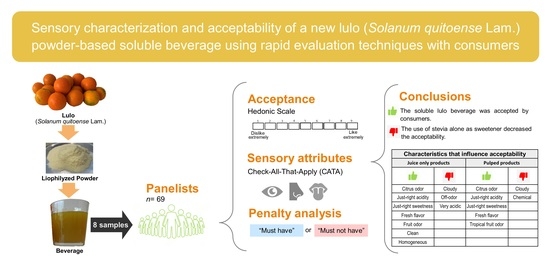

Sensory Characterization and Acceptability of a New Lulo (Solanum quitoense Lam.) Powder-Based Soluble Beverage Using Rapid Evaluation Techniques with Consumers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Preparation of Formulations before Dehydration

2.2.1. Beverage Formulation

2.2.2. Pulp and Juice Extraction

2.2.3. Additive Incorporation

2.2.4. Homogenization

2.3. Lulo-Powder Obtention

- Freezing phase: cooling to 5 °C for 30 min, then temperature reduction to −60 °C at 0.5 °C/min, and then the conditions were maintained at −60 °C for 12 h;

- Primary drying: temperature was increased to −40 °C at 0.2 °C/min, with vacuum pressure of 0.05 mbar, and then the conditions were maintained for 38 h;

- Secondary drying: temperature was raised to 25 °C at 0.2 °C/min, at maximum vacuum pressure, and then the conditions were maintained for 7 h.

2.4. Rehydration

2.5. Sensory Study

2.5.1. Participants

2.5.2. Tasting Room Conditions

2.5.3. Sample Presentation

2.5.4. Sensory Tests

2.5.5. Ethical and Security Aspects

2.6. Statistical Analysis

3. Results

3.1. Consumers’ Sensory Description of the Lulo-Powder-Based Soluble Beverage

3.2. Consumers’ Overall Acceptability

3.3. Penalty Analysis to Identify Drivers of Liking

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramírez, F.; Kallarackal, J.; Davenport, T.L. Lulo (Solanum quitoense Lam.) reproductive physiology: A review. Sci. Hortic. 2018, 238, 163–176. [Google Scholar] [CrossRef]

- Gómez-Merino, F.C.; Trejo-Téllez, L.I.; García-Albarado, J.C. Lulo (Solanum quitoense [Lamarck.]) as new landscape crop in the Mexican agro-ecosystem. Rev. Mex. De Cienc. Agrícolas 2014, 5, 1741–1753. [Google Scholar]

- Sabbe, S.; Van Damme, P.; Verbeke, W. European market environment for selected Latin American tropical fruit species. Acta Hortic. 2013, 975, 615–623. [Google Scholar] [CrossRef]

- Forero, D.P.; Orrego, C.E.; Peterson, D.G.; Osorio, C. Chemical and sensory comparison of fresh and dried lulo (Solanum quitoense Lam.) fruit aroma. Food Chem. 2015, 169, 85–91. [Google Scholar] [CrossRef]

- Forero, D.P.; Masatani, C.; Fujimoto, Y.; Coy-Barrera, E.; Peterson, D.G.; Osorio, C. Spermidine derivatives in lulo (Solanum quitoense Lam.) fruit: Sensory (taste) versus biofunctional (ACE-Inhibition) properties. J. Agric. Food Chem. 2016, 64, 5375–5383. [Google Scholar] [CrossRef] [PubMed]

- Hinestroza-Córdoba, L.I.; Duarte Serna, S.; Seguí, L.; Barrera, C.; Betoret, N. Characterization of powdered lulo (Solanum quitoense) bagasse as a functional food ingredient. Foods 2020, 9, 723. [Google Scholar] [CrossRef] [PubMed]

- Altendorf, S.; Minor Tropical Fruits (Mainstreaming a Niche Market). Food Outlook 2018. pp. 67–75. Available online: https://www.fao.org/fileadmin/templates/est/COMM_MARKETS_MONITORING/Tropical_Fruits/Documents/Minor_Tropical_Fruits_FoodOutlook_1_2018.pdf (accessed on 13 August 2022).

- Igual, M.; Ramires, S.; Mosquera, L.H.; Martínez-Navarrete, N. Optimization of spray drying conditions for lulo (Solanum quitoense L.) pulp. Powder Technol 2014, 256, 233–238. [Google Scholar] [CrossRef]

- Morton, J.F.; Dowling, C.F. Naranjilla. Solanum quitoense Lam. In Fruits of Warm Climates; Distributed by Creative Resources Systems: Miami, FL, USA; Winterville, NC, USA, 1987; pp. 425–428. [Google Scholar]

- Acosta, Ó.; Pérez, A.M.; Vaillant, F. Chemical characterization, antioxidant properties, and volatile constituents of naranjilla (Solanum quitoense Lam.) cultivated in Costa Rica. Arch. Latinoam. Nutr. 2009, 59, 89–94. [Google Scholar]

- Paltrinieri, G.; Figuerola, F. Procesamiento a Pequeña Escala de Frutas y Hortalizas Amazónicas Nativas e Introducidas; Ameritan Printers; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 1997. [Google Scholar]

- Mosquera Chaverra, L.M.; Chaverra Molina, M.; Huertado Cuesta, J.N. Elaboración de néctar de lulo (Solanum sessiliflorum Dunal). Rev. Sinerg. 2019, 5, 64–81. [Google Scholar]

- Paula, F.J.A.; Guiné, R.P.F.; Cruz-Lopes, L.; Duarte, A.C.; Fragata, A.O.S.; Reis, M.A.L. Effects of pre- and post-harvest factors on the selected elements contents in fruit juices. Czech. J. Food Sci. 2015, 33, 384–391. [Google Scholar] [CrossRef] [Green Version]

- Pinto, T.; Vilela, A.; Cosme, F. Chemical and sensory characteristics of fruit juice and fruit fermented beverages and their consumer acceptance. Beverages 2022, 8, 33. [Google Scholar] [CrossRef]

- Salazar, D.; Acurio, L.; Pérez, L.; Valencia, A.; Arancibia, M.; Guanoquiza, A.; Rodríguez, C.; Álvarez, F. Effect of the inclusion of batata (Ipomoea batata) in the preparation of naranjilla jam (Solanum quitoense). Agroind. Sci. 2018, 8, 153–157. [Google Scholar] [CrossRef] [Green Version]

- Gaona-Gonzaga, J.; Montesdeoca-Espin, D.; Brito-Grandes, B.; Sotomayor-Correa, A.; Viera, W. Aprovechamiento de la naranjilla (Solanum quitoense Lam.) variedad INIAP Quitoense-2009 para la obtención de una bebida carbonatada. Enfoque UTE 2019, 10, 107–114. [Google Scholar] [CrossRef]

- Granados, C.; Torrenegra, M.E.; Acevedo, D.; Romero, P. Evaluación fisicoquímica y microbiológica del aperitivo vínico de lulo (Solanum quitoense L.). Inf. Tecnol. 2013, 24, 11–12. [Google Scholar] [CrossRef] [Green Version]

- Cerón, A.F.; Osorio, M.O.; Huertado, B.A. Identificación de ácidos grasos contenidos en aceites extraídos a partir de semillas de tres diferentes especies de frutas. Acta Agron. 2012, 61, 126–132. [Google Scholar]

- Chacon, W.D.C.; Valencia, G.A.; Rojas, G.M.A.; Henao, A.C.A. Drying and pyrolysis of lulo peel: Non-isothermal analysis of physicochemical, kinetics, and master Plots. Bioenerg. Res. 2020, 13, 927–938. [Google Scholar] [CrossRef]

- Forero, D.; Carriazo, J.; Osorio, C. Effect of different drying methods on morphological, thermal, and biofunctional properties of lulo (Solanum quitoense Lam.) fruit powders. Dry Technol. 2016, 34, 1085–1094. [Google Scholar] [CrossRef]

- Khaing Hnin, K.; Zhang, M.; Mujumdar, A.S.; Zhu, Y. Emerging food drying technologies with energy-saving characteristics: A review. Dry Technol. 2019, 37, 1465–1480. [Google Scholar] [CrossRef]

- Michalska-Ciechanowska, A.; Majerska, J.; Brzezowska, J.; Wojdyło, A.; Figiel, A. The influence of maltodextrin and inulin on the physico-chemical properties of cranberry juice powders. Chem. Eng. 2020, 4, 12. [Google Scholar] [CrossRef] [Green Version]

- Odebrecht Dias, C.O.; dos Santos Opuski de Almeida, J.; Silvia Pinto, S.; de Oliveira Santana, F.C.; Verruck, S.; Olivera Müller, C.M.; Schwinden Prudêncio, E.; de Mello Castanho Amboni, R. Development and physico-chemical characterization of microencapsulated Bifidobacteria in passion fruit juice: A functional non-dairy product for probiotic delivery. Food Biosci. 2018, 24, 26–36. [Google Scholar] [CrossRef]

- Chen, X.D.; Özkan, N. Stickiness, functionality, and microstructure of food powders. Dry Technol. 2007, 25, 959–969. [Google Scholar] [CrossRef]

- Otálora, M.C.; Carriazo, J.G.; Iturriaga, L.; Nazareno, M.A.; Osorio, C. Microencapsulation of betalains obtained from cactus fruit (Opuntia Ficus-Indica) by spray drying using cactus cladode mucilage and maltodextrin as encapsulating agents. Food Chem. 2015, 187, 174–181. [Google Scholar] [CrossRef]

- Gupta, N.; Jangid, A.K.; Pooja, D.; Kulhari, H. Inulin: A Novel and stretchy polysaccharide tool for biomedical and nutritional applications. Int. J. Biol. Macromol. 2019, 132, 852–863. [Google Scholar] [CrossRef]

- Saavedra-Leos, M.Z.; Leyva-Porras, C.; Martínez-Guerra, E.; Pérez-García, S.A.; Aguilar-Martínez, J.A.; Álvarez-Salas, C. Physical properties of inulin and inulin–orange juice: Physical characterization and technological application. Carbohydr. Polym. 2014, 105, 10–19. [Google Scholar] [CrossRef]

- Myers, A.; Fig, D.; Tugendhaft, A.; Mandle, J.; Myers, J.; Hofman, K. Sugar and health in South Africa: Potential challenges to leveraging policy change. Glob. Public Health 2017, 12, 98–115. [Google Scholar] [CrossRef]

- Fitch, C.; Keim, K.S. Position of the academy of nutrition and dietetics: Use of nutritive and nonnutritive sweeteners. J. Acad. Nutr. Diet. 2012, 112, 739–758. [Google Scholar] [CrossRef] [PubMed]

- Grembecka, M. Sugar alcohols—Their role in the modern world of sweeteners: A review. Eur. Food Res. Technol. 2015, 241, 1–14. [Google Scholar] [CrossRef] [Green Version]

- O´Sullivan, M.G. A Handbook for Sensory and Consumer-Driven New Product Development, 1st ed.; Elsevier: Cambridge, UK, 2017; pp. 3–218. [Google Scholar]

- Adams, J.; Wiliams, A.; Lancaster, B.; Foley, M. Advantages and uses of Check-All-That-Apply response compared to traditional scaling of attributes for salty snacks. In Proceedings of the 7th Pangborn Sensory Science Symposium, Minneapolis, MN, USA, 12–16 August 2007. [Google Scholar]

- Reinbach, H.C.; Giacalone, D.; Machado, L.R.; Bredie, W.L.P.; Frost, M.B. Comparison of three sensory profiling methods to study consumer perception: CATA, CATA with intensity ratings and napping®. In Proceedings of the 5th European Conference on Sensory and Consumer Research, A Sense Inspiration, Bern, Switzerland, 9–12 September 2012. [Google Scholar]

- Dooley, L.; Lee, Y.; Meullenet, J.-F. The application of Check-All-That-Apply (CATA) consumer profiling to preference mapping of vanilla ice cream and its comparison to classical external preference mapping. Food Qual. Prefer. 2010, 21, 394–401. [Google Scholar] [CrossRef]

- Reinbach, H.C.; Giacalone, D.; Ribeiro, L.M.; Bredie, W.L.P.; Frøst, M.B. Comparison of three sensory profiling methods based on consumer perception: CATA, CATA with intensity and napping®. Food Qual. Prefer. 2014, 32, 160–166. [Google Scholar] [CrossRef]

- Ares, G.; Deliza, R.; Barreiro, C.; Giménez, A.; Gámbaro, A. Comparison of two sensory profiling techniques based on consumer perception. Food Qual. Prefer. 2010, 21, 417–426. [Google Scholar] [CrossRef]

- Ares, G.; Jaeger, S. Check-All-That-Apply (CATA) questions with consumers in practice: Experimental considerations and impact on outcome. In Rapid Sensory Profiling Techniques; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Kent, UK, 2015; pp. 227–245. [Google Scholar]

- Ares, G.; Dauber, C.; Fernández, E.; Giménez, A.; Varela, P. Penalty analysis based on CATA questions to identify drivers of liking and directions for product reformulation. Food Qual. Prefer. 2014, 32, 65–76. [Google Scholar] [CrossRef]

- González-Bonilla, S.M.; Marín-Arroyo, M.R. Use of “Just about right” scales for the formulation of a new soluble beverage from lulo (Solanum quitoense Lam.). In Proceedings of the 10th European Conference on Sensory and Consumer Research (EUROSENSE), Turku, Finland, 13–16 September 2022. [Google Scholar]

- Silveira, A.C. Use of additives and physical methods to maintain the quality of fresh cut produces. Agrociencia 2017, 21, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Williams, E. Experimental designs balanced for the estimation of residual effects of treatments. Aust. J. Sci. Res. B 1949, 2, 149–168. [Google Scholar] [CrossRef]

- Carbonell, L.; Izquierdo, L.; Carbonell, I. Sensory analysis of Spanish mandarin juices. Selection of attributes and panel performance. Food Qual. Prefer. 2007, 18, 329–341. [Google Scholar] [CrossRef]

- Pérez-Cacho, P.R.; Galan-Soldevilla, H.; Mahattanatawee, K.; Elston, A.; Rouseff, R.L. Sensory lexicon for fresh squeezed and processed orange juices. Food Sci. Technol. Int. 2008, 14 (Suppl. 5), 131–141. [Google Scholar] [CrossRef]

- Meyners; Castura, J.C. Check-All-That-Apply Questions. In Novel Techniques in Sensory Characterization and Consumer Profiling; CRC Press: Boca Ratón, FL, USA, 2014; pp. 272–301. [Google Scholar]

- Sheskin, D. Handbook of Parametric and Nonparametric Statistical Procedures, 5th ed.; Chapman and Hall/CRC: London, UK, 2011. [Google Scholar]

- Tenenhaus, M.; Pagès, J.; Ambroisine, L.; Guinot, C. PLS methodology to study relationships between hedonic judgements and product characteristics. Food Qual. Prefer. 2005, 16, 315–325. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Principal Component Analysis, 2nd ed.; Springer Series in Statistics; Springer: New York, NY, USA, 2002. [Google Scholar]

- Ning, X.; Zhou, Y.; Wang, Z.; Zheng, X.; Pan, X.; Chen, Z.; Liu, Q.; Du, W.; Cao, X.; Wang, L. Evaluation of passion fruit mesocarp flour on the paste, dough, and quality characteristics of dried noodles. Food Sci. Nutr. 2022, 10, 1657–1666. [Google Scholar] [CrossRef]

- Martínez-Navarrete, N.; Camacho, M.M.; Agudelo, C.; Salvador, A. Sensory characterization of juice obtained via rehydration of freeze-dried and spray-dried grapefruit. J. Sci. Food Agric. 2019, 99, 244–252. [Google Scholar] [CrossRef] [Green Version]

- Rega, B.; Fournier, N.; Nicklaus, S.; Guichard, E. Role of pulp in flavor release and sensory perception in orange juice. J. Agric. Food Chem. 2004, 52, 4204–4212. [Google Scholar] [CrossRef]

- Berlinet, C.; Guichard, E.; Fournier, N.; Ducruet, V. Effect of pulp reduction and pasteurization on the release of aroma compounds in industrial orange juice. J. Food Sci. 2007, 72, S535–S543. [Google Scholar] [CrossRef]

- Tan, V.W.K.; Wee, M.S.M.; Tomic, O.; Forde, C.G. Temporal sweetness and side tastes profiles of 16 sweeteners using Temporal Check-All-That-Apply (TCATA). Int. Food Res. J. 2019, 121, 39–47. [Google Scholar] [CrossRef]

- Cadena, R.S.; Cruz, A.G.; Netto, R.R.; Castro, W.F.; de Faria, J.A.F.; Bolini, H.M.A. Sensory profile and physicochemical characteristics of mango nectar sweetened with high intensity sweeteners throughout storage time. Int. Food Res. J. 2013, 54, 1670–1679. [Google Scholar] [CrossRef] [Green Version]

- Spillane, W.J. Optimising Sweet Taste in Foods, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2006. [Google Scholar]

- Bernal Estrada, J.A.; Díaz Diez, C.A.; Materiales Locales y Mejorados de Tomate de Árbol, Mora y Lulo Sembrados por los Agricultores y Cultivares Disponibles para su Evaluación en Colombia. Corporación Colombiana de Investigación Agropecuaria Agrosavia, Boletín Divulgativo 7. 2006. Available online: http://hdl.handle.net/20.500.12324/1225 (accessed on 13 August 2022).

- Alizadeh, A.; Oskuyi, A.S.; Amjadi, S. The optimization of prebiotic sucrose-free mango nectar by response surface methodology: The effect of stevia and inulin on physicochemical and rheological properties. Food Sci. Technol. Int. 2019, 25, 243–251. [Google Scholar] [CrossRef]

| Sample * | Juice (g) | Pulp (g) | Citric Acid (g) | Ascorbic Acid (g) | Maltodextrin (g) | Inulin (g) | Erythritol (g) | Xylitol (g) | Stevia (g) | Water (g) |

|---|---|---|---|---|---|---|---|---|---|---|

| JMS | 48.8 | 0 | 0 | 0 | 4.9 | 0 | 0 | 0 | 0.029 | 46.4 |

| JIS | 48.8 | 0 | 0 | 0 | 0 | 4.9 | 0 | 0 | 0.029 | 46.4 |

| JMX | 45.7 | 0 | 0 | 0 | 4.6 | 0 | 5.0 | 1.3 | 0.016 | 43.5 |

| JIX | 45.7 | 0 | 0 | 0 | 0 | 4.6 | 5.0 | 1.3 | 0.016 | 43.5 |

| PMS | 0 | 32.0 | 0.10 | 0.48 | 3.2 | 0 | 0 | 0 | 0.029 | 64.1 |

| PIS | 0 | 32.0 | 0.10 | 0.48 | 0 | 3.2 | 0 | 0 | 0.029 | 64.1 |

| PMX | 0 | 30.0 | 0.09 | 0.45 | 3.0 | 0 | 5.0 | 1.3 | 0.016 | 60.0 |

| PIX | 0 | 30.0 | 0.09 | 0.45 | 0 | 3.0 | 5.0 | 1.3 | 0.016 | 60.0 |

| Visual Attributes | Odor-Related Attributes | Flavor-Related Attributes | |||

|---|---|---|---|---|---|

| Term | Abbreviation | Term | Abbreviation | Term | Abbreviation |

| Cloudy | V–Cloudy | Very aromatic | O–Aromatic | Sweet | F–Sweet |

| Clean | V–Clean | Not very aromatic | O–N.Aromatic | Very acidic | F–V.Acidic |

| Opaque | V–Opaque | Fruity | O–Fruity | Not very acidic | F–N.Acidic |

| Green color | V–Green | Floral | O–Floral | Very sweet | F–V.Sweet |

| Yellow color | V–Yellow | Chemical/artificial | O–Chemical | Not very sweet | F–N.Sweet |

| Brown color | V–Brown | Unripe fruit | O–Unripe | Just-right acidity | F–J.Acidity |

| Homogeneous appearance | V–Homogeneous | Citrus | O–Citrus | Just-right sweetness | F–J.Sweetness |

| Heterogeneous appearance | V–Heterogeneous | Tropical fruit | O–T.Fruit | Bitter | F–Bitter |

| Sediments | V–Sediments | Moldy/musty | O–Moldy | Metallic | F–Metallic |

| Very intense color | V–V.Color | Ripe fruit | O–Ripe | Fresh | F–Fresh |

| Not very intense color | V–N.Color | Sweet | O–Sweet | Off-flavor | F–Off |

| Bright | V–Bright | Medicine | O–Medicine | Unripe fruit | F–Unripe |

| Off-odor | O–Off | Ripe fruit | F–Ripe | ||

| Kiwi aroma | O–Kiwi | Rough | F–Rough | ||

| Pineapple aroma | O–Pineapple | Chemical/artificial | F–Chemical | ||

| Lemon aroma | O–Lemon | Dryness | F–Dryness | ||

| Orange aroma | O–Orange | Liquorous | F–Liquorous | ||

| Kiwi flavor | F–Kiwi | ||||

| Pineapple flavor | F–Pineapple | ||||

| Lemon flavor | F–Lemon | ||||

| Orange flavor | F–Orange | ||||

| Attributes | Ideal | Samples * | |||||||

|---|---|---|---|---|---|---|---|---|---|

| JMS | JIS | JMX | JIX | PMS | PIS | PMX | PIX | ||

| Visual (V) | |||||||||

| V-V.Color | 56.5 | 5.8 c | 7.2 bc | 15.9 abc | 8.7 bc | 24.6 ab | 33.3 a | 30.4 a | 23.2 abc |

| V-Clean | 53.6 | 15.9 ab | 1.4 b | 17.4 a | 13.0 ab | 18.8 a | 8.7 ab | 15.9 ab | 13.0 ab |

| V-Bright | 44.9 | 10.1 ab | 0.0 b | 14.5 ab | 11.6 ab | 14.5 ab | 13.0 ab | 11.6 ab | 17.4 a |

| V-Yellow | 43.5 | 21.7 b | 11.6 b | 24.6 b | 23.2 b | 65.2 a | 63.8 a | 66.7 a | 68.1 a |

| V-Green | 13.0 | 65.2 a | 68.1 a | 73.9 a | 63.8 a | 2.9 b | 2.9 b | 1.4 b | 1.4 b |

| V-Opaque | 7.2 | 26.1 b | 50.7 a | 23.2 b | 26.1 b | 24.6 b | 39.1 ab | 31.9 ab | 27.5 b |

| V-Sediments | 7.2 | 29.0 bcd | 14.5 d | 23.2 cd | 34.8 abc | 42.0 abc | 49.3 a | 46.4 ab | 42.0 abc |

| V-Cloudy | 4.3 | 37.7 b | 63.8 a | 37.7 b | 40.6 b | 30.4 b | 27.5 b | 30.4 b | 31.9 b |

| V-N.Color | 4.3 | 27.5 a | 26.1 ab | 21.7 ab | 23.2 ab | 8.7 b | 15.9 ab | 10.1 ab | 18.8 ab |

| V-Heterogeneous | 1.4 | 13.0 b | 15.9 ab | 10.1 b | 15.9 ab | 11.6 b | 13.0 b | 20.3 ab | 29.0 a |

| Odor (O) | |||||||||

| O-Aromatic | 43.5 | 15.9 ab | 21.7 a | 18.8 ab | 18.8 ab | 11.6 ab | 8.7 ab | 13.0 ab | 5.8 b |

| O-Ripe | 26.1 | 10.1 ab | 14.5 ab | 7.2 b | 11.6 ab | 15.9 ab | 23.2 a | 17.4 ab | 13.0 ab |

| O-N.Aromatic | 4.3 | 20.3 b | 29.0 ab | 24.6 b | 18.8 b | 34.8 ab | 39.1 ab | 36.2 ab | 49.3 a |

| Flavor (F) | |||||||||

| F-J.Acidity | 66.7 | 33.3 ab | 26.1 ab | 33.3 ab | 46.4 a | 20.3 b | 24.6 ab | 31.9 ab | 40.6 ab |

| F-Sweet | 31.9 | 15.9 ab | 13.0 ab | 15.9 ab | 8.7 b | 17.4 ab | 20.3 ab | 20.3 ab | 27.5 a |

| F-V.Acidic | 7.2 | 31.9 ab | 40.6 a | 36.2 a | 31.9 ab | 15.9 bc | 11.6 c | 10.1 c | 11.6 c |

| F-Chemical | 0.0 | 18.8 abc | 21.7 abc | 7.2 c | 13.0 bc | 33.3 a | 29.0 ab | 17.4 abc | 10.1 c |

| Attributes | Ideal | Juice Only Samples * | |||

|---|---|---|---|---|---|

| JMS | JIS | JMX | JIX | ||

| Visual (V) | |||||

| V-Clean | 53.6 | 15.9 a | 1.4 b | 17.4 a | 13.0 ab |

| V-Bright | 44.9 | 10.1 ab | 0.0 b | 14.5 a | 11.6 a |

| V-Opaque | 7.2 | 26.1 b | 50.7 a | 23.2 b | 26.1 b |

| V-Sediments | 7.2 | 29.0 ab | 14.5 b | 23.2 ab | 34.8 a |

| V-Cloudy | 4.3 | 37.7 b | 63.8 a | 37.7 b | 40.6 b |

| Flavor-related (F) | |||||

| F-J.Acidity | 66.7 | 33.3 ab | 26.1 b | 33.3 ab | 46.4 a |

| F-Bitter | 1.4 | 23.2 a | 17.4 ab | 7.2 b | 10.1 ab |

| F-Metallic | 0.0 | 15.9 a | 7.2 ab | 5.9 ab | 4.3 b |

| F-Chemical | 0.0 | 18.8 ab | 21.7 a | 7.2 b | 13.0 ab |

| Ideal | With pulp samples * | ||||

| PMS | PIS | PMX | PIX | ||

| Visual (V) | |||||

| V-Homogeneous | 72.5 | 40.6 a | 30.4 ab | 33.3 ab | 26.1 b |

| V-Heterogeneous | 1.4 | 11.6 b | 13.0 b | 20.3 ab | 29.0 a |

| Odor-related (O) | |||||

| O-Citrus | 50.7 | 15.9 ab | 27.5 a | 13.0 b | 23.2 ab |

| O-Medicine | 0.0 | 18.8 a | 14.5 ab | 10.1 ab | 7.2 b |

| Flavor-related (F) | |||||

| F-J.Acidity | 66.7 | 20.3 b | 24.6 ab | 31.9 ab | 40.6 a |

| F-Off | 0.0 | 26.1 a | 27.5 a | 11.6 b | 14.5 ab |

| F-Chemical | 0.0 | 33.3 a | 29.0 a | 17.4 ab | 10.1 b |

| Sample * | Hedonic Score 1 |

|---|---|

| PMX | 6.0 (1.7) a |

| JMX | 5.9 (1.8) ab |

| PIX | 5.9 (1.7) ab |

| JIX | 5.9 (1.9) ab |

| PIS | 5.3 (2.0) bc |

| JMS | 5.0 (1.9) c |

| JIS | 5.0 (2.0) c |

| PMS | 4.9 (2.0) c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marín-Arroyo, M.R.; González-Bonilla, S.M. Sensory Characterization and Acceptability of a New Lulo (Solanum quitoense Lam.) Powder-Based Soluble Beverage Using Rapid Evaluation Techniques with Consumers. Foods 2022, 11, 3129. https://doi.org/10.3390/foods11193129

Marín-Arroyo MR, González-Bonilla SM. Sensory Characterization and Acceptability of a New Lulo (Solanum quitoense Lam.) Powder-Based Soluble Beverage Using Rapid Evaluation Techniques with Consumers. Foods. 2022; 11(19):3129. https://doi.org/10.3390/foods11193129

Chicago/Turabian StyleMarín-Arroyo, María Remedios, and Sofía Marcela González-Bonilla. 2022. "Sensory Characterization and Acceptability of a New Lulo (Solanum quitoense Lam.) Powder-Based Soluble Beverage Using Rapid Evaluation Techniques with Consumers" Foods 11, no. 19: 3129. https://doi.org/10.3390/foods11193129