1. Introduction

Due to the restricted length of reinforcing bars and transportation constraints, rebar splicing is an unavoidable challenge in RC constructions [

1,

2,

3]. Indeed, the transferring of loads from one rebar to another, and thereby confining the concrete, confer on splices a very significant function in the reaction of RC components. Splices serve the primary role of joining reinforcement rebars in standard structural elements such as connections between the other elements, columns, walls, beams, and slabs. The most popular connection method is the lap splice, which is employed more than other approaches such as welding and mechanical solutions, due to its ease of usage [

4,

5,

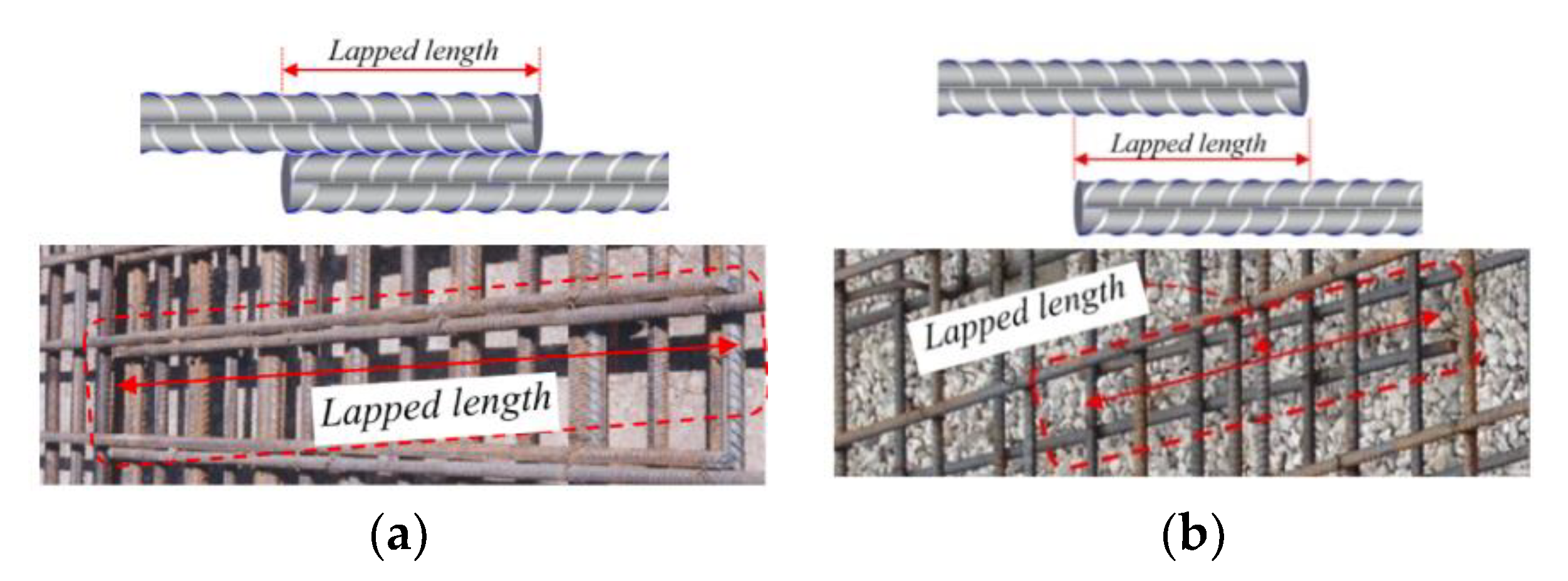

6]. As seen in

Figure 1, this method requires overlapping and clamping two parallel rebars and is classified as either a contacting (

Figure 1a) or a non-contacting splice (

Figure 1b).

The performance of lap splices is highly dependent on numerous parameters including lapped length, concrete cover, lapped rebar percentage, reinforcement rebar diameter, transverse reinforcement consideration near the splice, concrete mechanical qualities, and casting location [

7,

8,

9]. One of the fundamental requirements for the appropriate analysis and design of RC buildings is the bond behavior between the reinforcing steel and the surrounding concrete. This has an impact on the serviceability and eventual limit states of a reinforced concrete structure. The behavior is significant for analyzing the sites where bond characteristics become the governing element for the structure’s stability and integrity. The ribs of a non-contacting lapped rebar under tensile stress (such as tensile rebars in a RC beam) carry an angled compressive force induced by the surrounding concrete (

Figure 1). This mechanism is responsible for splitting fractures [

10,

11,

12]. The movement of bar ribs adds lateral stress to contact lap splices, while diagonal compression links between the rebars transfer stresses between the rebars. Research indicates that transverse reinforcement and surrounding concrete create restricting tensile forces [

13]. In general, crucial bond behavior areas include (i) at the contra flexure point or the continuous supports, (ii) at deep beam supports, (iii) at connections between the beam and the column, and (v) at the mid-span of simply supported beams. Strengthening of inadequate lap splices could lessen the earthquake susceptibility of old, inadequate RC structures, lowering economic and social hazards. Thus, this paper discusses a variety of techniques for enhancing the binding strength of RC components with inadequate splices. Almost all strengthening techniques will be thoroughly detailed in the following sections.

This study focuses on earlier investigations on short, insufficient splices and joints that fall short of code requirements for strengthening which were conducted on a variety of concrete components, including pull-out samples, spliced beams, columns, and beam–column joints. This study is significant because it lists, summaries, contrasts, and identifies the benefits and drawbacks of each strengthening technique that was utilized to restore the damaged area in the existing concrete elements, which comprised short splices. The research also uncovers fresh areas that are worth exploring. Debonding, which occurs at the splice region (and is primarily caused by inadequate lapped length as a result of design or construction errors, design based on outdated codes, or natural disasters), is another common failure encountered in lap splice locations. Therefore, it is necessary to strengthen existing subpar splices in RC structures. The goal of this study is to review and analyze experimental strengthening techniques for poor splices. Therefore, the following topics are examined in this research: bond failure modes; the most popular confining techniques, such as spiral confining; other confining methods including with internal or external steel stirrups, or with CFRP; concrete jacketing; FRP; post-tensioning of prestressed concrete; external confining with CFRP; near surface mounted (NSM) techniques; UHPC; fiber reinforced concrete (FRC); and combinations of two techniques. Each method of strengthening is assessed according to its effectiveness, advantages, disadvantages, application-specific elements, and factors affecting the design and scope of applicability. In addition, a comparison of the most prominent methodologies was conducted. We provide the most up-to-date research and recommendations for improving subpar lap splices.

2. Test Methods of Splices

Numerous specimens have been utilized to-date to test bond characteristics, as depicted in

Figure 2. Pull-out specimens (

Figure 2a), beam end samples (

Figure 2b), Rilem beams (

Figure 2c) and lap-spliced beams (

Figure 2d) are specimens typically used in splice testing.

The pull-out specimens were used in the majority of the bond-slip investigations. The simplicity of altering their characteristics, such as the cover, diameter of the bar, material, confinement, and development length, as well as the fact that they are affordable and portable, are the key reasons why pull-out specimens are popular within the research community. However, because the concrete is pressed during examination while the steel stays in tension, pull-out samples do not accurately depict the actual state of stress in structural materials under flexure. The splice beam specimen, depicted in

Figure 2d, is a much more realistic beam sample that has been extensively used to research bond behavior. The splice beam specimen is heavily represented in the ACI data set for the development of the design formulas in ACI 408 R [

14] and ACI 318 R [

15].

Although the limited length assures equal bonding stresses throughout the bonded distance, local irregularities generated by disintegration in concrete under environmental influence may considerably alter bond behavior. As a result, the pull-out sample does not adequately depict bonding behavior and, consequently, investigators have recently preferred beam samples for studying bonding-slippage behavior. The recommended developed (bonded) length of splices in steel rebars according to international norms will be thoroughly detailed in the following sections.

3. Bond Failure Modes

The most common failure reported in lapped splice zones is bond loss, which occurs in the lapped area and is mostly caused by insufficient lapped length. Longitudinal bars glide along each other during lap splice debonding, causing longitudinal fractures (

Figure 3a). When debonding worsens, longitudinal fissures spread in the concrete cover, causing concrete spalling and reducing the flexural strength of the components. The spliced bars eventually separate, and then the element collapses totally. The collapse pattern of lapped splices in RC columns is depicted in

Figure 3. Furthermore, several disastrous collapses in these structures during the latest major earthquakes, such as Kashmir 2005 (

Figure 3a) and Loma Prieta earthquake (

Figure 3b) have been attributed to the weakness of inadequate quick lapped rebars—which have been generally offered at high-demand places like the column–footing interaction or above the beam–column joint. These lapped splices generally have distances of L

b = 20–24 d

b (d

b = bar diameter), which are shorter than the splice distances suggested by bond benchmarks of the latest design standards [

16,

17,

18] (which generally require L

b to be greater than 40–60 d

b) and thus insufficient to mobilize the full capacity of the spliced bars. The failure location always occurred at the end of a lapped splice (

Figure 3c) and took placed at the column bottom end (

Figure 3d). The failure mechanisms of the bond reaction will be thoroughly explored in the following sections.

Figure 4 depicts many common bond reaction failure patterns during pullout or spliced beam specimen testing. The bonding collapse mechanisms of the samples are classified into three kinds based on embedded length, concrete cover thickness and concrete type: pull-out, bonding splitting collapse, and bar rupture collapse. First, the majority of pulling out collapses occur in specimens with insufficient anchoring length, which is related to bond failures. There are no noteworthy phenomena on the concrete surface throughout the slow pullout procedure of the test rebar. As the testing force is increased, the bar is pulled out without any fractures on the surface of the concrete (

Figure 4a). Second, bond-splitting failure is most common in splice-beam specimens with insufficient anchoring lengths and a thin concrete cover at the beam soffit, as shown in

Figure 4b. Third, broken-bar failure: this occurs primarily in specimens with sufficient embedded lengths and no visible phenomena on the concrete’s surface. This may be explained by the fact that the bar is implanted for a significant length, causing the bond force to surpass the ultimate tensile force of the bar and causing it to break (

Figure 4c). Moreover, there is another type of bar failure that is commonly seen in FRP bars, called interlaminar shear failure between the bar resin surface and internal fibers, as reported in [

19]. Adequate bonding between the bar and the concrete through the lapped zone is critical for the RC structure’s construction. As the most susceptible portion of the member, it is critical to avoid splits and pullout collapses in the lapped regions. Various strategies for stabilizing such structures were examined.

4. ACI Design Provision for Lap Splice Lengths in Tension and Compression

Substandard bonded length is defined as the distance of embedded length that is shorter than the code-recommended distance. This ideal length is equal to 40–60 times d

b when the reinforcing bars are under tension and 20–40 times d

b when they are under compression, according to the Egyptian Code [

18]. Tensile developed (bonded) length (L

d) in ACI318-19 [

9] could be estimated with regard to the general Equation (1):

where

;

is the concrete cylindrical compressive strength;

is the area of all transverse reinforcement through spacing S; S is the spacing of lateral bars through

; n is the number of bars being lap spliced along the plane of splitting;

are factors varied from 1 to 1.3 according to ACI, 318–19 [

9];

is the lesser of one-half of the rebar distance and the length from the closest surface of the concrete;

must not exceed 1.7; and

is yield strength of the reinforcing bar.

In addition, as stated in the ACI guideline [

9], the bonded length of a smaller ribbed bar of less than 19 mm in diameter, in tension, can be evaluated as:

where

is the position indication—which is 1.3 when the rebars are fixed horizontally above a concrete thickness of more than 300 mm; or is 1 in all other cases.

According to ACI 318-19 [

9], compression lap splice length is limited by the following conditions:

For ≤ 420 MPa: is the larger of 0.071 and 300 mm; while for larger than 420 MPa: is the larger of (0.13 -24) and 300 mm.

The recommendations of Eurocode 2 [

20] are: (1) lap splices should not be positioned at high moment or plastic hinge, (2) net distance between lapped rods should not be larger than 4 times bar diameter or 50 mm, (3) the longitudinal distance between two adjacent rebars should not be less than 0.3 times the lap length, (4) in adjacent laps, net distance between adjacent bars should not be less than 2 times bar diameter or 20 mm, (5) permissible percentage of spliced rebars in tension is 100% and 50% when the bars are in one or several layers, respectively, and (6) minimum lapped distance is 200 mm.

The recommendations of UBC [

21] are: (1) minimum diameter of lap-spliced bar should be larger than no. 11, (2) minimum lapped distance in tension is 305 mm, and (3) minimum lapped distance in compression is 0.0005

for

larger than 60,000 Psi.

5. Strengthening Approaches

Strengthening of inadequate lapped spliced elements could lessen the earthquake susceptibility of present inadequate RC structures, lowering social and economic hazards. The improvement of structural elements is complex and costly, but is necessary in construction. Causes of structural members’ insufficient capability include design with now-obsolete code rules, natural calamities, and environmental influences. As a result, structural elements are weakened and must be reinforced. In order to improve defective structural elements, all available building materials must be utilized in strengthening procedures. Prior to strengthening, deteriorated structural elements must be evaluated and thoroughly studied to determine their in situ state. As a result, strengthening indicators must be estimated based on the structural condition in situ.

Numerous methods, including spiral confinement [

20], concrete jacketing with interior and exterior steel ties [

21,

22,

23], other jacketing using metal [

24,

25,

26], fiber reinforced concrete (FRC) and concrete jacketing [

27,

28,

29], and externally confined by using FRP [

29,

30,

31,

32,

33], have been performed for enhancing RC members provided by tight lapped splices.

Eight reinforced concrete columns with inadequate lap splice length were investigated for their behavior [

34]. Five columns were evaluated after retrofitting with CFRP; one column was tested after retrofitting with a traditional steel jacket; and two columns were tested as reference specimens. All test specimens were put through cycles of increasing lateral displacement and constant gravity load. The test specimens had 1.5 or 2.0 aspect ratios and rectangular cross sections. Low-cycle fatigue rupture of the longitudinal bars instead of lap splice failure and/or flexural failure was the mode of failure due to CFRP and steel jacketing. The gap between the jacket and the column base was the main area of damage in all of the modified examples. The upgraded columns maintained their lateral strength at displacement ductility coefficient values of 7 or above. The ductility levels attained by each of the retrofitted specimens were 1.1 to 1.4 times higher than those of the as-built specimens.

All of the following strengthening approaches have been shown to improve the adhesion capacity of inferior splices. In the following sections, each strengthening technique will be explained and evaluated based on its performance, benefits, drawbacks, application-specific elements, and variables influencing the design and scope of applicability.

5.1. Confining Spirals

Tepfers [

22] investigated the impact of steel reinforcement spirals around splice areas under tension, as seen in

Figure 5. These experiments were carried out on lap-spliced beams utilizing a four-point bending flexure test. The main factors included concrete strength, existing spirals at the splice, spiral diameter, and splice length. It was discovered that both concrete strength and confining spirals had a remarkable effect on the structural behavior of the beams. As the diameter of the spirals increased, the bonding performance improved, clearly indicating that the number of reinforcing spirals had a major effect on the splice’s bond strength, and that the increase in contact area between spirals and concrete positively affects the bonding performance.

5.2. Confining with Internal/External Steel Stirrups or CFRP

Concrete confinement is one of the most successful methods for enhancing performance under monotonic and seismic loads. Confinement of the concrete inside the crucial hinging zones of structures in high seismic hazard locations improves the splice behavior of the reinforcing rebars under tensile force and hence the seismic response of structures. The usage of lateral ties made from close stirrups is one of the most prevalent methods of concrete confinement [

35,

36,

37,

38,

39]. Assaad [

40] (

Figure 6) conducted experiments on bonding behavior resulting from the effects of actively confining RC using exterior lateral compression plus passively confining, carried out by one of the following methods: (i) lateral reinforcement stirrups, (ii) CFRP jacketing, (iii) combination of lateral reinforcement stirrups and CFRP jacketing and (iv) combination of CFRP jacketing and connectors made from CFRP. All specimens displayed three separate bond failure mechanisms: splitting mode related to concrete cover splitting, pull-out type corresponding to steel bar withdrawal, and a combination of splitting and pullout forms. In comparison to unconfined concrete, confinement of the concrete using each method enhanced the local bond strength considerably, changed collapse from split concrete cover to another mode, and increased the deformability of the bonding stress–slippage relationship. These enhancements were strongly reliant on the kind and amount of confinement employed, along with the ratio between the cover and rebar diameter.

5.3. Concrete Jacketing with UHPFRC

The usage of RC jacketing is the first and most common way to strengthen splice connections. These jackets are typically made of high-strength concrete. RC jacketing is a reinforcing technique that, despite its shortcomings, is commonly used before or after strengthening [

41,

42,

43,

44]. Because it has been demonstrated that RC jacket methods do provide enhanced spliced mechanical performance, can change the failure to outside the spliced region, and improve overall strength and energy dissipation, the procedure has been proven to be the most preferred option for engineers in seismic-prone areas over the last decades [

45,

46]. For example, using ultra-high-performance fiber reinforced concrete (UHPFRC) improved the column–footing connection [

47] (

Figure 7). The obvious drawbacks of concrete jacketing systems are the labor-intensive operations required. Furthermore, jacketing expands member sizes, reducing available floor space while increasing mass and changing stiffness. As a result, jacketing procedures modify the dynamic properties of the structure. Changes in dynamics may result in increasing demands in unexpected places [

43,

44], necessitating an effect on the overall performance of the entire system. Karayannis [

48] studied a unique reinforced concrete jacketing to rehabilitate cyclically deformed reinforced concrete external beam–column connections. The considered jacket is exceedingly thin and features steel bars with tiny diameters. The benefits of the suggested thin and locally applied reinforced concrete jacketing over generally utilized reinforced concrete jacket are centered on the fact that the dimensions of repaired pieces minimally vary in comparison to their original dimensions, and their applications are not significantly limited by space constraints. Indeed, the hysteretic property of repaired samples was completely restored or enhanced with reference to the property of the original samples in the starting loading. In addition, the suggested jacketing technique appears to be a straightforward, reliable, and effective method for mending and rehabilitating faulty connections. In comparison to the original specimens, the retrofitted specimens exhibited enhanced maximum load and distortion rates, greater energy dissipation and stiffness, and a substantial improvement in strength characteristics. The thinner and locally implemented RC jacket in question either improves the damage performance of the beam–column junction by transitioning from a brittle to a ductile collapse type, or does not change the original joint’s failure characteristics if they are ductile.

All of the specimens that initially exhibited joint shear failure were retrofitted with schemes that moved the damage to flexural hinging at the beam area. In the retrofitted specimens, thin diagonal fractures were observed across the joint region of the jacket, but there was no evidence of the cover sliding off. Similarities in the harm level advancement during testing between the retrofitted samples with reinforced thin jacketing and their original samples revealed that the suggested jacket is an effective maintenance method, as the reconditioned joints had smaller collapse indicator variables than the original specimens. Furthermore, the proposed use of thick reinforcement in the suggested jacketing may be classified as a strengthening strategy because the retrofitted specimens demonstrated significantly lower failure levels than the originals at the same load levels in the majority of the tested cases.

5.4. FRP and TRM

The advantageous features afforded by these materials include corrosion resistance, ease and speed of installation, a high strength to weight ratio, and little change in dimensions. In addition, the usage of FRPs has acquired substantial popularity among all jacketing procedures. In general, FRP confinement causes an external force on the strengthened element (

Figure 8). Many investigations [

48,

49] have shown enhanced behavior in FRP confined lap-spliced zones. FRP jackets offer confinement in areas with straight lap-spliced rebars, increasing friction strength between lapped splice and preventing slippage of the bar. Slippage is not activated in the lapped splice of a simple rebar with a 180° hook, and is thus not an issue [

49]. Additionally, several challenges for strengthening were overcome when FRP (fiber-reinforced polymers) became available to the building business. Fakharifar et al. [

50] employed FRP sheets as stirrups to enhance the behavior of RC constructions. FRP stirrups enhanced strength, stiffness, and energy dissipation, according to the findings. FRPs offer higher strength development and durability performance, according to Siddika et al. [

51], whose study also gives a clear outlook for increasing the application and performance of RC beams by FRP strengthening. In addition, Hamad et al. [

52,

53] investigated the effect of FRP on the strengthening of lapped and spliced RC beams. They discovered that employing one or two wraps made from GFRP boosted bonding resistance by 8% and 33%, respectively. In other investigations on normal reinforced concrete beam specimens, it was discovered that the effects of wraps made from CFRP on normal and high strength concrete beams are similar. The use of several CFRP wraps over normal concrete enhanced bonding resistance by 11–34%. According to Bournas [

32], the confinement of composite jackets (FRP and textile reinforced mesh, or TRM) adds to the bonding strength of lapped rebars and the concrete. The bond stress evolution at crucial sections of full-size columns under cyclic load was studied. In contrast to pullout bonding experiments, the test system used in the work in question accurately represented almost all bonding responses between lapped spliced rebars and the concrete in the plastic hinge area of seismically loaded columns. The findings revealed that a small lapped spliced distance of 20 d

b is insufficient for bonded length of longitudinal bar yield strength, but a longer lapped length of 40 d

b is enough for bonded length of bar yield stress. As TRM and FRP jacketing reduced the formation of longitudinal splitting cracks, the bonding resistance between lapped spliced rebars and concrete was enhanced. In general, external confinement with composite jackets and improved bonding–slippage relationships throughout the lapped splice zone improved constrained columns’ global reaction as measured by deformation capacity and strength upon failure.

5.5. Post-Tensioning

Post-tensioning is a technique nearly universally employed in prestressed concrete constructions to improve performance by subjecting the concrete to compression stress prior to loading. Historically, this approach began by strengthening spliced structural elements such as columns and spliced beam specimens. The tension force is often provided using high tensile steel bars or straps. Following post-tensioning, the bars or straps are secured mechanically using push-mode seals and jaws to retain the tension force. This actively confines members, enhancing their capacity and ductility even before loads. The post-tensioning method utilizing strap (PTMS) strengthening provides benefits over other strengthening procedures: for example, simplicity and application speed, cheapness, ease in release or in replacement of damaged straps, and flexibility to reinforce several types of structural parts. The PTMS may be easily strengthened around reinforced concrete columns [

54,

55], but where metal straps cannot be installed due to an existing slab, anchoring plates are needed to fasten the PTMS to the surface of beam–column joints or beams. PTMS strengthening on a substandard full-scale RC building was successfully secured using such an anchoring strategy [

32]. In general, it is anticipated that employing PTMS to reinforce weak structural elements will result in faster and more affordable solutions than other traditional repair techniques, especially in poorer countries where material costs make up the majority of repair expenditures. Helal [

56] used the PTMS technique and steel confinement to strengthen short splices in RC beams (

Figure 9). For a short length, the major flexural reinforcement of the beams was lap spliced (10 bar diameters). The results revealed that: (i) unconfined control specimens with tight splices failed in a brittle manner due to splitting of the concrete cover around the splice; (ii) steel confined beams collapsed by splitting at similar or slightly greater loads (up to 12% greater) and bond capabilities (up to 14% greater) than unconfined specimens; (iii) PTMS confinement slowed lap splice splitting collapse, and PTMS confinement increased bond capacity by up to 58%; (iv) despite the strap losses, the suggested PTMS strengthening approach proved exceptionally efficient at retaining beam integrity even after significant splitting occurred; (vi) the experimental results of this work show that PTMS confinement improves the behavior of reinforced concrete elements under monotonic loads. The behavior of structural components has been examined in a range of studies [

57,

58,

59,

60,

61,

62,

63,

64,

65,

66,

67,

68,

69,

70,

71,

72].

5.6. External Confining with CFRP

Concrete strength can be effectively enhanced by external FRP confinement [

73]. In the past 2 decades, externally bonded FRP has been routinely used to enhance response to seismic activity of vulnerable building parts. Compared to all other reinforcement technologies, FRP offers advantages such as excellent corrosion resistance, high strength with respect to weight, application speed, and the capability of specifically enhancing the seismically inadequate portions only. Several experiments [

28,

74,

75,

76,

77,

78,

79,

80,

81] have shown that FRP confining improves the behavior of columns with inadequate lengths of lapped reinforcement (for example, L

b = 20–35 d

b). Moreover, Garcia [

82] examined the bond strength of externally bonded CFRP in the lapped splice region of reinforced concrete beam specimens. CFRP confines an increase in bonding resistance of 65%, because CFRP confinement enhances the concrete strength, and thus the bond strength.

As a seismic retrofit measure for inadequate lap splices, Harries et al. [

49] prompted an investigation into the usage of carbon fiber-reinforced polymer (CFRP) jackets. Three full-scale construction column specimens with lap spliced longitudinal reinforcing bars were tested under combined axial and cyclic lateral loads. The columns were purposefully made so that the lap splices would fail before they could stretch to their full capacity. While the other columns had CFRP jackets installed, one column was examined as a control specimen without any refitting. In addition, comparisons were made with the test outcomes of comparable columns without lap splices. It was demonstrated that the column’s nominal flexural capacity may be attained by retrofitting a CFRP jacket. However, the slide of the spliced bars, which causes a splitting failure in the lap splice zone, limits the ductility of the restored column.

In rectangular reinforced concrete (RC) columns, Harajli [

81,

82,

83,

84,

85] experimentally examined the usage of external fiber-reinforced polymer (FRP) wraps for bond strengthening of spliced reinforcement and the ensuing impact on the seismic response of the columns. The column specimens that were tested had lap-spliced reinforcement at the base that were fully scaled, or were unconfined, or FRP-confined. Additionally, companion columns that met the ACI building code criteria for areas with high seismic hazards (earthquake-resistant columns) were tested for comparison. These columns included continuous reinforcement and internal steel confinement. It was discovered that enclosing the spliced zone with FRP wraps improved the spliced bars’ bond strength, decreased bond deterioration and pinching under cyclic loading, and improved the columns’ lateral load resistance and ductility. The upgrades were similar to those of the earthquake-proof columns. As the ratio of concrete cover to splice diameter decreased and the area of FRP wraps rose, the lateral strain in the FRP increased.

5.7. Near Surface Mounted Technique

When compared to other known approaches for strengthening bond strength, FRP confinement and the near surface mounted (NSM) technique are both quite promising. On lap-spliced beams, the effects of the NSM technique with steel bars and CFRP have been explored. Some studies found that: (1) flexure capabilities of reinforced beams improved by 73–91% compared to lapped spliced beams as well as 27–40% compared to beam specimens with no lapped rebars, and (2) deformability that occurred due to the NSM technique was larger than that in the external bonded reinforcement strengthening (EBR) method, which was investigated by Allam [

86]. Garcia et al. [

82,

87] evaluated the lap-splice zone confinement effects utilizing stirrups (internally) and CFRP confinement (externally). Stirrups enhanced bond strength by 14%, whereas CFRP confinement boosted the former by 65%. Anagnostou et al. [

88] conducted research on stiffening columns with lapped rebar using FRP confining.

Garcia et al. [

89] studied the efficiency of FRP in preventing bonding split collapse. While research on the benefits of the NSM technique for enhancing lapped spliced reinforced concrete beams is limited, no studies have been identified that examine the effect of combining the NSM and FRP technologies for the aforementioned task. Short splices in unconfined control beams caused the concrete cover to fracture, leading to brittle failure. Steel-confined beams failed by splitting at similar or slightly greater loads (13%) and bond strengths (18%) as compared to unconfined specimens. However, bar slips went up by as much as 590%. After splitting, steel-confined beams showed a slightly ductile behavior and could resist considerable additional deformations with a progressive loss of strength. The use of CFRP confinement that was externally bonded prevented the laps from splitting prematurely. CFRP confinement also increased the bond strength and bar slip by up to 49% and 1200%, respectively, in comparison to unconfined specimens. Through increasing the splice bond strength, strengthening treatments using one or two CFRP layers were highly successful. Any more confinement than this appeared unnecessary—and therefore uneconomical—for developing the full bond strength of the lap.

On lap-spliced RC beams with short lap-splice length, Mousavi et al. [

90] examined NSM effects and combining NSM-CFRP approaches to confinement strengthening (

Figure 10). As well as enhancing the mechanism, the bottom concrete cover and NSM bar length were parameters to consider. The findings revealed that strengthening techniques improve the capacity ability, energy absorption capacity, and ductility of lapped and spliced RC beam specimens. NSM rebar specimens with a longer length have a smaller ductility than NSM rebar specimens with a short length. In contrast, longer NSM bar beams have better energy dissipation capacity and flexure capacity. The addition of CFRP confining to lapped spliced RC beam specimens reinforced with the NSM technique (NSM-CFRP confinement) improves energy dissipation capability and ductility, as well as causing a significant improvement in load-bearing capacity. Strengthening techniques have a significantly greater impact on boosting the flexure capacity of the specimens cast with more concrete coverings. Additionally, the impact of CFRP wrap on enhancing energy dissipation capacity and ductility is less than that of concrete cover.

5.8. Ultra High Performance Concrete

Several methods for strengthening poorly defined lap splice joints in circular or square columns by giving external confinement to the element have already been discussed and implemented. These procedures, however, are not applicable to lap splices, which are not rectangular structural elements such as beams and columns. In these cases, it is necessary to investigate other methods for strengthening the bond of lap splices. Canbay and Frosch [

91] identify two failure modes associated with deformed bars under tension: pullout and splitting. Fiber-reinforced concrete (FRC) can reduce or even eliminate concrete splitting, helping to strengthen the binding mechanism in lap-splice zones (Harajli [

92]). With the recent availability of self-compacting FRC and, more recently, ultra-high-performance fiber-reinforced concrete (UHPFRC), new prospects for reinforcing defective structures have emerged (Habel et al. [

93]). The capacity of FRC to control the opening of splitting cracks caused by bond stress component pressure acting perpendicularly to the bar axis seemed to be a solution for enhancing lap splice behavior (Harajli et al. [

94]). UHPFRC had an advantage over FRC because its compressive strength was higher. Additionally, UHPC is stronger and has better material qualities than FRC built of regular concrete.

Vachon and Massicotte [

95] investigated this route. Marc carried out an experiment to assess the role of UHPFRC in reducing the splitting failure mechanisms of defective tensile lap splices. Splice length, repair depth, and bar arrangement were the parameters investigated. The results indicated that normal concrete specimens with shorter splice lengths failed by splitting the concrete in the splice zone. Failures were unexpected and characterized by a complete absence of resistance. UHPFRC was efficient in strengthening the weak lap splice. Due to the high tensile strength and energy-absorption characteristics of the UHPFRC utilized, failure by splitting in the lap splice zone was delayed or even eliminated. Bond stresses in specimens enhanced with UHPFRC were found to be more than double those of conventional concrete. Stirrups or transverse reinforcement might be used to improve the behavior of lap splices even further.

5.9. Fiber Reinforced Concrete

Steel fiber (SF) and polypropylene fiber (PF) have been used for decades to enhance the mechanical characteristics of concrete. Moreover, with the fast advancement of the construction of structures, fiber reinforced concrete (FRC) comprising SF and/or PF has gained widespread recognition for its effective improvement in energy dissipation, crack resistance, and tension [

96,

97,

98]. The bond resistance of the steel bar is mainly governed by the concrete’s compressive strength, which is considerably altered by the addition of the fiber to the concrete. The mechanical behavior of FRC constructions when subjected to static or dynamic loadings is heavily influenced by the performance of the bond between reinforcing bars and FRC. Furthermore, employing FRC as an option in key sections of a structure (for example, column bases, the centers of beams, and beam–column interfaces) has been recognized as a viable way to prevent premature bond breakdown [

99]. Numerous studies have been conducted in this area, with several positive outcomes [

100,

101,

102,

103,

104,

105]. Güneyisi et al. [

100] found that utilizing SF greatly improved adhesion resistance. An increase in slippage was also detected following the insertion of fibers [

106,

107]. In addition, a number of studies [

106,

107,

108,

109,

110] found that the usage of steel fiber reinforced concrete (SFRC) reduced structural damage while increasing earthquake resistance. Huang [

110] experimentally studied the bonding behavior of the bar embedded in polypropylene/steel hybrid fiber reinforced concrete. A pullout test was performed on 112 samples that were subjected to cycling and static loads. He investigated the effect of slenderness ratio and content of steel fiber, grade of the concrete and confinement using ties on bonding behavior. It was shown that polypropylene/steel hybrid fiber significantly improved bonding behavior (increase in ductility, ultimate bonding response, and ultimate slippage).

Others, however, observed an opposing outcome [

111,

112,

113,

114]: for example, Harajli et al. [

112] proved that a negligible rise could be credited to the inclusion of SF, and the advancement was viewed as a by-product of the rise in concrete resistance. Moreover, Dancygier et al. [

114] found that fiber integration significantly weakened bonding, with a reported 30% decrease in bonding resistance due to local matrix disruption near the embedded bar, and no correlation was found between bonding and concrete resistances.

6. Summary of the Strengthening Methods

To perform a well-rounded comparison between different strengthening methods, a comprehensive study is required on identical RC members such as columns and beams with the same testing setup and similar samples that differ only in respect of the splice strengthening approaches. This section makes a general comparison based on the findings of the studies in this paper, as shown in

Table 1. These findings were classified into three categories: investigations into RC spliced beam specimens, investigations into RC columns with short splices, and investigations into pullout specimens with poorly embedded bar length. It is noteworthy that almost all previous studies were conducted on embedded lengths varying from 5 to 32.2 times the bar diameter, which were found to be less than the standard bonded length according to national codes. In addition, it was clear that all strengthening methods enhanced the bond resistance of the short splices in the different elements. When different strengthening methods are compared, the use of UHPFRC with different thicknesses at splice regions achieves the highest increase in bond strength (100%) while the usage of GFRP wrap has the least increase in bond strength (8–34%). When compared to uncontrolled splices, bond strength gains were reported to be 50–65% for construction joints confined with steel stirrups and 30–70% for splices confined with FRP. Steel and concrete jacketing treatments are frequently invasive, labor-intensive, time-consuming, and can disrupt building functionality. The concrete jacketing also adds bulk to the structure, placing it under more seismic stress. The initial cost of FRP, on the other hand, may dissuade its use as a strengthening option in low- and middle-income developing countries. To replace and improve RC connections, epoxy repair, concrete jacketing, steel jacketing, and fiber-reinforced polymer (FRP) composite solutions are all employed. Each approach needs a distinct amount of creative elaboration as well as labor, expense, disturbance of building occupancy, and a wide range of other considerations. Almost all scientists studying the influence of fibers on bonding strength have concluded that fibers have a favorable impact on bonding strength, increasing it by roughly 35%. In contrast, a few studies found that using steel fiber reduced bonding strength by about 30%. (i.e., Dancygier [

114]). This unexpected decline occurred because the fibers generated local disturbance of the concrete mixture which prevented proper compaction close to the rebar surface [

114].

Table 2 summarizes advantages and drawbacks of each retrofitting approach used for strengthening RC elements, including availability, cost, construction technology, application, construction time and efficiency.

Using recycled concrete powder (RP) as an alternative binder can effectively reduce construction and demolition waste and contribute to developing eco-friendly repair materials. The effect of RP on magnesium potassium phosphate cement has been studied by He et al. [

115]; and case study investigations on concrete wall drying process have been carried out by Vertal et al. [

116]. Moreover, the improvement mechanism of water resistance and volume stability of magnesium oxychloride cement was studied (Ma et al. [

117]).

It is crucial to discuss cost analysis and perform a comparison of the different strengthening methods which fall into two broad categories: internal approaches and external approaches. Constricting spirals and constricting using internal steel stirrups are examples of internal modes that are used before the element is built. The remaining methods are considered external modes because they are used after the element is built. In comparison to any external approach, internal solutions are extremely inexpensive, quick, and simple to install. Yet, when mistakes are made in the design and construction of the requisite splice length, external reinforcing methods have to be used, even if though expensive. All strengthening techniques that rely on CFRP are more expensive than others, such as UHPC and concrete jacketing. Examples include externally confining with CFRP, externally mounting CFRP sheets or rods, post-tensioning prestressed FRP, and externally confining with CFRP. Notably, UHPC is more expensive than concrete jacketing. In addition, employing steel bars or sheets for near-surface mounting is less expensive than both concrete jacketing and UHPC.

7. Summary and Conclusions

Splicing of reinforcement bars is an unavoidable issue that has a significant impact on the overall performance of RC structures under static and dynamic loads at serviceability and ultimate limit states. Debonding is the most prevalent failure discovered in lap splice sites. It occurs at the splice region and is caused mostly by insufficient lapped length as a result of design or construction error, design under an antiquated code, and natural disasters. As a result, reinforcing existing poor splices in RC structures is critical—and the purpose of this study was thus to provide a current review of the strengthening methods used for inadequately connecting steel bars.

There are two categories of these strengthening techniques: internal approaches and external approaches. Constricting spirals and constricting by means of internal steel stirrups are examples of internal modes that are used before the element is built. The remaining methods are considered external modes because they are effectuated after the element is built. In comparison to any external approach, internal solutions are extremely inexpensive, quick, and simple to install. However, when mistakes have been made in the design and construction of the requisite splice length, external reinforcing methods have to be used, even if they are expensive. All strengthening techniques that rely on CFRP are more expensive than others, such as UHPC and concrete jacketing. Examples of these CFRP techniques include externally confining with CFRP, externally mounting CFRP sheets or rods, post-tensioning prestressed FRP, and externally confining with CFRP. Significantly, UHPC is itself more expensive than concrete jacketing. In addition, employing steel bars or sheets for near-surface mounting is less expensive than both concrete jacketing and UHPC.

Numerous strengthening techniques were presented in the current paper, each with its own comprehensive definition, literature analysis, failure mechanisms, suggestions, benefits, and drawbacks. Furthermore, the approaches were compared in terms of overall performance, construction time and cost, and necessary equipment and expertise. The following are the most noteworthy conclusions:

- (1)

Pull-out specimens, beam end specimens, Rilem beams, and lapped spliced beam specimens can all be used to test steel splices.

- (2)

By default, there are three types of mechanisms in specimens with splices. First, there is pull-out failure, which happens most frequently in specimens with insufficient anchoring lengths. Second, bond splitting failure is most prevalent in splice-beam specimens with inadequate anchoring lengths. Third, bar break failure occurs more often in specimens with sufficient embedded lengths.

- (3)

Concrete strength and confining spirals has a considerable influence on beam structural performance. Furthermore, the number of reinforcing spirals has a significant impact on the splice’s bond strength.

- (4)

The use of FRPs has increased in popularity across all jacketing techniques as a result of the advantages these materials offer, including a high strength-to-weight ratio, corrosion resistance, ease and speed of application, and little change in geometry. Research results show that FRP stirrups enhance stiffness, strength, and energy dissipation. Bond strength is enhanced by 8% and 33% by using one and two layers of GFRP wrap, respectively, over the splices at the mid span of simply supported beams. Additionally, according to research, the local bond strength is greatly raised, the failure mode is altered from splitting to pull-out or mixed splitting/pull-out, and the ductility of the local bond stress–slip response is improved by enclosing the concrete in CFRP jackets.

- (5)

Confining the spliced zone with FRP wraps improves the spliced bars’ bond strength, decreases bond deterioration and pinching under cyclic loading, and improves the columns’ lateral load resistance and ductility.

- (6)

One of the clearest disadvantages of the concrete jacketing method is the labor-intensive tasks that must be performed. Furthermore, jacketing reduces available floor space by expanding member sizes while increasing mass and modifying stiffness. As a result, jacketing methods alter the structure’s dynamic qualities. Changes in dynamics may result in unanticipated increases in demand, with an influence on the overall system. On the other hand, ultra-high-performance fiber-reinforced concrete (UHPFRC) technology can be used for lap splices of rectangular structural elements such as beams and columns. UHPFRC can also decrease or eliminate concrete splitting. The UHPFRC significantly reinforces the weak lap splice. Failure by splitting in the lap splice zone is delayed or even prevented because of the high tensile strength and energy-absorption qualities of the UHPFRC used.

- (7)

The confinement of composite jackets FRP and textile reinforced mesh (TRM) increases bond resistance between lap-spliced bars and concrete by preventing the formation of longitudinal splitting cracks.

- (8)

The post-tensioning technique using straps (PTMS) has advantages over other strengthening processes, such as ease of application and speed, low material cost, convenience of removing/replacing damaged straps, and flexibility to reinforce various types of structural elements. PTMS confinement reduces lap splice splitting collapse and enhances bond capacity by up to 58%.

- (9)

The effect of slenderness/content of steel fiber, grade of the concrete and confinement using ties on bonding behavior of the concrete has been studied. It was shown that polypropylene/steel hybrid fiber significantly improved bonding behavior (with an increase in ductility, ultimate bonding response, and ultimate slippage).

8. Recommendations for Further Research

Despite the vast number of studies conducted on various strengthening techniques for enhancing substandard splices in RC elements, there are still numerous concerns that need to be examined and solved by further research. The following are some of the most important areas that should be considered:

- (1)

There are no design requirements that mandate treatments for RC components with inadequate splices. Lack of research on the behavior of RC members with inadequate splices in the plastic hinge region may be the root cause of this issue. In order to provide recommendations on the usage of various strengthening strategies in RC members, sections, beams, columns, and beam–column connections, extensive research is required.

- (2)

Studying ways of strengthening column–footing connections with short splices must consider bar diameter, splice length, contacting and non-contacting splices, loading type (monotonic and cyclic), and their geometry.

- (3)

Different strengthening methods for the column–slab joint should be explored, with all the previous parameters. In addition, the effect of transversely reinforcing bars through splices must be considered.

- (4)

The impact of hook and head at the splice end has not previously been studied for any short splice strengthening procedure. This lacuna must now be addressed, by examining the effect on bond reaction of the lateral bars perpendicular to the spliced bar.

- (5)

Although almost all researchers who studied the influence of fibers on bonding strength discovered that fibers had a favorable impact on bonding strength, increasing it by roughly 35%, a few studies found that using steel fibers resulted in a 30% decrease in bonding strength (e.g., Dancygier [

114]): this is therefore an area that would also benefit from further research.

Author Contributions

Conceptualization and methodology, S.F., W.M., T.A.T., P.S. and D.K.; software, validation, formal analysis, data curation, visualization, writing—original draft preparation and writing—review and editing, S.F., W.M., T.A.T., P.S. and D.K.; investigation, S.F. and D.K.; resources, supervision, and project administration, S.F. and D.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

This paper was elaborated with the support of the research project VEGA 1/0626/22 of the Scientific Grant Agency, the Ministry of Education, Science, Research, and Sport of the Slovak Republic and the Slovak Academy of Sciences.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Metelli, G.; Cairns, J.; Plizzari, G. The influence of percentage of bars lapped on performance of splices. Mater. Struct. 2015, 48, 2983–2996. [Google Scholar] [CrossRef]

- Mabrouk, R.T.S.; Mounir, A. Behavior of RC beams with tension lap splices confined with transverse reinforcement using different types of concrete under pure bending. Alex. Eng. J. 2018, 57, 1727–1740. [Google Scholar] [CrossRef]

- Tarabia, A.M.; Mahmoud, Z.I.; Shoukry, M.S.; Abudina, A.A. Performance of RC slabs with lap splices using headed bars. Alex. Eng. J. 2016, 55, 2729–2740. [Google Scholar] [CrossRef] [Green Version]

- Alyousef, R.; Topper, T.; Al-Mayah, A. Crack growth modeling of tension lap spliced reinforced concrete beams strengthened with fibre reinforced polymer wrapping under fatigue loading. Constr. Build. Mater. 2018, 166, 345–355. [Google Scholar] [CrossRef]

- Karabinis, A.I. Reinforced concrete beam-column joints with lap splices under cyclic loading. Struct. Eng. Mech. 2002, 14, 649–660. [Google Scholar] [CrossRef]

- Najafgholipour, M.A.; Dehghan, S.M.; Khani, M.; Heidari, A. The performance of lap splices in RC beams under inelastic reversed cyclic loading. Structures 2018, 15, 279–291. [Google Scholar] [CrossRef]

- Goksu, C.; Yilmaz, H.; Chowdhury, S.R.; Orakcal, K.; Ilki, A. The effect of lap splice length on the cyclic lateral load behavior of RC members with low-strength concrete and plain bars. Adv. Struct. Eng. 2014, 17, 639–658. [Google Scholar] [CrossRef]

- Al-Quraishi, H.; Al-Farttoosi, M.; AbdulKhudhur, R. Tension lap splice length of reinforcing bars embedded in reactive powder concrete (RPC). Structures 2019, 19, 362–368. [Google Scholar] [CrossRef]

- ACI, 318–19; Building Code Requirement for Structural Concrete and Commentary, Reported by American Concrete Institute Committee. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Sanchez, D.; Feldman, L. The effect of splice length and distance between lapped reinforcing bars in concrete block specimens. In Proceedings of the 12th Canadian Masonry Symposium, Vancouver, BC, Canada, 2–5 June 2013. [Google Scholar]

- Grant, J.P. Non-Contact Lap Splices in Dissimilar Concretes. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2015. [Google Scholar]

- Schuller, M.P.; Hammons, M.I.; Atkinson, R.H. Interim Report on a Study to Determine Lap Splice Requirements for Reinforced Masonry. ASTM Spec. Tech. Publ. 1993, 1180, 75. [Google Scholar]

- Sagan, V.; Gergely, P.; White, R. Behavior and design of noncontact lap splices subjected to repeated inelastic tensile loading. Struct. J. 1991, 88, 420–431. [Google Scholar]

- ACI Committee 408; Bond and Development of Straight Reinforcing Bars in Tension. American Concrete Institute: Farmington Hills, MI, USA, 2003.

- American Concrete Institute Committee 318; Building Code Requirements for Structural Concrete (ACI 318-99) and Commentary (ACI 318R-99). American Technical Publishers: Orland Park, IL, USA, 1999.

- ACI Committee 408; 408R-03: Bond and Development of Straight Reinforcing Bars in Tension (Reapproved 2012). American Concrete Institute: Farmington Hills, MI, USA, 2012.

- Taerwe, L.; Matthys, S. Fib Model Code for Concrete Structures 2010; Ernst & Sohn, Wiley: Berlin, Germany, 2013. [Google Scholar]

- ECP 203-2018; Egyptian Code for the Design and Construction of Concrete Structures. HBRC: Cairo, Egypt, 2018.

- Liao, J.; Zeng, J.-J.; Bai, Y.-L.; Zhang, L. Bond strength of GFRP bars to high strength and ultra-high strength fiber reinforced seawater sea-sand concrete (SSC). Compos. Struct. 2022, 281, 115013. [Google Scholar] [CrossRef]

- European Commission. Eurocode 2: Design of Concrete Structures, Part 1-1: General Rules for Building; CEN: Brussels, Belgium, 2004.

- UBC-97; Uniform Building Code. International Council of Building Officials: Lansing, MI, USA, 1977.

- Tepfers, R. Overlap splices for ribbed bars for free use in a concrete structure. Nord. Concr. Res. 1988, 7, 273–283. [Google Scholar]

- Coffman, H.L.; Marsh, M.L.; Brown, C.B. Seismic durability of retrofitted reinforced-concrete columns. J. Struct. Eng. 1993, 119, 1643–1661. [Google Scholar] [CrossRef]

- Lynn, A.C.; Moehle, J.P.; Mahin, S.A.; Holmes, W.T. Seismic evaluation of existing reinforced concrete building columns. Earthq. Spectra 1996, 12, 715–739. [Google Scholar] [CrossRef]

- Melek, M.; Conte, J.P.; Wallace, J.W. Experimental Assessment of Columns with Short Lap Splices Subjected to Cyclic Loads; University of California: Berkeley, CA, USA, 2003. [Google Scholar]

- Aboutaha, R.S.; Engelhardt, M.D.; Jirsa, J.O.; Kreger, M.E. Retrofit of concrete columns with inadequate lap splices by the use of rectangular steel jackets. Earthq. Spectra 1996, 12, 693–714. [Google Scholar] [CrossRef]

- ChaiI, Y.H.; Priestley, M.J.N.; Seible, F. Seismic retrofit of circular bridge columns for enhanced flexural performance. Struct. J. 1991, 88, 572–584. [Google Scholar]

- Elgawady, M.; Endeshaw, M.; McLean, D.; Sack, R. Retrofitting of rectangular columns with deficient lap splices. J. Compos. Constr. 2010, 14, 22–35. [Google Scholar] [CrossRef]

- Beschi, C.; Meda, A.; Riva, P. Column and joint retrofitting with high performance fiber reinforced concrete jacketing. J. Earthq. Eng. 2011, 15, 989–1014. [Google Scholar] [CrossRef]

- Bousias, S.; Spathis, A.-L.; Fardis, M.N. Seismic retrofitting of columns with lap spliced smooth bars through FRP or concrete jackets. J. Earthq. Eng. 2007, 11, 653–674. [Google Scholar] [CrossRef]

- Karayannis, C.G.; Chalioris, C.E.; Sirkelis, G.M. Local retrofit of exterior RC beam–column joints using thin RC jackets—An experimental study. Earthq. Eng. Struct. Dyn. 2008, 37, 727–746. [Google Scholar] [CrossRef]

- Bournas, D.A.; Triantafillou, T.C. Bond strength of lap-spliced bars in concrete confined with composite jackets. J. Compos. Constr. 2011, 15, 156–167. [Google Scholar] [CrossRef]

- Breña, S.F.; Schlick, B.M. Hysteretic behavior of bridge columns with FRP-jacketed lap splices designed for moderate ductility enhancement. J. Compos. Constr. 2007, 11, 565–574. [Google Scholar] [CrossRef]

- Harajli, M.H. Seismic behavior of RC columns with bond-critical regions: Criteria for bond strengthening using external FRP jackets. J. Compos. Constr. 2008, 12, 69–79. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Seible, F. Design of seismic retrofit measures for concrete and masonry structures. Constr. Build. Mater. 1995, 9, 365–377. [Google Scholar] [CrossRef]

- Sause, R.; Harries, K.A.; Walkup, S.L.; Pessiki, S.; Ricles, J.M. Flexural behavior of concrete columns retrofitted with carbon fiber-reinforced polymer jackets. Struct. J. 2004, 101, 708–716. [Google Scholar]

- Eligehausen, R.; Popov, E.P.; Bertero, V.V. Local Bond Stress-Slip Relationships of Deformed Bars under Generalized Excitations; Report No. UCB/EERC-83/23; Earthquake Engineering Research Center, College of Engineering, University of California: Berkeley, CA, USA, 1983. [Google Scholar]

- Orangun, C.O.; Jirsa, J.O.; Breen, J.E. A reevaluation of test data on development length and splices. ACI J. Proc. 1977, 74, 114–122. [Google Scholar]

- Darwin, D.; Lutz, L.A.; Zuo, J. Recommended provisions and commentary on development and lap splice lengths for deformed reinforcing bars in tension. ACI Struct. J. 2005, 102, 892–900. [Google Scholar]

- Assaad, F.; Hany, N.; Fawaz, G.; Hantouche, E.; Harajli, M. Effect of active and passive concrete confinement on the bond stress-slip response of steel bars in tension. Constr. Build. Mater. 2021, 305, 124737. [Google Scholar] [CrossRef]

- Tsonos, A.G. Lateral load response of strengthened reinforced concrete beam-to-column joints. ACI Struct. J. 1999, 96, 46–56. [Google Scholar]

- Lowes, L.N.; Moehle, J.P. Evaluation and retrofit of beam–column T-joints in older reinforced concrete bridge structures. ACI Struct. J. 1999, 96, 519–533. [Google Scholar]

- Dritsos, S.E. Seismic retrofit of buildings a Greek perspective. Bull. N. Z. Soc. Earthq. Eng. 2005, 38, 165–181. [Google Scholar] [CrossRef]

- Tsonos, A.G. Seismic repair of exterior R/C beam-to-column joints using two-sided and three-sided jackets. Struct. Eng. Mech. 2002, 13, 17–34. [Google Scholar] [CrossRef]

- Alcocer, S.A.; Jirsa, J.O. Strength of reinforced concrete frame connections rehabilitated by jacketing. ACI Struct. J. 1993, 90, 249–261. [Google Scholar]

- Engindeniz, M.; Kahn, L.F.; Zureick, A.-H. Repair and strengthening of reinforced concrete beam–column joints: State of the art. ACI Struct. J. 2005, 102, 1–14. [Google Scholar]

- Rodriguez, M.; Park, R. Seismic load tests on reinforced concrete columns strengthened by jacketing. ACI Struct. J. 1994, 91, 150–159. [Google Scholar]

- Karayannis, C.G.; Sirkelis, G.M.; Chalioris, C.E. Seismic performance of RC beam–column joints retrofitted using light RC jacket—Experimental study. In Proceedings of the 1st European Conference on Earthquake Engineering and Seismology, Geneva, Switzerland, 3–8 September 2006; p. 136. [Google Scholar]

- Harries, K.A.; Ricles, J.R.; Pessiki, S.; Sause, R. Seismic retrofit of lap splices in nonductile square columns using carbon fiber-reinforced jackets. ACI Struct. J. 2006, 103, 874–884. [Google Scholar]

- Fakharifar, M.; Dalvand, A.; Sharbatdar, M.K.; Chen, G.; Sneed, L. Innovative hybrid reinforcement constituting conventional longitudinal steel and FRP stirrups for improved seismic strength and ductility of RC structures. Front. Struct. Civ. Eng. 2016, 10, 44–62. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, A.; Alyousef, R.; Amran, Y.H.M. Strengthening of reinforced concrete beams by using fiber reinforced polymer composites: A review. J. Build. Eng. 2019, 25, 100796. [Google Scholar] [CrossRef]

- Hamad, B.S.; Rteil, A.A.; Soudki, K.A. Bond strength of tension lap splices in high-strength concrete beams strengthened with glass fiber reinforced polymer wraps. J. Compos. Constr. 2004, 8, 14–21. [Google Scholar] [CrossRef]

- Hamad, B.S.; Rteil, A.A.; Salwan, B.R.; Soudki, K.A. Behavior of bond-critical regions wrapped with fiber-reinforced Polymer sheets in normal and high-strength concrete. J. Compos. Constr. 2004, 8, 248–257. [Google Scholar] [CrossRef]

- Moghaddam, H.; Samadi, M.; Pilakoutas, K.; Mohebbi, S. Axial compressive behavior of concrete actively confined by metal strips; part A: Experimental study. Mater. Struct. 2010, 43, 1369–1381. [Google Scholar] [CrossRef]

- Garcia, R.; Hajirasouliha, I.; Guadagnini, M.; Helal, Y.; Jemaa, Y.; Pilakoutas, K.; Mongabure, P.; Chrysostomou, C.; Kyriakides, N.; Ilki, A.; et al. Full-scale shaking table tests on a sub-standard RC building repaired and strengthened with Post-Tensioned Metal Straps. J. Earthq. Eng. 2014, 18, 187–213. [Google Scholar] [CrossRef] [Green Version]

- Helal, Y.; Garcia, R.; Pilakoutas, K.; Guadagnini, M.; Hajirasouliha, I. Strengthening of short splices in RC beams using Post-Tensioned Metal Straps. Mater. Struct. 2016, 49, 133–147. [Google Scholar] [CrossRef] [Green Version]

- Khalil, A.; Etman, E.; Atta, A.; Fayed, S. Strengthening of RC Box Beams Using External Prestressing Technique. In Proceedings of the 10th International Conference on the “Role of Engineering towards a Better Environment” (RETBE’14), Alexandria, Egypt, 15–17 December 2014. [Google Scholar]

- Khalil, A.-H.A.-K.; Etman, E.; Atta, A.; Fayed, S. Torsional Strengthening of RC Box Beams Using External Prestressing Technique. IOSR J. Mech. Civ. Eng. 2015, 12, 30–41. [Google Scholar]

- Asran, A.G.; EL-Esnawi, H.H.; Fayed, S. Numerical Investigation of RC Exterior Beam Colum Connections under Monotonic Loads. IOSR J. Mech. Civ. Eng. (IOSR-JMCE) 2016, 13, 60–67. [Google Scholar]

- Asran, A.G.; EL-Esnawi, H.H.; Fayed, S. A Review on Reinforced Concrete Beam-Column connections. In Proceedings of the 11th International Conference on Civil and Architecture Engineering ICCAE-11, Cairo, Egypt, 19–21 April 2016. [Google Scholar]

- Asran, A.G.; EL-Esnawi, H.H.; Fayed, S. Behavior of RC beam-column joint under cyclic loads. In Proceedings of the Ninth Alexandria International Conference on Structural and Geotechnical Engineering (AICSGE9), Alexandria, Egypt, 19–21 December 2016. [Google Scholar]

- Asran, A.G.; EL-Esnawi, H.H.; Fayed, S. Experimental Investigation of RC Exterior Beam Column Connection with Eccentric Beam Subjected to Reversible Quasi Static Loads. Civ. Eng. J. 2017, 3, 221–236. [Google Scholar] [CrossRef]

- Basha, A.M.; Fayed, S. Behavior of RC Eccentric Corner Beam-Column Joint under Cyclic Loading: An Experimental Work. Civ. Eng. J. 2019, 5, 295–308. [Google Scholar] [CrossRef] [Green Version]

- Basha, A.; Fayed, S.; Elsamak, G. Flexural Behavior of Cracked RC Beams Retrofitted with Strain Hardening Cementitious Composites. KSCE J. Civ. Eng. 2019, 23, 1–13. [Google Scholar] [CrossRef]

- Fayed, S.; Basha, A.; Hamoda, A. Shear strengthening of RC beams using aluminum plates: An experimental work. Constr. Build. Mater. 2019, 221, 122–138. [Google Scholar] [CrossRef]

- Hamoda, A.; Basha, A.; Fayed, S.; Sennah, K. Experimental and Numerical Assessment of Reinforced Concrete Beams with Disturbed Depth. Int. J. Concr. Struct. Mater. 2019, 13, 55. [Google Scholar] [CrossRef]

- Fayed, S. Flexural Strengthening of Defected RC Slabs Using Strain-Hardening Cementitious Composites (SHCC): An Experimental Work. Arab. J. Sci. Eng. 2019, 45, 1–12. [Google Scholar] [CrossRef]

- Elsamak, G.; Fayed, S. Parametric studies on punching shear behavior of RC flat slabs without shear reinforcement. Comput. Concr. 2020, 25, 355–367. [Google Scholar]

- Basha, A.; Fayed, S.; Mansour, W. Flexural strengthening of RC one way solid slab with Strain Hardening Cementitious Composites (SHCC). Adv. Concr. Constr. 2020, 9, 511–527. [Google Scholar]

- Fayed, S.; Basha, A.; Elsamak, G. Behavior of RC stepped beams with different configurations: An experimental and numerical study. Struct. Concr. 2020, 21, 2601–2627. [Google Scholar] [CrossRef]

- Fayed, S.; Mansour, W. Evaluate the effect of steel, polypropylene and recycled plastic fibers on concrete properties. Adv. Concr. Constr. 2020, 10, 319–332. [Google Scholar]

- Mansour, W.; Fayed, S. Effect of interfacial surface preparation technique on bond characteristics of both NSC-UHPFRC and NSC-NSC composites. Structures 2021, 29, 147–166. [Google Scholar] [CrossRef]

- Galal, E.; Fayed, S. Flexural strengthening of RC beams using externally bonded aluminum plates: An experimental and numerical study. Adv. Concr. Constr. 2021, 11, 481–492. [Google Scholar]

- Baraghith, A.T.; Mansour, W.; Behiry, R.N.; Fayed, S. Effectiveness of SHCC strips reinforced with glass fiber textile mesh layers for shear strengthening of RC beams: Experimental and numerical assessments. Constr. Build. Mater. 2022, 327, 127036. [Google Scholar] [CrossRef]

- Jiang, C. Strength enhancement due to FRP confinement for coarse aggregate-free concretes. Eng. Struct. 2023, 277, 115370. [Google Scholar] [CrossRef]

- Saadatmanesh, H.; Ehsani, M.R.; Jin, L. Seismic strengthening of circular bridge pier models with fiber composites. J. Struct. Eng. ASCE 1996, 91, 434–447. [Google Scholar]

- Saadatmanesh, H.; Ehsani, M.R.; Jin, L. Seismic retrofitting of rectangular bridge columns with composite straps. Earthq. Spectra 1997, 13, 281–304. [Google Scholar] [CrossRef]

- Seible, F.; Priestley, M.J.N.; Hegemier, G.A.; Innamorato, D. Seismic retrofit of RC columns with continuous carbon fiber jackets. J. Compos. Constr. 1997, 1, 52–62. [Google Scholar] [CrossRef]

- Ma, R.; Xiao, Y. Seismic retrofit and repair of circular bridge columns with advanced composite materials. Earthq. Spectra 1999, 15, 747–764. [Google Scholar] [CrossRef]

- Elsouri, A.M.; Harajli, M.H. Seismic repair and strengthening of lap splices in RC columns: Carbon fiber-reinforced polymer versus steel confinement. J. Compos. Constr. 2011, 15, 721–731. [Google Scholar] [CrossRef]

- Kim, I.S.; Jirsa, J.O.; Bayrak, O. Use of carbon fiber-reinforced polymer anchors to repair and strengthen lap splices of reinforced concrete columns. ACI Struct. J. 2011, 108, 630–640. [Google Scholar]

- Garcia, R.; Helal, Y.; Pilakoutas, K.; Guadagnini, M. Bond behaviour of substandard splices in RC beams externally confined with CFRP. Constr. Build. Mater. 2014, 50, 340–351. [Google Scholar] [CrossRef] [Green Version]

- Harajli, M.H.; Rteil, A.A. Effect of confinement using fiber-reinforced polymer or fiber-reinforced concrete on seismic performance of gravity load-designed columns. ACI Struct. J. 2004, 101, 47–56. [Google Scholar]

- Harajli, M.H.; Dagher, F. Seismic strengthening of bond-critical regions in rectangular reinforced concrete columns using fiber-reinforced polymer wraps. ACI Struct. J. 2008, 105, 68–77. [Google Scholar]

- Harajli, M.H.; Khalil, Z. Seismic FRP retrofit of bond-critical regions in circular RC columns: Validation of proposed design methods. ACI Struct. J. 2008, 105, 760–769. [Google Scholar]

- Allam, S.M. Flexural strengthening of RC beams with lap splices. Int. Rev. Civ. Eng. 2013, 4, 256–273. [Google Scholar]

- Garcia, R.; Helal, Y.; Pilakoutas, K.; Guadagnini, M. Bond strength of short lap splices in RC beams confined with steel stirrups or external CFRP. Mater. Struct. 2015, 48, 277–293. [Google Scholar] [CrossRef]

- Anagnostou, E.; Rousakis, T.C.; Karabinis, A.I. Seismic retrofitting of damaged RC columns with lap-spliced bars using FRP sheets. Compos. Part B Eng. 2019, 166, 598–612. [Google Scholar] [CrossRef]

- Garcia, R.; Guadagnini, M.; Pilakoutas, K.; Pech Poot, L.A. FRP strengthening of substandard lap-spliced RC members: A comprehensive survey. Adv. Struct. Eng. 2017, 20, 976–1001. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Sohrabi, M.R.; Moodi, Y.; Gholamhosseini, E. Strengthening of Lap-Spliced RC Beams Using Near-Surface Mounting Method. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 251–259. [Google Scholar] [CrossRef]

- Canbay, E.; Frosch, R.J. Bond strength of lap-spliced bars. ACI Struct. J. 2005, 102, 605–614. [Google Scholar]

- Harajli, M.H. Bond behavior in steel fiber-reinforced concrete zones under static and cyclic loading: Experimental evaluations and analytical modeling. J. Mater. Civ. Eng. 2010, 22, 674–686. [Google Scholar] [CrossRef]

- Habel, K.; Charron, J.-P.; Braike, S.; Douglas Hooton, R.; Gauvreau, P.; Massicotte, B. Ultra-high performance fibre reinforced concrete mix design in central Canada. Can. J. Civ. Eng. 2008, 35, 217–224. [Google Scholar] [CrossRef]

- Harajli, M.; Hamad, B.; Karam, K. Bond-slip response of reinforcing bars embedded in plain and fiber concrete. J. Mater. Civ. Eng. 2002, 14, 503–511. [Google Scholar] [CrossRef]

- Vachon, D.; Massicotte, B. Seismic retrofitting of rectangular bridge piers with FRC jackets. In Proceedings of the 6th RILEM Symposium on Fibre Reinforced Concrete, PRO 39, Bagneaux, France; 2004; pp. 1247–1256. [Google Scholar]

- Dagenais, M.-A.; Massicotte, B. Tension Lap Splices Strengthened with Ultrahigh-Performance Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2014, 27, 04014206. [Google Scholar] [CrossRef] [Green Version]

- Shah, A.A.; Ribakov, Y. Recent trends in steel fibered high-strength concrete. Mater. Des. 2011, 32, 4122–4151. [Google Scholar] [CrossRef]

- Qian, C.X.; Stroeven, P. Development of hybrid polypropylene-steel fiber reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Mansour, F.R.; Bakar, S.A.; Ibrahim, I.S.; Marsono, A.K.; Marabi, B. Flexural performance of a precast concrete slab with steel fiber concrete topping. Constr. Build. Mater. 2015, 75, 112–120. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Ipek, S. Effect of steel fiber addition and aspect ratio on bond strength of cold-bonded fly ash lightweight aggregate concretes. Constr. Build. Mater. 2013, 47, 358–365. [Google Scholar] [CrossRef]

- Ezeldin, A.S.; Balaguru, P.N. Bond behavior of normal and high-strength fiber reinforced concrete. ACI Mater. J. 1989, 86, 515–524. [Google Scholar]

- Won, J.P.; Park, C.G.; Kim, H.H.; Lee, S.W.; Jang, C.I. Effect of fibers on the bonds between FRP reinforcing bars and high-strength concrete. Compos. Part B Eng. 2008, 39, 747–755. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Shin, H.O.; Yang, J.M.; Yoon, Y.S. Material and bond properties of ultra-high performance fiber reinforced concrete with micro steel fibers. Compos. Part B Eng. 2014, 58, 122–133. [Google Scholar] [CrossRef]

- Li, J.; Gao, X.L.; Zhang, P. Experimental investigation on the bond of reinforcing bars in high performance concrete under cyclic loading. Mater. Struct. 2007, 40, 1027–1044. [Google Scholar] [CrossRef]

- Di Prisco, M.; Felicetti, R.; Plizzari, G. PRO 39: 6th International RILEM Symposium on Fibre-Reinforced Concretes; RILEM Publications: Champs sur Marne, France, 2004. [Google Scholar]

- ACI Committee 544.1 R-96 (R2002); State-of-the-Art Report on Fiber Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2002.

- Naaman, A.; Harajli, M. Mechanical Properties of High Performance Fiber Concrete: A State-of-the-Art Report; Research Report No. SHRP-C/WP-90-004, Strategic Highway Research Program; National Research Council: Washington, DC, USA, 1990. [Google Scholar]

- Wight, J.K.; Montesinos, G.J.P.; Canbolat, B.A. Seismic Behavior of High-Performance Fiber Reinforced Cement Composite Coupling Beams. A Volume on “Performance-Based Engineering for Earthquake Resistant Reinforced Concrete Structures” Honoring Shunsuke; Kabeyasawa, O.T., Shiohara, H., Eds.; American Concrete Institute: Farmington Hills, MI, USA, 2005; pp. 357–372. [Google Scholar]

- Parra-Montesinos, G.; Canbolat, B.A.; Kim, K.K.Y. Fiber reinforced cement composites for seismic resistant elements with shear-dominated behavior. In Proceedings of the 6th International RILEM Symposium on Fibre Reinforced Concretes, Varenna, Italy, 20–22 September 2004; RILEM Publications Sarl: Champs sur Marne, France, 2004; pp. 1237–1246. [Google Scholar]

- Huang, L.E.; Chi, Y.; Xu, L.; Chen, P.; Zhang, A. Local bond performance of rebar embedded in steel-polypropylene hybrid fiber reinforced concrete under monotonic and cyclic loading. Constr. Build. Mater. 2016, 103, 77–92. [Google Scholar] [CrossRef]

- Ding, Y.N.; Ning, X.L.; Zhang, Y.L.; Torgal, F.P.; Aguiar, J.B. Fibres for enhancing of the bond capacity between GFRP rebar and concrete. Constr. Build. Mater. 2014, 51, 303–312. [Google Scholar] [CrossRef] [Green Version]

- Harajli, M.H.; Hout, M.; Jalkh, W. Local bond stress-slip behavior of reinforcing bars embedded in plain and fiber concrete. ACI Mater. J. 1995, 92, 343–354. [Google Scholar]

- Golafshani, E.M.; Rahai, A.; Sebt, M.H. Bond behavior of steel and GFRP bars in self-compacting concrete. Constr. Build. Mater. 2014, 61, 230–240. [Google Scholar] [CrossRef]

- Dancygier, A.N.; Katz, A.; Wexler, U. Bond between deformed reinforcement and normal and high-strength concrete with and without fibers. Mater. Struct. 2010, 43, 839–856. [Google Scholar] [CrossRef]

- He, Z.H.; Xu, H.; Huynh, T.P.; Shi, J.Y.; Ma, Z.M.; Hu, Y.J.; Chen, F.J. Multi-scale characteristics of magnesium potassium phosphate cement enhanced by waste concrete powder. Ceram. Int. 2022, 48, 12467–12475. [Google Scholar] [CrossRef]

- Vertal, M.; Vaskova, A.; Korjenic, A.; Katunsky, D. Case study investigations on drying process cellular concrete external walls with ETCIS. Bauphysik 2016, 38, 378–388. [Google Scholar]

- Ma, C.; Chen, G.; Shi, J.; Zhou, H.; Ren, W.; Du, Y. Improvement mechanism of water resistance and volume stability of magnesium oxychloride cement: A comparison study on the influences of various gypsum. Sci. Total Environ. 2022, 829, 154546. [Google Scholar] [CrossRef] [PubMed]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).