Non-Alcoholic and Craft Beer Production and Challenges

Abstract

:1. Introduction

2. An Overview of Non-Alcoholic and Craft Beer

2.1. Market Landscape and Consumers Preference

2.1.1. Non-Alcoholic Beers: Alcohol-Free and Low-Alcohol Beers

2.1.2. Craft Beer

3. NAB and LAB Brewing Process

3.1. Techniques for Complete or Partial Alcohol Removal

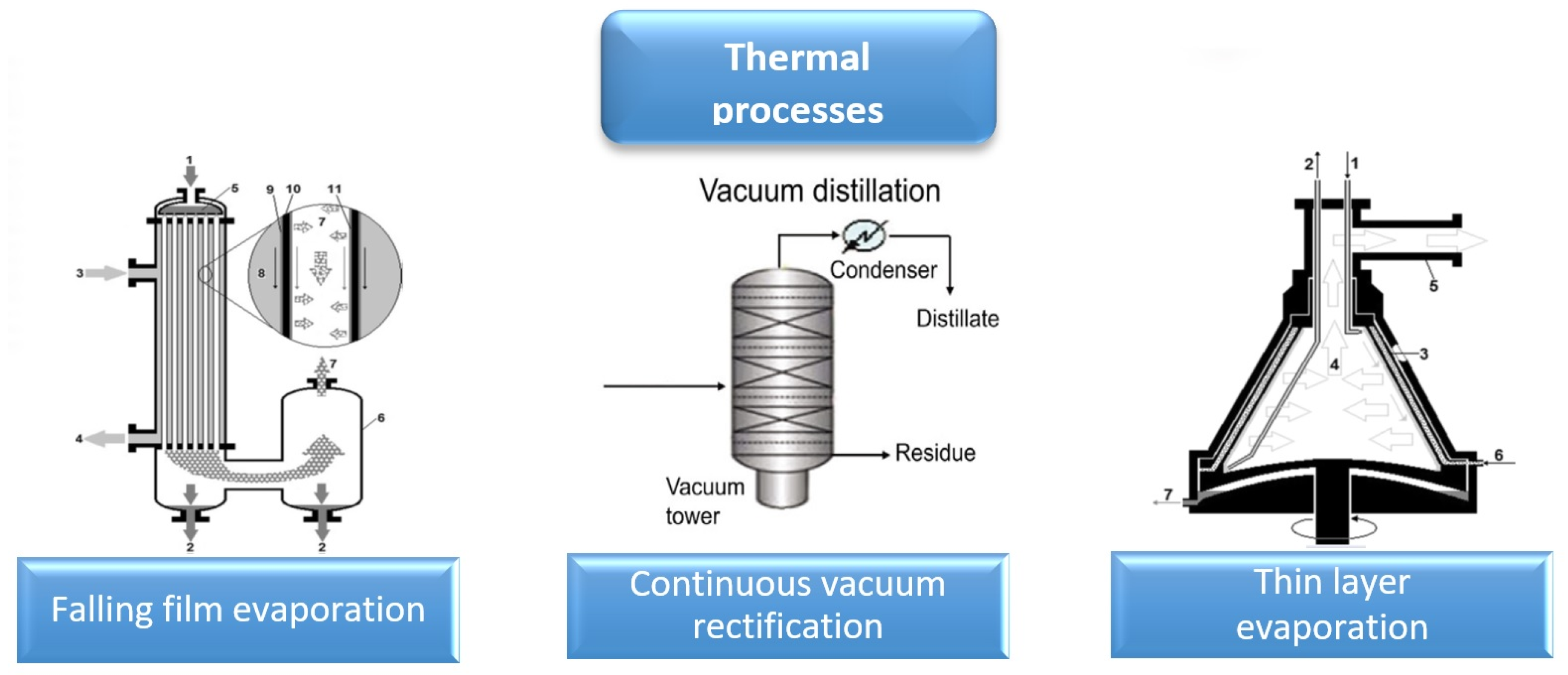

3.1.1. Thermal Treatments

3.1.2. Falling Film Evaporation

3.1.3. Vacuum Rectification

3.1.4. Thin Layer Evaporation

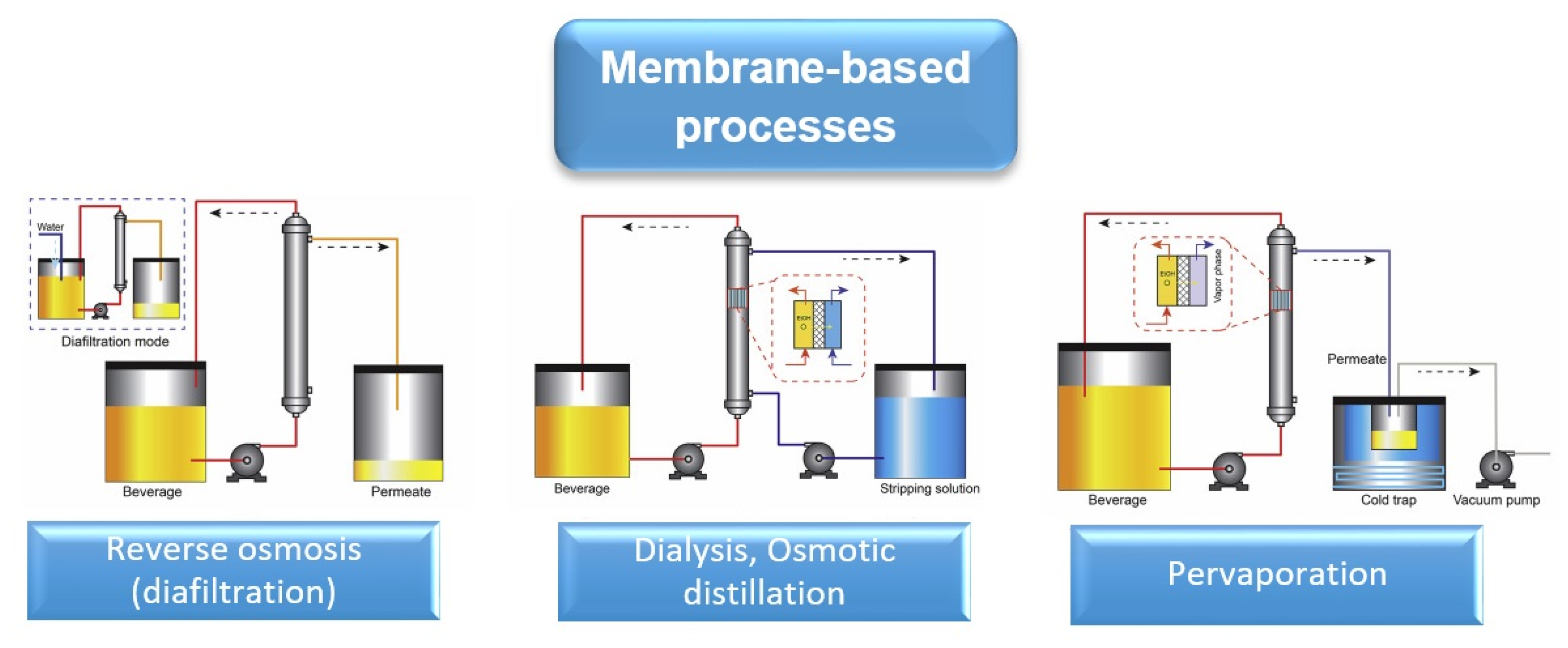

3.2. Membrane Separation Processes

3.2.1. Reverse Osmosis

3.2.2. Dialysis

3.2.3. Osmotic Distillation

3.2.4. Pervaporation

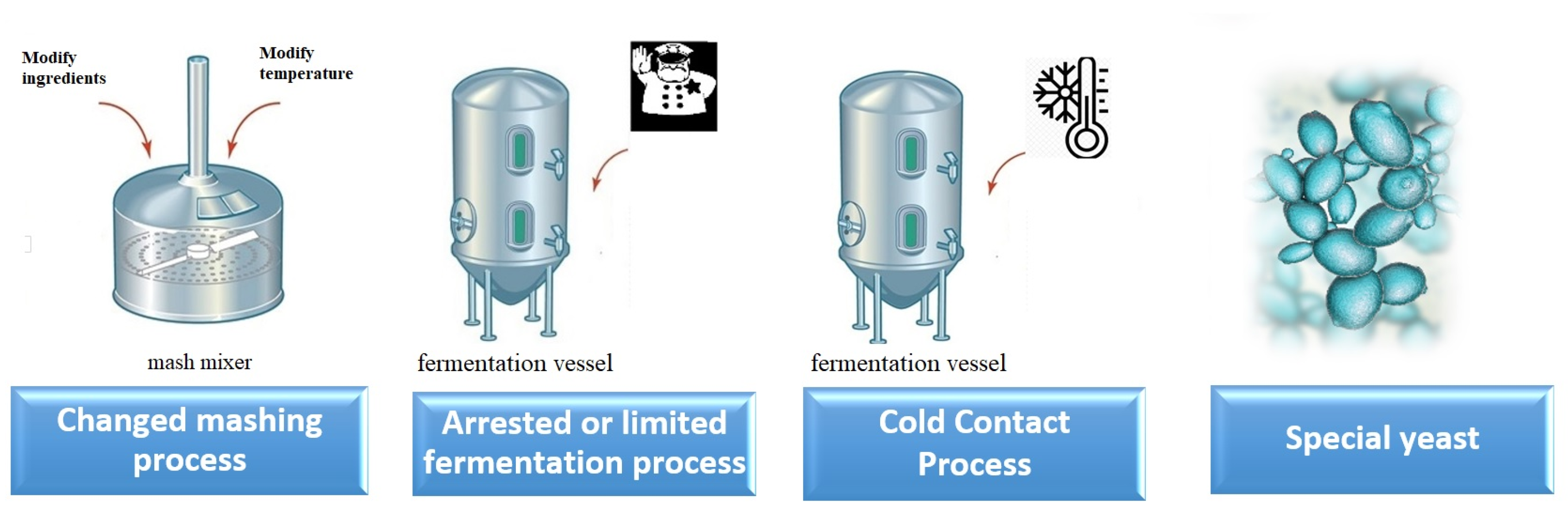

3.3. Biological Processes

3.3.1. Changed Mashing Process

3.3.2. Arrested or Limited Fermentation Process

3.3.3. Cold Contact Process

3.3.4. Utilization of Special Yeast

3.3.5. Continuous Fermentation

4. Strengths and Weaknesses of Alcohol Removal Techniques

5. New Trends Regarding Yeasts Involved in Fermentation of Special Beers

6. Compounds Involved in Special Beers’ Stability and Quality

6.1. Impact of Polyphenols on Beer Flavor Stability

6.2. Prenylflavonoids

6.3. Beer Color

6.4. Haze Stability

6.5. Protein in Beer—Influence on Beer Flavor Stability

7. Beer Enhancements and New Special Beer Designs

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Violino, S.; Figorilli, S.; Costa, C.; Pallottino, F. Internet of beer: A review on smart technologies from mash to pint. Foods 2020, 9, 950. [Google Scholar] [CrossRef] [PubMed]

- Pereira de Moura, F.; Rocha dos Santos Mathias, T. A comparative study of dry and wet milling of barley malt and its influence on granulometry and wort composition. Beverages 2018, 4, 51. [Google Scholar] [CrossRef] [Green Version]

- Sohrabvandi, S.; Mousavi, S.M.; Razavi, S.H.; Mortazavian, A.M.; Rezaei, K. Alcohol-free beer: Methods of production, sensorial defects, and healthful effects. Food Rev. Int. 2010, 26, 335–352. [Google Scholar] [CrossRef]

- Sohrabvandi, S.; Mortazavian, A.M.; Rezaei, K. Advanced analytical methods for the analysis of chemical and microbiological properties of beer. J. Food Drug Anal. 2011, 19, 202–222. [Google Scholar]

- Salanţă, L.; Tofană, M.; Pop, C.; Pop, A.; Coldea, T. Beverage alcohol choice among university students: Perception, consumption and preferences. Bull. Univ. Agric. Sci. Vet. Med. 2017, 74, 23. [Google Scholar] [CrossRef]

- Oak, M.; Auger, C.; Belcastro, E.; Park, S.-H.; Lee, H.; Schini-Kerth, V.B. Potential mechanisms underlying cardiovascular protection by polyphenols: Role of the endothelium. Free Radic. Biol. Med. 2018, 122, 161–170. [Google Scholar] [CrossRef] [PubMed]

- Neto, O.J.R.; de Oliveira, T.S.; Ghedini, P.C.; Vaz, B.G.; de Souza Gil, E. Antioxidant and vasodilatory activity of commercial beers. J. Funct. Foods 2017, 34, 130–138. [Google Scholar] [CrossRef]

- Sohrabvandi, S.; Mortazavian, A.M.; Rezaei, K. Health-related aspects of beer: A review. Int. J. Food Prop. 2012, 15, 350–373. [Google Scholar] [CrossRef]

- De Gaetano, G.; Costanzo, S.; Di Castelnuovo, A.; Badimon, L.; Bejko, D.; Alkerwi, A.; Chiva-Blanch, G.; Estruch, R.; La Vecchia, C.; Panico, S.; et al. Effects of moderate beer consumption on health and disease: A consensus document. Nutr. Metab. Cardiovasc. Dis. 2016, 26, 443–467. [Google Scholar] [CrossRef] [Green Version]

- Mellor, D.D.; Hanna-Khalil, B.; Carson, R. A review of the potential health benefits of low alcohol and alcohol-free beer: Effects of ingredients and craft brewing processes on potentially bioactive metabolites. Beverages 2020, 6, 25. [Google Scholar] [CrossRef]

- Bellut, K.; Krogerus, K.; Arendt, E.K. Lachancea fermentati strains isolated from Kombucha: Fundamental insights, and practical application in low alcohol beer brewing. Front. Microbiol. 2020, 11, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Veljovic, M.; Despotovic, S.; Stojanovic, M.; Pecic, S.; Vukosavljevic, P.; Belovic, M.; Leskosek-Cukalovic, I. The fermentation kinetics and physicochemical properties of special beer with addition of Prokupac grape variety. Chem. Ind. Chem. Eng. Q. 2015, 21, 391–397. [Google Scholar] [CrossRef]

- Martínez, A.; Vegara, S.; Martí, N.; Valero, M.; Saura, D. Physicochemical characterization of special persimmon fruit beers using bohemian pilsner malt as a base. J. Inst. Brew. 2017, 123, 319–327. [Google Scholar] [CrossRef] [Green Version]

- Dias M de, O.; Falconi, D. The evolution of craft beer industry in Brazil. J. Econ. Bus. 2018, 1. [Google Scholar] [CrossRef] [Green Version]

- Humia, B.V.; Santos, K.S.; Barbosa, A.M.; Sawata, M.; da Mendonça, M.C.; Padilha, F.F. Beer molecules and its sensory and biological properties: A review. Molecules 2019, 24, 1568. [Google Scholar] [CrossRef] [Green Version]

- Bogdan, P.; Kordialik-Bogacka, E. Alternatives to malt in brewing. Trends Food Sci. Technol. 2017, 65, 1–9. [Google Scholar] [CrossRef]

- Mezgebe, A.G.; Abegaz, K.; Taylor, J.R.N. Relationship between waxy (high amylopectin) and high protein digestibility traits in sorghum and malting quality. J. Cereal Sci. 2018, 79, 319–327. [Google Scholar] [CrossRef] [Green Version]

- Ducruet, J.; Rébénaque, P.; Diserens, S.; Kosińska-Cagnazzo, A.; Héritier, I.; Andlauer, W. Amber ale beer enriched with goji berries—The effect on bioactive compound content and sensorial properties. Food Chem. 2017, 226, 109–118. [Google Scholar] [CrossRef]

- Mayer, H.; Ceccaroni, D.; Marconi, O.; Sileoni, V.; Perretti, G.; Fantozzi, P. Development of an all rice malt beer: A gluten free alternative. LWT Food Sci. Technol. 2016, 67, 67–73. [Google Scholar] [CrossRef]

- Mascia, I.; Fadda, C.; Karabín, M.; Dostálek, P.; Del Caro, A. Aging of craft durum wheat beer fermented with sourdough yeasts. LWT Food Sci. Technol. 2016, 65, 487–494. [Google Scholar] [CrossRef]

- Salanță, L.C.; Tofană, M.; Socaci, S.; Pop, A.; Odagiu, A.; Nagy, M.; Cuceu, A. Evaluation of volatile compounds from Hüller Bitterer variety grown in Romania by chemometric methods. J. Agroaliment. Process. Technol. 2015, 21, 231–236. [Google Scholar]

- Salanță, L.C.; Socaci, S.A.; Tofană, M.; Mudura, E.; Pop, C.R.; Nagy, M.; Odagiu, A. Characterization of volatile components in hop pellets using in-tube extraction GC-MS analysis. Rom. Biotechnol. Lett. 2018, 23, 13541–13550. [Google Scholar]

- Michiu, D.; Socaci, S.A.; Jimborean, M.A.; Mudura, E.; Fărcaş, A.C.; Biriş-Dorhoi, S.E.; Tofană, M. Determination of Volatile markers from Magnum hops in beer by in-tube extraction–gas chromatography–mass spectrometry. Anal. Lett. 2018, 51, 2967–2980. [Google Scholar] [CrossRef]

- Oladokun, O.; James, S.; Cowley, T.; Dehrmann, F.; Smart, K.; Hort, J.; Cook, D. Perceived bitterness character of beer in relation to hop variety and the impact of hop aroma. Food Chem. 2017, 230, 215–224. [Google Scholar] [CrossRef]

- Liu, S.; Ying, A.; Quek, H. Evaluation of beer fermentation with a novel yeast Williopsis saturnus. Food Technol. Biotechnol. 2016, 54, 403–412. [Google Scholar] [CrossRef]

- Fanari, M.; Forteschi, M.; Sanna, M.; Piu, P.P.; Porcu, M.C.; D’hallewin, G.; Secchi, N.; Zinellu, M.; Pretti, L. Pilot plant production of craft fruit beer using Ohmic-treated fruit puree. J. Food Process. Preserv. 2020, 44, 1–8. [Google Scholar] [CrossRef]

- Daenen, L.; Sterckx, F.; Delvaux, F.R.; Verachtert, H.; Derdelinckx, G. Evaluation of the glycoside hydrolase activity of a Brettanomyces strain on glycosides from sour cherry (Prunus cerasus L.) used in the production of special fruit beers. FEMS. Yeast Res. 2008, 8, 1103–1114. [Google Scholar] [CrossRef] [Green Version]

- Rošul, M.; Mandić, A.; Mišan, A.; Đerić, N.; Pejin, J. Review of trends in formulation of functional beer. Food Feed Res. 2019, 46, 23–35. [Google Scholar] [CrossRef]

- Bellut, K.; Arendt, E.K. Chance and challenge: Non-saccharomyces yeasts in nonalcoholic and low alcohol beer brewing–A review. J. Am. Soc. Brew. Chem. 2019, 77, 77–91. [Google Scholar] [CrossRef]

- Ignat, V.M.; Salanță, L.C.; Pop, O.L.; Pop, C.R.; Tofană, M.; Mudura, E.; Coldea, T.E.; Borșa, A.; Pasqualone, A. Current functionality and potential improvements of non-alcoholic fermented cereal beverages. Foods 2020, 9, 1031. [Google Scholar] [CrossRef]

- Riu-Aumatell, M.; Miró, P.; Serra-Cayuela, A.; Buxaderas, S.; López-Tamames, E. Assessment of the aroma profiles of low-alcohol beers using HS-SPME-GC-MS. Food Res. Int. 2014, 57, 196–202. [Google Scholar] [CrossRef]

- Jackowski, M.; Trusek, A. Non-alcoholic beer Production–an overview. Pol. J. Chem. Technol. 2018, 20, 32–38. [Google Scholar] [CrossRef] [Green Version]

- Muller, C.; Neves, L.E.; Gomes, L.; Guimarães, M.; Ghesti, G. Processes for alcohol-free beer production: A review. Food Sci. Technol. 2020, 40, 273–281. [Google Scholar] [CrossRef] [Green Version]

- Mulero-Cerezo, J.; Briz-Redón, Á.; Serrano-Aroca, Á. Saccharomyces cerevisiae var. boulardii: Valuable probiotic starter for craft beer production. Appl. Sci. 2019, 9, 3250. [Google Scholar] [CrossRef] [Green Version]

- Pokrivčák, J.; Supeková, S.C.; Lančarič, D.; Savov, R.; Tóth, M.; Vašina, R. Development of beer industry and craft beer expansion. J. Food Nutr. Res. 2019, 58, 63–74. [Google Scholar]

- da Costa Jardim, C.; de Souza, D.; Cristina Kasper Machado, I.; Massochin Nunes Pinto, L.; de Souza Ramos, R.; Garavaglia, J. Sensory profile, consumer preference and chemical composition of craft beers from Brazil. Beverages 2018, 4, 106. [Google Scholar] [CrossRef] [Green Version]

- Liguori, L.; De Francesco, G.; Russo, P.; Albanese, D.; Perretti, G.; Di Matteo, M. Quality improvement of low alcohol craft beer produced by evaporative pertraction. Chem. Eng. Trans. 2015, 43, 13–18. [Google Scholar] [CrossRef]

- Brewers Association Best Practices Guide to Quality Craft Beer. 2013. Available online: https://www.brewbound.com/news/brewers-association-releases-best-practices-guide-to-quality-craft-beer/ (accessed on 30 October 2020).

- European beer trends. In European Beer Trends Statistics Reports; The Brewers of Europe: Bruxelles, Belgium, 2019.

- The Contribution made by Beer to the European Economy; The brewers of Europe: Bruxelles, Belgium, 2020.

- A Guide on How to Improve the Experience for Your Beer Shoppers; Marston’s Off Trade Beer Report; Marston’s Beer Company: Wolverhampton, UK, 2018.

- Brányik, T.; Silva, D.P.; Baszczyňski, M.; Lehnert, R.; Almeida, E.; Silva, J.B. A review of methods of low alcohol and alcohol-free beer production. J. Food Eng. 2012, 108, 493–506. [Google Scholar] [CrossRef]

- Blanco, C.A.; Andrés-Iglesias, C.; Montero, O. Low-alcohol beers: Flavor compounds, defects, and improvement strategies. Crit. Rev. Food Sci. Nutr. 2016, 56, 1379–1388. [Google Scholar] [CrossRef]

- Ghasemi-Varnamkhasti, M.; Mohtasebi, S.S.; Rodriguez-Mendez, M.L.; Lozano, J.; Razavi, S.H.; Ahmadi, H.; Apetrei, C. Classification of non-alcoholic beer based on aftertaste sensory evaluation by chemometric tools. Expert Syst. Appl. 2012, 39, 4315–4327. [Google Scholar] [CrossRef]

- Carvalho, F.R.; Moors, P.; Wagemans, J.; Spence, C. The influence of color on the consumer’s experience of beer. Front. Psychol. 2017, 8, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Salanță, L.C.; Tofană, M.; Mudura, E.; Pop, C.R.; Pop, A.; Coldea, T.E. The alcoholic beverage consumption preference of university students: A preliminary Romanian case study. Bull. Uasvm Food Sci. Technol. 2016, 73, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Salanță, L.C.; Tofană, M.; Pop, C.R.; Pop, A.; Coldea, T.E.; Mihai, M. Risk Factors associated with alcohol consumption among Romanian university students- Preliminary research. Bull. UASVM Food Sci. Technol. 2018, 75, 86–89. [Google Scholar] [CrossRef]

- Bokulich, N.A.; Bamforth, C.W. The microbiology of malting and brewing. Microbiol. Mol. Biol. Rev. 2013, 77, 157–172. [Google Scholar] [CrossRef] [Green Version]

- Capece, A.; Romaniello, R.; Siesto, G.; Romano, P. Conventional and non-conventional yeasts in beer production. Fermentation 2018, 4, 38. [Google Scholar] [CrossRef] [Green Version]

- Ceccaroni, D.; Sileoni, V.; Marconi, O.; De Francesco, G.; Lee, E.G.; Perretti, G. Specialty rice malt optimization and improvement of rice malt beer aspect and aroma. LWT 2019, 99, 299–305. [Google Scholar] [CrossRef]

- Aquilani, B.; Laureti, T.; Poponi, S.; Secondi, L. Beer choice and consumption determinants when craft beers are tasted: An exploratory study of consumer preferences. Food Qual. Prefer. 2015, 41, 214–224. [Google Scholar] [CrossRef]

- Andrés-Iglesias, C.; García-Serna, J.; Montero, O.; Blanco, C.A. Simulation and flavor compound analysis of dealcoholized beer via one-step vacuum distillation. Food Res. Int. 2015, 76, 751–760. [Google Scholar] [CrossRef] [Green Version]

- Holt, S.; Miks, M.H.; De Carvalho, B.T.; Foulquié-Moreno, M.R.; Thevelein, J.M. The molecular biology of fruity and floral aromas in beer and other alcoholic beverages. Fems Microbiol. Rev. 2019, 43, 193–222. [Google Scholar] [CrossRef] [Green Version]

- Menz, G.; Andrighetto, C.; Lombardi, A.; Corich, V.; Aldred, P.; Vriesekoop, F. Isolation, identification, and characterisation of beer-spoilage lactic acid bacteria from microbrewed beer from Victoria, Australia. J. Inst. Brew. 2010, 116, 14–22. [Google Scholar] [CrossRef]

- Malfliet, S.; Opstaele, F.; Clippeleer, J.; Syryn, E.; Goiris, K.; Cooman, L.; Aerts, G. Flavour instability of pale lager beers: Determination of analytical markers in relation to sensory ageing. J. Inst. Brew. 2008, 114, 180–192. [Google Scholar] [CrossRef]

- Silva, A.P.; Jager, G.; van Bommel, R.; van Zyl, H.; Voss, H.P.; Hogg, T.; Pintado, M.; de Graaf, C. Functional or emotional? How Dutch and Portuguese conceptualise beer, wine and non-alcoholic beer consumption. Food Qual. Prefer. 2016, 49, 54–65. [Google Scholar] [CrossRef]

- Wojtyra, B. How and why did craft breweries ‘revolutionise’ the beer market? The case of Poland. Morav. Geogr. Rep. 2020, 28, 81–97. [Google Scholar] [CrossRef]

- Wojtyra, B.; Grudzień, Ł. Development of the beer industry in Poland in the period of “the craft beer revolution” (2011–2016). Stud. Ind. Geogr. Comm. Pol. Geogr. Soc. 2017, 31, 52–67. [Google Scholar] [CrossRef]

- Garavaglia, C.; Swinnen, J. The craft beer revolution: An international perspective. Choices 2017, 32, 1–8. [Google Scholar]

- Giannakopoulos, I.A. Small Firm size and Craft Production as a Sustainable Competitive Advantage. The Case of Beer in Belgium and the Netherlands. Master’s Thesis, Wageningen University, Wa Geningen, The Netherlands, 2019. [Google Scholar]

- Kloos, A.F. The economic success recipe of craft beer brewers: An Analysis of the Definition of Success and Associated Business Strategies of European Craft Beer Brewers. Master’s Thesis, Wageningen University, Wageningen, The Netherlands, August 2018. [Google Scholar]

- Callejo, M.J.; Tesfaye, W.; González, M.C.; Morata, A. Craft beers: Current situation and future trends. In New Advances on Fermentation Processes; Martínez-Espinosa, R.M., Ed.; IntechOpen: London, UK, 2019; pp. 1–18. [Google Scholar]

- Clemons, E.K.; Gao, G.; Hitt, L.M. When online reviews meet hyperdifferentiation: A study of the craft beer industry. J. Manag. Inf. Syst 2006, 23, 149–171. [Google Scholar] [CrossRef] [Green Version]

- Luneia, S.; Zannoli, R.; Farchioni, M.; Sensidoni, M.; Luneia, R. Craft beers made with addition of Umbrian legumes: Healthy and nutritional characterization. Nat. Prod. Commun. 2018, 13, 1161–1162. [Google Scholar] [CrossRef] [Green Version]

- Almaguer, C.; Schönberger, C.; Gastl, M.; Arendt, E.K.; Becker, T. Humulus Lupulus–a story that begs to be told. A review. J. Inst. Brew. 2014, 120, 289–314. [Google Scholar] [CrossRef]

- Lafontaine, S.R.; Shellhammer, T.H. Impact of static dry-hopping rate on the sensory and analytical profiles of beer. J. Inst. Brew. 2018, 124, 434–442. [Google Scholar] [CrossRef] [Green Version]

- Liguori, L.; Russo, P.; Albanese, D.; Di Matteo, M. Production of Low-Alcohol Beverages: Current Status and Perspectives; Elsevier Inc: Amsterdam, The Netherlands, 2018; ISBN 9780128114476. [Google Scholar]

- Montanari, L.; Marconi, O.; Mayer, H.; Fantozzi, P. Production of alcohol-free beer. In Beer in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: Cambridge, MA, USA, 2009; pp. 61–75. ISBN 978-0-12-373891-2. [Google Scholar]

- Mangindaan, D.; Khoiruddin, K.; Wenten, I.G. Beverage dealcoholization processes: Past, present, and future. Trends Food Sci. Technol. 2018, 71, 36–45. [Google Scholar] [CrossRef]

- Ambrosi, A.; Cardozo, N.S.M.; Tessaro, I.C. Membrane separation processes for the beer industry: A review and state of the art. Food Bioprocess. Technol. 2014, 7, 921–936. [Google Scholar] [CrossRef]

- Catarino, M.; Mendes, A.; Madeira, L.M.; Ferreira, A. Alcohol removal from beer by reverse osmosis. Sep. Sci. Technol. 2007, 42, 3011–3027. [Google Scholar] [CrossRef]

- Pilipovik, M.V.; Riverol, C. Assessing dealcoholization systems based on reverse osmosis. J. Food Eng. 2005, 69, 437–441. [Google Scholar] [CrossRef]

- Liguori, L.; De Francesco, G.; Russo, P.; Perretti, G.; Albanese, D.; Di Matteo, M. Quality Attributes of low-alcohol top-fermented beers produced by membrane contactor. Food Bioprocess. Technol. 2016, 9, 191–200. [Google Scholar] [CrossRef]

- Purwasasmita, M.; Kurnia, D.; Mandias, F.C.; Khoiruddin; Wenten, I.G. Beer dealcoholization using non-porous membrane distillation. Food Bioprod. Process. 2015, 94, 180–186. [Google Scholar] [CrossRef]

- Del Olmo, Á.; Blanco, C.A.; Palacio, L.; Prádanos, P.; Hernández, A. Pervaporation methodology for improving alcohol-free beer quality through aroma recovery. J. Food Eng. 2014, 133, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Prestes Alves, K.M.; da Silva, B.J.G.; de Paula Scheer, A. Beer aroma recovery and dealcoholisation by a two-step pervaporation process. J. Inst. Brew. 2020, 126, 67–76. [Google Scholar] [CrossRef]

- Mueller, N.C.; Van der Bruggen, B.; Keuter, V.; Luis, P.; Melin, T.; Pronk, W.; Reisewitz, R.; Rickerby, D.; Rios, G.M.; Wennekes, W.; et al. Nanofiltration and nanostructured membranes-Should they be considered nanotechnology or not? J. Hazard. Mater. 2012, 211–212, 275–280. [Google Scholar] [CrossRef]

- Muller, R. A mathematical model of the formation of fermentable sugars from starch hydrolysis during high-temperature mashing. Enzym. Microb. Technol. 2000, 27, 337–344. [Google Scholar] [CrossRef]

- Puerari, C.; Strejc, J.; Souza, A.C.; Karabín, M.; Schwan, R.F.; Brányik, T. Optimization of alcohol-free beer production by lager and cachaça yeast strains using response surface methodology. J. Inst. Brew. 2016, 122, 69–75. [Google Scholar] [CrossRef] [Green Version]

- Juvonen, R.; Virkajärvi, V.; Priha, O.; Laitila, A. Microbiological Spoilage and Safety Risks in Non-Beer Beverages; Vtt Tiedotteita–Research Notes: Jyväskylä, Finland, 2011; ISBN 9789513877873. [Google Scholar]

- Michiu, D.; Tofana, M.; Mudura, E.; Muntean, F. Preliminary research concerning the determination of beer wort flavor compounds during primary fermentation. Bull. Univ. Agric. Sci. Vet. Med. Cluj Napoca Agric. 2010, 67, 309–313. [Google Scholar] [CrossRef]

- Suzuki, K.; Asano, S.; Iijima, K.; Kitamoto, K. Sake and beer spoilage lactic acid bacteria–A review. J. Inst. Brew. 2008, 114, 209–223. [Google Scholar] [CrossRef]

- Lawton, M.R.; Alcaine, S.D. Leveraging endogenous barley enzymes to turn lactose-containing dairy by-products into fermentable adjuncts for Saccharomyces cerevisiae-based ethanol fermentations. J. Dairy Sci. 2019, 102, 2044–2050. [Google Scholar] [CrossRef] [PubMed]

- Vilela, A. The importance of yeasts on fermentation quality and human health-promoting compounds. Fermentation 2019, 5, 46. [Google Scholar] [CrossRef] [Green Version]

- Walker, G.; Stewart, G. Saccharomyces cerevisiae in the production of fermented beverages. Beverages 2016, 2, 30. [Google Scholar] [CrossRef]

- Capece, A.; Romaniello, R.; Pietrafesa, A.; Siesto, G.; Pietrafesa, R.; Zambuto, M.; Romano, P. Use of Saccharomyces cerevisiae var. boulardii in co-fermentations with S. cerevisiae for the production of craft beers with potential healthy value-added. Int. J. Food Microbiol. 2018, 284, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Gibson, B.; Geertman, J.M.A.; Hittinger, C.T.; Krogerus, K.; Libkind, D.; Louis, E.J.; Magalhães, F.; Sampaio, J.P. New yeasts-new brews: Modern approaches to brewing yeast design and development. FEMS Yeast Res. 2017, 17, 1–13. [Google Scholar] [CrossRef]

- Senkarcinova, B.; Graça Dias, I.A.; Nespor, J.; Branyik, T. Probiotic alcohol-free beer made with Saccharomyces cerevisiae var. boulardii. LWT 2019, 100, 362–367. [Google Scholar] [CrossRef]

- Değirmencioğlu, N.; Gurbuz, O.; Şahan, Y. The Monitoring, via an in vitro digestion system, of the bioactive content of vegetable juice fermented with Saccharomyces cerevisiae and Saccharomyces boulardii. J. Food Process. Preserv. 2016, 40, 798–811. [Google Scholar] [CrossRef]

- Lazo-Vélez, M.A.; Serna-Saldívar, S.O.; Rosales-Medina, M.F.; Tinoco-Alvear, M.; Briones-García, M. Application of Saccharomyces cerevisiae var. boulardii in food processing: A review. J. Appl. Microbiol. 2018, 125, 943–951. [Google Scholar]

- Domizio, P.; House, J.F.; Joseph, C.M.L.; Bisson, L.F.; Bamforth, C.W. Lachancea thermotolerans as an alternative yeast for the production of beer. J. Inst. Brew. 2016, 122, 599–604. [Google Scholar] [CrossRef] [Green Version]

- Serra Colomer, M.; Funch, B.; Forster, J. The raise of Brettanomyces yeast species for beer production. Curr. Opin. Biotechnol. 2019, 56, 30–35. [Google Scholar] [CrossRef] [PubMed]

- Zdaniewicz, M.; Satora, P.; Pater, A.; Bogacz, S. Low lactic acid-producing strain of lachancea thermotolerans as a new starter for beer production. Biomolecules 2020, 10, 256. [Google Scholar] [CrossRef] [Green Version]

- Canonico, L.; Ciani, E.; Galli, E.; Comitini, F.; Ciani, M. Evolution of aromatic profile of Torulaspora delbrueckii mixed fermentation at microbrewery plant. Fermentation 2020, 6, 7. [Google Scholar] [CrossRef] [Green Version]

- Bellut, K.; Michel, M.; Zarnkow, M.; Hutzler, M.; Jacob, F.; De Schutter, D.P.; Daenen, L.; Lynch, K.M.; Zannini, E.; Arendt, E.K. Application of non-Saccharomyces yeasts isolated from kombucha in the production of alcohol-free beer. Fermentation 2018, 4, 66. [Google Scholar] [CrossRef] [Green Version]

- Canonico, L.; Agarbati, A.; Comitini, F.; Ciani, M. Torulaspora delbrueckii in the brewing process: A new approach to enhance bioflavour and to reduce ethanol content. Food Microbiol. 2016, 56, 45–51. [Google Scholar] [CrossRef] [PubMed]

- Michel, M.; Meier-Dörnberg, T.; Jacob, F.; Methner, F.J.; Wagner, R.S.; Hutzler, M. Review: Pure non-Saccharomyces starter cultures for beer fermentation with a focus on secondary metabolites and practical applications. J. Inst. Brew. 2016, 122, 569–587. [Google Scholar] [CrossRef]

- Rój, E.; Tadić, V.M.; Mišić, D.; Žižović, I.; Arsić, I.; Dobrzyńska-Inger, A.; Kostrzewa, D. Supercritical carbon dioxide hops extracts with antimicrobial properties. Open Chem. 2015, 13, 1157–1171. [Google Scholar] [CrossRef]

- Mudura, E.; Coldea, T. Hop-derived prenylflavonoids and their importance in brewing technology: A review. Bull. BUASVM Food Sci. Technol. 2015, 72, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Karabín, M.; Hudcová, T.; Jelínek, L.; Dostálek, P. Biologically active compounds from hops and prospects for their use. Compr. Rev. Food Sci. Food Saf. 2016, 15, 542–567. [Google Scholar] [CrossRef] [Green Version]

- Mudura, E.; Coldea, T.E.; Socaciu, C.; Ranga, F.; Pop, C.R.; Rotar, A.M.; Pasqualone, A. Brown beer vinegar: A potentially functional product based on its phenolic profile and antioxidant activity. J. Serb. Chem. Soc. 2018, 83, 19–30. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, M. Effects of mashing on total phenolic contents and antioxidant activities of malts and worts. Int. J. Food Sci. Technol. 2012, 47, 240–247. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.; Sun, G.; Yang, B.; Zhao, M. Assessment of endogenous antioxidative compounds and antioxidant activities of lager beers. J. Sci. Food Agric. 2013, 93, 910–917. [Google Scholar] [CrossRef]

- Wannenmacher, J.; Gastl, M.; Becker, T. Phenolic substances in beer: Structural diversity, reactive potential and relevance for brewing process and beer quality. Compr. Rev. Food Sci. Food Saf. 2018, 17, 953–988. [Google Scholar] [CrossRef] [Green Version]

- Vanderhaegen, B.; Neven, H.; Verachtert, H.; Derdelinckx, G. The chemistry of beer aging—A critical review. Food Chem. 2006, 95, 357–381. [Google Scholar] [CrossRef]

- Baert, J.J.; De Clippeleer, J.; Hughes, P.S.; De Cooman, L.; Aerts, G. On the origin of free and bound staling aldehydes in beer. J. Agric. Food Chem. 2012, 60, 11449–11472. [Google Scholar] [CrossRef]

- Mudura, E.; Paucean, A.; Rotar, A. Rapid method for evaluation of beer stability. Bull. UASVM Agric. 2012, 69, 508–509. [Google Scholar]

- Suruceanu, N.; Socaci, S.; Coldea, T.; Mudura, E. Revaluation of waste yeast from beer production. Bull. Univ. Agric. Sci. Vet. Med. Cluj Napoca. Food Sci. Technol. 2013, 70, 118. [Google Scholar] [CrossRef] [Green Version]

- Mudura, E.; Muste, S.; Tofana, M.; Socaci, S.A.; Goina, V. Improving the hop utilization in the beer biotechnology. Bull. Univ. Agric. Sci. Vet. Med. Cluj Napoca Agric. 2008, 65, 281–286. [Google Scholar] [CrossRef]

- Cao, L.; Zhou, G.; Guo, P.; Li, Y. Influence of pasteurising intensity on beer flavour stability. J. Inst. Brew. 2011, 117, 587–592. [Google Scholar] [CrossRef]

- Furukawa Suárez, A.; Kunz, T.; Cortés Rodríguez, N.; MacKinlay, J.; Hughes, P.; Methner, F.J. Impact of colour adjustment on flavour stability of pale lager beers with a range of distinct colouring agents. Food Chem. 2011, 125, 850–859. [Google Scholar] [CrossRef]

- Callemien, D.; Collin, S. Involvement of flavanoids in beer color instability during storage. J. Agric. Food Chem. 2007, 55, 9066–9073. [Google Scholar] [CrossRef]

- Dvořáková, M.; Hulín, P.; Karabín, M.; Dostálek, P. Determination of polyphenols in beer by an effective method based on solid-phase extraction and high performance liquid chromatography with diode-array detection. Czech. J. Food Sci. 2007, 25, 182–188. [Google Scholar] [CrossRef] [Green Version]

- Mcmurrough, I.; Kelly, R.; Byrne, J.; Brien, M.O.; Mcmurrough, I.; Kelly, R.; Byrne, J.; Brewing, G.; James, S.; Dublin, G. Effect of the removal of sensitive proteins and proanthocyanidins on the colloidal stability of lager beer. J. Am. Soc. Brew. Chem. 1992, 50. [Google Scholar] [CrossRef]

- McMurrough, I.; Madigan, D.; Kelly, R.J.; Smyth, M.R. The role of flavanoid polyphenols in beer stability. J. Am. Soc. Brew. Chem. 1996, 54, 141–148. [Google Scholar] [CrossRef]

- Olaniran, A.O.; Hiralal, L.; Mokoena, M.P.; Pillay, B. Flavour-active volatile compounds in beer: Production, regulation and control. J. Inst. Brew. 2017, 123, 13–23. [Google Scholar] [CrossRef] [Green Version]

- Díaz-Rubio, M.E.; Saura-Calixto, F. Dietary fiber complex in beer. J. Am. Soc. Brew. Chem. 2009, 67, 38–43. [Google Scholar] [CrossRef]

- Nardini, M.; Foddai, M.S. Phenolics profile and antioxidant activity of special beers. Molecules 2020, 25, 2466. [Google Scholar] [CrossRef]

- Nardini, M.; Garaguso, I. Characterization of bioactive compounds and antioxidant activity of fruit beers. Food Chem. 2020, 305, 125437. [Google Scholar] [CrossRef]

- Jahn, A.; Kim, J.; Bashir, K.M.I.; Cho, M. gi Antioxidant content of aronia infused beer. Fermentation 2020, 6, 71. [Google Scholar] [CrossRef]

- Ulloa, P.A.; Vidal, J.; Ávila, M.I.; Labbe, M.; Cohen, S.; Salazar, F.N. Effect of the addition of propolis extract on bioactive compounds and antioxidant activity of craft beer. J. Chem. 2017, 2017. [Google Scholar] [CrossRef] [Green Version]

- Bröhan, M.; Jerkovic, V.; Collin, S. Potentiality of red sorghum for producing stilbenoid-enriched beers with high antioxidant activity. J. Agric. Food Chem. 2011, 59, 4088–4094. [Google Scholar] [CrossRef]

- Leitao, C.; Marchioni, E.; Bergaentzlé, M.; Zhao, M.; Didierjean, L.; Taidi, B.; Ennahar, S. Effects of processing steps on the phenolic content and antioxidant activity of beer. J. Agric. Food Chem. 2011, 59, 1249–1255. [Google Scholar] [CrossRef]

- Wannenmacher, J.; Cotterchio, C.; Schlumberger, M.; Reuber, V.; Gastl, M.; Becker, T. Technological influence on sensory stability and antioxidant activity of beers measured by ORAC and FRAP. J. Sci. Food Agric. 2019, 99, 6628–6637. [Google Scholar] [CrossRef]

| Capacity | Extra Set Up Needed | Advantages/Disadvantages | |

|---|---|---|---|

| Falling film evaporator | 1–150 hL/h | − evaporator column − vapor separator − vapor condenser − rectifying column for flavor compounds recovery (optional) | + low acquisition and operation cost, high efficiency, easy to construct and easy to clean. − final product with considerable losses of flavor compounds |

| Vacuum Rectification | 4–200 hL /h | − heat plate exchanger − vacuum degasser − rectifying column cooler | − sensory properties of NABs are significantly changed, high energy requirements |

| Thin layer Evaporation Centritherm | 0.5–100 hL/h | − centrifugal evaporator − external Condenser for volatile compounds | + easy to operate, service-friendly and hygienic − high maintenance expenditure, high energy requirements |

| Pressure/Temperature | Extra Set Up Needed | Advantages/Disadvantages | |

|---|---|---|---|

| Reverse Osmosis | 10–60 bar 5–20 °C | − reverse osmosis equipment − carbonation equipment − high-pressure pump cooling system | − high energy consumption, low flux rate, high pressure requirement, significant losses of volatiles + lower costs than that of a conventional distillation system |

| Dialysis | 10–60 bar (1–6 °C) | − dialysis equipment cooling system | + low operational costs and very low working temperatures − lack of body in the final product |

| Osmotic Distillation | 20–80 bar 5–20 °C, | − osmotic distillation equipment − volatile compounds recovery unit − high-pressure pump | + higher energy efficiency than RO or distillation − depletion of main volatile compounds than RO |

| Pervaporation | 1 bar 10–20 °C | − pervaporation equipment − separate beer dealcoholisation unit | + the most effective membrane process for the recovery of aroma compounds in beverages − partial ethanol removal |

| PROCESS | INSTALLATION COSTS | OPERATIONAL COSTS | BEER QUALITY |

|---|---|---|---|

| BIOLOGICAL PROCESSES | |||

| Changed mashing process | $ | $$ |  |

| Cold Yeast Contact | $ | $$ |  |

| Special yeast | $ | $$ |  |

| Immobilized Yeast | $$ | $$ |  |

| THERMAL PROCESSES | |||

| Thin layer Evaporation | $$$ | $ |   |

| Vacuum Rectification | $$$ | $ |   |

| Falling film evaporator | $$$ | $$ |  |

| MEMBRANE PROCESSES | |||

| Reverse Osmosis | $$ | $$ |   |

| Osmotic Distillation | $$ | $$ |   |

| Dialysis | $$$ | $ |  |

| Pervaporation | $$ | $$ |    |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salanță, L.C.; Coldea, T.E.; Ignat, M.V.; Pop, C.R.; Tofană, M.; Mudura, E.; Borșa, A.; Pasqualone, A.; Zhao, H. Non-Alcoholic and Craft Beer Production and Challenges. Processes 2020, 8, 1382. https://doi.org/10.3390/pr8111382

Salanță LC, Coldea TE, Ignat MV, Pop CR, Tofană M, Mudura E, Borșa A, Pasqualone A, Zhao H. Non-Alcoholic and Craft Beer Production and Challenges. Processes. 2020; 8(11):1382. https://doi.org/10.3390/pr8111382

Chicago/Turabian StyleSalanță, Liana Claudia, Teodora Emilia Coldea, Maria Valentina Ignat, Carmen Rodica Pop, Maria Tofană, Elena Mudura, Andrei Borșa, Antonella Pasqualone, and Haifeng Zhao. 2020. "Non-Alcoholic and Craft Beer Production and Challenges" Processes 8, no. 11: 1382. https://doi.org/10.3390/pr8111382