3.1. Amylose Content and Hydration Properties

The amylose content and hydration properties (WAC, WAI, WSI, and SP) are presented in

Table 2. Amylose concentrations ranged from 2.78 to 22.08%. As expected, waxy maize and waxy rice samples showed the lowest amylose concentrations, whereas wheat and normal maize showed the highest values, followed by tapioca, potato, and normal rice. Previous works have reported the following amylose concentrations in starches: maize ranging from 0% (waxy) to 40%, rice from 0% (waxy) to 30% [

30], wheat from 13 to 32% [

16,

32], potato from 18 to 28% [

33,

34,

35,

36], and tapioca from 15 to 25% [

37,

38,

39].

The WAC values allowed grouping the samples into two main groups: one containing wheat, waxy rice, normal rice, and tapioca that showed the lowest values (0.82–0.89 g/g), and one containing normal maize, waxy maize, and potato that showed the higher values (1.01–1.08 g/g). The variation in WAC could be due to variations in starch structure, resulting in variations in the formation of covalent and hydrogen bonds between the starch chains and, thereby, in the availability of water binding sites [

23,

40]. WAI allowed the samples to be divided into three groups: potato and waxy maize, which showed the lowest values (4.2–4.3 g/g), followed by normal maize, tapioca, and wheat (7.0–8.0 g/g), and finally normal rice and waxy rice, which showed the highest results (12.4–12.5 g/g). The thermal contribution of the test dissociated the hydrogen bridge interactions of the starch, allowing the hydroxyl groups of the polysaccharide to interact with water, thereby increasing the solubility and swelling of the granules [

30]. Swelling power (SP), which followed the same trend as WAI, is linked to the ability of starch granules to absorb water during gelatinization [

41]. Solubility (WSI) and swelling power reflect the interaction between the amorphous and crystalline regions of starch granules [

30,

42]. Waxy rice and normal rice showed the highest SP and WAI values, indicating that the difference in amylose concentration did not substantially modify the water binding capacity of these starch samples, a behavior that could be explained by the similar structure of amylopectin in both samples [

30]. These two starches also had the same and the lowest WSI values, reinforcing the idea that the amount of amylose does not exert the main effect on the swelling and solubilization of the starch granules of these two samples. On the contrary, waxy and normal maize starches showed the most marked differences in WSI values, with the waxy type showing the highest solubility and the normal maize presenting one of the lowest values. Because all studied samples were of different sources and natures, it is not possible to use amylose content alone to predict swelling capacity and solubility, as these variables are also influenced by the structure of amylopectin and the extent of interaction between the amorphous and crystalline zones [

30,

43,

44]. The extension and ability of starch granules to swell is mainly a property of their amylopectin content, but amylose may also have an inhibiting or delaying effect on it [

45].

3.2. Thermal Properties

The results from the DSC analyses are presented in

Table 3. Potato starch showed the highest enthalpy of gelatinization (18.0 J/g), followed by the waxy starch samples (16.2 J/g (rice) and 15.68 J/g (maize)). Wheat starch had the lowest gelatinization enthalpy, following the general premise that samples with higher amylose content usually have lower ΔH(G) values [

37]. Potato starch is reported to have long external chains on the amylopectin molecule, which exert a higher enthalpy of gelatinization in the granule [

31]. The elevated ΔH(G) in potato starch might also be explained by its high crystallinity; thus, more energy is required to break it down [

46].

Wheat starch showed the lowest onset temperature of gelatinization (To), followed by potato and waxy rice, whereas normal rice had the highest value. In rice starch samples, a higher amylose content has been correlated with a higher gelatinization temperature [

47]; however, this correlation was not found in other starch samples, such as wheat starch or normal and waxy maize, suggesting that the internal structure of the starch granule exerts an important effect on the gelatinization process [

14,

48].

In general, peak (Tp) and ending (Te) temperatures of gelatinization varied among starches in the same order as To, with some exceptions due to the different shapes and widths (ΔT = Te − To) of the gelatinization peaks. Potato recorded the narrowest gelatinization peak (ΔT = 9.2 °C), whereas waxy rice showed the widest (19 °C), denoting a more complex and heterogeneous crystalline structure.

The enthalpy of the melting of amylopectin recrystallized after 7 days of storage at 2 ± 2 °C; the DR and the temperatures of this transition are also shown in

Table 3. The highest DR values were observed for potato, normal maize, and wheat starches, highlighting that the non-waxy cereal samples (wheat, normal maize, and normal rice) did not show statistical differences between their DR values. The double helices formed by amylopectin are shorter than those formed by amylose due to the branched structure and branch lengths of amylopectin [

30]; thus, amylopectin molecules with longer chains, as in the case of potato starch, would form more stable structures and would be expected to have a greater value of retrogradation enthalpy. The values of DR are related to the ease of rearrangement between starch molecules in which samples with higher amounts of amylose, such as non-waxy cereal samples, have a higher retrogradation capacity [

49], and they would be expected to show higher percentages of this parameter. The waxy rice samples showed the lowest DR values, which can be attributed to a higher proportion of A-chains and shorter external chains in the amylopectin molecule [

50]. The retrogradation peaks showed lower To values and higher ΔT values than those corresponding to the gelatinization scans, which is similar to other samples of starchy products tested previously [

29,

51,

52,

53], suggesting that fewer perfect crystalline regions were formed during storage [

54,

55]. The highest ΔT values of retrogradation were observed in potato (38 °C) and waxy rice (36 °C) starches, whereas the other samples ranged between 25 and 29 °C.

The amylose–lipid complex dissociation peak, which appeared in the range of 85 and 105 °C, was only recorded in normal maize, normal rice, and wheat starches. Normal rice showed the highest amylose–lipid dissociation enthalpy. As expected, it was not detected in waxy starches due to their low amylose content; it was not observed in tuber starches such as potato and tapioca either, despite their significant amounts of amylose. The occurrence of amylose–lipid complex dissociation peaks is common in cereals, which may contain about 1% lipid content, whereas starches from tubers, legumes, and waxy starches contain practically no lipids [

56]; thus, values for samples such as potato are very low or undetectable [

48].

3.3. Pasting Profiles

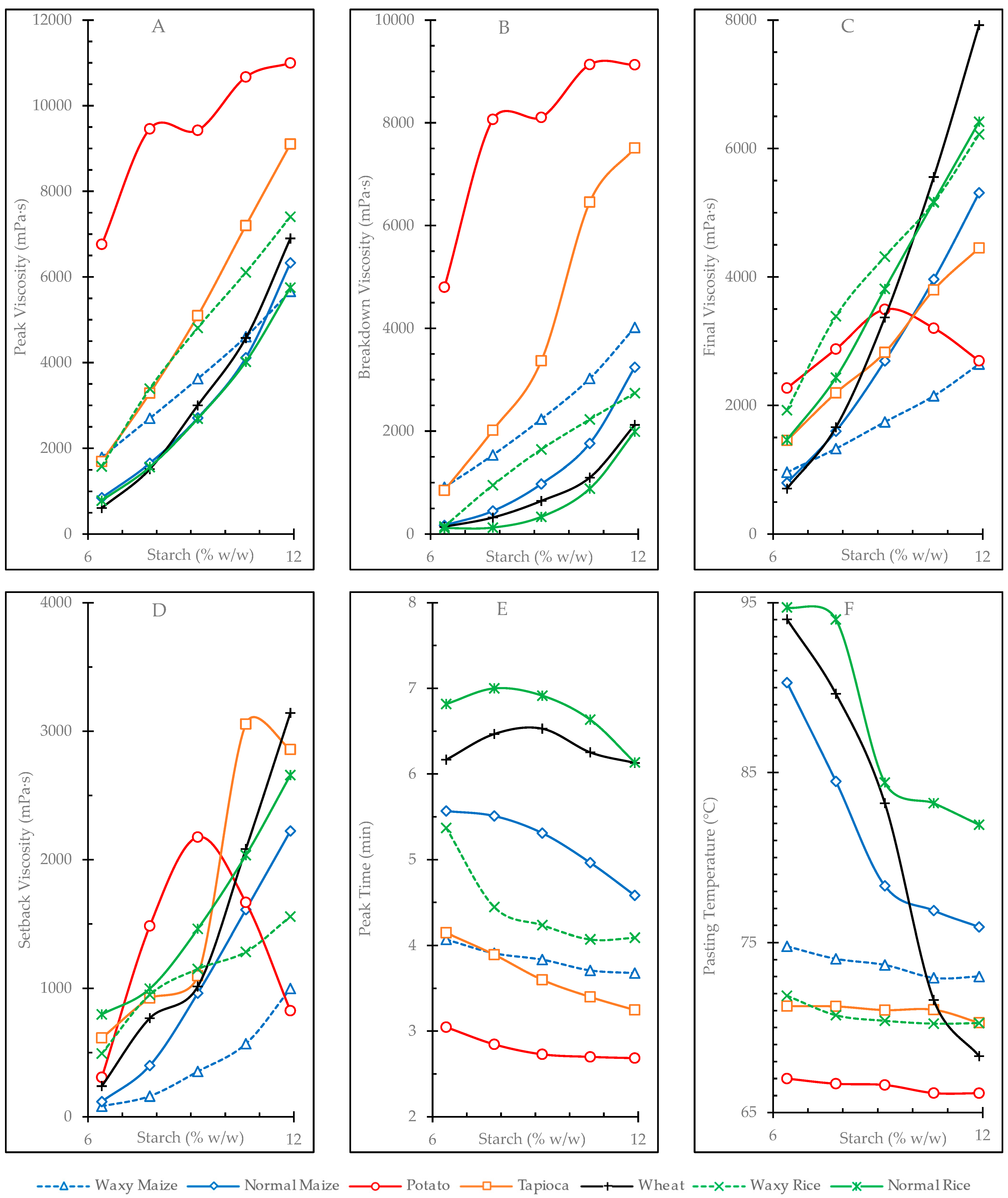

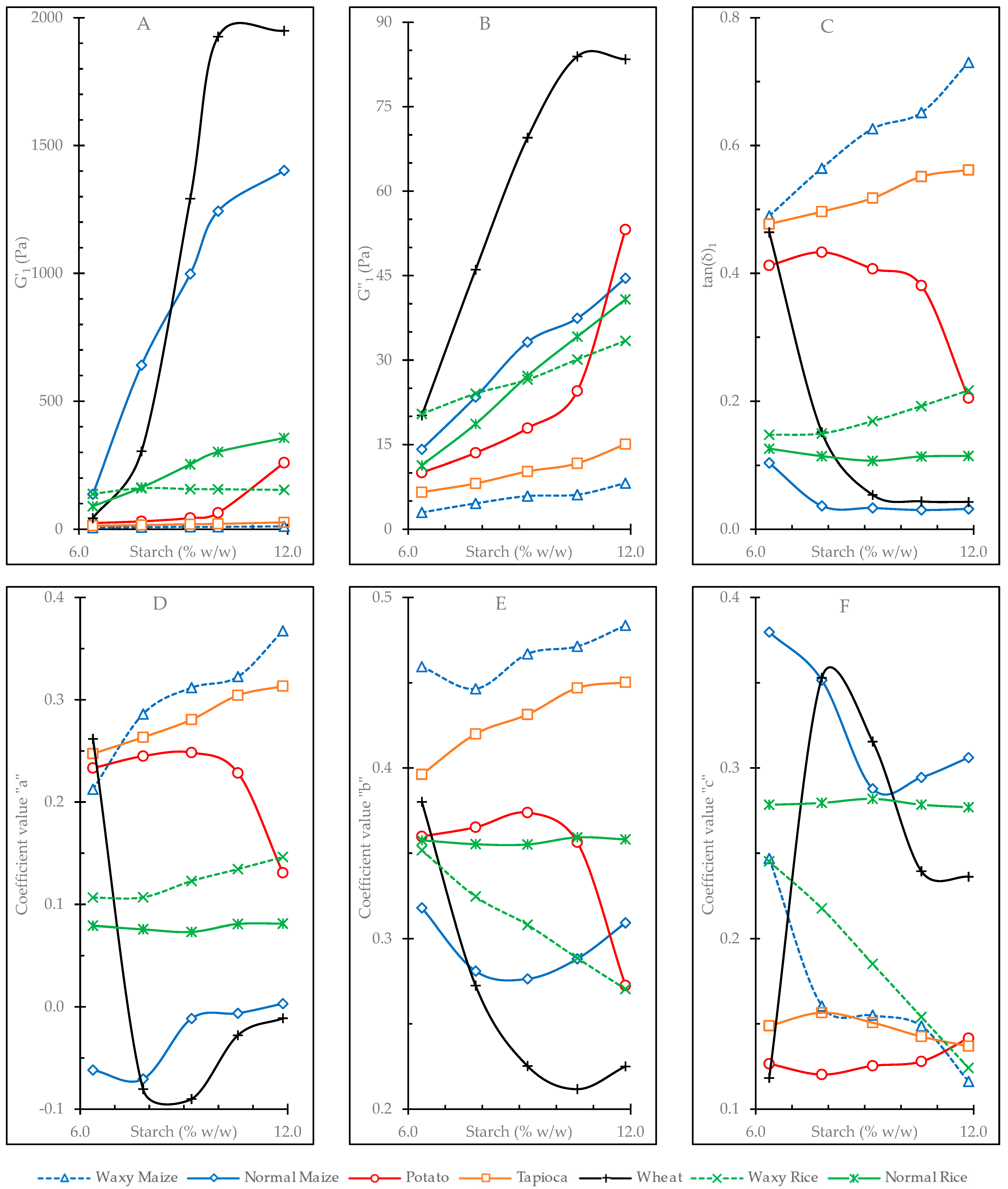

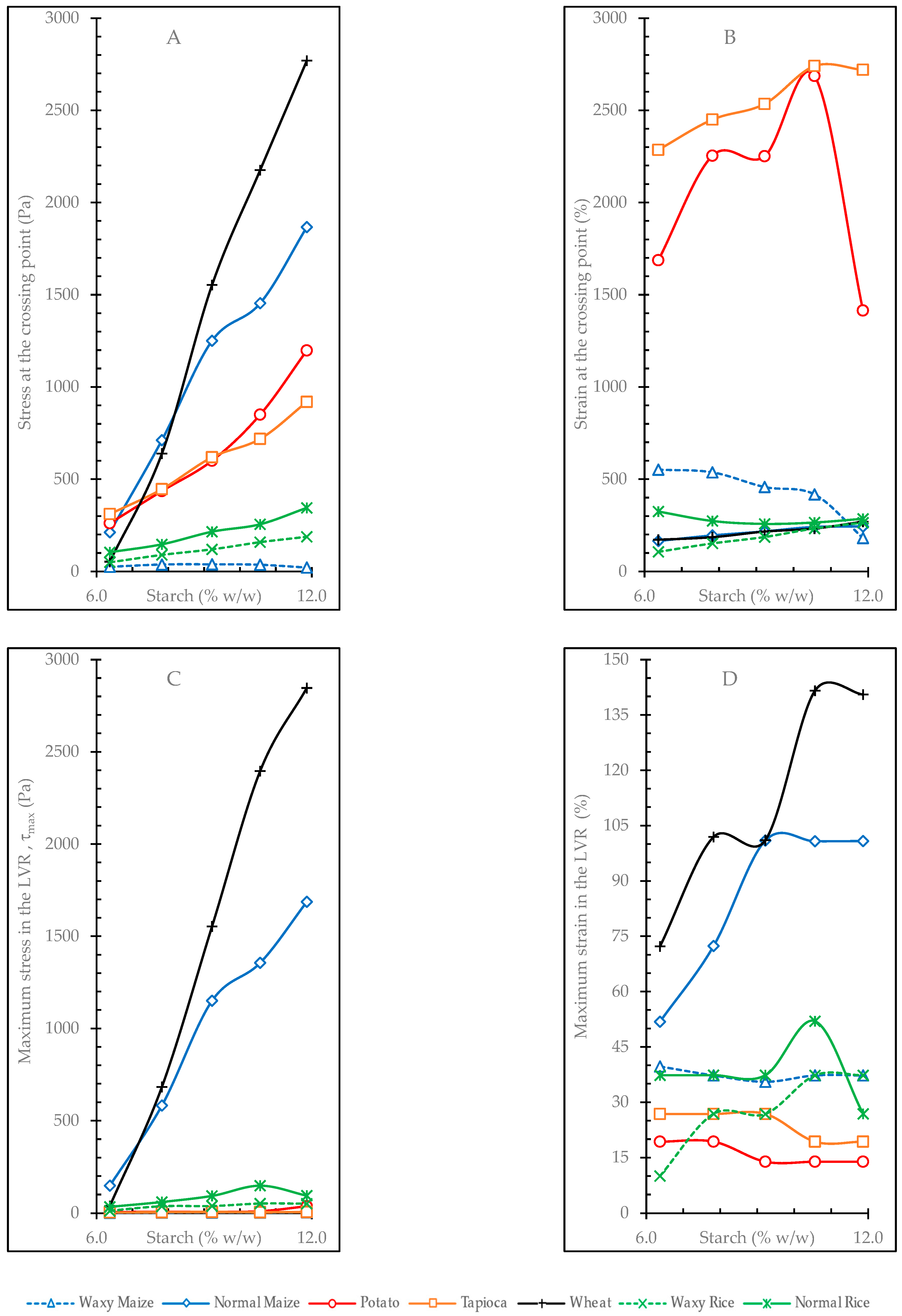

The pasting properties of the starches at all concentrations studied are presented in

Table S1. The evolution of pasting parameters with concentrations are presented in

Figure 1. The values obtained from fitting this evolution to a potential equation, P = k∙C

e, are summarized in

Table 4. The dependence of pasting viscosities (PV, TV, BV, FV, and SV) on starch concentration, in general, fit well to the potential model (with R

2 coefficients ranging 94–99) except for potato starch, which was always far from this potential evolution, and tapioca starch, which did not follow it in the cases of TV and SV. This procedure facilitates the comparison between starches regarding the effect that concentration has on their pasting properties by using only two values: the fitting coefficient

k (which quantifies the value of the evaluated property, P, at a concentration of 1 g/100 g) and the exponent

e (which informs the rate of increase of the P parameter with concentration).

Potato starch gels showed the highest PV values (6763–10,998 mPa·s), which presented significantly equal values at concentrations ≥9.2 g/100 g. This can also be evaluated from its very high

k coefficient for PV and the very low

e exponent, indicating little dependence of this variable on concentration. Normal rice, normal maize, and wheat starches showed the lowest PV values at low concentrations and the highest rate of increase with concentration, as evidenced by their low

k coefficient values and high

e exponents (

Table 4). On the contrary, potato, waxy maize, and waxy rice starches had the highest PV values at low concentration and the lowest rates of increase with concentration. When starch undergoes gelatinization and its granules become larger because of swelling, amylose is released and forms a network around the swollen structures, restricting the final swelling of the granules and peak viscosity [

14]. In this sense, when comparing starches of the same botanical origin, such as natural maize or rice and their waxy counterparts, higher amylose content usually leads to a decrease in PV [

57,

58,

59,

60]. However, pasting properties are affected by many factors in addition to amylose content, such as lipid and phosphorus content, starch granule size, the branch chain length distribution of amylopectin, and the molecular size of amylose [

60]. It was observed that the volume of gluten-free breads correlated positively with the peak viscosity of the flour [

61]; thus, this parameter could be used to predict the quality of the product made with these ingredients. The amount of raw material should also be considered for the preparation of gluten-free products because some materials register more pronounced changes in PV than others as the concentration changes.

Potato starch also showed the highest breakdown viscosity (BV) values (4801–9129 mPa·s) denoting its lowest stability against heating and stirring (

Figure 1B). Breakdown in the non-waxy cereal and tapioca samples showed a greater dependence on concentration, as indicated by their higher exponent

e (

Table 4). A significant negative correlation has been reported between breakdown viscosity and the specific volume of gluten-free breads [

62]. It has been reported that waxy starches provide textures with good acceptability to the processed products [

16,

17], but they also show high breakdown values; thus, the amounts of them used in the formulations must be balanced to obtain food products of higher quality. The concentration of starches in the formulations could also be important, as the BV values in some samples showed important changes when changing concentration.

FV increased potentially with concentration in all studied starches (see

Table 4 and R

2 values >98%) except potato starch. As shown in

Figure 1C, the FV of potato starch followed a parabolic evolution, presenting its maximum at a concentration of 9.2%. Within the other samples, the results are consistent with the general idea that starches with higher amylose content (such as wheat, normal maize, and normal rice) generally have higher FV values (usually measured at concentrations close to 10%) [

32,

63]. The highest FV at the gel concentration of 11.9 g/100 g corresponded to samples with higher amylose content (wheat (7922 mPa·s) and normal rice (6223 mPa·s)).

The SV that results from the difference FV − TV is related to amylose retrogradation, and it is generally lower in waxy or low-amylose content starches [

2,

63,

64,

65]. In the studied samples, SV behaved differently according to the starch concentration in the gel (

Figure 1D), which is similar to what was determined for FV. At higher concentrations of gels, their overall behavior was closer to predicted: samples with higher amylose content (wheat, normal rice and normal maize) showed higher SV values, whereas waxy samples had lower values. Tapioca and potato did not follow the expected SV trend with respect to amylose content, a behavior that is also shown in other parameters studied in this work, which could be explained by the presence of long amylopectin chains [

66,

67] and the high crystallinity of the samples [

68], which reduce the effect of amylose on the mentioned parameters.

The potato starch gels followed an inverted U-shaped trend in SV values with increasing concentration, showing a maximum value (2176 mPa-s) at 9.2%

w/

w (

Figure 1D), which does not allow a proper fit to a potential equation (

Table 4). This behavior indicates that potato starch could reach saturation conditions where parameters such as the starch–water interaction would be different, and the effect of concentration would not be equal to that observed at low concentrations. Tapioca starch had the highest SV with respect to the other starches at a concentration of 10.6%

w/

w (3056 mPa·s), a value that then decreased at 11.9%

w/

w, indicating that tapioca starch, like potato starch, experienced saturation behavior at high gel concentrations.

Increasing the concentration of the gels tends to maintain or decrease the peak time (Pt), with negative

e exponents and values <1 (

Table 4). Among all of the parameters measured during pasting events, Pt changed the least with changes in concentration. As a general trend, the samples with the lowest Pt values were those with the lowest amylose content; however, tuber starches did not follow this trend, showing the lowest peak times at all concentration levels (

Figure 1E). Cereal samples with higher amylose content (normal rice, wheat, and normal maize) showed the highest Pt values at all concentration levels.

Pt tended to decrease with increasing gel concentration in all cases (

Figure 1F,

Table 4). The non-waxy cereal samples (wheat, normal maize and normal rice) showed a strong dependence of Pt on gel concentration (given by the coefficient

e) and on high Pt values at each concentration, which is explained by the high coefficient

k. Samples with lower amylose content registered variations of Pt ~1 °C between the lowest and highest gel concentration values (1.65 °C and 1.86 °C for waxy rice and waxy maize, respectively). A similar behavior was observed for tuber starches (0.86 °C and 0.98 °C for potato and tapioca, respectively), showing once again the low dependence of the measured parameters on the amylose content of these two samples. On the other hand, non-waxy cereal samples with higher amylose content showed a marked decrease in Pt with increasing starch concentration in the gels. Thus, wheat starch recorded the highest difference in Pt (25.71 °C) between the 6.4 and 11.9%

w/

w concentration gels, followed by normal maize (14.39 °C) and normal rice (12.80 °C). This marked change in the cereal samples shows more clearly that as gel concentration increases, amylose loses the ability to delay granule swelling, requiring a lower temperature to initiate the pasting process. The PT provides important information about the quality of gluten-free bakery products. A significant positive correlation between the specific volume of bread and PT has been reported [

62]. Given the results presented in this work, not only is PT relevant in the selection of starches for food processing, but also the concentration of the starch selected in the formulation, as some starches can have very important variations at different ratios during processing.

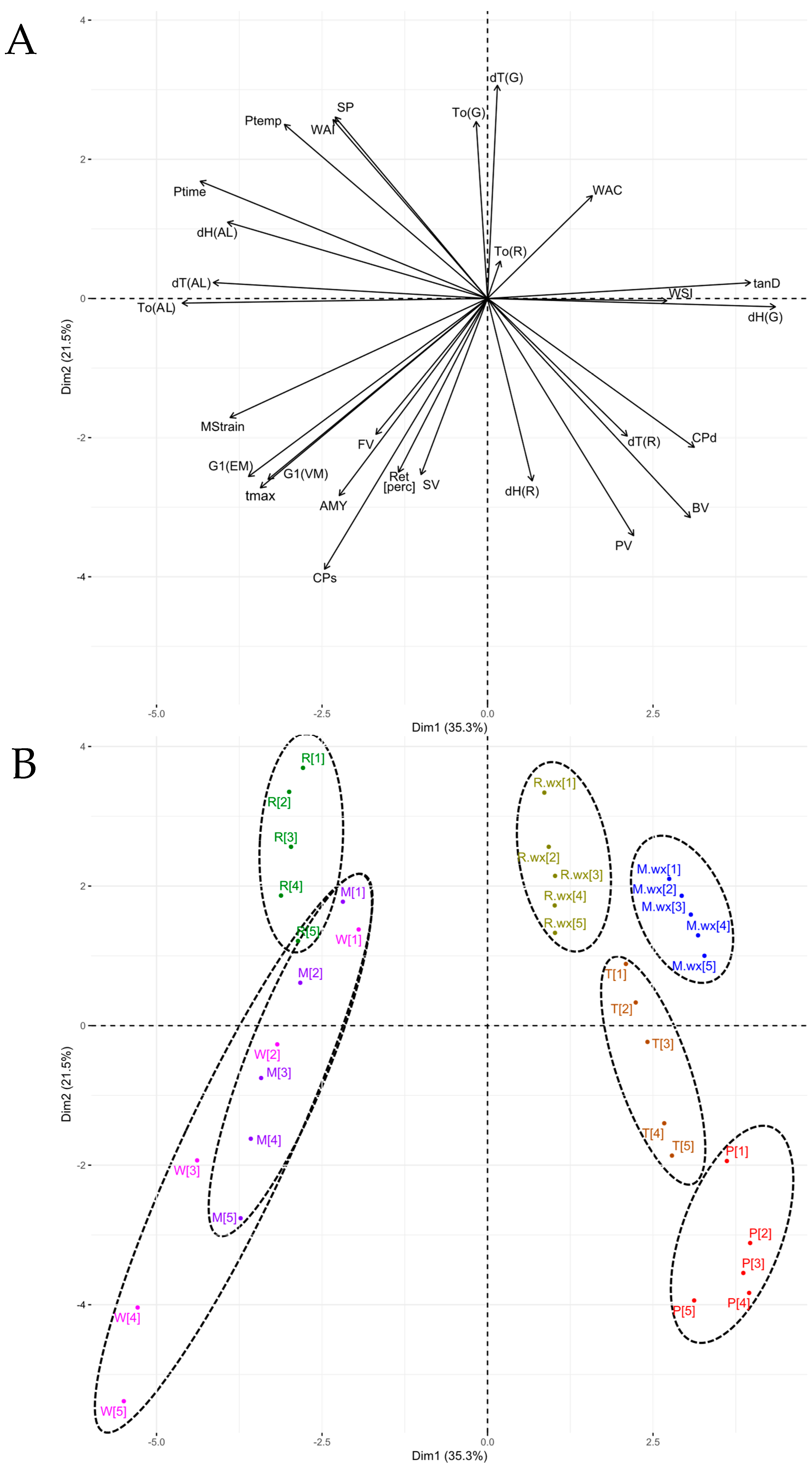

3.5. Principal Components Analysis

The conducted principal component analysis (PCA) is illustrated in

Figure 4, with starch samples identified with different colors and variables represented in black.

The model explains 56.8% of the total variation between samples. It consists of two dimensions, where Dim1 is presented in the horizontal axis and Dim2 in the vertical axis. The central point of the graph, which defines four quadrants, represents the zero-contribution value from which the studied parameters emerge as vectors, depending on whether they are positively or negatively correlated with each of the two dimensions.

Cereal samples with higher amounts of amylose (wheat, normal rice, and normal maize) are located in the zone of negative Dim1 values, where the greatest effect of amylose concentration and calorimetric parameters of dissociation of the amylose–lipid complex are found. The wheat starch gels at different concentrations show an enormous dispersion along Dim1, which is related to the pronounced separation of pasting temperature with increasing concentration as well as a stronger relationship of the more concentrated gels with the vectors of FV, SV and some rheological parameters (maximum stress, maximum strain, G′1, G″1 and crossing point stress), which is in agreement with the high e coefficients shown by this starch in these parameters. The normal maize starch gels have a very similar distribution on the graph as wheat starch, but they are less dispersed, whereas normal rice starch has a much narrower distribution. With respect to the range of positive Dim1 values, waxy rice and waxy maize samples were placed in the positive quadrant of Dim2, whereas potato starch gels are in the negative quadrant of Dim2, and tapioca starch gels are in an intermediate position. Gels of waxy samples, potato, and tapioca were found to be opposite to the effect of amylose concentration and are also shown to be less affected by parameters such as pasting temperature, crossing point stress, and maximum stress, which did not vary greatly with increasing concentrations in these four materials.

Regarding Dim2, tapioca and potato samples showed the highest values of deformation at the crossing point as well as the highest values of PV. With respect to the latter variable, wheat starch samples showed the greatest increase in PV with concentration, as evidenced by the evolution of the higher concentration gels towards negative Dim2 values, as did the PV vector. Potato, wheat, and normal maize samples showed the highest values in the retrogradation degree and high values in retrogradation enthalpy. The waxy maize and normal maize gels are in the positive quadrant of Dim 2, agreeing with the records of the highest values in WAI, SP, and ΔT(G) together with normal maize and tapioca gels.

The high tan(δ)1 values in the waxy rice and tapioca gels coincide with the position of these samples in the vicinity of the vector of this variable. Potato starch gels showed lower tan(δ)1 values for samples of higher concentration, which is illustrated by the greater distance of the higher concentration gels to the vector of this variable. The waxy starch gels, together with potato and tapioca, had the highest ΔH(G) values, justifying the closeness of these samples to the vector of this variable.