The Seepage Control of the Tunnel Excavated in High-Pressure Water Condition Using Multiple Times Grouting Method

Abstract

:1. Introduction

2. Materials and Methods

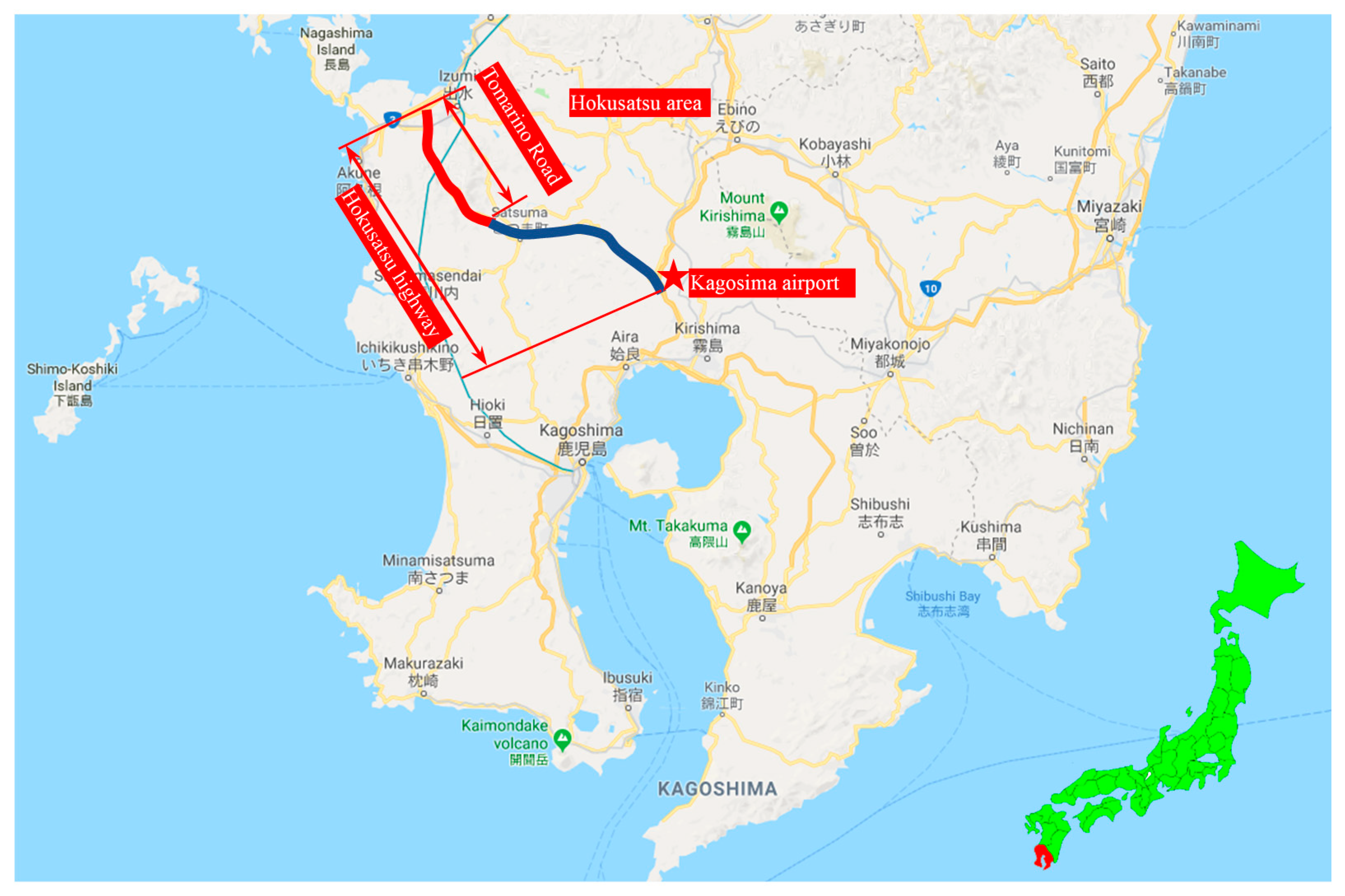

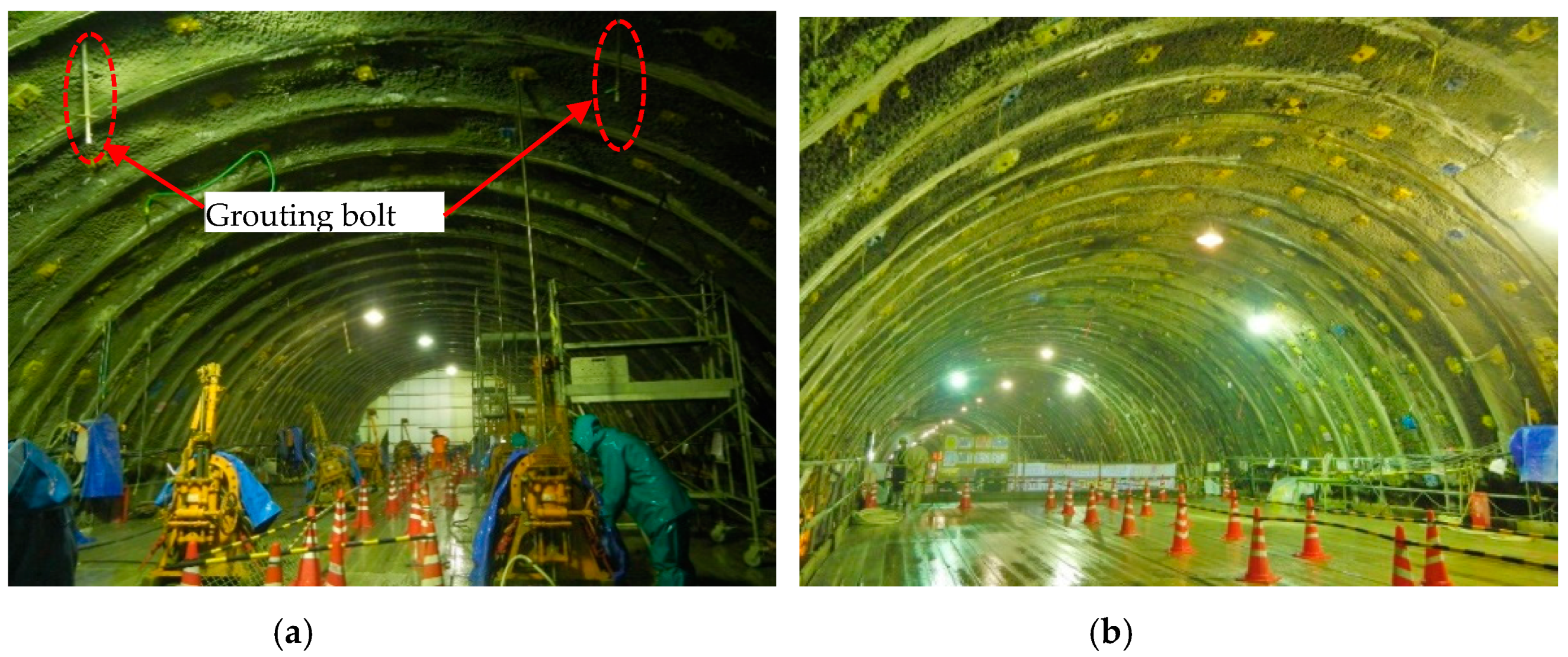

2.1. Description of the Hokusatsu Tunnel

2.2. Numerical Simulation of Groundwater Control in the Hokusatsu Tunnel

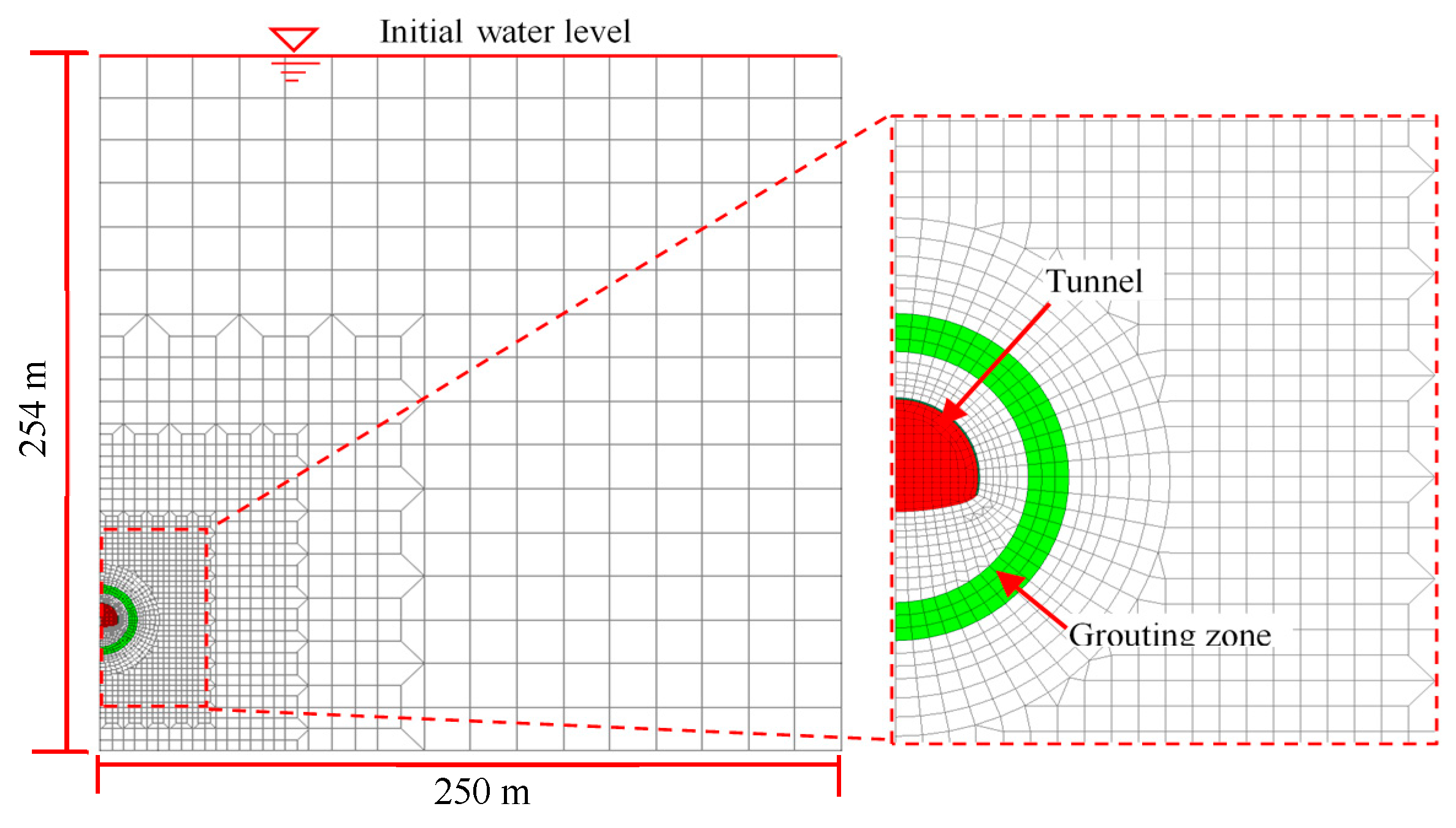

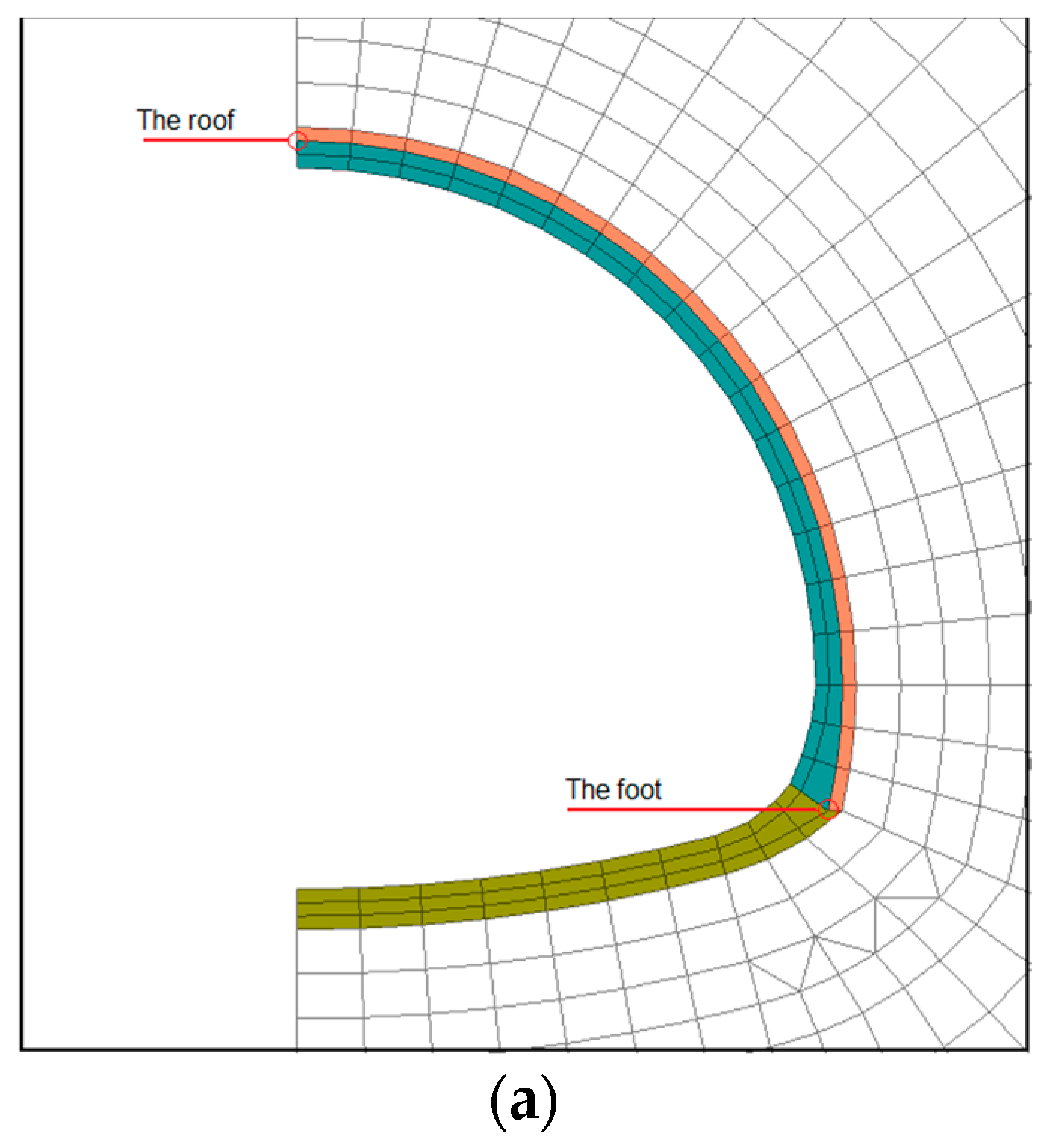

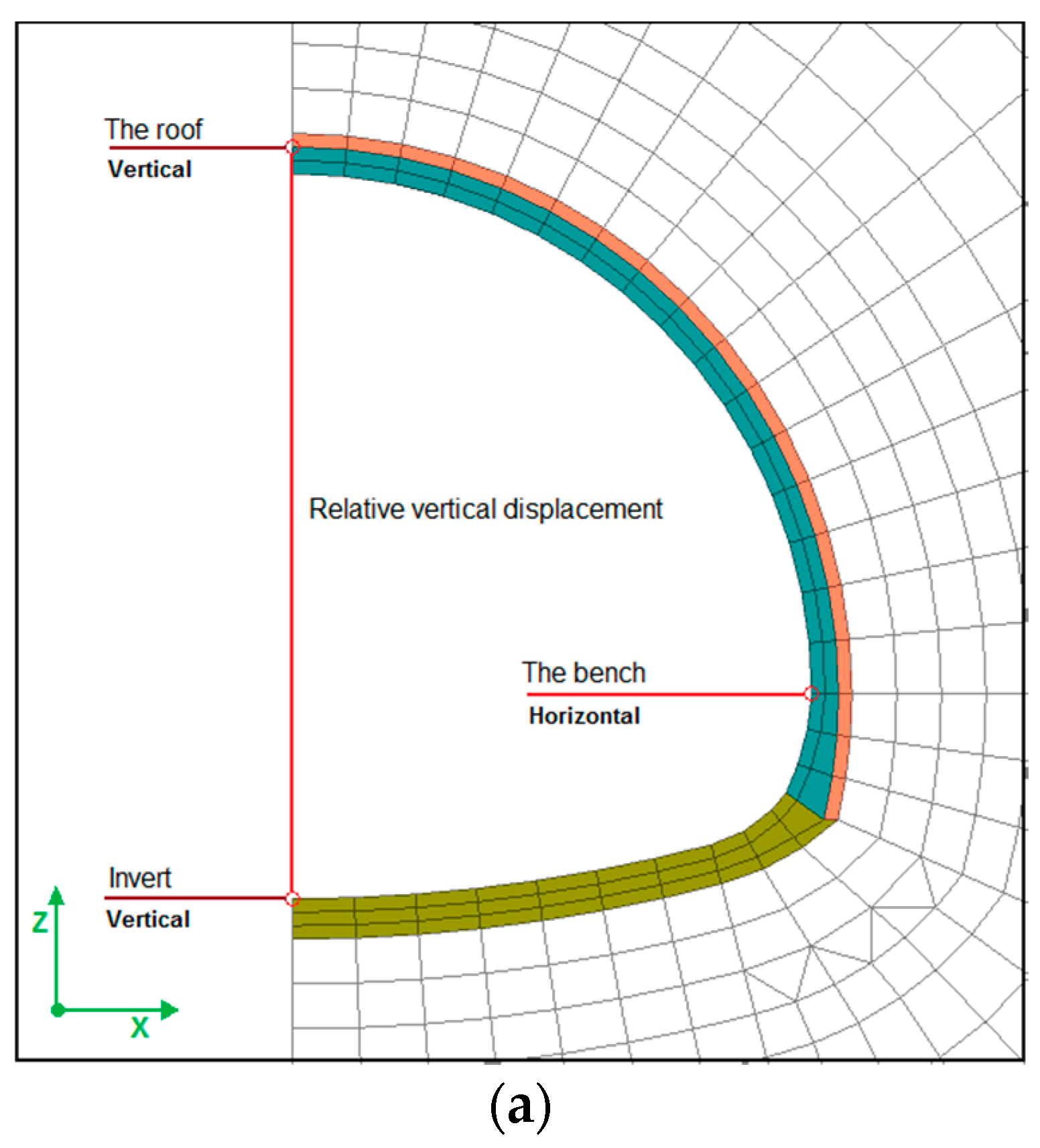

2.2.1. Numerical Model and Boundary Conditions

2.2.2. Rock Parameters and Reinforced Concrete Lining Properties

2.2.3. Numerical Simulation Cases and Procedure

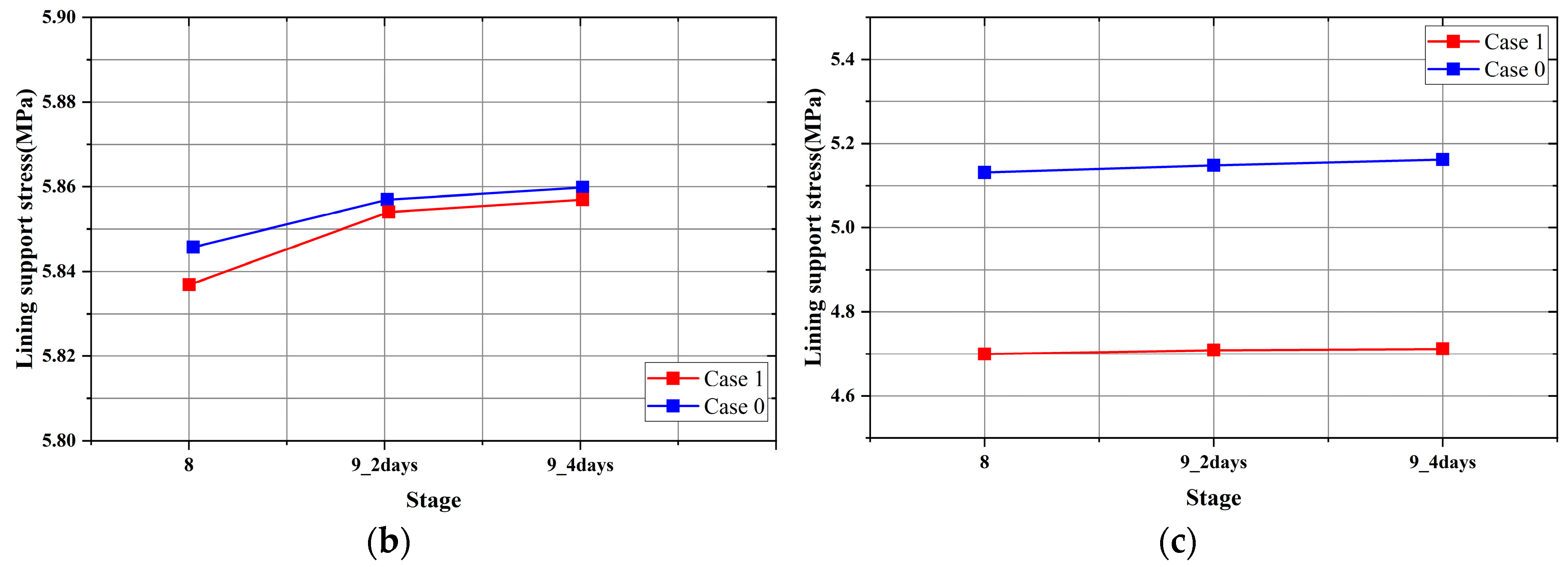

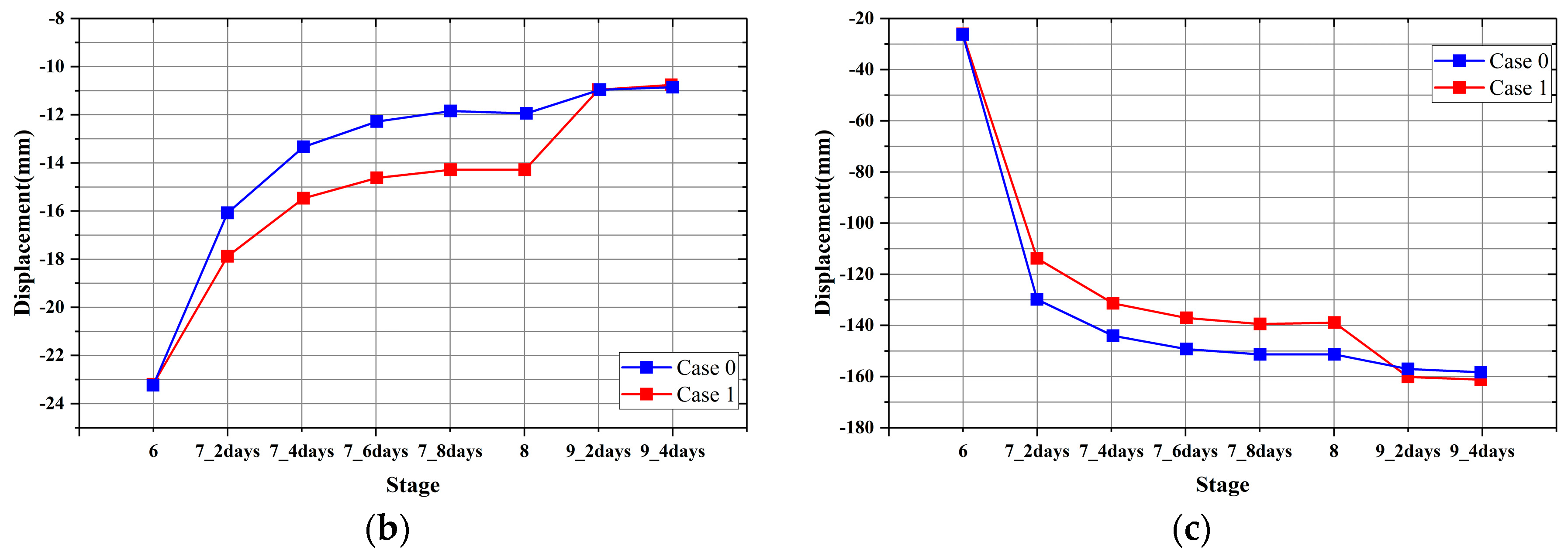

3. Results and Discussion

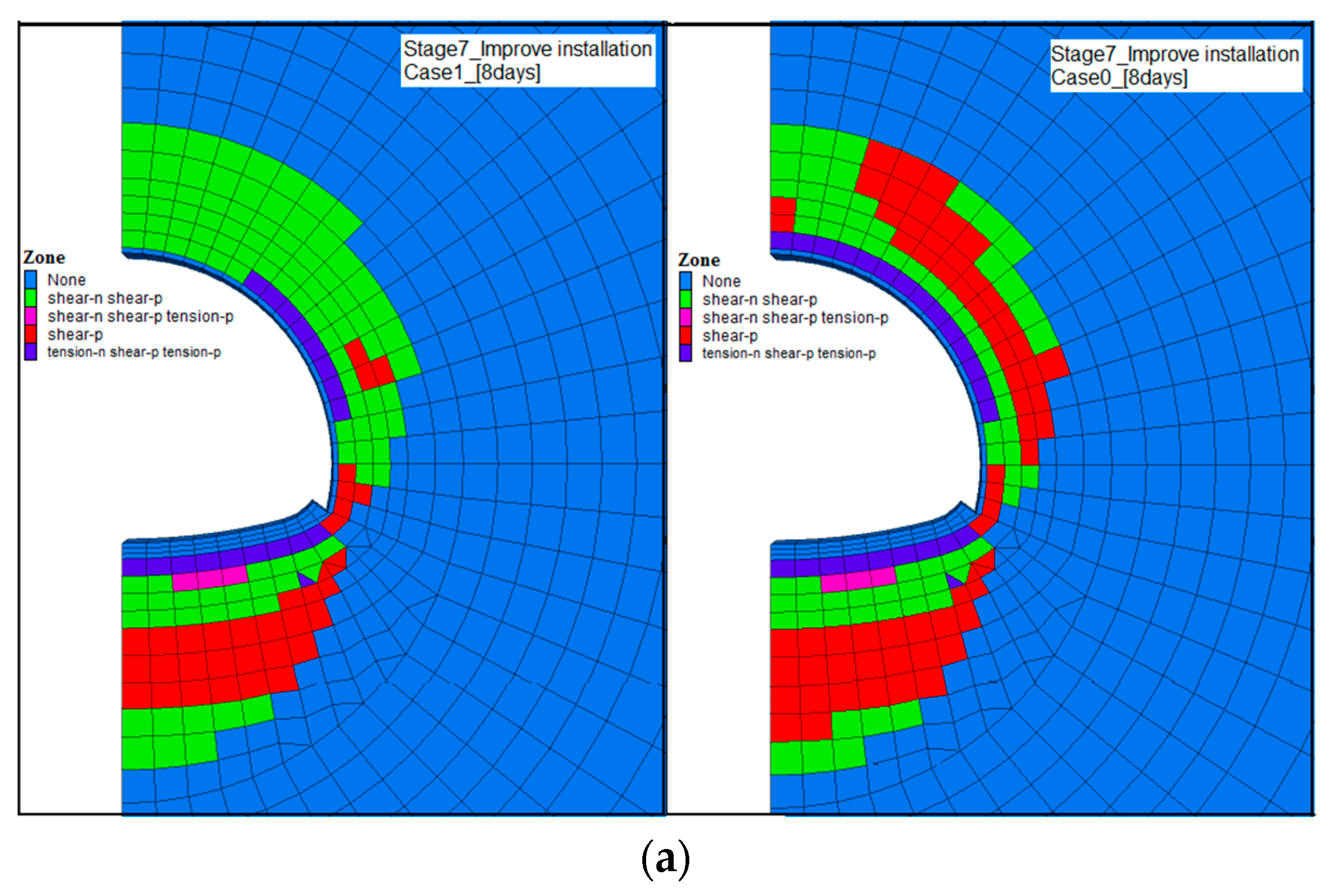

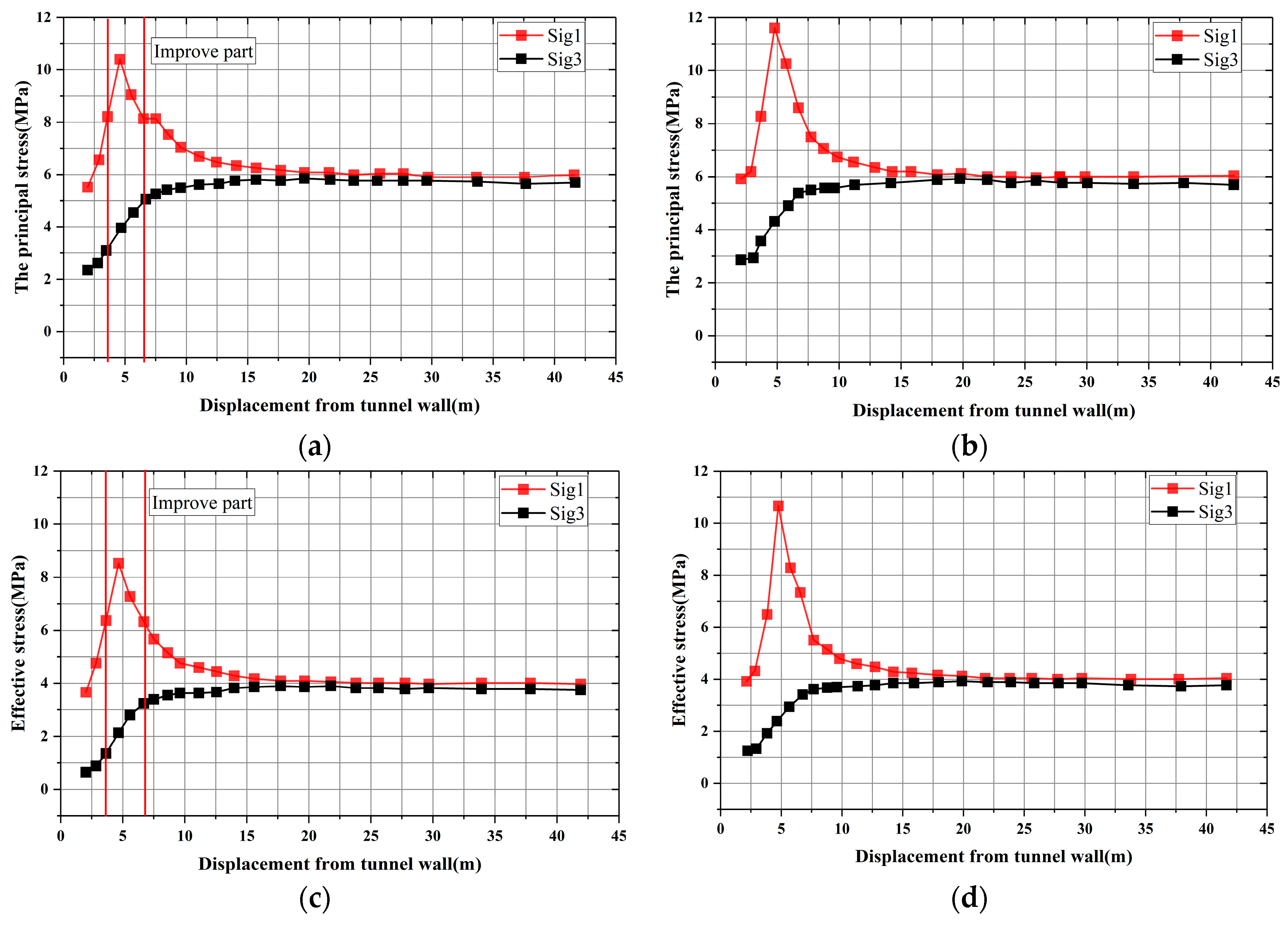

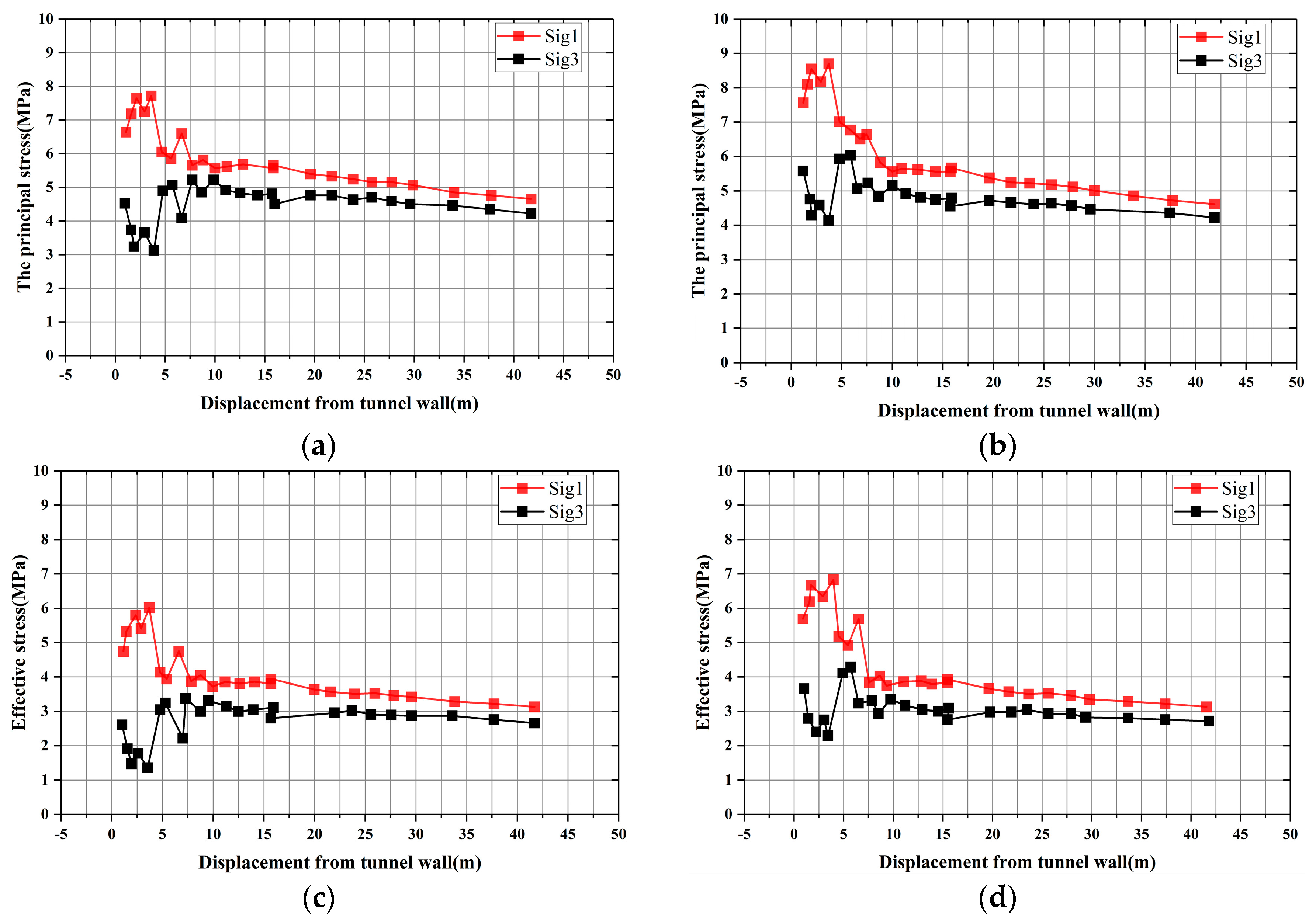

3.1. The Failure Behavior Surrounding the Tunnel

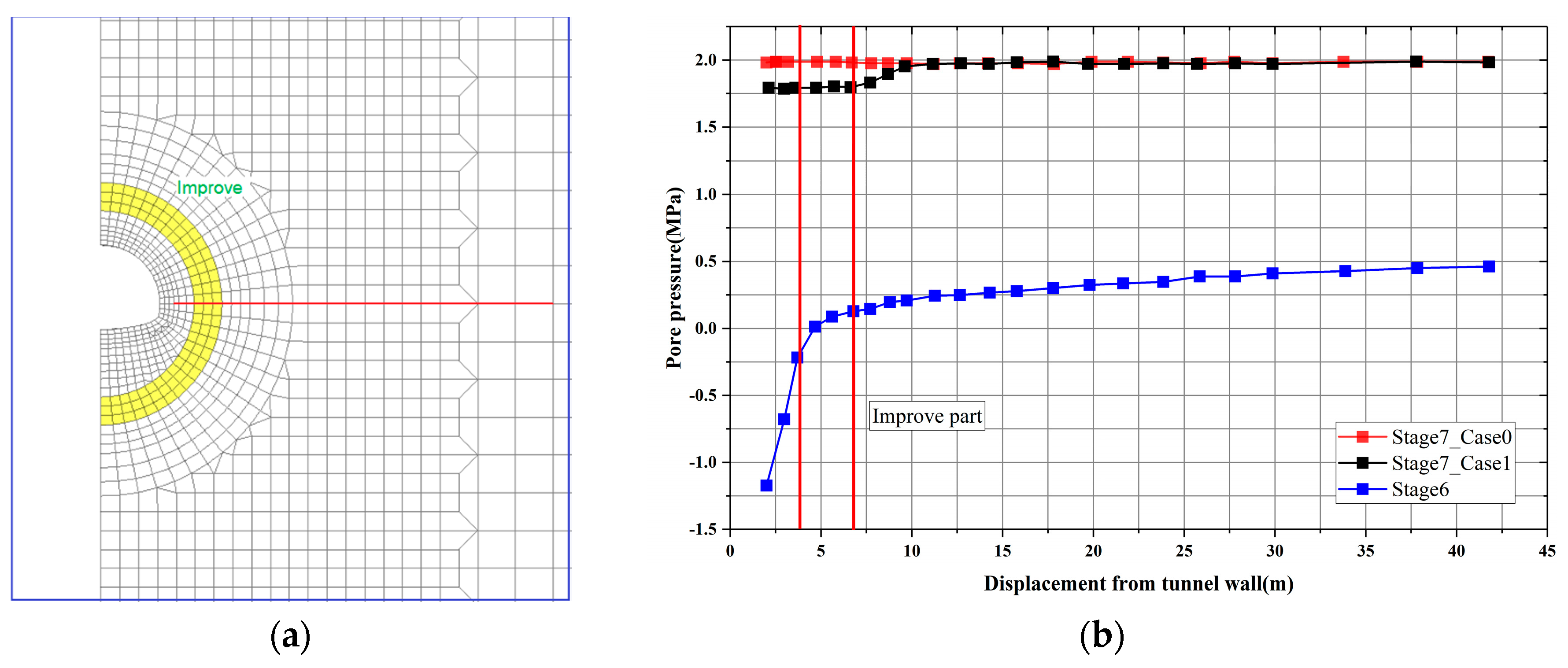

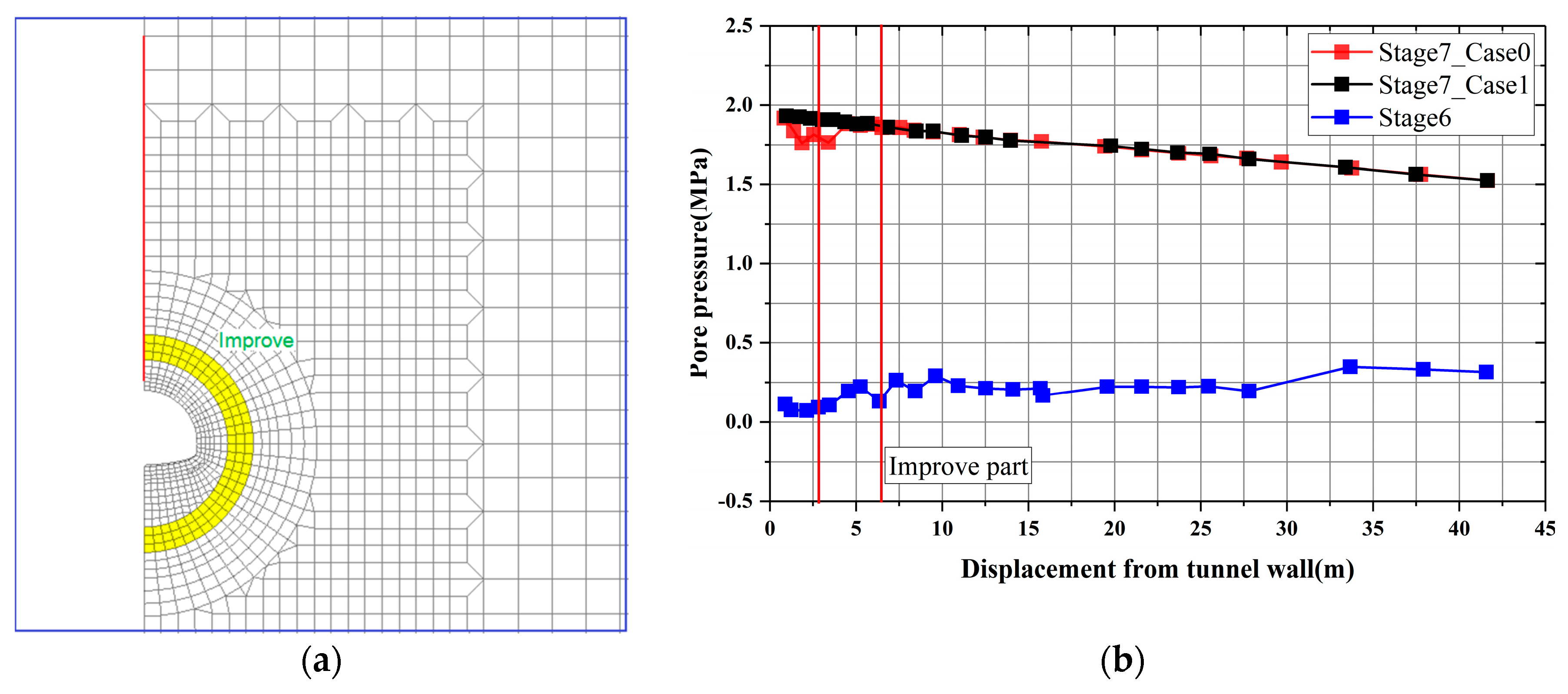

3.2. The Deformation and Pore Pressure Distribution around the Tunnel

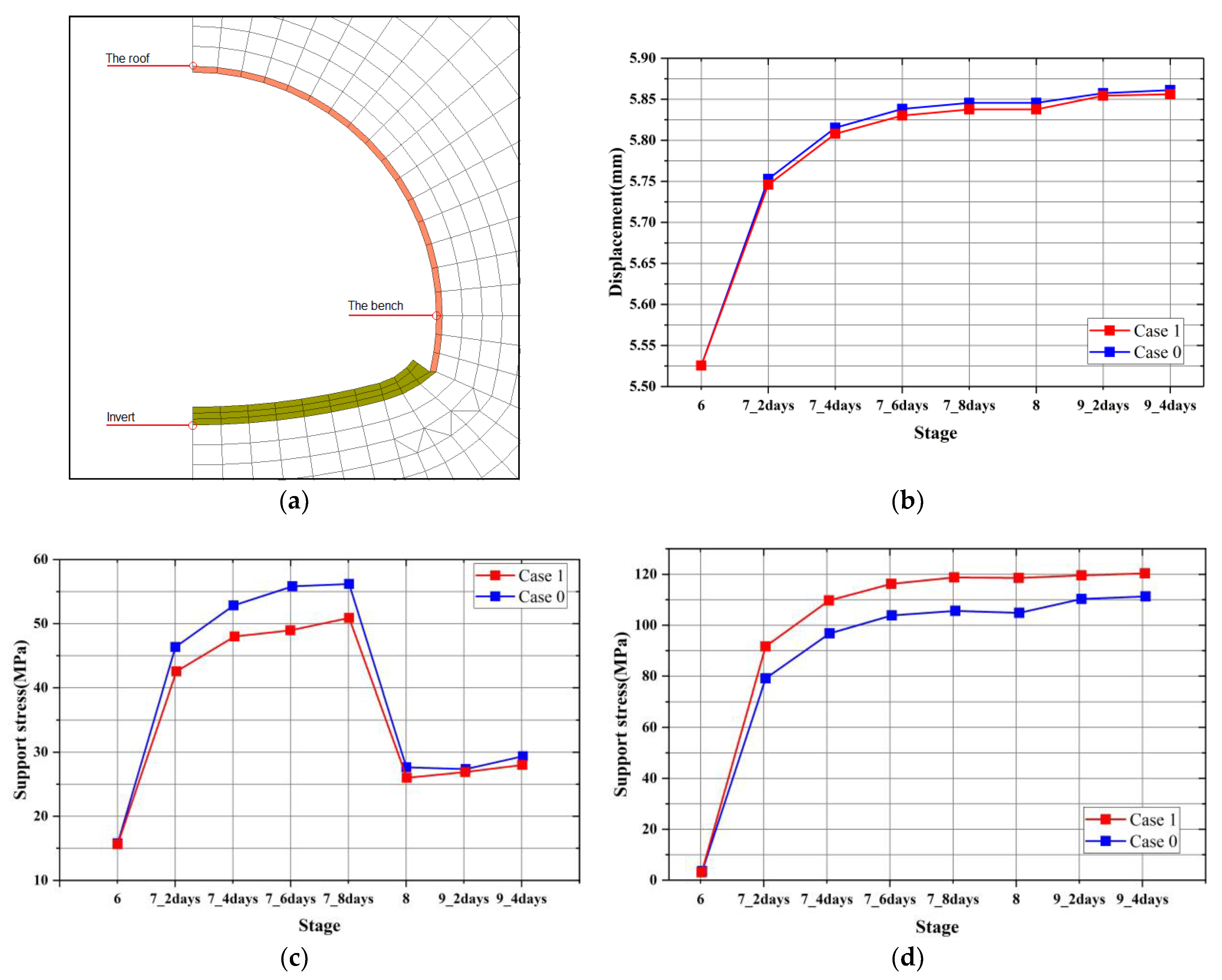

3.3. Validation with Field Application

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.; Wang, M.; Zhang, M. Theoretical and experimental study of external water pressure on tunnel lining in controlled drainage under high water level. Tunn. Undergr. Space Technol. 2008, 23, 552–560. [Google Scholar] [CrossRef]

- Arjnoi, P.; Jeong, J.H.; Kim, C.Y.; Park, K.H. Effect of drainage conditions on porewater pressure distributions and lining stresses in drained tunnels. Tunn. Undergr. Space Technol. 2009, 24, 376–389. [Google Scholar] [CrossRef]

- Zingg, S.; Anagnostou, G. An investigation into efficient drainage layouts for the stabilization of tunnel faces in homogeneous ground. Tunn. Undergr. Space Technol. 2016, 58, 49–73. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, S.; Guo, W. Physical simulation of high-pressure water inrush through the floor of a deep mine. Mine Water Environ. 2017, 36, 542–549. [Google Scholar] [CrossRef]

- Li, D.Y.; Li, X.B.; Charlie, C.L. Case studies of groundwater flow into tunnels and an innovative water-gathering system for water drainage. Tunn. Undergr. Space Technol. 2009, 24, 260–268. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, W.; Li, Y. Experimental simulation of fault water inrush channel evolution in a coal mine floor. Mine Water Environ. 2017, 36, 443–451. [Google Scholar] [CrossRef]

- Kucuk, K.; Genis, M.; Onargan, T.; Aksoy, C.O.; Guney, A.; Altındag, R. Chemical injection to prevent building damage induced by groundwater drainage from shallow tunnels. Int. J. Rock Mech. Min. Sci. 2009, 46, 1136–1143. [Google Scholar] [CrossRef]

- Piotrowski, J.A. Subglacial hydrology in north-western Germany during the last glaciation: Groundwater flow, tunnel valleys and hydrological cycles. Quat. Sci. Rev. 1997, 16, 169–185. [Google Scholar] [CrossRef]

- Maleki, M.R. Groundwater Seepage Rate (GSR). a new method for prediction of groundwater inflow into jointed rock tunnels. Tunn. Undergr. Space Technol. 2018, 71, 505–517. [Google Scholar] [CrossRef]

- Lee, S.W.; Jung, J.W.; Nam, S.W.; Lee, I.M. The influence of seepage forces on ground reaction curve of circular opening. Tunn. Undergr. Space Technol. 2007, 21, 28–38. [Google Scholar] [CrossRef]

- Polubarinova-Kochina, P.Y. Russian Translation. (Book Reviews: Theory of Ground Water Movement). Science 1963, 139, 820–821. [Google Scholar] [CrossRef]

- Sundaram, P.N.; Goodman, R.E.; Wang, C.Y. Precursory and coseismic water-pressure variations in stick-slip experiments. Geology 1976, 4, 108–110. [Google Scholar] [CrossRef]

- Freeze, R.A.; Witherspoon, P.A. Theoretical analysis of regional groundwater flow: 2. Effect of water-table configuration and subsurface permeability variation. Water Resour. Res. 1967, 3, 623–634. [Google Scholar] [CrossRef]

- Custodio, E.; Galofre, A. Hidráulica de captaciones de agua subterránea. Hidrología Subterránea 1983, 2, 91–99. [Google Scholar]

- Zhang, L.; Franklin, J.A. Prediction of water flow into rock tunnels: An analytical solution assuming an hydraulic conductivity gradient. Int. J. Rock Mech. Min. Sci. 1993, 30, 37–46. [Google Scholar] [CrossRef]

- Lei, S. An analytical solution for steady flow into a ttonnel. Groundwater 1999, 37, 23–26. [Google Scholar] [CrossRef]

- Toth, J. A theoretical analysis of groundwater flow in small drainage basins. J. Geophys. Res. 1963, 68, 4795–4812. [Google Scholar] [CrossRef]

- Battermann, A.; Gablonsky, J.M.; Patrick, A. Solution of a groundwater control problem with implicit filtering. Optim. Eng. 2002, 3, 189–199. [Google Scholar] [CrossRef]

- Davis, G.M.; Horswill, P. Groundwater control and stability in an excavation in Magnesian Limestone near Sunderland, NE England. Eng. Geol. 2002, 66, 1–18. [Google Scholar] [CrossRef]

- Fahimifar, A.; Zareifard, M.R. A new elasto-plastic solution for analysis of underwater tunnels considering strain-dependent permeability. Struct. Infrastruct. Eng. 2014, 10, 1432–1450. [Google Scholar] [CrossRef]

- Cesano, D.; Bagtzoglou, A.C.; Olofsson, B. Quantifying fractured rock hydraulic heterogeneity and groundwater inflow prediction in underground excavations: The heterogeneity index. Groundwater 2003, 18, 19–34. [Google Scholar] [CrossRef]

- Perrochet, P.; Dematteis, A. Modeling transient discharge into a tunnel drilled in a heterogeneous formation. Groundwater 2007, 45, 786–790. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.H.; Lu, C.C. A semi-analytical method for analyzing the tunnel water inflow. Tunn. Undergr. Space Technol. 2007, 22, 39–46. [Google Scholar] [CrossRef]

- Park, K.H.; Owatsiriwong, A.; Lee, J.G. Analytical solution for steady-state groundwater inflow into a drained circular tunnel in a semi-infinite aquifer: A revisit. Tunn. Undergr. Space Technol. 2008, 23, 206–209. [Google Scholar] [CrossRef]

- Mohamed, E.T. Circular tunnel in a semi-infinite aquifer. Tunn. Undergr. Space Technol. 2003, 18, 49–55. [Google Scholar] [CrossRef]

- Kolymbas, D.; Wagner, P. Groundwater ingress to tunnels–the exact analytical solution. Tunn. Undergr. Space Technol. 2007, 22, 23–27. [Google Scholar] [CrossRef]

- Lee, I.M.; Nam, S.W.; Ahn, J.H. Effect of seepage forces on tunnel face stability. Can. Geotech. J. 2003, 40, 342–350. [Google Scholar] [CrossRef]

- Shin, J.H.; Potts, D.M.; Zdravkovic, L. The effect of pore-water pressure on NATM tunnel linings in decomposed granite soil. Can. Geotech. J. 2005, 42, 1585–1599. [Google Scholar] [CrossRef]

- Huangfu, M.; Wang, M.S.; Tan, Z.S.; Wang, X.Y. Analytical solutions for steady seepage into an underwater circular tunnel. Tunn. Undergr. Space Technol. 2010, 25, 391–396. [Google Scholar] [CrossRef]

- Carranza, T.C.; Zhao, J. Analytical and numerical study of the effect of water pressure on the mechanical response of cylindrical lined tunnels in elastic and elasto-plastic porous media. Int. J. Rock Mech. Min. Sci. 2009, 46, 531–547. [Google Scholar] [CrossRef]

- Fahimifar, A.; Zareifard, M.R. A theoretical solution for analysis of tunnels below groundwater considering the hydraulic–mechanical coupling. Tunn. Undergr. Space Technol. 2009, 24, 634–646. [Google Scholar] [CrossRef]

- Shin, Y.J.; Song, K.I.; Lee, I.M.; Cho, G.C. Interaction between tunnel supports and ground convergence—Consideration of seepage forces. Int. J. Rock Mech. Min. Sci. 2011, 48, 394–405. [Google Scholar] [CrossRef]

- Nam, S.W.; Bobet, A. Liner stresses in deep tunnels below the water table. Tunn. Undergr. Space Technol. 2006, 21, 626–635. [Google Scholar] [CrossRef]

- Itasca. FLAC3D Software Version 5.01, Advanced Three Dimensional Continuum Modelling for Geotechnical Analysis of Rock, Soil and Structural Support. In User’s Manual 2015. Available online: http://www.itasca.co.uk/sites/itascacg.com/files/ICG13-BRO-FLAC3D-501-101.pdf (accessed on 2 September 2018).

| Rock | Improve | |

|---|---|---|

| Modulus of Elasticity (GPa) | 1000 | |

| Poisson’s ratio | 0.4 | |

| Density (kN/m3) | 27 | |

| Cohesion (MPa) | 0.4 | |

| Friction angle (deg) | 35 | |

| Porosity | 0.2 | |

| Permeability (cm/sec) | 4 × 10−4 | 4 × 10−6 |

| Shotcrete Layer | Lining Invert | Beam | Rock Bolts | |

|---|---|---|---|---|

| Modulus of Elasticity (MPa) | 4000 22,000 (hardened) | 22,000 | 200,000 | 210,000 |

| Poisson’s ratio | 0.2 | 0.2 | 0.3 | – |

| Thickness (m) | 0.15 | 0.3 | – | – |

| Permeability (cm/sec) | 4 × 10−8 | 4 × 10−8 | – | – |

| Sectional area (m2) | – | – | 30 × 10−4 | 3.0 × 10−4 |

| Second axial moment of area (m4) | – | – | 839 × 10−8 | – |

| Summary | Calculation Mode | Content | |

|---|---|---|---|

| Stage 1 | Initial equilibrium | – | Calculation for the stress distribution of surrounding rock before excavation. |

| Stage 2 | Top heading excavation | Mechanical | Excavation for the top heading of the tunnel and release of the stress by 40%. |

| Stage 3 | Top heading drainage | Hydraulic–mechanical coupling | The pore pressure along the top heading is set to 0 MPa, the model begins to discharge (4 days) 2. |

| Stage 4 | Shotcrete Steel support | Mechanical | Shotcrete layer and set steel support (beam, rock bolt) 1, release the stress by 100%. |

| Stage 5 | Lower bench excavation | Mechanical | Excavation for the lower bench and release the stress of the invert part by 40%. |

| Stage 6 | Invert installation | Mechanical | Invert installation and release the stress of the invert by 100%. |

| Stage 7 | Improve installation | Hydraulic–mechanical coupling | Discharge the groundwater (8 days) and initiate improve part. |

| Stage 8 | Liner installation | Mechanical | Liner installation. |

| Stage 9 | Steady state | Hydraulic–mechanical coupling | The coupled, drained simulation is executed until the steady-state condition was reached for each case (4 days) 2. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, B.; Jiang, Y.; Okatsu, K.; Wu, X.; Teduka, J.; Aoki, K. The Seepage Control of the Tunnel Excavated in High-Pressure Water Condition Using Multiple Times Grouting Method. Processes 2018, 6, 159. https://doi.org/10.3390/pr6090159

Gong B, Jiang Y, Okatsu K, Wu X, Teduka J, Aoki K. The Seepage Control of the Tunnel Excavated in High-Pressure Water Condition Using Multiple Times Grouting Method. Processes. 2018; 6(9):159. https://doi.org/10.3390/pr6090159

Chicago/Turabian StyleGong, Bin, Yujing Jiang, Keisuke Okatsu, Xuezhen Wu, Jin Teduka, and Koichi Aoki. 2018. "The Seepage Control of the Tunnel Excavated in High-Pressure Water Condition Using Multiple Times Grouting Method" Processes 6, no. 9: 159. https://doi.org/10.3390/pr6090159