Utilization of By-Products from Livestock: Study on the Mechanical and Thermal Properties of Biodegradable Containers Made with Pork Skin Gelatin Polymer

Abstract

:1. Introduction

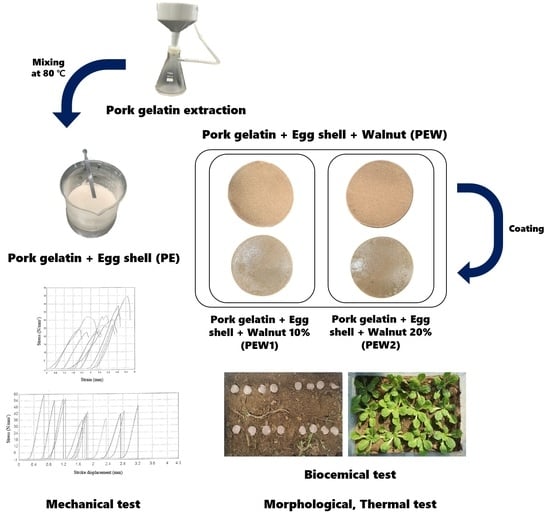

2. Materials and Methods

2.1. Material and Preparation of Pork Gelatin Powder

2.2. Manufacture of Biodegradable Containers

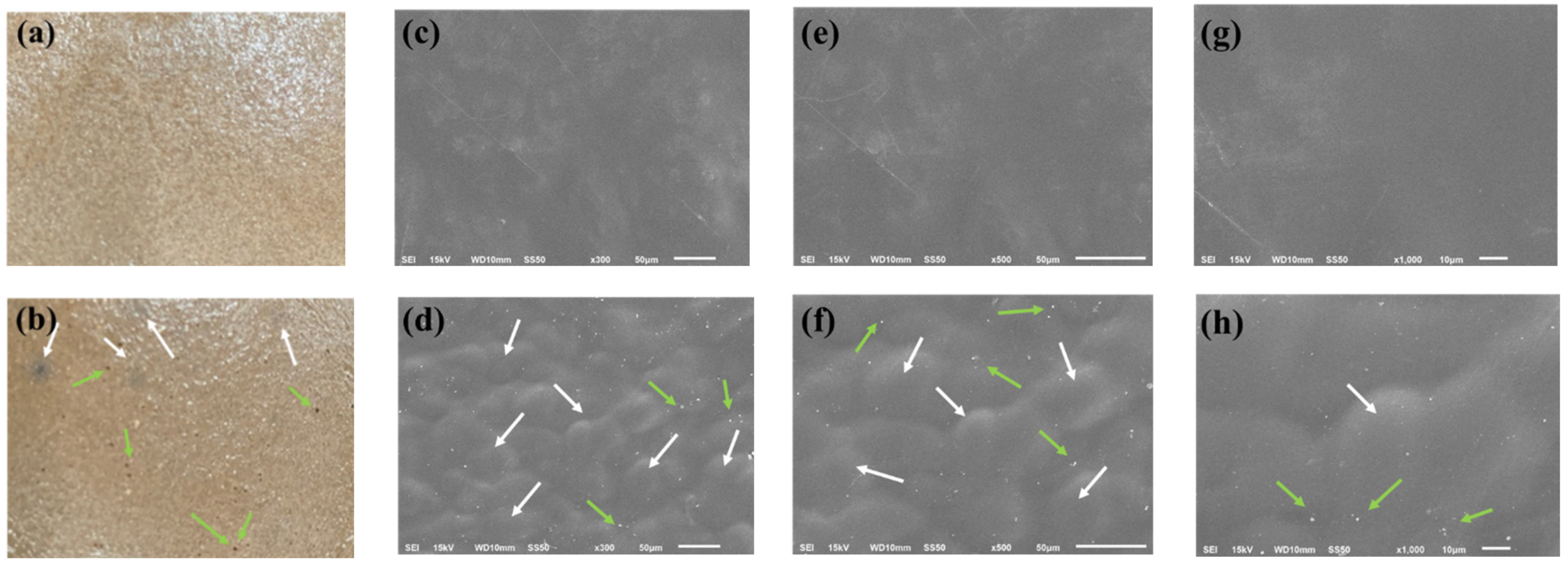

2.3. Morphological Properties

2.4. Mechanical Properties

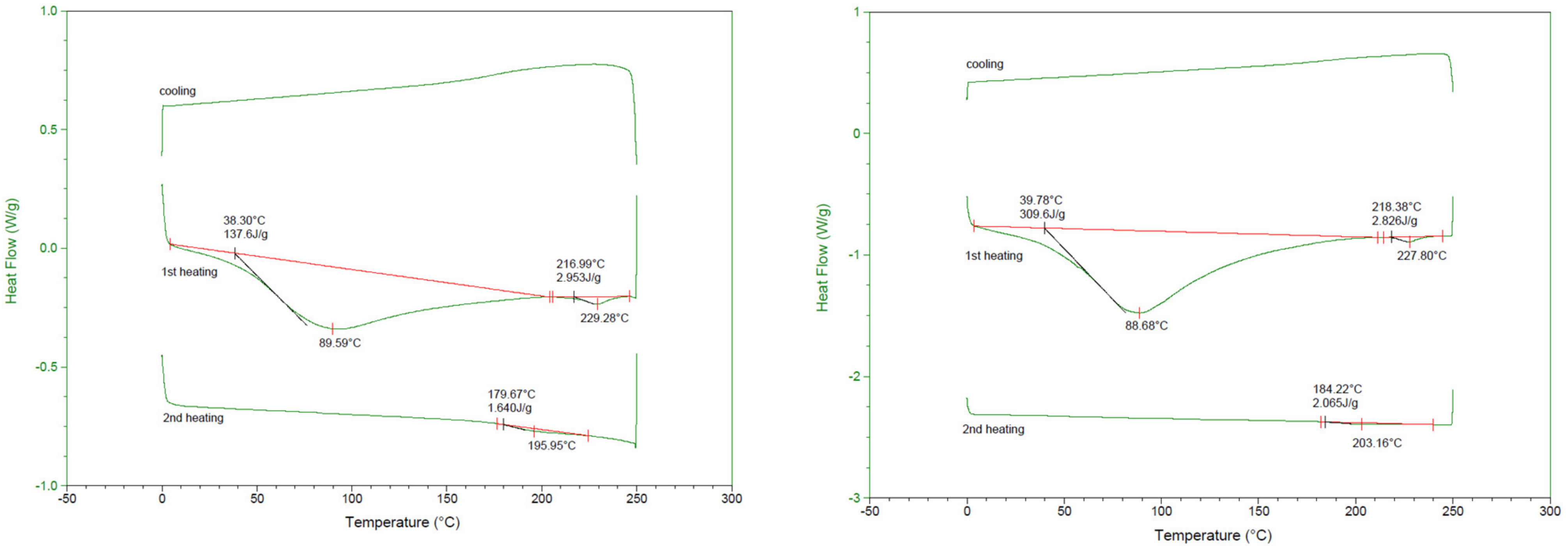

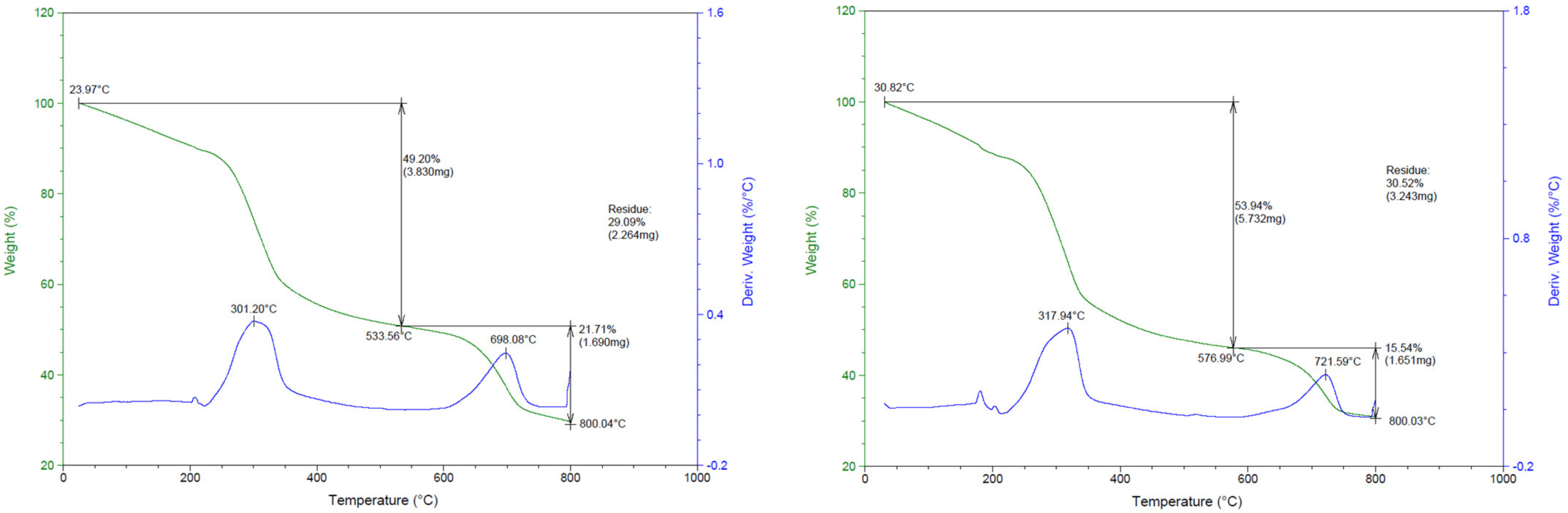

2.5. Thermal Properties

2.6. Biodegradability Performed Indoors

2.7. Statistical Analysis

3. Results

3.1. Scanning Electron Microscopy

3.2. Mechanical Properties

3.3. DSC (Differential Scanning Calorimetry)

3.4. TGA (Thermogravimetry Analysis)

3.5. Biodegradability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bumbudsanpharoke, N.; Ko, S. Packaging technology for home meal replacement: Innovations and future prospective. Food Control 2022, 132, 108470. [Google Scholar] [CrossRef]

- Global $156+ Billion Ready Meals Market to 2025, Research and Markets; 2020. Available online: https://www.globenewswire.com/news-release/2020/12/02/2138109/28124/en/Global-156-Billion-Ready-Meals-Market-to-2025.html#:~:text=The%20global%20ready%20meals%20market,US%24105.489%20billion%20in%202019. (accessed on 8 June 2021).

- Lee, S.; Ham, S. Food service industry in the era of COVID-19: Trends and research implications. Nutr. Res. Pract. 2021, 15, S22–S31. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Liew, M.S. Tertiary recycling of plastics waste: An analysis of feedstock, chemical and biological degradation methods. J. Mater. Cycles Waste Manag. 2021, 23, 32–43. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Flury, M. Is biodegradable plastic mulch the solution to agriculture’s plastic problem? Environ. Sci. Technol. 2017, 51, 1068–1069. [Google Scholar] [CrossRef] [PubMed]

- Amobonye, A.; Bhagwat, P.; Singh, S.; Pillai, S. Plastic biodegradation: Frontline microbes and their enzymes. Sci. Total Environ. 2021, 759, 143536. [Google Scholar] [CrossRef]

- Zurier, H.S.; Goddard, J.M. Biodegradation of microplastics in food and agriculture. Curr. Opin. Food Sci. 2021, 15, 37–44. [Google Scholar] [CrossRef]

- Davis, G.; Song, J.H. Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind. Crops Prod. 2006, 23, 47–161. [Google Scholar] [CrossRef]

- Yang, I.M.; Park, C. Factors influencing consumer’s attitude and buying behavior on the green products. Asia Pac. J. Bus. Ventur. Entrep. 2012, 7, 55–64. [Google Scholar] [CrossRef]

- Cenci, M.P.; Scarazzato, T.; Munchen, D.D.; Dartora, P.C.; Veit, H.M.; Bernardes, A.M.; Dias, P.R. Eco-friendly electronics—A comprehensive review. Adv. Mater. Technol. 2022, 7, 2001263. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Jafari, S.M.; Salehabadi, A.; Nafchi, A.M.; Uthaya Kumar, U.S.; Khalil, H.P.S.A. Biodegradable green packaging with antimicrobial functions based on the bioactive compounds from tropical plants and their by-products. Trends Food Sci. Technol. 2020, 100, 262–277. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Lai, T.K.; Tye, Y.Y.; Paridah, M.T.; Fazita, M.R.N.; Azniwati, A.A.; Dungani, R.; Rizal, S. Preparation and characterization of microcrystalline cellulose from sacred bali bamboo as reinforcing filler in seaweed-based composite film. Fibers Polym. 2018, 19, 423–434. [Google Scholar] [CrossRef]

- Weng, J.K.; Li, X.; Bonawitz, N.D.; Chapple, C. Emerging strategies of lignin engineering and degradation for cellulosic biofuel production. Curr. Opin. Biotechnol. 2008, 19, 166–172. [Google Scholar] [CrossRef]

- Di Filippo, M.F.; Dolci, L.S.; Liccardo, L.; Bigi, A.; Bonvicini, F.; Gentilomi, G.A.; Passerini, N.; Panzavolta, S.; Albertini, B. Cellulose derivatives-snail slime films: New disposable eco-friendly materials for food packaging. Food Hydrocoll. 2021, 111, 106247. [Google Scholar] [CrossRef]

- Thakur, S.; Govender, P.P.; Mamo, M.A.; Tamulevicius, S.; Thakur, V.K. Recent progress in gelatin hydrogel nanocomposites for water purification and beyond. Vacuum 2017, 146, 396–408. [Google Scholar] [CrossRef]

- Guo, L.; Colby, R.H.; Lusignan, C.P.; Whitesides, T.H. Kinetics of triple helix formation in semidilute gelatin solutions. Macromolecules 2003, 36, 9999–10008. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Giménez, B.; López-Caballero, M.E.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827. [Google Scholar] [CrossRef]

- Farris, S.; Song, J.; Huang, Q. Alternative reaction mechanism for the cross-linking of gelatin with glutaraldehyde. J. Agric. Food Chem. 2010, 58, 998–1003. [Google Scholar] [CrossRef]

- Fukunaga, S.; Karck, M.; Harringer, W.; Cremer, J.; Rhein, C.; Haverich, A. The use of gelatin-resorcin-formalin glue in acute aortic dissection type A. Eur. J. Cardio Thorac. Surg. 1999, 15, 564–570. [Google Scholar] [CrossRef]

- Siburian, W.Z.; Rochima, E.; Andriani, Y.; Praseptiangga, D. Fish gelatin (definition, manufacture, analysis of quality characteristics, and application): A review. Int. J. Fish. Aquat. Stud. 2020, 8, 90–95. [Google Scholar]

- Mo, X.; Iwata, H.; Matsuda, S.; Ikada, Y. Soft tissue adhesive composed of modified gelatin and polysaccharides. J. Biomater. Sci. Polym. Ed. 2000, 11, 341–351. [Google Scholar] [CrossRef]

- Choe, J.; Kim, H.Y. Effects of chicken feet gelatin extracted at different temperatures and wheat fiber with different particle sizes on the physicochemical properties of gels. Poult. Sci. 2018, 97, 1082–1088. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Jeong, C.H.; Oh, Y.; Kim, H.Y. Analysis of quality properties, microbial stability, and biodegradability of biodegradable containers made of pork skin gelatin. Food Eng. Prog. 2021, 25, 347–353. [Google Scholar] [CrossRef]

- Han, J.M. Eco Friendly Bowl Made by Agar, Sodium Alginate and Calcium Lactate. Korea Patent 10-2021-0029958, 29 March 2021. [Google Scholar]

- Naresh, G.; Rajasekhar, A.; Bharali, J.; Ramesh, K. Homogeneous molten salt formulations as thermal energy storage media and heat transfer fluid. J. Energy Storage 2022, 50, 104200. [Google Scholar] [CrossRef]

- Fernando, T.N.; Ariadurai, S.A.; Disanayaka, C.K.; Kulathunge, S.; Aruggoda, A.G.B. Development of radiation grafted super absorbent polymers for agricultural applications. Energy Procedia 2017, 127, 163–177. [Google Scholar] [CrossRef]

- Katekhong, W.; Wongphan, P.; Klinmalai, P.; Harnkarnsujarit, N. Thermoplastic starch blown films functionalized by plasticized nitrite blended with PBAT for superior oxygen barrier and active biodegradable meat packaging. Food Chem. 2022, 374, 131709. [Google Scholar] [CrossRef] [PubMed]

- Kweon, H.; Choi, S.; Kim, Y.; Nam, K. Development of a new UTM (universal testing machine) system for the nano/MICRO in-process measurement. Int. J. Mod. Phys. B 2006, 20, 4432–4438. [Google Scholar] [CrossRef]

- Choi, Y.; Yuan, R.L. Experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC. Cem. Concr. Res. 2005, 35, 1587–1591. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Splitting tensile strength of SFRC. Indian Concr. J. 2001, 75, 287–290. [Google Scholar]

- Lu, J.Z.; Wu, Q.; McNabb, H.S. Chemical coupling in wood fiber and polymer composites: A review of coupling agents and treatments. Wood Fiber Sci. 2000, 32, 88–104. [Google Scholar]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Biodegradable poly (butylene adipate-co-terephthalate) and thermoplastic starch-blended TiO2 nanocomposite blown films as functional active packaging of fresh fruit. Polymers 2021, 13, 4192. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S. Effects of rice hull particle size and content on the mechanical properties and visual appearance of wood plastic composites prepared from poly (vinyl chloride). J. Bionic Eng. 2013, 10, 110–117. [Google Scholar] [CrossRef]

- Crighton, J.S.; Wilburn, F.W. The role of heat transfer in the production of DSC curves. Thermochim. Acta 1992, 203, 1–5. [Google Scholar] [CrossRef]

- Wang, T.X.; Huang, W.M.; Chen, H.; Xiao, R.; Lu, H.B.; Kang, S.F. Temperature memory effect and its stability revealed via differential scanning calorimetry in ethylene-vinyl acetate within glass transition range. J. Polym. Sci. B 2016, 54, 1731–1737. [Google Scholar] [CrossRef]

- Rebers, L.; Reichsöllner, R.; Regett, S.; Tovar, G.E.M.; Borchers, K.; Baudis, S.; Southan, A. Differentiation of physical and chemical cross-linking in gelatin methacryloyl hydrogels. Sci. Rep. 2021, 11, 3256. [Google Scholar] [CrossRef] [PubMed]

- Van Hoorick, J.; Gruber, P.; Markovic, M.; Tromayer, M.; Van Erps, J.; Thienpont, H.; Liska, R.; Ovsianikov, A.; Dubruel, P.; Van Vlierberghe, S. Cross-linkable gelatins with superior mechanical properties through carboxylic acid modification: Increasing the two-photon polymerization potential. Biomacromolecules 2017, 18, 3260–3272. [Google Scholar] [CrossRef]

- Bigi, A.; Cojazzi, G.; Panzavolta, S.; Rubini, K.; Roveri, N. Mechanical and thermal properties of gelatin films at different degrees of glutaraldehyde crosslinking. Biomaterials 2001, 22, 763–768. [Google Scholar] [CrossRef]

- Saldarriaga, J.F.; Aguado, R.; Pablos, A.; Amutio, M.; Olazar, M.; Bilbao, J. Fast characterization of biomass fuels by thermogravimetric analysis (TGA). Fuel 2015, 140, 744–751. [Google Scholar] [CrossRef]

- Aida, T.M.; Yamagata, T.; Watanabe, M.; Smith, R.L., Jr. Depolymerization of sodium alginate under hydrothermal conditions. Carbohydr. Polym. 2010, 80, 296–302. [Google Scholar] [CrossRef]

- Yu, H.; Tang, Q.; Wu, J.; Lin, Y.; Fan, L.; Huang, M.; Lin, J.; Li, Y.; Yu, F. Using eggshell membrane as a separator in supercapacitor. J. Power Sources 2012, 206, 463–468. [Google Scholar] [CrossRef]

- El-Sayed, S.A.; Mostafa, M.E. Pyrolysis characteristics and kinetic parameters determination of biomass fuel powders by differential thermal gravimetric analysis (TGA/DTG). Energy Convers. Manag. 2014, 85, 165–172. [Google Scholar] [CrossRef]

- Ago, M.; Okajima, K.; Jakes, J.E.; Park, S.; Rojas, O.J. Lignin-based electrospun nanofibers reinforced with cellulose nanocrystals. Biomacromolecules 2012, 13, 918–926. [Google Scholar] [CrossRef] [PubMed]

- Arvanitoyannis, I.S. Totally and partially biodegradable polymer blends based on natural and synthetic macromolecules: Preparation, physical properties, and potential as food packaging materials. J. Macromol. Sci. Part C Polym. Rev. 1999, 39, 205–271. [Google Scholar] [CrossRef]

- Siracusa, V.; Rocculi, P.; Romani, S.; Dalla Rosa, M.D. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Martucci, J.F.; Ruseckaite, R.A. Biodegradation behavior of three-layer sheets based on gelatin and poly (lactic acid) buried under indoor soil conditions. Polym. Degrad. Stab. 2015, 116, 36–44. [Google Scholar] [CrossRef]

- Di Franco, C.R.; Cyras, V.P.; Busalmen, J.P.; Ruseckaite, R.A.; Vázquez, A. Degradation of polycaprolactone/starch blends and composites with sisal fibre. Polym. Degrad. Stab. 2004, 86, 95–103. [Google Scholar] [CrossRef]

- Oyeoka, H.C.; Ewulonu, C.M.; Nwuzor, I.C.; Obele, C.M.; Nwabanne, J.T. Packaging and degradability properties of polyvinyl alcohol/gelatin nanocomposite films filled water hyacinth cellulose nanocrystals. J. Bioresour. Bioprod. 2021, 6, 168–185. [Google Scholar] [CrossRef]

- Kimbuathong, N.; Leelaphiwat, P.; Harnkarnsujarit, N. Inhibition of melanosis and microbial growth in Pacific white shrimp (Litopenaeus vannamei) using high CO2 modified atmosphere packaging. Food Chem. 2020, 312, 126114. [Google Scholar] [CrossRef]

- Dalev, P.G.; Patil, R.D.; Mark, J.E.; Vassileva, E.; Fakirov, S. Biodegradation of chemically modified gelatin films in soil. J. Appl. Polym. Sci. 2000, 78, 1341–1347. [Google Scholar] [CrossRef]

| Treatments 1 | Ultimate Tensile Stress (MPa) | Ultimate Tensile Strain (%) |

|---|---|---|

| PEW1 | 28.40 ± 0.72 b | 26.23 ± 0.68 NS |

| PEW2 | 37.86 ± 1.38 a | 33.37 ± 1.26 |

| Treatments 1 | Sample mass/mg | 1st Heating | 2nd Heating | ||||

|---|---|---|---|---|---|---|---|

| Tg/°C | Tm/°C | ΔH/Jg | Tg/°C | Tm/°C | ΔH/Jg | ||

| PEW1 | 3.04 | 38.30 | 89.59 | 137.60 | 179.67 | 195.95 | 1.64 |

| PEW2 | 3.84 | 39.78 | 88.68 | 309.60 | 184.22 | 203.16 | 2.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-H.; Kim, H.-Y. Utilization of By-Products from Livestock: Study on the Mechanical and Thermal Properties of Biodegradable Containers Made with Pork Skin Gelatin Polymer. Foods 2022, 11, 2513. https://doi.org/10.3390/foods11162513

Lee S-H, Kim H-Y. Utilization of By-Products from Livestock: Study on the Mechanical and Thermal Properties of Biodegradable Containers Made with Pork Skin Gelatin Polymer. Foods. 2022; 11(16):2513. https://doi.org/10.3390/foods11162513

Chicago/Turabian StyleLee, Sol-Hee, and Hack-Youn Kim. 2022. "Utilization of By-Products from Livestock: Study on the Mechanical and Thermal Properties of Biodegradable Containers Made with Pork Skin Gelatin Polymer" Foods 11, no. 16: 2513. https://doi.org/10.3390/foods11162513