Integrated and Hybrid Processes for the Treatment of Actual Wastewaters Containing Micropollutants: A Review on Recent Advances

Abstract

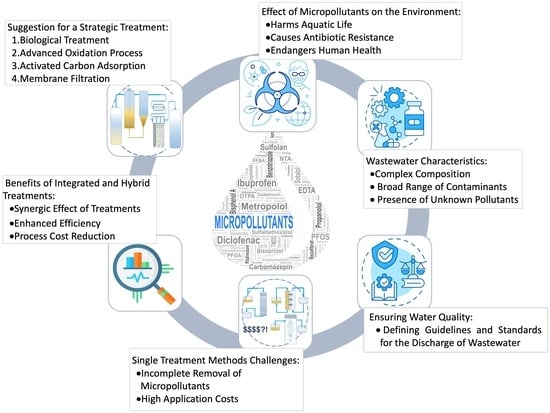

:1. Introduction

2. Regulations for MP Removal

3. Characterization of Actual Wastewater Containing MPs

- Wastewater from hospitals and agricultural activities stands out as having high concentrations of suspended solids and biological oxygen demand. The maximum COD level for these specific wastewater types is considerably lower compared to that of wastewater originating from the pharmaceutical industry. This implies that integrated filtration and biological treatment could potentially treat the wastewater from hospitals and agricultural activities.

- The pharmaceutical industry produces wastewater with high chemical oxygen demand, total nitrogen (TN), and total organic carbon (TOC); as well as a wide range of pH, indicating that advanced treatment technologies along with conventional methods might be the only option for effective treatment.

- Municipal wastewater has the mildest properties among all other classes in terms of total nitrogen, phosphorus, and chemical and biological oxygen demand, leaving the choice of treatment techniques to local authorities and owners with the desired removal level.

4. Advanced Wastewater Treatment Technologies

4.1. Membrane Processes

4.2. Advanced Oxidation Processes (AOPs)

4.3. Adsorption

4.4. Advanced Biological Treatment

5. Hybrid and Integrated Treatment Methods

5.1. Sequential Treatment Strategies

5.1.1. Biological Treatment and AOPs

- The efficiency of the integrated process for removing MPs ranges between 70 and 100% depending on the operating condition, the treatment technique used, and the nature of the wastewater.

- The degree of mineralization and organic content removal varies between 26 and 97%, and 38 and 100%, mainly due to applying AOPs as a pre-treatment stage to degrade the pollutants to simple organic compounds, but it fails to fully mineralize them.

- The solar Fenton and ozonation processes are studied extensively at full-scale and pilot-scale, showing their potential to be added to a current WWTP; however, the implication regarding the ozonation process needs further investigation.

- Sequential batch reactors (SBRs) and activated sludge bioreactors are the most common types of biological treatment used.

- The application of AOP before biological treatment increased biodegradability significantly; however, it is not preferred, due to the added cost of chemicals and power supply.

5.1.2. Biological Treatment and Activated Carbon Adsorption

| Source of Wastewater | Treatment Sequence | Study Specification | Findings | Reference |

|---|---|---|---|---|

| Hospital | AS-Sonochemical, AS-Sono_PF | Lab-scale, Biological process: RT = 36 h MLSS dose= AOP: RT = 90 min [Fe2+] = 5 power density = 88 | Pharmaceutical removal: 58.82% (sonochemical), 82.86% (sono_PF), No inhibitory effect of effluent from the sonochemical process, pharmaceuticals removal by AS+ sono_PF: 91.13%. | [75] |

| CF-UV/H2O2-AS, CF-UV/H2O2-Fungal biological | Lab-scale, Fungal treatment: FBR reactor, RT =7 d, AS: CSTR reactor, HRT = 48 h, SRT = 20–22 d, AOP reactor: immersion-type, RT= 10 min, [H2O2] = 15 . | AOP+ fungal treatment: 94% removal efficiency, AOP+ AS treatment: 83% removal efficiency, Biological treatment+ AOP: 93–95% removal efficiency, saving energy and chemicals, AOP+ AS is the only sequence reducing toxicity, | [158] | |

| SPF-AC | Lab-scale, Fe2+: single shot and three-stage addition strategy, and 15 , H2O2 dose = 50 and 150 , AC dose = (0.05–1) , EBCT = (5–65) min. | Single Fe2+ addition: 20% primary degradation, 3.05% mineralization, Consecutive Fe2+ addition: 58% primary degradation, 12.07% mineralization, Low removal of highly polar TPs, High aromatic product removal during the adsorption. | [164] | |

| Pharmaceutical manufacturing industry | SBR-EF, EF-SBR | Lab-scale, 0.1 mM caffeine and 5-fluorouracil, SBR: RT = 1 d, COD/N/P = 100:5:1, AOP: pH = 2.9, [Na2SO4] = 0.05 M, [Fe2+] = 0.2 mM, RT = 2 h and 4 h, I = 200 mA, TSS0 = 19 , COD0 = 120 , BOD5/COD = 0.03. | SBR pre-treatment: 57% caffeine, 82% 5-fluorouracil, and 50% COD removal, AOP post-treatment: 100% removal of pharmaceuticals, 99% COD removal, AOP pre-treatment: 60% COD removal, 100% pharmaceutical removal, Biodegradability= 0.33, SBR post-treatment: 100% COD and pharmaceutical removal. | [71] |

| EF-AO | Lab-scale, Cathode: carbon fiber, Anode: DSA mesh or Nb/BDD plate, Electrolyte: K2SO4 0.05 M, COD0 = 1200 , TOC0= 431.55 , BOD5/COD = 0.14. | Observed 97.1% TOC removal, Observed similar biodegradability increment in EF-BDD and EF-DSA, Achieved nearly complete mineralization by EF-BDD, EF-DSA process cost: 2.20 , EF-BDD process cost: 2.54 . | [153] | |

| Fenton-AC | Lab-scale, AC column Q = 0.3 , Fenton: [H2O2] = 8.5 , RT = 25 min, TOC0 = 43,595, COD0 = 162,933 , BOD5/COD = 0.29, [CBZ]0 = 442 . | Carbamazepine removal: 49.39% by Fenton process, Total carbamazepine removal: 99.51%, Complete detoxification, Zero-discharge process for high-strength wastewater on-site treatment. | [165] | |

| Flocculation-AC | Pilot-scale, Secondary effluent, TOC0 = 26.7 , P-PO43− = 1.5 , N-NH4+ = 0.95 . | Increased bacterial diversity at each stage, Total removal percentages: 95% TOC, 98% P-PO43, 83% N-NH4+, Total pharmaceutical removal of 90%. | [166] | |

| Coagulation-E-beam irradiation-AS | Lab-scale, HSWW and LSWW from equipment washing, Irradiation dose rate = 100 . | COD removal: 89% (HSWW), 94% (LSWW), E-beam effluent biodegradability: 0.77 (LSWW), 0.74 (HSWW), Complete detoxification, Best coagulant: FeCl3, Best oxidant: H2O2, Process cost: 1.37 (HSWW), 2.85 (LSWW). | [167] | |

| DF-AS, SPF-AS, EF-AS | Lab-scale, HSWW and LSWW from equipment washing, Solar intensity = 900 , HRT = 120 min, LSWW: [Fe2+] = 0.05 [H2O2] = 0.25 HSWW: [Fe2+] = 0.1 , [H2O2] = 1 MLSS = 3200 , RT = 8 d. | Best performance: SPF, Complete detoxification by sequential method, Total COD removal: LSWW: 78% (DF), 84% (SPF), and 70% (EF), HSWW: 67% (DF), 82% (SPF), and 54% (EF), Eliminated coagulation stage before AS treatment by using Fenton process. | [168] | |

| SPF-Ozonation (SPFO), Fenton-Ozonation (FO) | Lab-scale, TOC0 = 5000 COD0 =18,300 pH = 9.2, O3 dose= 0.1 Recirculation flow rate = 50 SPFO: RT = 2 h, [Fe2+] = 10 FO: RT = 3 h, [Fe2+] = 100 [H2O2]/COD = stoichiometric. | SPFO COD, TOC, and TN removal: 60%, 11%, 10%, FO COD, TOC, and TN removal: 65%, 25%, 26%, Estimated SPFO cost: 12.69 , Estimated FO cost: 14.97 , The effluent did not meet the standard discharge limit. | [169] | |

| Fenton-SBR | Full-scale and continuous Fenton, Lab-scale SBR, Fenton: Q = 3 , HRT = 60 min, [FeSO4] = 0.024 , [CuSO4] = 0.0021 , [H2O2] = 21.5 , P = 1.5atm, T = 120 , SBR: HRT = 2 d, SRT = 20 d, V = 15 L, TOC0 = 1440 , COD0 = 7010 , BOD5/COD = 0.17. | Fenton: COD and TOC removal: 85–90%, 90%, Sequential process: TOC removal: >90%, 65% less use of oxidant, Decreased operating temperature from 120 to 70 , Biological process cost: 11% of overall cost, Estimated cost for Fenton: 25 , Estimated cost for sequential process:16 | [170] | |

| MWWTP | Ozonation-SF, Ozonation-MBBR, Ozonation-FBBR, Ozonation-AC | , HRT = 43 and 13 min, EBCTMB = (14.5–25) min. | Removal of more than 79% for 200 MPs. NDMA reduced by 41–83%, SF performed the best for removal of TSS, DOC, Biological treatment failed to remove the TPs. GAC removed most of MPs, Estimated upgrading cost with ozonation: 0.06 . | [16] |

| SBR-SPCO, SBR-SPFO, SBR-Ozonation | , SBR setup: HRT =7 h, DO =3 , AOP setup: [Fe]3+ = 2.8 , [TiO2] = 250 , O3 reactor flow rate = 0.58 , [O3] = 13 . | SPCO removal efficiency: 95% ECs, 40% TOC, 59% COD removal, SPFO removal efficiency: 100% EC, 26% TOC, 38% COD, Ozonation removal efficiency: 100% EC, 35% TOC, 58% COD, Best performance: SPFO and ozonation for pharmaceutical removal. | [58] | |

| MBBR-SPF, AS-SPF, CF-SPF, MBBR-UV/H2O2, ASUV/H2O2, CF-UV/H2O2 | Lab-scale, Primary effluent, [Venlafaxine] = 200–1000, T = 22 , [H2O2] = 25 , SPF intensity = 900 , Fe/H2O2 = 5:25. | Venlafaxine removal: 90%, Achieved venlafaxine removal in 5 min with UV/H2O2, Required 120 min of operation for venlafaxine removal in SPF, Best effluent quality order: MBBR > AS > CF. | [60] | |

| Ozonation-BAF, Ozonation-Nonaerated biofilter, Ozonation-Aerated GAC, Ozonation-Nonaerated GAC | Pilot-scale, Secondary effluent, O3 dose = 0.33 , HRT = 12.6 min, , , D 2. | Increased anti-estrogenic and mutagenic effects by ozonation, Decreased anti-androgenic activity by ozonation, Better performance of aerated/nonaerated AC in pollutant and toxicity removal. | [157] | |

| Ozonation-BAC-Coagulation-CMF | , BAC EBCT = 4.5 min. | Accelerated membrane fouling due to released SMP in BAC, Increased permeate quality by reducing residual O3 and DBPs, Decreased permeability by 20% in the first 305 h of treatment by BAC. | [162] | |

| AS-SF, AS-AC Aerobic biomass-SF | , Monitored 52 Pharmaceuticals and 6 ARGs. | Antibiotic (Abs) removal in all treatment plants: 80–88%, COD removal in treatment plants: 55–74%, Increased concentration of some antibiotics after AS treatment. | [171] | |

| SPF/H2O2-GAC | Pilot-scale AOP, SE from CAS and MBR, [Ab] = 100 , [H2O2]CAS = 100 , RTCAS = 115 min, [H2O2]MBR = 50 , RTMBR = 111 min,. | Achieved full disinfection after 60 min of treatment by SPF, Increased effluent toxicity by SPF, Achieved full toxicity and >95% Ab removal by sequential SPF and AC. | [172] | |

| Multilayer filter column-IEX-UV/H2O2, Multilayer filter column-O3/biofiltration-UV/H2O2 | Full-scale IEX, Pilot-scale UV/H2O2, [C]0, DOC0 = (10–20) , Filter rate = 25 , IEX: Q = 750 , EBCT = 2 min, UV/H2O2: [H2O2] = 10 , UV dose = 1500 and 300 , O3/biofilter: RT = 15 min, [O3] = 15.3 . | Removal of humic fraction of organic matter in Ion exchange, Removal of hydrophobic fraction of organic matters in O3/biofiltration, Organic matter removal in IEX and O3/biofiltration: 45–65%, Reduced energy consumption in sequential IEX and UV/H2O2 by 84%, Estimated cost of sequential IEX and UV/H2O2 0.34 . | [173] | |

| Laundry WW | UF permeate-AC, UF permeate-Polymeric resin filtration, UF permeate-EO, UF permeate-NF | Lab-scale, UF TMP = (10–18) psi, , Cathode: graphite, stainless steel, Anode: BDD, Ti/Pt, and Ti/IrO2, RT = 120 min, NF TMP = (100–200) psi, AC and resin HRT = (6–30) min. | UF removal efficiency: 50% COD, 95% TSS, 97% turbidity, 75% nonylphenol ethoxylates, EO removal efficiency: 73% COD, NF removal efficiency for COD, turbidity, and nonylphenol ethoxylates = 80%, AC removal efficiency: (40–45)% COD, 80% nonylphenol ethoxylates, and no turbidity removal. | [163] |

| Filtration-IEX-AC- Ozonation | Lab-scale, Primary effluent, Q 1 = [0.1–5] , O3 dose = (1–5) , | Best filter arrangement: Polypropylene + IEX + AC, TSS and BOD5 removal of 80%, Removal of all coliforms by disinfection. | [174] | |

| Agricultural industry | PCO-AnBT | Lab-scale, PCO: SCPC reactor, Catalyst: TiO2-P25, Oxidant: H2O2, TiO2 dose = 100 , RT= 3 h, RT in bioreactor = 28 d. | AOP removal efficiency: 59.26% COD, 44.18% TOC, Biological treatment removal: 46.4% COD, 86.6% TOC, Sequential process removal efficiency: 72.2% COD, 53% TOC. | [65] |

5.1.3. Activated Carbon Adsorption and AOPs

5.2. Hybrid Treatment Strategies

5.2.1. Membrane Bioreactor

| Source of Wastewater | Treatment Process | Study Specification | Findings | Reference |

|---|---|---|---|---|

| Pharmaceutical manufacturing industry | MBR/PAC | Lab-scale, OLR = 1–2 , RT = 145 , COD0 = 18,000 , TMP = 200 mbar, Qair = 8–10 , DO = 4.6 , T =25 , PAC dose = 2 . | Increased removal from 73% to 97% in hybrid method, Observed Cake adsorption as the main fouling mechanism, COD removal = 90%. | [190] |

| Fenton/AS | Lab-Scale, Effluent of CBZ production plant, [CBZ] = 50, pH = 3, [Fe2+] = 100, [H2O2] = 200 , RT = 4 h. | CBZ degradation: 97.32% by Fenton, TOC removal: 10.07% by Fenton, Achieved total removal of 97.90% (CBZ) and 28.87% (TOC). | [195] | |

| Electro-flocculation/catalytic ozonation | , catalyst dose = (5–15) , DC volts = (5–15) V, [Abs]0 = (50–100) . | Observed 41% and 77% BOD and COD removal, Abs removal = (55–100)%. | [196] | |

| MFC | Lab-Scale, Two-chambered MFC, Anode: stainless steel, Cathodes: Pt-Ti or Pd/Ir-Ti, COD0 = 7440 , pH = 9.2, HRT = 30 h. | . | [197] | |

| MWWTP | UF/PAC, UF/BPAC | , TMP = 0.1 , Qair = 3 . | DOC removal: 63.2% (PAC), 54.1% (BPAC), , Increased membrane flux by 15.6% (PAC) and 25.1% (BPAC). | [177] |

| O3/CM | , . | MP removal ranged from 89.33% to 99.49%, Achieved DOC removal of 30%, Reduced irreversible membrane fouling by 10.17%. | [198] | |

| Catalytic ozonation | , T = 25 °C. | Permanent disinfection of wastewater, Full pathogen removal in the hybrid process, Reduction in energy consumption: 12%. | [199] | |

| PAC/DBF | ,, Iron dose = 0.1 , Qfiltration = 30. | 80% MP removal, TSS removal = 63.8%, Turbidity removal = 91.2%, DOC removal = 31.3%, P removal = 52.6%. | [200] |

5.2.2. Biological Activated Carbon

5.3. Hybrid and Sequential Treatment Strategies

| Source of Wastewater | Treatment Sequence | Study Specification | Findings | Reference |

|---|---|---|---|---|

| Pharmaceutical manufacturing facility | O3-Anaerobic MBR | , , MBR: submerged flat sheet/hallow fiber module, operation time = 167 d. | O3 pre-treatment reduced inhibition of MOs. Ozonation COD removal = 26%, Best membrane: hollow fiber module, Total COD removal: 80–90%, Total etodolac removal: 90–99%, After 168 days, no flux was observed. | [70] |

| O3/GAC-PS-TiO2 photocatalysis | , PS-TiO2 dose = (200–300) g, RT = 4 h, COD0 = 1000 ppm, [phenol]0 = 4.75 ppm. | Total COD removal = 71%, Total phenol removal = 100%, Achieved 95% COD removal after 12 h operation. | [151] | |

| Chlorine dioxide oxidation (ClO2)-BAC | . | OTC removal = 98.3%, COD removal = 68.1%, Biodegradability increased from 0.04 to 0.23. | [231] | |

| MWWTP | MBR without phosphorus precipitation-NF, MBR with phosphorus precipitation-PCD | , , , , , , HRT =21 h. | MBR +NF reached 84% MP, 99% COD, and 99% DOC removal, MBR+ PCD reached 90% MP, 92% COD, and 86% DOC removal, MBR+ NF allowed recovery of phosphorus, MBR without precipitation had a better MP removal. | [14] |

| BAC-UF | , | Total pharmaceutical removal of 78 to 89%, GAC played the main role in removal, 35% sulfamethoxazole, 22% ciprofloxacin, and 32% azithromycin removal due to biofilm, TOC removal = 11.9%, COD removal = 37.9%. | [61] | |

| Ozonation-BAC-MF | , . | Reduced fouling index by 4 times, Removal of Humic substances: 57%, biopolymers: 100%, DOC: 10%, Decreased water quality but increased permeate flux by BAC addition. | [232] | |

| MF-RO-UV/H2O2, O3-BAC-UV/H2O2, MF-RO-UV/HOCl, O3-BAC-UV/HOCl | , . | Best sequence: O3 > BAC > MF > RO > UV/H2O2. Total removal: 97%, O3 > BAC sequence: Higher NDMA removal, MF/RO sequence: Higher NMOR removal, UV/H2O2 was more effective in removal of –NDMA and NDMA precursors and controlling toxicity. | [233] | |

| MBR-UV/H2O2 | , . | At high pharmaceutical concentrations, complete removal can be achieved only by increasing the dose of oxidant and treatment time, The removal at various pharmaceutical concentrations ranges from 95 to 100%. | [234] | |

| Ozonation-MF-BAC- RO-UV-Chlorination | . | Out of 109 TrOCs found in feed water, 34 were in product water, Full toxicity and TrOC removal, Nitrosamine removal: 100%, The presence of NDMA in reject water had no environmental impact. | [143] | |

| Enhanced coagulation-UF (CUF), Coagulation-adsorption-UF (CAUF), Coagulation-oxidation-UF (COUF) | , RT = 60 min. | COD removal efficiencies: 22.4% UF, 27.3% CUF, 54% CAUF, 57.9% COUF, Observed minimum toxicity for CAUF, Transmembrane pressure increase rate: highest for UF, lowest for CAUF, CAUF showed the highest MP removal ranging from 74 to 96%, Enhanced coagulation alleviated membrane fouling. | [235] | |

| Anaerobic AS-Aerobic AS-MBBRs/AS (Hybas)-Anaerobic MBBR-Aerobic MBBR | . | Removal efficiency of 14 out of 21 pharmaceuticals exceeded 50%, Achieved 92% COD and 97% NH4+ removal, Faster pharmaceutical degradation rate in aerobic reactors, Intermittent biomass feeding strategy increase pharmaceutical removal. | [236] | |

| UV/H2O2-BAC | . | Achieved DOC removal of 45–49%, No salinity effect on nitrification was observed, Achieved ammonia and nitrite removal of 90% and 80%, TN removal ranged from 30 to 47%, Maximum Nitrate removal: 39%. | [237] |

6. Prospects of Integrated Treatment Processes

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abs | Antibiotics |

| AC | Activated Carbon |

| AnBT | Anaerobic Biological Treatment |

| AO | Anodic Oxidation |

| AOP | Advanced Oxidation Process |

| ARGs | Antibiotic Resistance Genes |

| AS | Activated Sludge |

| BAC | Biological Activated Carbon |

| BAF | Biological Aerated Filter |

| BDD | Boron-Doped Diamond |

| BPAC | Biological Powdered Activated Carbon |

| CAS | Conventional Activated Sludge |

| CAUF | Coagulation–Adsorption–Ultrafiltration |

| CBZ | Carbamazepine |

| CF | Coagulation–Flocculation |

| CI | Current Intensity |

| CM | Catalytic Membrane |

| CMF | Ceramic Membrane Filtration |

| COD | Chemical Oxygen Demand |

| COUF | Coagulation–Oxidation–Ultrafiltration |

| CSTR | Continuous Stirred Tank Reactor |

| CUF | Enhanced Coagulation |

| D | Diameter |

| DBP | Disinfection By-Product |

| DOC | Dissolved Organic Carbon |

| DOM | Dissolved Organic Matter |

| DSA | Dimensionally Stable Anode |

| EBCT | Empty Bed Contact Time |

| EC | Electro-Coagulation |

| ECs | Emerging Contaminants |

| EF | Electro-Fenton |

| EO | Electro-Oxidation |

| FBR | Fluidized Bed Reactor |

| FBBR | Fluidized Bed Bioreactor |

| FLUT | Flutamide |

| GAC | Granular Activated Carbon |

| HRT | Hydraulic Retention Time |

| HSWW | High-Strength Wastewater |

| IEX | Ion Exchange |

| LSWW | Low-Strength Wastewater |

| MBR | Membrane bioreactor |

| MBBR | Moving-Bed Bioreactor |

| MF | Microfiltration |

| MFC | Microbial Fuel Cell |

| MLSS | Mixed Liquor Suspended Solids |

| MO | Microorganisms |

| MPs | Micropollutants |

| MWCO | Molecular Weight Cut-Off |

| MWW | Municipal Wastewater |

| MWWTP | Municipal Wastewater Treatment Plant |

| NDMA | N-nitrosodimethylamine |

| NF | Nanofiltration |

| NMOR | N-nitrosomorpholine |

| NOM | Natural Organic Matter |

| OLR | Organic Loading Rate |

| OM | Organic Matter |

| OMP | Organic Micropollutant |

| OTC | Oxytetracycline |

| OTP | Oxidation Transformation Products |

| PAC | Powdered Activated Carbon |

| PAlCl | Polyaluminium Chloride |

| PCD | Pulsed Corona Discharge |

| PCO | Photocatalytic Oxidation |

| PE | Primary Effluent |

| p.e. | Population equivalent |

| Q | Flow rate |

| RO | Reverse Osmosis |

| RT | Retention Time |

| SBR | Sequencing Batch Reactors |

| SCPC | Solar Compound Parabolic Collector |

| SE | Secondary Effluent |

| SF | Sand Filtration |

| SMP | Soluble Microbial Products |

| Sono_PF | Sono-Photo-Fenton |

| SPCO | Solar Photocatalytic Ozonation |

| SPF | Solar Photo-Fenton |

| SPFO | Solar Photo-Fenton Ozonation |

| SRT | Sludge Retention Time |

| SWW | Sewage Wastewater |

| TE | Tertiary Effluent |

| TMP | Trans Membrane Pressure |

| TN | Total Nitrogen |

| TOC | Total Organic Carbon |

| TP | Total Phosphorous |

| TPs | Transformation Products |

| TrOC | Trace Organic Contaminant |

| UF | Ultrafiltration |

| V | Volume |

| WW | Wastewater |

| WWTP | Wastewater treatment Plant |

References

- Kavitha, R.V.; Murthy, V.K.; Makam, R.; Asith, K. a Physico-Chemical Analysis of Effluents from Pharmaceutical Industry and Its Efficiency Study. Int. J. Eng. Res. Appl. 2012, 2, 103–110. [Google Scholar]

- Hai, F.I.; Nguyen, L.N.; Nghiem, L.D.; Liao, B.Q.; Koyuncu, I.; Price, W.E. Trace Organic Contaminants Removal by Combined Processes for Wastewater Reuse. Handb. Environ. Chem. 2016, 45, 39–77. [Google Scholar]

- Luo, Y.; Guo, W.; Ngo, H.H.; Nghiem, L.D.; Hai, F.I.; Zhang, J.; Liang, S.; Wang, X.C. A Review on the Occurrence of Micropollutants in the Aquatic Environment and Their Fate and Removal during Wastewater Treatment. Sci. Total Environ. 2014, 473–474, 619–641. [Google Scholar] [CrossRef]

- Launay, M.A.; Dittmer, U.; Steinmetz, H. Organic Micropollutants Discharged by Combined Sewer Overflows—Characterisation of Pollutant Sources and Stormwater-Related Processes. Water Res. 2016, 104, 82–92. [Google Scholar] [CrossRef]

- Becouze-Lareure, C.; Dembélé, A.; Coquery, M.; Cren-Olivé, C.; Bertrand-Krajewski, J.-L. Assessment of 34 Dissolved and Particulate Organic and Metallic Micropollutants Discharged at the Outlet of Two Contrasted Urban Catchments. Sci. Total Environ. 2019, 651, 1810–1818. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Ali, J.; Jamil, S.U.U.; Zahra, N.; Tayaba, T.B.; Iqbal, M.J.; Waseem, H. Chapter 22—Removal of Micropollutants. In Environmental Micropollutants; Hashmi, M.Z., Wang, S., Ahmed, Z., Eds.; Advances in Pollution Research; Elsevier: Amsterdam, The Netherlands, 2022; pp. 443–461. ISBN 978-0-323-90555-8. [Google Scholar]

- Altaf, F.; Hashmi, M.Z.; Farooq, U.; Rehman, Z.U.; Hmeed, M.U.; Batool, R.; Pongpiachan, S. Chapter 21—Nanotechnology to Treat the Environmental Micropollutants. In Environmental Micropollutants; Hashmi, M.Z., Wang, S., Ahmed, Z., Eds.; Advances in Pollution Research; Elsevier: Amsterdam, The Netherlands, 2022; pp. 407–441. ISBN 978-0-323-90555-8. [Google Scholar]

- Silva, C.P.; Otero, M.; Esteves, V. Processes for the Elimination of Estrogenic Steroid Hormones from Water: A Review. Environ. Pollut. 2012, 165, 38–58. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Nguyen, M.N.; Li, Y.; Yang, C.; Schäfer, A.I. Steroid Hormone Micropollutant Removal from Water with Activated Carbon Fiber-Ultrafiltration Composite Membranes. J. Hazard. Mater. 2020, 391, 122020. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, R.Y.; Manikandan, S.; Subbaiya, R.; Biruntha, M.; Govarthanan, M.; Karmegam, N. Removal of Emerging Micropollutants Originating from Pharmaceuticals and Personal Care Products (PPCPs) in Water and Wastewater by Advanced Oxidation Processes: A Review. Environ. Technol. Innov. 2021, 23, 101757. [Google Scholar] [CrossRef]

- Abbasi, N.A.; Shahid, S.U.; Majid, M.; Tahir, A. Chapter 17—Ecotoxicological Risk Assessment of Environmental Micropollutants. In Environmental Micropollutants; Hashmi, M.Z., Wang, S., Ahmed, Z., Eds.; Advances in Pollution Research; Elsevier: Amsterdam, The Netherlands, 2022; pp. 331–337. ISBN 978-0-323-90555-8. [Google Scholar]

- Hazra, A.; Mondal, A.; Paul, S.; Bej, S.; Mondal, U.; Nag, S.; Banerjee, P. Chapter 17—Chemosensing Technology for Rapid Detection of Emerging Contaminants. In Emerging Contaminants in the Environment; Sarma, H., Dominguez, D.C., Lee, W.-Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 407–464. ISBN 978-0-323-85160-2. [Google Scholar]

- Khoo, Y.S.; Goh, P.S.; Lau, W.J.; Ismail, A.F.; Abdullah, M.S.; Mohd Ghazali, N.H.; Yahaya, N.K.E.M.; Hashim, N.; Othman, A.R.; Mohammed, A.; et al. Removal of Emerging Organic Micropollutants via Modified-Reverse Osmosis/Nanofiltration Membranes: A Review. Chemosphere 2022, 305, 135151. [Google Scholar] [CrossRef] [PubMed]

- Arola, K.; Hatakka, H.; Mänttäri, M.; Kallioinen, M. Novel Process Concept Alternatives for Improved Removal of Micropollutants in Wastewater Treatment. Sep. Purif. Technol. 2017, 186, 333–341. [Google Scholar] [CrossRef]

- Chavoshani, A.; Hashemi, M.; Mehdi Amin, M.; Ameta, S.C. Introduction. In Micropollutants and Challenges: Emerging in the Aquatic Environments and Treatment Processes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–33. ISBN 978-0-12-818612-1. [Google Scholar]

- Bourgin, M.; Beck, B.; Boehler, M.; Borowska, E.; Fleiner, J.; Salhi, E.; Teichler, R.; von Gunten, U.; Siegrist, H.; McArdell, C.S. Evaluation of a Full-Scale Wastewater Treatment Plant Upgraded with Ozonation and Biological Post-Treatments: Abatement of Micropollutants, Formation of Transformation Products and Oxidation by-Products. Water Res. 2018, 129, 486–498. [Google Scholar] [CrossRef]

- Kim, J.; Shi, W.; Yuan, Y.; Benjamin, M.M. A Serial Filtration Investigation of Membrane Fouling by Natural Organic Matter. J. Membr. Sci. 2007, 294, 115–126. [Google Scholar] [CrossRef]

- Bui, X.T.; Vo, T.P.T.; Ngo, H.H.; Guo, W.S.; Nguyen, T.T. Multicriteria Assessment of Advanced Treatment Technologies for Micropollutants Removal at Large-Scale Applications. Sci. Total Environ. 2016, 563–564, 1050–1067. [Google Scholar] [CrossRef]

- Aljuboury, D.; Palaniandy, P.; Abdul Aziz, H.; Feroz, S. Treatment of Petroleum Wastewater by Conventional and New Technologies A Review Oil Palm Frond(OPF) in Leachate Treatment View Project USM-MOSTI Project View Project Treatment of Petroleum Wastewater by Conventional and New Technologies-A Review. Glob. Nest J. 2017, 19, 439–452. [Google Scholar]

- Rajaraman, T.S.; Gandhi, V.; Parikh, S.P. Advanced Oxidation Processes for Wastewater Remediation: Fundamental Concepts to Recent Advances. Mater. Res. Found. 2021, 91, 37–86. [Google Scholar] [CrossRef]

- Mohajerani, M.; Mehrvar, M.; Ein-Mozaffari, F. An Overview of the Integration of Advanced Oxidation Technologies and Other Processes for Water and Wastewater Treatment. Int. J. Eng. 2009, 3, 120–146. [Google Scholar]

- Phoon, B.L.; Ong, C.C.; Mohamed Saheed, M.S.; Show, P.L.; Chang, J.S.; Ling, T.C.; Lam, S.S.; Juan, J.C. Conventional and Emerging Technologies for Removal of Antibiotics from Wastewater. J. Hazard. Mater. 2020, 400, 122961. [Google Scholar] [CrossRef] [PubMed]

- Metcalf, L.; Eddy, H.; Tchobanoglous, G. Wastewater Engineering: Treatment, Disposal, and Reuse, 4th ed.; Tchobanoglous, G., Stensel, H.D., Burton, F.L., Eds.; McGraw-Hill: New York, NY, USA, 1991; ISBN 0-07-124140-X. [Google Scholar]

- Mowla, A.; Mehrvar, M.; Dhib, R. Combination of Sonophotolysis and Aerobic Activated Sludge Processes for Treatment of Synthetic Pharmaceutical Wastewater. Chem. Eng. J. 2014, 255, 411–423. [Google Scholar] [CrossRef]

- Suárez, S.; Carballa, M.; Omil, F.; Lema, J.M. How Are Pharmaceutical and Personal Care Products (PPCPs) Removed from Urban Wastewaters? Rev. Environ. Sci. Biotechnol. 2008, 7, 125–138. [Google Scholar] [CrossRef]

- Gedda, G.; Balakrishna, K.; Devi, U.R.; Shah, K.J. Introduction to Conventional Wastewater Treatment Technologies: Limitations and Recent Advances. Mater. Res. Found. 2021, 91, 1–36. [Google Scholar] [CrossRef]

- Bolong, N.; Ismail, A.F.; Salim, M.R.; Matsuura, T. A Review of the Effects of Emerging Contaminants in Wastewater and Options for Their Removal. Desalination 2009, 239, 229–246. [Google Scholar] [CrossRef]

- Su, C.X.H.; Low, L.W.; Teng, T.T.; Wong, Y.S. Combination and Hybridisation of Treatments in Dye Wastewater Treatment: A Review. J. Environ. Chem. Eng. 2016, 4, 3618–3631. [Google Scholar] [CrossRef]

- Doyle, E. Delcan Corporation Wastewater Collection and Treatment; The Walkerton Inquiry; Ontario Ministry of the Attorney General: Toronto, ON, Canada, 2002; p. 182. [Google Scholar]

- Shestakova, M.; Sillanpää, M. Removal of Dichloromethane from Ground and Wastewater: A Review. Chemosphere 2013, 93, 1258–1267. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W. Adsorptive Removal of Antibiotics from Water and Wastewater: Progress and Challenges. Sci. Total Environ. 2015, 532, 112–126. [Google Scholar] [CrossRef] [PubMed]

- Pauletto, P.S.; Lütke, S.F.; Dotto, G.L.; Salau, N.P.G. Adsorption Mechanisms of Single and Simultaneous Removal of Pharmaceutical Compounds onto Activated Carbon: Isotherm and Thermodynamic Modeling. J. Mol. Liq. 2021, 336, 116203. [Google Scholar] [CrossRef]

- Shearer, L.; Pap, S.; Gibb, S.W. Removal of Pharmaceuticals from Wastewater: A Review of Adsorptive Approaches, Modelling and Mechanisms for Metformin and Macrolides. J. Environ. Chem. Eng. 2022, 10, 108106. [Google Scholar] [CrossRef]

- Cuerda-correa, E.M.; Alexandre-franco, M.F.; Fernández-González, C. Advanced Oxidation Processes for the Removal of Antibiotics from Water. An Overview. Water 2020, 12, 102. [Google Scholar] [CrossRef]

- Loganathan, P.; Vigneswaran, S.; Kandasamy, J.; Cuprys, A.K.; Maletskyi, Z.; Ratnaweera, H. Treatment Trends and Combined Methods in Removing Pharmaceuticals and Personal Care Products from Wastewater—A Review. Membranes 2023, 13, 158. [Google Scholar] [CrossRef] [PubMed]

- Kiejza, D.; Kotowska, U.; Polińska, W.; Karpińska, J. Peracids—New Oxidants in Advanced Oxidation Processes: The Use of Peracetic Acid, Peroxymonosulfate, and Persulfate Salts in the Removal of Organic Micropollutants of Emerging Concern—A Review. Sci. Total Environ. 2021, 790, 148195. [Google Scholar] [CrossRef]

- Ahmed, M.J. Adsorption of Quinolone, Tetracycline, and Penicillin Antibiotics from Aqueous Solution Using Activated Carbons: Review. Environ. Toxicol. Pharmacol. 2017, 50, 1–10. [Google Scholar] [CrossRef]

- Mansour, F.; Al-Hindi, M.; Yahfoufi, R.; Ayoub, G.M.; Ahmad, M.N. The Use of Activated Carbon for the Removal of Pharmaceuticals from Aqueous Solutions: A Review. Rev. Environ. Sci. Biotechnol. 2018, 17, 109–145. [Google Scholar] [CrossRef]

- Benstoem, F.; Nahrstedt, A.; Boehler, M.; Knopp, G.; Montag, D.; Siegrist, H.; Pinnekamp, J. Performance of Granular Activated Carbon to Remove Micropollutants from Municipal Wastewater—A Meta-Analysis of Pilot- and Large-Scale Studies. Chemosphere 2017, 185, 105–118. [Google Scholar] [CrossRef]

- Guo, Y.; Qi, P.S.; Liu, Y.Z. A Review on Advanced Treatment of Pharmaceutical Wastewater. IOP Conf. Ser. Earth Environ. Sci. 2017, 63, 012025. [Google Scholar] [CrossRef]

- Bhanot, P.; Celin, S.M.; Sreekrishnan, T.R.; Kalsi, A.; Sahai, S.K.; Sharma, P. Application of Integrated Treatment Strategies for Explosive Industry Wastewater—A Critical Review. J. Water Process Eng. 2020, 35, 101232. [Google Scholar] [CrossRef]

- Mansouri, F.; Chouchene, K.; Roche, N.; Ksibi, M. Removal of Pharmaceuticals from Water by Adsorption and Advanced Oxidation Processes: State of the Art and Trends. Appl. Sci. 2021, 11, 6659. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Development Document for Final Effluent Limitations Guidelines and Standards for the Pharmaceutical Manufacturing Point Source Category; Engineering and Analysis Division Office Science and Technology, U.S. Environmental Protection Agency: Washington, DC, USA, 1998; p. 469. [Google Scholar]

- Government of Canada. Wastewater Systems Effluent Regulations, Fisheries Act; En14-376/2016E-PDF; Environment and Climate Change Canada, Public Inquiries Centre: Gatineau, QC, Canada, 2016; p. 39.

- The Corporation of the City of Thunder Bay. Amended Environmental Compliance Approval; Ministry of the Environment and Climate Change: Toronto, ON, Canada, 2014; p. 18.

- NRMMC; EPHC; NHMRC. Australian Guidelines for Water Recycling: Augmentation of Drinking Water Supplies (Phase 2); National Water Quality Management Strategy; Biotext Pty Ltd.: Canberra, Australia, 2008; p. 174. [Google Scholar]

- Foen, S.M.; Beer, M. Implementation of the Protocol on Water and Health in Switzerland; Article 7 of the Protocol; Federal Food Safety and Federal Office for the Environment FOEN Veterinary Office, Federal Office for the Environment: Bern, Switzerland, 2012; p. 53. [Google Scholar]

- Council of the European Union. Council Directive 91/271/EEC of 21 May 1991 concerning urban waste-water treatment. Off. J. Eur. Communities 1991, L 135, 40–52. Available online: http://data.europa.eu/eli/dir/1991/271/oj (accessed on 16 January 2024).

- Bhawan, P. General Standards for Discharge of Environmental Pollutants. In Pollution Control Acts, Rules, and Notifications (Green Book), 4th ed.; Central Pollution Control Board, Ministry of Environment, Forest & Climate Change, Government of India: Delhi, India, 2021; pp. 380–395. Available online: https://cpcb.nic.in/env-protection-act/ (accessed on 26 August 2022).

- Environmental Protection Agency. Code of Federal Regulations, Title 40 Protection of Environment; Environmental Protection Agency: Washington, DC, USA, 2000.

- Benefield, L.A. Rule Development Committee Issue Research Report. Wastewater Quality/Strength/Content; Wastewater Management Program; Washington State Department of Health: Tumwater, WA, USA, 2002; pp. 1–18. [Google Scholar]

- Bélanger, M.-C.; Gilbert, Y.; Séguin, M. Considerations and Challenges of Treating High Strength Wastewater Treatment—Comparing Different Approaches. 2022. Available online: https://www.oowa.org/wp-content/uploads/2022/02/HighstrengthWW_article.pdf (accessed on 16 January 2024).

- Jiang, J.-Q.; Zhou, Z.; Sharma, V.K. Occurrence, Transportation, Monitoring and Treatment of Emerging Micro-Pollutants in Waste Water—A Review from Global Views. Microchem. J. 2013, 110, 292–300. [Google Scholar] [CrossRef]

- Vedenyapina, M.D.; Kurmysheva, A.Y.; Rakishev, A.K.; Kryazhev, Y.G. Activated Carbon as Sorbents for Treatment of Pharmaceutical Wastewater (Review). Solid Fuel Chem. 2019, 53, 382–394. [Google Scholar] [CrossRef]

- Lee, L.Y.; Ng, H.Y.; Ong, S.L.; Hu, J.Y.; Tao, G.; Kekre, K.; Viswanath, B.; Lay, W.; Seah, H. Ozone-Biological Activated Carbon as a Pretreatment Process for Reverse Osmosis Brine Treatment and Recovery. Water Res. 2009, 43, 3948–3955. [Google Scholar] [CrossRef] [PubMed]

- Grover, D.P.; Zhou, J.L.; Frickers, P.E.; Readman, J.W. Improved Removal of Estrogenic and Pharmaceutical Compounds in Sewage Effluent by Full Scale Granular Activated Carbon: Impact on Receiving River Water. J. Hazard. Mater. 2011, 185, 1005–1011. [Google Scholar] [CrossRef]

- Pradhan, S.; Fan, L.; Roddick, F.A. Removing Organic and Nitrogen Content from a Highly Saline Municipal Wastewater Reverse Osmosis Concentrate by UV/H2O2-BAC Treatment. Chemosphere 2015, 136, 198–203. [Google Scholar] [CrossRef]

- Gimeno, O.; García-Araya, J.F.; Beltrán, F.J.; Rivas, F.J.; Espejo, A. Removal of Emerging Contaminants from a Primary Effluent of Municipal Wastewater by Means of Sequential Biological Degradation-Solar Photocatalytic Oxidation Processes. Chem. Eng. J. 2016, 290, 12–20. [Google Scholar] [CrossRef]

- Martín de Vidales, M.J.; Millán, M.; Sáez, C.; Cañizares, P.; Rodrigo, M.A. Irradiated-Assisted Electrochemical Processes for the Removal of Persistent Pollutants from Real Wastewater. Sep. Purif. Technol. 2017, 175, 428–434. [Google Scholar] [CrossRef]

- Giannakis, S.; Hendaoui, I.; Jovic, M.; Grandjean, D.; De Alencastro, L.F.; Girault, H.; Pulgarin, C. Solar Photo-Fenton and UV/H2O2 Processes against the Antidepressant Venlafaxine in Urban Wastewaters and Human Urine. Intermediates Formation and Biodegradability Assessment. Chem. Eng. J. 2017, 308, 492–504. [Google Scholar] [CrossRef]

- Sbardella, L.; Comas, J.; Fenu, A.; Rodriguez-Roda, I.; Weemaes, M. Advanced Biological Activated Carbon Filter for Removing Pharmaceutically Active Compounds from Treated Wastewater. Sci. Total Environ. 2018, 636, 519–529. [Google Scholar] [CrossRef] [PubMed]

- Jiménez, B. Treatment Technology and Standards for Agricultural Wastewater Reuse: A Case Study in Mexico. Irrig. Drain. 2005, 54, S23–S33. [Google Scholar] [CrossRef]

- Sun, G.; Zhao, Y.; Allen, S.; Cooper, D. Generating “Tide” in Pilot-Scale Constructed Wetlands to Enhance Agricultural Wastewater Treatment. Eng. Life Sci. 2006, 6, 560–565. [Google Scholar] [CrossRef]

- Lopez, A.; Pollice, A.; Lonigro, A.; Masi, S.; Palese, A.M.; Cirelli, G.L.; Toscano, A.; Passino, R. Agricultural Wastewater Reuse in Southern Italy. Desalination 2006, 187, 323–334. [Google Scholar] [CrossRef]

- Becerra, D.; Barrientos, I.; Rodriguez, A.; Machuca-Martinez, F.; Ramírez, L. Treatment of Agricultural Wastewater with Chlorpyrifos by Coupling of Heterogeneous Photocatalysis and Anaerobic Biological Process. Top. Catal. 2020, 63, 1261–1271. [Google Scholar] [CrossRef]

- Hu, K.; Sarrà, M.; Caminal, G. Comparison between Two Reactors Using Trametes Versicolor for Agricultural Wastewater Treatment under Non-Sterile Condition in Sequencing Batch Mode. J. Environ. Manag. 2021, 293, 112859. [Google Scholar] [CrossRef]

- Snyder, S.A.; Adham, S.; Redding, A.M.; Cannon, F.S.; DeCarolis, J.; Oppenheimer, J.; Wert, E.C.; Yoon, Y. Role of Membranes and Activated Carbon in the Removal of Endocrine Disruptors and Pharmaceuticals. Desalination 2007, 202, 156–181. [Google Scholar] [CrossRef]

- Wang, K.; Liu, S.; Zhang, Q.; He, Y. Pharmaceutical Wastewater Treatment by Internal Micro-electrolysis–Coagulation, Biological Treatment and Activated Carbon Adsorption. Environ. Technol. 2009, 30, 1469–1474. [Google Scholar] [CrossRef]

- Ng, K.K.; Shi, X.; Tang, M.K.Y.; Ng, H.Y. A Novel Application of Anaerobic Bio-Entrapped Membrane Reactor for the Treatment of Chemical Synthesis-Based Pharmaceutical Wastewater. Sep. Purif. Technol. 2014, 132, 634–643. [Google Scholar] [CrossRef]

- Kaya, Y.; Bacaksiz, A.M.; Bayrak, H.; Gönder, Z.B.; Vergili, I.; Hasar, H.; Yilmaz, G. Treatment of Chemical Synthesis-Based Pharmaceutical Wastewater in an Ozonation-Anaerobic Membrane Bioreactor (AnMBR) System. Chem. Eng. J. 2017, 322, 293–301. [Google Scholar] [CrossRef]

- Ganzenko, O.; Trellu, C.; Papirio, S.; Oturan, N.; Huguenot, D.; van Hullebusch, E.D.; Esposito, G.; Oturan, M.A. Bioelectro-Fenton: Evaluation of a Combined Biological—Advanced Oxidation Treatment for Pharmaceutical Wastewater. Environ. Sci. Pollut. Res. 2018, 25, 20283–20292. [Google Scholar] [CrossRef]

- Gupta, R.; Sati, B.; Gupta, A. Treatment and Recycling of Wastewater from Pharmaceutical Industry. In Advances in Biological Treatment of Industrial Waste Water and their Recycling for a Sustainable Future, Applied Environmental Science and Engineering for a Sustainable Future; Singh, R.L., Singh, R.P., Eds.; Applied Environmental Science and Engineering for a Sustainable Future; Springer: Singapore, 2019; pp. 267–302. ISBN 9789811314681. [Google Scholar]

- Carraro, E.; Bonetta, S.; Bertino, C.; Lorenzi, E.; Bonetta, S.; Gilli, G. Hospital Effluents Management: Chemical, Physical, Microbiological Risks and Legislation in Different Countries. J. Environ. Manag. 2016, 168, 185–199. [Google Scholar] [CrossRef] [PubMed]

- Loos, G.; Scheers, T.; Van Eyck, K.; Van Schepdael, A.; Adams, E.; Van der Bruggen, B.; Cabooter, D.; Dewil, R. Electrochemical Oxidation of Key Pharmaceuticals Using a Boron Doped Diamond Electrode. Sep. Purif. Technol. 2018, 195, 184–191. [Google Scholar] [CrossRef]

- Serna-Galvis, E.A.; Silva-Agredo, J.; Botero-Coy, A.M.; Moncayo-Lasso, A.; Hernández, F.; Torres-Palma, R.A. Effective Elimination of Fifteen Relevant Pharmaceuticals in Hospital Wastewater from Colombia by Combination of a Biological System with a Sonochemical Process. Sci. Total Environ. 2019, 670, 623–632. [Google Scholar] [CrossRef] [PubMed]

- Verlicchi, P.; Al Aukidy, M.; Zambello, E. What Have We Learned from Worldwide Experiences on the Management and Treatment of Hospital Effluent?—An Overview and a Discussion on Perspectives. Sci. Total Environ. 2015, 514, 467–491. [Google Scholar] [CrossRef] [PubMed]

- Emmanuel, E.; Perrodin, Y.; Keck, G.; Blanchard, J.-M.; Vermande, P. Ecotoxicological Risk Assessment of Hospital Wastewater: A Proposed Framework for Raw Effluents Discharging into Urban Sewer Network. J. Hazard. Mater. 2005, 117, 1–11. [Google Scholar] [CrossRef]

- Meo, M.; Haydar, S.; Nadeem, O.; Hussain, G.; Rashid, H. Characterization of Hospital Wastewater, Risk Waste Generation and Management Practices in Lahore. In Proceedings of the Pakistan Academy of Sciences; Pakistan Academy of Sciences: Islamabad, Pakistan, 2014; Volume 51, pp. 317–329. [Google Scholar]

- Fatimazahra, S.; Latifa, M.; Laila, S.; Monsif, K. Review of Hospital Effluents: Special Emphasis on Characterization, Impact, and Treatment of Pollutants and Antibiotic Resistance. Environ. Monit. Assess. 2023, 195, 393. [Google Scholar] [CrossRef] [PubMed]

- Teodosiu, C.; Gilca, A.-F.; Barjoveanu, G.; Fiore, S. Emerging Pollutants Removal through Advanced Drinking Water Treatment: A Review on Processes and Environmental Performances Assessment. J. Clean. Prod. 2018, 197, 1210–1221. [Google Scholar] [CrossRef]

- Michael, I.; Rizzo, L.; McArdell, C.S.; Manaia, C.M.; Merlin, C.; Schwartz, T.; Dagot, C.; Fatta-Kassinos, D. Urban Wastewater Treatment Plants as Hotspots for the Release of Antibiotics in the Environment: A Review. Water Res. 2013, 47, 957–995. [Google Scholar] [CrossRef] [PubMed]

- Petrie, B.; McAdam, E.J.; Scrimshaw, M.D.; Lester, J.N.; Cartmell, E. Fate of Drugs during Wastewater Treatment. TrAC Trends Anal. Chem. 2013, 49, 145–159. [Google Scholar] [CrossRef]

- Gadipelly, C.; Pérez-González, A.; Yadav, G.D.; Ortiz, I.; Ibáñez, R.; Rathod, V.K.; Marathe, K.V. Pharmaceutical Industry Wastewater: Review of the Technologies for Water Treatment and Reuse. Ind. Eng. Chem. Res. 2014, 53, 11571–11592. [Google Scholar] [CrossRef]

- Luo, Z.; He, Y.; Zhi, D.; Luo, L.; Sun, Y.; Khan, E.; Wang, L.; Peng, Y.; Zhou, Y.; Tsang, D.C.W. Current Progress in Treatment Techniques of Triclosan from Wastewater: A Review. Sci. Total Environ. 2019, 696, 133990. [Google Scholar] [CrossRef]

- Xu, H.; Luo, Y.; Wang, P.; Zhu, J.; Yang, Z.; Liu, Z. Removal of Thallium in Water/Wastewater: A Review. Water Res. 2019, 165, 114981. [Google Scholar] [CrossRef]

- Hai, F.I.; Yang, S.; Asif, M.B.; Sencadas, V.; Shawkat, S.; Sanderson-Smith, M.; Gorman, J.; Xu, Z.Q.; Yamamoto, K. Carbamazepine as a Possible Anthropogenic Marker in Water: Occurrences, Toxicological Effects, Regulations and Removal by Wastewater Treatment Technologies. Water 2018, 10, 107. [Google Scholar] [CrossRef]

- Villegas, L.G.C.; Mashhadi, N.; Chen, M.; Mukherjee, D.; Taylor, K.E.; Biswas, N. A Short Review of Techniques for Phenol Removal from Wastewater. Curr. Pollut. Rep. 2016, 2, 157–167. [Google Scholar] [CrossRef]

- Li, C.; Cabassud, C.; Guigui, C. Evaluation of Membrane Bioreactor on Removal of Pharmaceutical Micropollutants: A Review. Desalination Water Treat. 2015, 55, 845–858. [Google Scholar] [CrossRef]

- Homem, V.; Santos, L. Degradation and Removal Methods of Antibiotics from Aqueous Matrices—A Review. J. Environ. Manag. 2011, 92, 2304–2347. [Google Scholar] [CrossRef]

- Weng, X.D.; Ji, Y.L.; Ma, R.; Zhao, F.Y.; An, Q.F.; Gao, C.J. Superhydrophilic and Antibacterial Zwitterionic Polyamide Nanofiltration Membranes for Antibiotics Separation. J. Membr. Sci. 2016, 510, 122–130. [Google Scholar] [CrossRef]

- Wu, D.; Cao, Y.; Chen, J.; Gao, H.; Ye, X.; Liu, D.; Chen, S. Feasibility Study on Water Reclamation from the Sorting/Grading Operation in Mandarin Orange Canning Production. J. Clean. Prod. 2016, 113, 224–230. [Google Scholar] [CrossRef]

- Sarasidis, V.C.; Plakas, K.V.; Patsios, S.I.; Karabelas, A.J. Investigation of Diclofenac Degradation in a Continuous Photo-Catalytic Membrane Reactor. Influence of Operating Parameters. Chem. Eng. J. 2014, 239, 299–311. [Google Scholar] [CrossRef]

- Darowna, D.; Wróbel, R.; Morawski, A.W.; Mozia, S. The Influence of Feed Composition on Fouling and Stability of a Polyethersulfone Ultrafiltration Membrane in a Photocatalytic Membrane Reactor. Chem. Eng. J. 2017, 310, 360–367. [Google Scholar] [CrossRef]

- Akpotu, S.O.; Oseghe, E.O.; Ayanda, O.S.; Skelton, A.A.; Msagati, T.A.M.; Ofomaja, A.E. Photocatalysis and Biodegradation of Pharmaceuticals in Wastewater: Effect of Abiotic and Biotic Factors. Clean Technol. Environ. Policy 2019, 21, 1701–1721. [Google Scholar] [CrossRef]

- Ribeiro, J.P.; Nunes, M.I. Recent Trends and Developments in Fenton Processes for Industrial Wastewater Treatment—A Critical Review. Environ. Res. 2021, 197, 110957. [Google Scholar] [CrossRef]

- Stasinakis, A.S. Use of Selected Advanced Oxidation Processes (AOPs) for Wastewater Treatment—A Mini Review. Glob. Nest J. 2008, 10, 376–385. [Google Scholar] [CrossRef]

- Ghafoori, S.; Shah, K.K.; Mehrvar, M.; Chan, P.K. Pharmaceutical Wastewater Treatment Using Granular Activated Carbon and UV/H2O2 Processes: Experimental Analysis and Modelling. Can. J. Chem. Eng. 2014, 92, 1163–1173. [Google Scholar] [CrossRef]

- Ghafoori, S.; Mowla, A.; Jahani, R.; Mehrvar, M.; Chan, P.K. Sonophotolytic Degradation of Synthetic Pharmaceutical Wastewater: Statistical Experimental Design and Modeling. J. Environ. Manag. 2015, 150, 128–137. [Google Scholar] [CrossRef]

- Jahani, R.; Dhib, R.; Mehrvar, M. Photochemical Degradation of Aqueous Artificial Sweeteners by UV/H2O2 and Their Biodegradability Studies. J. Chem. Technol. Biotechnol. 2020, 95, 2509–2521. [Google Scholar] [CrossRef]

- Johnson, M.B.; Mehrvar, M. Aqueous Metronidazole Degradation by UV/H2O2 Process in Single-and Multi-Lamp Tubular Photoreactors: Kinetics and Reactor Design. Ind. Eng. Chem. Res. 2008, 47, 6525–6537. [Google Scholar] [CrossRef]

- Arvai, A.; Jasim, S.; Biswas, N. Bromate Formation in Ozone and Advanced Oxidation Processes. Ozone Sci. Eng. 2012, 34, 325–333. [Google Scholar] [CrossRef]

- Kienle, C.; Werner, I.; Fischer, S.; Lüthi, C.; Schifferli, A.; Besselink, H.; Langer, M.; McArdell, C.S.; Vermeirssen, E.L.M. Evaluation of a Full-Scale Wastewater Treatment Plant with Ozonation and Different Post-Treatments Using a Broad Range of in Vitro and in Vivo Bioassays. Water Res. 2022, 212, 118084. [Google Scholar] [CrossRef] [PubMed]

- Bustillo-Lecompte, C.F.; Mehrvar, M. Slaughterhouse Wastewater Characteristics, Treatment, and Management in the Meat Processing Industry: A Review on Trends and Advances. J. Environ. Manag. 2015, 161, 287–302. [Google Scholar] [CrossRef] [PubMed]

- Tabrizi, G.B.; Mehrvar, M. Integration of Advanced Oxidation Technologies and Biological Processes: Recent Developments, Trends, and Advances. J. Environ. Sci. Health Part Toxic Hazard. Subst. Environ. Eng. 2004, 39, 3029–3081. [Google Scholar] [CrossRef]

- Paździor, K.; Bilińska, L.; Ledakowicz, S. A Review of the Existing and Emerging Technologies in the Combination of AOPs and Biological Processes in Industrial Textile Wastewater Treatment. Chem. Eng. J. 2019, 376, 120597. [Google Scholar] [CrossRef]

- Giwa, A.; Yusuf, A.; Balogun, H.A.; Sambudi, N.S.; Bilad, M.R.; Adeyemi, I.; Chakraborty, S.; Curcio, S. Recent Advances in Advanced Oxidation Processes for Removal of Contaminants from Water: A Comprehensive Review. Process Saf. Environ. Prot. 2021, 146, 220–256. [Google Scholar] [CrossRef]

- Reynolds, T.D.; Richards, P.A. Unit Operation and Process in Environmental Engineering, 2nd ed.; PWS Publishing Co.: Boston, MA, USA, 1995; ISBN 978-0-534-94884-9. [Google Scholar]

- Sorrels, J.L.; Baynham, A.; Randall, D.D.; Schaffner, K.S. Carbon Adsorbers; U.S. Environmental Protection Agency: Research Triangle Park, NC, USA, 2018; pp. 1–47.

- Finn, M.; Giampietro, G.; Mazyck, D.; Rodriguez, R. Activated Carbon for Pharmaceutical Removal at Point-of-Entry. Processes 2021, 9, 1091. [Google Scholar] [CrossRef]

- Perrich, J.R. Activated Carbon Adsorption for Wastewater Treatment; CRC Press: Boca Raton, FL, USA, 2018; ISBN 0-8493-5693-8. [Google Scholar]

- Hamura, D.; Sagayaga, A.; Babcock, R., Jr. Literature Review of GAC Regeneration Methods and Local Disposal Alternatives; Water Resources Research Center University of Hawai’i At Manoa: Honolulu, HI, USA, 1998; p. 97. [Google Scholar]

- El Gamal, M.; Mousa, H.A.; El-Naas, M.H.; Zacharia, R.; Judd, S. Bio-Regeneration of Activated Carbon: A Comprehensive Review. Sep. Purif. Technol. 2018, 197, 345–359. [Google Scholar] [CrossRef]

- Suri, R.P.S.; Liu, J.; Crittenden, J.C.; Hand, D.W. Removal and Destruction of Organic Contaminants in Water Using Adsorption, Steam Regeneration, and Photocatalytic Oxidation: A Pilot-Scale Study. J. Air Waste Manag. Assoc. 1999, 49, 951–958. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Castilla, C. Adsorption of Organic Molecules from Aqueous Solutions on Carbon Materials. Carbon 2004, 42, 83–94. [Google Scholar] [CrossRef]

- Rostvall, A.; Zhang, W.; Dürig, W.; Renman, G.; Wiberg, K.; Ahrens, L.; Gago-Ferrero, P. Removal of Pharmaceuticals, Perfluoroalkyl Substances and Other Micropollutants from Wastewater Using Lignite, Xylit, Sand, Granular Activated Carbon (GAC) and GAC+Polonite® in Column Tests—Role of Physicochemical Properties. Water Res. 2018, 137, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Guillossou, R.; Le Roux, J.; Mailler, R.; Vulliet, E.; Morlay, C.; Nauleau, F.; Gasperi, J.; Rocher, V. Organic Micropollutants in a Large Wastewater Treatment Plant: What Are the Benefits of an Advanced Treatment by Activated Carbon Adsorption in Comparison to Conventional Treatment? Chemosphere 2019, 218, 1050–1060. [Google Scholar] [CrossRef] [PubMed]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and Adsorption Capacities of Low-Cost Sorbents for Wastewater Treatment: A Review. Sustain. Mater. Technol. 2016, 9, 10–40. [Google Scholar] [CrossRef]

- Devi, P.; Saroha, A.K. Utilization of Sludge Based Adsorbents for the Removal of Various Pollutants: A Review. Sci. Total Environ. 2017, 578, 16–33. [Google Scholar] [CrossRef]

- Mu’azu, N.D.; Jarrah, N.; Zubair, M.; Alagha, O. Removal of Phenolic Compounds from Water Using Sewage Sludge-Based Activated Carbon Adsorption: A Review. Int. J. Environ. Res. Public Health 2017, 14, 1094. [Google Scholar] [CrossRef]

- González-García, P. Activated Carbon from Lignocellulosics Precursors: A Review of the Synthesis Methods, Characterization Techniques and Applications. Renew. Sustain. Energy Rev. 2018, 82, 1393–1414. [Google Scholar] [CrossRef]

- Shaarani, F.W.; Hameed, B.H. Ammonia-Modified Activated Carbon for the Adsorption of 2,4-Dichlorophenol. Chem. Eng. J. 2011, 169, 180–185. [Google Scholar] [CrossRef]

- Li, C.; Jiang, F.; Sun, D.; Qiu, B. Catalytic Ozonation for Advanced Treatment of Incineration Leachate Using (MnO2-Co3O4)/AC as a Catalyst. Chem. Eng. J. 2017, 325, 624–631. [Google Scholar] [CrossRef]

- Masoudian, N.; Rajabi, M.; Ghaedi, M. Titanium Oxide Nanoparticles Loaded onto Activated Carbon Prepared from Bio-Waste Watermelon Rind for the Efficient Ultrasonic-Assisted Adsorption of Congo Red and Phenol Red Dyes from Wastewaters. Polyhedron 2019, 173, 114105. [Google Scholar] [CrossRef]

- Rehman, A.; Park, M.; Park, S.J. Current Progress on the Surface Chemical Modification of Carbonaceous Materials. Coatings 2019, 9, 103. [Google Scholar] [CrossRef]

- Hassan, M.F.; Sabri, M.A.; Fazal, H.; Hafeez, A.; Shezad, N.; Hussain, M. Recent Trends in Activated Carbon Fibers Production from Various Precursors and Applications—A Comparative Review. J. Anal. Appl. Pyrolysis 2020, 145, 104715. [Google Scholar] [CrossRef]

- Korotta-Gamage, S.M.; Sathasivan, A. A Review: Potential and Challenges of Biologically Activated Carbon to Remove Natural Organic Matter in Drinking Water Purification Process. Chemosphere 2017, 167, 120–138. [Google Scholar] [CrossRef]

- dos Santos, P.R.; Daniel, L.A. A Review: Organic Matter and Ammonia Removal by Biological Activated Carbon Filtration for Water and Wastewater Treatment. Int. J. Environ. Sci. Technol. 2020, 17, 591–606. [Google Scholar] [CrossRef]

- Kanaujiya, D.K.; Paul, T.; Sinharoy, A.; Pakshirajan, K. Biological Treatment Processes for the Removal of Organic Micropollutants from Wastewater: A Review. Curr. Pollut. Rep. 2019, 5, 112–128. [Google Scholar] [CrossRef]

- LeviRam, I.; Gross, A.; Lintern, A.; Obayomi, O.; Chalifa-Caspi, V.; Gillor, O.; Henry, R.; Schang, C.; Herzberg, M.; McCarthy, D.T. Engineering a Biofilters Microbiome with Activated Carbon and Bioaugmentation to Improve Stormwater Micropollutant Removal. Environ. Technol. Innov. 2023, 32, 103338. [Google Scholar] [CrossRef]

- Piai, L.; Dykstra, J.; Van Der Wal, A.; Langenhoff, A. Bioaugmentation of Biological Activated Carbon Filters for Enhanced Micropollutant Removal. ACS EST Water 2022, 2, 2359–2366. [Google Scholar] [CrossRef]

- Yoon, M.K.; Drewes, J.E.; Amy, G.L. Fate of Bulk and Trace Organics during a Simulated Aquifer Recharge and Recovery (ARR)-Ozone Hybrid Process. Chemosphere 2013, 93, 2055–2062. [Google Scholar] [CrossRef] [PubMed]

- Boonnorat, J.; Kanyatrakul, A.; Prakhongsak, A.; Honda, R.; Panichnumsin, P.; Boonapatcharoen, N. Effect of Hydraulic Retention Time on Micropollutant Biodegradation in Activated Sludge System Augmented with Acclimatized Sludge Treating Low-Micropollutants Wastewater. Chemosphere 2019, 230, 606–615. [Google Scholar] [CrossRef] [PubMed]

- Muter, O.; Perkons, I.; Selga, T.; Berzins, A.; Gudra, D.; Radovica-Spalvina, I.; Fridmanis, D.; Bartkevics, V. Removal of Pharmaceuticals from Municipal Wastewaters at Laboratory Scale by Treatment with Activated Sludge and Biostimulation. Sci. Total Environ. 2017, 584–585, 402–413. [Google Scholar] [CrossRef]

- Helbling, D.E. Bioremediation of Pesticide-Contaminated Water Resources: The Challenge of Low Concentrations. Curr. Opin. Biotechnol. 2015, 33, 142–148. [Google Scholar] [CrossRef]

- Casas, M.E.; Chhetri, R.K.; Ooi, G.; Hansen, K.M.S.; Litty, K.; Christensson, M.; Kragelund, C.; Andersen, H.R.; Bester, K. Biodegradation of Pharmaceuticals in Hospital Wastewater by Staged Moving Bed Biofilm Reactors (MBBR). Water Res. 2015, 83, 293–302. [Google Scholar] [CrossRef] [PubMed]

- Ternes, T.A.; Prasse, C.; Eversloh, C.L.; Knopp, G.; Cornel, P.; Schulte-Oehlmann, U.; Schwartz, T.; Alexander, J.; Seitz, W.; Coors, A.; et al. Integrated Evaluation Concept to Assess the Efficacy of Advanced Wastewater Treatment Processes for the Elimination of Micropollutants and Pathogens. Environ. Sci. Technol. 2017, 51, 308–319. [Google Scholar] [CrossRef] [PubMed]

- Ben, W.; Zhu, B.; Yuan, X.; Zhang, Y.; Yang, M.; Qiang, Z. Occurrence, Removal and Risk of Organic Micropollutants in Wastewater Treatment Plants across China: Comparison of Wastewater Treatment Processes. Water Res. 2018, 130, 38–46. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, M.; Grillini, V.; Mutavdžić Pavlović, D.; Verlicchi, P. Activated Carbon Coupled with Advanced Biological Wastewater Treatment: A Review of the Enhancement in Micropollutant Removal. Sci. Total Environ. 2021, 790, 148050. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.D.; Cho, J.; Kim, I.S.; Vanderford, B.J.; Snyder, S.A. Occurrence and Removal of Pharmaceuticals and Endocrine Disruptors in South Korean Surface, Drinking, and Waste Waters. Water Res. 2007, 41, 1013–1021. [Google Scholar] [CrossRef] [PubMed]

- Grandclément, C.; Seyssiecq, I.; Piram, A.; Wong-Wah-Chung, P.; Vanot, G.; Tiliacos, N.; Roche, N.; Doumenq, P. From the Conventional Biological Wastewater Treatment to Hybrid Processes, the Evaluation of Organic Micropollutant Removal: A Review. Water Res. 2017, 111, 297–317. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Jiang, Q.; Ngo, H.H.; Nghiem, L.D.; Hai, F.I.; Price, W.E.; Wang, J.; Guo, W. Evaluation of Micropollutant Removal and Fouling Reduction in a Hybrid Moving Bed Biofilm Reactor–Membrane Bioreactor System. Bioresour. Technol. 2015, 191, 355–359. [Google Scholar] [CrossRef] [PubMed]

- Sonune, A.; Ghate, R. Developments in Wastewater Treatment Methods. Desalination 2004, 167, 55–63. [Google Scholar] [CrossRef]

- Allinson, M.; Kadokami, K.; Shiraishi, F.; Nakajima, D.; Zhang, J.; Knight, A.; Gray, S.R.; Scales, P.J.; Allinson, G. Wastewater Recycling in Antarctica: Performance Assessment of an Advanced Water Treatment Plant in Removing Trace Organic Chemicals. J. Environ. Manag. 2018, 224, 122–129. [Google Scholar] [CrossRef]

- Kårelid, V.; Larsson, G.; Björlenius, B. Pilot-Scale Removal of Pharmaceuticals in Municipal Wastewater: Comparison of Granular and Powdered Activated Carbon Treatment at Three Wastewater Treatment Plants. J. Environ. Manag. 2017, 193, 491–502. [Google Scholar] [CrossRef]

- Metcalfe, C.D.; Miao, X.S.; Koenig, B.G.; Struger, J. Distribution of Acidic and Neutral Drugs in Surface Waters near Sewage Treatment Plants in the Lower Great Lakes, Canada. Environ. Toxicol. Chem. 2003, 22, 2881–2889. [Google Scholar] [CrossRef] [PubMed]

- Teimoori, S.; Hassani, A.H.; Panahi, M.; Mansouri, N. A Review, Methods for Removal and Adsorption of Volatile Organic Compounds from Environmental Matrixes. Anal. Methods Environ. Chem. J. 2020, 3, 34–58. [Google Scholar] [CrossRef]

- Ferreira, J.A.; Varjani, S.; Taherzadeh, M.J. A Critical Review on the Ubiquitous Role of Filamentous Fungi in Pollution Mitigation. Curr. Pollut. Rep. 2020, 6, 295–309. [Google Scholar] [CrossRef]

- Wang, J.; De Ridder, D.; Van Der Wal, A.; Sutton, N.B. Harnessing Biodegradation Potential of Rapid Sand Filtration for Organic Micropollutant Removal from Drinking Water: A Review. Crit. Rev. Environ. Sci. Technol. 2021, 51, 2086–2118. [Google Scholar] [CrossRef]

- Castro-Gutierrez, V.; Pickering, L.; Cambronero-Heinrichs, J.; Holden, B.; Haley, J.; Jarvis, P.; Jefferson, B.; Helgason, T.; Moir, J.; Hassard, F. Bioaugmentation of Pilot-Scale Slow Sand Filters Can Achieve Compliant Levels for the Micropollutant Metaldehyde in a Real Water Matrix. Water Res. 2022, 211, 118071. [Google Scholar] [CrossRef] [PubMed]

- Jose, J.; Philip, L. Continuous Flow Pulsed Power Plasma Reactor for the Treatment of Aqueous Solution Containing Volatile Organic Compounds and Real Pharmaceutical Wastewater. J. Environ. Manag. 2021, 286, 112202. [Google Scholar] [CrossRef] [PubMed]

- Ratnawati, R.; Enjarlis, E.; Slamet, S. Combination of Ozonation and Photocatalysis for Pharmaceutical Wastewater Treatment. In Proceedings of the 3rd International Symposium on Applied Chemistry, Jakarta, Indonesia, 23–24 October 2017; American Institute of Physics: College Park, MD, USA, 2017; Volume 1904, p. 9. [Google Scholar]

- Guieysse, B.; Norvill, Z.N. Sequential Chemical-Biological Processes for the Treatment of Industrial Wastewaters: Review of Recent Progresses and Critical Assessment. J. Hazard. Mater. 2014, 267, 142–152. [Google Scholar] [CrossRef] [PubMed]

- Olvera-Vargas, H.; Gore-Datar, N.; Garcia-Rodriguez, O.; Mutnuri, S.; Lefebvre, O. Electro-Fenton Treatment of Real Pharmaceutical Wastewater Paired with a BDD Anode: Reaction Mechanisms and Respective Contribution of Homogenneous and Heterogenous [Rad]OH. Chem. Eng. J. 2021, 404, 126524. [Google Scholar] [CrossRef]

- Cao, W.; Mehrvar, M. Slaughterhouse Wastewater Treatment by Combined Anaerobic Baffled Reactor and UV/H2O2 Processes. Chem. Eng. Res. Des. 2011, 89, 1136–1143. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; You, H.; Ding, Y.; Yao, J.; Jin, C. Advanced Treatment of Biologically Pretreated Coal Chemical Industry Wastewater Using the Catalytic Ozonation Process Combined with a Gas-Liquid-Solid Internal Circulating Fluidized Bed Reactor. Water Sci. Technol. 2018, 77, 1931–1941. [Google Scholar] [CrossRef] [PubMed]

- Miklos, D.B.; Hartl, R.; Michel, P.; Linden, K.G.; Drewes, J.E.; Hübner, U. UV/H2O2 Process Stability and Pilot-Scale Validation for Trace Organic Chemical Removal from Wastewater Treatment Plant Effluents. Water Res. 2018, 136, 169–179. [Google Scholar] [CrossRef] [PubMed]

- Schneider, I.; Abbas, A.; Bollmann, A.; Dombrowski, A.; Knopp, G.; Schulte-Oehlmann, U.; Seitz, W.; Wagner, M.; Oehlmann, J. Post-Treatment of Ozonated Wastewater with Activated Carbon and Biofiltration Compared to Membrane Bioreactors: Toxicity Removal in Vitro and in Potamopyrgus Antipodarum. Water Res. 2020, 185, 116104. [Google Scholar] [CrossRef] [PubMed]

- Mir-Tutusaus, J.A.; Jaén-Gil, A.; Barceló, D.; Buttiglieri, G.; Gonzalez-Olmos, R.; Rodriguez-Mozaz, S.; Caminal, G.; Sarrà, M. Prospects on Coupling UV/H2O2 with Activated Sludge or a Fungal Treatment for the Removal of Pharmaceutically Active Compounds in Real Hospital Wastewater. Sci. Total Environ. 2021, 773, 145374. [Google Scholar] [CrossRef] [PubMed]

- Quist-Jensen, C.A.; Macedonio, F.; Drioli, E. Membrane Technology for Water Production in Agriculture: Desalination and Wastewater Reuse. Desalination 2015, 364, 17–32. [Google Scholar] [CrossRef]

- Skouteris, G.; Saroj, D.; Melidis, P.; Hai, F.I.; Ouki, S. The Effect of Activated Carbon Addition on Membrane Bioreactor Processes for Wastewater Treatment and Reclamation—A Critical Review. Bioresour. Technol. 2015, 185, 399–410. [Google Scholar] [CrossRef] [PubMed]

- Menya, E.; Olupot, P.W.; Storz, H.; Lubwama, M.; Kiros, Y. Production and Performance of Activated Carbon from Rice Husks for Removal of Natural Organic Matter from Water: A Review. Chem. Eng. Res. Des. 2018, 129, 271–296. [Google Scholar] [CrossRef]

- Im, D.; Nakada, N.; Fukuma, Y.; Tanaka, H. Effects of the Inclusion of Biological Activated Carbon on Membrane Fouling in Combined Process of Ozonation, Coagulation and Ceramic Membrane Filtration for Water Reclamation. Chemosphere 2019, 220, 20–27. [Google Scholar] [CrossRef]

- Khosravanipour Mostafazadeh, A.; Benguit, A.T.; Carabin, A.; Drogui, P.; Brien, E. Development of Combined Membrane Filtration, Electrochemical Technologies, and Adsorption Processes for Treatment and Reuse of Laundry Wastewater and Removal of Nonylphenol Ethoxylates as Surfactants. J. Water Process Eng. 2019, 28, 277–292. [Google Scholar] [CrossRef]

- Della-Flora, A.; Wilde, M.L.; Thue, P.S.; Lima, D.; Lima, E.C.; Sirtori, C. Combination of Solar Photo-Fenton and Adsorption Process for Removal of the Anticancer Drug Flutamide and Its Transformation Products from Hospital Wastewater. J. Hazard. Mater. 2020, 396, 122699. [Google Scholar] [CrossRef]

- Dwivedi, K.; Morone, A.; Chakrabarti, T.; Pandey, R.A. Evaluation and Optimization of Fenton Pretreatment Integrated with Granulated Activated Carbon (GAC) Filtration for Carbamazepine Removal from Complex Wastewater of Pharmaceutical Industry. J. Environ. Chem. Eng. 2018, 6, 3681–3689. [Google Scholar] [CrossRef]

- Tardy, V.; Bonnineau, C.; Bouchez, A.; Miège, C.; Masson, M.; Jeannin, P.; Pesce, S. A Pilot Experiment to Assess the Efficiency of Pharmaceutical Plant Wastewater Treatment and the Decreasing Effluent Toxicity to Periphytic Biofilms. J. Hazard. Mater. 2021, 411, 125121. [Google Scholar] [CrossRef]

- Changotra, R.; Rajput, H.; Guin, J.P.; Khader, S.A.; Dhir, A. Techno-Economical Evaluation of Coupling Ionizing Radiation and Biological Treatment Process for the Remediation of Real Pharmaceutical Wastewater. J. Clean. Prod. 2020, 242, 118544. [Google Scholar] [CrossRef]

- Changotra, R.; Rajput, H.; Dhir, A. Treatment of Real Pharmaceutical Wastewater Using Combined Approach of Fenton Applications and Aerobic Biological Treatment. J. Photochem. Photobiol. Chem. 2019, 376, 175–184. [Google Scholar] [CrossRef]

- Sanchis, S.; Meschede-Anglada, L.; Serra, A.; Simon, F.X.; Sixto, G.; Casas, N.; Garcia-Montaño, J. Solar Photo-Fenton with Simultaneous Addition of Ozone for the Treatment of Real Industrial Wastewaters. Water Sci. Technol. 2018, 77, 2497–2508. [Google Scholar] [CrossRef] [PubMed]

- Martínez, F.; Molina, R.; Rodríguez, I.; Pariente, M.I.; Segura, Y.; Melero, J.A. Techno-Economical Assessment of Coupling Fenton/Biological Processes for the Treatment of a Pharmaceutical Wastewater. J. Environ. Chem. Eng. 2018, 6, 485–494. [Google Scholar] [CrossRef]

- Sabri, N.A.; van Holst, S.; Schmitt, H.; van der Zaan, B.M.; Gerritsen, H.W.; Rijnaarts, H.H.M.; Langenhoff, A.A.M. Fate of Antibiotics and Antibiotic Resistance Genes during Conventional and Additional Treatment Technologies in Wastewater Treatment Plants. Sci. Total Environ. 2020, 741, 140199. [Google Scholar] [CrossRef]

- Michael, S.G.; Michael-Kordatou, I.; Beretsou, V.G.; Jäger, T.; Michael, C.; Schwartz, T.; Fatta-Kassinos, D. Solar Photo-Fenton Oxidation Followed by Adsorption on Activated Carbon for the Minimisation of Antibiotic Resistance Determinants and Toxicity Present in Urban Wastewater. Appl. Catal. B Environ. 2019, 244, 871–880. [Google Scholar] [CrossRef]

- Hofman-Caris, C.H.M.; Siegers, W.G.; van de Merlen, K.; de Man, A.W.A.; Hofman, J.A.M.H. Removal of Pharmaceuticals from WWTP Effluent: Removal of EfOM Followed by Advanced Oxidation. Chem. Eng. J. 2017, 327, 514–521. [Google Scholar] [CrossRef]

- Naghsh Javaheri, M.; Tishehzan, P.; Moazed, H. Development of a Complete and Straightforward Hybrid Model for Gray Water Treatment. Clean Technol. Environ. Policy 2020, 22, 1745–1753. [Google Scholar] [CrossRef]

- Hao, R.; Xiao, X.; Zuo, X.; Nan, J.; Zhang, W. Efficient Adsorption and Visible-Light Photocatalytic Degradation of Tetracycline Hydrochloride Using Mesoporous BiOI Microspheres. J. Hazard. Mater. 2012, 209–210, 137–145. [Google Scholar] [CrossRef]

- Du, Z.; Jia, R.; Li, C.; Cui, P.; Song, W.; Liu, J. Pilot-Scale UV/H2O2-BAC Process for Drinking Water Treatment—Analysis and Comparison of Different Activated Carbon Columns. Chem. Eng. J. 2020, 382, 123044. [Google Scholar] [CrossRef]

- Sun, L.; Gao, C.; He, N.; Yang, B.; Duan, X.; Chen, T. The Removal of Antibiotic Resistance Genes in Secondary Effluent by the Combined Process of PAC-UF. J. Environ. Sci. Health Part Toxic Hazard. Subst. Environ. Eng. 2019, 54, 1075–1082. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, S.T.; Roddick, F.A. Effects of Ozonation and Biological Activated Carbon Filtration on Membrane Fouling in Ultrafiltration of an Activated Sludge Effluent. J. Membr. Sci. 2010, 363, 271–277. [Google Scholar] [CrossRef]

- Reyes-Contreras, C.; Matamoros, V.; Ruiz, I.; Soto, M.; Bayona, J.M. Evaluation of PPCPs Removal in a Combined Anaerobic Digester-Constructed Wetland Pilot Plant Treating Urban Wastewater. Chemosphere 2011, 84, 1200–1207. [Google Scholar] [CrossRef] [PubMed]

- Reungoat, J.; Escher, B.I.; Macova, M.; Argaud, F.X.; Gernjak, W.; Keller, J. Ozonation and Biological Activated Carbon Filtration of Wastewater Treatment Plant Effluents. Water Res. 2012, 46, 863–872. [Google Scholar] [CrossRef] [PubMed]

- Melo-Guimarães, A.; Torner-Morales, F.J.; Durán-Álvarez, J.C.; Jiménez-Cisneros, B.E. Removal and Fate of Emerging Contaminants Combining Biological, Flocculation and Membrane Treatments. Water Sci. Technol. 2013, 67, 877–885. [Google Scholar] [CrossRef] [PubMed]

- Ávila, C.; Bayona, J.M.; Martín, I.; Salas, J.J.; García, J. Emerging Organic Contaminant Removal in a Full-Scale Hybrid Constructed Wetland System for Wastewater Treatment and Reuse. Ecol. Eng. 2015, 80, 108–116. [Google Scholar] [CrossRef]

- Ferrer-Polonio, E.; Iborra-Clar, A.; Mendoza-Roca, J.A.; Iborra-Clar, M.I. Combination of Adsorption and Biological Treatment in a SBR for Colour Elimination in Municipal Wastewater with Discharges of Textile Effluents. Desalination Water Treat. 2015, 55, 1915–1921. [Google Scholar] [CrossRef]

- Tagliavini, M.; Weidler, P.G.; Njel, C.; Pohl, J.; Richter, D.; Böhringer, B.; Schäfer, A.I. Polymer-Based Spherical Activated Carbon—Ultrafiltration (UF-PBSAC) for the Adsorption of Steroid Hormones from Water: Material Characteristics and Process Configuration. Water Res. 2020, 185, 116249. [Google Scholar] [CrossRef] [PubMed]

- Melin, T.; Jefferson, B.; Bixio, D.; Thoeye, C.; De Wilde, W.; De Koning, J.; van der Graaf, J.; Wintgens, T. Membrane Bioreactor Technology for Wastewater Treatment and Reuse. Desalination 2006, 187, 271–282. [Google Scholar] [CrossRef]

- Judd, S. The Status of Membrane Bioreactor Technology. Trends Biotechnol. 2008, 26, 109–116. [Google Scholar] [CrossRef]

- Ozgun, H.; Dereli, R.K.; Ersahin, M.E.; Kinaci, C.; Spanjers, H.; Van Lier, J.B. A Review of Anaerobic Membrane Bioreactors for Municipal Wastewater Treatment: Integration Options, Limitations and Expectations. Sep. Purif. Technol. 2013, 118, 89–104. [Google Scholar] [CrossRef]

- Lin, H.; Wang, F.; Ding, L.; Hong, H.; Chen, J.; Lu, X. Enhanced Performance of a Submerged Membrane Bioreactor with Powdered Activated Carbon Addition for Municipal Secondary Effluent Treatment. J. Hazard. Mater. 2011, 192, 1509–1514. [Google Scholar] [CrossRef]

- Hosseinpour, S.; Azimian-Kivi, M.; Jafarzadeh, Y.; Yegani, R. Pharmaceutical Wastewater Treatment Using Polypropylene Membranes Incorporated with Carboxylated and PEG-Grafted Nanodiamond in Membrane Bioreactor (MBR). Water Environ. J. 2021, 35, 1249–1259. [Google Scholar] [CrossRef]

- Kaya, Y.; Bacaksiz, A.M.; Golebatmaz, U.; Vergili, I.; Gönder, Z.B.; Yilmaz, G. Improving the Performance of an Aerobic Membrane Bioreactor (MBR) Treating Pharmaceutical Wastewater with Powdered Activated Carbon (PAC) Addition. Bioprocess Biosyst. Eng. 2016, 39, 661–676. [Google Scholar] [CrossRef]

- Lee, J.J.; Woo, Y.C.; Kang, J.S.; Kang, C.Y.; Kim, H.S. Effect of Various Pretreatments on the Performance of Nanofiltration for Wastewater Reuse. Desalination Water Treat. 2016, 57, 7522–7530. [Google Scholar] [CrossRef]

- Rasouli, Y.; Abbasi, M.; Hashemifard, S.A. A New Combination of Microfiltration, Powdered Activated Carbon and Coagulation for Treatment of Oily Wastewater. Int. J. Environ. Sci. Technol. 2019, 16, 5595–5610. [Google Scholar] [CrossRef]

- Amaral, P.; Partlan, E.; Li, M.; Lapolli, F.; Mefford, O.T.; Karanfil, T.; Ladner, D.A. Superfine Powdered Activated Carbon (S-PAC) Coatings on Microfiltration Membranes: Effects of Milling Time on Contaminant Removal and Flux. Water Res. 2016, 100, 429–438. [Google Scholar] [CrossRef]

- Ding, A.; Wang, J.; Lin, D.; Zeng, R.; Yu, S.; Gan, Z.; Ren, N.; Li, G.; Liang, H. Effects of GAC Layer on the Performance of Gravity-Driven Membrane Filtration (GDM) System for Rainwater Recycling. Chemosphere 2018, 191, 253–261. [Google Scholar] [CrossRef]

- Lee, Y.-Y.; Fan, C.; Haque, F. Hybrid Combination of Advanced Oxidation and Biological Processes for the Micropollutant Removal of Carbamazepine. Npj Clean Water 2022, 5, 60. [Google Scholar] [CrossRef]

- Masood, Z.; Ikhlaq, A.; Farooq, U.; Qi, F.; Javed, F.; Aziz, H.A. Removal of Anti-Biotics from Veterinary Pharmaceutical Wastewater Using Combined Electroflocculation and Fe-Zn Loaded Zeolite 5A Based Catalytic Ozonation Process. J. Water Process. Eng. 2022, 49, 103039. [Google Scholar] [CrossRef]

- Amari, S.; Boshrouyeh Ghandashtani, M. Non-Steroidal Anti-Inflammatory Pharmaceutical Wastewater Treatment Using a Two-Chambered Microbial Fuel Cell. Water Environ. J. 2020, 34, 413–419. [Google Scholar] [CrossRef]

- He, Y.; Chen, Z.; Huang, X.; Wang, X.; Wen, X. A Novel Catalytic Membrane Integrated with Ozone Process for Secondary Wastewater Treatment: Micropollutant Removal, Membrane Fouling Control, and Its Mechanisms. Desalination 2023, 565, 116869. [Google Scholar] [CrossRef]

- Gomes, J.; Frasson, D.; Quinta-Ferreira, R.M.; Matos, A.; Martins, R.C. Removal of Enteric Pathogens from Real Wastewater Using Single and Catalytic Ozonation. Water 2019, 11, 127. [Google Scholar] [CrossRef]

- Löwenberg, J.; Zenker, A.; Krahnstöver, T.; Boehler, M.; Baggenstos, M.; Koch, G.; Wintgens, T. Upgrade of Deep Bed Filtration with Activated Carbon Dosage for Compact Micropollutant Removal from Wastewater in Technical Scale. Water Res. 2016, 94, 246–256. [Google Scholar] [CrossRef] [PubMed]

- Jafarinejad, S. Activated Sludge Combined with Powdered Activated Carbon (PACT Process) for the Petroleum Industry Wastewater Treatment: A Review. Chem. Int. 2017, 03, 368. [Google Scholar] [CrossRef]

- Van Der Hoek, J.P.; Hofman, J.A.M.H.; Graveland, A. The Use of Biological Activated Carbon Filtration for the Removal of Natural Organic Matter and Organic Micropollutants from Water. Water Sci. Technol. 1999, 40, 257–264. [Google Scholar] [CrossRef]

- Serrano, D.; Suárez, S.; Lema, J.M.; Omil, F. Removal of Persistent Pharmaceutical Micropollutants from Sewage by Addition of PAC in a Sequential Membrane Bioreactor. Water Res. 2011, 45, 5323–5333. [Google Scholar] [CrossRef]

- Qin, W.; Li, W.G.; Zhang, D.Y.; Huang, X.F.; Song, Y. Ammonium Removal of Drinking Water at Low Temperature by Activated Carbon Filter Biologically Enhanced with Heterotrophic Nitrifying Bacteria. Environ. Sci. Pollut. Res. 2016, 23, 4650–4659. [Google Scholar] [CrossRef]

- Agudosi, E.S.; Abdullah, E.C.; Mubarak, N.M.; Khalid, M.; Pudza, M.Y.; Agudosi, N.P.; Abutu, E.D. Pilot Study of In-Line Continuous Flocculation Water Treatment Plant. J. Environ. Chem. Eng. 2018, 6, 7185–7191. [Google Scholar] [CrossRef]

- Fisher, I.; Kastl, G.; Sathasivan, A.; Chen, P.; Van Leeuwen, J.; Daly, R.; Holmes, M. Tuning the Enhanced Coagulation Process to Obtain Best Chlorine and THM Profiles in the Distribution System. Water Supply 2004, 4, 235–243. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Zhou, L. Influence of Excess KMnO4 on the Adsorption of Powdered Activated Carbon. Chem. Eng. J. 2013, 226, 279–285. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Hogland, W.; Marques, M.; Sillanpää, M. An Overview of the Modification Methods of Activated Carbon for Its Water Treatment Applications. Chem. Eng. J. 2013, 219, 499–511. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X. Comparative Toxicity of New Halophenolic DBPs in Chlorinated Saline Wastewater Effluents against a Marine Alga: Halophenolic DBPs Are Generally More Toxic than Haloaliphatic Ones. Water Res. 2014, 65, 64–72. [Google Scholar] [CrossRef]

- Pramanik, B.K.; Roddick, F.A.; Fan, L. Long-Term Operation of Biological Activated Carbon Pre-Treatment for Microfiltration of Secondary Effluent: Correlation between the Organic Foulants and Fouling Potential. Water Res. 2016, 90, 405–414. [Google Scholar] [CrossRef]

- Xu, L.; Zhou, Z.; Zhu, L.; Han, Y.; Lin, Z.; Feng, W.; Liu, Y.; Shuai, X.; Chen, H. Antibiotic Resistance Genes and Microcystins in a Drinking Water Treatment Plant. Environ. Pollut. 2020, 258, 113718. [Google Scholar] [CrossRef] [PubMed]

- Margot, J.; Kienle, C.; Magnet, A.; Weil, M.; Rossi, L.; de Alencastro, L.F.; Abegglen, C.; Thonney, D.; Chèvre, N.; Schärer, M.; et al. Treatment of Micropollutants in Municipal Wastewater: Ozone or Powdered Activated Carbon? Sci. Total Environ. 2013, 461–462, 480–498. [Google Scholar] [CrossRef] [PubMed]

- Mailler, R.; Gasperi, J.; Rocher, V.; Gilbert-Pawlik, S.; Geara-Matta, D.; Moilleron, R.; Chebbo, G. Biofiltration vs Conventional Activated Sludge Plants: What about Priority and Emerging Pollutants Removal? Environ. Sci. Pollut. Res. 2014, 21, 5379–5390. [Google Scholar] [CrossRef] [PubMed]

- Tang, K.; Spiliotopoulou, A.; Chhetri, R.K.; Ooi, G.T.H.; Kaarsholm, K.M.S.; Sundmark, K.; Florian, B.; Kragelund, C.; Bester, K.; Andersen, H.R. Removal of Pharmaceuticals, Toxicity and Natural Fluorescence through the Ozonation of Biologically-Treated Hospital Wastewater, with Further Polishing via a Suspended Biofilm. Chem. Eng. J. 2019, 359, 321–330. [Google Scholar] [CrossRef]

- Ooi, G.T.H.; Tang, K.; Chhetri, R.K.; Kaarsholm, K.M.S.; Sundmark, K.; Kragelund, C.; Litty, K.; Christensen, A.; Lindholst, S.; Sund, C.; et al. Biological Removal of Pharmaceuticals from Hospital Wastewater in a Pilot-Scale Staged Moving Bed Biofilm Reactor (MBBR) Utilising Nitrifying and Denitrifying Processes. Bioresour. Technol. 2018, 267, 677–687. [Google Scholar] [CrossRef]

- Qian, F.Y.; Sun, X.B.; Liu, Y.D. Effect of Ozone on Removal of Dissolved Organic Matter and Its Biodegradability and Adsorbability in Biotreated Textile Effluents. Ozone Sci. Eng. 2013, 35, 7–15. [Google Scholar] [CrossRef]

- Li, H.; Pan, Y.; Wang, Z.; Chen, S.; Guo, R.; Chen, J. An Algal Process Treatment Combined with the Fenton Reaction for High Concentrations of Amoxicillin and Cefradine. RSC Adv. 2015, 5, 100775–100782. [Google Scholar] [CrossRef]

- Aravind, P.; Subramanyan, V.; Ferro, S.; Gopalakrishnan, R. Eco-Friendly and Facile Integrated Biological-Cum-Photo Assisted Electrooxidation Process for Degradation of Textile Wastewater. Water Res. 2016, 93, 230–241. [Google Scholar] [CrossRef] [PubMed]

- Welter, J.B.; da Silva, S.W.; Schneider, D.E.; Rodrigues, M.A.S.; Ferreira, J.Z. Performance of Nb/BDD Material for the Electrochemical Advanced Oxidation of Prednisone in Different Water Matrix. Chemosphere 2020, 248, 126962. [Google Scholar] [CrossRef]

- Paadzior, K.; Bilinska, L. Microscopic Analysis of Activated Sludge in Industrial Textile Wastewater Treatment Plant. Autex Res. J. 2022, 22, 358–364. [Google Scholar] [CrossRef]

- Da Costa Filho, B.M.; da Silva, V.M.; de Oliviera Silva, J.; da Hora Machado, A.E.; Trovó, A.G. Coupling Coagulation, Flocculation and Decantation with Photo-Fenton Process for Treatment of Industrial Wastewater Containing Fipronil: Biodegradability and Toxicity Assessment. J. Environ. Manag. 2016, 174, 71–78. [Google Scholar] [CrossRef]

- Altmann, D.; Schaar, H.; Bartel, C.; Schorkopf, D.L.P.; Miller, I.; Kreuzinger, N.; Möstl, E.; Grillitsch, B. Impact of Ozonation on Ecotoxicity and Endocrine Activity of Tertiary Treated Wastewater Effluent. Water Res. 2012, 46, 3693–3702. [Google Scholar] [CrossRef]

- Feng, M.; Yan, L.; Zhang, X.; Sun, P.; Yang, S.; Wang, L.; Wang, Z. Fast Removal of the Antibiotic Flumequine from Aqueous Solution by Ozonation: Influencing Factors, Reaction Pathways, and Toxicity Evaluation. Sci. Total Environ. 2016, 541, 167–175. [Google Scholar] [CrossRef]

- Lu, J.; Fan, L.; Roddick, F.A. Potential of BAC Combined with UVC/H2O2 for Reducing Organic Matter from Highly Saline Reverse Osmosis Concentrate Produced from Municipal Wastewater Reclamation. Chemosphere 2013, 93, 683–688. [Google Scholar] [CrossRef]

- Altmann, J.; Ruhl, A.S.; Zietzschmann, F.; Jekel, M. Direct Comparison of Ozonation and Adsorption onto Powdered Activated Carbon for Micropollutant Removal in Advanced Wastewater Treatment. Water Res. 2014, 55, 185–193. [Google Scholar] [CrossRef]

- Chedeville, O.; Barrot, Y.; Versaveau, F.; Pineau, A.; Cagnon, B. Endocrine Disrupter Removal by Ozone/Activated Carbon Coupling in Continuous Flow at Pilot Scale. J. Environ. Eng. 2015, 141, 3–9. [Google Scholar] [CrossRef]