Pore Fluid Movability in Fractured Shale Oil Reservoir Based on Nuclear Magnetic Resonance

Abstract

:1. Introduction

2. Materials and Methods

2.1. High-Speed Centrifugation + NMR Test

2.2. Imbibition + NMR Test

- (1)

- Experimental study on mixed wettability

- (2)

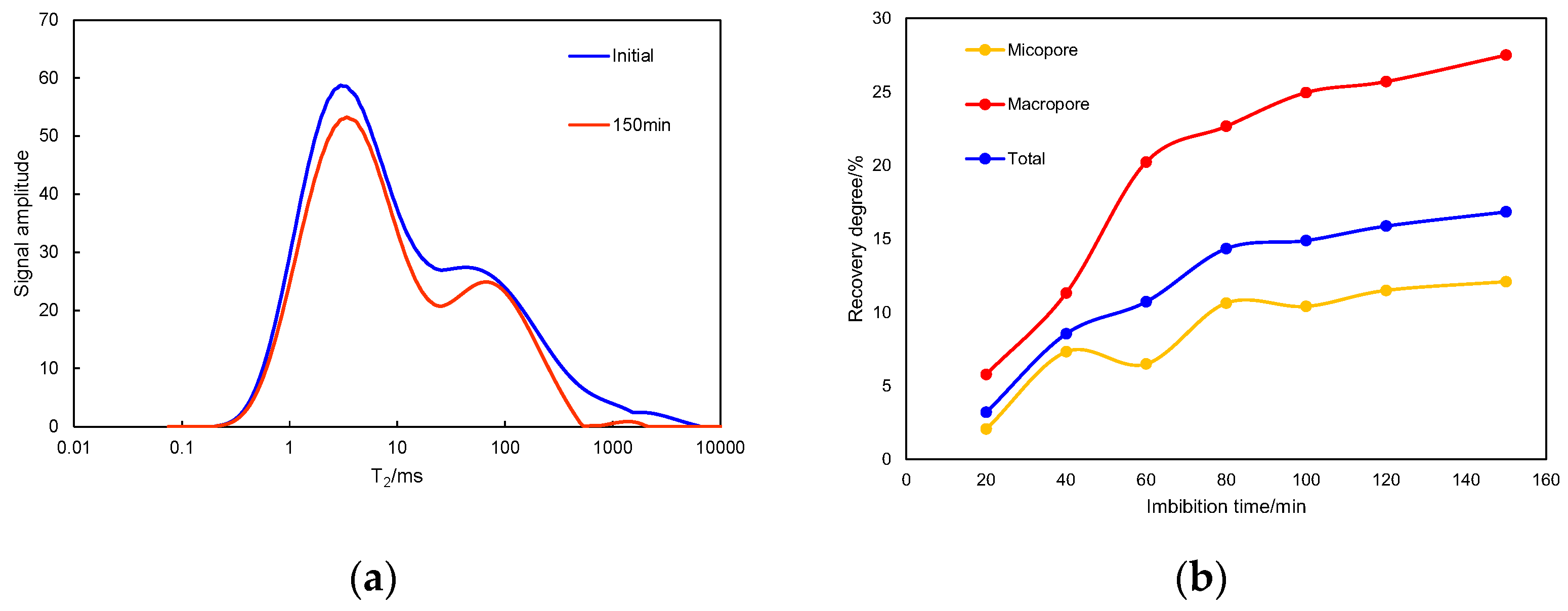

- Spontaneous imbibition + NMR test

- (3)

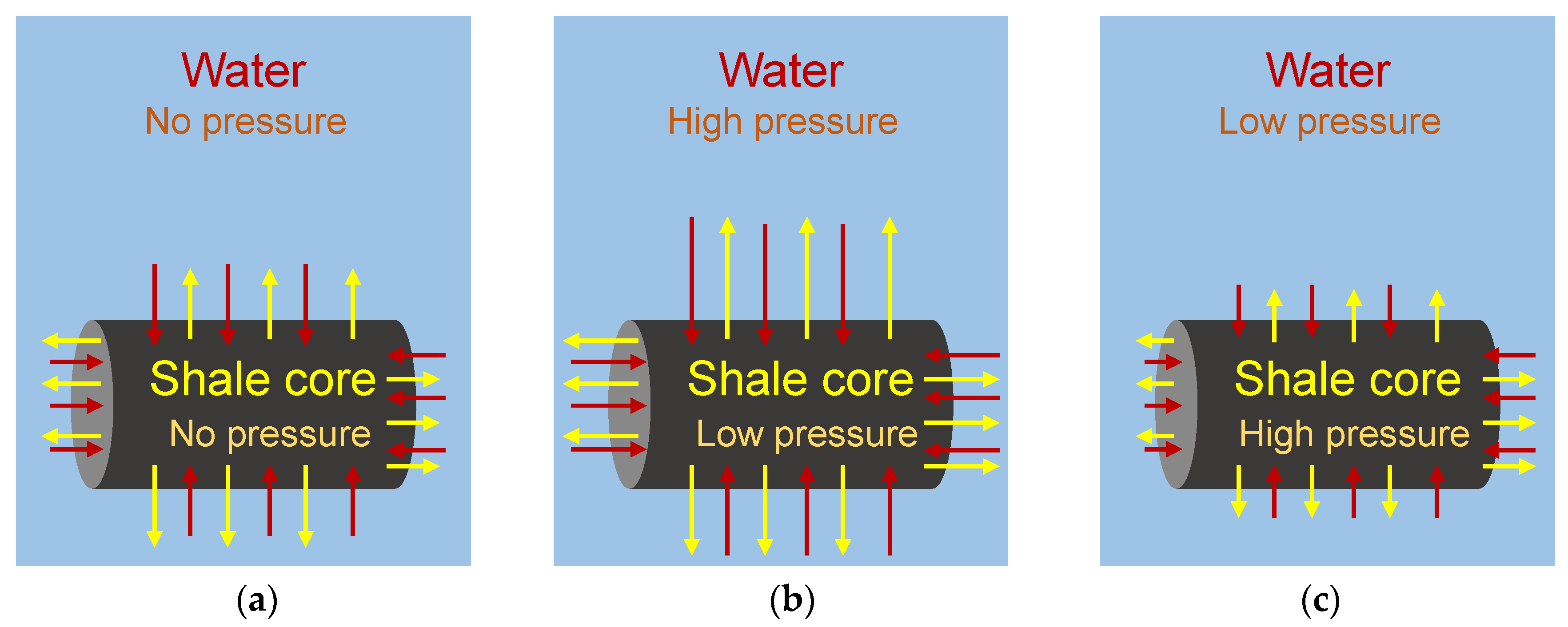

- Overpressure imbibition/underpressure imbibition + NMR test

2.3. Experimental Samples

3. Results and Discussion

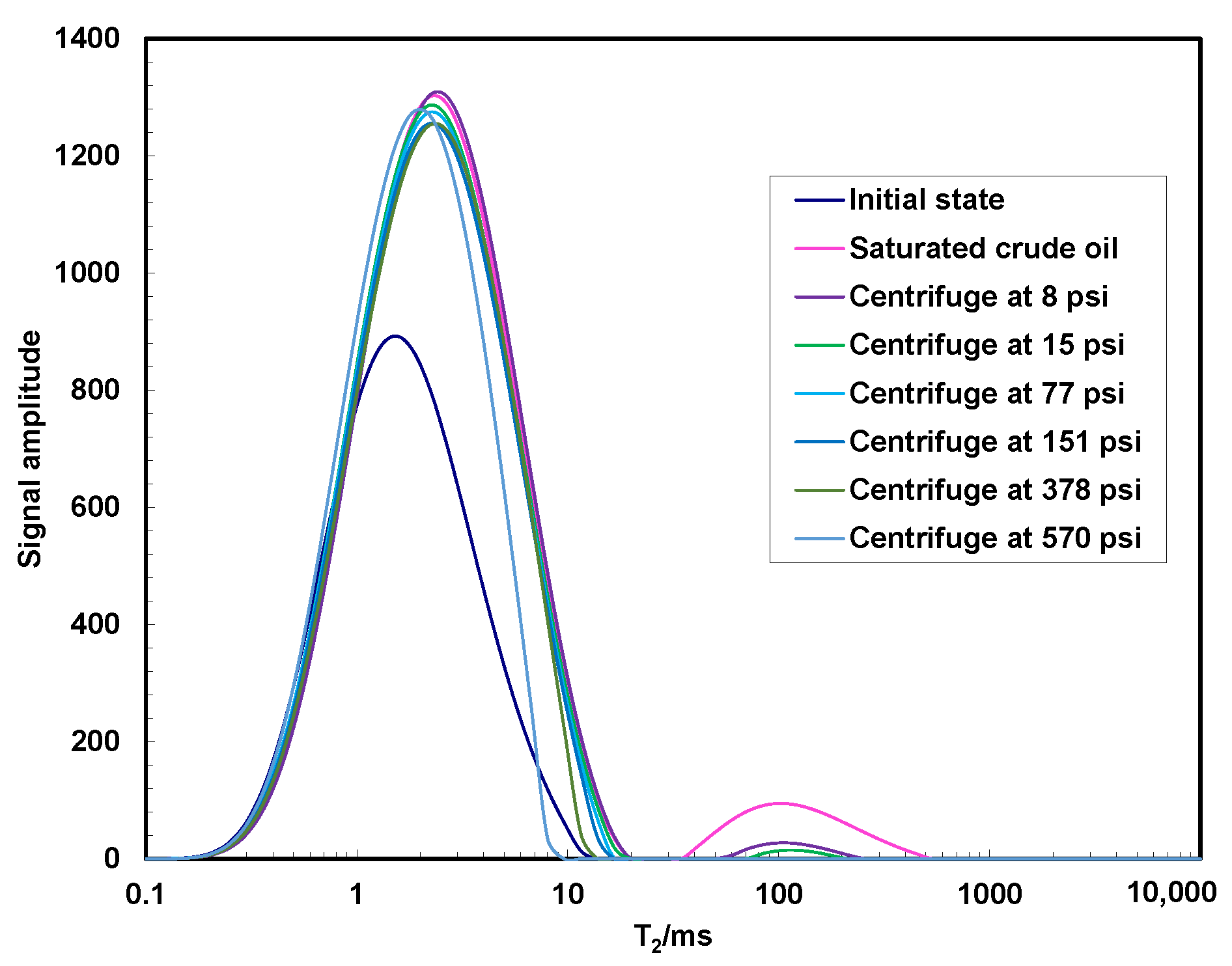

3.1. Results of High-Speed Centrifugation + NMR Test

3.2. Wettability Test Results

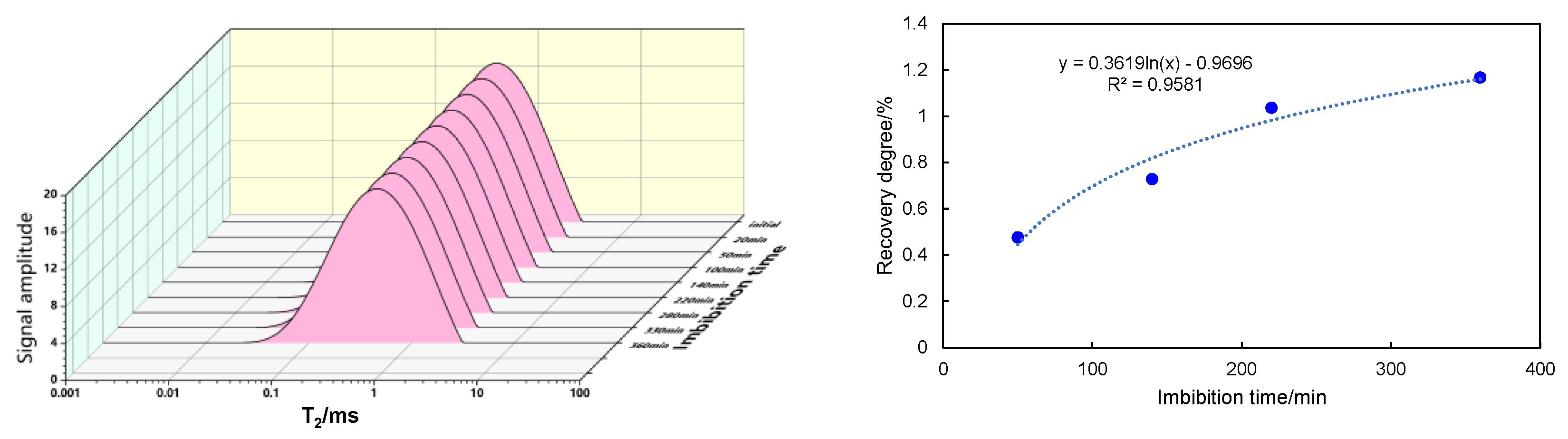

3.3. Characteristics of Spontaneous Imbibition and the Movability of Different Pore Fluids

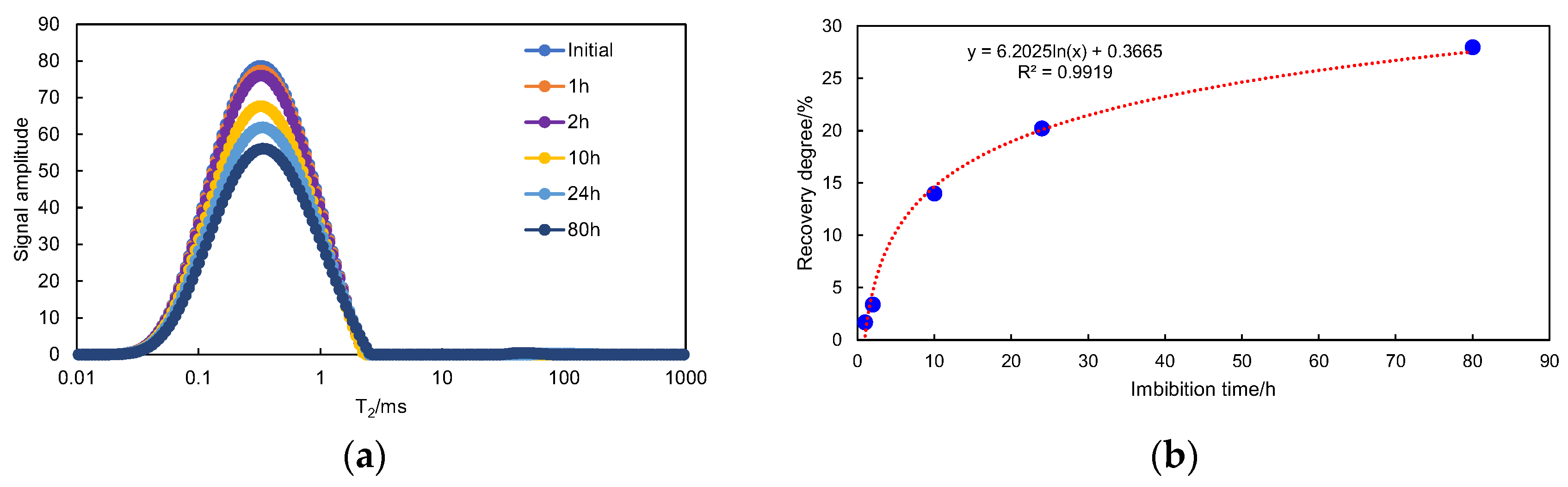

3.4. Characteristics of Overpressure Imbibition/Underpressure Imbibition on the Movability of Different Pore Fluid

4. Conclusions

- (1)

- During the backflow stage, the matrix pore fluid is difficult to unlock under differential pressure drive, and under the action of high-speed centrifugal differential pressure, up to 18.1% of the fluid can be utilized; the main contribution is provided by microscale pores. The utilization of nanoscale pore fluids is almost impossible.

- (2)

- The mixed wetting of porous and fractured dual media indicated that fluid imbibition has different effects in different media. The experimental results indicated that the fractured media are oil-wet, while the porous media show neutral wetting. This is unfavorable for flow of shale cores with the main flow channels of foliated fractures but beneficial to the flow of crude oil that mainly exists in pores.

- (3)

- The fracturing pressure is crucial for the imbibition effect of matrix pores. When the fracture pressure is higher than matrix pore pressure, the imbibition efficiency is 27.9%; spontaneous imbibition efficiency when relying solely on capillary force is poor, at 16.8%; when the fracture pressure is lower than the matrix pore pressure, the imbibition efficiency is the lowest, at 1.3%.

- (4)

- During the process of shut-in well backflow, it is necessary to ensure that the fracturing pressure is sufficiently higher than the pore pressure, which not only maintains the fracture morphology but also efficiently utilizes the imbibition effect to drive a continuous oil/water displacement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lei, Z.; Li, J.; Chen, Z.; Dai, X.; Ji, D.; Wang, Y.; Liu, Y. Characterization of Multiphase Flow in Shale Oil Reservoirs Considering Multiscale Porous Media by High-Resolution Numerical Simulation. SPE J. 2023, 1–16. [Google Scholar] [CrossRef]

- Li, J.; Lu, S.; Zhang, J.; Zhang, P.; Xue, H. Quantitative evaluation models of adsorbed and free shale oil and its microscopic occurrence mechanism. Oil Gas Geol. 2019, 40, 583–592. [Google Scholar]

- Jiang, Q.; Shen, B.; Yang, Y.; Li, Z.; Ma, Y.; Qian, M. Kinetic analysis of hydrocarbon generation components in shales from the Bonan sub-Sag and its significance for hydrocarbon exploration. Pet. Geol. Exp. 2016, 38, 231–239. [Google Scholar]

- Yao, C.; Chen, H.; Onishi, T.; Datta-Gupta, A.; Mawalkar, S.; Mishra, S.; Pasumarti, A. Robust CO2 Plume Imaging Using Joint Tomographic Inversion of Distributed Pressure and Temperature Measurements. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 21–23 September 2021. [Google Scholar]

- Zhang, X.; Yang, S.; Zhang, Z. Optimization of injection-production parameters for CO2 /N2 composite gas huff and puff in fault-block reservoirs considering starting pressure gradient. Sci. Technol. Eng. 2021, 21, 14127–14132. [Google Scholar]

- Xu, G.; Zhou, X.; Shang, D.; Zhang, G. Determination method of pressure behind blanking plug considering starting pressure gradient and its field application. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 80–85. [Google Scholar]

- Jia, R.; Shi, X.; Yu, W.; Yu, J. Simulated experimental research on starting pressure gradient of flow permeability reservoir in Nanpu Sag. Mud Logging Eng. 2021, 32, 119–123. [Google Scholar]

- Ren, J.; Lu, B.; Ren, S. Improved pressure depletion method measures the porosity and permeability of shale. Pet. Reserv. Eval. Dev. 2020, 10, 49–55. [Google Scholar]

- Zhao, Z. Contact angle and its application in surface chemistry research. Chem. Res. Appl. 2000, 4, 370–374. [Google Scholar]

- Liang, C.; Xiao, L.; Zhou, C.; Guo, L.; Hu, F.; Liao, G.; Song, X.; Ge, G. Nuclear magnetic resonance characterizes rock wettability: Preliminary experimental results. Chin. J. Geophys. 2019, 62, 4472–4481. [Google Scholar]

- SY/T 5153-2017; Test Method of Reservoir Rock Wettability. National Energy Administration: Beijing, China, 2017.

- He, W.; Cui, B.; Wang, F.; Wang, Y.; Zhang, J.; Zhao, H.; Wang, R.; Bai, Y.; Lin, X.; Zhao, Y.; et al. Study on reservoir spaces and oil states of the Cretaceous Qingshankou Formation in Gulong Sag, Songliao Basin. Geol. Rev. 2022, 68, 693–741. [Google Scholar]

- Sang, Q.; Zhang, S.; Li, Y.; Dong, M.; Bryant, S. Determination of organic and inorganic hydrocarbon saturations and effective porosities in shale using vacuum-imbibition method. Int. J. Coal Geol. 2018, 200, 123–134. [Google Scholar] [CrossRef]

- Tian, W.; Wu, K.; Gao, Y.; Chen, Z.; Gao, Y.; Li, J. A Critical Review of Enhanced Oil Recovery by Imbibition: Theory and Practice. Energy Fuels 2021, 35, 5643–5670. [Google Scholar] [CrossRef]

| Relative Wettability Index I | −1.0 ≤ I < −0.7 | −0.7 ≤ I < −0.3 | −0.3 ≤ I< −0.1 | −0.1 ≤ I ≤ 0.1 | 0.1 < I ≤ 0.3 | 0.3 < I ≤ 0.7 | 0.7 < I ≤ 1.0 |

|---|---|---|---|---|---|---|---|

| Wettability | Strong oil wetting | Oil wetting | Weak oil wetting | Intermediate wetting | Weak water wetting | Water wetting | Strong water wetting |

| Experimental Samples | Diameter (mm) | Length (mm) | Volume (cm3) | Porosity (%) | Permeability (mD) | Photos of Shale Cores |

|---|---|---|---|---|---|---|

| High speed centrifugation + NMR | 25.12 | 49.44 | 24.50 | 7.93 | 3.66 × 10−3 |  |

| Spontaneous imbibition + NMR | 25.09 | 54.87 | 27.11 | 6.94 | 3.16 × 10−3 |  |

| Overpressure imbibition + NMR | 25.05 | 50.33 | 24.80 | 8.23 | 4.05 × 10−3 |  |

| Underpressure imbibition + NMR | 25.28 | 64.83 | 32.54 | 7.20 | 5.82 × 10−3 |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Chen, Z.; Ji, D.; Peng, Y.; Hou, Y.; Lei, Z. Pore Fluid Movability in Fractured Shale Oil Reservoir Based on Nuclear Magnetic Resonance. Processes 2023, 11, 3365. https://doi.org/10.3390/pr11123365

Liu Y, Chen Z, Ji D, Peng Y, Hou Y, Lei Z. Pore Fluid Movability in Fractured Shale Oil Reservoir Based on Nuclear Magnetic Resonance. Processes. 2023; 11(12):3365. https://doi.org/10.3390/pr11123365

Chicago/Turabian StyleLiu, Yishan, Zhewei Chen, Dongqi Ji, Yingfeng Peng, Yanan Hou, and Zhengdong Lei. 2023. "Pore Fluid Movability in Fractured Shale Oil Reservoir Based on Nuclear Magnetic Resonance" Processes 11, no. 12: 3365. https://doi.org/10.3390/pr11123365