1. Introduction

Since its origins, robotics has been intrinsically related to the interaction between humans and machines. Initially, robots were intended to replace human operators in the performance of repetitive and risky tasks and activities that required more precision. In recent decades, scientific–technical advances have made great strides. This has led to increasing contact between humans and robots, allowing robots to interact, help, serve, and explore next to human beings. Thanks to this, robotics is present in several daily life activities, for example, in the industrial, entertainment, and military fields.

Medicine is one of the fields that has benefited the most from the scientific–technical advances associated with robots, which day by day materialize in the manufacturing of tools for assisting medical work and helping patient rehabilitation.

Since the 1970s, robots have been used for rehabilitation purposes. These applications initially were centered on the substitution of lost functions in individuals with physical disabilities through the use of devices such as robot orthosis, workstations, feeding devices, and robotic wheelchairs [

1].

The study of robots used for the physical rehabilitation of patients has become crucial. In general, the objective of rehabilitation is to recover the patient from a physical impediment or disability and improve his mobility, functional capacity, and quality of life. Disabilities could be the result of a stroke, an injury, or a neurological condition. In this context, the concept of the exoskeleton arises. An exoskeleton is a structure to be used on the human body as a piece of clothing, i.e., a wearable robot (WR), whether to complement the function of a limb or to completely replace it. Exoskeletons combine human intelligence and machine strength and thus enhance the intelligence of the machine and the power of the human operator. As a result, the human operator can achieve goals that he would not be able to reach on his own [

2].

Studies have shown [

3,

4,

5] that one of the most frequent causes of disability is lower limb injuries. These injuries may have different origins, such as car accidents, sport injuries, aging, degenerative and congenital diseases, and unhealthy lifestyles. To improve the quality of life of people who have suffered any of the injuries above, rehabilitation therapies are necessary, as they play a key role in maintaining, recovering, and developing movement in the affected limb. These therapies may consist of exercise and minimal interaction between physiotherapist and patient by means of exoskeletons [

6]. There is another type of robot able to add external power to the leg joints through mechanical actuators, which are used in everyday life as walking assistance [

7]. It is well known that effective recovery from motor impairment of the lower limbs requires intensive limb training [

8]. One of the most widely used exoskeletons is the cyborg-type robot called the Hybrid assistive limb (HAL), which improves and/or increases the body function of a user [

5] and helps a person with physical disabilities to move, enabling a torque higher than the usual (

Figure 1a). Another widespread exoskeleton used in rehabilitation is Lokomat [

9], shown in

Figure 1b, a robotic orthotic device that provides variable body weight support and assistance to the patient’s lower limbs when he walks on a treadmill. The exoskeleton known as Motomed letto 2 is another robot that balances the lack of movement in patients prostrated in bed [

10]. Patients can use it to train their legs or arms from a bed in passive mode, assisted by a motor, or in active mode, as shown in

Figure 1c, preventing muscle atrophy and enabling contracture prophylaxis. The ReWalk exoskeleton, created by someone suffering from paraplegia due to a traffic accident [

11], is used to help people with paraplegia. This exoskeleton offers two systems: ReWalk Personal 6.0 for personal use and ReWalk Rehabilitation for use in clinics from the company [

12].

The development of new exoskeletons is constantly evolving due to the many challenges in improving their performance, reducing their weight, and increasing their adaptability to users. Although affordability, ease of use, and comfort were prioritized in the past, more advanced exoskeleton improvements can enable the transition from exercise to social interaction and, finally, their use in daily activities [

13].

Undoubtedly, the development of control strategies is a relevant topic in the development of exoskeletons. Therefore, different control algorithms have been developed in recent years, from simple solutions with proportional–integrative–derivative (PID) controllers to more complex solutions that use controllers implemented with neural networks.

Currently, there are diverse classifications for control strategies, and one of the most complete was conducted in ref. [

14], in which control algorithms were categorized according to the human–robot interaction model, specifically based on:

Signals from the human body.

Force signals from the interaction between the human being and the exoskeleton.

Signals from the exoskeleton.

Human–robot interaction is based on the measurement of signals from the human body, which directly reflect the intention of human movement. Studies have demonstrated that a treatment is effective only when the patient actively contributes to movement [

15,

16], which is not always the case when robots are guiding a human being in predefined trajectories. To record this information, two sensing techniques are usually employed: electroencephalography (EEG) and electromyography (EMG).

EEG is responsible for capturing the intention of movement, while EMG records muscle intensity, allowing exoskeletons to compensate for muscular activity and perform desired movements. This synergy between both techniques is essential for the effective control of exoskeletons and contributes to the field of assisted robotics.

Table 1 presents the main characteristics of these two sensing techniques is presented below.

Increasingly, EEG signals are being employed in the lower limbs to promote active patient participation in rehabilitation, stimulating the corticospinal pathways and facilitating cerebral reorganization post-injury [

17]. The SSVEP (steady state visual evoked potential) system streamlines lower limb control through therapist-assigned tasks, during which EEG signals are recorded and processed to interpret user intent [

17]. On the other hand, the NeuroRex system combines the Rex exoskeleton with a brain–computer interface (BCI) to enable independent walking, coordinating cerebral and manual control with autonomous robot algorithms [

18]. Widely studied EMG signals possess the capability to predict desired movements, even in cases of muscle weakness [

19,

20]. Additionally, they are used to estimate joint angles and enhance exoskeleton stability [

21,

22], as well as to predict movement in hemiplegic patients, utilizing EMG signals from unaffected limbs [

23].

The utilization of force signals derived from the interaction between individuals and exoskeletons is of paramount importance in the field of exoskeleton control, serving as a fundamental complement to signals originating from the human body. These interaction force signals, stemming from various sources such as user movements and exoskeleton responses, play multifaceted roles in exoskeleton control [

12]. They encompass force detection, enabled through the integration of force sensors within exoskeletons, providing real-time feedback on the forces exchanged during physical interaction. Moreover, interaction force signals facilitate force control, allowing algorithms to dynamically adjust the assistance levels and the compliance of exoskeletons in response to detected forces, thereby ensuring safe and effective interaction. Additionally, these signals are pivotal in ensuring safety and collision avoidance, as exoskeletons such as HAL-5 can respond to unusually high forces by activating safety mechanisms or modifying their behavior, thus preventing potential injuries or discomfort [

14,

24]. Furthermore, the analysis of interaction force signals yields valuable insights into user intentions, movements, and preferences, serving as a foundation for enhancing control algorithms. This, in turn, enables the implementation of adaptive or learning-based approaches for exoskeleton control, ultimately elevating the overall user experience and performance [

24].

A critical aspect in the control strategies for exoskeletons lies in the utilization of signals acquired directly from the exoskeletons themselves. This classification underscores the pivotal role of sensor data, encompassing a diverse array of sensors. Encoders and potentiometers deliver angular position information, elucidating joint configurations and movements. Force and momentum sensors, including load cells, facilitate the precise quantification of forces and momenta exerted on joints or contact points. Inertial sensors, notably accelerometers and gyroscopes, furnish data on linear acceleration, angular velocity, and exoskeleton orientation, which are pivotal for comprehending movements and positional alterations. Pressure sensors, occasionally integrated into exoskeletons, discern pressure distribution across user contact surfaces, thereby enabling adaptive responses based on contact forces. Furthermore, the BLEEX (Berkeley lower extremity exoskeleton) [

25] exemplifies a control system that exclusively relies on exoskeleton-derived information, eliminating the need for human body signals or interactive forces to predict movement intentions. This approach, while reducing reliance on additional interfaces, demands a robust dynamic model for optimal performance. The amalgamation of these sensor-based signals propels the evolution of exoskeleton control strategies, offering enhanced functionality and adaptability in a myriad of applications.

In ref. [

26], the control system of an exoskeleton is classified according to its model system, physical parameters, hierarchy, and usage. However, such systems add additional control challenges [

27]. The choice of precise models is paramount [

26], aligning with control engineering principles, with dynamic and muscle-based models playing complementary roles [

26]. The use of experimental data, such as EMG signals [

28], supports model validation, while the application of artificial intelligence, exemplified by wavelet neural networks [

28], highlights how computational innovation can enhance accuracy. Furthermore, the consideration of parametric models, such as the “hill-based” model [

29], adds depth to muscle-based modeling, enabling predictions of muscular forces based on neuromuscular activity and joint dynamics. It is crucial to remember that the implementation of exoskeletons raises ethical and practical issues [

30] that must also be addressed in the research and development of these systems.

Another common controller classification is found in ref. [

26], in which controllers are categorized according to physical parameters such as their position, torque/force, and force interaction. In the first case, the control scheme is often used to guarantee that the joints of an exoskeleton turn in the desired angle and is generally implemented as a low-level controller. The second controller of this classification (torque/force) is applied as a high-level controller. Its main objective is to provide adequate assistance to the user when performing a task, with an impedance or admittance controller as a possible controller for the interaction force. The basic notion of an impedance controller is that it accepts the position and produces the force, while the reverse is true for admittance controllers, which accept the force and produce the position.

According to their use, the control system of an exoskeleton can be classified into three primary categories: virtual reality controllers for upper limb applications, teleoperation controllers facilitating remote robotic collaboration, and gait controllers primarily targeting lower limb exoskeletons. Gait controllers, exemplified by the LOPES (power-extremity powered exoskeleton) [

31], employ intricate hierarchical control structures to ensure patient safety and optimize therapy outcomes. Innovative approaches, such as sensors and SEA (series elastic actuator)-type controllers [

32], electromagnetic drives [

33] in the AUTONOMYO exoskeleton, and versatile control interfaces such as EEG and joysticks [

34] in the Auto-LEE (autonomous lower extremity exoskeleton), expand the horizons of exoskeleton functionality. Pioneering systems such as BioComEx [

35], featuring elastic actuation and variable rigidity, offer promising solutions for rehabilitation and enhanced mobility, while the THKAF (trunk–hip–knee–ankle–foot) device [

36] reduces muscular activity, benefiting older individuals and those with disabilities. The Wearable Walking Helper (WWH) [

37] demonstrates notable improvements in gait performance, underlining the transformative potential of exoskeletons across diverse domains.

On the other hand, actuators are critical components in the field of exoskeletons. They are responsible for producing motion and providing the necessary force to assist or augment the wearer’s movements. The choice of actuators can significantly impact the design, performance, and usability of an exoskeleton. Several types of actuators are commonly used in exoskeleton systems. Brushless DC motors are widely used in exoskeletons due to their high power-to-weight ratio and efficient operation. They provide torque and angular displacement for joint movements. Additionally, their precise control capabilities are essential for creating natural and smooth motions. Due to their previously mentioned characteristics, ref. [

38] highlights that brushless DC motors are the most commonly used actuator in LLEs (lower limb exoskeletons). This type of actuator was recently used in the design of a joint for a pediatric lower limb exoskeleton for children from 6–11 years old, with the orthosis being controlled through state feedback during gait tracking [

39]. This type of actuator is also combined with harmonic drive gears in LLEs developed for children with cerebral palsy, as this fusion offers high efficiency. In the case of the three degrees of freedom exoskeleton (hip–knee–ankle) developed by [

40], which employs the aforementioned combination, a proportional–derivative (PD) impedance control with gravity compensation is used. Unlike some other types of actuators, such as series elastic actuators, brushless DC motors can be inherently rigid. This can make the exoskeleton’s motion less natural or means the user may perceive less feedback during movement.

Another commonly used type of actuator is the stepper motor. This kind of actuator is used for applications that require precise and controlled angular movements, such as gait assistance or rehabilitation exercises. It operates in discrete steps, allowing for accurate joint positioning. This type of actuator can be controlled in an open loop as long as the motor allows it, as is the case with the exoskeleton developed by [

41]. Various control algorithms have been employed in exoskeletons equipped with stepper motor actuators, as in the development of a PID controller using a neuro-fuzzy controller as a compensator [

42] for 3-DoF LLE control, which yielded excellent results when compared to a standalone PID controller. Despite being proposed in cases such as [

43,

44], it’s worth noting that the size and weight of stepper motors must be balanced with their power and torque capabilities, and they can also consume a significant amount of energy, which can be a challenge given the need for exoskeletons to be mobile and battery-operated.

Linear actuators convert rotary motion into linear motion and are often used to create push–pull movements in exoskeletons, as in the knee extension assistance device designed in [

45], which was used to perform the function of standing–sitting–standing. This type of actuator allows precise control of speed, position, and force [

46,

47]. It’s worth noting that in some cases, the range of motion for these actuators is limited, and some of them require regular maintenance.

Hydraulic actuators are known for their high force output, making them suitable for heavy-duty exoskeletons used in industrial or military applications. However, they are less common in wearable exoskeletons due to their size and complexity. Nevertheless, some researchers have employed them, as seen in [

48], where they were used in a rehabilitation exoskeleton. For their control, a fault-tolerant neural controller is designed based on a nonlinear observer. In ref. [

49], a neural sliding mode repetitive learning control based on a disturbance observer was used for an exoskeleton equipped with this type of actuator. Despite the ability of this actuator to generate high torque, it comes with disadvantages such as the need for more robust control, as well as a requirement for additional components in hydraulic systems to perform their operation.

Recently, actuators known as shape memory alloys (SMAs) have been used in exoskeletons. SMAs are materials that change shape in response to temperature changes. They are employed in some exoskeleton designs to create lightweight and compact actuators for applications such as hand rehabilitation. Despite their primary use in hand applications, they can also be found in some lower limb exoskeletons, as is the case in the knee exoskeleton designed by [

50], where a PID controller for the SMA actuator was used. It’s important to note that in these types of actuators, repeated phase transformation cycles can lead to material fatigue over time. Additionally, while heating SMAs to activate their shape memory effect is straightforward, rapid cooling is often necessary for fast actuation cycles. This can be a challenge, especially in compact designs. One of the main challenges posed by SMAs is their use in exoskeletons that require quick responses and high force output.

Series elastic actuators (SEAs) have attracted significant attention due to their ability to maintain low impedance across various frequency ranges [

39]. Control strategies for SEAs show remarkable diversity and include the use of proportional–integral (PI) controllers enhanced with speed feedback to improve movement precision and stability [

51,

52]. Furthermore, the introduction of radial basis function (RBF) neural networks has emerged as a promising approach to enhance the precision of exoskeleton movements, effectively addressing inherent uncertainties in system models [

53].

The pursuit of high-performance decoupled torque controllers specifically designed for SEAs is an ambitious undertaking. These controllers must accommodate a wide range of operational scenarios in exoskeletons, dealing with significant parametric uncertainties, nonlinearities, and unmodeled uncertainties in the system. In conjunction with these efforts, the development of robust adaptive algorithms that effectively compensate for these uncertainties is of utmost importance [

54].

A distinctive research path is characterized by investigations aimed at enhancing the force precision of SEAs through careful sensor placement and the integration of internal control feedback loops [

55]. The inherent benefits of SEAs, including their compact size and cost-effectiveness, make them a preferred choice for lower limb exoskeletons [

56]. The pursuit of innovation in SEA technology has given rise to the development of variable rigidity SEAs reinforced by robust controllers based on acceleration, significantly expanding their range of applications, particularly in industrial settings [

57]. Safety considerations remain of utmost importance, as exemplified by velocity-sourced series elastic actuators, which demonstrate an ability to mitigate the risk of head injuries during collisions, thus enhancing their suitability for exoskeletons that prioritize safe force and torque transmission [

58].

The evolution of SEA technology also encompasses the development of innovative actuator designs, as exemplified by the introduction of the conjugate cylindrical cam-based nonlinear actuator, referred to as N3CSEA. This groundbreaking actuator configuration aims to improve joint performance in knee orthoses, thus contributing to a reduction in energy consumption and addressing the control complexities associated with conventional SEAs [

59]. Furthermore, it’s important to note that while SEAs offer advantageous features, they also have certain limitations, particularly their inherent low damping dynamics. To address this limitation, researchers have undertaken efforts to enhance the damping performance of SEAs through a linear control architecture. This architectural innovation involves the implementation of cascade control schemes with the integration of three distinct controllers, namely, proportional–integral controllers, proportional–derivative controllers, and a specialized generalized controller tailored for damping oscillations. To overcome challenges related to frequency–domain constraints, an optimization framework that encompasses both frequency and time-domain objectives is presented. Robust design considerations are essential to account for model imbalances resulting from the underestimation of motor coupling effects. The effectiveness of this advanced control architecture is substantiated through empirical validation, demonstrating improved damping performance in real-world scenarios subject to external disturbances [

60].

The choice of actuator type depends on the specific application and requirements of the exoskeleton. Factors such as weight, power consumption, force output, precision, and cost play a crucial role in determining the most suitable actuation system. In many cases, a combination of actuator types may be used to optimize the exoskeleton’s performance and functionality. Additionally, advanced control algorithms and sensory feedback systems are often integrated to ensure safe and natural user interaction with the exoskeleton.

In the healthcare sector, one of the primary benefits associated with exoskeletons is the reduction in clinical costs related to assisting and rehabilitating individuals with neurological and age-related disorders. Actuators, one of the most important components of exoskeletons, also contribute to their reduced weight and improved accessibility. Depending on the control signals they receive, actuators have the capability to generate the necessary forces and torques for carrying out required movements. While pneumatic artificial muscle (PAM)-type actuators are less commonly used in exoskeletons, they offer two essential features: their operation mimics that of a natural human muscle, and they can generate substantial force and torque.

Pneumatic artificial muscles, also known as pneumatic muscles [

61] or pneumatic actuators, are gaining attention in the exoskeleton field. PAMs consist of an elastomeric bladder encased in a woven sleeve. When pressurized, they contract and expand, mimicking the behavior of human muscles. PAMs are lightweight, highly compliant, and provide a more natural range of motion, making them suitable for wearable exoskeletons [

62]. PAMs may have a slightly slower response time compared to other actuation methods, which can pose a challenge in applications requiring rapid reflexive actions. That is why, in our study, we analyzed the effects of introducing time delay into the control system. This type of actuator tends to be more complex to control than the conventional actuators mentioned earlier.

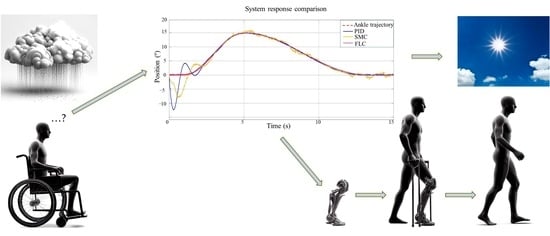

Almost all studies that present a control strategy for a PAM only compare the proposed controller with a PID controller. However, as shown in this work, one of the most employed techniques for commanding this type of actuator is sliding mode control (SMC). Therefore, this work addresses the design and implementation of three controllers —proportional–integrative–derivative controllers, sliding mode controllers, and fuzzy logic controllers (FLCs)—using each of them in the tracking of three different trajectories performed by an exoskeleton. Additionally, the analysis centers on both the response of the controller to external disturbances and the reaction of controllers when the time delay inherent to their dynamic is added to the mathematical model. Finally, the results are compared, revealing through the analysis of performance indexes and time response that the FLC is the controller that exhibits the best global results in the tracking of the different trajectories. There are very few studies that consider and relate topics such as those addressed in this work; additionally, there are even fewer studies that examine control techniques applied to the same exoskeleton and that do not include time delays, external disturbances, data from physical actuators, etc., when addressing this topic in the same work.

This article is divided into five sections.

Section 2 reviews the pneumatic muscles used in exoskeletons.

Section 3 introduces the dynamics of pneumatic artificial muscles and their antagonistic configuration.

Section 4 presents the design of controllers and a comparison of their performances. Lastly, the conclusions of this work are addressed in

Section 5.

2. PAMs in Exoskeletons

Actuator selection in the context of exoskeletons depends on crucial considerations of safety and performance. A pivotal concern is the capability to guarantee user safety even in unexpected or challenging situations. According to their actuators, exoskeletons can be classified into exoskeletons driven by motors, by pneumatic artificial muscles, and by a combination of both. In the bibliography consulted, the authors proposed that one of the most important aspects in the design of an exoskeleton is the proper selection of its actuators [

38,

63,

64,

65,

66].

An actuator can be classified as active or passive depending on the source of its movement. An active exoskeleton uses a source of energy to activate its actuators, and can be electric, pneumatic, or hydraulic. In turn, a passive exoskeleton is a device without an energy source that employs kinematic forces, for example, through the use of springs and dampers.

Most exoskeletons employ direct current (DC) motors to perform movements. However, in recent years, series elastic actuators (SEAs) have been used and diverse studies about their control have been conducted. Contrary to rigid actuators, SEAs contain an elastic element in a series that provides them with several unique properties, including low impedance of mechanical output, tolerance to impact loads, increases in their maximum output power, and passive storage of mechanical energy.

In the case of PAMs, these do not have sliding mechanical parts, and therefore there is no external friction. PAMs have the peculiarity of being exceptionally light and able to reach close power/weight and power/volume relationships compared with other types of actuators. The main limitations of PAMs are high hysteresis and their non-linear force contraction features, which result in a complex design and mechanical control, especially when large ranges of movements and high torques are required. Despite this, their use is more frequent in exoskeletons, as they can more closely simulate the natural behavior of a human muscle.

The study conducted by [

67] proposes that of the 52 exoskeletons used as samples for actuation, 66% employ SEAs as actuators, whereas 17% use pneumatic actuation, of which only 3% employ PAMs.

Pneumatic Artificial Muscles

PAMs are inverse bellows, i.e., they contract with inflation. Their force does not only depend on pressure, but also on their inflation state, which constitutes a second spring-like behavior. In addition, they are extremely light because their central element is no more than a membrane; however, they can still transfer the same quantity of energy as cylinders because they operate within the same pressure and volume ranges. Therefore, PAMs are very resourceful when employed to drive exoskeletons and mobile robots.

Inside pneumatic artificial muscles, also known as McKibben pneumatic artificial muscles, fluidic muscles, or biomimetic actuators, is a tubular actuator characterized by a reduction in actuation length when pressurized [

68]. The most renowned member of the McKibben muscle family was invented in the 1950s by the physician Joseph L. McKibben, who used it as an orthopedic device for patients with polio. Additionally, PAMs were first commercialized by the Bridgestone rubber company of Japan in the 1980s.

PAMs are significantly lighter actuators characterized by a smooth, accurate, and fast response; additionally, they are able to produce a significant force when completely stretched [

69]. As shown in

Figure 2, there are numerous actuators of this type.

Some of the multiple advantages of PAM-type actuators are their capacity to provide high-power outputs with relatively light weights and their satisfaction of the need for safety, simplicity, and lightness in human–robot interactions. These characteristics, alongside the fact that PAMs have properties similar to human muscle, make PAMs a promising actuator option for therapeutic devices designed as rehabilitation therapy for patients with degenerative muscle diseases, limb deterioration, or neurological lesions affecting their kinetic abilities. However, PAMs have some important drawbacks, mainly regarding their control. Due to their high nonlinearity, several problems need to be solved, i.e., a difficulty in achieving accurate force and motion control and slow responses to control inputs [

70]. Despite these inconveniences, the use of PAMs is increasing in the medical field, especially in rehabilitation. For example, the exoskeleton developed in [

71] consists of a hip orthosis equipped with PAMs to assist movements in the lower limbs when a patient has a physical disability.

PAMs find diverse applications in the realm of exoskeletons, including knee rehabilitation, as elucidated in [

72]. Here, a sophisticated control algorithm leveraging a neural network is advanced for a one-degree of freedom (DoF) manipulator robot, which serves as an instrumental component in knee rehabilitation efforts. Experimental validation is conducted, underscoring the efficacy of the proposed control strategy across varying patient conditions and therapeutic regimens. Furthermore, PAMs’ versatility extends to innovative motorized orthoses, as highlighted in [

73], designed to facilitate intensive home-based gait training for individuals grappling with neurological disorders. In a notable departure, ref. [

74] showcases the integration of PAMs within a robotic arm operating with energy assistance, outfitted with rubber PAMs concealed beneath exoskeleton suits to faithfully replicate the actions of bi-articular muscles. Meanwhile, ref. [

75] presents the development of a lower limb exoskeleton tailored to fortify and actively aid in gait training. This cutting-edge exoskeleton harnesses the power of PAMs to propel both leg orthoses, ushering in new prospects for gait rehabilitation.

In ref. [

76], the development of isokinetic equipment driven by PAMs is presented for hip and knee joint recovery exercises. Another application of this type of actuator is shown in [

77], in which a new knee joint rehabilitation device is tested for controlled active movement (CAM) therapy. This system is a re-design of an originally passive CAM device called CAMOped, which consists of a device with an adjustable mechanical resistance thanks to the use of torque-controlled PAMs. These actuators are inherently compatible and can produce both variable resistance and variable rigidity through contraction.

In ref. [

78], tracking control for PAM-based rehabilitation is introduced, which employs a multiple-input–multiple-output (MIMO) echo state network (ESN). Due to the intrinsic characteristics of an exoskeleton using PAMs, i.e., nonlinearities, time-varying parameters, hysteresis, unmodelled uncertainties, etc., modelling the system accurately is challenging. Therefore, MIMO ESN is used to approach the dynamic model of the PMA-driven exoskeleton with a nonlinear autoregressive exogenous model. Additionally, the construction of a single layer network (SLN) is proposed to solve the quadratic programming problem over a finite horizon. The employed control strategy is asymptotically stable when the MIMO ESN is able to approximate the dynamics of this type of actuator. Additionally, this control strategy performed better than the traditional approach in trajectory tracking tasks.

In ref. [

79], a PAM-based rehabilitation lower limb exoskeleton is proposed. To achieve this, an experimental platform based on the DSPACE (digital signal processing and control engineering) system is developed and a fuzzy adaptive PID controller is applied. The results of these experiments show that adding pre-feedback control based on fuzzy adaptive PID controllers can significantly reduce the response time of the system. Additionally, an elevated level of coordination is noticed between user swing motion and the exoskeleton’s leg.

Robot-assisted therapy significantly helps in the rehabilitation of older people and patients with neurological lesions. Therefore, in ref. [

80], a PAM-based exoskeleton is developed that has an innovative design to improve user comfort during walking. To control this exoskeleton, a model-free control strategy known as proxy-based sliding mode control is proposed.

Despite diverse advantages, the non-linearities inherent to PAM hysteresis have a strong influence on the precision of PAM trajectory tracking. Furthermore, systems actuated by PAMs imply high economic costs, although these have decreased in recent years.

The modified Prandtl–Ishlinskii (MPI) model proposed in ref. [

81] allows for the characterization of the asymmetrical hysteresis and compensation of PAMs through the use of rapid commutation valves. The parameters of the model proposed are identified using the Levenberg–Marquardt (L-M) method. In turn, cascade control is employed to compensate for non-linear length/pressure hysteresis, thereby reducing costs. Rapid commutation valves based on the inverse MPI model are employed for the control of trajectory tracking. The effectiveness of this control scheme has been demonstrated experimentally.

In ref. [

82], a humanoid lower limb exoskeleton (HLLE) activated by PAMs is presented, which is manufactured according to the McKibben principle. In addition, a fuzzy self-tuning PID (FSPID) control based on pulse-width modulation (PWM) is built. Additionally, inertial measurement units (IMU) are installed in specific parts of the HLLE to obtain accurate information concerning its movements and thus provide timely feedback for the control system.

A control strategy for a high conformity lower limb rehabilitation system called AIRGAIT is proposed in ref. [

83]. The trajectory tracking control employed in this orthosis is based on a modified calculated pair control that uses a fractional derivative. In addition, this work proposes a new method for the control of robot orthosis compliance, which is employed in an assistance training strategy as necessary.

There is no doubt that PAMs have emerged as a promising actuation technology for powered exoskeletons due to their high power-to-weight ratio, compliance, and customizability compared to traditional actuators such as electric motors. Unlike electric motors, which provide rotary motion, PAMs contract linearly like biological muscles when pressurized with air, enabling more biomimetic and compliant actuation.

A key advantage of PAMs is their inherent compliance and shock absorption capabilities. Exoskeletons designed around rigid actuators can cause discomfort or injury if a collision occurs. In contrast, the natural compliance of PAMs provides a “cushioning” effect that enhances safety. This is especially important for physical human–robot interaction in rehabilitation or assistive applications.

Furthermore, PAMs can be customized in terms of size and contraction force by changing parameters such as diameter and length. This facilitates the modular design of exoskeletons tailored to individual user anatomy and strength requirements. Conventional motors are more limited in scalability and configurability.

However, the nonlinear hysteretic behavior of PAMs presents challenges for precise control. Advanced control strategies are needed to account for the complex dynamics. Two promising trends in PAM control systems are model-based methods such as sliding mode control and model predictive control, as well as data-driven methods such as neural networks. These can provide the robust and adaptive control needed for safe and seamless human–exoskeleton interaction.

In summary, pneumatic artificial muscles hold great promise as actuators for exoskeletons due to their biomechanical compliance, customizability, and high-power density. Continued research into modeling and control will be critical to overcoming their nonlinear dynamics and enabling their adoption in advanced assistive devices. The development of soft wearable robots driven by PAMs could lead to a higher quality of life for many patient populations, according to leading researchers.