1. Introduction

Bulk materials find wide application across various industries, including pharmaceuticals, chemicals, paper, and textiles. They are used as intermediates in technological processes and often constitute finished products. Utilizing materials in bulk form facilitates transportation, storage, and processing [

1,

2,

3]. The agglomeration of granular materials contributes to the creation of conditions that promote the growth of microorganisms, thereby increasing the risk of material losses [

4,

5].

Classical methods of testing bulk materials of plant origin primarily involve evaluating their chemical parameters, such as determining chemical composition, reactivity, and hydrogen loss. Additionally, physical parameters, including the study of particle shape and structure, as well as the examination of technological properties like bulk density and powder flowability, are essential [

6]. It is worth noting that the storage conditions of the powder significantly influence these parameters. Among the most critical physical factors influencing changes in the properties of bulk materials, particularly those of technological importance such as flowability, moisture content stands out [

7,

8,

9,

10,

11]. Storing bulk materials like wheat flour and potato starch poses significant challenges for food manufacturers and suppliers. Maintaining proper storage conditions is crucial for ensuring the quality and safety of these products. Food powders prove highly sensitive to variations in process conditions [

12,

13]. Consequently, poorly adjusted parameters during production and storage can lead to the occurrence of undesirable phenomena, such as caking, abrasion, and segregation, impeding material processing [

2,

14,

15]. Among the aforementioned mechanisms, caking is considered as one of the most problematic phenomena that can occur at every stage of processing bulk raw materials. It is a process in which loose powder particles, influenced by various factors, begin to aggregate into larger agglomerates [

16,

17]. Inadequate storage or packaging parameters can transform an easily flowing powder into a less free-flowing state, forming aggregates composed of individual particles bound together that even promote the growth of microorganisms [

4,

5].

Powder agglomerates significantly disrupt the technological process and can, at times, lead to damage to the production lines. Restoring agglomerated material to a state suitable for reuse requires additional effort and generates extra costs. In many instances, caked material becomes unsuitable for further processes, resulting in losses for the company [

3,

18]. Clumping poses a serious problem in silos, with the main causes being fluctuations in humidity levels and external temperature. Additionally, the transport air, which forces the material into the tank, often has high humidity and is warm, increasing the risk of condensation on the surface of the stored powder. Consequently, some hygroscopic materials, such as flour or starch, can absorb water rapidly, leading to agglomerate formation. The presence of clumps in the stored material can cause disruptions during container emptying and, in some cases, even blockages preventing material removal [

19].

The appropriate storage temperature plays a crucial role in preserving the quality of both wheat flour and potato starch. For wheat flour, temperatures below 25 °C are generally recommended to prevent excessive moisture loss and potential product degradation. In the case of potato starch, recommended storage temperatures typically range from 15 °C to 20 °C. Storage humidity also significantly influences the quality maintenance of wheat flour and potato starch. Excessive ambient humidity can result in the absorption of water by these products, leading to changes in their structure and the formation of lumps. Conversely, overly low moisture content may cause excessive drying and a loss of product functionality. Water activity is an important parameter of powders influencing conditions for microbial growth.

Organizations and institutions responsible for regulating food standards, such as the U.S. Food and Drug Administration (FDA) and other international bodies, frequently establish acceptable humidity and storage temperature limits for wheat flour and potato starch. For instance, in accordance with certain guidelines, the humidity in warehouses storing these products should be maintained below 60–65% to prevent excessive moisture absorption by flour and starch. Recommended temperature values often range between 15 °C and 25 °C. Adhering to temperature and humidity standards for storage in warehouses is crucial. However, there are situations in which maintaining the recommended temperature and humidity of stored materials may be disrupted. This can occur during the filling of a storage tank or result from its leakage or collapse. The water adsorbed by the granular material can change its mechanical properties. Their understanding is essential for the rapid and proper protection of the material from degradation and avoiding financial losses. Therefore, the motivation behind this research was the aspiration to identify and expand knowledge in the realm of sudden, unexpected increases in humidity in selected food powders.

One of the phenomena, not fully understood, characterized by the alternating slipping and sticking of particles of granular material is the slip-stick effect. Its understanding is crucial, inter alia, in industries such as pharmaceutical and food manufacturing for precise dosing, as well as in powder coating processes for achieving uniform coating thickness and quality finishes. From the analysis of the literature, it appears that there is a negligible number of scientific publications on the slip-stick phenomenon. Those that exist do not analyze the influence of the storage parameters on the phenomenon but only confirm its presence. Since the slip-stick phenomenon significantly affects the course of technological processes involving powders and granular materials, it is necessary to study this phenomenon also under conditions of storage deviating from those recommended by standards. Considering it during the design of equipment for the transport and processing of granular materials enhances the efficiency of conducted processes and significantly reduces the risk of losses. No comprehensive study on the slip-stick phenomena in food powders under excessive ambient humidity has been reported so far, thus resulting in a research gap. There are also a limited number of publications on new methods of studying the caking of powders.

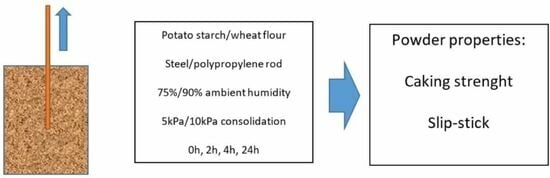

This paper explores storage practices, along with monitoring and controlling storage conditions, to mitigate potential hazards associated with the mentioned bulk materials. The strength of potato starch and wheat flour under various storage conditions with load consolidation has been measured using a new testing station. Two types of materials for the measuring rod were employed to evaluate their impact on the caking strength of the examined materials. Additionally, this paper discusses the slip-stick phenomenon observed during experimental tests, and parameters characterizing this phenomenon have been calculated. A comprehensive understanding of these parameters, which is crucial in designing devices and technological processes involving the tested materials, ensures the maintenance of high product quality and process safety.

2. Materials and Methods

In this experiment, commercially available potato starch (PPZ, Trzemeszno, Poland) and wheat flour type 500 (Młyn Szczepanki, Łasin, Poland) were utilized. The materials were dried to 3% moisture content and then subjected to daily exposure to either 75% or 90% relative humidity (RH). Measurements were conducted using a pull-based tester specifically designed for assessing the strength of consolidated bulk materials. A detailed description of the tester with figures and measurement methods is presented in detail in the work [

20] and patents PAT.241621 and PAT.241622. The pull-based tester consisted of a perforated cylindrical vessel with dimensions of 24 mm in diameter and 30 mm in height, featuring a mesh diameter of 1.5 mm. A measurement rod was centrally positioned within the vessel, resting on a steel plate secured to the device with a centering cutout. Equipped with a holder to maintain the measuring rod vertically and support the weight loading of the sample, the pull-based tester ensured consistency. A load cell, also embedded in the stem, measures the value of the force transmitted by the rope in the range of 5 N. The rod was pulled into the sample at a rate of 1.75 mm/min. The measuring rods took the form of cylinders with a cone-shaped lower base, measuring 93.7 mm in length and 4.82 mm in diameter. The tests were carried out using rods made of stainless steel and polypropylene, both featuring a notch depth of 0.65 mm. The choice of the measuring rod material was determined by its common use as a structural material in the construction of machinery and equipment for the food industry.

The test powders were subjected to consolidation stress of 5 kPa and 10 kPa, followed by storage for 24 h under specified humidity conditions. Measurements were taken at 0, 2, 4, and 24 h. The experimental design is outlined in

Table 1, and all variations were conducted in five replicates. The measurement procedure followed the method described in patent PAT.241622. Additionally, a control test was performed on powders moistened at 75% and 90% ambient humidity, subjected to loading but not subjected to time consolidation.

3. Results and Discussion

3.1. Evolution of the Pulling Force over Time

The evolutions of the pulling force over time, measured for wheat flour and potato starch consolidated at 90% ambient humidity under a pressure of 10 kPa within a time range from 0 to 24 h, are illustrated in

Figure 1 and

Figure 2. In the case of wheat flour, the pulling force gradually increased with the extended consolidation time, reaching more than twice the strength after 24 h compared to the measurement for the control sample. The differences in forces between control samples of potato starch and those subjected to a 24 h consolidation process were significantly smaller than those calculated for wheat flour. For potato starch, the increase in consolidation time from 0 to 4 h resulted in a negligible change in the pulling force.

The graphs presented in

Figure 1 and

Figure 2 start with a force value below zero, which is related to the calibration of the device and the subtraction of the mass of the test rods to obtain results strictly for the powder. Regardless of the type of tested material, a cyclic strengthening followed by a subsequent decrease in its strength was observed. This phenomenon, known as the slip-stick effect, exists in physical systems where relative displacement occurs. The slip-stick friction leads to spontaneous, jerky movements or self-excited oscillations of constant or variable frequency [

21]. They occur as a consequence of compaction and dilatation around the shear region in the material [

22]. Many bulk solids of plant origin exhibit this peculiar behavior, including wheat flour, maize starch, potato starch, and milk powder [

23,

24,

25]. It was found that the slip-stick response is affected by, among other factors, shear velocity, coefficient of interparticle friction, stiffness of the material, and its compressibility [

20,

26,

27,

28].

3.2. Agglomerate Strength

The strength of the agglomerate was determined as the ratio between the maximum force obtained in the first peak of the pulling force vs. time curve and the lateral surface area of the measuring rod. The values of agglomerate strength calculated for two types of measuring rod materials, under various ambient humidity and consolidation times, are presented in

Figure 3.

In the case of wheat flour, an increase in material strength was observed with increasing consolidation time, which is a trend more pronounced under higher ambient humidity. The heightened availability of water in the environment led to increased water adsorption by wheat flour particles, fostering material caking and, consequently, enhancing its strength. The substantial rise in the caking strength of wheat flour after 24 h of consolidation highlights that even a one-day exposure to unfavorable moisture conditions can markedly impact strength parameters and clumping, potentially impeding technological processes.

An increase in agglomerate strength with the increasing time of consolidation was observed in samples of potato starch. In contrast to wheat flour, potato starch exhibited slight sensitivity to ambient humidity. At lower humidity levels, the strength values determined for both materials were similar. However, at a humidity of 90%, the strength of potato starch was nearly half that obtained for wheat flour.

Large differences in strength values obtained for the samples tested immediately after consolidation (0 h) and those subjected to a consolidation load for 2 h indicated the hygroscopic properties of starch and the rapid adsorption of water from the air. In this material, the greatest increase in the caking strength was observed after a day of consolidation under both 5 kPa and 10 kPa loading. For both wheat flour and potato starch, the effect of the consolidation load on the caking strength of the powder, measured after 24 h using the measurement rod made of polypropylene, was negligible. These results indicate that, in some cases, steel is a more appropriate material to use when determining the strength parameters of powders under consolidation.

The difference in the agglomerate strength of wheat flour and potato starch could be related to the difference in their physical composition, including the specific structure of the starch grains [

24]. Wheat flour and potato starch have different chemical compositions, especially in terms of the proportions of amylose and amylopectin, which affect their physical properties. The main components of potato starch and wheat flour that can interact with the water present in the environment are starch and protein. These components are capable of absorbing water and forming various structures as a result of these interactions. Starch interacts with water through the process of gelation. When starch comes into contact with water, the starch molecules absorb water and form gel-like structures. As a result of starch gelation, its structure changes, which affects functional properties such as thickening, stabilizing, or changing the texture of products. In the case of proteins, they combine with water to form networks that affect the elasticity and structure of material [

29,

30].

3.3. Slip-Stick Effect

A cyclic strengthening of materials followed by a subsequent decrease in their strength was recorded when the measuring rods were removed from the samples.

Figure 4 shows the number of peaks in the pulling force vs. time curves at two ambient humidities. The average number of oscillations was calculated within 120 s from the moment when the sensor force increased or within a shorter time until the oscillation ceased.

Regardless of the examined powder and the material of the measuring rod, the number of oscillations decreased gradually as the time of consolidation increased. At lower ambient humidity, a significant decrease in the number of oscillations with increasing consolidation load was observed in wheat flour when examined using the steel measuring rod, which was not observed for the rod made of polypropylene. The number of oscillations in samples examined directly after subjecting the consolidation load varied from 30, when the polypropylene rod was used, to 57 for the steel rod at an ambient moisture of 75%. An increase in ambient humidity to 90% resulted in a twofold or nearly threefold increase in the number of oscillations, indicating a strong effect of the water content in the sample on that parameter. These results show that the number of oscillations in wheat flour increases rapidly after a certain threshold value of water content in the sample is exceeded. This is likely due to the presence of additional components in wheat flour, such as proteins, which can interact with adsorbed water [

31]. The presence of these components and the lower content of crystalline structures may contribute to the instability of the material during the initial phase of the experiment [

20].

Contrary to wheat flour, potato starch exhibited a decreasing number of oscillations with increasing ambient humidity, indicating different mechanisms of interaction between materials of rod and these powders. The probable reason for such behavior is that its structure changes as a result of gelation, which affects functional properties such as thickening, stabilizing, or altering the texture. The more intensive water absorption by starch particles at higher ambient humidity resulted in an extended sliding time of starch particles in contact. Wajs et al. [

20] did not observe such a trend for potato starch with a moisture content of 9.5%. These authors reported that, regardless of the consolidation load, the number of oscillations was 40 and 30 for the rod made of steel and polypropylene, respectively. These data were similar to the ones obtained in this study for an ambient humidity of 75%. Only an increase in humidity to 90% decreased the number of oscillations, indicating a slight impact of humidity on the number of oscillations in the tested samples until its critical value was exceeded.

In both materials, under specific storage conditions, the slip-stick effect either did not occur or was brief, leading to a lack of data in

Figure 4 and

Figure 5. Such a situation was observed more frequently in potato starch, which could be due to the inherent properties of the starch particles or their specific interactions under those storage conditions. Starch granules are composed of layers that consist of large crystalline aggregates called trichids, extending from the outer to the central part of the grain. Alongside these crystalline aggregates, there are also amorphous structures present in the grain. Starch grains are essentially insoluble in water. Starch does not dissolve in cold water and only absorbs a portion of the water without altering its shape and intrinsic properties. Therefore, the reaction with the needle material differs due to the lubricating effect of water.

Along with the number of oscillations of the pulling force recorded for the tested powders, their frequency is strongly affected by the storage conditions and the time of consolidation of the material. The frequency of oscillations was defined as a ratio between the number of oscillations and the unit of time. The calculations were performed for a selected segment of the pulling force evolution over time, which were considered representative. For both tested materials, the oscillation frequency decreased as the consolidation load and the time of consolidation increased. At 75% ambient humidity and a consolidation load of 5 kPa, the frequencies of oscillation in wheat flour were higher when the steel measuring rod was used. In other storage conditions, this tendency was evident only for materials consolidated for 4 and 24 h. The differences between the frequencies of oscillation induced by different measuring rods in potato starch were also more pronounced at smaller ambient humidity and consolidation load. For a consolidation load of 10 kPa, a significant difference between frequencies of oscillation was observed only for control samples. An increase in ambient humidity to 95% resulted in nearly a twofold increase in the frequency of oscillations in control samples compared to those calculated at lower ambient humidity. This was attributed to a higher amount of water adsorbed by the material. The moisture content of the control samples of potato starch was 8%, which increased to 13% after storing the material for 24 h at 75% ambient humidity. An increase in ambient humidity to 90% resulted in an increase in the moisture content of the powder to 20%. Similar effects to those found in the current study were observed by Stasiak et al. [

32], where the authors analyzed the experimental waveforms of the stress–strain relationship of different types of starch. The enhancement of the slip-stick effect with increasing consolidation stress was observed by Stasiak et al. [

33] in plant and industrial powders. A study on starches in their native state and those modified by physical and chemical treatments, conducted by Stasiak et al. [

34], also revealed a strong sensitivity of the slip-stick response to consolidation load. Larger frequencies of oscillations and amplitudes of shear stress were observed under higher consolidation stress. Molenda et al. [

24] reported that the frequency of shear stress oscillations in wheat flour was lower than that in potato starch, and the oscillations were less regular. Among moisture content and consolidation stress, shear rate is considered a factor strongly affecting the frequency of oscillations of shear forces in powders. Frequencies of oscillations ranging from 1 to 10 Hz are often observed when the shear velocity ranges from 1 to 2 mm/s [

21].

An analysis of the results obtained for wheat flour and potato starch using the pull-based tester revealed good accuracy and repeatability of the measurements, indicating the potential of the proposed method to assess the degree of caking of these powders. It was observed that even a brief exposure of the tested powders to 75% and 90% ambient humidity affects the mechanical properties of the powder, including the occurrence of oscillations in the force acting between the grains of powders and the measuring rods pulling out of the powder. For both powders, differences in the strength of agglomerates and changes in the frequency of oscillations of the pulling force were observed after just two hours of consolidation, irrespective of the consolidation load and the material of the measuring rod. Consolidating the tested materials for 24 h led to significant alterations in the caking strength of the powders, which is a factor of great importance for the technology of both production and storage of these materials. The results obtained using the pull-based tester may also be utilized for the identification and analysis of the slip-stick effect, which is a phenomenon that is crucial in the design of devices and influences product quality and process safety.

The application of measuring rods made of two different materials allowed for the indication of differences in interactions between the grains of powders and the tester element. The more distinct differences in parameter values determined under various storage conditions using a steel rod incline towards considering this material more suitable for the undertaken studies.