Data-Mining for Processes in Chemistry, Materials, and Engineering

Abstract

:1. Introduction

2. Typical Studies

Mining the Trends and Properties in Chemistry and Materials

3. Processes in Engineering

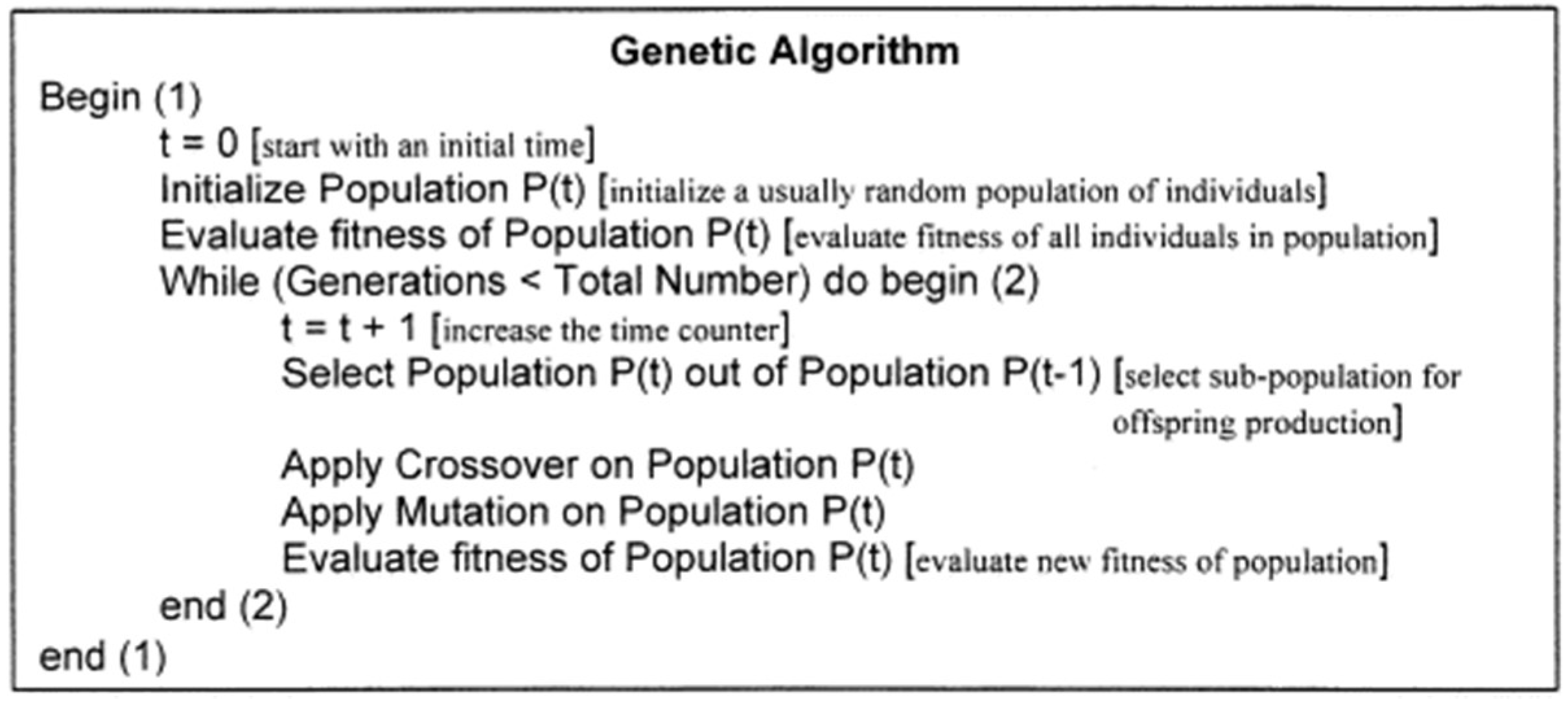

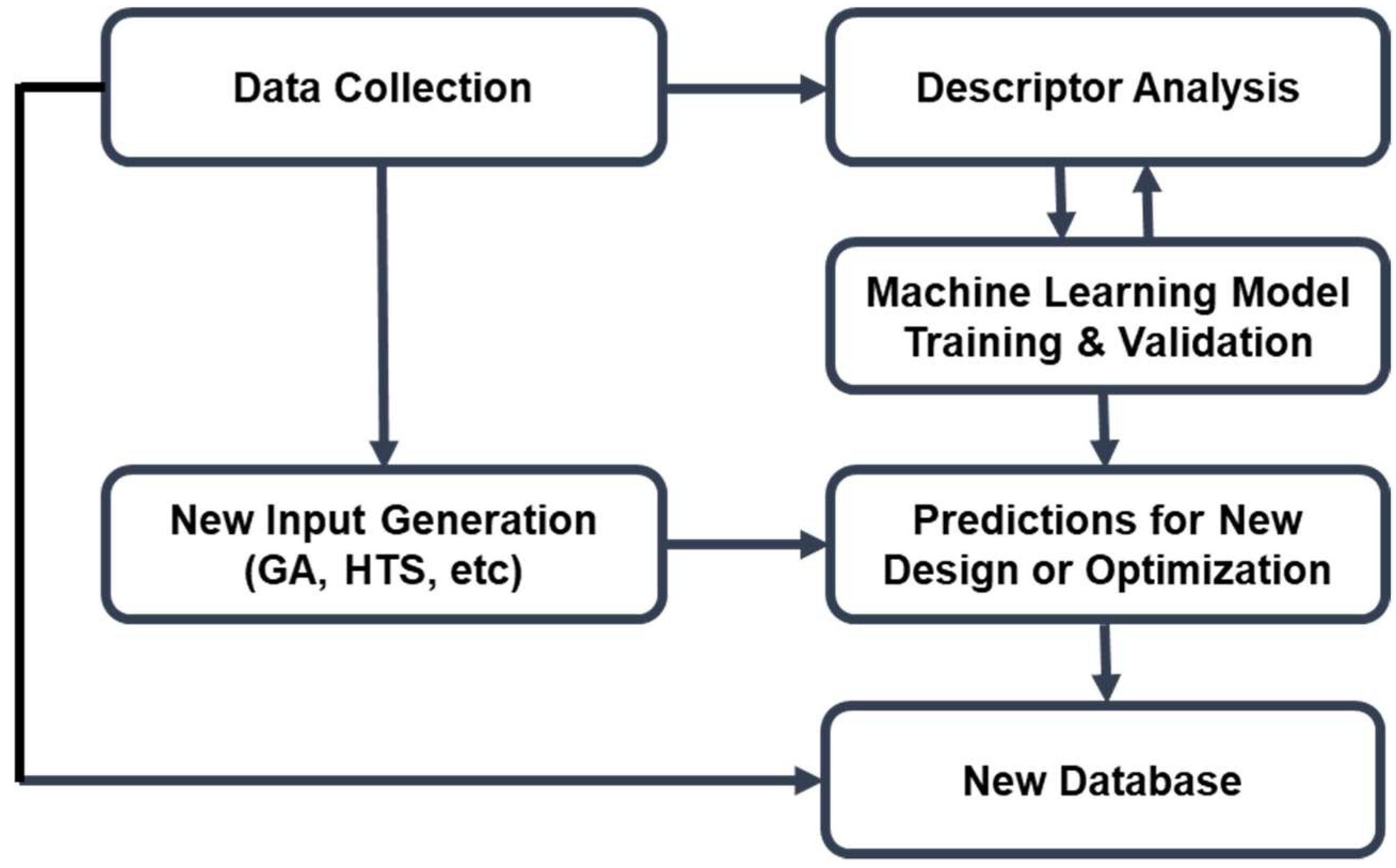

3.1. Engineering Optimization and Design

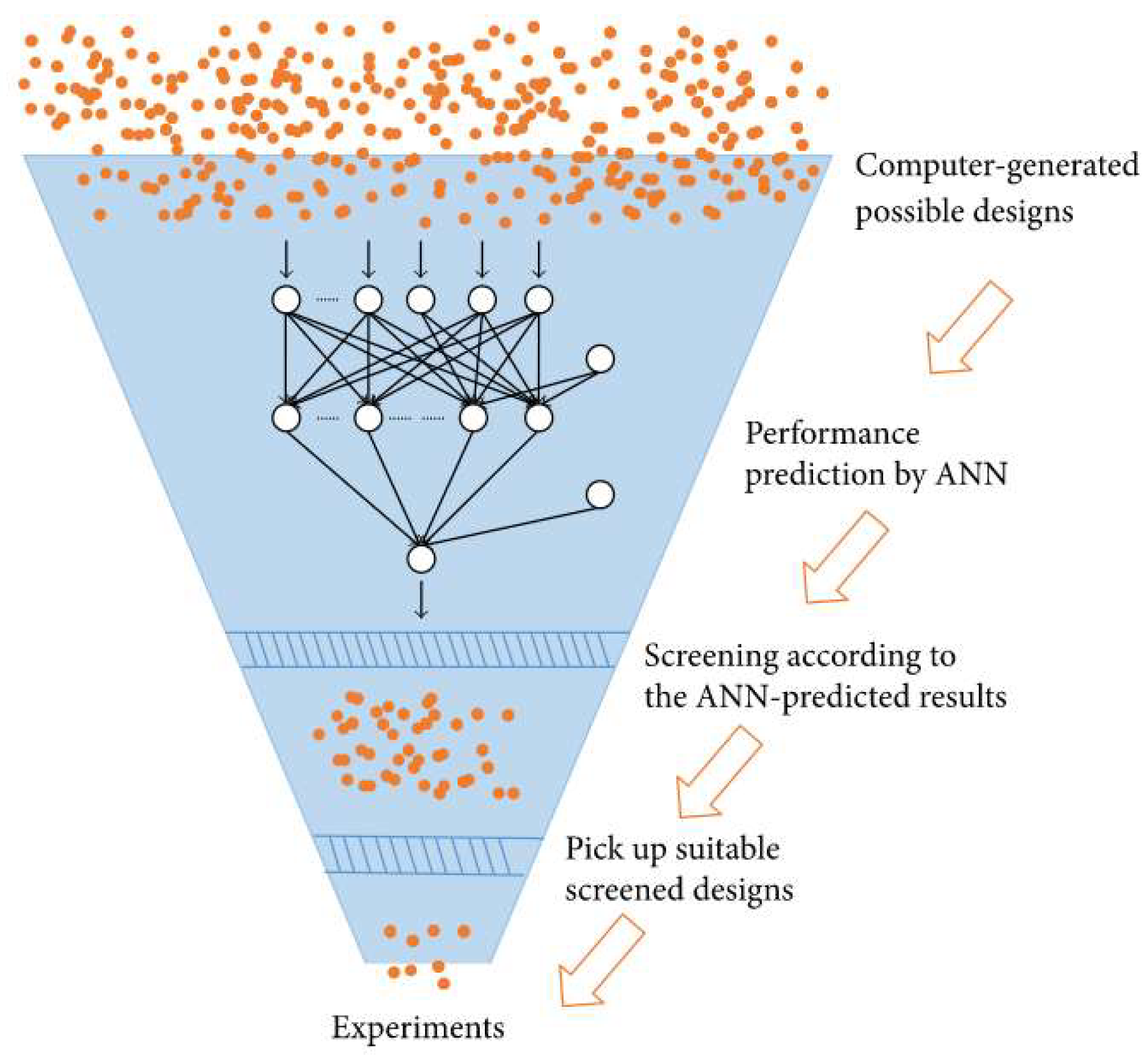

3.2. A Computational High-Throughput Screenig Method

4. Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, X.; Kumar, V.; Ross Quinlan, J.; Ghosh, J.; Yang, Q.; Motoda, H.; McLachlan, G.J.; Ng, A.; Liu, B.; Yu, P.S.; et al. Top 10 algorithms in data mining. Knowl. Inf. Syst. 2008, 14, 1–37. [Google Scholar] [CrossRef]

- Goh, K.L.; Singh, A.K. Comprehensive Literature Review on Machine Learning Structures for Web Spam Classification. Procedia Comput. Sci. 2015, 70, 434–441. [Google Scholar] [CrossRef] [Green Version]

- Sattlecker, M.; Stone, N.; Bessant, C. Current trends in machine-learning methods applied to spectroscopic cancer diagnosis. TrAC Trends Anal. Chem. 2014, 59, 17–25. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep Learning in neural networks: An overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef] [PubMed]

- Kotsiantis, S.B. Supervised Machine Learning: A Review of Classification Techniques. Informatica 2007, 31, 249–268. [Google Scholar] [CrossRef]

- Lin, J.; Yuan, J.-S. Analysis and Simulation of Capacitor-Less ReRAM-Based Stochastic Neurons for the in-Memory Spiking Neural Network. IEEE Trans. Biomed. Circuits Syst. 2018, 12, 1004–1017. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Yuan, J. Capacitor-less RRAM-Based Stochastic Neuron for Event-Based Unsupervised Learning. In Proceedings of the 2017 IEEE Biomedical Circuits and Systems Conference (BioCAS), Turin, Italy, 19–21 October 2017. [Google Scholar]

- Li, H.; Zhang, Z.; Liu, Z. Application of Artificial Neural Networks for Catalysis: A Review. Catalysts 2017, 7, 306. [Google Scholar] [CrossRef]

- Li, H.; Chen, F.; Cheng, K.; Zhao, Z.; Yang, D. Prediction of Zeta Potential of Decomposed Peat via Machine Learning: Comparative Study of Support Vector Machine and Artificial Neural Networks. Int. J. Electrochem. Sci. 2015, 10, 6044–6056. [Google Scholar]

- Li, H.; Tang, X.; Wang, R.; Lin, F.; Liu, Z.; Cheng, K. Comparative Study on Theoretical and Machine Learning Methods for Acquiring Compressed Liquid Densities of 1,1,1,2,3,3,3-Heptafluoropropane (R227ea) via Song and Mason Equation, Support Vector Machine, and Artificial Neural Networks. Appl. Sci. 2016, 6, 25. [Google Scholar] [CrossRef]

- Kawamoto, Y.; Takagi, H.; Nishiyama, H.; Kato, N. Efficient Resource Allocation Utilizing Q-Learning in Multiple UA Communications. IEEE Trans. Netw. Sci. Eng. 2018. [Google Scholar] [CrossRef]

- Siniscalchi, S.M.; Salerno, V.M. Adaptation to new microphones using artificial neural networks with trainable activation functions. IEEE Trans. Neural Netw. Learn. Syst. 2017, 28, 1959–1965. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, T. Unsupervised learning by probabilistic Latent Semantic Analysis. Mach. Learn. 2001, 42, 77–196. [Google Scholar] [CrossRef]

- Witten, I.H.; Frank, E. Data Mining: Practical Machine Learning Tools and Techniques; Morgan Kaufmann: Boston, MA, USA, 2005. [Google Scholar]

- Wu, H.; Yu, Y.; Fu, H.; Zhang, L. On the prediction of chemical exergy of organic substances using least square support vector machine. Energy Sources Part A Recover. Util. Environ. Eff. 2017, 39, 2210–2215. [Google Scholar] [CrossRef]

- Wu, K.; Liu, D.; Tang, Y. In-situ single-step chemical synthesis of graphene-decorated CoFe2O4composite with enhanced Li ion storage behaviors. Electrochim. Acta 2018, 263, 515–523. [Google Scholar] [CrossRef]

- Wu, K.; Du, K.; Hu, G. Red-blood-cell-like (NH4)[Fe2(OH)(PO4)2]•2H2O particles: Fabrication and application in high-performance LiFePO4 cathode materials. J. Mater. Chem. A 2018, 6, 1057–1066. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Zhang, W.; Wang, J.; Soltanian, M.R.; Olabi, A.G. Effectiveness of amino acid salt solutions in capturing CO2: A review. Renew. Sustain. Energy Rev. 2018, 98, 179–188. [Google Scholar] [CrossRef]

- Song, J.; Feng, Q.; Wang, X.; Fu, H.; Jiang, W.; Chen, B.; Song, J.; Feng, Q.; Wang, X.; Fu, H.; et al. Spatial Association and Effect Evaluation of CO2 Emission in the Chengdu-Chongqing Urban Agglomeration: Quantitative Evidence from Social Network Analysis. Sustainability 2018, 11, 1. [Google Scholar] [CrossRef]

- Li, H.; Henkelman, G. Dehydrogenation Selectivity of Ethanol on Close-Packed Transition Metal Surfaces: A Computational Study of Monometallic, Pd/Au, and Rh/Au Catalysts. J. Phys. Chem. C 2017, 121, 27504–27510. [Google Scholar] [CrossRef]

- Li, H.; Evans, E.J.; Mullins, C.B.; Henkelman, G. Ethanol Decomposition on Pd–Au Alloy Catalysts. J. Phys. Chem. C 2018, 122, 22024–22032. [Google Scholar] [CrossRef]

- Wu, K.; Yang, H.; Jia, L.; Pan, Y.; Hao, Y.; Zhang, K.; Du, K.; Hu, G. Smart construction of 3D N-doped graphene honeycombs with (NH4)2SO4 as a multifunctional template for Li-ion battery anode: “A choice that serves three purposes”. Green Chem. 2019. [Google Scholar] [CrossRef]

- Sun, Q.; Yang, Y.; Zhao, Z.; Zhang, Q.; Zhao, X.; Nie, G.; Jiao, T.; Peng, Q. Elaborate design of polymeric nanocomposites with Mg(ii)-buffering nanochannels for highly efficient and selective removal of heavy metals from water: Case study for Cu(ii). Environ. Sci. Nano 2018, 5, 2440–2451. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Z.; Liu, Y.; Cen, W.; Luo, X. Functional Group Effects on the HOMO–LUMO Gap of g-C3N. Nanomaterials 2018, 8, 589. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Zhang, Z.; Liu, Z. Non-Monotonic Trends of Hydrogen Adsorption on Single Atom Doped g-C3N. Catalysts 2019, 9, 84. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.; Cui, D.; Luo, X.; Liang, B.; Yang, L.; Liu, T.; Wang, A.; Luo, S. Ultrafine palladium nanoparticles supported on 3D self-supported Ni foam for cathodic dechlorination of florfenicol. Chem. Eng. J. 2018, 359, 894–901. [Google Scholar] [CrossRef]

- Shi, C.; He, Y.; Ding, M.; Wang, Y.; Zhong, J. Nanoimaging of food proteins by atomic force microscopy. Part II: Components, imaging modes, observation ways, and research types. Trends Food Sci. Technol. 2018. [Google Scholar] [CrossRef]

- Shi, C.; He, Y.; Ding, M.; Wang, Y.; Zhong, J. Nanoimaging of food proteins by atomic force microscopy. Part I: Components, imaging modes, observation ways, and research types. Trends Food Sci. Technol. 2018, 0–1. [Google Scholar] [CrossRef]

- Li, N.; Tang, S.; Rao, Y.; Qi, J.; Zhang, Q.; Yuan, D. Peroxymonosulfate enhanced antibiotic removal and synchronous electricity generation in a photocatalytic fuel cell. Electrochim. Acta 2019, 298, 59–69. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, D.; Rao, Y.; Li, M.; Shi, G.; Gu, J.; Zhang, T. Percarbonate promoted antibiotic decomposition in dielectric barrier discharge plasma. J. Hazard. Mater. 2019, 366, 669–676. [Google Scholar] [CrossRef] [PubMed]

- Kang, L.; Du, H.L.; Du, X.; Wang, H.T.; Ma, W.L.; Wang, M.L.; Zhang, F.B. Study on dye wastewater treatment of tunable conductivity solid-waste-based composite cementitious material catalyst. Desalin. Water Treat. 2018, 125, 296–301. [Google Scholar] [CrossRef]

- Voyant, C.; Notton, G.; Kalogirou, S.; Nivet, M.L.; Paoli, C.; Motte, F.; Fouilloy, A. Machine learning methods for solar radiation forecasting: A review. Renew. Energy 2017, 105, 569–582. [Google Scholar] [CrossRef]

- Liu, X.; He, Y.; Fu, H.; Chen, B.; Wang, M.; Wang, Z. How Environmental Protection Motivation Influences on Residents’ Recycled Water Reuse Behaviors: A Case Study in Xi’an City. Water 2018, 10, 1282. [Google Scholar] [CrossRef]

- Liu, G.; Chen, B.; Jiang, S.; Fu, H.; Wang, L.; Jiang, W.; Liu, G.; Chen, B.; Jiang, S.; Fu, H.; et al. Double Entropy Joint Distribution Function and Its Application in Calculation of Design Wave Height. Entropy 2019, 21, 64. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, S.; Zhang, Z.; Yurchenko, D. High-performance piezoelectric wind energy harvester with Y-shaped attachments. Energy Convers. Manag. 2019, 181, 645–652. [Google Scholar] [CrossRef]

- Wang, J.; Tang, L.; Zhao, L.; Zhang, Z. Efficiency investigation on energy harvesting from airflows in HVAC system based on galloping of isosceles triangle sectioned bluff bodies. Energy 2019, 172, 1066–1078. [Google Scholar] [CrossRef]

- Yang, G.; Wang, J.; Zhang, H.; Jia, H.; Zhang, Y.; Gao, F. Applying bio-electric field of microbial fuel cell-upflow anaerobic sludge blanket reactor catalyzed blast furnace dusting ash for promoting anaerobic digestion. Water Res. 2019, 149, 215–224. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Li, Y.P. A flexible-possibilistic stochastic programming method for planning municipal-scale energy system through introducing renewable energies and electric vehicles. J. Clean. Prod. 2019, 207, 772–787. [Google Scholar] [CrossRef]

- Yu, L.; Li, Y.P.; Huang, G.H. Planning municipal-scale mixed energy system for stimulating renewable energy under multiple uncertainties—The City of Qingdao in Shandong Province, China. Energy 2019, 166, 1120–1133. [Google Scholar] [CrossRef]

- Eichler, U.; Brändle, M.; Sauer, J. Predicting Absolute and Site Specific Acidities for Zeolite Catalysts by a Combined Quantum Mechanics/Interatomic Potential Function Approach. J. Phys. Chem. B 2002, 101, 10035–10050. [Google Scholar] [CrossRef]

- Zurek, E.; Grochala, W. Predicting crystal structures and properties of matter under extreme conditions via quantum mechanics: The pressure is on. Phys. Chem. Chem. Phys. 2015, 17, 2917–2934. [Google Scholar] [CrossRef] [PubMed]

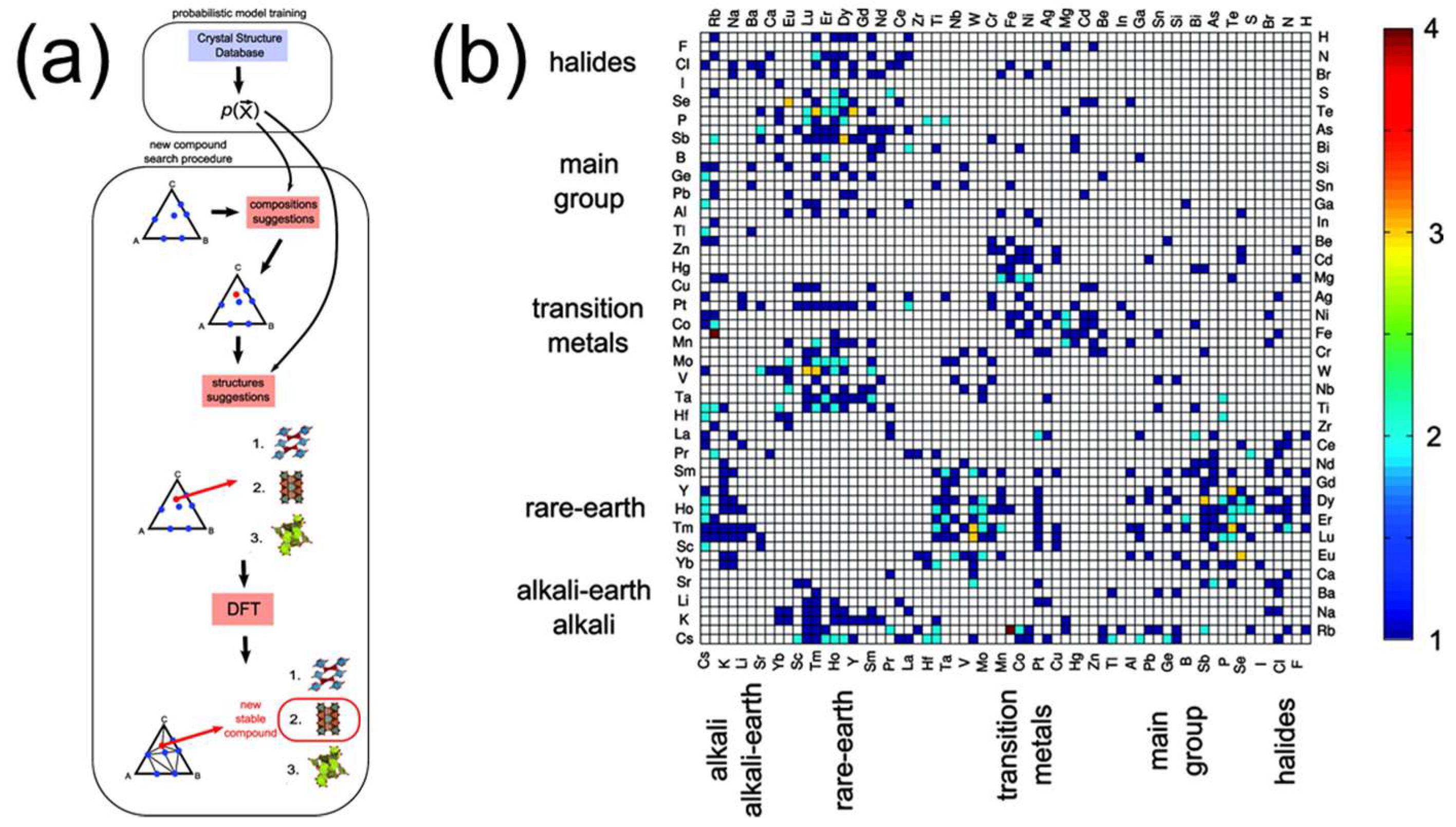

- Fischer, C.C.; Tibbetts, K.J.; Morgan, D.; Ceder, G. Predicting crystal structure by merging data mining with quantum mechanics. Nat. Mater. 2006, 5, 641. [Google Scholar] [CrossRef] [PubMed]

- Ceder, G.; Morgan, D.; Fischer, C.; Tibbetts, K.; Curtarolo, S. Data-mining-driven quantum mechanics for the prediction of structure. MRS Bull. 2006, 31, 981–985. [Google Scholar] [CrossRef]

- Kim, H.; Stumpf, A.; Kim, W. Analysis of an energy efficient building design through data mining approach. Autom. Constr. 2011, 20, 37–43. [Google Scholar] [CrossRef]

- Fan, C.; Xiao, F.; Wang, S. Development of prediction models for next-day building energy consumption and peak power demand using data mining techniques. Appl. Energy 2014, 127, 1–10. [Google Scholar] [CrossRef]

- Prakash Maran, J.; Priya, B. Comparison of response surface methodology and artificial neural network approach towards efficient ultrasound-assisted biodiesel production from muskmelon oil. Ultrason. Sonochem. 2015, 23, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.-M.; Hung, T.-H.; Liu, Y.-C.; Kuo, C.-H.; Shieh, C.-J. Green Synthesis of Ultraviolet Absorber 2-Ethylhexyl Salicylate: Experimental Design and Artificial Neural Network Modeling. Catalysts 2017, 7, 342. [Google Scholar] [CrossRef]

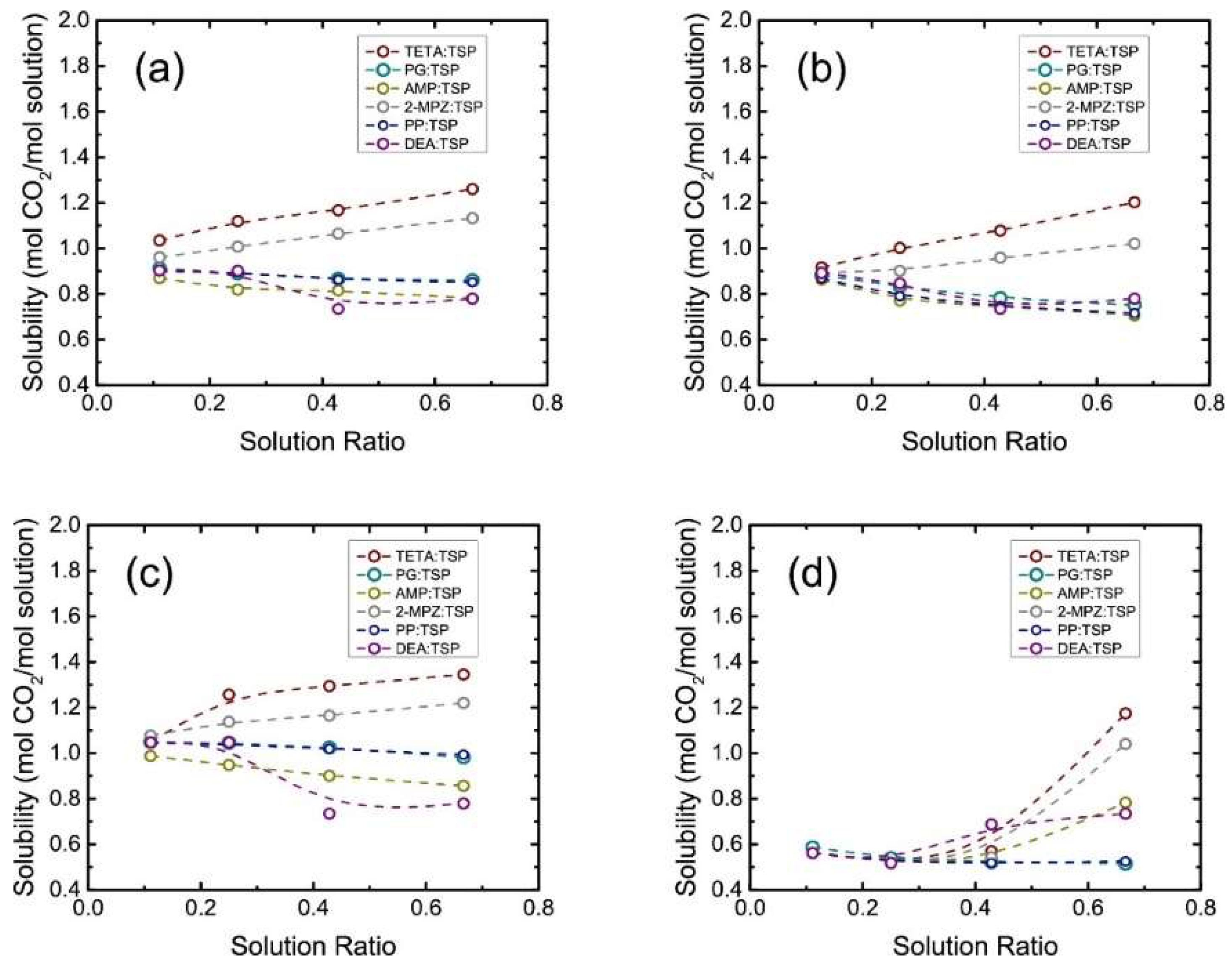

- Li, H.; Zhang, Z. Mining the intrinsic trends of CO2 solubility in blended solutions. J. CO2 Util. 2018, 26, 496–502. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, H.; Chang, H.; Pan, Z.; Luo, X. Machine Learning Predictive Framework for CO2 Thermodynamic Properties in Solution. J. CO2 Util. 2018, 26, 152–159. [Google Scholar] [CrossRef]

- Abdi-Khanghah, M.; Bemani, A.; Naserzadeh, Z.; Zhang, Z. Prediction of solubility of N-alkanes in supercritical CO2 using RBF-ANN and MLP-ANN. J. CO2 Util. 2018. [Google Scholar] [CrossRef]

- Soroush, E.; Shahsavari, S.; Mesbah, M.; Rezakazemi, M.; Zhang, Z. A robust predictive tool for estimating CO2 solubility in potassium based amino acid salt solutions. Chin. J. Chem. Eng. 2018, 26, 740–746. [Google Scholar] [CrossRef]

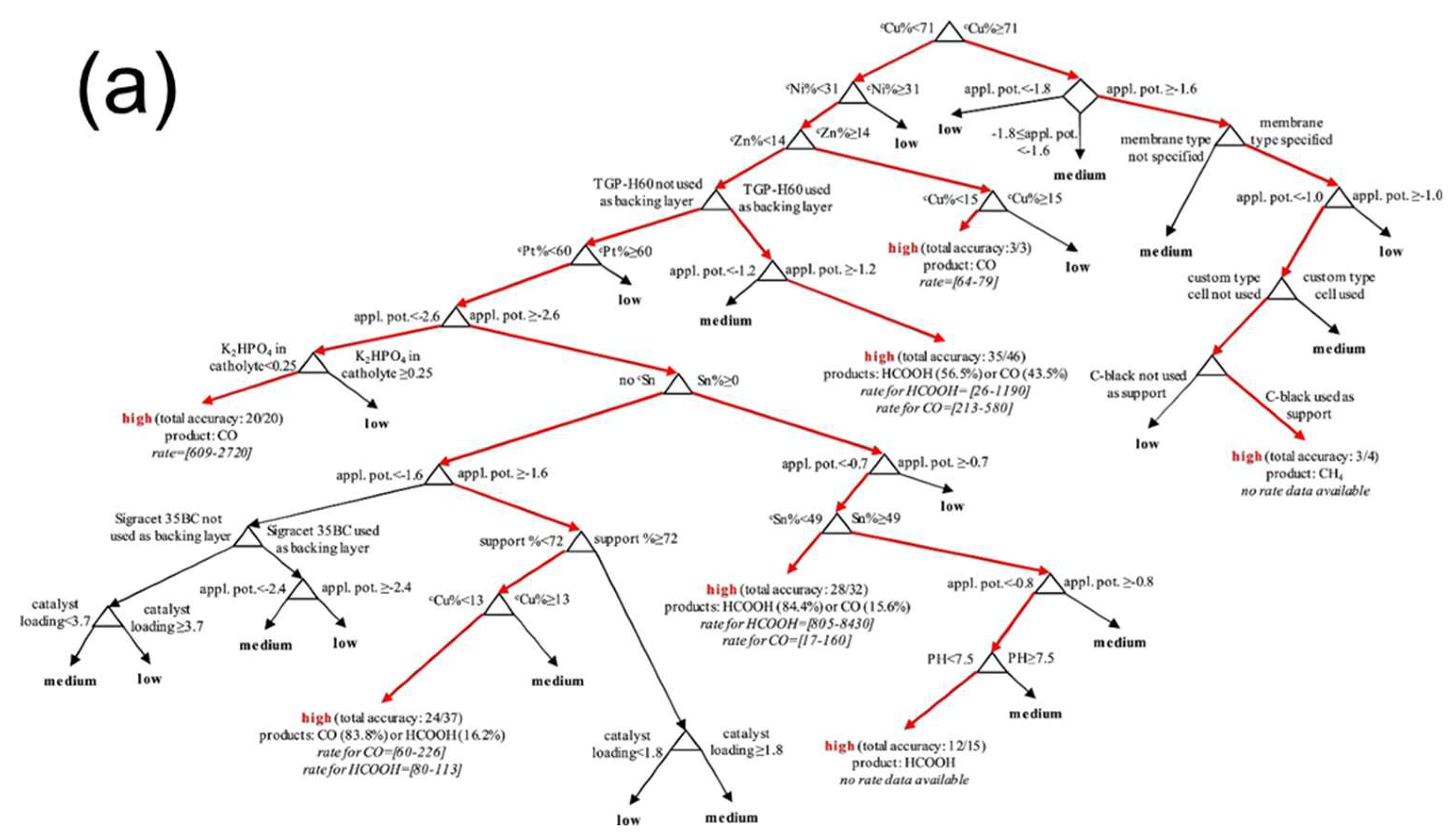

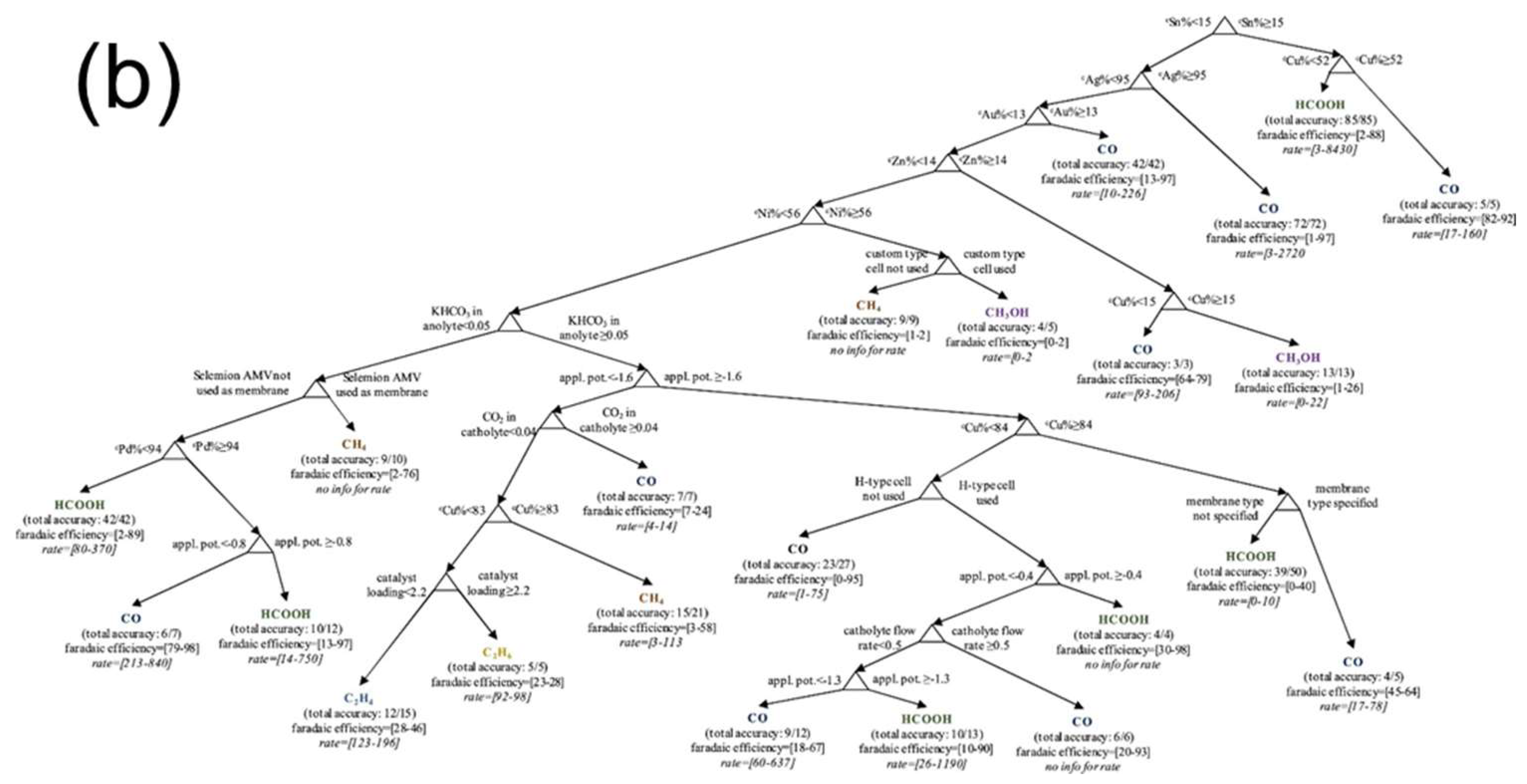

- Günay, M.E.; Türker, L.; Tapan, N.A. Decision tree analysis for efficient CO2 utilization in electrochemical systems. J. CO2 Util. 2018, 28, 83–95. [Google Scholar] [CrossRef]

- Günay, M.E.; Yildirim, R. Neural network analysis of selective CO oxidation over copper-based catalysts for knowledge extraction from published data in the literature. Ind. Eng. Chem. Res. 2011, 50, 12488–12500. [Google Scholar] [CrossRef]

- Davran-Candan, T.; Günay, M.E.; Yildirim, R. Structure and activity relationship for CO and O2 adsorption over gold nanoparticles using density functional theory and artificial neural networks. J. Chem. Phys. 2010, 132, 174113. [Google Scholar] [CrossRef] [PubMed]

- Hautier, G.; Fischer, C.C.; Jain, A.; Mueller, T.; Ceder, G. Finding natures missing ternary oxide compounds using machine learning and density functional theory. Chem. Mater. 2010, 22, 3762–3767. [Google Scholar] [CrossRef]

- Li, H.; Shin, K.; Henkelman, G. Effects of Ensembles, Ligand, and Strain on Adsorbate Binding to Alloy Surfaces. J. Chem. Phys. 2018, 149, 174705. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Luo, L.; Kunal, P.; Bonifacio, C.S.; Duan, Z.; Yang, J.C.; Humphrey, S.M.; Crooks, R.M.; Henkelman, G. Oxygen Reduction Reaction on Classically Immiscible Bimetallics: A Case Study of RhAu. J. Phys. Chem. C 2018, 122, 2712–2716. [Google Scholar] [CrossRef]

- Kim, C.; Chandrasekaran, A.; Huan, T.D.; Das, D.; Ramprasad, R. Polymer Genome: A Data-Powered Polymer Informatics Platform for Property Predictions. J. Phys. Chem. C 2018, 122, 17575–17585. [Google Scholar] [CrossRef]

- Graser, J.; Kauwe, S.K.; Sparks, T.D. Machine Learning and Energy Minimization Approaches for Crystal Structure Predictions: A Review and New Horizons. Chem. Mater. 2018, 30, 3601–3612. [Google Scholar] [CrossRef]

- Mansouri Tehrani, A.; Oliynyk, A.O.; Parry, M.; Rizvi, Z.; Couper, S.; Lin, F.; Miyagi, L.; Sparks, T.D.; Brgoch, J. Machine Learning Directed Search for Ultraincompressible, Superhard Materials. J. Am. Chem. Soc. 2018, 140, 9844–9853. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Kang, L.; Li, H. Enhancement of photocatalytic hydrogen production of BiFeO3 by Gd3+ doping. Ceram. Int. 2018, 45, 8017–8022. [Google Scholar] [CrossRef]

- Duan, C.; Huo, J.; Li, F.; Yang, M.; Xi, H. Ultrafast room-temperature synthesis of hierarchically porous metal–organic frameworks by a versatile cooperative template strategy. J. Mater. Sci. 2018, 53, 16276–16287. [Google Scholar] [CrossRef]

- Duan, C.; Li, F.; Xiao, J.; Liu, Z.; Li, C.; Xi, H. Rapid room-temperature synthesis of hierarchical porous zeolitic imidazolate frameworks with high space-time yield. Sci. China Mater. 2017, 60, 1205–1214. [Google Scholar] [CrossRef]

- Yin, K.; Chu, D.; Dong, X.; Wang, C.; Duan, J.A.; He, J. Femtosecond laser induced robust periodic nanoripple structured mesh for highly efficient oil-water separation. Nanoscale 2017, 9, 14229–14235. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Pang, J.; Li, L.; Zhou, S.; Li, Y.; Zhang, T. Synthesis of hydrophobic carbon nanotubes/reduced graphene oxide composite films by flash light irradiation. Front. Chem. Sci. Eng. 2018, 12, 376–382. [Google Scholar] [CrossRef]

- Kai, W.; Li, L.; Lan, Y.; Dong, P.; Xia, G. Application Research of Chaotic Carrier Frequency Modulation Technology in Two-Stage Matrix Converter. Math. Probl. Eng. 2019, 2019, 8. [Google Scholar] [CrossRef]

- Kai, W.; Shengzhe, Z.; Yanting, Z.; Jun, R.; Liwei, L.; Yong, L. Synthesis of Porous Carbon by Activation Method and its Electrochemical Performance. Int. J. Electrochem. Sci. 2018, 13, 10766–10773. [Google Scholar] [CrossRef]

- Duan, C.; Cao, Y.; Hu, L.; Fu, D.; Ma, J. Synergistic effect of TiF3 on the dehydriding property of α-AlH3 nano-composite. Mater. Lett. 2019, 238, 254–257. [Google Scholar] [CrossRef]

- Duan, C.W.; Hu, L.X.; Ma, J.L. Ionic liquids as an efficient medium for the mechanochemical synthesis of α-AlH3 nano-composites. J. Mater. Chem. A 2018, 6, 6309–6318. [Google Scholar] [CrossRef]

- Yin, K.; Yang, S.; Dong, X.; Chu, D.; Gong, X.; Duan, J.-A. Femtosecond laser fabrication of shape-gradient platform: Underwater bubbles continuous self-driven and unidirectional transportion. Appl. Surf. Sci. 2018, 471, 999–1004. [Google Scholar] [CrossRef]

- Yin, K.; Yang, S.; Dong, X.; Chu, D.; Duan, J.A.; He, J. Robust laser-structured asymmetrical PTFE mesh for underwater directional transportation and continuous collection of gas bubbles. Appl. Phys. Lett. 2018, 112, 243701. [Google Scholar] [CrossRef]

- Constantinou, L.; Gani, R. New group contribution method for estimating properties of pure compounds. AIChE J. 1994, 40, 1697–1710. [Google Scholar] [CrossRef]

- Behler, J.; Parrinello, M. Generalized neural-network representation of high-dimensional potential-energy surfaces. Phys. Rev. Lett. 2007, 98, 146401. [Google Scholar] [CrossRef] [PubMed]

- Kalogirou, S.A. Optimization of solar systems using artificial neural-networks and genetic algorithms. Appl. Energy 2004, 77, 383–405. [Google Scholar] [CrossRef]

- Kumar, M.; Husian, M.; Upreti, N.; Gupta, D. Genetic Algorithm: Review and Application. Int. J. Inf. Technol. Knowl. Manag. 2010, 2, 451–454. [Google Scholar]

- Iba, H.; Aranha, C.C. Adaptation, Learning, and Optimization; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Whitley, D. A genetic algorithm tutorial. Stat. Comput. 1994, 4, 65–85. [Google Scholar] [CrossRef]

- Li, H.; Liu, Z.; Liu, K.; Zhang, Z. Predictive Power of Machine Learning for Optimizing Solar Water Heater Performance: The Potential Application of High-Throughput Screening. Int. J. Photoenergy 2017, 2017, 4194251. [Google Scholar] [CrossRef]

- Li, H.; Liu, Z. Performance Prediction and Optimization of Solar Water Heater via a Knowledge-Based Machine Learning Method. In Handbook of Research on Power and Energy System Optimization; IGI Global: Hershey, PA, USA, 2018; pp. 55–74. [Google Scholar] [Green Version]

- Tetko, I.V.; Livingstone, D.J.; Luik, A.I. Neural Network Studies. 1. Comparison of Overfitting and Overtraining. J. Chem. Inf. Comput. Sci. 1995, 35, 826–833. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhang, Z.; Zhao, Z.-Z. Data-Mining for Processes in Chemistry, Materials, and Engineering. Processes 2019, 7, 151. https://doi.org/10.3390/pr7030151

Li H, Zhang Z, Zhao Z-Z. Data-Mining for Processes in Chemistry, Materials, and Engineering. Processes. 2019; 7(3):151. https://doi.org/10.3390/pr7030151

Chicago/Turabian StyleLi, Hao, Zhien Zhang, and Zhe-Ze Zhao. 2019. "Data-Mining for Processes in Chemistry, Materials, and Engineering" Processes 7, no. 3: 151. https://doi.org/10.3390/pr7030151