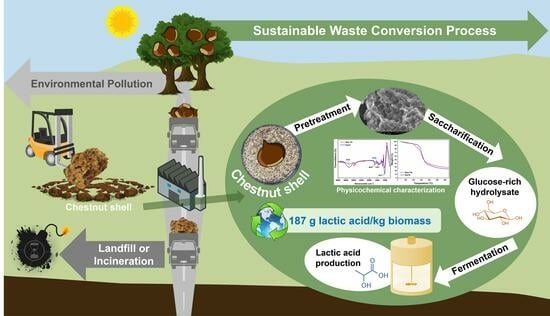

Physicochemical Characterization of Potassium Hydroxide Pretreated Chestnut Shell and Its Bioconversion to Lactic Acid by Lacticaseibacillus rhamnosus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biomass, Chemicals, and Enzymes

2.2. Alkali Pretreatment of Biomass

2.3. Characterization of Raw and KOH-Pretreated Biomass

2.4. Enzymatic Saccharification for Glucose Production

2.5. Strain Selection for Efficient Lactic Acid Production

2.6. Lactic Acid Fermentation Profiling

2.7. Analytical Methods

= (produced lactic acid (g)/consumed glucose (g)) × 100.

3. Results

3.1. Effect of Alkali Pretreatment on the Chemical Composition of Chestnut Shell

3.2. Effect of Alkali Pretreatment on the Physicochemical Properties of Chestnut Shell

3.2.1. Surface Morphology

3.2.2. Surface Chemistry

3.2.3. Thermal Properties

3.3. Bioconversion of Chestnut Shell Hydrolysate into Lactic Acid

3.3.1. Strain Selection for Efficient Lactic Acid Production

3.3.2. Lactic Acid Fermentation Using Chestnut Shell Hydrolysate

3.4. Evaluation of Overall Bioprocesses for Valorizing Waste Chestnut Shell

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mehmood, A.; Raina, N.; Phakeenuya, V.; Wonganu, B.; Cheenkachorn, K. The Current Status and Market Trend of Polylactic Acid as Biopolymer: Awareness and Needs for Sustainable Development. Mater. Today Proc. 2023, 72, 3049–3055. [Google Scholar] [CrossRef]

- Swetha, T.A.; Ananthi, V.; Bora, A.; Sengottuvelan, N.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A review on biodegradable polylactic acid (PLA) production from fermentative food waste—Its applications and degradation. Int. J. Biol. Macromol. 2023, 234, 123703. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Xue, Y.; Yu, B.; Wang, L.; Zhou, C.; Ma, Y. A Review of the Recent Developments in the Bioproduction of Polylactic Acid and Its Precursors Optically Pure Lactic Acids. Molecules 2021, 26, 6446. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.H.; Jang, Y.W.; Lee, J.; Kim, S.; Park, C.; Yoo, H.Y. Statistical Optimization of Alkali Pretreatment to Improve Sugars Recovery from Spent Coffee Grounds and Utilization in Lactic Acid Fermentation. Processes 2021, 9, 494. [Google Scholar] [CrossRef]

- Lee, Y.G.; Ju, Y.; Sun, L.; Park, S.; Jin, Y.S.; Kim, S.R. Acetate-rich Cellulosic Hydrolysates and Their Bioconversion Using Yeasts. Biotechnol. Bioprocess Eng. 2022, 27, 890–899. [Google Scholar] [CrossRef]

- Supaporn, P.; Yeom, S.H. Optimized Sugar Extraction and Bioethanol Production from Lipid-extracted Sewage Sludge. Biotechnol. Bioprocess Eng. 2022, 27, 119–125. [Google Scholar] [CrossRef]

- Sarangi, P.K.; Mishra, S.; Mohanty, P.; Singh, P.K.; Srivastava, R.K.; Pattnaik, R.; Adhya, T.K.; Das, T.; Lenka, B.; Gupta, V.K.; et al. Food and Fruit Waste Valorisation for Pectin Recovery: Recent Process Technologies and Future Prospects. Int. J. Biol. Macromol. 2023, 235, 123929. [Google Scholar] [CrossRef]

- Kim, D.S.; Lee, J.H.; Shin, H.J. Optimization of Vacuum Frying Process for Sweet Potato Chip Manufacturing Using Response Surface Methodology and Artificial Neural Network Model. Biotechnol. Bioprocess Eng. 2023, 28, 554–567. [Google Scholar] [CrossRef]

- Marzo-Gago, C.; Venus, J.; López-Gómez, J.P. Production of lactic acid from pasta wastes using a biorefinery approach. Biotechnol. Biofuels Bioprod. 2022, 15, 128. [Google Scholar] [CrossRef]

- Bustamante, D.; Tortajada, M.; Ramón, D.; Rojas, A. Production of D-Lactic Acid by the Fermentation of Orange Peel Waste Hydrolysate by Lactic Acid Bacteria. Fermentation 2020, 6, 1. [Google Scholar] [CrossRef]

- Ozer Uyar, G.E.; Uyar, B. Potato Peel Waste Fermentation by Rhizopus oryzae to Produce Lactic Acid and Ethanol. Food Sci. Nutr. 2023, 11, 5908–5917. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Kim, S.; Lee, K.H.; Lee, S.K.; Chun, Y.; Kim, S.W.; Park, C.; Yoo, H.Y. Improvement of Bioethanol Production from Waste Chestnut Shells via Evaluation of Mass Balance-Based Pretreatment and Glucose Recovery Process. Environ. Technol. Innov. 2022, 28, 102955. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, S.K.; Lee, J.; Kim, S.; Park, C.; Kim, S.W.; Yoo, H.Y. Improvement of Enzymatic Glucose Conversion from Chestnut Shells through Optimization of KOH Pretreatment. Int. J. Environ. Res. Public Health 2021, 18, 3772. [Google Scholar] [CrossRef] [PubMed]

- Chun, Y.; Lee, S.K.; Yoo, H.Y.; Kim, S.W. Recent Advancements in Biochar Production According to Feedstock Classification, Pyrolysis Conditions, and Applications: A Review. Bioresources 2021, 16, 6512–6547. [Google Scholar] [CrossRef]

- Jang, H.-A.; Bae, E.-K.; Kim, M.-H.; Park, S.-J.; Choi, N.-Y.; Pyo, S.-W.; Lee, C.; Jeong, H.-Y.; Lee, H.; Choi, Y.-I.; et al. CRISPR-Knockout of CSE Gene Improves Saccharification Efficiency by Reducing Lignin Content in Hybrid Poplar. Int. J. Mol. Sci. 2021, 22, 9750. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Wang, X.; Wu, Z.; Xu, J.; Hu, L.; Lin, L. Integration of Hemicellulose Pre-Extraction and Solid Alkali-Oxygen Cooking Processes for Lignocellulose Fractionation with Emphasis on Xylan Valorization. Korean J. Chem. Eng. 2021, 38, 788–796. [Google Scholar] [CrossRef]

- Shahzad, H.M.A.; Khan, S.J.; Khan, M.; Schönberger, H.; Weber, F.A. Performance and Cost-Benefit Analysis of Anaerobic Moving Bed Biofilm Reactor for Pretreatment of Textile Wastewater. Korean J. Chem. Eng. 2023, 40, 1389–1400. [Google Scholar] [CrossRef]

- Wang, X.; He, J.; Pang, S.; Yao, S.; Zhu, C.; Zhao, J.; Liu, Y.; Liang, C.; Qin, C. High-Efficiency and High-Quality Extraction of Hemicellulose of Bamboo by Freeze-Thaw Assisted Two-Step Alkali Treatment. Int. J. Mol. Sci. 2022, 23, 8612. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J. Statistical optimization of aqueous ammonia pretreatment and enzymatic hydrolysis of corn cob powder for enhancing sugars production. Biochem. Eng. J. 2021, 174, 108106. [Google Scholar] [CrossRef]

- Dev, B.; Bakshi, A.; Paramasivan, B. Prospects of Utilizing Seawater as a Reaction Medium for Pretreatment and Saccharification of Rice Straw. Chemosphere 2022, 293, 133528. [Google Scholar] [CrossRef]

- Souza, L.D.S.; Pereira, A.M.; Farias, M.A.D.; Oliveira, R.L.; Duvoisin, S.; Quaresma, J.N.N. Valorization of Andiroba (Carapa guianensis Aubl.) residues through optimization of alkaline pretreatment to obtain fermentable sugars. Bioresources 2020, 15, 894–909. [Google Scholar] [CrossRef]

- Zhang, K.; Si, M.; Liu, D.; Zhuo, S.; Liu, M.; Liu, H.; Yan, X.; Shi, Y. A bionic system with Fenton reaction and bacteria as a model for bioprocessing lignocellulosic biomass. Biotechnol. Biofuels 2018, 11, 31. [Google Scholar] [CrossRef] [PubMed]

- Ariyanti, D.; Lesdantina, D.; Purbasari, A.; Astuti, Y. Synthesis of Graphene-Like Material Derived from Biomass from Agricultural Waste and Its Application in Cu(II) Removal. Korean J. Chem. Eng. 2023, 40, 964–974. [Google Scholar] [CrossRef]

- Rahmadiawan, D.; Abral, H.; Kotodeli, R.A.; Sugiarti, E.; Muslimin, A.N.; Admi, R.I.; Arafat, A.; Kim, H.-J.; Sapuan, S.M.; Kosasih, E.A. A Novel Highly Conductive, Transparent, and Strong Pure-Cellulose Film from TEMPO-Oxidized Bacterial Cellulose by Increasing Sonication Power. Polymers 2023, 15, 643. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Xu, B.; Wang, X.; Lang, J.; Zhang, H. Chemical and Structural Elucidation of Lignin and Cellulose Isolated Using DES from Bagasse Based on Alkaline and Hydrothermal Pretreatment. Polymers 2022, 14, 2756. [Google Scholar] [CrossRef]

- Dallé, D.; Hansen, B.; Zattera, A.J.; Francisquetti, E.L.; Catto, A.L.; Borsoi, C. Kinetic Evaluation of Tobacco Stalk Waste Exposed to Alkaline Surface Treatment Under Different Conditions. Cellulose 2021, 28, 2053–2073. [Google Scholar] [CrossRef]

- Ho, M.C.; Wu, T.Y.; Chee, S.W.Q.; Ngang, C.Y.; Chew, I.M.L.; Teoh, W.H.; Jahim, J.M.; Mohammad, A.W. An Application of Low Concentration Alkaline Hydrogen Peroxide at Non-Severe Pretreatment Conditions Together with Deep Eutectic Solvent to Improve Delignification of Oil Palm Fronds. Cellulose 2019, 26, 8557–8573. [Google Scholar] [CrossRef]

- Abdel-Rahman, M.A.; Tashiro, Y.; Sonomoto, K. Lactic Acid Production from Lignocellulose-Derived Sugars Using Lactic Acid Bacteria: Overview and Limits. J. Biotechnol. 2011, 156, 286–301. [Google Scholar] [CrossRef]

- Yang, X.-Y.; Huang, C.; Guo, H.-J.; Xiong, L.; Luo, J.; Wang, B.; Chen, X.-F.; Lin, X.-Q.; Chen, X.-D. Beneficial Effect of Acetic Acid on the Xylose Utilization and Bacterial Cellulose Production by Gluconacetobacter xylinus. Indian J. Microbiol. 2014, 54, 268–273. [Google Scholar] [CrossRef]

- Molina-Ramírez, C.; Enciso, C.; Torres-Taborda, M.; Zuluaga, R.; Gañán, P.; Rojas, O.J.; Castro, C. Effects of Alternative Energy Sources on Bacterial Cellulose Characteristics Produced by Komagataeibacter medellinensis. Int. J. Biol. Macromol. 2018, 117, 735–741. [Google Scholar] [CrossRef]

- Lee, J.; Lee, K.H.; Kim, S.; Son, H.; Chun, Y.; Park, C.; Yoo, H.Y. Microbial Production of Bacterial Cellulose Using Chestnut Shell Hydrolysates by Gluconacetobacter xylinus ATCC 53524. J. Microbiol. Biotechnol. 2022, 32, 1479–1484. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, C.; Zhang, H.; Qu, G.; Li, C.; Liu, L. Biotransformation of Polyphenols in Apple Pomace Fermented by β-Glucosidase-Producing Lactobacillus rhamnosus L08. Foods 2021, 10, 1343. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Reddy, R.; Xavier, K.M.; Balange, A.K.; Kumar, H.S.; Nayak, B.B. Comparative Evaluation of Microbial Ensilaging of Fish, Vegetable and Fish-Vegetable Composite Wastes. Waste Biomass Valorization 2023, 14, 1657–1666. [Google Scholar] [CrossRef]

- Pérez-Davila, S.; González-Rodríguez, L.; Lama, R.; López-Álvarez, M.; Oliveira, A.L.; Serra, J.; Novoa, B.; Figueras, A.; González, P. 3D-Printed PLA Medical Devices: Physicochemical Changes and Biological Response after Sterilisation Treatments. Polymers 2022, 14, 4117. [Google Scholar] [CrossRef] [PubMed]

| Component | Sample | |

|---|---|---|

| CS | KpCS | |

| Cellulose | 45.1% 1 | 69.1% 2 |

| Hemicellulose | 5.9% 1 | 4.3% |

| Lignin | 16.6% | 9.6% |

| Others | 32.4% | 17.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, S.; Son, H.; Lee, K.H.; Park, C.; Yoo, H.Y. Physicochemical Characterization of Potassium Hydroxide Pretreated Chestnut Shell and Its Bioconversion to Lactic Acid by Lacticaseibacillus rhamnosus. Processes 2023, 11, 3340. https://doi.org/10.3390/pr11123340

Lee J, Kim S, Son H, Lee KH, Park C, Yoo HY. Physicochemical Characterization of Potassium Hydroxide Pretreated Chestnut Shell and Its Bioconversion to Lactic Acid by Lacticaseibacillus rhamnosus. Processes. 2023; 11(12):3340. https://doi.org/10.3390/pr11123340

Chicago/Turabian StyleLee, Jeongho, Seunghee Kim, Hyerim Son, Kang Hyun Lee, Chulhwan Park, and Hah Young Yoo. 2023. "Physicochemical Characterization of Potassium Hydroxide Pretreated Chestnut Shell and Its Bioconversion to Lactic Acid by Lacticaseibacillus rhamnosus" Processes 11, no. 12: 3340. https://doi.org/10.3390/pr11123340