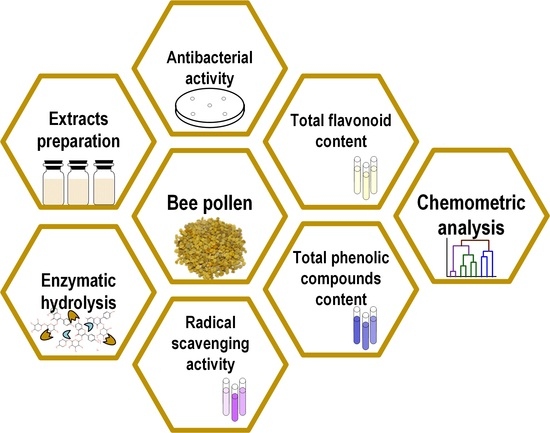

Nine samples of bee pollen underwent hydrolysis using lipase, protease, cellulase, Clara-diastase, Viscozyme® L, and amyloglucosidase. The impact of enzymatic hydrolysis was assessed by comparing total phenolic compounds, flavonoid content, radical scavenging, and antibacterial activity before and after hydrolysis. To the best of our knowledge, this is the first study to optimize the duration and amount of enzymes used in the enzymatic hydrolysis of bee pollen.

3.1. Determination of Optimal pH for Enzymes Activity

The relationship between enzymatic activity and substrate pH was determined following the manufacturer’s recommendations (see

Table 2). Enzymatic activity was controlled within the pH ranges of 3.6–5.6 and 5.8–7.8 using sodium acetate and sodium phosphate buffers. The results are presented in

Figure 2 and

Figure 3.

The data indicate that the optimal pH for achieving the highest activity of

Viscozyme® L and cellulase is 5.0, while for amyloglucosidase, the optimal pH is 5.2 (

Figure 2). An optimal pH value of 6.8 is identified for achieving the highest activity of

Clara-diastase, and a pH of 7.0 is optimal for the highest activity of lipase and protease (

Figure 3). Uchida and Santos [

22] also determined that the best activity of cellulase is achieved at pH 5. Furthermore,

Viscozyme® L is identified as a cellulolytic enzyme mixture, with its maximum activity observed at the same pH. A similar optimal pH for amyloglucosidase was reported by Malik et al. [

23]. Additionally, studies by Xiang et al. [

24] for lipase activity and Otroshi et al. [

25] for protease activity indicated a maximum activity at pH 7. The determined optimal pH conditions for the enzymes were employed for further experiments with bee pollen.

3.2. Optimization of Conditions for Bee Pollen Enzymatic Hydrolysis

The optimization of enzymatic hydrolysis duration was evaluated using a randomly chosen Lithuanian pollen sample. The chosen sample was enzymatically hydrolyzed with six commercial enzymes: Clara-diastase, Viscozyme® L, amyloglucosidase, protease, lipase, and cellulase. The optimization of enzymatic hydrolysis involved the comparison of TPC, TFC, RSA, and oxidation-reduction potential after 1, 2, 3, 4 and 5 h of the hydrolysis process, utilizing 50, 100, 150, 200 and 300 µL of each enzyme.

The study revealed that enzymatic hydrolysis had a positive effect on increasing the content of biologically active compounds. However, the extent of the increase depended on both duration and the ratio of bee pollen to enzyme. The amounts of measured compounds in bee pollen samples significantly increased after exposure to different enzymes: TPC increased by 1.3–2.3 times (p ≤ 0.05), TFC increased by 1.2–2.2 times (p ≤ 0.05), and RSA increased by 1.3–1.8 times (p ≤ 0.05). Oxidation-reduction potential indicated a significant variation between samples, ranging from 133.68 to 195.00 mV (p ≤ 0.05). The impact of the bee pollen to enzyme ratio was tested by altering the volume of the enzyme solution. A significant increase in the total phenolic compounds content by 1.3–2.3 times was observed in the tested samples (p ≤ 0.05). The increase of evaluated TFC after enzymatic hydrolysis of bee pollen was statistically significant and ranged from 1.3 to 1.8 times at p ≤ 0.05. Based on the obtained results, it was determined that RSA increased from 9.23 ± 0.03 to 16.01 ± 0.03 mg RUE/g and correlated with total phenolic content (0.816 at p ≤ 0.05). Oxidation-reduction potentials varied from 133.68 to 203.00 mV in bee pollen samples after the addition of different volumes of enzymes.

The determination of the optimal amount of enzyme and the optimal duration of enzymatic hydrolysis was grounded on the alterations in TPC, TFC, RSA, and oxidation-reduction potential as previously described. Approximated functional dependencies for each parameter were found and derivatives were derived. Subsequently, parameter derivative curves were plotted after interpolation. The presentation of the optimal duration of enzymatic hydrolysis is depicted in

Figure 4, while the optimal amount of enzyme is illustrated in

Figure 5.

The determination of the optimal amount of enzyme and the optimal duration of enzymatic hydrolysis for each specific tested enzyme was based on derivative curves of each parameter function. The maximum point of each parameter corresponded to the point where the magnitude of the derivative curve changed from positive to negative upon crossing the x-coordinate axis.

Based on the previously described derivatives of TPC, TFC, RSA, and oxidation-reduction potential, it was determined that the optimal duration of enzymatic hydrolysis using cellulase,

Viscozyme® L and

Clara-diastase is 3 h 15 min, whereas for protease, lipase and amyloglucosidase it is 3 h 45 min (

Figure 3). The optimal amount of cellulase,

Viscozyme® L, and

Clara-diastase for enzymatic hydrolysis was found to be 175 µL, while for protease, lipase, and amyloglucosidase, it was 200 µL (

Figure 4). A shorter duration of enzymatic hydrolysis and a lower amount of cellulase,

Viscozyme® L, and

Clara-diastase can be considered for bee pollen hydrolyzation.

Viscozyme® L and

Clara-diastase enzyme mixtures include cellulase. Bee pollen contains cellulose in the inner layer of the cell wall, which can be easily broken down by cellulase, potentially leading to the release of biologically active compounds [

8].

3.3. Variation of Total Phenolic Compounds, Flavonoid Content, and Radical Scavenging Activity in Natural and Enzymatically Hydrolyzed Bee Pollen

The extracts were prepared from nine bee pollen samples originating different regions of Europe, including Sweden, Spain, Netherlands, Italy, Poland, Denmark, Slovakia, Malta, and Lithuania. The hydrolysis process was applied using lipase, cellulase, protease, amyloglucosidase,

Viscozyme® L, and

Clara-diastase enzymes. The impact of the enzymatic hydrolysis was assessed by comparing changes in TPC, TFC, and RSA before and after the enzymatic hydrolysis process, and statistically significant (

p ≤ 0.05) variations are presented in

Table 4.

Enzymatic hydrolysis under optimized conditions resulted in an increase in TPC by 1.1 to 2.5 times at a significance level of

p ≤ 0.05. Prior to fermentation, all bee pollen samples exhibited TPC levels ranging from 8.07 to 12.67 mg RUE/g. After hydrolysis with protease, TPC changed from 23.6 to 94.4%; lipase from 6.8 to 41.9%; cellulase from 55.8 to 150.0%;

Clara-diastase from 36.0 to 113.9%;

Viscozyme® L from 21.3 to 135.0% and amyloglucosidase from 1.5 to 34.8%. According to the results, the increase in TPC was dependent on the geographical origin of bee pollen. Given that geographic location is correlated with climate, it can reasonably be assumed that bee pollen accumulates a higher quantity of biologically active substances in cooler regions, leading to a greater release during enzymatic hydrolysis [

26]. The findings revealed that bee pollen from the northern part of Europe exhibited a higher TPC compared to pollen from the south, with a statistically significant difference ranging from 1.1 to 2.0 times (

p ≤ 0.05).

Furthermore, the amount of TPC obtained after enzymatic hydrolysis of bee pollen with cellulase,

Viscozyme® L and

Clara-diastase was 19.8 to 55.5% higher compared to hydrolysis with protease, amyloglucosidase, and lipase. The highest TPC was determined after hydrolysis with cellulase (ranging from 12.57 ± 0.02 to 31.67 ± 0.05 mg RUE/g), while the lowest was observed with amyloglucosidase (ranging from 8.84 ± 0.09 to 16.17 ± 0.05 mg RUE/g) (

Table 4). A higher quantity of TPC was determined after enzymatic hydrolysis with

Viscozyme® L and

Clara-diastase due to the presence of cellulase in their composition. The greater increase in biologically active substances could be attributed to the cellulase and the mixture’s ability to break down the pollen cell wall, which consists of an external layer made of sporopollenin and an internal layer composed of pectin and cellulose [

1,

27]. TFC also significantly (

p ≤ 0.05) increased by 1.1 to 3.0 times after treatments with all tested enzymes (see

Table 4). The results revealed that bee pollen enzymatically hydrolyzed with cellulase,

Viscozyme® L and

Clara-diastase exhibited 1.5 to 2.5 times higher flavonoid content compared to hydrolysis with lipase, protease, and amyloglucosidase. Furthermore, bee pollen hydrolyzed with cellulase released the highest flavonoid content (ranging from 6.46 ± 0.06 to 15.83 ± 0.05 mg RUE/g), while the lowest results were observed with amyloglucosidase (ranging from 4.41 ± 0.06 to 8.08 ± 0.05 mg RUE/g) at

p ≤ 0.05.

A strong relation between flavonoid content and TPC was observed through statistical analysis. A strong correlation was determined in both natural bee pollen samples (0.813) and samples after hydrolysis with lipase, cellulase, protease, amyloglucosidase,

Viscozyme® L, and

Clara-diastase (0.779, 1.000, 0.820, 1.000, 1.000, 1.000, respectively) (see

Section 3.5). Such results could be explained by the fact that flavonoids, especially flavones, and flavonols, constitute the largest group of phenolic compounds. Additionally, these biologically active compounds, owing to their chemical structure, are responsible for the antioxidant activity of bee pollen [

28,

29].

Enzymatic treatments of bee pollen led to a significant (

p ≤ 0.05) increase in RSA, ranging from 2.0 to 246.4% (

Table 4), with the highest activity values obtained after enzymatic hydrolysis with cellulase,

Viscozyme® L and

Clara-diastase in comparison to hydrolysis with lipase, protease, and amyloglucosidase. The correlation relationships between total phenolic compounds and RSA, as well as between total flavonoid compounds and RSA, were as follows: correlation coefficients were 0.837 and 0.965 in natural bee pollen, respectively, and within the range of 0.787 to 1.000, and 0.881 to 1.000, respectively, depending on the enzyme used during hydrolysis (see

Section 3.5). The very high correlation characteristics confirmed that enzymatic treatment of bee pollen effectively degrades the matrix of the pollen cell wall, releases specific phenolic and flavonoid molecules, and enhances the bioavailability of natural antioxidant sources.

The topic of enzymatic hydrolysis of bee pollen in scientific literature is relatively new, with only a few initial studies having been published. An increase in TPC after enzymatic hydrolysis was also determined by Zuluaga-Dominguez et al. [

12], where the amount of phenolics significantly increased by 83 to 106% after hydrolysis with different protease mixtures, flavonoids increased by 85 to 96% and antioxidant activity increased up to 68%. In another study by Zuluaga et al. [

4], it was reported that after thermal treatment and enzymatic hydrolysis with

Protamex™ (endoprotease), bioactive compounds and antioxidant capacity significantly increased by 13 to 14%. During our research, enzymatic hydrolysis with protease led to changes in the amount of TPC by 23 to 94%, TFC by 32 to 57%, and antioxidant capacity by 57 to 134%. The results of other authors align with our study and confirm positive trends of bee pollen hydrolysis with proteases. The main factors influencing the results are the geographical and botanical origins of bee pollen and its freshness, as well as the specificity of the enzyme used for treatment. However, some studies have shown a negative impact of enzymatic hydrolysis on bee pollen compounds. Benavides-Guevara et al. [

3] determined a decrease in phenolic compounds (from 15.19 ± 0.58 to 7.00 ± 0.06 mg gallic acid/g) and antioxidant activity (from 0.029 ± 0.001 to 0.006 ± 0.000 mmol Trolox/g in ferric reducing antioxidant power assay; from 0.079 ± 0.014 to 0.015 ± 0.004 mmol Trolox/g in the Trolox equivalent antioxidant capacity assay) after bee pollen enzymatic hydrolysis with

ProtamexTM. The discrepancies between these results and our study may be attributed to the use of different technological processes of enzymatic hydrolysis.

3.4. Antibacterial Activity in Natural and Enzymatically Hydrolyzed Bee Pollen

The antibacterial activity (AA) of nine bee pollen samples from Sweden, Spain, Netherlands, Italy, Poland, Denmark, Slovakia, Malta, and Lithuania after hydrolysis using lipase, cellulase, protease, amyloglucosidase,

Viscozyme® L and

Clara-diastase enzymes was evaluated and the results are presented in

Table 5. The inhibition zone of antibacterial activity was compared with the antibacterial activity of ceftazidime (µg CEF/mL).

To our knowledge, this is the first study to evaluate the AA of enzymatically hydrolyzed bee pollen. However, the AA of natural (non-treated) bee pollen has already been analyzed. The AA of natural bee pollen extracts was demonstrated against

Bacillus thuringiensis,

S. aureus,

Escherichia coli, and

Salmonella enterica by Sawicki et al. [

30]. Velásquez et al. [

31] determined the antibacterial effect of sixteen bee pollen samples from Chile against

S. aureus,

E. coli,

Streptococcus pyogenes, and

Pseudomonas aeruginosa. The sensitivity of

E. coli,

Staphylococcus epidermidis, and

Candida albicans to Brazilian bee pollen extracts was also described by Soares de Arruda et al. [

32].

A positive effect of enzymatic hydrolysis on bee pollen AA against Gram-positive

S. aureus,

L. monocytogenes, and Gram-negative

S. enteritidis,

S. typhimurium bacteria cultures was observed. The highest changes in antibacterial activity were determined after enzymatic hydrolysis with cellulase (1.2 to 3.3 times) and

Viscozyme® L (1.2 to 3.1 times), while the lowest changes were observed with amyloglucosidase (1.1 to 1.6 times). In a previous study [

9], lactic acid fermentation was applied, also revealing a positive effect of the treatment on the enhancement of bee pollen antibacterial activity against

Micrococcus luteus,

S. aureus, and

E. coli.

AA was strongly influenced by the strain of pathogenic bacteria. Gram-positive bacteria cultures were found to be 1.1 to 2.5 times more sensitive to natural and enzymatically hydrolyzed bee pollen extracts compared to Gram-negative bacteria. This difference in susceptibility between Gram-positive and Gram-negative bacteria may be attributed to the distinct composition of their cell walls. The membrane of Gram-positive bacteria is rich in low-abundant lipids, which could serve as a specific target for antibacterial compounds found in bee pollen extracts [

33]. Similarly, other studies have also analyzed and successfully demonstrated the more effective AA of bee pollen extracts against Gram-positive bacteria cultures. Velasueze et al. [

31] and Bakour et al. [

34] evaluated the antibacterial impact of bee pollen on

S. aureus,

E. coli, and

P. aeruginosa and both studies reported higher activity of the extracts against Gram-positive bacteria strains.

The antibacterial activity, both before and after enzymatic hydrolysis, was found to exhibit a strong correlation with TPC, TFC, and RSA. The observed trend, characterized by high correlation coefficient values for tested characteristics (see

Section 3.5), suggested that the composition and quantity of biologically active compounds have a significant impact on the antibacterial activity of bee pollen. This relationship between the high levels of bioactive compounds, antioxidant content, and AA has also been analyzed and confirmed by other studies [

30,

31,

32,

33,

34,

35].

3.5. Chemometric Analysis of the Samples

TPC, TFC, RSA, and AA of natural and enzymatically hydrolyzed bee pollen exhibited a high correlation (see

Table 6).

Principal component analysis (PCA) and clustering analysis were employed to gain a better understanding of the relationship among the results and to determine the similarity of bee pollen samples both before and after the enzymatic hydrolysis process. Two principal components, accounting for 96.54 to 99.65% of the total initial variance in the input variables were suggested by the PCA method. The k-means clustering algorithm was used to visually depict the distribution of various bee pollen samples before and after enzymatic hydrolysis based on the measured parameters, including TPC, TFC, RSA, and AA against

S. aureus,

L. monocytogenes,

S. enteritidis,

S. typhimurium.

Figure 6 shows the grouping of the samples according to the measured parameter.

The clustering results revealed that eight groups were delineated based on the measured characteristic used as an input, specifically TPC and TFC results (see

Figure 6a,b). One cluster was formed by samples from Italy and Spain, which exhibited similarity to a sample from Malta. Additionally, the profiles of bee pollen samples from Sweden and Lithuania were distinct from those of Southern European bee pollen. Notably, all bee-collected samples formed individual groups based on RSA results (

Figure 6c). Similarly, in terms of TPC and TFC, pollen from Malta was more closely related to samples from Italy, while samples from Sweden were more similar to those from Lithuania, and samples from the Netherlands showed similarities to those from Slovakia and Poland. It could be inferred that the similarity of the tested samples was influenced by their geographical and botanical origins, ranging from northern to southern Europe.

Bee pollen samples were grouped into 5–7 clusters depending on their measured antibacterial activity (

Figure 6d–g). Again, distinct groups were observed for Lithuanian and Sweden samples before and after enzymatic hydrolysis. In contrast, samples from South Europe (Malta, Spain, and Italy) and samples from Central Europe (Poland, Slovakia, Denmark, and The Netherlands) exhibited highly similar profiles.

However, the k-means clustering algorithm results exposed that the enzyme used during the hydrolysis process had a more significant impact on clustering than the geographical origin of the bee-collected samples. The clustering results based on TPC, TFC, and RSA, yielded seven clusters before enzymatic hydrolysis. Furthermore, after hydrolysis with amyloglucosidase six groups were identified, while with Viscozyme® L and Clara-diastase, seven groups were formed. With protease and cellulase, eight groups were suggested, and with lipase, nine groups were observed. The results of antibacterial activity for bee pollen before and after enzymatic hydrolysis revealed 6–7 groups and demonstrated that samples from Central and Northern Europe had distinct profiles, whereas samples from South Europe revealed highly similar profiles.