Application of Two-Stage Variable Temperature Drying in Hot Air-Drying of Paddy Rice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thin-Layer Drying of Paddy Rice

2.3. Drying of Paddy Rice in Grain Dryer

2.4. Determination Appearance Quality of Samples of the in 15 Ton Batch Type Recirculating Grain Dryer

2.4.1. The Fissuring Rate of the Samples

2.4.2. The Husked Rice Yield of the Samples

2.4.3. The Head Rice Yield of the Samples

2.4.4. Color Difference

2.5. Determination of Chemical Indicators

2.5.1. Amylose Content

2.5.2. Determination of Fat Acidity

2.5.3. Crude Fat Content

2.6. Pasting Property of Rice

2.7. Extraction of Starch and Observation of Granular Morphology

2.8. Sensory Assessment of Cooked Rice

2.9. Texture Profile Analysis (TPA) of Cooked Rice

2.10. Statistical Analysis

3. Results

3.1. Single Factor Experiments Results and RSM Design and RSM Results

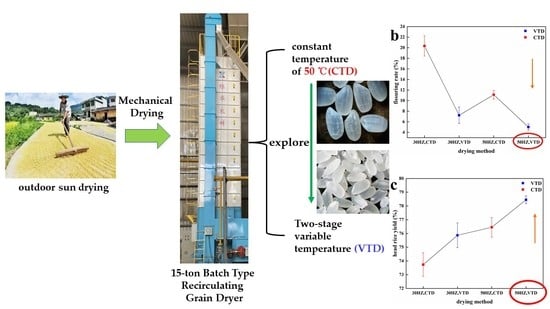

3.2. Applied on the 15 Ton Batch Type Recirculating Grain Dryer

3.3. Appearance Quality

3.4. Chemical Indicators

3.5. Microstructural Observation of Starch Granules

3.6. Pasting Properties of Rice Samples

3.7. Cooked Rice’s Sensory Characteristics

3.8. Changes in the Textural Features of Paddy Rice

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abayawickrama, A.; Reinke, R.F.; Fitzgerald, M.A.; Harper, J.D.I.; Burrows, G.E. Influence of high daytime temperature during the grain filling stage on fissure formation in rice. J. Cereal Sci. 2017, 74, 256–262. [Google Scholar] [CrossRef] [Green Version]

- Müller, A.; Nunes, M.T.; Maldaner, V.; Coradi, P.C.; Moraes, R.S.d.; Martens, S.; Leal, A.F.; Pereira, V.F.; Marin, C.K. Rice Drying, Storage and Processing: Effects of Post-Harvest Operations on Grain Quality. Rice Sci. 2022, 29, 16–30. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Siebenmorgen, T.J. Glass transition effects on milling yields in a cross-flow drying column. Dry. Technol. 2017, 36, 723–735. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Siebenmorgen, T.J. Effect of airflow rate on drying air and moisture content profiles inside a cross-flow drying column. Dry. Technol. 2017, 36, 1326–1341. [Google Scholar] [CrossRef]

- Tong, C.; Gao, H.; Luo, S.; Liu, L.; Bao, J. Impact of Postharvest Operations on Rice Grain Quality: A Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 626–640. [Google Scholar] [CrossRef] [Green Version]

- Kumar, D.; Kalita, P. Reducing Postharvest Losses during Storage of Grain Crops to Strengthen Food Security in Developing Countries. Foods 2017, 6, 8. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Wu, W.; Fu, D.; Xu, W.; Xu, Y.; Zhang, Y. Energy and Exergy Analyses of Rice Drying in a Novel Electric Stationary Bed Grain-Drying System with Internal Circulation of the Drying Medium. Foods 2021, 11, 101. [Google Scholar] [CrossRef]

- Cnossen, A.G.; Siebenmorgen, T.J.; Yang, W. The glass transition temperature concept in rice drying and tempering: Effect on drying rate. Trans. ASAE 2002, 45, 759–766. [Google Scholar] [CrossRef]

- Lv, W.; Li, D.; Lv, H.; Jin, X.; Han, Q.; Su, D.; Wang, Y. Recent development of microwave fluidization technology for drying of fresh fruits and vegetables. Trends Food Sci. Technol. 2019, 86, 59–67. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, M.; Xu, B.; Sun, J.; Mujumdar, A.S. Artificial intelligence assisted technologies for controlling the drying of fruits and vegetables using physical fields: A review. Trends Food Sci. Technol. 2020, 105, 251–260. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, H.; Li, F. A study on drying models and internal stresses of the rice kernel during infrared drying. Dry. Technol. 2017, 35, 680–688. [Google Scholar] [CrossRef]

- Xu, Z.M. Prediction of Neural Network Model on Impact of Vacuum Drying Parameters to Rice Taste Value. In Proceedings of the International Conference on Future Management Science and Engineering (ICFMSE 2011), Bali Island, Indonesia, 4–5 August 2011; pp. 219–224. [Google Scholar]

- Chua, K.J.; Chou, S.K. Low-cost drying methods for developing countries. Trends Food Sci. Technol. 2003, 14, 519–528. [Google Scholar] [CrossRef]

- Song, Q.; Wei, X. Establishment of Rice Quality Prediction Model for Intermittent Drying. Trans. ASABE 2021, 64, 1355–1363. [Google Scholar] [CrossRef]

- Buggenhout, J.; Brijs, K.; Celus, I.; Delcour, J.A. The breakage susceptibility of raw and parboiled rice: A review. J. Food Eng. 2013, 117, 304–315. [Google Scholar] [CrossRef]

- Song, Q.; Wei, X.; Sun, W.; Li, D. Model predictive control strategy of head rice yield in paddy rice intermittent drying. Dry. Technol. 2021, 1–11. [Google Scholar] [CrossRef]

- Geng, Z.; Huang, X.; Wang, J.; Xiao, H.; Yang, X.; Zhu, L.; Qi, X.; Zhang, Q.; Hu, B. Pulsed Vacuum Drying of Pepper (Capsicum annuum L.): Effect of High-Humidity Hot Air Impingement Blanching Pretreatment on Drying Kinetics and Quality Attributes. Foods 2022, 11, 318. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, W.; Jiang, Z.; Chen, X.; Cao, J.; Dong, W.; Dai, B. Changes in Physicochemical, Structural, and Sensory Properties of Irradiated Brown Japonica Rice during Storage. J. Agric. Food Chem. 2015, 63, 4361–4369. [Google Scholar] [CrossRef]

- Ugarčić-Hardi, Ž.; Perić, L.; Strelec, I.; Koceva, D. Comparison of colorimetric and spectrophotometric methods for colour determination in pasta. Z. Für. Lebensm. Und.-Forsch. A 1999, 208, 383–387. [Google Scholar] [CrossRef]

- Cheevitsopon, E.; Noomhorm, A. Effects of Superheated Steam Fluidized Bed Drying on the Quality of Parboiled Germinated Brown Rice. J. Food Processing Preserv. 2015, 39, 349–356. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, H.; Guo, B.; Xu, K.; Dai, Q.; Wei, C.; Zhou, G.; Huo, Z. Effects of nitrogen level on structure and physicochemical properties of rice starch. Food Hydrocoll. 2017, 63, 525–532. [Google Scholar] [CrossRef]

- Sangwongchai, W.; Tananuwong, K.; Krusong, K.; Thitisaksakul, M. Yield, Grain Quality, and Starch Physicochemical Properties of 2 Elite Thai Rice Cultivars Grown under Varying Production Systems and Soil Characteristics. Foods 2021, 10, 2601. [Google Scholar] [CrossRef] [PubMed]

- Govindaraju, I.; Zhuo, G.-Y.; Chakraborty, I.; Melanthota, S.K.; Mal, S.S.; Sarmah, B.; Baruah, V.J.; Mahato, K.K.; Mazumder, N. Investigation of structural and physico-chemical properties of rice starch with varied amylose content: A combined microscopy, spectroscopy, and thermal study. Food Hydrocoll. 2022, 122, 107093. [Google Scholar] [CrossRef]

- Pan, L.; Xing, J.; Luo, X.; Li, Y.; Sun, D.; Zhai, Y.; Yang, K.; Chen, Z. Influence of Electron Beam Irradiation on the Moisture and Properties of Freshly Harvested and Sun-Dried Rice. Foods 2020, 9, 1139. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Jia, C.C.; Siebenmorgen, T.J.; Pan, Z.; Cnossen, A.G. Relationship of kernel moisture content gradients and glass transition temperatures to head rice yield. Biosyst. Eng. 2003, 85, 467–476. [Google Scholar] [CrossRef]

- Iguaz, A.; Rodriguez, M.; Virseda, P. Influence of handling and processing of rough rice on fissures and head rice yields. J. Food Eng. 2006, 77, 803–809. [Google Scholar] [CrossRef]

- Cnossen, A.G.; Jimenez, M.J.; Siebenmorgen, T.J. Rice fissuring response to high drying and tempering temperatures. J. Food Eng. 2003, 59, 61–69. [Google Scholar] [CrossRef]

- Aquerreta, J.; Iguaz, A.; Arroqui, C.; Virseda, P. Effect of high temperature intermittent drying and tempering on rough rice quality. J. Food Eng. 2007, 80, 611–618. [Google Scholar] [CrossRef]

- Sun, Z. The Mechanism of Brown Rice Kernel Cracking Rate and Rice Broken Rate. Trans. Chin. Soc. Agric. Eng. 1995, 11, 6. [Google Scholar]

- Perdon, A.; Siebenmorgen, T.J.; Mauromoustakos, A. Glassy state transition and rice drying: Development of a brown rice state diagram. Cereal Chem. 2000, 77, 708–713. [Google Scholar] [CrossRef] [Green Version]

- Cnossen, A.G.; Siebenmorgen, T.J. The glass transition temperature concept in rice drying and tempering: Effect on milling quality. Trans. ASAE 2000, 43, 1661–1667. [Google Scholar] [CrossRef] [Green Version]

- Chatchavanthatri, N.; Junyusen, T.; Arjharn, W.; Treeamnuk, T.; Junyusen, P.; Pakawanit, P. Effects of parboiling and infrared radiation drying on the quality of germinated brown rice. J. Food Process. Preserv. 2021, 45, e15892. [Google Scholar] [CrossRef]

- Scariot, M.A.; Karlinski, L.; Dionello, R.G.; Radünz, A.L.; Radünz, L.L. Effect of drying air temperature and storage on industrial and chemical quality of rice grains. J. Stored Prod. Res. 2020, 89, 101717. [Google Scholar] [CrossRef]

- Kamruzzaman, M.D.; Uyeh, D.D.; Jang, I.K.J.; Woo, S.M.; Ha, Y.S. Drying characteristics and milling quality of parboiled Japonica rice under various drying conditions. Eng. Agric. Environ. Food 2017, 10, 292–297. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Chen, F.; Yong, F. Lipid oxidation of brown rice stored at different temperatures. Int. J. Food Sci. Technol. 2017, 52, 188–195. [Google Scholar] [CrossRef]

- Ratseewo, J.; Warren, F.J.; Siriamornpun, S. The influence of starch structure and anthocyanin content on the digestibility of Thai pigmented rice. Food Chem. 2019, 298, 124949. [Google Scholar] [CrossRef]

- Zhou, Z.; Robards, K.; Helliwell, S.; Blanchard, C. Ageing of Stored Rice: Changes in Chemical and Physical Attributes. J. Cereal Sci. 2002, 35, 65–78. [Google Scholar] [CrossRef] [Green Version]

- Peng, Y.; Mao, B.; Zhang, C.; Shao, Y.; Wu, T.; Hu, L.; Hu, Y.; Tang, L.; Li, Y.; Tang, W.; et al. Influence of physicochemical properties and starch fine structure on the eating quality of hybrid rice with similar apparent amylose content. Food Chem. 2021, 353, 129461. [Google Scholar] [CrossRef]

- Huang, Y.T.; Wu, W.; Zou, W.X.; Wu, H.P.; Cao, D.D. Drying temperature affects rice seed vigor via gibberellin, abscisic acid, and antioxidant enzyme metabolism. J. Zhejiang Univ. Sci. B 2020, 21, 796–810. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, Y.; Chen, X.; Zhang, L.; Li, H.; Sui, Z.; Corke, H. Polishing conditions in rice milling differentially affect the physicochemical properties of waxy, low- and high-amylose rice starch. J. Cereal Sci. 2021, 99, 103183. [Google Scholar] [CrossRef]

- Li, D. Experimental Study on the Development and Control of Stress Cracks of Rough Rice in Drying. Ph.D. Thesis, China Agricultural University, Beijing, China, 2001. [Google Scholar]

- Zheng, X.Z.; Liu, C.H.; Chen, Z.Y.; Ding, N.Y.; Jin, C.J. Effect of Drying Conditions on the Texture and Taste Characteristics of Rough Rice. Dry. Technol. 2011, 29, 1297–1305. [Google Scholar] [CrossRef]

- Mestres, C.; Ribeyre, F.; Pons, B.; Fallet, V.; Matencio, F. Sensory texture of cooked rice is rather linked to chemical than to physical characteristics of raw grain. J. Cereal Sci. 2011, 53, 81–89. [Google Scholar] [CrossRef]

- Chen, Z.K.; Du, Y.F.; Mao, Z.L.; Zhang, Z.J.; Li, P.; Cao, C.G. Grain starch, fatty acids, and amino acids determine the pasting properties in dry cultivation plus rice cultivars. Food Chem. 2022, 373, 11. [Google Scholar] [CrossRef] [PubMed]

- Li, H.Y.; Prakash, S.; Nicholson, T.M.; Fitzgerald, M.A.; Gilbert, R.G. The importance of amylose and amylopectin fine structure for textural properties of cooked rice grains. Food Chem. 2016, 196, 702–711. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luangmalawata, P.; Prachayawarakorn, S.; Nathakaranakule, A.; Soponronnarit, S. Effect of temperature on drying characteristics and quality of cooked rice. LWT-Food Sci. Technol. 2008, 41, 716–723. [Google Scholar] [CrossRef]

- Sarker, M.S.H.; Ibrahim, M.N.; Ab Aziz, N.; Salleh, P.M. Energy and rice quality aspects during drying of freshly harvested paddy with industrial inclined bed dryer. Energy Convers. Manag. 2014, 77, 389–395. [Google Scholar] [CrossRef]

| Level | Temperature of First Stage (°C) | Temperature of Second Stage (°C) | Drying Time (min) | Tempering Time (min) |

|---|---|---|---|---|

| 1 | 75 | 40 | 12 | 60 |

| 2 | 70 | 45 | 14 | 70 |

| 3 | 65 | 50 | 16 | 80 |

| 4 | 60 | 55 | 18 | 90 |

| 5 | 55 | 60 | 20 | 100 |

| Model | Weight of Dryer (kg) | Length, Width and Height (mm) | The Power of the Dryer (kw) | Capacity(kg) |

|---|---|---|---|---|

| 5HXJ-15 | 3420 | 3575 × 2990 × 11,595 | 9.04 | Paddy rice: 2800–15,000 |

| Wheat: 3400–18,200 |

| Level | A, Temperature of First Stage (°C) | B, Temperature of Second Stage (°C) | C, Drying Time (min) |

|---|---|---|---|

| 1 | 65 | 50 | 12 |

| 0 | 60 | 45 | 14 |

| −1 | 55 | 40 | 16 |

| Response | Equation from the RSM | p-Value | R-Squared | Adj R-Squared | Pred R-Squared |

|---|---|---|---|---|---|

| HRY | = 70 − 2.19A − 1.7B − 1.22C − 1.05AB − 1.16AC − 0.1BC | <0.0001 | 0.9623 | 0.9367 | 0.8971 |

| Total Drying Time | = 11.58 − 0.91A − 1.96B − 0.4C + 0.2AB + 0.025AC + 0.13BC + 0.73A2 − 0.12B2 + 1.11C2 | <0.0001 | 0.9856 | 0.9670 | 0.7898 |

| Drying Method | Drying Temperature (°C) | Cycle Speed (Hz) | Initial Moisture Content (%) | Final Moisture Content (%) | Drying Time (h) |

|---|---|---|---|---|---|

| CTD | 50 | 50 | 25 ± 0.3 | 14.0 ± 0.5 | 14.2 ± 0.2 a |

| 30 | 29 ± 0.5 | 14.0 ± 0.5 | 14.7 ± 0.4 a | ||

| VTD | 60, 45 | 50 | 25 ± 0.3 | 14.0 ± 0.5 | 13.5 ± 0.2 b |

| 30 | 29 ± 0.5 | 14.0 ± 0.5 | 14.5 ± 0.2 a |

| Test | Crude Fat (%) | Fat Acidity (mg KOH/100 g) | Amylose Content (mg/g) |

|---|---|---|---|

| VTD | 1.67 ± 0.21 | 16.73 ± 0.52 | 12.35 ± 0.13 ** |

| CTD | 1.66 ± 0.31 | 17.12 ± 0.35 | 18.67 ± 0.06 |

| Test | Peak Viscosity | Minimum Viscosity | Breakdown | Final Viscosity | Setback | Peak Time | Pasting Temperature |

|---|---|---|---|---|---|---|---|

| VTD | 2550 ± 82 ** | 1091 ± 24 ** | 1459 ± 74 | 1653 ± 27 ** | 562 ± 14 ** | 5.37 ± 0.08 ** | 72.6 ± 0.9 |

| CTD | 2971 ± 83 | 1567 ± 78 | 1404 ± 79 | 2203 ± 78 | 636 ± 6 | 5.75 ± 0.10 | 71.9 ± 0.4 |

| Drying Method | Hardness (g) | Adhesiveness (g s) | Springiness (%) | Gumminess (g) | Chewiness (g) |

|---|---|---|---|---|---|

| CTD | 1929.9 ± 78.5 | −203.2 ± 102.3 | 88.9 ± 3.3 | 916.5 ± 105.7 | 812.9 ± 69.8 |

| VTD | 1619.9 ± 71.3 ** | −291.3 ± 107.7 | 89.9 ± 0.5 | 853.9 ± 40.0 | 767.3 ± 39.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Zhao, T.; Ma, J.; Song, Q.; Wei, Q.; Sun, W. Application of Two-Stage Variable Temperature Drying in Hot Air-Drying of Paddy Rice. Foods 2022, 11, 888. https://doi.org/10.3390/foods11060888

Xu X, Zhao T, Ma J, Song Q, Wei Q, Sun W. Application of Two-Stage Variable Temperature Drying in Hot Air-Drying of Paddy Rice. Foods. 2022; 11(6):888. https://doi.org/10.3390/foods11060888

Chicago/Turabian StyleXu, Xingang, Tianyuan Zhao, Jianing Ma, Qi Song, Qiao Wei, and Weihong Sun. 2022. "Application of Two-Stage Variable Temperature Drying in Hot Air-Drying of Paddy Rice" Foods 11, no. 6: 888. https://doi.org/10.3390/foods11060888