Influences of Particle Size and Addition Level on the Rheological Properties and Water Mobility of Purple Sweet Potato Dough

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Particle Size Distributions

2.3. Preparation of the Formulated Flour

2.4. Pasting Properties

2.5. Mixing Properties

2.6. Dynamic Rheological Properties

2.7. Scanning Electron Microscopy (SEM)

2.8. Differential Scanning Calorimetry (DSC)

2.9. Low-Field 1H Nuclear Magnetic Resonance (LF-NMR)

2.10. Statistical Analysis

3. Results and Discussion

3.1. Particle Size Distribution and Nutrient Distribution

3.2. Pasting Properties

3.3. Mixing Properties

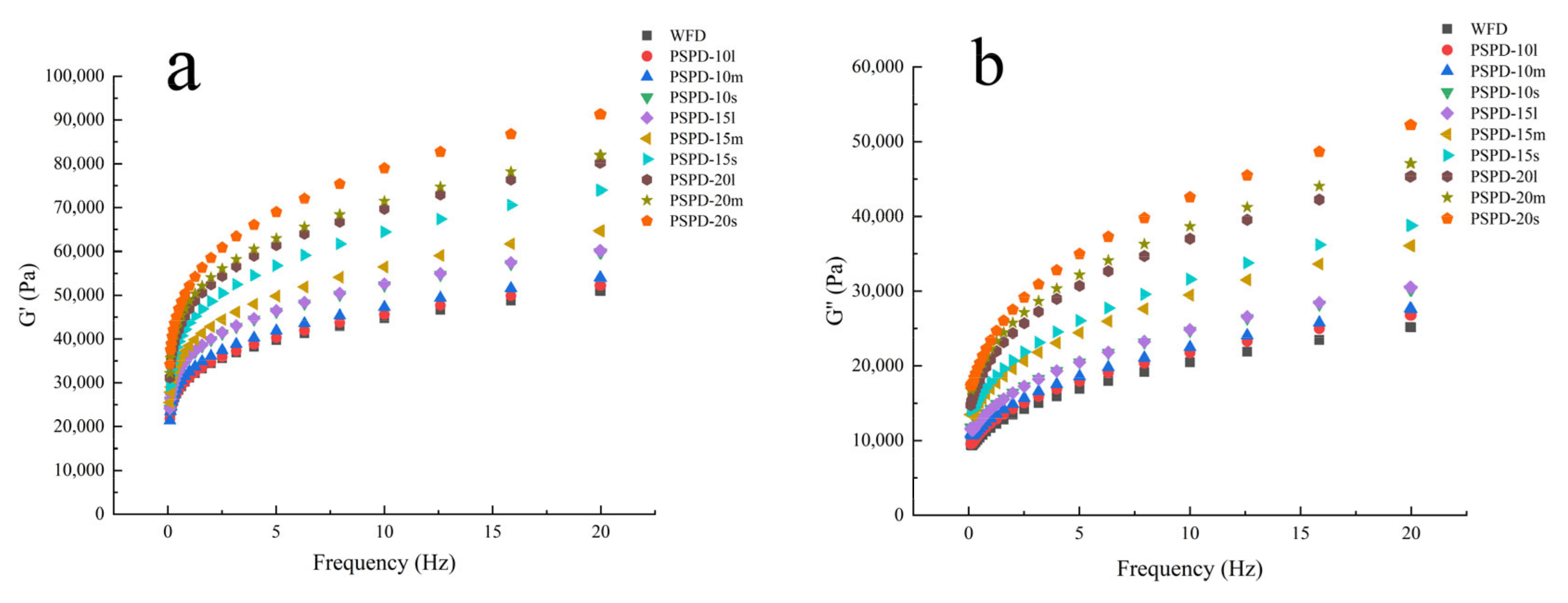

3.4. Dynamic Rheological Properties

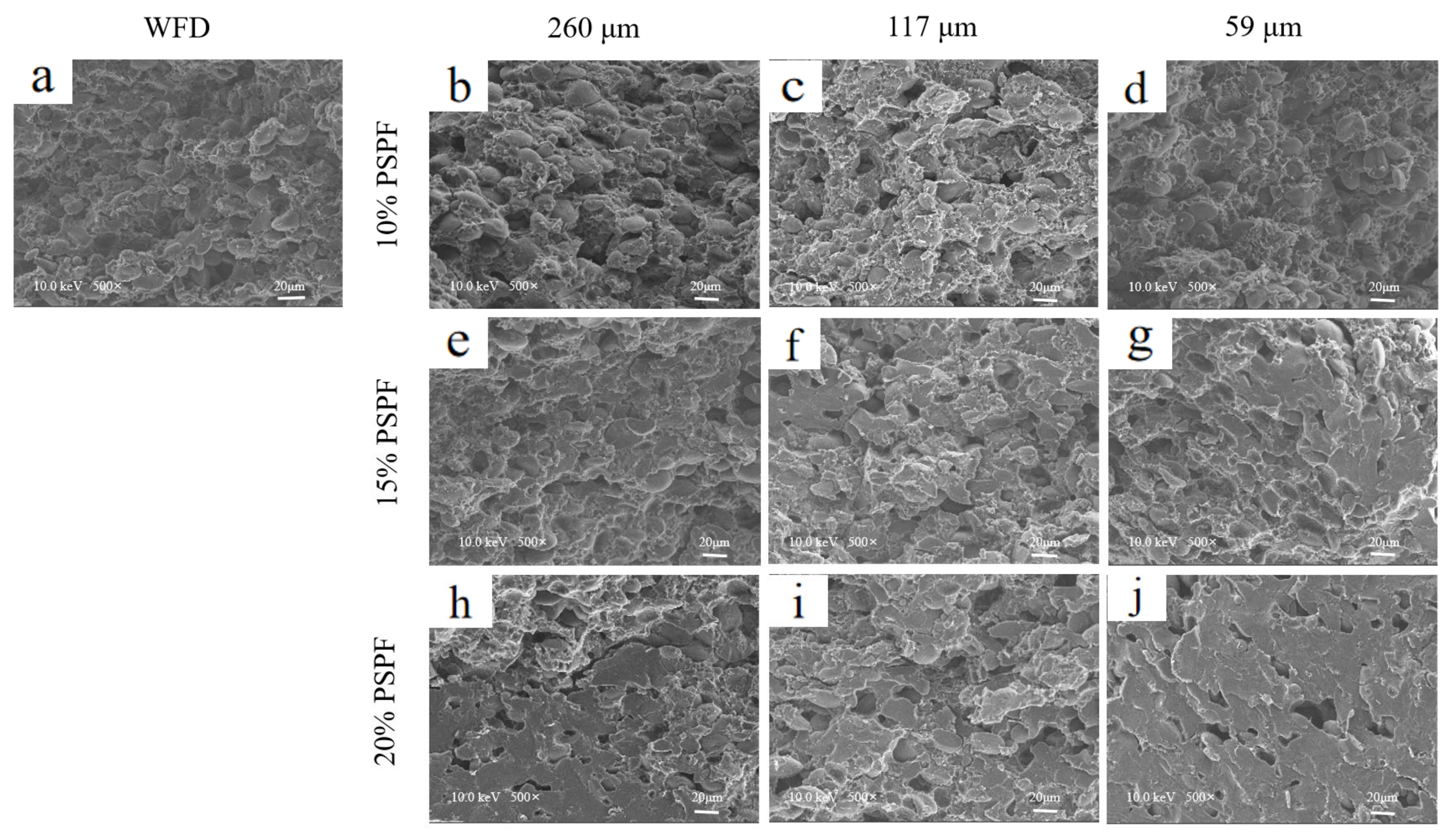

3.5. Microstructure

3.6. DSC

3.7. LF-NMR

3.8. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jokioja, J.; Linderborg, K.M.; Kortesniemi, M. Anthocyanin-rich extract from purple potatoes decreases postprandial glycemic response and affects inflammation markers in healthy men. Food Chem. 2020, 310, 125797. [Google Scholar] [CrossRef] [PubMed]

- Cui, R.; Zhu, F. Changes in structure and phenolic profiles during processing of steamed bread enriched with purple sweetpotato flour. Food Chem. 2022, 369, 130578. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, M.; Wang, C. Effect of extrusion processing and addition of purple sweet potatoes on the structural properties and in vitro digestibility of extruded rice. Food Funct. 2021, 12, 739–746. [Google Scholar] [CrossRef] [PubMed]

- Cannas, M.; Pulina, S.; Conte, P.; Del Caro, A.; Urgeghe, P.P.; Piga, A.; Fadda, C. Effect of Substitution of Rice Flour with Quinoa Flour on the Chemical-Physical, Nutritional, Volatile and Sensory Parameters of Gluten-Free Ladyfinger Biscuits. Foods 2020, 9, 808. [Google Scholar] [CrossRef] [PubMed]

- Pasqualone, A.; Costantini, M.; Faccia, M.; Difonzo, G.; Caponio, F.; Summo, C. The Effectiveness of Extruded-Cooked Lentil Flour in Preparing a Gluten-Free Pizza with Improved Nutritional Features and a Good Sensory Quality. Foods 2022, 11, 482. [Google Scholar] [CrossRef]

- Scheuer, P.M.; Luccio, M.D.; Zibetti, A.W.; Miranda, M.Z.D.; Francisco, A.D. Relationship between Instrumental and Sensory Texture Profile of Bread Loaves Made with Whole-Wheat Flour and Fat Replacer. J. Texture Stud. 2015, 47, 14–23. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.N.; Wu, S.H.; Zhu, K.X. Effect of superheated steam treatment on quality characteristics of whole wheat flour and storage stability of semi-dried whole wheat noodle. Food Chem. 2020, 322, 126738. [Google Scholar] [CrossRef]

- Luo, W.; Sun, D.W.; Zhu, Z.; Wang, Q.J. Improving freeze tolerance of yeast and dough properties for enhancing frozen dough quality—A review of effective methods. Trends Food Sci. Technol. 2017, 72, 25–33. [Google Scholar] [CrossRef]

- Dahiya, S.; Bajaj, B.K.; Kumar, A.; Tiwari, S.K.; Singh, B. A review on biotechnological potential of multifarious enzymes in bread making. Process Biochem. 2020, 99, 290–306. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Kindelspire, J.; Krishnan, P.; Zhao, S. Microstructural, textural, and sensory properties of whole-wheat noodle modified by enzymes and emulsifiers. Food Chem. 2017, 223, 16–24. [Google Scholar] [CrossRef]

- Lai, S.; Chen, Z.; Zhang, Y.; Li, G.; Wang, Y.; Cui, Q. Micronization Effects on Structural, Functional, and Antioxidant Properties of Wheat Bran. Foods 2023, 12, 98. [Google Scholar] [CrossRef]

- Lin, S.; Jin, X.; Gao, J. Impact of wheat bran micronization on dough properties and bread quality: Part I—Bran functionality and dough properties. Food Chem. 2021, 353, 129407. [Google Scholar] [CrossRef]

- Azeem, M.; Mu, T.H.; Zhang, M. Influence of particle size distribution of orange-fleshed sweet potato flour on dough rheology and simulated gastrointestinal digestion of sweet potato-wheat bread. LWT 2020, 131, 109690. [Google Scholar] [CrossRef]

- Hu, X.; Cheng, L.; Hong, Y.; Li, Z.; Li, C.; Gu, Z. Impact of celluloses and pectins restrictions on gluten development and water distribution in potato-wheat flour dough. Int. J. Biol. Macromol. 2022, 206, 534–542. [Google Scholar] [CrossRef]

- Roudaut, G.; Debeaufort, F. Moisture loss, gain and migration in foods. Food Beverage Stab. Shelf Life 2011, 63–105. [Google Scholar] [CrossRef]

- Wang, N.; Hou, G.G.; Dubat, A. Effects of flour particle size on the quality attributes of reconstituted whole-wheat flour and Chinese southern-type steamed bread. LWT 2017, 82, 147–153. [Google Scholar] [CrossRef]

- Yang, L.; Zhou, Y.; Wu, Y. Preparation and physicochemical properties of three types of modified glutinous rice starches. Carbohydr. Polym. 2016, 137, 305–313. [Google Scholar] [CrossRef]

- Li, L.; Zhou, W.; Wu, A. Effect of Ginkgo Biloba Powder on the Physicochemical Properties and Quality Characteristics of Wheat Dough and Fresh Wet Noodles. Foods 2022, 11, 698. [Google Scholar] [CrossRef]

- Mironeasa, S.; Codină, G.G. Dough Rheological Behavior and Microstructure Characterization of Composite Dough with Wheat and Tomato Seed Flours. Foods 2019, 8, 626. [Google Scholar] [CrossRef] [Green Version]

- Zheng, K.; Chen, Z.; Fu, Y.; Chen, L.; Zhu, X.; Chen, X.; Ding, W. Effect of Tea Polyphenols on the Storage Stability of Non-Fermented Frozen Dough: Protein Structures and State of Water. Foods 2023, 12, 80. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Ren, G.; Cui, G.; Han, S.; Liu, J. Effects of konjac glucomannan on the water distribution of frozen dough and corresponding steamed bread quality. Food Chem. 2020, 330, 127243. [Google Scholar] [CrossRef] [PubMed]

- Bosmans, G.M.; Lagrain, B.; Ooms, N.; Fierens, E.; Delcour, J.A. Storage of parbaked bread affects shelf life of fully baked end product: A ¹H NMR study. Food Chem. 2014, 165, 149–156. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.M.; Mu, T.H. Effects of extraction methods and particle size distribution on the structural, physicochemical, and functional properties of dietary fiber from deoiled cumin. Food Chem. 2016, 194, 237–246. [Google Scholar] [CrossRef] [PubMed]

- Chau, C.F.; Wen, Y.L.; Wang, Y.T. Improvement of the functionality of a potential fruit insoluble fibre by micron technology. Int. J. Food Sci. Technol. 2006, 41, 1054–1060. [Google Scholar] [CrossRef]

- Zhu, F.; Sun, J. Physicochemical and sensory properties of steamed bread fortified with purple sweet potato flour. Food Biosci. 2019, 30, 100411. [Google Scholar] [CrossRef]

- Xiao, F.; Zhang, X.; Niu, M.; Xiang, X.; Wu, Y. Gluten development and water distribution in bread dough influenced by bran components and glucose oxidase. LWT 2020, 137, 110427. [Google Scholar] [CrossRef]

- Han, X.Z.; Campanella, O.H.; Mix, N.C.; Hamaker, B.R. Consequence of Starch Damage on Rheological Properties of Maize Starch Pastes 1. Cereal Chem. 2002, 79, 897–901. [Google Scholar] [CrossRef]

- Nevara, G.A.; Yea, C.S.; Karim, R.; Muhammad, K.; Ghazali, H.M. Effects of moist-heat treatments on color improvement, physicochemical, antioxidant, and resistant starch properties of drum-dried purple sweet potato powder. J. Food Process Eng. 2019, 42, e12951. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Guan, E.; Zhang, T.; Li, M.; Bian, K. Influence of water addition methods on water mobility characterization and rheological properties of wheat flour dough. J. Cereal Sci. 2019, 89, 102791. [Google Scholar] [CrossRef]

- Wang, Q.; Yin, L.; Sun, F.; Li, X.; He, G. Tannins improve dough mixing properties through affecting physicochemical and structural properties of wheat gluten proteins. Food Res. Int. 2015, 69, 64–71. [Google Scholar] [CrossRef]

- Zhang, D.; Mu, T.; Sun, H. Comparative study of the effect of starches from five different sources on the rheological properties of gluten-free model doughs. Carbohydr Polym. 2017, 176, 345–355. [Google Scholar] [CrossRef]

- Watanabe, A.; Yokomizo, K.; Eliasson, A.-C. Effect of physical states of nonpolar lipids on rheology, ultracentrifugation, and microstructure of wheat flour dough. Cereal Chem. 2003, 80, 281–284. [Google Scholar] [CrossRef]

- Nour, V.; Ionica, M.E.; Trandafir, I. Bread enriched in lycopene and other bioactive compounds by addition of dry tomato waste. J. Food Sci. Technol. 2015, 52, 8260–8267. [Google Scholar] [CrossRef] [Green Version]

- Culetu, A.; Duta, D.E.; Papageorgiou, M.; Varzakas, T. The Role of Hydrocolloids in Gluten-Free Bread and Pasta; Rheology, Characteristics, Staling and Glycemic Index. Foods 2021, 10, 3121. [Google Scholar] [CrossRef]

- Mármol-Soler, C.; Matias, S.; Miranda, J.; Larretxi, I.; Fernández-Gil, M.d.P.; Bustamante, M.Á.; Churruca, I.; Martínez, O.; Simón, E. Gluten-Free Products: Do We Need to Update Our Knowledge? Foods 2022, 11, 3839. [Google Scholar] [CrossRef]

- Xue, C.; Guo, X.; Zhu, K. Effect of Tartary Buckwheat Bran Substitution on the Quality, Bioactive Compounds Content, and In Vitro Starch Digestibility of Tartary Buckwheat Dried Noodles. Foods 2022, 11, 3696. [Google Scholar] [CrossRef]

- Kerch, G.; Glonin, A.; Zicans, J.; Meri, R.M. A DSC study of the effect of ascorbic acid on bound water content and distribution in chitosan-enriched bread rolls during storage. J. Therm. Anal. Calorim. 2012, 108, 73–78. [Google Scholar] [CrossRef]

- Zhu, X.; Yuan, P.; Zhang, T. Effect of carboxymethyl chitosan on the storage stability of frozen dough: State of water, protein structures and quality attributes. Food Res. Int. 2022, 151, 110863. [Google Scholar] [CrossRef]

- Huang, G.; Guo, Q.; Wang, C.; Ding, H.H.; Cui, S.W. Fenugreek fibre in bread: Effects on dough development and bread quality. LWT 2016, 71, 274–280. [Google Scholar] [CrossRef]

- Li, J.; Kang, J.; Wang, L. Effect of water migration between arabinoxylans and gluten on baking quality of whole wheat bread detected by magnetic resonance imaging (MRI). J. Agric. Food Chem. 2012, 60, 6507–6514. [Google Scholar] [CrossRef]

- Liu, X.; Yang, L.; Zhao, S.; Zhang, H. Characterization of the dough rheological and steamed bread fortified with extruded purple sweet potato flour. Int. J. Food Prop. 2020, 23, 765–776. [Google Scholar] [CrossRef]

- Chikpah, S.K.; Korese, J.K.; Hensel, O.; Sturm, B. Effect of Sieve Particle Size and Blend Proportion on the Quality Properties of Peeled and Unpeeled Orange Fleshed Sweet Potato Composite Flours. Foods 2020, 9, 740. [Google Scholar] [CrossRef] [PubMed]

| Sample | Size (D4,3 μm) | Moisture (%) | Starch (g/100 g) | Protein (g/100 g) | Cellulose (g/100 g) |

|---|---|---|---|---|---|

| WF | 80 ± 0 c | 14.25 ± 0.14 a | 66.22 ± 0.77 a | 17.42 ± 0.60 a | 1.50 ± 0.07 d |

| PSPF 100 mesh | 260 ± 1 a | 6.76 ± 0.11 d | 44.17 ± 0.09 b | 3.42 ± 0.11 b | 2.77 ± 0.01 a |

| 140 mesh | 117 ± 2 b | 7.42 ± 0.07 c | 41.20 ± 0.54 c | 3.14 ± 0.13 c | 2.46 ± 0.38 b |

| 180 mesh | 59 ± 1 d | 8.02 ± 0.42 b | 38.29 ± 1.20 d | 2.65 ± 0.11 d | 2.07 ± 0.17 c |

| Sample | PV (cP) | HV (cP) | BD (cP) | FV (cP) | SB (cP) |

|---|---|---|---|---|---|

| WF | 2045.33 ± 79.13 a | 1334.33 ± 61.06 a | 711.00 ± 18.08 a | 2449.67 ± 86.09 a | 1115.33 ± 86.31 a |

| FF-10l | 1336.00 ± 53.45 bz | 849.00 ± 42.88 by | 487.00 ± 11.13 az | 1670.67 ± 63.31 bz | 821.67 ± 21.12 bz |

| FF-10m | 1617.00 ± 157.64 by | 1044.67 ± 97.12 bx | 572.33 ± 60.71 ay | 1973.33 ± 159.17 by | 928.67 ± 62.96 by |

| FF-10s | 2013.67 ± 76.35 bx | 1058.67 ± 63.10 bx | 955.00 ± 118.83 ax | 2011.00 ± 116.05 bx | 952.33 ± 57.27 bx |

| FF-15l | 1220.67 ± 85.94 cz | 793.33 ± 72.59 cy | 427.33 ± 21.22 bz | 1510.00 ± 96.16 cz | 716.67 ± 30.92 cz |

| FF-15m | 1473.67 ± 93.14 cy | 802.67 ± 85.70 cx | 671.00 ± 41.38 by | 1553.00 ± 147.25 cy | 750.33 ± 62.04 cy |

| FF-15s | 1815.33 ± 44.41 cx | 951.00 ± 27.49 cx | 864.33 ± 49.09 bx | 1834.00 ± 32.90 cx | 883.00 ± 11.35 cx |

| FF-20l | 1162.67 ± 33.85 dz | 752.33 ± 31.34 cy | 410.33 ± 19.65 cz | 1474.00 ± 43.71 cz | 721.67 ± 22.50 cz |

| FF-20m | 1380.67 ± 76.78 dy | 906.00 ± 67.08 cx | 483.67 ± 18.77 cy | 1717.33 ± 115.39 cy | 811.33 ± 49.16 cy |

| FF-20s | 1480.00 ± 75.62 dx | 940.67 ± 62.69 cx | 539.33 ± 15.56 cx | 1804.67 ± 109.46 cx | 864.00 ± 46.77 cx |

| Two-way ANOVA p value | |||||

| Factor I: Addition level | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Factor II: Particle size | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Factor I × Factor II | <0.001 | 0.030 | <0.001 | 0.020 | ns |

| Sample | WA (%) | DT (min) | ST (min) | Bw (mNm) |

|---|---|---|---|---|

| WF | 57.47 ± 0.23 c | 2.03 ± 0.06 c | 1.30 ± 0.00 a | 25.33 ± 0.58 a |

| FF-10l | 57.13 ± 0.12 bz | 2.47 ± 0.12 by | 1.07 ± 0.06 bx | 28.33 ± 0.58 ax |

| FF-10m | 58.30 ± 0.00 by | 2.70 ± 0.17 bx | 0.93 ± 0.12 by | 21.00 ± 1.00 ay |

| FF-10s | 59.03 ± 0.23 bx | 2.57 ± 0.06 by | 0.67 ± 0.12 bz | 22.33 ± 1.53 ay |

| FF-15l | 57.00 ± 0.00 bz | 2.57 ± 0.06 by | 1.07 ± 0.06 bx | 30.67 ± 2.89 ax |

| FF-15m | 58.83 ± 0.46 by | 2.83 ± 0.12 bx | 1.00 ± 0.20 by | 21.67 ± 1.53 ay |

| FF-15s | 59.23 ± 0.11 bx | 2.60 ± 0.00 by | 0.60 ± 0.00 bz | 21.67 ± 1.15 ay |

| FF-20l | 57.80 ± 0.00 az | 2.77 ± 0.06 ay | 1.07 ± 0.21 bx | 25.67 ± 0.58 bx |

| FF-20m | 58.83 ± 0.46 ay | 2.97 ± 0.06 ax | 0.87 ± 0.15 by | 20.33 ± 0.58 by |

| FF-20s | 59.63 ± 0.06 ax | 2.83 ± 0.06 ay | 0.67 ± 0.06 bz | 21.33 ± 1.15 by |

| Two-way ANOVA p value | ||||

| Factor I: PSPP addition | <0.001 | <0.001 | ns | <0.001 |

| Factor II: Particle size | <0.001 | <0.001 | <0.001 | 0.011 |

| Factor I × Factor II | <0.001 | ns | ns | 0.042 |

| Sample | G′ = K″·ωn′ | G″ = K″·ωn″ | ||||

|---|---|---|---|---|---|---|

| K′ (Pa sn′) | n′ | R2 | K″ (Pa sn″) | n″ | R2 | |

| WFD | 31,356.33 ± 118.72 g | 0.156 ± 0.002 e | 0.996 | 12,309.32 ± 213.02 h | 0.223 ± 0.008 c | 0.972 |

| PSPD-10l | 31,529.03 ± 126.82 g | 0.162 ± 0.002 de | 0.997 | 12,900.99 ± 208.74 g | 0.229 ± 0.008 b | 0.977 |

| PSPD-10m | 32,606.38 ± 114.55 f | 0.163 ± 0.001 d | 0.998 | 13,755.12 ± 256.69 f | 0.216 ± 0.009 d | 0.965 |

| PSPD-10s | 35,939.03 ± 126.06 e | 0.165 ± 0.002 d | 0.998 | 15,035.27 ± 259.05 e | 0.217 ± 0.008 d | 0.970 |

| PSPD-15l | 36,213.81 ± 134.36 e | 0.164 ± 0.002 d | 0.997 | 14,955.14 ± 263.36 e | 0.222 ± 0.009 c | 0.971 |

| PSPD-15m | 38,621.43 ± 138.76 d | 0.167 ± 0.002 c | 0.997 | 17,820.99 ± 286.04 d | 0.221 ± 0.008 c | 0.975 |

| PSPD-15s | 43,934.30 ± 169.17 c | 0.168 ± 0.001 c | 0.996 | 18,777.33 ± 311.37 d | 0.228 ± 0.008 b | 0.976 |

| PSPD-20l | 47,204.90 ± 179.05 b | 0.171 ± 0.003 bc | 0.997 | 21,572.31 ± 258.38 c | 0.237 ± 0.006 a | 0.989 |

| PSPD-20m | 48,868.44 ± 196.16 b | 0.174 ± 0.002 b | 0.998 | 23,191.29 ± 320.38 b | 0.224 ± 0.007 c | 0.982 |

| PSPD-20s | 52,526.19 ± 213.71 a | 0.179 ± 0.004 a | 0.997 | 24,434.93 ± 344.08 a | 0.242 ± 0.007 a | 0.985 |

| PSPF (%) | 260 μm | 117 μm | 59 μm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ΔH (J·g−1) | FzW (%) | NFW (%) | ΔH (J·g−1) | FzW (%) | NFW (%) | ΔH (J·g−1) | FzW (%) | NFW (%) | |

| 0 | 52.85 ± 1.22 a | 43.20 ± 0.87 a | 56.82 ± 0.74 d | 52.85 ± 1.22 a | 43.20 ± 0.87 a | 56.82 ± 0.47 c | 52.85 ± 1.22 a | 43.20 ± 0.87 a | 56.82 ± 0.47 d |

| 10 | 47.46 ± 0.98 b | 41.43 ± 0.50 b | 58.57 ± 1.24 c | 47.09 ± 0.24 b | 39.27 ± 1.20 b | 60.73 ± 2.13 b | 46.24 ± 0.22 b | 38.15 ± 1.08 b | 61.85 ± 0.43 c |

| 15 | 46.23 ± 1.76 bc | 40.04 ± 0.89 c | 59.96 ± 2.20 b | 44.33 ± 0.38 c | 39.09 ± 0.60 b | 60.90 ± 1.59 b | 41.07 ± 1.67 c | 37.02 ± 0.54 bc | 63.01 ± 1.12 b |

| 20 | 43.71 ± 0.63 c | 38.19 ± 1.16 d | 61.80 ± 0.16 a | 41.06 ± 0.99 d | 36.60 ± 0.69 c | 63.35 ± 1.72 a | 39.32 ± 1.07 d | 35.44 ± 0.33 c | 64.59 ± 1.10 a |

| PSPF (%) | Peak Area (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 260 μm | 117 μm | 59 μm | |||||||

| A21 | A22 | A23 | A21 | A22 | A23 | A21 | A22 | A23 | |

| 0 | 9.26 ± 0.05 d | 90.37 ± 1.68 a | 0.46 ± 0.03 c | 9.26 ± 0.05 d | 90.37 ± 1.68 a | 0.46 ± 0.03 d | 9.26 ± 0.05 d | 90.37 ± 1.68 a | 0.46 ± 0.03 b |

| 10 | 12.07 ± 0.34 c | 87.60 ± 1.05 b | 0.39 ± 0.07 c | 16.11 ± 0.24 c | 83.04 ± 1.50 b | 0.97 ± 0.01 b | 16.85 ± 0.27 c | 82.66 ± 2.43 b | 0.39 ± 0.09 c |

| 15 | 20.01 ± 0.57 b | 77.12 ± 0.32 c | 2.84 ± 0.09 a | 23.54 ± 0.71 b | 74.50 ± 0.77 c | 1.93 ± 0.07 a | 23.86 ± 0.21 b | 75.59 ± 1.45 c | 0.62 ± 0.03 a |

| 20 | 24.82 ± 0.24 a | 73.86 ± 0.98 d | 1.33 ± 0.14 b | 32.27 ± 0.30 a | 66.95 ± 0.41 d | 0.60 ± 0.06 c | 31.90 ± 0.21 a | 67.70 ± 1.09 d | 0.36 ± 0.02 c |

| PV | HV | BD | FV | SB | WA | DT | ST | Bw | A21 | A22 | A23 | ΔH | FzW | NFW | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PV | 1 | ||||||||||||||

| HV | 0.863 ** | 1 | |||||||||||||

| BD | 0.884 ** | 0.527 | 1 | ||||||||||||

| FV | 0.876 ** | 0.998 ** | 0.552 | 1 | |||||||||||

| SB | 0.889 ** | 0.987 ** | 0.583 | 0.995 ** | 1 | ||||||||||

| WA | 0.316 | 0.049 | 0.490 | 0.069 | 0.098 | 1 | |||||||||

| DT | −0.566 | −0.690 * | −0.308 | −0.690 * | −0.685 * | 0.539 | 1 | ||||||||

| ST | −0.21 | 0.128 | −0.475 | 0.096 | 0.049 | −0.838 ** | −0.507 | 1 | |||||||

| Bw | −0.376 | −0.231 | −0.426 | −0.244 | −0.262 | −0.881 ** | −0.478 | 0.598 | 1 | ||||||

| A21 | −0.431 | −0.505 | −0.252 | −0.514 | −0.522 | 0.640 * | 0.852 ** | −0.54 | −0.485 | 1 | |||||

| A22 | 0.489 | 0.565 | 0.294 | 0.579 | 0.593 | −0.581 | −0.855 ** | 0.490 | 0.411 | −0.993 ** | 1 | ||||

| A23 | −0.524 | −0.536 | −0.390 | −0.580 | −0.636 * | −0.402 | 0.168 | 0.337 | 0.479 | 0.059 | −0.175 | 1 | |||

| ΔH | 0.382 | 0.570 | 0.111 | 0.557 | 0.534 | −0.701 * | −0.838 ** | 0.741 * | 0.473 | −0.928 ** | 0.910 ** | 0.046 | 1 | ||

| FzW | 0.198 | 0.395 | −0.038 | 0.383 | 0.363 | −0.812 ** | −0.820 ** | 0.833 ** | 0.613 | −0.897 ** | 0.865 ** | 0.144 | 0.949 ** | 1 | |

| NFW | −0.193 | −0.391 | 0.042 | −0.379 | −0.359 | 0.814 ** | 0.816 ** | −0.835 ** | −0.612 | 0.895 ** | −0.863 ** | −0.146 | −0.949 ** | −1 ** | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Zhou, X.; Zhang, Y.; Zhou, W.; Zhang, L. Influences of Particle Size and Addition Level on the Rheological Properties and Water Mobility of Purple Sweet Potato Dough. Foods 2023, 12, 398. https://doi.org/10.3390/foods12020398

Hu H, Zhou X, Zhang Y, Zhou W, Zhang L. Influences of Particle Size and Addition Level on the Rheological Properties and Water Mobility of Purple Sweet Potato Dough. Foods. 2023; 12(2):398. https://doi.org/10.3390/foods12020398

Chicago/Turabian StyleHu, Han, Xiangyu Zhou, Yuxin Zhang, Wenhua Zhou, and Lin Zhang. 2023. "Influences of Particle Size and Addition Level on the Rheological Properties and Water Mobility of Purple Sweet Potato Dough" Foods 12, no. 2: 398. https://doi.org/10.3390/foods12020398