The Environmental Profile of Ecuadorian Export Banana: A Life Cycle Assessment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Scope Definition

2.1.1. Functional Unit

2.1.2. System Boundaries

2.1.3. System Description

Banana Growing Stage

Banana Packaging Stage

Further Quality Assurance Stage

Transport to the Port of Guayaquil

Transport to Foreign Port Destination

2.2. Life Cycle Inventory Analysis

2.2.1. Data on Agricultural Inputs

Direct Agricultural Inputs (Foreground System)

Background Processes

2.2.2. Determination of Field Emissions

Emissions from the Application of Fertilizers and Agricultural Lime

Emissions Associated with the Application of Pesticides

2.3. Life cycle Impact Assessment

Impact Assessment Methodology

3. Results and Discussion

3.1. Life Cycle Inventory Analysis

3.2. Life Cycle Impact Assessment

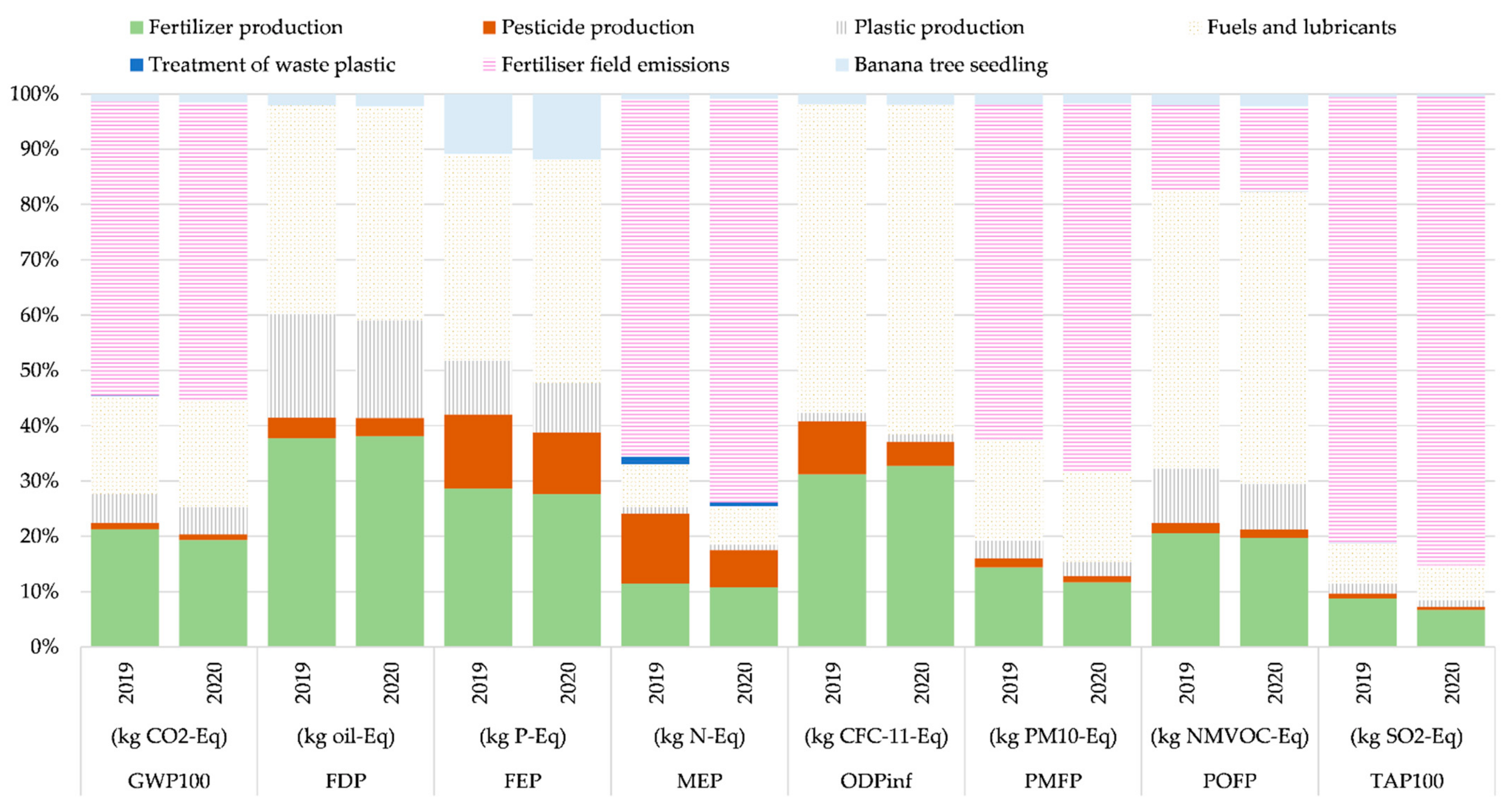

3.2.1. Banana at-the-Farm-Gate

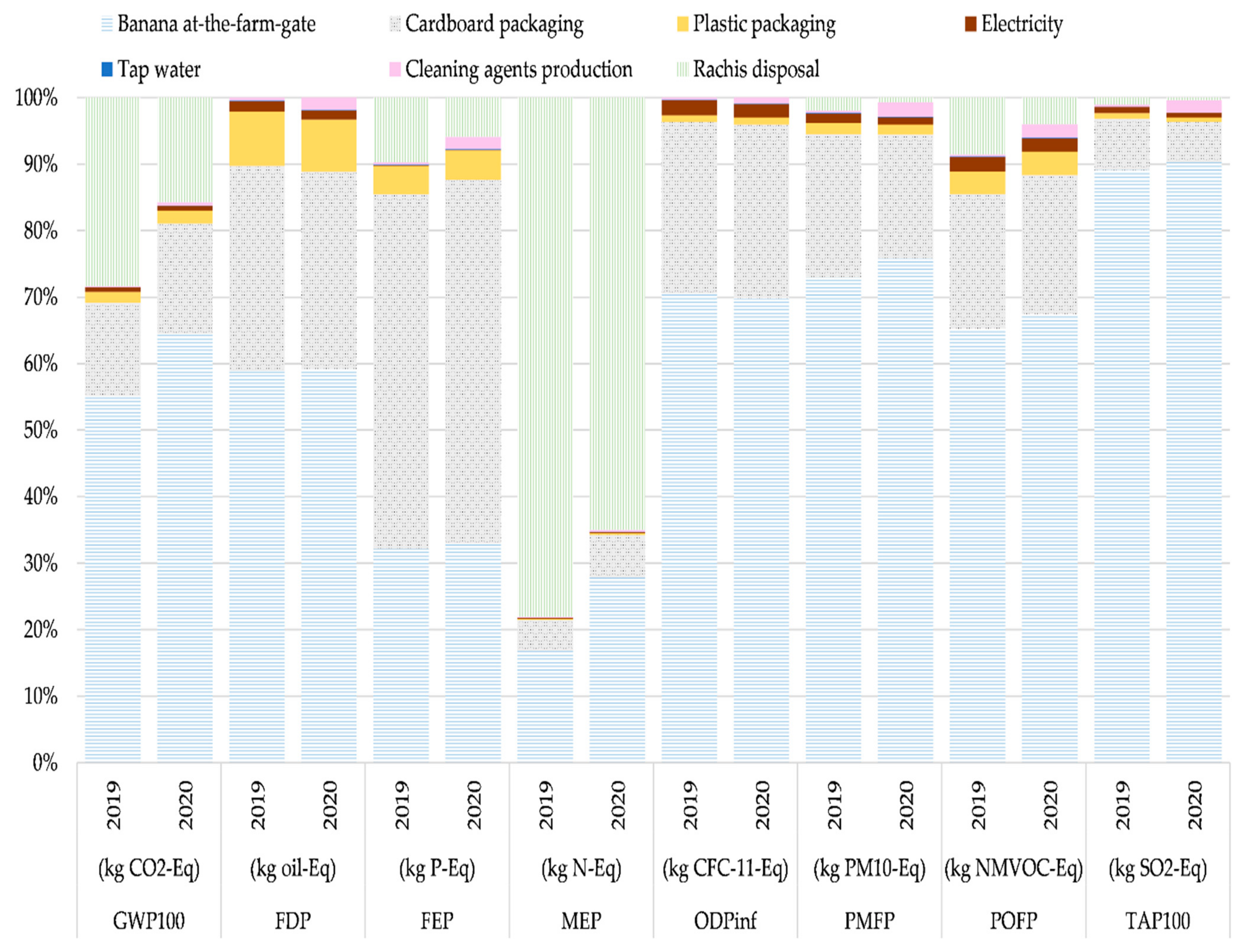

3.2.2. Banana at-the-Packaging-Stage-Gate

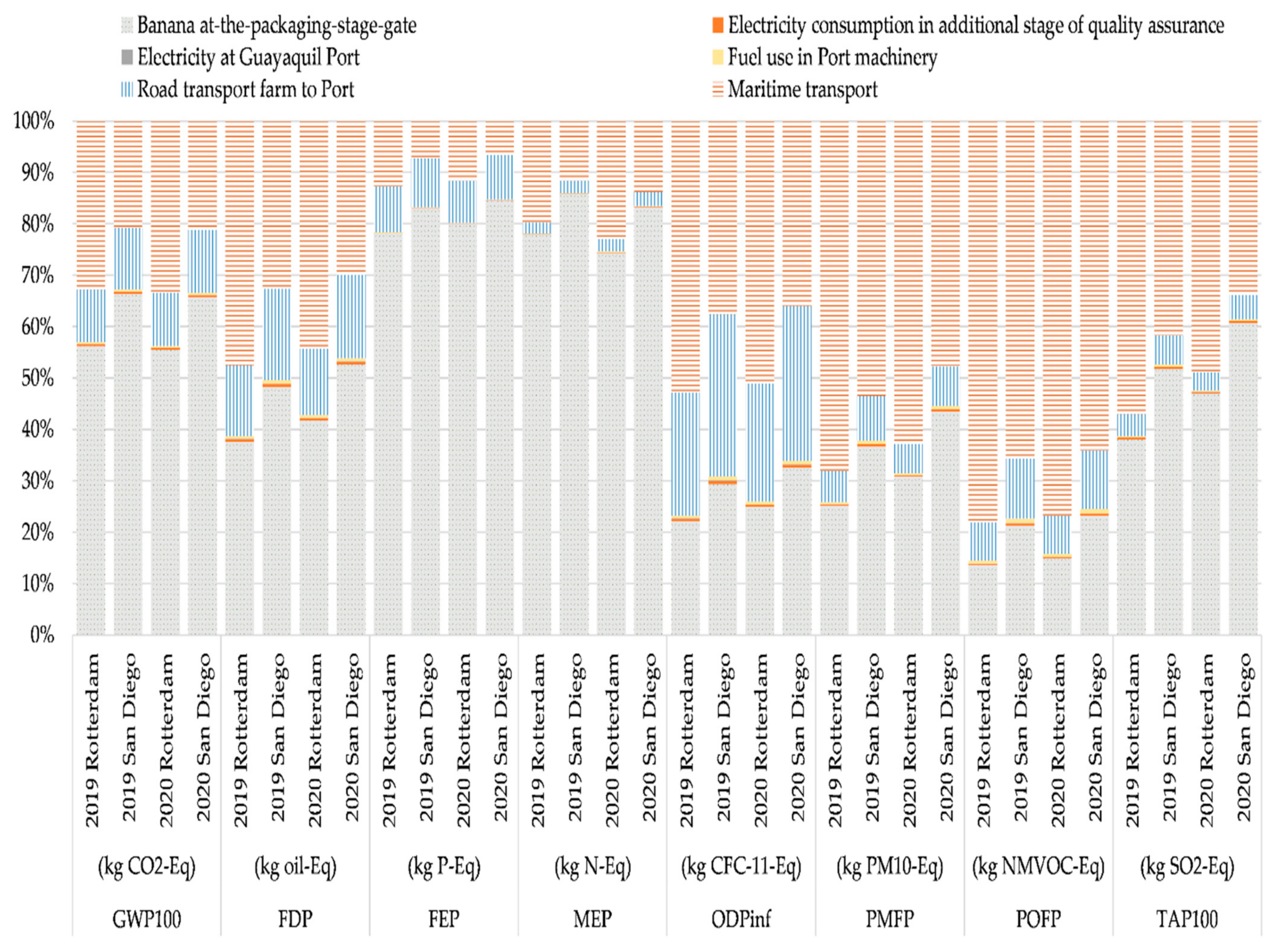

3.2.3. Banana at-the-Foreign-Port

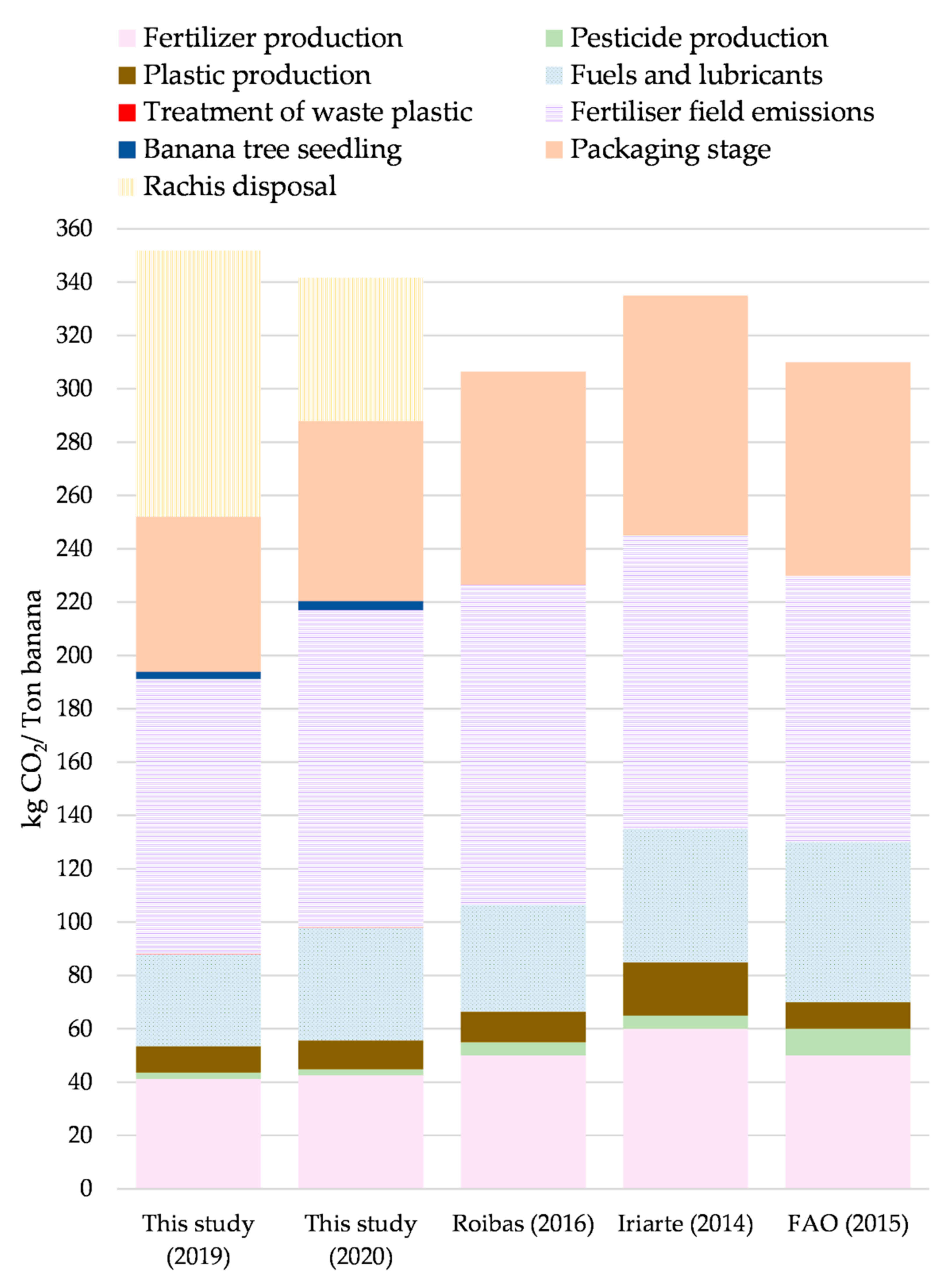

3.2.4. Comparison with Carbon Footprint Studies of Banana in the Literature

3.3. Recommendations for Improvement

3.4. Limitations and Further Research

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FOECD/FAO; OCDE-FAO. Perspectivas Agrícolas 2020-2029; OECD Publishing, Ed.; OCDE-FAO Perspectivas Agrícolas; OECD: Paris, France, 2020; ISBN 9789264418950. [Google Scholar]

- FAO. Análisis Del Mercado Del Banano: Resultados Preliminares 2019; FAO: Rome, Italy, 2020. [Google Scholar]

- OECD-FAO. OECD-FAO Agricultural Outlook 2021–2030; OECD Publishing: Paris, France, 2021; ISBN 978-92-5-134608-2. [Google Scholar]

- FAO. Banana Market Review—Preliminary Results 2021; FAO: Rome, Italy, 2021. [Google Scholar]

- Oluwatimilehin, I.A.; Ayanlade, A. Agricultural Community-Based Impact Assessment and Farmers’ Perception of Climate Change in Selected Ecological Zones in Nigeria. Agric. Food Secur. 2021, 10, 3. [Google Scholar] [CrossRef]

- Machado, A.C.Z.; Zagatto, M.R.G.; Neto, F.S.; da Silva, S.A.; Júnior, L.A.Z. Impact of Crop Management Systems on Soil Nematode Communities in South Brazil. Sci. Agric. 2020, 79, 1–7. [Google Scholar] [CrossRef]

- León Serrano, L.A.; Arcaya Sisalima, M.F.; Barbotó Velásquez, N.A.; Bermeo Pineda, Y.L. Ecuador: Análisis Comparativo de Las Exportaciones de Banano Orgánico y Convencional e Incidencia En La Balanza Comercial, 2018. Rev. Científica Tecnológica UPSE 2020, 7, 38–46. [Google Scholar] [CrossRef]

- Sánchez, A. Sector Bananero Ecuatoriano; Universidad Técnica de Ambato: Tungurahua, Ecuador, 2020. [Google Scholar]

- BCE. Cuentas Nacionales Trimestrales Del Ecuador Resultados De Las Variables Macroeconómicas, 2020.III; Banco Central del Ecuador: Quito, Ecuador, 2020. [Google Scholar]

- BCE. Banco Central del Ecuador; Banco Central del Ecuador: Quito, Ecuador, 2021; pp. 2020–2021. [Google Scholar]

- ISO. ISO 14040:2006: Gestión Ambiental—Análisis Del Ciclo de Vida—Principios y Marco de Referencia. Available online: https://www.iso.org/obp/ui#iso:std:iso:14040:ed-2:v1:es (accessed on 11 November 2021).

- Iriarte, A.; Almeida, M.G.; Villalobos, P. Carbon Footprint of Premium Quality Export Bananas: Case Study in Ecuador, the World’s Largest Exporter. Sci. Total Environ. 2014, 472, 1082–1088. [Google Scholar] [CrossRef]

- Coltro, L.; Karaski, T.U. Environmental Indicators of Banana Production in Brazil: Cavendish and Prata Varieties. J. Clean. Prod. 2019, 207, 363–378. [Google Scholar] [CrossRef]

- Mfitumukiza, D.; Nambasa, H.; Walakira, P. Life Cycle Assessment of Products from Agro-Based Companies in Uganda. Int. J. Life Cycle Assess. 2019, 24, 1925–1936. [Google Scholar] [CrossRef] [Green Version]

- Svanes, E.; Aronsson, A.K.S. Carbon Footprint of a Cavendish Banana Supply Chain. Int. J. Life Cycle Assess. 2013, 18, 1450–1464. [Google Scholar] [CrossRef]

- Stoessel, F.; Juraske, R.; Pfister, S.; Hellweg, S. Life Cycle Inventory and Carbon and Water Foodprint of Fruits and Vegetables: Application to a Swiss Retailer. Environ. Sci. Technol. 2012, 46, 3253–3262. [Google Scholar] [CrossRef]

- Roibás, L.; Elbehri, A.; Hospido, A. Carbon Footprint along the Ecuadorian Banana Supply Chain: Methodological Improvements and Calculation Tool. J. Clean. Prod. 2016, 112, 2441–2451. [Google Scholar] [CrossRef]

- USC. Huella de Carbono del Banano Ecuatoriano; FAO: Santiago de Compostela, Spain, 2011. [Google Scholar]

- Lescot, T. Carbon Footprint Analysis in Banana Production. In Proceedings of the Second Conference of the World Banana Forum, Guayaquil, Ecuador, 28–29 February 2012; pp. 28–29. [Google Scholar]

- Adsal, K.A.; Üçtuğ, F.G.; Arikan, O.A. Environmental Life Cycle Assessment of Utilizing Stem Waste for Banana Production in Greenhouses in Turkey. Sustain. Prod. Consum. 2020, 22, 110–125. [Google Scholar] [CrossRef]

- Torres, T.; Oleson, K. Quantifying the Environmental Footprint of Doubling Hawaiʻi’s Local Food Supply. Master’s Thesis, University of Hawai’i at Manoa, Honolulu, HI, USA, 2020. [Google Scholar]

- Avadí, A.; Bolaños, C.; Sandoval, I.; Ycaza, C. Life Cycle Assessment of Ecuadorian Processed Tuna. Int. J. Life Cycle Assess. 2015, 20, 1415–1428. [Google Scholar] [CrossRef] [Green Version]

- Franze, J.; Ciroth, A. A Comparison of Cut Roses from Ecuador and the Netherlands. Int. J. Life Cycle Assess. 2011, 16, 366–379. [Google Scholar] [CrossRef]

- Pérez Neira, D. Energy Sustainability of Ecuadorian Cacao Export and Its Contribution to Climate Change. A Case Study through Product Life Cycle Assessment. J. Clean. Prod. 2016, 112, 2560–2568. [Google Scholar] [CrossRef]

- Pazmiño, M.L.; Ramirez, A.D. Life Cycle Assessment as a Methodological Framework for the Evaluation of the Environmental Sustainability of Pig and Pork Production in Ecuador. Sustainability 2021, 13, 11693. [Google Scholar] [CrossRef]

- Ramirez, A.D.; Duque-Rivera, J. Life Cycle Assessment Of Greenhouse Gas Emissions Arising From The Production Of Glued And Pressed Wall Panels Derived From Guadua Angustifolia Kunth (Bamboo) In Ecuador. WIT Trans. Built Environ. 2014, 142, 447–457. [Google Scholar] [CrossRef] [Green Version]

- Guerrero, A.B.; Muñoz, E. Life Cycle Assessment of Second Generation Ethanol Derived from Banana Agricultural Waste: Environmental Impacts and Energy Balance. J. Clean. Prod. 2017, 174, 710–717. [Google Scholar] [CrossRef]

- Arcentales-Bastidas, D.; Silva, C.; Ramirez, A.D. The Environmental Profile of Ethanol Derived from Sugarcane in Ecuador: A Life Cycle Assessment Including the Effect of Cogeneration of Electricity in a Sugar Industrial Complex. Energies 2022, 15, 5421. [Google Scholar] [CrossRef]

- Parra, C.R.; Corrêa-Guimarães, A.; Navas-Gracia, L.M.; Narváez, C.R.A.; Rivadeneira, D.; Ramirez, A.D. Bioenergy on Islands: An Environmental Comparison of Continental Palm Oil vs. Local Waste Cooking Oil for Electricity Generation. Appl. Sci. 2020, 10, 3806. [Google Scholar] [CrossRef]

- Riofrio, A.; Alcivar, T.; Baykara, H. Environmental and Economic Viability of Chitosan Production in Guayas-Ecuador: A Robust Investment and Life Cycle Analysis. ACS Omega 2021, 6, 23038–23051. [Google Scholar] [CrossRef]

- Villaseñor, D.; Prado, R.d.M.; Pereira da Silva, G.; Carrillo, M.; Durango, W. DRIS Norms and Limiting Nutrients in Banana Cultivation in the South of Ecuador. J. Plant Nutr. 2020, 43, 2785–2796. [Google Scholar] [CrossRef]

- FAO. Todo Sobre Los Bananos: Lo Que Debería Saber Acercade Esta Fruta Tropical; FAO: Rome, Italy, 2016; p. 3. [Google Scholar]

- Vargas, A.; Villalta, R.; Guzmán, M.; Rivas, R. Materiales de Empaque y Su Relación Con Características Poscosecha e Incidencia de Enfermedades En Banano (Musa AAA, Cv. Grande Naine). Corbana 2017, 63, 79–105. [Google Scholar]

- Castellanos, D.A. Aspectos Relevantes En El Almacenamiento de Banano En Empaques Con Atmósferas Modificadas. Rev. Iberoam. Tecnol. Postcosecha 2011, 12, 114–134. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; et al. The Ecoinvent Database: Overview and Methodological Framework. Int. J. Life Cycle Assess. 2005, 10, 3–9. [Google Scholar] [CrossRef]

- Ecoinvent The Ecoinvent Database. Available online: https://www.ecoinvent.org/database/database.html (accessed on 23 November 2021).

- Colomb, V.; Ait, S.A.; Mens, C.B.; Gac, A.; Gaillard, G.; Koch, P.; Mousset, J.; Salou, T.; Tailleur, A.; Van Der Werf, H.M.G. AGRIBALYSE®, the French LCI Database for Agricultural Products: High Quality Data for Producers and Environmental Labelling. OCL Oilseeds Fats 2015, 22, D104. [Google Scholar] [CrossRef] [Green Version]

- Ramirez, A.D.; Rivela, B.; Boero, A.; Melendres, A.M. Lights and Shadows of the Environmental Impacts of Fossil-Based Electricity Generation Technologies: A Contribution Based on the Ecuadorian Experience. Energy Policy 2019, 125, 467–477. [Google Scholar] [CrossRef]

- Ramirez, A.D.; Boero, A.; Rivela, B.; Melendres, A.M.; Espinoza, S.; Salas, D.A. Life Cycle Methods to Analyze the Environmental Sustainability of Electricity Generation in Ecuador: Is Decarbonization the Right Path? Renew. Sustain. Energy Rev. 2020, 134, 110373. [Google Scholar] [CrossRef]

- IPCC. Emisiones de N2O de Los Suelos Gestionados Y Emisiones de Co2 Derivadas de La Aplicación de Cal y Urea; IPCC: Geneva, Switzerland, 2006; Volume 4, pp. 1–56. [Google Scholar]

- Veldkamp, E.; Keller, M. Nitrogen Oxide Emissions from a Banana Plantation in the Humid Tropics. J. Geophys. Res. Atmos. 1997, 102, 15889–15898. [Google Scholar] [CrossRef]

- Nemecek, T.; Kagi, T. Life Cycle Inventories of Agricultural Production Systems, Ecoinvent Report No. 15; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Battye, W.; Barrows, R. Review of Ammonia Emission Modeling Techniques for Natural Landscapes and Fertilized Soils; Work Assignment No. 2-09; Environmental Protection Agency: Washington, DC, USA, 2004. [Google Scholar]

- Nemecek, T. Estimating Direct Field and Farm Emissions; Federal Department of Economic Affairs FDEA Agroscope: Zurich, Switzerland, 2013. [Google Scholar]

- Prasuhn, V. Erfassung Der PO4-Austräge Für Die Ökobilanzierung—SALCA-Phosphor. Agroescope Reckenholz 2006, 22, 20. [Google Scholar]

- Raphael, L.; Sierra, J.; Recous, S.; Ozier-Lafontaine, H.; Desfontaines, L. Soil Turnover of Crop Residues from the Banana (Musa AAA Cv. Petite-Naine) Mother Plant and Simultaneous Uptake by the Daughter Plant of Released Nitrogen. Eur. J. Agron. 2012, 38, 117–123. [Google Scholar] [CrossRef]

- Lumina Decision Systems What Is Analytica? Available online: https://analytica.com/why-analytica/what-is-analytica/ (accessed on 23 November 2021).

- Dijkman, T.J.; Birkved, M.; Hauschild, M.Z. PestLCI 2.0: A Second Generation Model for Estimating Emissions of Pesticides from Arable Land in LCA. Int. J. Life Cycle Assess. 2012, 17, 973–986. [Google Scholar] [CrossRef]

- Huijbregts, M.; Steinmann, Z.J.N.; Elshout, P.M.F.M.; Stam, G.; Verones, F.; Vieira, M.D.M.; Zijp, M.; van Zelm, R. ReCiPe 2016—A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Report I: Characterization. Natl. Inst. Public Health Environ. 2016, 22, 194. [Google Scholar]

- Dekker, E.; Zijp, M.C.; van de Kamp, M.E.; Temme, E.H.M.; van Zelm, R. A Taste of the New ReCiPe for Life Cycle Assessment: Consequences of the Updated Impact Assessment Method on Food Product LCAs. Int. J. Life Cycle Assess. 2020, 25, 2315–2324. [Google Scholar] [CrossRef] [Green Version]

- FAO. Cambio Climático y Sostenibilidad Del Banano En El Ecuador: Evaluación de Impacto y Directrices de Política; FAO: Rome, Italy, 2015. [Google Scholar]

- Zghair, H.; Ali, A. Simulation Analysis of Processing Complexity and Production Variety in Automated Manufacturing System. In Proceedings of the 2017 Winter Simulation Conference, Las Vegas, NV, USA, 3–6 December 2017; pp. 4485–4487. [Google Scholar] [CrossRef]

- Bahr, E.; Hamer, U.; Chamba Zaragocin, D.; Makeschin, F. Different Fertilizer Types Affected Nitrogen and Carbon Cycling in Eroded and Colluvial Soils of Southern Ecuador. Agric. Sci. 2013, 4, 19–32. [Google Scholar] [CrossRef]

- Godoy Zúñiga, M.E.; Silva Recalde, M.F.; Palacios Fuentes, J.A. La producción de biogás por degradación de abono orgánico como alternativa de energía en ecuador. Rev. DELOS 2018, 11, 16. [Google Scholar]

- Chávez-Estudillo, V.; Valencia-Ordoñez, A.; Córdova-Nieto, C.; Flores Estévez, N.; Jarillo-Rodríguez, J.; Noa Carrazana, J.C. Lixiviados de Raquis de Plátano: Obtención y Usos Potenciales. Cuad. Biodivers. 2017, 53, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Fiallos-cárdenas, M.; Pérez-martínez, S.; Ramirez, A.D. Prospectives for the Development of a Circular Bioeconomy around the Banana Value Chain. Sustain. Prod. Consum. 2022, 30, 541–555. [Google Scholar] [CrossRef]

- Fiallos, M.; Ramirez, A.D.; Bonilla, H.R.; Ordoñez-viñan, M.; Ruiz-barzola, O.; Reinoso, M.A. Bacterial Nanocellulose Derived from Banana Leaf Extract: Yield and Variation Factors. Resources 2021, 10, 121. [Google Scholar] [CrossRef]

- Graefe, S.; Dufour, D.; Giraldo, A.; Muñoz, L.A.; Mora, P.; Solís, H.; Garcés, H.; Gonzalez, A. Energy and Carbon Footprints of Ethanol Production Using Banana and Cooking Banana Discard: A Case Study from Costa Rica and Ecuador. Biomass Bioenergy 2011, 35, 2640–2649. [Google Scholar] [CrossRef]

- Phirke, N.V.; Patil, R.P.; Chincholkar, S.B.; Kothari, R.M. Recycling of Banana Pseudostem Waste for Economical Production of Quality Banana. Resour. Conserv. Recycl. 2001, 31, 347–353. [Google Scholar] [CrossRef]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Review of High-Value Food Waste and Food Residues Biorefineries with Focus on Unavoidable Wastes from Processing. Resour. Conserv. Recycl. 2019, 149, 413–426. [Google Scholar] [CrossRef]

- Kamira, M.; Sivirihauma, C.; Ntamwira, J.; Ocimati, W.; Katungu, M.; Bigabwa, J.; Vutseme, L.; Blomme, G. Household Uses of the Banana Plant in Eastern Democratic Republic of Congo. J. Appl. Biosci. 2016, 95, 8915. [Google Scholar] [CrossRef]

- Tapia, C.; Paredes, N.; Lima, L. Representatividad de la diversidad del género musa en el Ecuador. Ecuador Calidad-Rev. Cient. Ecuat. 2019, 6, 53–58. [Google Scholar]

| Reference | System | Description and Boundaries | Geographic Limits | Functional Unit | Impact Categories |

|---|---|---|---|---|---|

| [20] | Banana production and supply to the end user in Turkey | Three scenarios were evaluated: conventional non-heated water; heating irrigation water with natural gas; heating irrigation water by using biogas from anaerobic digestion of banana stem residues. The system boundaries are cradle-to-grave. | Turkey, Anamur City, and the three big cities of Turkey (Ankara, Istanbul, Izmir). From agricultural production to delivery to a European port of destination | Total 2 ton of banana | Global warming potential, acidification potential, eutrophication potential, photochemical oxidants creation potential, ozone layer depletion potential, human toxicity potential |

| [21] | Food production in Hawaii | Assess the local (within Hawaii), distant (elsewhere), and global (both in Hawaii and elsewhere) environmental impacts of increased food production. The system boundaries are cradle-to-grave. | Islands Oahu, Maui, Kauai, and Hawaii | Total 1 kg of banana | Climate change, marine eutrophication, land use, water resource depletion |

| [13] | Two varieties of banana produced in Brazil: Cavendish and Prata | Determine environmental indicators for two varieties of banana produced in Brazil—Cavendish and Prata—in order to promote these products among consumers. The boundaries are cradle-to-gate. | Brazil: Ribeira Valley in Sao Paulo State and north of Minas Gerais | Total 1 kg of banana | Global warming potential, primary energy demand, abiotic depletion, eutrophication potential, acidification potential, land use, total freshwater use, blue water use, terrestrial ecotoxicity potential, human toxicity potential |

| [14] | Initiate and promote LCA in Uganda with the overall objective of promoting life cycle thinking to improve the competitiveness of agricultural products regionally and internationally | Evaluate and quantify the environmental impacts of the life cycle of selected products. The system boundaries are door-to-door based on processes in accordance with ISO 14040. | Uganda: Lubanja Village, Mityana District; Kangulumira, Kayunga District | Total 1 kg of banana | Carbon footprint, ecological toxicity, human toxicity, photochemical oxidation, abiotic depletion |

| [17] | Banana production in Ecuador direct to a European country | Life cycle evaluation of 17 Ecuadorian plantations (9 organic and 8 conventional, classified by size). The system boundaries are cradle-to-gate. | From Ecuador to Spain | Total 1 kg of banana | Water footprint, carbon footprint |

| [12] | Ecuadorian export premium banana production | Inventory of GHG emissions from Ecuadorian agricultural products using the concept of carbon footprint. The system boundaries are from agricultural production to delivery to a European port of destination (cradle-to-grave). | From Ecuador to Germany | Total 1 kg of banana | Carbon footprint |

| [18] | Project on bananas and climate change in Ecuador, as part of the FAO Multidonor Mechanism (FMM) program | Evaluation of the impacts of climate change on bananas in Ecuador. The study covers the entire supply chain, from production to final consumption. | From Ecuador to Madrid, Spain and port of Rotterdam, Holland | Total 1 kg of banana | Carbon footprint |

| [15] | Banana produced in two plantations in Costa Rica | Study the greenhouse gas emissions of bananas from cradle to retail and cradle to grave. | From Costa Rica to Oslo, Norway | Total 1 kg of banana | Carbon footprint |

| [16] | Fruit and vegetable production, including seedlings, use of machinery, greenhouse fuels, irrigation, fertilizers, pesticides, storage, and transport within Switzerland | Environmental assessment of an assortment of 34 fruits and vegetables from a large Swiss retailer | From 29 different countries to Switzerland | Total 1 kg of product | Climate change, water stress, human toxicity, eutrophication, acidification, soil fertility degradation, landscape changes. |

| [19] | Development of methods for analyzing product carbon footprint and life cycle assessment | Study on the development of methods for analyzing product carbon footprint (PCF) and life cycle assessment (LCA) | From Ecuador to east coast of USA or northern Europe | Total 1 kg of banana | Eutrophication, terrestrial eco-toxicity, sediment ecotoxicity, aquatic ecotoxicity, human toxicity |

| Scenario | Description |

|---|---|

| RM0 | Base case: treatment in an open dump + N2O and NOx emissions calculated based on IPCC |

| RM1 | N2O and NOx emissions calculated based on IPCC |

| RM2 | No rachis treatment (no burden associated with this flow) |

| GWP100 | FDP | FEP | MEP | ODPinf | PMFP | POFP | TAP100 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg CO2−Eq) | (kg Oil-Eq) | (kg P-Eq) | (kg N-Eq) | (kg CFC-11-Eq) | (kg PM10-Eq) | (kg NMVOC-Eq) | (kg SO2-Eq) | |||||||||

| 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | |

| Fertilizer production | 4.12 × 101 | 4.25 × 101 | 1.15 × 101 | 1.39 × 101 | 3.40 × 10−3 | 3.78 × 10−3 | 1.18 × 10−2 | 1.50 × 10−2 | 3.31 × 10−6 | 3.99 × 10−6 | 5.60 × 10−2 | 6.28 × 10−2 | 9.70 × 10−2 | 1.07 × 10−1 | 1.88 × 10−1 | 2.08 × 10−1 |

| Pesticide production | 2.37 | 2.27 | 1.14 | 1.19 | 1.59 × 10−3 | 1.51 × 10−3 | 1.28 × 10−2 | 9.18 × 10−3 | 1.01 × 10−6 | 5.22 × 10−7 | 6.26 × 10−3 | 6.04 × 10−3 | 8.98 × 10−3 | 8.52 × 10−3 | 1.92 × 10−2 | 1.81 × 10−2 |

| Plastic production | 9.92 | 1.08 × 101 | 5.75 | 6.47 | 1.15 × 10−3 | 1.22 × 10−3 | 1.30 × 10−3 | 1.41 × 10−3 | 1.63 × 10−7 | 1.68 × 10−7 | 1.25 × 10−2 | 1.35 × 10−2 | 4.63 × 10−2 | 4.47 × 10−2 | 3.68 × 10−2 | 3.89 × 10−2 |

| Fuels and lubricants | 3.45 × 101 | 4.24 × 101 | 1.15 × 101 | 1.41× 101 | 4.45 × 10−3 | 5.52 × 10−3 | 7.84 × 10−3 | 9.63 × 10−3 | 5.92 × 10−6 | 7.27 × 10−6 | 7.14 × 10−2 | 8.76 × 10−2 | 2.38 × 10−1 | 2.88 × 10−1 | 1.58 × 10−1 | 1.95 × 10−1 |

| Treatment of waste plastic | 1.32 × 10−1 | 9.62 × 10−2 | 1.40 × 10−3 | 1.02 × 10−3 | 1.24 × 10−7 | 9.04 × 10−8 | 4.58 × 10−5 | 3.33 × 10−5 | 6.11 × 10−7 | 4.44 × 10−7 | ||||||

| Fertilizer fieldemissions | 1.03 × 102 | 1.19 × 102 | 6.60 × 10−2 | 1.01 × 10−1 | 2.36 × 10−1 | 3.58 × 10−1 | 7.26 × 10−2 | 8.39 × 10−2 | 1.72 | 2.65 | ||||||

| Banana tree seedling | 2.71 | 3.40 | 6.49× 10−1 | 8.13 × 10−1 | 1.29 × 10−3 | 1.61 × 10−3 | 9.70 × 10−4 | 1.21 × 10−3 | 1.95 × 10−7 | 2.44 × 10−7 | 7.38 × 10−3 | 9.24 × 10−3 | 9.69 × 10−3 | 1.21 × 10−2 | 1.34 × 10−2 | 1.68 × 10−2 |

| Total | 1.94 × 102 | 2.20 × 102 | 3.06 × 101 | 3.66 × 101 | 1.19 × 10−2 | 1.36 × 10−2 | 1.02 × 10−1 | 1.38 × 10−1 | 1.06 × 10−5 | 1.22 × 10−5 | 3.89 × 10−1 | 5.37 × 10−1 | 4.72 × 10−1 | 5.44 × 10−1 | 2.14 | 3.13 |

| GWP100 | FDP | FEP | MEP | ODPinf | PMFP | POFP | TAP100 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg CO2−Eq) | (kg Oil-Eq) | (kg P-Eq) | (kg N-Eq) | (kg CFC-11-Eq) | (kg PM10-Eq) | (kg NMVOC-Eq) | (kg SO2-Eq) | |||||||||

| 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | 2019 | 2020 | |

| Banana at-the-farm-gate | 1.94 × 102 | 2,20 × 102 | 3.06 × 101 | 3.66 × 101 | 1.19 × 10−2 | 1.36 × 10−2 | 1.02 × 10−1 | 1.38 × 10−1 | 1.06 × 10−5 | 1.22 × 10−5 | 3.89 × 10−1 | 5.37 × 10−1 | 4.72 × 10−1 | 5.44 × 10−1 | 2.14 | 3.13 |

| Cardboard packaging | 4.92 × 101 | 5.65 × 101 | 1.60 × 101 | 1.84 × 101 | 1.97 × 10−2 | 2.27 × 10−2 | 2.77 × 10−2 | 3.19 × 10−2 | 3.88 × 10−6 | 4.56 × 10−6 | 1.15 × 10−1 | 1.32 × 10−1 | 1.46 × 10−1 | 1.68 × 10−1 | 1.86 × 10−1 | 2.13 × 10−1 |

| Plastic packaging | 5.87 | 6.75 | 4.24 | 4.86 | 1.59 × 10−3 | 1.82 × 10−3 | 1.21 × 10−3 | 1.39 × 10−3 | 1.57 × 10−7 | 1.86 × 10−7 | 9.28 × 10−3 | 1.07 × 10−2 | 2.49 × 10−2 | 2.86 × 10−2 | 1.99 × 10−2 | 2.29 × 10−2 |

| Electricity | 2.33 | 2.43 | 7.81 × 10−1 | 8.16 × 10−1 | 2.37 × 10−5 | 2.48 × 10−5 | 9.00 × 10−4 | 9.40 × 10−4 | 3.39 × 10−7 | 3.54 × 10−7 | 7.44 × 10−3 | 7.77 × 10−3 | 1.53 × 10−2 | 1.59 × 10−2 | 2.23 × 10−2 | 2.33 × 10−2 |

| Tap water | 1.95 × 10−1 | 2.15 × 10−1 | 7.12 × 10−2 | 7.85 × 10−2 | 3.73 × 10−5 | 4.12 × 10−5 | 4.60 × 10−5 | 5.10 × 10−5 | 1.48 × 10−8 | 1.64 × 10−8 | 3.90 × 10−4 | 4.30 × 10−4 | 6.10 × 10−4 | 6.80 × 10−4 | 6.20 × 10−4 | 6.80 × 10−4 |

| Cleaning agent production | 5.69 × 10−1 | 1.71 | 2.37 × 10−1 | 1.15 | 1.41 × 10−4 | 7.67 × 10−4 | 9.65 × 10−4 | 1.37 × 10−3 | 4.60 × 10−8 | 1.52 × 10−7 | 1.96 × 10−3 | 1.58 × 10−2 | 2.20 × 10−3 | 1.66 × 10−2 | 6.75 × 10−3 | 6.67 × 10−2 |

| Rachis disposal | 9.96 × 101 | 5.37 × 101 | 3.59 × 10−3 | 2.45 × 10−3 | 4.73 × 10−1 | 3.23 × 10−1 | 1.04 × 10−2 | 4.87 × 10−3 | 6.20 × 10−2 | 3.22 × 10−2 | 2.65 × 10−2 | 1.24 × 10−2 | ||||

| Total | 3.52 × 102 | 3.42 × 102 | 5.19 × 101 | 6.18 × 101 | 3.70 × 10−2 | 4.14 × 10−2 | 6.06 × 10−1 | 4.97 × 10−1 | 1.50 × 10−5 | 1.75 × 10−5 | 5.34 × 10−1 | 7.09 × 10−1 | 7.24 × 10−1 | 8.06 × 10−1 | 2.40 | 3.46 |

| Impact Category | 2019 | 2020 | |||||

|---|---|---|---|---|---|---|---|

| Name | Unit | RM0 | RM1 | RM2 | RM0 | RM1 | RM2 |

| GWP100 | kg CO2-Eq | 361.9498 | 329.1613 | 262.3156 | 353.1016 | 330.6849 | 299.4056 |

| FDP | kg oil-Eq | 53.4987 | 53.4987 | 53.4987 | 63.7866 | 63.7866 | 63.7866 |

| FEP | kg P-Eq | 0.03764 | 0.03406 | 0.03406 | 0.04218 | 0.03973 | 0.03973 |

| MEP | kg N-Eq | 0.6116 | 0.1402 | 0.1384 | 0.5045 | 0.1822 | 0.1813 |

| ODPinf | kg CFC-11-Eq | 0.0000156 | 0.0000156 | 0.0000156 | 0.0000182 | 0.0000182 | 0.0000182 |

| PMFP | kg PM10-Eq | 0.55421 | 0.55419 | 0.54382 | 0.73733 | 0.73731 | 0.73246 |

| POFP | kg NMVOC-Eq | 0.74871 | 0.73384 | 0.68673 | 0.83534 | 0.82518 | 0.80314 |

| TAP100 | kg SO2-Eq | 2.51381 | 2.51369 | 2.48731 | 3.62916 | 3.62907 | 3.61673 |

| GWP100 (kg CO2-Eq) | FDP (kg oil-Eq) | FEP (kg P-Eq) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2019 Rotterdam | 2019 San Diego | 2020 Rotterdam | 2020 San Diego | 2019 Rotterdam | 2019 San Diego | 2020 Rotterdam | 2020 San Diego | 2019 Rotterdam | 2019 San Diego | 2020 Rotterdam | 2020 San Diego | |

| Banana at-the- packaging-stage-gate | 3.52 × 102 | 3.52 × 102 | 3.42 × 102 | 3.42 × 102 | 5.19 × 101 | 5.19 × 101 | 6.18 × 101 | 6.18 × 101 | 3.70 × 10−2 | 3.70 × 10−2 | 4.14 × 10−2 | 4.14 × 10−2 |

| Electricity collection center | 2.03 | 2.03 | 2.03 | 2.03 | 6.83 × 10−1 | 6.83 × 10−1 | 6.84 × 10−1 | 6.84 × 10−1 | 2.07 × 10−5 | 2.07 × 10−5 | 2.08 × 10−5 | 2.08 × 10−5 |

| Electricity at Guayaquil Port | 3.94 × 10−1 | 3.94 × 10−1 | 3.94 × 10−1 | 3.94 × 10−1 | 1.33 × 10−1 | 1.33 × 10−1 | 1.33 × 10−1 | 1.33 × 10−1 | 4.07 × 10−6 | 4.07 × 10−6 | 4.07 × 10−6 | 4.07 × 10−6 |

| Fuel use in port machinery | 2.05 | 2.05 | 2.05 | 2.05 | 6.90 × 10−1 | 6.90 × 10−1 | 6.90 × 10−1 | 6.90 × 10−1 | 5.84 × 10−5 | 5.84 × 10−5 | 5.84 × 10−5 | 5.84 × 10−5 |

| Road transport farm to port | 6.39 × 101 | 6.39 × 101 | 6.39 × 101 | 6.39 × 101 | 1.91 × 101 | 1.91 × 101 | 1.91 × 101 | 1.91 × 101 | 4.24 × 10−3 | 4.24 × 10−3 | 4.24 × 10−3 | 4.24 × 10−3 |

| Maritime transport | 2.05 × 102 | 1.10 × 102 | 2.05 × 102 | 1.10 × 102 | 6.55 × 101 | 3.52 × 101 | 6.57 × 101 | 3.52 × 101 | 6.02 × 10−3 | 3.22 × 10−3 | 6.02 × 10−3 | 3.22 × 10−3 |

| Total | 6.25 × 102 | 5.30 × 102 | 6.15 × 102 | 5.20 × 102 | 1.38 × 102 | 1.08 × 102 | 1.48 × 102 | 1.18 × 102 | 4.73 × 10−2 | 4.45 × 10−2 | 5.17 × 10−2 | 4.89 × 10−2 |

| MEP (kg N−Eq) | ODPinf (kg CFC-11-Eq) | PMFP (kg PM10-Eq) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2019 Rotterdam | 2019 San Diego | 2020 Rotterdam | 2020 San Diego | 2019 Rotterdam | 2019 San Diego | 2020 Rotterdam | 2020 San Diego | 2019 Rotterdam | 2019 San Diego | 2020 Rotterdam | 2020 San Diego | |

| Banana at-the- packaging-stage-gate | 6.06 × 10−1 | 6.06 × 10−1 | 4.97 × 10−1 | 4.97 × 10−1 | 1.50 × 10−5 | 1.50 × 10−5 | 1.75 × 10−5 | 1.75 × 10−5 | 5.34 × 10−1 | 5.34 × 10−1 | 7.09 × 10−1 | 7.09 × 10−1 |

| Electricity collection center | 7.90 × 10−4 | 7.90 × 10−4 | 7.90 × 10−4 | 7.90 × 10−4 | 2.97 × 10−7 | 2.97 × 10−7 | 2.97 × 10−7 | 2.97 × 10−7 | 6.51 × 10−3 | 6.51 × 10−3 | 6.51 × 10−3 | 6.51 × 10−3 |

| Electricity at Guayaquil Port | 1.50 × 10−4 | 1.50 × 10−4 | 1.50 × 10−4 | 1.50 × 10−4 | 5.75 × 10−8 | 5.75 × 10−8 | 5.75 × 10−8 | 5.75 × 10−8 | 1.26 × 10−3 | 1.26 × 10−3 | 1.26 × 10−3 | 1.26 × 10−3 |

| Fuel use in port machinery | 9.90 × 10−4 | 9.90 × 10−4 | 9.90 × 10−4 | 9.90 × 10−4 | 3.55 × 10−7 | 3.55 × 10−7 | 3.55 × 10−7 | 3.55 × 10−7 | 8.52 × 10−3 | 8.52 × 10−3 | 8.52 × 10−3 | 8.52 × 10−3 |

| Road transport farm to port | 1.62 × 10−2 | 1.62 × 10−2 | 1.62 × 10−2 | 1.62 × 10−2 | 1.62 × 10−5 | 1.62 × 10−5 | 1.62 × 10−5 | 1.62 × 10−5 | 1.28 × 10−1 | 1.28 × 10−1 | 1.28 × 10−1 | 1.28 × 10−1 |

| Maritime transport | 1.54 × 10−1 | 8.27 × 10−2 | 1.54 × 10−1 | 8.27 × 10−2 | 3.58 × 10−5 | 1.92 × 10−5 | 3.58 × 10−5 | 1.92 × 10−5 | 1.45 | 7.77 × 10−1 | 1.45 | 7.77 × 10−1 |

| Total | 7.78 × 10−1 | 7.07 × 10−1 | 6.69 × 10−1 | 5.98 × 10−1 | 6.77 × 10−5 | 5.11 × 10−5 | 7.02 × 10−5 | 5.36 × 10−5 | 2.12 | 1.46 | 2.30 | 1,63 |

| POFP (kg NMVOC-Eq) | TAP100 (kg SO2-Eq) | |||||||

|---|---|---|---|---|---|---|---|---|

| 2019 Rotterdam | 2019 San Diego | 2020 Rotterdam | 2020 San Diego | 2019 Rotterdam | 2019 San Diego | 2020 Rotterdam | 2020 San Diego | |

| Banana at-the- packaging-stage-gate | 7.4 × 10−1 | 7.24 × 10−1 | 8.06 × 10−1 | 8.06 × 10−1 | 2.40 | 2.40 | 3.46 | 3.46 |

| Electricity collection center | 1.34 × 10−2 | 1.34 × 10−2 | 1.34 × 10−2 | 1.34 × 10−2 | 1.95 × 10−2 | 1.95 × 10−2 | 1.95 × 10−2 | 1.95 × 10−2 |

| Electricity at Guayaquil Port | 2.59 × 10−3 | 2.59 × 10−3 | 2.59 × 10−3 | 2.59 × 10−3 | 3.78 × 10−3 | 3.78 × 10−3 | 3.78 × 10−3 | 3.78 × 10−3 |

| Fuel use in port machinery | 2.90 × 10−2 | 2.90 × 10−2 | 2.90 × 10−2 | 2.90 × 10−2 | 1.64 × 10−2 | 1.64 × 10−2 | 1.64 × 10−2 | 1.64 × 10−2 |

| Road transport farm to port | 3.99 × 10−1 | 3.99 × 10−1 | 3.99 × 10−1 | 3.99 × 10−1 | 2.67 × 10−1 | 2.67 × 10−1 | 2.68 × 10−1 | 2.68 × 10−1 |

| Maritime transport | 4.15 | 2.23 | 4.15 | 2.23 | 3.60 | 1.93 | 3.60 | 1.93 |

| Total | 5.32 | 3.40 | 5.40 | 3.48 | 6.30 | 4.64 | 7.37 | 5.70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Veliz, K.; Chico-Santamarta, L.; Ramirez, A.D. The Environmental Profile of Ecuadorian Export Banana: A Life Cycle Assessment. Foods 2022, 11, 3288. https://doi.org/10.3390/foods11203288

Veliz K, Chico-Santamarta L, Ramirez AD. The Environmental Profile of Ecuadorian Export Banana: A Life Cycle Assessment. Foods. 2022; 11(20):3288. https://doi.org/10.3390/foods11203288

Chicago/Turabian StyleVeliz, Kevin, Leticia Chico-Santamarta, and Angel D. Ramirez. 2022. "The Environmental Profile of Ecuadorian Export Banana: A Life Cycle Assessment" Foods 11, no. 20: 3288. https://doi.org/10.3390/foods11203288