Experimental Investigation on Emissions Characteristics from Urban Bus Fueled with Diesel, Biodiesel and an Oxygenated Additive from Residual Glycerin from Biodiesel Production

Abstract

:1. Introduction

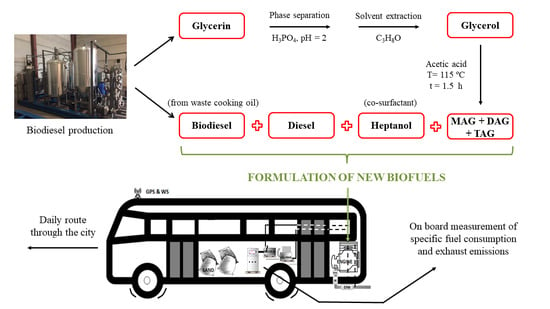

2. Materials and Methods

2.1. Fuels, Raw Materials and Reagents

Production of the Oxygenated Additive

2.2. Analytical Methods

2.3. Biofuels Formulation

2.4. Urban Bus

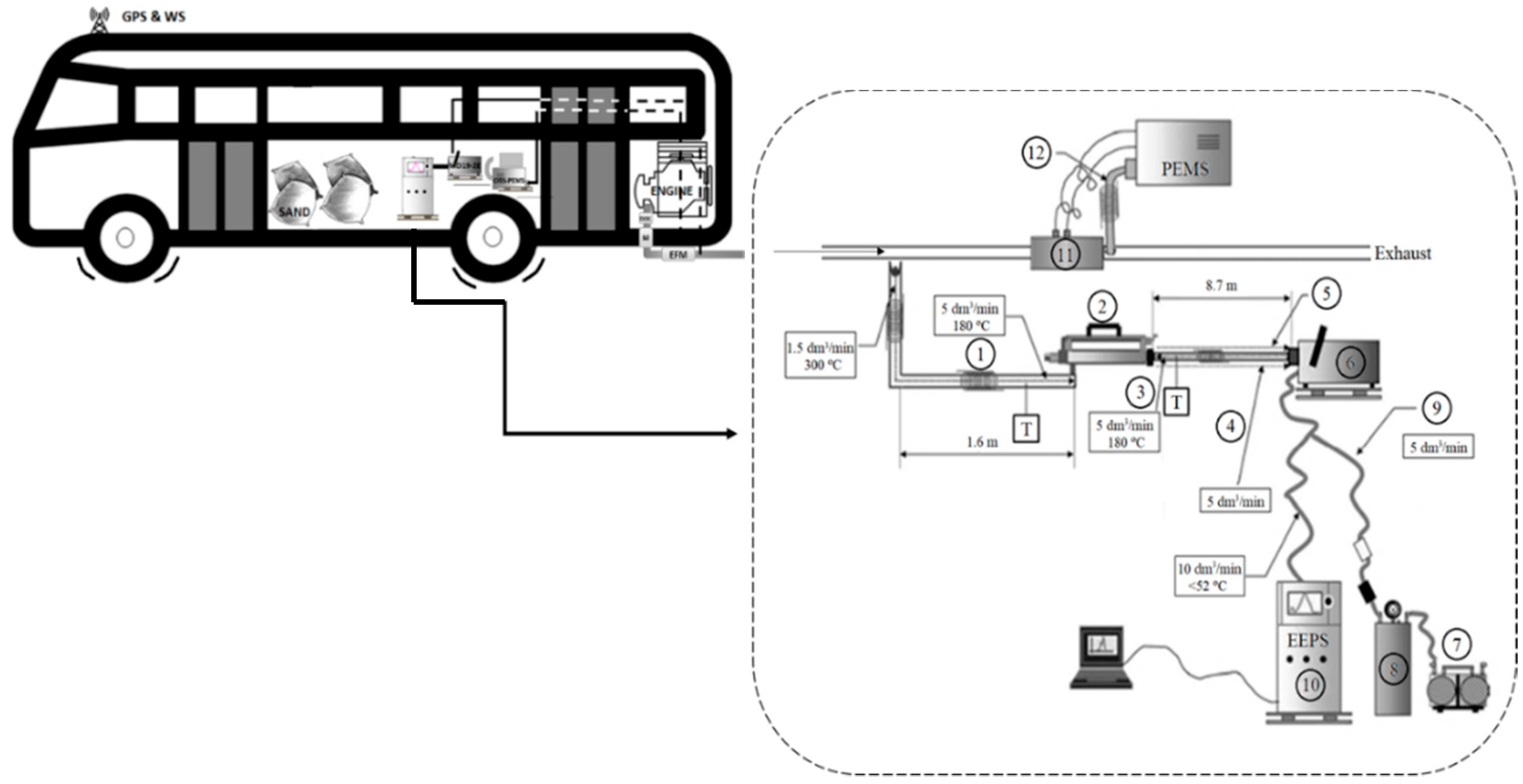

2.5. Onboard Test System

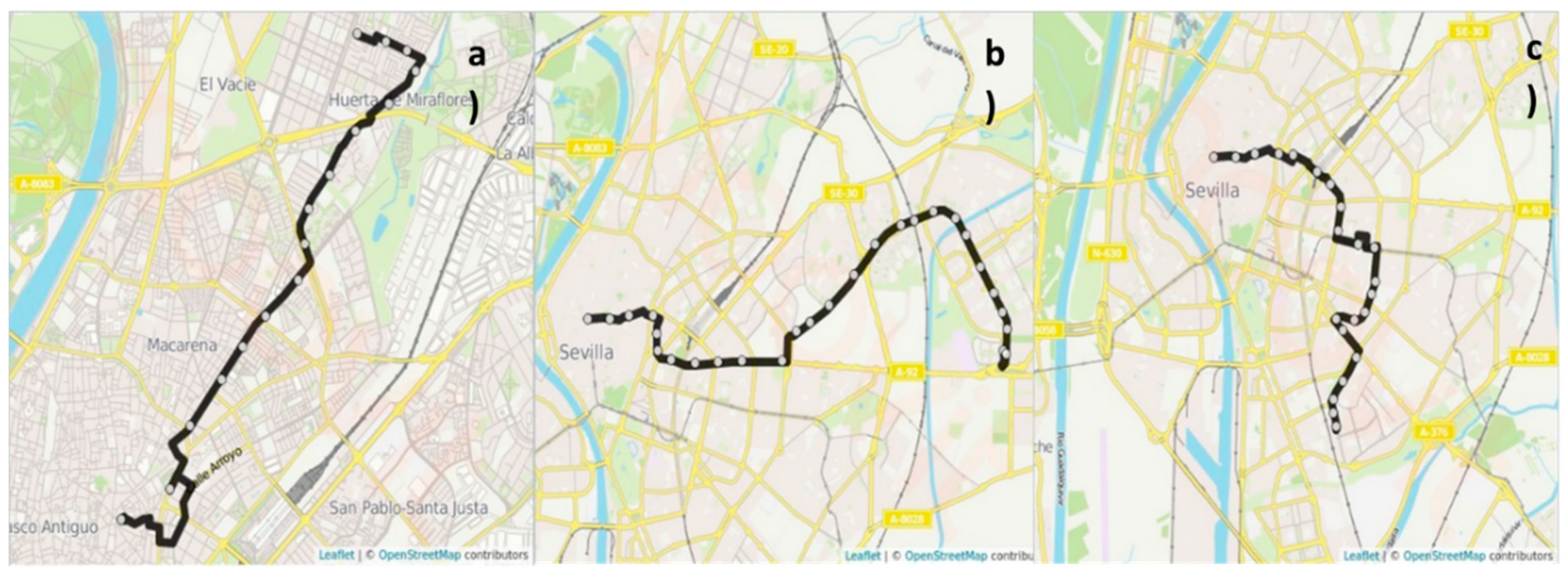

2.6. Test Design and Routes

2.6.1. Experimental Design

2.6.2. Sampling Methods and Operating Conditions

Sampling Methods

Operating Conditions

3. Results and Discussion

3.1. Urban Bus Tests

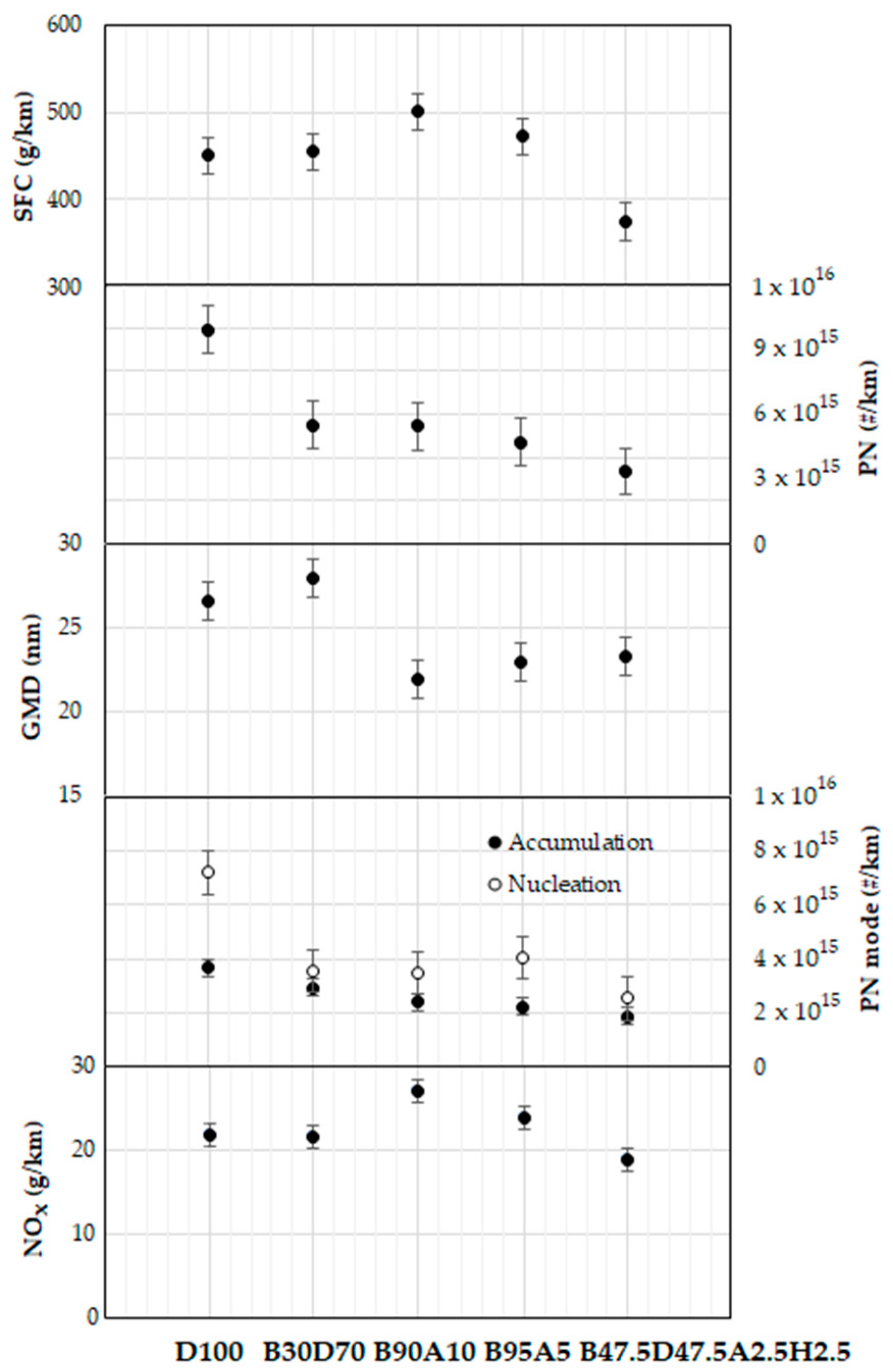

3.2. Fuel Blends Effects on Fuel Consumption

3.3. Fuel Blends Effects on Particulate Emission Characteristics

3.4. Fuel Blends Effects on Geometric Mean Diameter (GMD)

3.5. Fuel Blends Effects on NOx Emission

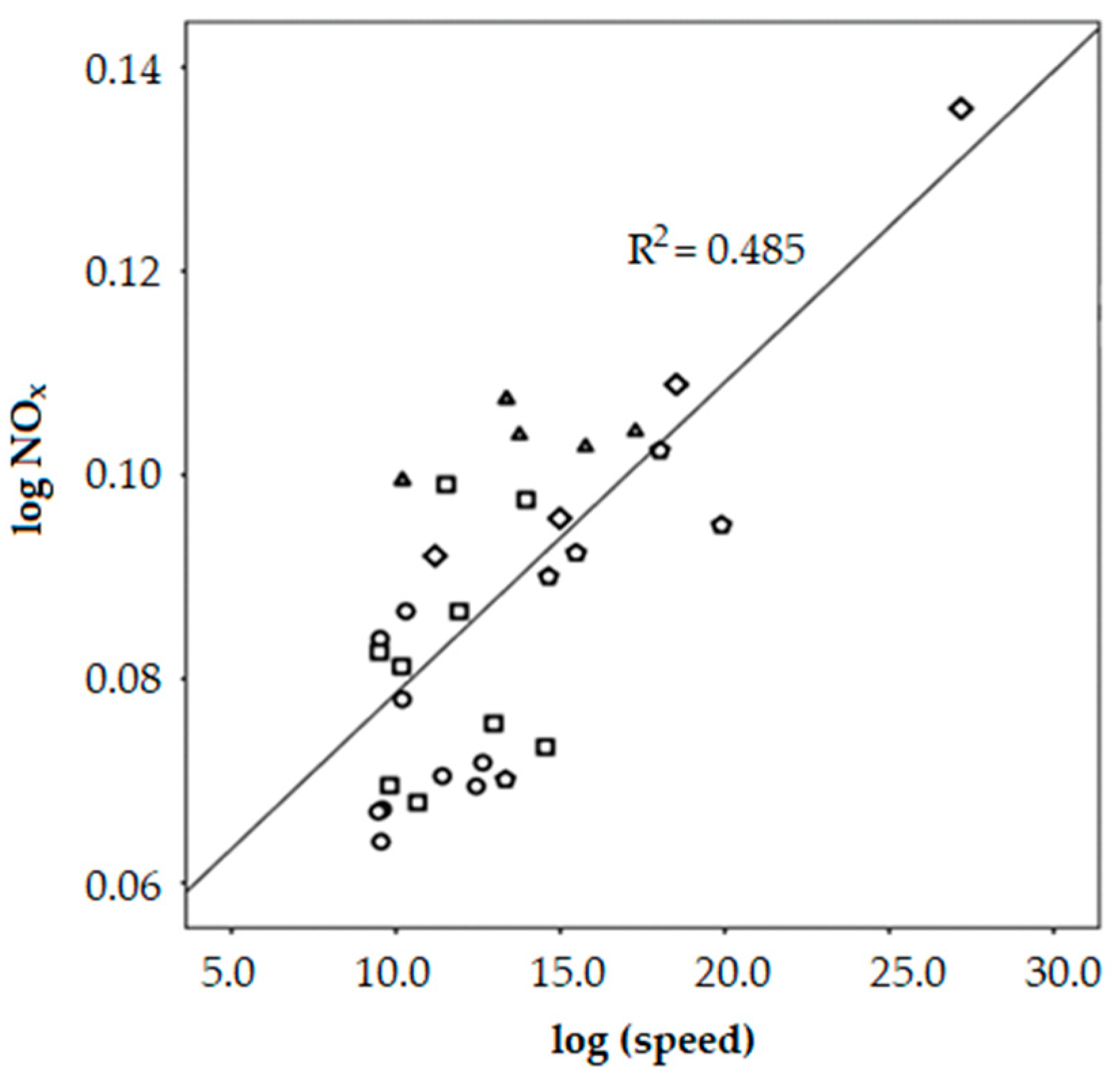

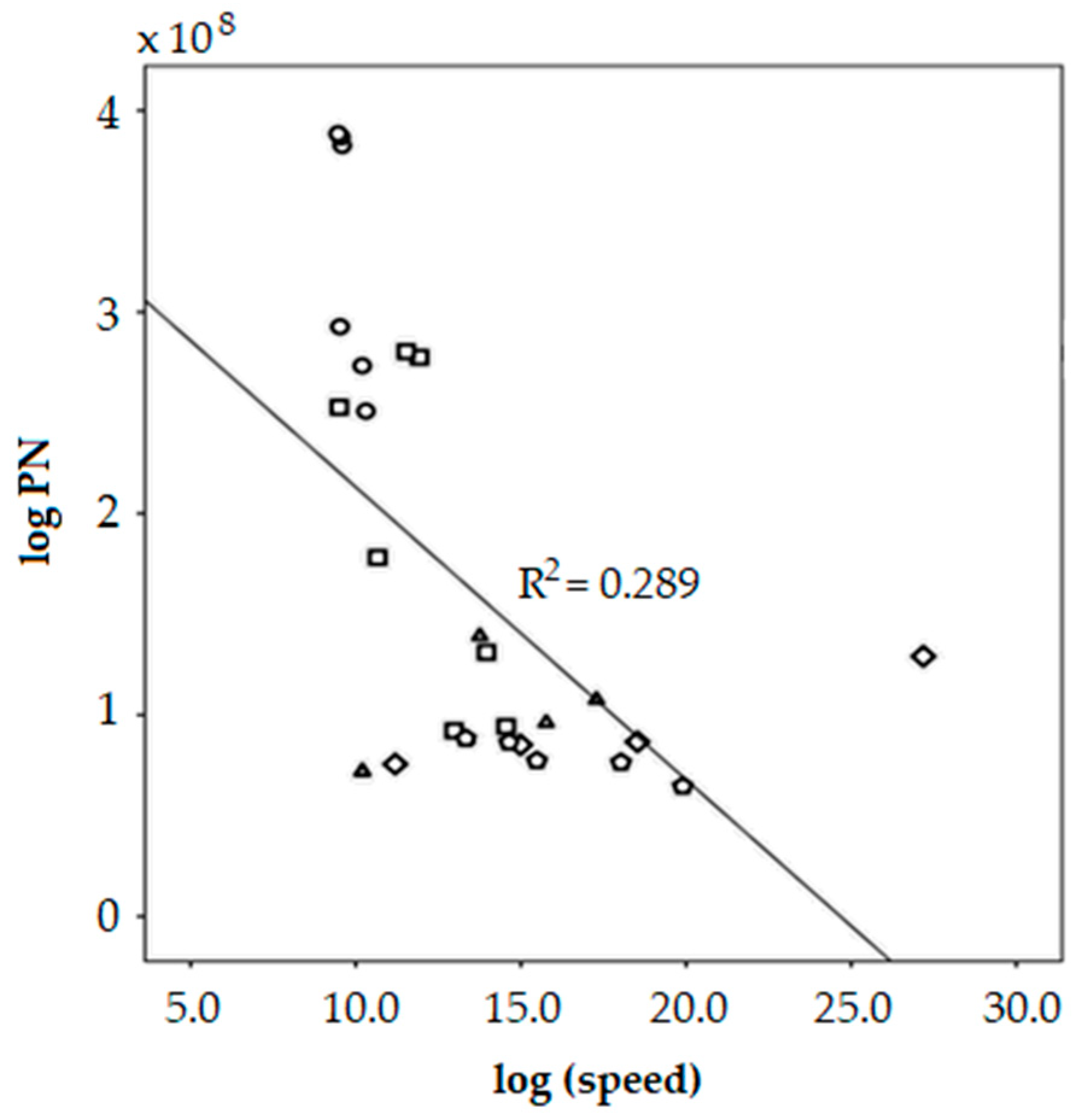

3.6. Effects of Bus Speed and Fuel Type on NOx and Particles Emissions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Monjardino, J.; Barros, N.; Ferreira, F.; Tente, H.; Fontes, T.; Pereira, P.; Manso, C. Improving air quality in Lisbon: Modelling emission abatement scenarios. IFAC-PapersOnLine 2018, 51, 61–66. [Google Scholar] [CrossRef]

- Fameli, K.M.; Assimakopoulos, V.D. Development of a road transport emission inventory for Greece and the Greater Athens Area: Effects of important parameters. Sci. Total Environ. 2015, 505, 770–786. [Google Scholar] [CrossRef] [Green Version]

- Bentita, D.; Fallole, D. Panorama et Évaluation des Différentes Filières D’autobus Urbains; Librairie Adame: Lille, France, 2018; 100p. [Google Scholar]

- Zhang, Y.; Lou, D.; Tan, P.; Hu, Z. Particulate emissions from urban bus fueled with biodiesel blend and their reducing characteristics using particulate after-treatment system. Energy 2018, 155, 77–86. [Google Scholar] [CrossRef]

- Chow, J.C.; Watson, J.G.; Savage, N.; Solomon, C.J.; Cheng, Y.S.; Mc Murry, P.H.; Corey, L.M.; Bruce, G.M.; Pleus, R.C.; Pleus, R.C.; et al. Nanoparticles and the environment. J. Air Waste Manag. Assoc. 2005, 55, 1411–1417. [Google Scholar] [CrossRef] [Green Version]

- La Milia, D.I.; Sciaraffa, R.; Borghini, A.; Montuschi, P.; Gerosa, G.; Ricciardi, W.; Moscato, U. Impact of air pollution on respiratory diseases in urban areas: A systematic review. In Proceedings of the 11th European Public Health Conference, Ljubljana, Slovenia, 28 November–1 December 2018; pp. 317–318. [Google Scholar]

- Dehhaghi, M.; Kazemi Shariat Panahi, H.; Aghbashlo, M.; Lam, S.S.; Tabatabaei, M. The effects of nanoadditives on the performance and emission characteristics of spark-ignition gasoline engines: A critical review with a focus on health impacts. Energy 2021, 225, 120259. [Google Scholar] [CrossRef]

- Cornejo, A.; Barrio, I.; Campoy, M.; Lázaro, J.; Navarrete, B. Oxygenated fuel additives from glycerol valorization. Main production pathways and effects on fuel properties and engine performance: A critical review. Renew. Sustain. Energy Rev. 2017, 79, 1400–1413. [Google Scholar] [CrossRef]

- García-Martín, J.F.; Barrios, C.C.; Alés-Álvarez, F.J.; Dominguez-Sáez, A.; Alvarez-Mateos, P. Biodiesel production from waste cooking oil in an oscillatory flow reactor. Performance as a fuel on a TDI diesel engine. Renew. Energy 2018, 125, 546–556. [Google Scholar] [CrossRef]

- García-Martín, J.F.; Alés-Álvarez, F.J.; Torres-García, M.; Feng, C.-H.; Álvarez-Mateos, P. Production of Oxygenated Fuel Additives from Residual Glycerine Using Biocatalysts Obtained from Heavy-Metal-Contaminated Jatropha curcas L. Roots. Energies 2019, 12, 740. [Google Scholar] [CrossRef] [Green Version]

- Agencia Andaluza de la Energía. Datos energéticos de Andalucía 2017; Agencia Andaluza de la Energía: Sevilla, Spain, 2017. [Google Scholar]

- Álvarez-Mateos, P.; García-Martín, J.F.; Guerrero-Vacas, F.J.; Naranjo-Calderón, C.; Barrios, C.C.; Pérez Camino, M. del C. Valorization of a high-acidity residual oil generated in the waste cooking oils recycling industries. Grasas Aceites 2019, 70, e335. [Google Scholar] [CrossRef] [Green Version]

- Rahmat, N.; Abdullah, A.Z.; Mohamed, A.R. Recent progress on innovative and potential technologies for glycerol transformation into fuel additives: A critical review. Renew. Sustain. Energy Rev. 2010, 14, 987–1000. [Google Scholar] [CrossRef]

- Shah, P.R.; Ganesh, A. A comparative study on influence of fuel additives with edible and non-edible vegetable oil based on fuel characterization and engine characteristics of diesel engine. Appl. Therm. Eng. 2016, 102, 800–812. [Google Scholar] [CrossRef]

- Mallesham, B.; Govinda Rao, B.; Reddy, B.M. Production of biofuel additives by esterification and acetalization of bioglycerol. C. R. Chim. 2016, 19, 1194–1202. [Google Scholar] [CrossRef]

- García-Martín, J.F.; Alés-Álvarez, F.J.; del López-Barrera, M.C.; Martín-Domínguez, I.; Álvarez-Mateos, P. Cetane number prediction of waste cooking oil-derived biodiesel prior to transesterification reaction using near infrared spectroscopy. Fuel 2019, 240, 10–15. [Google Scholar] [CrossRef]

- Attaphong, C.; Do, L.; Sabatini, D.A. Vegetable oil-based microemulsions using carboxylate-based extended surfactants and their potential as an alternative renewable biofuel. Fuel 2012, 94, 606–613. [Google Scholar] [CrossRef]

- Balcan, M.; Mihǎilescu, F.C.; Anghel, D.F.; Vǎcǎreşteanu, I.C.; Aricov, L.; Vasilescu, E.L. Microemulsion systems containing diesel and colza oil as alternative fuels: Phase studies, interfacial tension and solubilization. Fuel 2014, 117, 251–258. [Google Scholar] [CrossRef]

- Leng, L.; Yuan, X.; Zeng, G.; Chen, X.; Wang, H.; Li, H.; Fu, L.; Xiao, Z.; Jiang, L.; Lai, C. Rhamnolipid based glycerol-in-diesel microemulsion fuel: Formation and characterization. Fuel 2015, 147, 76–81. [Google Scholar] [CrossRef]

- Zemb, T.N.; Klossek, M.; Lopian, T.; Marcus, J.; Schöettl, S.; Horinek, D.; Prevost, S.F.; Touraud, D.; Diat, O.; Marčelja, S.; et al. How to explain microemulsions formed by solvent mixtures without conventional surfactants. Proc. Natl. Acad. Sci. USA 2016, 113, 4260–4265. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shenavaei Zare, T.; Khoshsima, A.; Zarenezhad, B. Production of New Surfactant-free Microemulsion Biofuels: Phase Behavior and Nanostructure Identification. Energy Fuels 2020, 34, 4643–4659. [Google Scholar] [CrossRef]

- Attaphong, C.; Sabatini, D.A. Phase behaviors of vegetable oil-based microemulsion fuels: The effects of temperatures, surfactants, oils, and water in ethanol. Energy Fuels 2013, 27, 6773–6780. [Google Scholar] [CrossRef]

- Kayali, I.; Jyothi, C.K.; Qamhieh, K.; Olsson, U. Surfactant-free alternative fuel: Phase behavior and diffusion properties. J. Colloid Interface Sci. 2016, 463, 173–179. [Google Scholar] [CrossRef] [PubMed]

- Johnson, T.; Caldow, R.; Pöcher, A.; Mirme, A.; Kittelson, D. A new electrical mobility particle sizer spectrometer for engine exhaust particle measurements. SAE Tech. Pap. 2004, 3–5. [Google Scholar] [CrossRef]

- Kasper, M. The number concentration of non-volatile particles—Design study for an instrument according to the PMP recommendations. SAE Tech. Pap. 2004, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Nabi, M.N.; Minami, M.; Ogawa, H.; Miyamoto, N. Ultra low emission and high performance diesel combustion with highly oxygenated fuel. SAE Tech. Pap. 2000, 3–5. [Google Scholar] [CrossRef]

- Ogawa, H.; Nabi, N.; Minami, M.; Miyamoto, N.; Kim, B.S. Ultra low emissions and high performance diesel combustion with a combination of high EGR, three-way catalyst, and a highly oxygenated fuel, dimethoxy methane (DMM). SAE Tech. Pap. 2000, 106, 3–5. [Google Scholar]

- Barrios, C.C.; Domínguez-Sáez, A.; Hormigo, D. Influence of hydrogen addition on combustion characteristics and particle number and size distribution emissions of a TDI diesel engine. Fuel 2017, 199, 162–168. [Google Scholar] [CrossRef]

- Domínguez-Sáez, A.; Viana, M.; Barrios, C.C.; Rubio, J.R.; Amato, F.; Pujadas, M.; Querol, X. Size-resolved particle number emission patterns under real-world driving conditions using positive matrix factorization. Environ. Sci. Technol. 2012, 46, 11187–11194. [Google Scholar] [CrossRef]

- Horiba Inc. On Board Emission Measurement System OBS-2200, Instruction Manual; Horiba Inc.: Kyoto, Japan, 2007. [Google Scholar]

- Proyectos Medioambientales. Available online: https://www.tussam.es/es/tussam/tussam-sostenible/proyectos-medioambientales (accessed on 7 October 2020).

- Jeevanantham, A.K.; Nanthagopal, K.; Ashok, B.; Al-Muhtaseb, A.H.; Thiyagarajan, S.; Geo, V.E.; Ong, H.C.; Samuel, K.J. Impact of addition of two ether additives with high speed diesel- Calophyllum Inophyllum biodiesel blends on NOx reduction in CI engine. Energy 2019, 185, 39–54. [Google Scholar] [CrossRef]

- Dogan, B.; Cakmak, A.; Kadir Yesilyurt, M.; Erol, D. Investigation on 1-heptanol as an oxygenated additive with diesel fuel for compression-ignition engine applications: An approach in terms of energy, exergy, exergoeconomic, enviroeconomic, and sustainability analyses. Fuel 2020, 275, 117973. [Google Scholar] [CrossRef]

- Barrios, C.C.; Martín, C.; Domínguez-Sáez, A.; Álvarez, P.; Pujadas, M.; Casanova, J. Effects of the addition of oxygenated fuels as additives on combustion characteristics and particle number and size distribution emissions of a TDI diesel engine. Fuel 2014, 132, 92–100. [Google Scholar] [CrossRef]

- Gill, S.S.; Tsolakis, A.; Herreros, J.M.; York, A.P.E. Diesel emissions improvements through the use of biodiesel or oxygenated blending components. Fuel 2012, 95, 578–586. [Google Scholar] [CrossRef]

- Barrios, C.C.; Domínguez-Sáez, A.; Martín, C.; Álvarez, P. Effects of animal fat based biodiesel on a TDI diesel engine performance, combustion characteristics and particle number and size distribution emissions. Fuel 2014, 117, 618–623. [Google Scholar] [CrossRef]

- Lapuerta, M.; Martos, F.J.; Herreros, J.M. Effect of engine operating conditions on the size of primary particles composing diesel soot agglomerates. J. Aerosol Sci. 2007, 38, 455–466. [Google Scholar] [CrossRef]

- Sungur, B.; Topaloglu, B.; Ozcan, H. Effects of nanoparticle additives to diesel on the combustion performance and emissions of a flame tube boiler. Energy 2016, 113, 44–51. [Google Scholar] [CrossRef]

| Property | Commercial Diesel | Biodiesel | Additive | Heptanol |

|---|---|---|---|---|

| Formula | C12H22.44 | C19H36O2 | C9H14O6 | C7H16O |

| Cetane number | 51.3 | 62.5 | -- | -- |

| Viscosity at 25 °C (mPa·s) | 2.9 | 4.1 | 23.0 | 7.4 |

| Density at 15 °C (g/dm3) | 840 | 882 | 1155 | 820 |

| Boiling point (°C) | -- | 345 | 259 | 176 |

| Stoichiometric fuel/air ratio (m/m) | 1/14.5 | 1/12.5 | 1/6.0 | 1/12.4 |

| Latent heat of vaporization (kJ/kg) | 270 | 22,888 | 18,312 | 7809 |

| Lower heating value (MJ/kg) | 43.9 | 38.9 | 17.0 | 40.0 |

| Flash point (°C) | 40.0 | 90.5 | 138.0 | 78.0 |

| C (%wt.) | 86.4 | 78.1 | 49.5 | 72.4 |

| O (%wt.) | 0.0 | 9.9 | 44.4 | 13.8 |

| H (%wt.) | 13.6 | 11.9 | 6.4 | 13.8 |

| Parameter | Value |

|---|---|

| Bus type | IVECO CURSOR 8 F28 E0682C |

| Model year | 2003 |

| Emission standard | Euro 3 |

| Configuration | In-line 6 cylinders |

| Air intake | Turbocharged with aftercooler |

| Fuel injection | Direct injection (Bosch type) |

| Displacement | 7790 cm3 |

| Diameter × stroke | 115 × 125 mm |

| Compression ratio | 16 ± 0.8: 1 |

| Max torque | 1100 Nm ≅ 1000 ÷ 1900 rpm |

| Max power | 213 kW (290 CV) ≅ 2400 rpm |

| Exhaust gas recirculation | Yes |

| Diesel particle filter | No |

| Length | 12,000 mm |

| Test | Route | Fuel | Route Length (km) | Average Speed (km/h) |

|---|---|---|---|---|

| 1 | a | D100 | 11.5 | 11.43 |

| 2 | a | B30D70 | 11.5 | 12.87 |

| 3 | a | B90A10 | 11.5 | 13.73 |

| 4 | a | B95A5 | 11.5 | 13.74 |

| 5 | a | B47.5D47.5A2.5H2.5 | 11.5 | 14.11 |

| 6 | b | D100 | 19.8 | 13.93 |

| 7 | b | B30D70 | 19.8 | 15.21 |

| 8 | b | B90A10 | 19.8 | 16.01 |

| 9 | b | B95A5 | 19.8 | 20.09 |

| 10 | b | B47.5D47.5 A2.5H2.5 | 19.8 | 19.37 |

| 11 | c | D100 | 15.6 | 11.17 |

| 12 | c | B30D70 | 15.6 | 11.81 |

| 13 | c | B90A10 | 15.6 | 12.30 |

| 14 | c | B95A5 | 15.6 | 13.77 |

| 15 | c | B47.5D47.5 A2.5H2.5 | 15.6 | 15.97 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrios, C.C.; Álvarez-Mateos, P.; Urueña, A.; Díez, D.; García-Martín, J.F. Experimental Investigation on Emissions Characteristics from Urban Bus Fueled with Diesel, Biodiesel and an Oxygenated Additive from Residual Glycerin from Biodiesel Production. Processes 2021, 9, 987. https://doi.org/10.3390/pr9060987

Barrios CC, Álvarez-Mateos P, Urueña A, Díez D, García-Martín JF. Experimental Investigation on Emissions Characteristics from Urban Bus Fueled with Diesel, Biodiesel and an Oxygenated Additive from Residual Glycerin from Biodiesel Production. Processes. 2021; 9(6):987. https://doi.org/10.3390/pr9060987

Chicago/Turabian StyleBarrios, Carmen C., Paloma Álvarez-Mateos, Ana Urueña, David Díez, and Juan Francisco García-Martín. 2021. "Experimental Investigation on Emissions Characteristics from Urban Bus Fueled with Diesel, Biodiesel and an Oxygenated Additive from Residual Glycerin from Biodiesel Production" Processes 9, no. 6: 987. https://doi.org/10.3390/pr9060987