, USA, 2002; pp. 1–32. ISBN 9780-1211-9062-0. [Google Scholar]

- Tokuyasu, K.; Yamagishi, K.; Matsuki, J.; Nei, D.; Sasaki, T.; Ike, M. “Nata puree”, a novel food material for upgrading vegetable powders, made by bacterial cellulose gel disintegration in the presence of (1,3)(1,4)-β-glucan. J. Appl. Glycosci. 2021, 68, 77–87. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Optimization of chocolate 3D printing by correlating thermal and flow properties with 3D structure modeling. Innov. Food Sci. Emerg. Technol. 2017, 44, 21–29. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Prakash, S.; Liu, Y. Physical properties of 3D printed baking dough as affected by different compositions. Innov. Food Sci. Emerg. Technol. 2018, 49, 202–210. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef]

- Kim, H.W.; Lee, J.H.; Park, S.M.; Lee, M.H.; Lee, I.W.; Doh, H.S.; Park, H.J. Effect of Hydrocolloids on Rheological Properties and Printability of Vegetable Inks for 3D Food Printing. J. Food Sci. 2018, 83, 2923–2932. [Google Scholar] [CrossRef] [PubMed]

- Anukiruthika, T.; Moses, J.A.; Chinnaswamy, A. 3D printing of egg yolk and white with rice flour blends. J. Food Eng. 2019, 265, 109691. [Google Scholar] [CrossRef]

- International Maize and Wheat Improvement Center. Available online: https://www.cimmyt.org/news/what-is-nixtamalization/ (accessed on 6 November 2022).

- Arendt, E.K.; Zannini, E. Maizes. In Cereal Grains for the Food and Beverage Industries; Woodhead Publishing: Sawston, UK, 2013; pp. 67–115. ISBN 9780-8570-9413-1. [Google Scholar]

- Flores-Farías, R.; Martínez-Bustos, F.; Salinas-Moreno, Y.; Ríos, E. Caracterización de harinas comerciales de maíz nixtamalizado. Agrociencia 2002, 36, 557–567. [Google Scholar]

- Rooney, L.W.; Suhendro, E.L. Perspectives on nixtamalization (alkaline cooking) of maize for tortillas and snacks. Cereal Foods World 1999, 44, 466–470. [Google Scholar]

- Quadratín México. Available online: https://mexico.quadratin.com.mx/mexicanos-comen-75-kilos-de-tortilla-al-ano-por-cabeza/#:~:text=CIUDAD%20DE%20M%C3%89XICO%2C%2024%20de,c%C3%A1pita%20es%20de%2075%20kilogramos (accessed on 6 November 2022).

- Yan, B.; Zhao, Z.; Zhang, N.; Ruan, H.; Yu, X.; Zhao, J.; Zhang, H.; Chen, W.; Fan, D. 3D food printing curing technology based on gellan gum. J. Food Eng. 2022, 327, 111036. [Google Scholar] [CrossRef]

- Chen, H.; Xie, F.; Chen, L.; Zheng, B. Effect of rheological properties of potato, rice and corn starches on their hot-extrusion 3D printing behaviors. J. Food Eng. 2019, 244, 150–158. [Google Scholar] [CrossRef]

- Rahman, J.M.H.; Shiblee, M.N.I.; Ahmed, K.; Khosla, A.; Kawakami, M.; Furukawa, H. Rheological and mechanical properties of edible gel materials for 3D food printing technology. Heliyon 2020, 6, e05859. [Google Scholar] [CrossRef] [PubMed]

- Larsson, M.; Duffy, J. An overview of measurement techniques for determination of yield stress. Annu. Trans. Nord. Rheol. Soc. 2013, 21, 125–138. [Google Scholar]

- Sahin, S.; Sumnu, S.G. Rheological Properties of Foods. In Physical Properties of Foods; Springer: New York, NY, USA, 2006; pp. 39–105. ISBN 9780-3873-0808-1. [Google Scholar]

- Paxton, N.; Smolan, W.; Böck, T.; Melchels, F.; Groll, J.; Jungst, T. Proposal to assess printability of bioinks for extrusion-based bioprinting and evaluation of rheological properties governing bioprintability. Biofabrication 2017, 9, 044107. [Google Scholar] [CrossRef]

- Gorb, S. Friction and adhesion: Fundamentals. In Attachment Devices of Insect Cuticle; Gorb, S., Ed.; Springer: Dordrecht, The Netherlands, 2001; pp. 1–8. ISBN 9780-3064-7515-3. [Google Scholar]

- Flitta, I.; Sheppard, T. Nature of friction in extrusion process and its effect on material flow. Mater. Sci. Technol. 2003, 19, 837–846. [Google Scholar] [CrossRef]

- Stable Micro Systems. Available online: https://www.stablemicrosystems.com/MeasureCohesiveness.html (accessed on 5 December 2022).

- Smith, P. Metallic Materials for Piping Components. In The Fundamentals of Piping Design; Peter, S., Ed.; Gulf Publishing Company: Houston, TX, USA, 2007; pp. 115–136. ISBN 9781-9337-6204-3. [Google Scholar]

- Zheng, Z.; Zhang, M.; Liu, Z. Investigation on evaluating the printable height and dimensional stability of food extrusion-based 3D printed foods. J. Food Eng. 2021, 306, 110636. [Google Scholar] [CrossRef]

- Bui, B.; Saasen, A.; Maxey, J.; Ozbayoglu, E.; Miska, S.; Yu, M. Viscoelastic properties of oil-based drilling fluids. Annu. Trans. Nord. Rheol. Soc. 2012, 20, 33–47. [Google Scholar]

- TA Instruments. Available online: https://www.tainstruments.com/pdf/literature/RH107.pdf (accessed on 30 June 2023).

| Symbol | Nixtamalized Corn Flour Content (wt%) | Purified Water Content (wt%) |

|---|---|---|

| M25 | 25.0 | 75.0 |

| M27.5 | 27.5 | 72.5 |

| M30 | 30.0 | 70.0 |

| M32.5 | 32.5 | 67.5 |

| M35 | 35.0 | 65.0 |

| M37.5 | 37.5 | 62.5 |

| M40 | 40.0 | 60.0 |

| Parameter | Condition |

|---|---|

| Print speed (stage movement speed) (mm/s) | 20 |

| Nozzle inner diameter (mm) | 2.0 |

| Initial nozzle height (mm) | 2.0 |

| Extrusion multiplier (-) | 2.0 |

| Infill pattern (-) | Concentric |

| Infill percent (%) | 100 |

| Number of outer shells (-) | 2 |

| Temperature (°C) | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Herrera, V.V.; Umeda, T.; Kozu, H.; Sasaki, T.; Kobayashi, I. Printability of Nixtamalized Corn Dough during Screw-Based Three-Dimensional Food Printing. Foods 2024, 13, 293. https://doi.org/10.3390/foods13020293

Rodríguez-Herrera VV, Umeda T, Kozu H, Sasaki T, Kobayashi I. Printability of Nixtamalized Corn Dough during Screw-Based Three-Dimensional Food Printing. Foods. 2024; 13(2):293. https://doi.org/10.3390/foods13020293

Chicago/Turabian StyleRodríguez-Herrera, Verónica Valeria, Takumi Umeda, Hiroyuki Kozu, Tomoko Sasaki, and Isao Kobayashi. 2024. "Printability of Nixtamalized Corn Dough during Screw-Based Three-Dimensional Food Printing" Foods 13, no. 2: 293. https://doi.org/10.3390/foods13020293