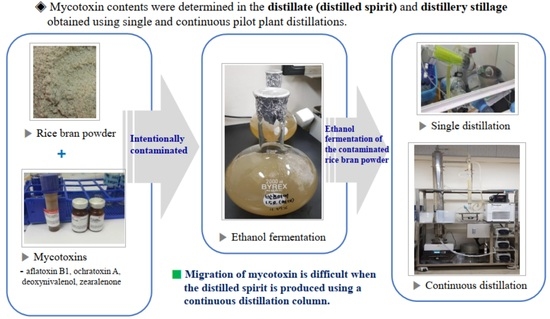

Migration Degree of Selected Mycotoxins in the Distillation Process and Their Determination in Distilled Spirits from Pilot-Scale Continuous Distillation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation of Mycotoxin Contamination for Ethanol Fermentation

2.3. Preparation of Distillate and Distillery Stillage from Single-Stage Distillation

2.4. Preparation of Distillate Fractions for Determining Aflatoxin B1 and Ochratoxin A from Pilot-Plant Scale Continuous Distillation Column

2.5. Preparation of Distilled Spirits and Distillery Stillage for Determining Aflatoxin B1 and Ochratoxin A Contents from Pilot-Plant Scale Distillation Column

2.6. Analysis of Ochratoxin A

2.7. Analysis of Aflatoxin B1

2.8. Analysis of Deoxynivalenol

2.9. Analysis of Zearalenone

3. Results and Discussion

3.1. Determination of Ochratoxin A, Aflatoxin B1, Deoxynivalenol, and Zearalenone Contents after Single-Stage Distillation

3.2. Determination of Ochratoxin A and Aflatoxin B1 after Repeated Single-Stage Distillation

3.3. Determination of Ochratoxin A and Aflatoxin B1 Contents in the Distillate Fractions Using Pilot-Plant Scale Distillation Column

3.4. Determination of Ochratoxin A and Aflatoxin B1 in the Distilled Spirit from Pilot-Plant Scale Distillation Column

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Spaho, N. Distillation techniques in the fruit spirits production. In Distillation—Innovative Application and Modeling; Mendes, M.F., Ed.; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef]

- Qin, Y.; Shin, J.A.; Lee, K.T. Determination of acetaldehyde, methanol and fusel oils in distilled liquors and sake’s by headspace gas chromatography. Food Sci. Biotechnol. 2020, 29, 331–337. [Google Scholar] [CrossRef] [PubMed]

- Loi, M.; Fanelli, F.; Zucca, P.; Liuzzi, V.C.; Quintieri, L.; Cimmarusti, M.T.; Monaci, L.; Haidukowski, M.; Logrieco, A.F.; Sanjust, E.; et al. Aflatoxin B1 and M1 degradation by Lac2 from Pleurotus pulmonarius and redox mediators. Toxins 2016, 8, 245. [Google Scholar] [CrossRef] [PubMed]

- Baydar, T.; Erkekoglu, P.; Sipahi, H.; Sahin, G. Aflatoxin B1, M1 and ochratoxin A levels in infant formulae and baby foods marketed in Ankara, Turkey. J. Food Drug Anal. 2007, 15, 89–92. [Google Scholar] [CrossRef]

- Marchese, S.; Polo, A.; Ariano, A.; Velotto, S.; Costantini, S.; Severino, L. Aflatoxin B1 and M1: Biological properties and their involvement in cancer development. Toxins 2018, 10, 214. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.; Baek, S.G.; Kim, S.; Paek, J.S.; Park, J.J.; Choi, J.; Choi, J.H.; Jang, J.Y.; Kim, J. Trends in mycotoxin contamination of cereals and cereal products in Korea. Res. Plant Dis. 2022, 28, 179–194. [Google Scholar] [CrossRef]

- Karlovsky, P.; Suman, M.; Berthiller, F.; de Meester, J.; Eisenbrand, G.; Perrin, I.; Oswald, I.P.; Speijers, G.; Chiodini, A.; Recker, T.; et al. Impact of food processing and detoxification treatments on mycotoxin contamination. Mycotoxin Res. 2016, 32, 179–205. [Google Scholar] [CrossRef] [PubMed]

- Kabak, B. The fate of mycotoxins during thermal food processing. J. Sci. Food Agric. 2009, 89, 549–554. [Google Scholar] [CrossRef]

- Zaki, M.; El-Midany, S.A.; Shaheen, H.M.; Rizzi, L. Mycotoxins in Animals: Occurrence, Effects, Prevention and Management. J. Toxicol. Environ. Health Sci. 2012, 4, 13–28. Available online: https://academicjournals.org/article/article1379602600_Zaki%20et%20al.pdf (accessed on 18 September 2023). [CrossRef]

- National Library of Medicine. Chemical and Physical Characteristics of the Principal Mycotoxins. IARC Sci. Publ. 2012, 158, 31–38. Available online: https://pubmed.ncbi.nlm.nih.gov/23477194/ (accessed on 18 September 2023).

- Mishra, S.; Dixit, S.; Dwivedi, P.D.; Pandey, H.P.; Das, M. Influence of temperature and pH on the degradation of deoxynivalenol (DON) in aqueous medium: Comparative cytotoxicity of DON and degraded product. Food Addit. Contam. 2014, 31, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Ryu, D.; Hanna, M.A.; Eskridge, K.M.; Bullerman, L.B. Heat stability of zearalenone in an aqueous buffered model system. J. Agric. Food Chem. 2003, 51, 1746–1748. [Google Scholar] [CrossRef] [PubMed]

- Inoue, T.; Nagatomi, Y.; Uyama, A.; Mochizuki, N. Degradation of aflatoxin B1 during the fermentation of alcoholic beverages. Toxins 2013, 5, 1219–1229. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.A.; Cho, H.; Seo, D.W.; Jeong, H.G.; Kim, S.C.; Lee, J.H.; Hong, S.T.; Lee, K.T. Approach study for mass balance of pesticide residues in distillers’ stillage along with distillate and absence verification of pesticides in distilled spirits from pilot-scale of distillation column. Molecules 2019, 24, 2572. [Google Scholar] [CrossRef] [PubMed]

- Nagatomi, Y.; Inoue, T.; Uyama, A.; Mochizuki, N. The fate of mycotoxins during the distillation process of barley shochu, a distilled alcoholic beverage. Biosci. Biotechnol. Biochem. 2012, 76, 202–204. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Food and Drug Safety. Food Code. 9.2.6 Ochratoxin A. 2023. Available online: https://various.foodsafetykorea.go.kr/fsd/#/ext/Document/FC (accessed on 18 September 2023).

- Ministry of Food and Drug Safety. Food Code. 9.2.2 Aflatoxin B1. 2023. Available online: https://various.foodsafetykorea.go.kr/fsd/#/ext/Document/FC (accessed on 18 September 2023).

- Ministry of Food and Drug Safety. Food Code. 9.2.7 Deoxynivalenol. 2023. Available online: https://various.foodsafetykorea.go.kr/fsd/#/ext/Document/FC (accessed on 18 September 2023).

- Ministry of Food and Drug Safety. Food Code. 9.2.8 Zearalenone. 2023. Available online: https://various.foodsafetykorea.go.kr/fsd/#/ext/Document/FC (accessed on 18 September 2023).

- Ministry of Food and Drug Safety. Food Code. 3. Food Standards and Specification. 2023. Available online: https://various.foodsafetykorea.go.kr/fsd/#/ext/Document/FC (accessed on 18 September 2023).

- Raters, M.; Matissek, R. Thermal stability of aflatoxin B1 and ochratoxin A. Mycotoxin Res. 2008, 24, 130–134. [Google Scholar] [CrossRef] [PubMed]

- Inoue, T.; Nagatomo, Y.; Uyama, A.; Mochizuki, N. Fate of mycotoxins during beer brewing and fermentation. Biosci. Biotechnol. Biochem. 2013, 77, 1410–1415. [Google Scholar] [CrossRef] [PubMed]

- Belincanta, J.; Kakuta Ravagnani, T.M.; Pereira, J.A.F. Hydrodynamic and tray efficiency behavior in parastillation column. Braz. J. Chem. Eng. 2006, 23, 135–146. [Google Scholar] [CrossRef]

| Mycotoxin | Solubility in Ethanol | Molecular Weight (g/mol) | Vapor Pressure | Log P |

|---|---|---|---|---|

| Aflatoxin B1 | Soluble in absolute ethanol (Sigma) | 312.3 | 2.65 × 10−10 mmHg at 25 °C | 1.23 (est) |

| Ochratoxin A | Soluble in ethanol (10–50 mg/mL) | 403.8 | 1.81 × 10−15 mm Hg at 25 °C | 5.19 |

| Deoxynivalenol | Soluble to 10 mg/mL in 100% ethanol (Sigma) | 296.3 | 6.8 × 10−11 mm Hg at 25 °C | −0.71 (est) |

| Zearalenone | Soluble to 20 mg/mL in ethanol | 318.4 | 0 mm Hg at 20 °C | 3–4 (predicted) |

| Mycotoxin | ||||

|---|---|---|---|---|

| Aflatoxin B1 | Ochratoxin A | Deoxynivalenol | Zearalenone | |

| Unit | ppb | ppb | ppm | ppb |

| Spiking amount | 40 | 20 | 4 | 800 |

| Raw material | ND 1 | 0.32 | ND | 17.43 |

| Distillate | ND | 0.19 | ND | ND |

| DMR (%) 2 | 0 | 0.95 | 0 | 0 |

| Distillery stillage | 21.60 | 14.50 | 3.06 | 769.34 |

| DSRR rate (%) 3 | 54.0 | 72.5 | 76.5 | 96.2 |

| 1st Distillation 1 | 2nd Distillation 2 | 3rd Distillation 2 | |

|---|---|---|---|

| Aflatoxin B1 | ND 3 | ND | ND |

| Ochratoxin A | 0.19 | Trace (0.11) 4 | 0.22 |

| Mycotoxin | ||||

|---|---|---|---|---|

| Aflatoxin B1 | Ochratoxin A | Deoxynivalenol | Zearalenone | |

| MRL 1 (ppb) | 10 | 5 | 1000 | 200 |

| LOD | 0.18 (μg/kg) | 0.05 (μg/kg) | 0.07 (mg/kg) | 2 (μg/kg) |

| LOQ | 0.55 (μg/kg) | 0.15 (μg/kg) | 0.23 (mg/kg) | 6 (μg/kg) |

| Calibration curves | Y = 1.9765 × 10−5 X (R2 = 0.999) | Y = 6.6425 × 10−5 X (R2 = 0.999) | Y = 9.6468 × 10−6 X (R2 = 0.999) | Y = 4.6 × 10−4 X (R2 = 0.999) |

| Standard concentration range | 0.1–2 (μg/mL) | 1–25 (ng/mL) | 0.1–2 (μg/mL) | 50–500 (μg/L) |

| Alcohol (%) | Distillate Volume (mL) | Amount of Ochratoxin A | DMR (%) 1 | |

|---|---|---|---|---|

| Contaminated content | - | - | 3.3 ppb (5 μg) | - |

| Distillate fraction 1 | 87.3 | 38 | ND 2 | 0 |

| Distillate fraction 2 | 74.8 | 28 | ND | 0 |

| Distillate fraction 3 | 33.7 | 110 | ND | 0 |

| Alcohol (%) | Distillate Volume (mL) | Amount of Aflatoxin B1 | DMR (%) 1 | |

|---|---|---|---|---|

| Contaminated content | - | - | 2 ppb (3 μg) | - |

| Distillate fraction 1 | 87.1 | 60 | ND 2 | 0 |

| Distillate fraction 2 | 47.6 | 40 | ND | 0 |

| Distillate fraction 3 | 15.4 | 65 | ND | 0 |

| Distillate fraction 4 | 5.5 | 40 | ND | 0 |

| Distillate fraction 5 | 3.3 | 130 | 2.35 ppb (0.3 μg) | 10 |

| Ochratoxin A | Aflatoxin B1 | ||

|---|---|---|---|

| Contaminated content | - | 3.84 ppb (7.5 μg) | 7.69 ppb (15 μg) |

| Fermented liquid | Content of mycotoxin | 4.05 ppb (7.9 μg) | 9.64 ppb (18.8 μg) |

| Recovery (%) 1 | 105.5 | 125.3 | |

| Distilled spirit | Obtained volume (mL) | 155 | 155 |

| Alcohol (%) | 93.9 | 95.4 | |

| Content of mycotoxin | ND 4 | ND | |

| DMR (%) 2 | 0 | 0 | |

| Distillery stillage | Content of mycotoxin | 2.70 ppb (5.26 μg) | 3.65 ppb (7.12 μg) |

| Alcohol (%) | 0 | 0 | |

| DSRR (%) 3 | 70.3 | 47.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.-A.; Lee, K.-T. Migration Degree of Selected Mycotoxins in the Distillation Process and Their Determination in Distilled Spirits from Pilot-Scale Continuous Distillation. Foods 2023, 12, 4189. https://doi.org/10.3390/foods12234189

Shin J-A, Lee K-T. Migration Degree of Selected Mycotoxins in the Distillation Process and Their Determination in Distilled Spirits from Pilot-Scale Continuous Distillation. Foods. 2023; 12(23):4189. https://doi.org/10.3390/foods12234189

Chicago/Turabian StyleShin, Jung-Ah, and Ki-Teak Lee. 2023. "Migration Degree of Selected Mycotoxins in the Distillation Process and Their Determination in Distilled Spirits from Pilot-Scale Continuous Distillation" Foods 12, no. 23: 4189. https://doi.org/10.3390/foods12234189