Olive Sound: A Sustainable Radical Innovation

Abstract

:1. Introduction

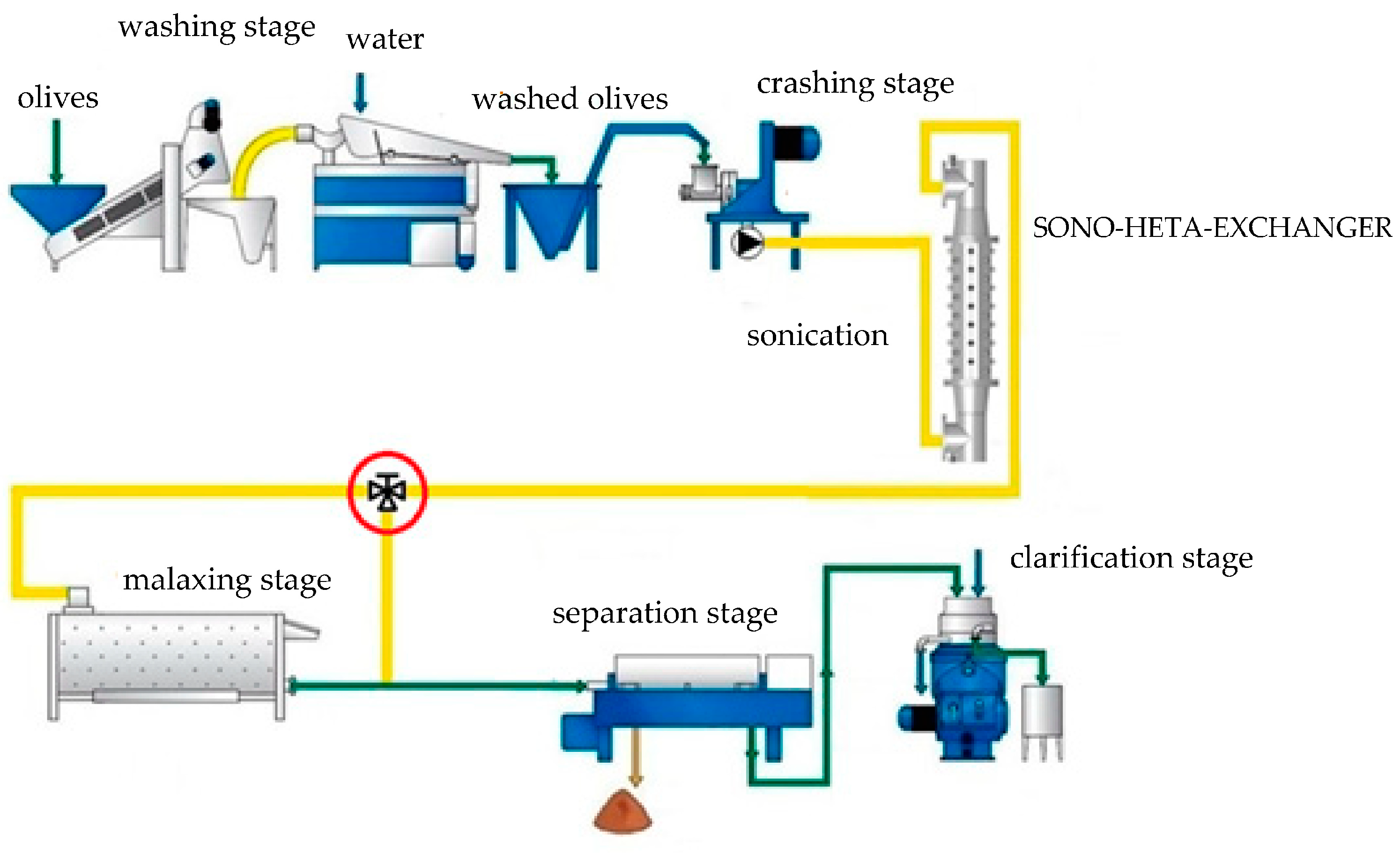

- Making the extraction process effectively continuous [7];

- Contracting processing times [8];

- Increasing extraction yields by reducing fat residues in the olive pomace [9];

- Using extraction temperatures (~20 °C) useful for the development of the volatile fraction without affecting the yields [13];

- Creating a sustainable process consistent with the objectives of the 2030 Agenda and in line both with the directives of the European Green Deal and with the emerging needs of consumers [14].

2. Fast Track to Innovation

3. Radical Innovations

- Planning (design);

- Physical realization (manufacturing);

- Marketing of the Sono-Heat-Exchanger.

3.1. The Design Phase

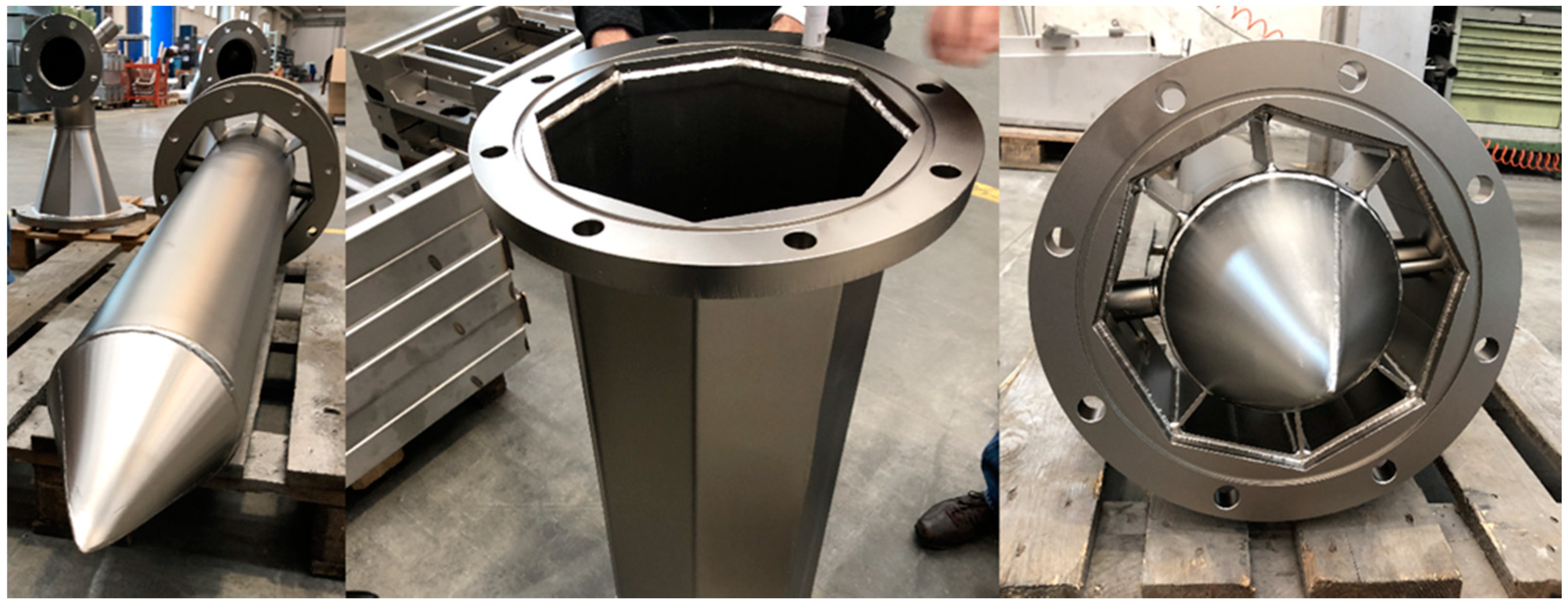

3.2. The Manufacturing of the Sono-Heat-Exchanger

3.3. The Marketing Strategy of the Sono-Heat-Exchanger

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Clodoveo, M.L. Industrial ultrasound applications in the extra-virgin olive oil extraction process: History, approaches, and key questions. Foods 2019, 8, 121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clodoveo, M.L.; Corbo, F.; Amirante, R. Does the introduction of ultrasound in extra-virgin olive oil extraction process improve the income of the olive millers? The first technology for the simultaneous increment of yield and quality of the product. In Technological Innovation in the Olive Oil Production Chain; IntechOpen: Rijeka, Croatia, 2018. [Google Scholar] [CrossRef] [Green Version]

- Conway, S.; Steward, F. Managing and Shaping Innovation; Oxford University Press: New York, NY, USA; Oxford, UK, 2009. [Google Scholar]

- Sørensen, E.; Torfing, J. Enhancing collaborative innovation in the public sector. Adm. Soc. 2011, 43, 842–868. [Google Scholar] [CrossRef]

- Amirante, P.; Clodoveo, M.L.; Leone, A.; Tamborrino, A.; Patel, V.B. Influence of different centrifugal extraction systems on antioxidant content and stability of virgin olive oil. In Olives and Olive Oil in Health and Disease Prevention; Academic Press: New York, NY, USA, 2010; pp. 85–93. [Google Scholar] [CrossRef]

- Tamborrino, A.; Clodoveo, M.L.; Leone, A.; Amirante, P.; Paice, A.G. The malaxation process: Influence on olive oil quality and the effect of the control of oxygen concentration in virgin olive oil. In Olives and Olive Oil in Health and Disease Prevention; Academic Press: New York, NY, USA, 2010; pp. 77–83. [Google Scholar] [CrossRef]

- Clodoveo, M.L. Malaxation: Influence on virgin olive oil quality. Past, present and future—An overview. Trends Food Sci. Technol. 2012, 25, 13–23. [Google Scholar] [CrossRef]

- Clodoveo, M.L.; Durante, V.; La Notte, D. Working towards the development of innovative ultrasound equipment for the extraction of virgin olive oil. Ultrason. Sonochem. 2013, 20, 1261–1270. [Google Scholar] [CrossRef] [PubMed]

- Clodoveo, M.L.; Dipalmo, T.; Schiano, C.; La Notte, D.; Pati, S. What’s now, what’s new and what’s next in virgin olive oil elaboration systems? A perspective on current knowledge and future trends. J. Agric. Eng. 2014, 45, 49–59. [Google Scholar] [CrossRef]

- Bellumori, M.; Cecchi, L.; Innocenti, M.; Clodoveo, M.L.; Corbo, F.; Mulinacci, N. The EFSA health claim on olive oil polyphenols: Acid hydrolysis validation and total hydroxytyrosol and tyrosol determination in Italian virgin olive oils. Molecules 2019, 24, 2179. [Google Scholar] [CrossRef] [Green Version]

- Roselli, L.; Clodoveo, M.L.; Corbo, F.; De Gennaro, B. Are health claims a useful tool to segment the category of extra-virgin olive oil? Threats and opportunities for the Italian olive oil supply chain. Trends Food Sci. Technol. 2017, 68, 176–181. [Google Scholar] [CrossRef]

- De Santis, S.; Cariello, M.; Piccinin, E.; Sabbà, C.; Moschetta, A. Extra virgin olive oil: Lesson from nutrigenomics. Nutrients 2019, 11, 2085. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Amirante, P.; Clodoveo, M.L.; Dugo, G.; Leone, A.; Tamborrino, A. Advance technology in virgin olive oil production from traditional and de-stoned pastes: Influence of the introduction of a heat exchanger on oil quality. Food Chem. 2006, 98, 797–805. [Google Scholar] [CrossRef]

- Colglazier, W. Sustainable development agenda: 2030. Science 2015, 349, 1048–1050. [Google Scholar] [CrossRef] [PubMed]

- Romero, D.; Molina, A. Collaborative networked organisations and customer communities: Value co-creation and co-innovation in the networking era. Prod. Plan. Control 2011, 22, 447–472. [Google Scholar] [CrossRef]

- Clodoveo, M.L.; Hbaieb, R.H. Beyond the traditional virgin olive oil extraction systems: Searching innovative and sustainable plant engineering solutions. Food Res. Int. 2013, 54, 1926–1933. [Google Scholar] [CrossRef]

- Clodoveo, M.L. New advances in the development of innovative virgin olive oil extraction plants: Looking back to see the future. Food Res. Int. 2013, 54, 726–729. [Google Scholar] [CrossRef]

- Clodoveo, M.L. An overview of emerging techniques in virgin olive oil extraction process: Strategies in the development of innovative plants. J. Agric. Eng. 2013. [Google Scholar] [CrossRef]

- Clodoveo, M.L.; Dipalmo, T.; Crupi, P.; Durante, V.; Pesce, V.; Maiellaro, I.; Lovece, A.; Mercurio, A.; Laghezza, A.; Corbo, F.; et al. Comparison between different flavored olive oil production techniques: Healthy value and process efficiency. Plant Foods Human Nutr. 2016, 71, 81–87. [Google Scholar] [CrossRef]

- De Luca, M.; Restuccia, D.; Clodoveo, M.L.; Puoci, F.; Ragno, G. Chemometric analysis for discrimination of extra virgin olive oils from whole and stoned olive pastes. Food Chem. 2016, 202, 432–437. [Google Scholar] [CrossRef]

- Amirante, R.; Clodoveo, M.L. Developments in the design and construction of continuous full-scale ultrasonic devices for the EVOO industry. Eur. J. Lipid Sci. Technol. 2017, 119, 1600438. [Google Scholar] [CrossRef] [Green Version]

- Cecchi, L.; Bellumori, M.; Corbo, F.; Milani, G.; Clodoveo, M.L.; Mulinacci, N. Implementation of the sono-heat-exchanger in the extra virgin olive oil extraction process: End-user validation and analytical evaluation. Molecules 2019, 24, 2379. [Google Scholar] [CrossRef] [Green Version]

- Rollwagen, I.; Cincera, M.; Costantino, L.; Franke, J.; Kalligatsi, K.; Mińska-Struzik, E.; Russo, E. Fast Track to Innovation Pilot (2015–2016) Final Evaluation; Publication Office of European Union: Brussels, Belgium, 2019. [Google Scholar] [CrossRef]

- Malerba, F.; McKelvey, M. Knowledge-intensive innovative entrepreneurship integrating Schumpeter, evolutionary economics, and innovation systems. Small Bus. Econ. 2020, 54, 503–522. [Google Scholar] [CrossRef] [Green Version]

- Jiménez, A.; Beltrán, G.; Uceda, M. High-power ultrasound in olive paste pretreatment. Effect on process yield and virgin olive oil characteristics. Ultrason. Sonochem. 2007, 14, 725–731. [Google Scholar] [CrossRef] [PubMed]

- Bejaoui, M.A.; Beltran, G.; Aguilera, M.P.; Jimenez, A. Continuous conditioning of olive paste by high power ultrasounds: Response surface methodology to predict temperature and its effect on oil yield and virgin olive oil characteristics. LWT-Food Sci. Technol. 2016, 69, 175–184. [Google Scholar] [CrossRef]

- Clodoveo, M.L.; Moramarco, V.; Paduano, A.; Sacchi, R.; Di Palmo, T.; Crupi, P.; Corbo, F.; Pesce, V.; Distaso, E.; Tamburrano, P.; et al. Engineering design and prototype development of a full scale ultrasound system for virgin olive oil by means of numerical and experimental analysis. Ultrason. Sonochem. 2017, 37, 169–181. [Google Scholar] [CrossRef] [PubMed]

- Amirante, R.; Distaso, E.; Tamburrano, P.; Paduano, A.; Pettinicchio, D.; Clodoveo, M.L. Acoustic cavitation by means ultrasounds in the extra virgin olive oil extraction process. Energy Procedia 2017, 126, 82–90. [Google Scholar] [CrossRef]

- Amirante, R.; Distaso, E.; Tamburrano, P.; Corbo, F.F.R.; Calò, G.; Clodoveo, M.L. Fluid dynamic-based Engineering design of a Full-Scale Device for the improvement of Extra Virgin Olive Oil Yield and Quality by means of Combined Acoustic Cavitation and Thermal Conditioning. E3S Web Conf. 2020, 197, 08010. [Google Scholar] [CrossRef]

- Plasquy, E.; García Martos, J.M.; Florido Fernández, M.D.C.; Sola-Guirado, R.R.; García Martín, J.F. Adjustment of Olive Fruit Temperature before Grinding for Olive Oil Extraction. Experimental Study and Pilot Plant Trials. Processes 2021, 9, 586. [Google Scholar] [CrossRef]

- Clodoveo, M.L.; Hbaieb, R.H.; Kotti, F.; Mugnozza, G.S.; Gargouri, M. Mechanical strategies to increase nutritional and sensory quality of virgin olive oil by modulating the endogenous enzyme activities. Compr. Rev. Food Sci. Food Saf. 2014, 13, 135–154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Santis, S.; Liso, M.; Verna, G.; Curci, F.; Milani, G.; Faienza, M.F.; Franchini, C.; Moschetta, A.; Chieppa, M.; Clodoveo, M.L.; et al. Extra Virgin Olive Oil Extracts Modulate the Inflammatory Ability of Murine Dendritic Cells Based on Their Polyphenols Pattern: Correlation between Chemical Composition and Biological Function. Antioxidants 2021, 10, 1016. [Google Scholar] [CrossRef] [PubMed]

| Technological Effect | Malaxer | Sono-Heat Exchanger |

|---|---|---|

| Efficacy | The malaxer is a batch machine, which works between two continuous devices, the fruit crusher and the decanter. Its long kneading times, in addition to it constituting a threat to the quality of the oil, make this phase of mixing the oil paste at a controlled temperature the "bottleneck" of the continuous process. | The Sono-Heat-Exchanger is a continuous device. The major advantages of continuous processing are lower equipment costs, a reduced overall footprint, and the elimination of redundant plant equipment. |

| Efficiency | A bottleneck in the process tends to create a queue and increase the overall cycle time. The bottlenecks in production cause stalls and slowdowns in the production flow as with the same resources, production is slower and therefore smaller quantities are produced. | The elimination of the bottleneck in the oil sector translates into an effective tool if the innovation is able to increase the yields and content of antioxidants, and it is efficient if it achieves these objectives in a sustainable way, reducing energy costs with benefits regarding company economies and the impact on the environment. |

| Number of the devices | In the olive mill, currently, the limited working capacity of the malaxer penalizes the production efficiency of the decanter; the main plant engineering solution adopted to manage this inefficiency consists in multiplying the number of malaxers, in series or in parallel, to ensure continuity of the process, but not without an increase in investment in the crusher. | The Sono-Heat-Exchanger is a continuous machine that allows to synchronize its flow rate with the flow rate of the decanter and effectively eliminates the bottleneck of the process. |

| Mechanical effects | The mechanical crusher produces fruit fragments containing hundreds of cells that pass intact into the malaxer. The malaxer can be considered a finishing phase of the crushing phase by the cutting action of the stone fragments, which tears the cells passed intact to the crusher in a delicate manner but in an extremely long time (from 30 to 60 min), therefore helping to break the cells of the drupe passed intact to the crusher releasing a further amount of oil. | The ultrasounds determine a transient pressure gradient which, in some moments, reaches values lower than the saturated vapor pressure of the water contained in the olive paste, causing vaporization at low temperatures. “Cavitation bubbles” are created, which progressively increase their volume until they reach a critical value beyond which they implode, generating jets of liquid at high pressure that instantly tear the cells that have passed intact to the pressing. |

| Thermal effect | The malaxer is a bad heat exchanger due to an unfavorable ratio between the big volume of olive paste that should be warmed (or cooled) and the small surface for the heat exchange. | The Sono-Heat-Exchanger is equipped with an inner part that consists of a highly efficient spiral heat exchanger able to modulate the olive paste temperature (fast heating up or fast cooling of olive paste) simultaneously with the sonication treatment, adapting the results to the needs of olive millers [30]. |

| Coalescence | The coalescence phenomena of oily drops inside the olive paste are due to hydrophobic interactions. During the malaxation, the drops of oil in the olive paste combine to form a larger drop. The role of the mixing in the hydrophobic interaction regards frequency of the collision of drops, which is one of the factors able to influence the coalescence of the oil in the olive paste. Mixing or agitation has been shown to improve coalescence by enhancing the rate of collisions. | The pulsating action of the transducers imposes swirling movements on the olive paste that agitate the flow of olive paste in transit in the apparatus, inducing agitation similar to what happens inside the malaxer, and favoring coalescence phenomena among the minute drops of oil released by cavitation, which, increasing in diameter, are more easily separable in the centrifugal field. |

| Plolyphenols | The mechanical action of the malaxer is mild and has a negligible effect on the ability to release further amounts of polyphenols. The thermal effect is limited to heating only, and the long stirring times are compatible with the activation kinetics of the oxidase enzymes [31], polyphenol oxidase, and peroxidase; therefore, the times favorable for kneading lengths to increase yields correspond to a loss of polyphenols and a lowering of oil quality. | The cavitation phenomena efficiently break the cells of the epicarp of the drupe, releasing high concentrations of polyphenols. The immediate thermal lowering of the olive paste temperature after olive crushing to lower than 20 °C permits partial inhibition of the endogenous enzymatic activity by polyphenol oxidase and peroxidase. The consequence is the reduction of degradation of phenolic compounds. |

| Volatile compounds | The lipoxygenase (LOX) pathway [31], responsible for the hydroperoxydation of polyunsaturated fatty acids, is activated upon crushing and grinding olive fruit tissue, which subsequently leads to the synthesis of volatile compounds. This biochemical reaction requires few seconds, if thermal condition are favorable (<24 °C). The malaxer, being a bad heat exchanger, could penalize the functionality of the pathway causing disharmonious organoleptic profiles if the temperatures of the crushed olive paste are high. | The sonicated oils have a more harmonious organoleptic profile and are rich in volatile components, as not only do the ultrasounds not damage the lipoxygenase pathway, but the rapidity of the transformation of the fruit into extra virgin olive oil contributes to a more timely stabilization of the product, thus avoiding technological threats, which could result in the loss or alteration of the profile of volatile compounds. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clodoveo, M.L.; Crupi, P.; Corbo, F. Olive Sound: A Sustainable Radical Innovation. Processes 2021, 9, 1579. https://doi.org/10.3390/pr9091579

Clodoveo ML, Crupi P, Corbo F. Olive Sound: A Sustainable Radical Innovation. Processes. 2021; 9(9):1579. https://doi.org/10.3390/pr9091579

Chicago/Turabian StyleClodoveo, Maria Lisa, Pasquale Crupi, and Filomena Corbo. 2021. "Olive Sound: A Sustainable Radical Innovation" Processes 9, no. 9: 1579. https://doi.org/10.3390/pr9091579