Development of Chinese-Style Sausage Enriched with Djulis (Chenopodium formosanum Koidz) Using Taguchi Method: Applying Modern Optimization to Indigenous People’s Traditional Food

Abstract

:1. Introduction

| Taguchi Method | Other Methods, such as Full Factorial | Reference | |

|---|---|---|---|

| Advantages * |

|

| [18,19,20] |

| |||

| Limitations |

|

| [20,21] |

|

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. Salted Casing Processing

2.2.2. Djulis Processing

2.2.3. Djulis-Based Sausage Processing

2.3. Experimental Design

2.3.1. Questionnaire on Djulis Sausage Ingredients

2.3.2. Taguchi Method

2.3.3. Calculation of Signal-to-Noise Ratio (S/N)

2.4. Sensory Evaluation Analysis

2.5. Physical Properties

2.5.1. Texture Profile Analysis (TPA)

2.5.2. CIE Color Analysis

2.6. Chemical Properties

2.6.1. Peroxide Value Test

2.6.2. DPPH Test

2.7. Statistical Analysis

3. Results and Discussions

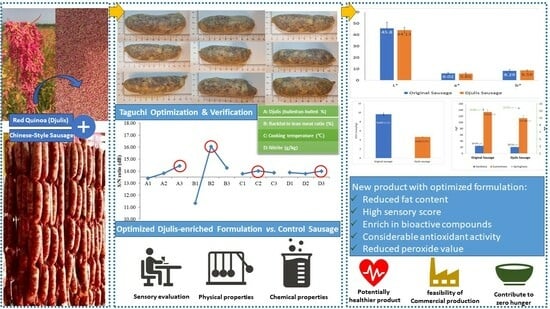

3.1. Appearance of Djulis Sausage

3.2. Sensory Evaluation

3.3. Taguchi Analysis of Sensory Aspects and Overall Acceptance of Djulis Sausage

3.4. Verification Analysis of Results

3.5. Physical Properties of the Products

3.5.1. Texture Profile Analysis of Sausages

3.5.2. CIE Color Values of Sausages

3.6. Chemical Properties of the Sausage Samples

3.6.1. Peroxide Value Test

3.6.2. DPPH Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Transparency Market. Research Hot Dogs and Sausages Market. 2016, pp. 1–167. Available online: https://www.transparencymarketresearch.com/hot-dogs-sausages-market.html (accessed on 11 September 2023).

- National Taiwan University Case Center. A Transforming Enterprise, Unchanging Flavor: Black Bridge’s Next Century (Report No. 71-2020-19). Available online: https://management.ntu.edu.tw/Case/Resources/71-2020-19 (accessed on 1 November 2023).

- Wang, W.-H.; Li, W.-L.; Chen, C.-Y.; Chang, M.-Y.; Huang, S.-L.; Shih, C.-H.; Lin, Y.-S. Antioxidant Ability of Chenopodium Formosanum Extracted Using an Ethanol–Ammonium Sulfate Two-Phase System. Chem. Biol. Technol. Agric. 2022, 9, 14. [Google Scholar] [CrossRef]

- Rong, M.; Liu, Y.; Wang, Y.; Deng, H. Effects of Vitamin C Supplementation on Chinese Sausage-Induced Liver Damage in Rats. Ital. J. Food Sci. 2023, 35, 130–140. [Google Scholar] [CrossRef]

- Faradina, A.; Tung, Y.-T.; Chen, S.-H.; Liao, Y.-C.; Chou, M.-J.; Teng, I.-C.; Lin, W.-L.; Wang, C.-C.; Sheu, M.-T.; Chou, P.-Y.; et al. Djulis Hull Enhances the Efficacy of Ferric Citrate Supplementation via Restoring Normal Iron Efflux through the IL-6–Hepcidin–Ferroportin Pathway in High-Fat-Diet-Induced Obese Rats. J. Agric. Food Chem. 2023, 71, 16691–16701. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-T.; Wang, W.-H.; Lin, W.-S.; Hu, S.-Y.; Chen, C.-Y.; Chang, M.-Y.; Lin, Y.-S.; Li, C.-P. Effects of Different Chenopodium Formosanum Parts on Antioxidant Capacity and Optimal Extraction Analysis by Taguchi Method. Materials 2021, 14, 4679. [Google Scholar] [CrossRef] [PubMed]

- Hung, Y.; de Kok, T.M.; Verbeke, W. Consumer Attitude and Purchase Intention towards Processed Meat Products with Natural Compounds and a Reduced Level of Nitrite. Meat Sci. 2016, 121, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Seyyedsalehi, M.S.; Mohebbi, E.; Tourang, F.; Sasanfar, B.; Boffetta, P.; Zendehdel, K. Association of Dietary Nitrate, Nitrite, and N-Nitroso Compounds Intake and Gastrointestinal Cancers: A Systematic Review and Meta-Analysis. Toxics 2023, 11, 190. [Google Scholar] [CrossRef] [PubMed]

- Thøgersen, R.; Gray, N.; Kuhnle, G.; Van Hecke, T.; De Smet, S.; Young, J.F.; Sundekilde, U.K.; Hansen, A.K.; Bertram, H.C. Inulin-Fortification of a Processed Meat Product Attenuates Formation of Nitroso Compounds in the Gut of Healthy Rats. Food Chem. 2020, 302, 125339. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.-Y.; Hsieh, C.-W.; Chen, P.-C.; Lin, S.-P.; Lin, Y.-F.; Cheng, K.-C. Development and Optimization of Djulis Sourdough Bread Fermented by Lactic Acid Bacteria for Antioxidant Capacity. Molecules 2021, 26, 5658. [Google Scholar] [CrossRef]

- Chen, S.-Y.; Chu, C.-C.; Chyau, C.-C.; Yang, J.-W.; Duh, P.-D. Djulis (Chenopodium Formosanum) and Its Bioactive Compounds Affect Vasodilation, Angiotensin Converting Enzyme Activity, and Hypertension. Food Biosci. 2019, 32, 100469. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Chu, Y.-L.; Sridhar, K.; Tsai, P.-J. Analysis and Determination of Phytosterols and Triterpenes in Different Inbred Lines of Djulis (Chenopodium Formosanum Koidz.) Hull: A Potential Source of Novel Bioactive Ingredients. Food Chem. 2019, 297, 124948. [Google Scholar] [CrossRef]

- Isnain, F.S.; Liao, N.-C.; Tsai, H.-Y.; Hsu, J.-L.; Tsai, P.-J.; Wardani, A.K.; Chen, Y.-K. Protective Effect of Ethanolic Extract of Djulis Hull on Indomethacin-Induced Gastric Injury. Appl. Sci. 2023, 13, 594. [Google Scholar] [CrossRef]

- Chung, P.-L.; Liaw, E.-T.; Gavahian, M.; Chen, H.-H. Development and Optimization of Djulis Sourdough Bread Using Taguchi Grey Relational Analysis. Foods 2020, 9, 1149. [Google Scholar] [CrossRef] [PubMed]

- Chou, C.F. Evaluation of Quality Properties of Emulsified Pork Sausages Containing Sorghum Distillers Grains. J. Food Process. Preserv. 2020, 44, e14968. [Google Scholar] [CrossRef]

- Gavahian, M.; Chu, R. Design, Development, and Performance Evaluation of an Ohmic Extractor to Valorize Fruit By-products Based on Taguchi Method: Reduced Energy Consumption and Enhanced Total Phenolics. J. Food Process. Eng. 2022, 45, e13825. [Google Scholar] [CrossRef]

- Bibi, S.; Wang, Z.-L.; Lin, C.; Min, S.-H.; Cheng, C.-Y. Two-Stage Cultivation Strategies for Optimal Production of Ganoderma Pellets with Potential Application in the Vegan Food Industry. J. Food Sci. Technol. 2023, 60, 1793–1802. [Google Scholar] [CrossRef] [PubMed]

- Raspopovic, M.; Cvetanovic, S.; Medan, I.; Ljubojevic, D. The Effects of Integrating Social Learning Environment with Online Learning. Int. Rev. Res. Open Distrib. Learn. 2017, 18, 142–160. [Google Scholar] [CrossRef]

- Kechagias, J.; Kitsakis, K.; Vaxevanidis, N. Comparison of Full versus Fractional Factorial Experimental Design for the Prediction of Cutting Forces in Turning of a Titanium Alloy: A Case Study. Int. J. Mater. 2017, 4, 1–4. [Google Scholar]

- Kechagias, J.D.; Aslani, K.-E.; Fountas, N.A.; Vaxevanidis, N.M.; Manolakos, D.E. A Comparative Investigation of Taguchi and Full Factorial Design for Machinability Prediction in Turning of a Titanium Alloy. Measurement 2020, 151, 107213. [Google Scholar] [CrossRef]

- OĞUZ, N.S.; AKARSLAN, F. Applications Of Taguchi Experimental Design Method In The Field Of Textile. Int. J. Eng. Innov. Res. 2022, 4, 134–142. [Google Scholar] [CrossRef]

- Cheng, C.-J.; Kuo, Y.-T.; Chen, J.-W.; Wei, G.-J.; Lin, Y.-J. Probabilistic Risk and Benefit Assessment of Nitrates and Nitrites by Integrating Total Diet Study-Based Exogenous Dietary Exposure with Endogenous Nitrite Formation Using Toxicokinetic Modeling. Environ. Int. 2021, 157, 106807. [Google Scholar] [CrossRef]

- Ministry of Health and Welfare. Standards for Specification, Scope, Application and Limitation of Food Additives; Ministry of Health and Welfare: Taiwan, China, 2023. [Google Scholar]

- Kathuria, D.; Dhiman, A.K.; Attri, S. Sous Vide, a Culinary Technique for Improving Quality of Food Products: A Review. Trends Food Sci. Technol. 2022, 119, 57–68. [Google Scholar] [CrossRef]

- Freddi, A.; Salmon, M. Introduction to the Taguchi Method. In Design Principles and Methodologies: From Conceptualization to First Prototyping with Examples and Case Studies; Springer: Berlin/Heidelberg, Germany, 2019; pp. 159–180. [Google Scholar]

- Stone, H.; Bleibaum, R.N.; Thomas, H.A. Sensory Evaluation Practices; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 9780128153345. [Google Scholar]

- Hu, H.; Li, Y.; Zhang, L.; Tu, H.; Wang, X.; Ren, L.; Dai, S.; Wang, L. Use of Tremella as Fat Substitute for the Enhancement of Physicochemical and Sensory Profiles of Pork Sausage. Foods 2021, 10, 2167. [Google Scholar] [CrossRef] [PubMed]

- Peleg, M. The Instrumental Texture Profile Analysis Revisited. J. Texture Stud. 2019, 50, 362–368. [Google Scholar] [CrossRef] [PubMed]

- Al-Hilphy, A.R.; Al-Shatty, S.M.; Al-Mtury, A.A.A.; Gavahian, M. Solar Energy-Assisted Extraction of Carp Fish Viscera Oil: New Sustainable Waste Valorization Platform. Waste Biomass Valorization 2023. [Google Scholar] [CrossRef]

- Haruna, S.A.; Li, H.; Zareef, M.; Hassan, M.M.; Arslan, M.; Geng, W.; Wei, W.; Abba Dandago, M.; Yao-Say Solomon Adade, S.; Chen, Q. Application of NIR Spectroscopy for Rapid Quantification of Acid and Peroxide in Crude Peanut Oil Coupled Multivariate Analysis. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 267, 120624. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Zhou, H.; Zhang, S.; Pan, X.; Li, S.; Zhu, N.; Wu, Q.; Wang, S.; Qiao, X.; Chen, W. Changes of Protein Oxidation, Lipid Oxidation and Lipolysis in Chinese Dry Sausage with Different Sodium Chloride Curing Salt Content. Food Sci. Hum. Wellness 2020, 9, 328–337. [Google Scholar] [CrossRef]

- Baliyan, S.; Mukherjee, R.; Priyadarshini, A.; Vibhuti, A.; Gupta, A.; Pandey, R.P.; Chang, C.-M. Determination of Antioxidants by DPPH Radical Scavenging Activity and Quantitative Phytochemical Analysis of Ficus Religiosa. Molecules 2022, 27, 1326. [Google Scholar] [CrossRef]

- Bessa, L.W.; Pieterse, E.; Sigge, G.; Hoffman, L.C. An Exploratory Study into the Use of Black Soldier Fly (Hermetia Illucens) Larvae in the Production of a Vienna-Style Sausage. Meat Muscle Biol. 2019, 3, 289–298. [Google Scholar] [CrossRef]

- Haghighi, H.; Belmonte, A.M.; Masino, F.; Minelli, G.; Lo Fiego, D.P.; Pulvirenti, A. Effect of Time and Temperature on Physicochemical and Microbiological Properties of Sous Vide Chicken Breast Fillets. Appl. Sci. 2021, 11, 3189. [Google Scholar] [CrossRef]

- Przybylski, W.; Jaworska, D.; Kajak-Siemaszko, K.; Sałek, P.; Pakuła, K. Effect of Heat Treatment by the Sous-Vide Method on the Quality of Poultry Meat. Foods 2021, 10, 1610. [Google Scholar] [CrossRef]

- Gil, M.; Rudy, M.; Stanisławczyk, R.; Duma-Kocan, P. Effect of Traditional Cooking and Sous Vide Heat Treatment, Cold Storage Time and Muscle on Physicochemical and Sensory Properties of Beef Meat. Molecules 2022, 27, 7307. [Google Scholar] [CrossRef] [PubMed]

- Song, D.H.; Yang, N.E.; Seomoon, K.M.; Jang, I.S.; Chin, K.B.; Kim, H.W. Sous-Vide Cooking as a Practical Strategy to Improve Quality Attributes and Shelf Stability of Reduced-Salt Chicken Breast Ham. Poult. Sci. 2023, 102, 102444. [Google Scholar] [CrossRef] [PubMed]

- Bıyıklı, M.; Akoğlu, A.; Kurhan, Ş.; Akoğlu, İ.T. Effect of Different Sous Vide Cooking Temperature-Time Combinations on the Physicochemical, Microbiological, and Sensory Properties of Turkey Cutlet. Int. J. Gastron. Food Sci. 2020, 20, 100204. [Google Scholar] [CrossRef]

- Hu, Y.; Li, Y.; Li, X.; Zhang, H.; Chen, Q.; Kong, B. Application of Lactic Acid Bacteria for Improving the Quality of Reduced-Salt Dry Fermented Sausage: Texture, Color, and Flavor Profiles. LWT 2022, 154, 112723. [Google Scholar] [CrossRef]

- Naımatı, S.; Doğan, S.C.; Asghar, M.U.; Wilk, M.; Korczyński, M. The Effect of Quinoa Seed (Chenopodium Quinoa Willd.) Extract on the Performance, Carcass Characteristics, and Meat Quality in Japanese Quails (Coturnix Coturnix Japonica). Animals 2022, 12, 1851. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Ahn, D.U. Lipid Oxidation and Its Implications to Meat Quality and Human Health. Food Sci. Biotechnol. 2019, 28, 1275–1285. [Google Scholar] [CrossRef]

- Fernández-López, J.; Viuda-Martos, M.; Sayas-Barberá, M.E.; Navarro-Rodríguez de Vera, C.; Lucas-González, R.; Roldán-Verdú, A.; Botella-Martínez, C.; Pérez-Alvarez, J.A. Chia, Quinoa, and Their Coproducts as Potential Antioxidants for the Meat Industry. Plants 2020, 9, 1359. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-H.; Lee, Y.-J.; Lim, J.-G.; Jeon, J.-H.; Yoon, K.-S. Effect of Quinoa (Chenopodium Quinoa Willd.) Starch and Seeds on the Physicochemical and Textural and Sensory Properties of Chicken Meatballs during Frozen Storage. Foods 2021, 10, 1601. [Google Scholar] [CrossRef]

- Chaari, M.; Elhadef, K.; Akermi, S.; Ben Hlima, H.; Fourati, M.; Chakchouk Mtibaa, A.; Ennouri, M.; D’Amore, T.; Salahuddin Ali, D.; Mellouli, L.; et al. Potentials of Beetroot (Beta Vulgaris L.) Peel Extract for Quality Enhancement of Refrigerated Beef Meat. Qual. Assur. Saf. Crops Foods 2023, 15, 99–115. [Google Scholar] [CrossRef]

- Hsu, B.Y.; Lin, S.W.; Inbaraj, B.S.; Chen, B.H. Simultaneous Determination of Phenolic Acids and Flavonoids in Chenopodium Formosanum Koidz. (Djulis) by HPLC-DAD-ESI–MS/MS. J. Pharm. Biomed. Anal. 2017, 132, 109–116. [Google Scholar] [CrossRef]

- Rice-Evans, C.A.; Miller, N.J.; Paganga, G. Structure-Antioxidant Activity Relationships of Flavonoids and Phenolic Acids. Free Radic. Biol. Med. 1996, 20, 933–956. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.-W.; Cheng, M.-C.; Chen, B.-Y.; Wang, C.-Y. Effects of High Pressure Extraction on the Extraction Yield, Phenolic Compounds, Antioxidant and Anti-Tyrosinase Activity of Djulis Hull. J. Food Sci. Technol. 2019, 56, 4016–4024. [Google Scholar] [CrossRef] [PubMed]

| Factor/Level | Independent Parameters | 1 | 2 | 3 |

|---|---|---|---|---|

| A | Djulis (hulled:un-hulled %) | 100:0 | 50:50 | 0:100 |

| B | Backfat to lean meat ratio (%) | 0/100 | 30/70 | 50/50 |

| C | Cooking temperature (°C) | 55 | 75 | 95 |

| D | Nitrite (g/kg) | 0.07 | 0.05 | 0.03 |

| Treatments/ Main Ingredients (%) | Hulled Djulis | Un-Hulled Djulis | Pork Lean | Pork Backfat | Nitrite |

|---|---|---|---|---|---|

| 1 | 16.8 ** | - | 100 | - | 0.023 |

| 2 | 16.8 | - | 70 | 30 | 0.016 |

| 3 | 16.8 | - | 50 | 50 | 0.01 |

| 4 | 8.4 | 8.4 | 100 | - | 0.01 |

| 5 | 8.4 | 8.4 | 70 | 30 | 0.023 |

| 6 | 8.4 | 8.4 | 50 | 50 | 0.016 |

| 7 | - | 16.8 | 100 | - | 0.016 |

| 8 | - | 16.8 | 70 | 30 | 0.01 |

| 9 | - | 16.8 | 50 | 50 | 0.023 |

| No. | Appearance | Aroma | Bitterness | Juicy | Overall Acceptance |

|---|---|---|---|---|---|

| 1 | 3.37 ± 0.24 c | 3.53 ± 0.15 c | 4.87 ± 0.20 b | 3.02 ± 0.25 c | 3.46 ± 0.22 c |

| 2 | 5.90 ± 0.20 a | 5.54 ± 0.07 a | 5.82 ± 0.08 a | 5.42 ± 0.10 b | 6.02 ± 0.13 a |

| 3 | 5.14 ± 0.16 b | 5.04 ± 0.10 b | 5.43 ± 0.24 b | 5.37 ± 0.22 b | 4.94 ± 0.11 b |

| 4 | 3.57 ± 0.22 c | 3.78 ± 0.08 c | 4.89 ± 0.15 b | 3.18 ± 0.15 c | 3.77 ± 0.12 b |

| 5 | 6.17 ± 0.15 a | 5.94 ± 0.05 a | 5.70 ± 0.12 a | 5.43 ± 0.09 b | 6.28 ± 0.13 a |

| 6 | 5.29 ± 0.14 b | 5.23 ± 0.06 b | 5.51 ± 0.17 b | 5.58 ± 0.05 a | 5.01 ± 0.05 b |

| 7 | 3.67 ± 0.09 c | 3.99 ± 0.14 c | 5.13 ± 0.06 b | 3.30 ± 0.12 c | 3.88 ± 0.13 b |

| 8 | 6.56 ± 0.08 a | 6.40 ± 0.12 a | 6.32 ± 0.19 a | 5.74 ± 0.08 a | 6.77 ± 0.06 a |

| 9 | 5.46 ± 0.04 b | 5.78 ± 0.15 a | 5.64 ± 0.16 b | 5.89 ± 0.15 a | 5.59 ± 0.15 a |

| L9(34) | Factor | Overall Acceptance Results | Ave | SD | S/N | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | Y1 | Y2 | Y3 | ||||

| EXP. 1 | 1 | 1 | 1 | 1 | 3.70 | 3.40 | 3.27 | 3.46 | 0.22 | 10.74 |

| EXP. 2 | 1 | 2 | 2 | 2 | 6.17 | 5.93 | 5.97 | 6.02 | 0.13 | 15.59 |

| EXP. 3 | 1 | 3 | 3 | 3 | 5.07 | 4.87 | 4.90 | 4.94 | 0.11 | 13.88 |

| EXP. 4 | 2 | 1 | 2 | 3 | 3.87 | 3.80 | 3.63 | 3.77 | 0.12 | 11.51 |

| EXP. 5 | 2 | 2 | 3 | 1 | 6.13 | 6.37 | 6.33 | 6.28 | 0.13 | 15.95 |

| EXP. 6 | 2 | 3 | 1 | 2 | 5.07 | 4.97 | 5.00 | 5.01 | 0.05 | 14.00 |

| EXP. 7 | 3 | 1 | 3 | 2 | 3.73 | 3.90 | 4.00 | 3.88 | 0.13 | 11.76 |

| EXP. 8 | 3 | 2 | 1 | 3 | 6.80 | 6.80 | 6.70 | 6.77 | 0.06 | 16.61 |

| EXP. 9 | 3 | 3 | 2 | 1 | 5.73 | 5.43 | 5.60 | 5.59 | 0.15 | 14.94 |

| Ave | 5.08 | 0.12 | 13.89 | |||||||

| Level | Factor | |||

|---|---|---|---|---|

| A | B | C | D | |

| 1 | 13.40 | 11.34 | 13.78 | 13.88 |

| 2 | 13.82 | 16.05 | 14.01 | 13.78 |

| 3 | 14.44 | 14.27 | 13.86 | 14.00 |

| Effect | 1.03 | 4.71 | 0.23 | 0.22 |

| Rank | 2 | 1 | 3 | 4 |

| Factor | SS | DOF | Var | F Ratio | Confidence | Significant |

|---|---|---|---|---|---|---|

| A | 1.69 | 2 | 0.84 | 49.46 | 100.00 | *** |

| B | 31.88 | 2 | 15.94 | 933.23 | 100.00 | *** |

| C | 0.04 | 2 | 0.02 | 1.13 | 65.51 | * |

| D | 0.17 | 2 | 0.09 | 5.02 | 98.15 | ** |

| Error | 0.31 | 18 | 0.02 | |||

| Total | 34.08 | 26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chung, P.-L.; Lufaniyao, K.-S.; Gavahian, M. Development of Chinese-Style Sausage Enriched with Djulis (Chenopodium formosanum Koidz) Using Taguchi Method: Applying Modern Optimization to Indigenous People’s Traditional Food. Foods 2024, 13, 91. https://doi.org/10.3390/foods13010091

Chung P-L, Lufaniyao K-S, Gavahian M. Development of Chinese-Style Sausage Enriched with Djulis (Chenopodium formosanum Koidz) Using Taguchi Method: Applying Modern Optimization to Indigenous People’s Traditional Food. Foods. 2024; 13(1):91. https://doi.org/10.3390/foods13010091

Chicago/Turabian StyleChung, Pei-Ling, Ku-Sang Lufaniyao, and Mohsen Gavahian. 2024. "Development of Chinese-Style Sausage Enriched with Djulis (Chenopodium formosanum Koidz) Using Taguchi Method: Applying Modern Optimization to Indigenous People’s Traditional Food" Foods 13, no. 1: 91. https://doi.org/10.3390/foods13010091