Physical Characteristics and Controlling Factors of Coal Gas Reservoir in Pingdingshan No. 10 Coal Mine

Abstract

:1. Introduction

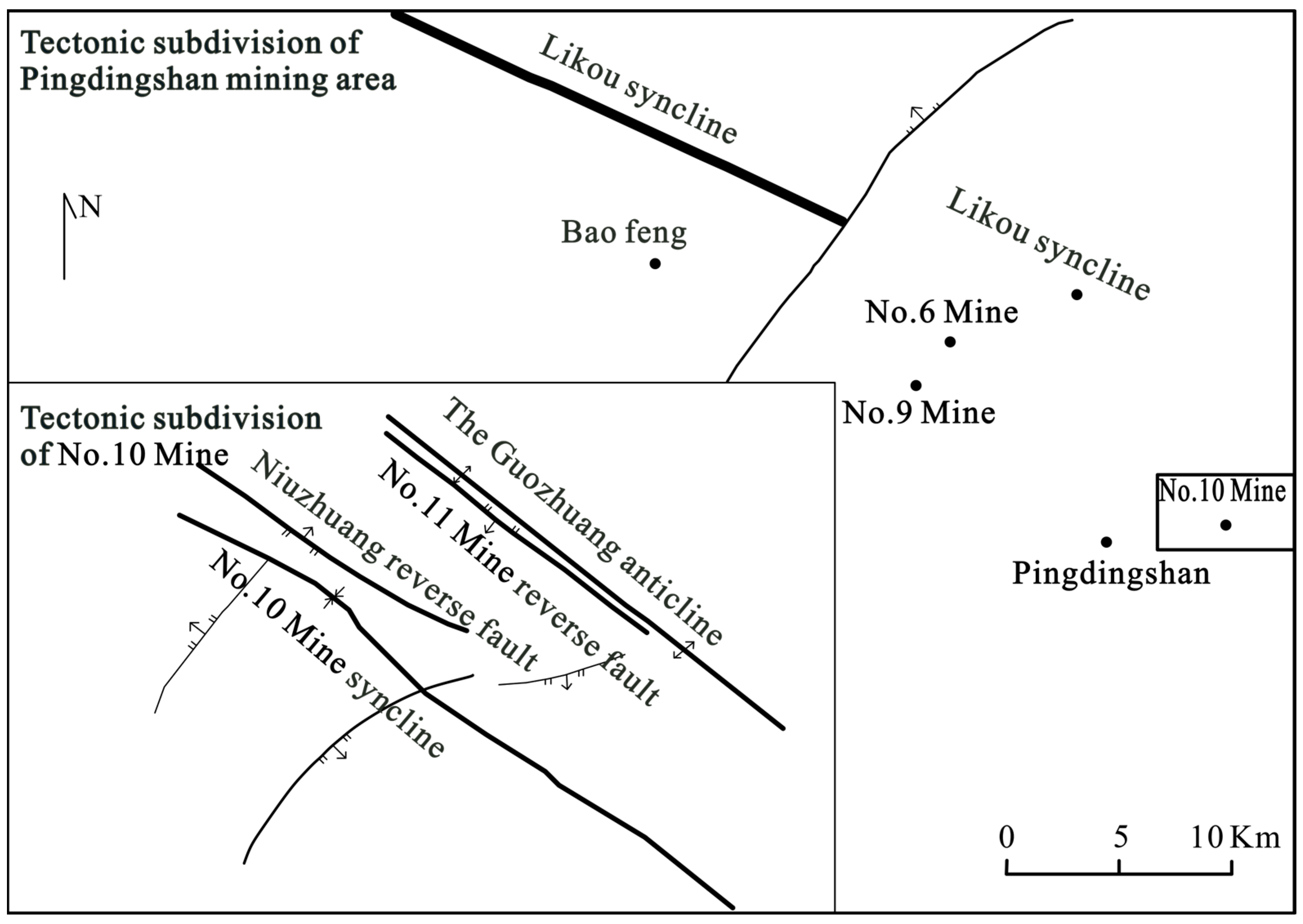

2. Geological Conditions and Background of Mining Area

2.1. Geological Conditions

2.2. Background

3. Samples and Experimental Methods

3.1. Samples

3.2. Petrographic Characteristics

3.3. Experimental Methods

3.3.1. HPMI

3.3.2. SEM

3.3.3. Isothermal Adsorption

3.3.4. The Coalbed Methane (CBM) Content

3.3.5. XRD

4. Results and Discussion

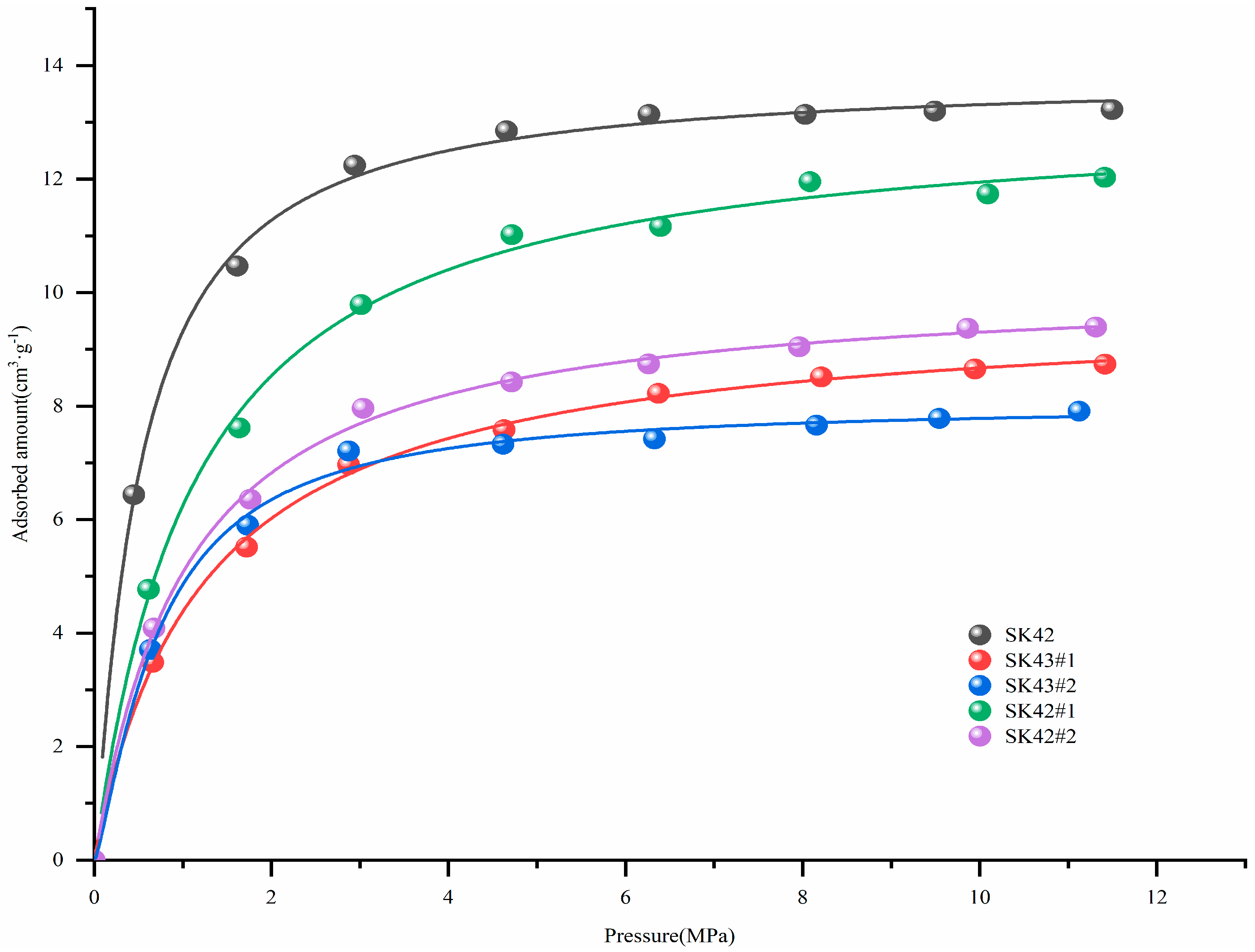

4.1. Adsorption Characteristics of Coal

4.2. Coal Seam Pore and Fracture Characteristics

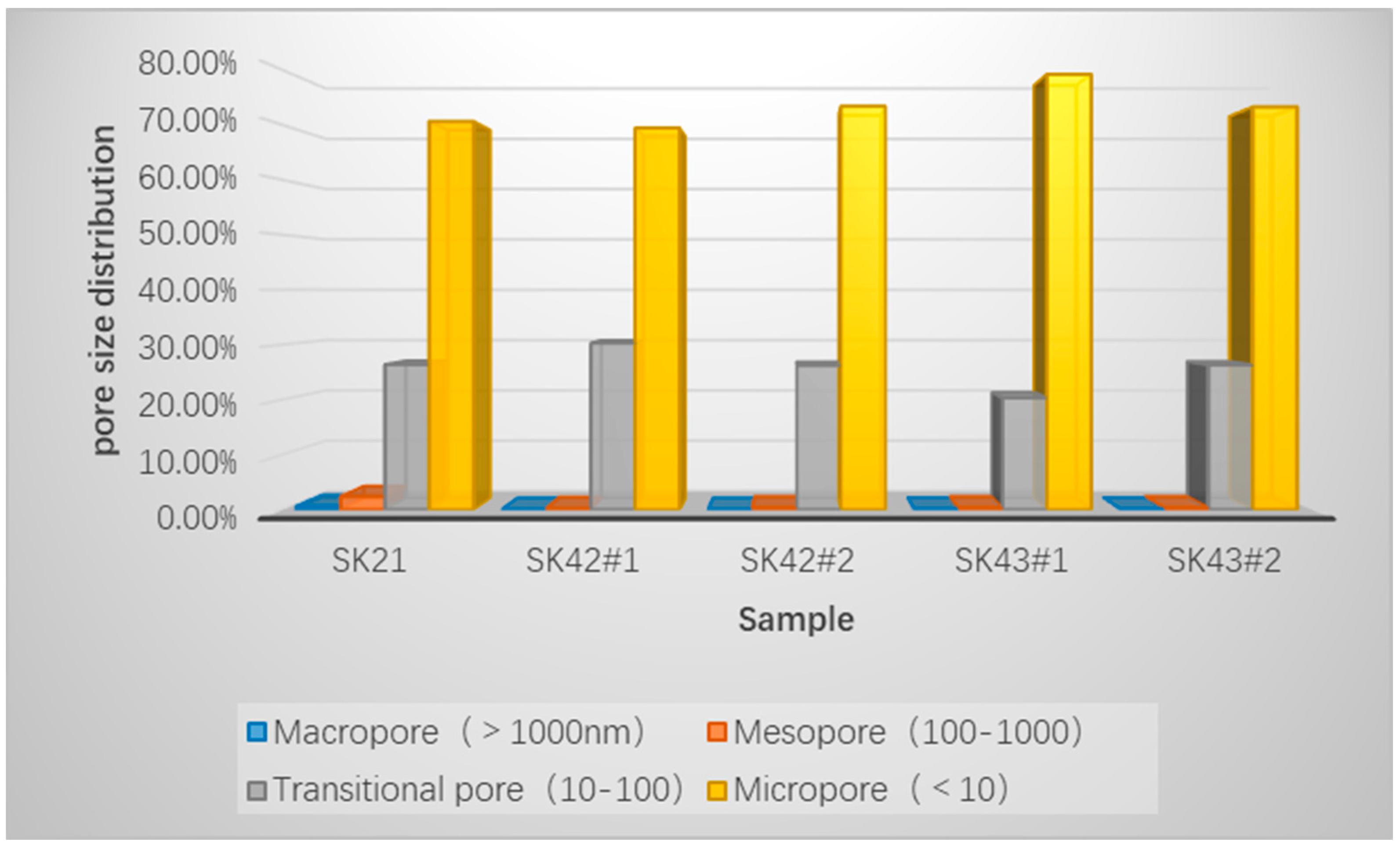

4.2.1. Coal Pore Characteristics

- SK21 porosity was 39.34% with pore sizes ranging from 5.48 to 342 917.58 nm, of which macropores (>1000 nm) accounted for 0.65%, mesopores (100–1000 nm) accounted for 2.36%, transitional pores (10–100 nm) accounted for 26.39%, and micropores (<10 nm) accounted for 70.60%.

- SK42 porosity was 4.98–5.17% with pore sizes ranging from 5.48 to 342 422.90 nm, comprising 0.08% macropores, 0.23–0.34% mesopores, 26.19–30.28% transitional pores, and 69.42–73.39% micropores.

- SK43 porosity was 5.78–8.08% with pore sizes ranging from 5.48 to 342 585.98 nm, comprising 0.13–0.14% macropores, 0.36% mesopores, 20.33–26.28% transitional pores, and 73.24–79.17% micropores.

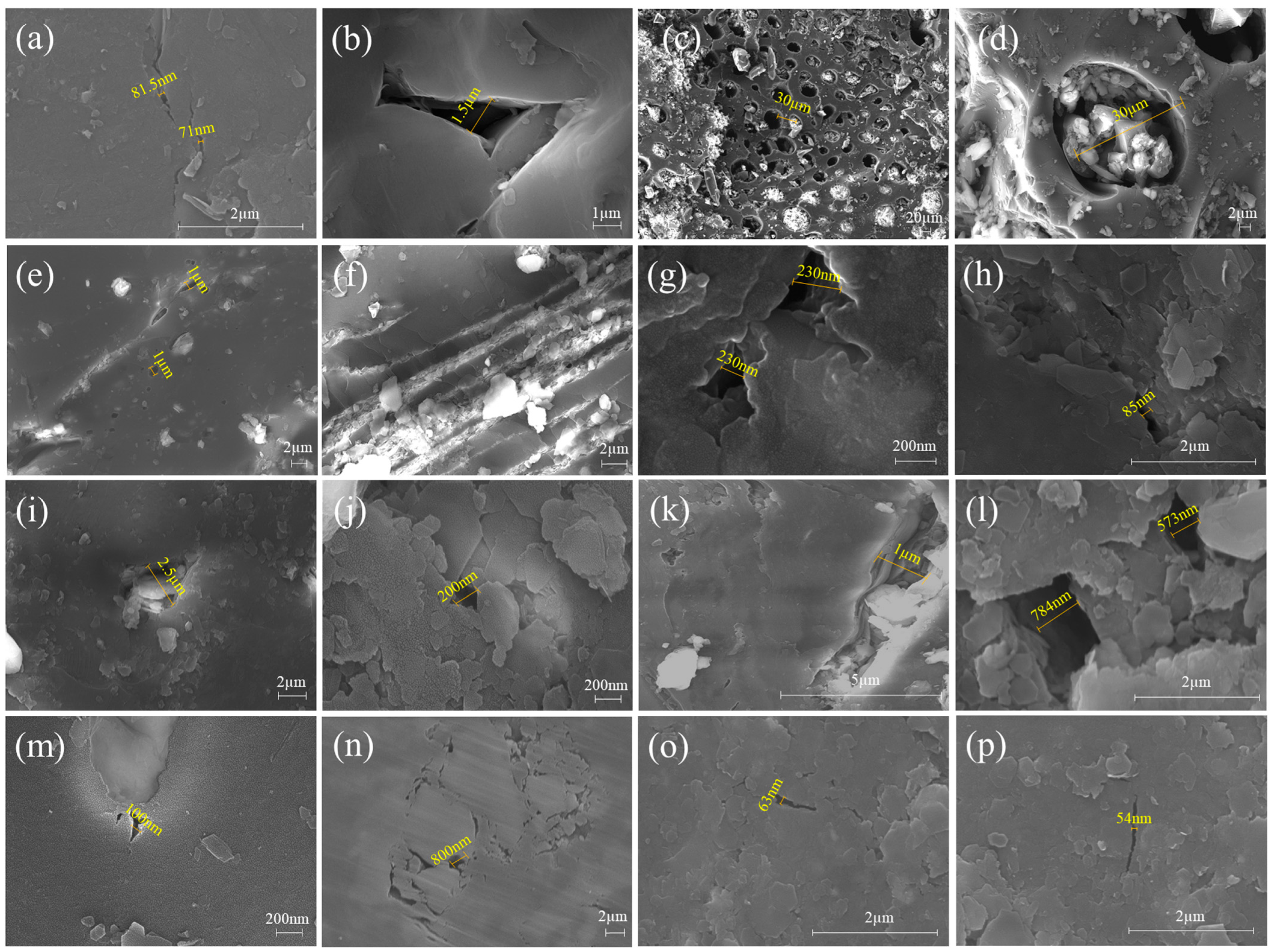

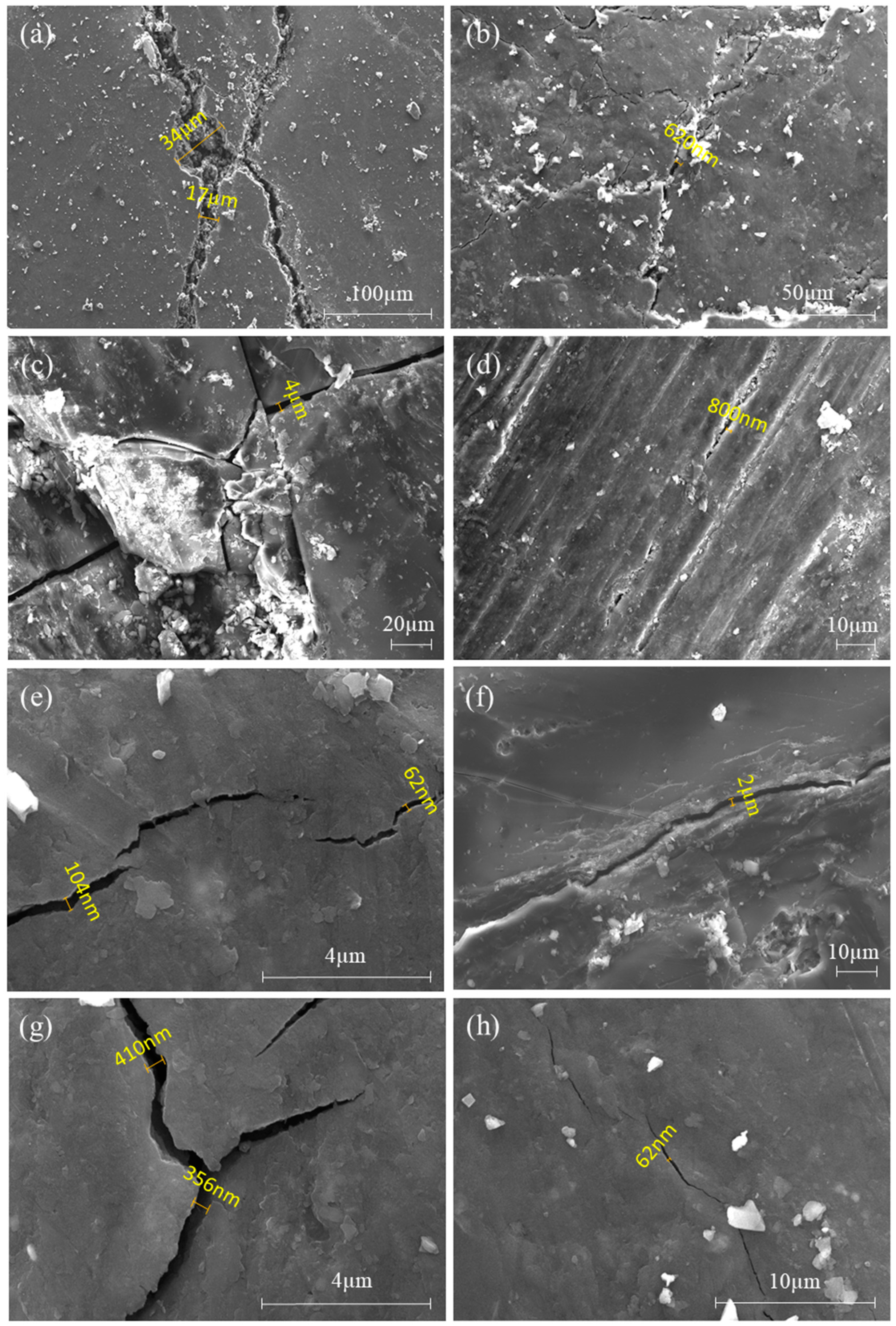

4.2.2. Coal Fracture Characterization

4.3. Mineral Composition of Coal

4.4. Analysis of Differences in Coalbed Gas Content and Control Factors

4.4.1. Coalbed Gas Content

4.4.2. The Influence of Coal Seam Thickness and Depth

4.4.3. The Influence of Coal Seam Roof and Floor Lithology

4.4.4. Characterization of the Organic Microcomponents of Coal

4.4.5. The Influence of Mineral Characteristics

4.5. Challenges and Prospects

5. Conclusions

- The average gas content of SK21 was 2.27 m3t−1; the average gas content of SK42 was 7.39 m3t−1; and the average gas content of SK43 was 7.03 m3t−1. Thus, the gas content of SK42 and SK43 in the No. 10 mine field was relatively high, and was obviously low for SK21. Moreover, the gas content and methane purity of the No. 4 coal seam were significantly higher than the No. 2 seam, and therefore they have better development potential than the No. 2 seam.

- Isothermal adsorption experiments indicate that the theoretical saturated adsorption amount of methane in the No. 4 coal seam was slightly below that of the No. 2 seam. The average adsorption time of the No. 2 coal seam was less than that of the No. 4 seam, and the adsorption time was shorter, making it easier to reach the peak production capacity of CBM wells in the short term, but was not conducive to long-term stable production of CBM. The adsorption curves indicate that the Langmuir volume of the No. 2 coal seam samples was significantly greater than for the No. 4 coal seam; however, the No. 4 coal seam contains about three times the amount of gas in the No. 2 seam.

- All three coal seams have high porosity, which was favorable for large amounts of CBM adsorption and storage. Micropores predominated; transitional pores were less frequent, and a few mesopores occurred; macropores were the least common. Samples from the No. 4 seam contained the highest proportion of micropores.

- Organic pores were common in the coal samples, with pore diameters not more than 30 µm, mainly concentrated between 50.5 and 1000 nm. Intergranular and intragranular pores were observed in inorganic minerals; a considerable proportion of the intergranular pores were filled with clay minerals. Microfractures with apertures less than 70 nm were relatively frequent, mainly in the 50–65 nm range. A large number of the nanoscale microfractures were curved or jagged.

- Fractures in the No. 2 and No. 4 coal seam samples with widths of 50 nm to 20 µm were more-developed, and many were filled with kaolinite, quartz, and other minerals; some of the filled fractures were spaced at the nanometer level, between 50 and 800 nm. The maximum open fracture aperture was not more than 2 µm, with the minimum averaging around 62 nm. These apertures were relatively simple in shape, with a hundred to several hundreds often occurring in the one place.

- The samples contained mostly layered silicate minerals (kaolinite), with hard granular minerals (quartz) next, and a very small quantity of iron-type minerals, such as siderite and pyrite in dendritic form.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Raza, S.; Orooji, Y.; Ghasali, E.; Hayat, A.; Karimi-Maleh, H.; Lin, H. Engineering approaches for CO2 converting to biomass coupled with nanobiomaterials as biomediated towards circular bioeconomy. J. CO2 Util. 2023, 67, 102295. [Google Scholar] [CrossRef]

- Raza, S.; Ghasali, E.; Orooji, Y.; Lin, H.; Karaman, C.; Dragoi, E.N.; Erk, N. Two dimensional (2D) materials and biomaterials for water desalination; structure, properties, and recent advances. Environ. Res. 2022, 219, 114998. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Pan, J.; Wang, K.; Mou, P.; Li, J. Fracture variation in high-rank coal induced by hydraulic fracturing using X-ray computer tomography and digital volume correlation. Int. J. Coal Geol. 2022, 252, 103942. [Google Scholar] [CrossRef]

- Prabu, V.; Mallick, N. Coalbed methane with CO2 sequestration: An emerging clean coal technology in India. Renew. Sustain. Energy Rev. 2015, 50, 229–244. [Google Scholar] [CrossRef]

- Teng, T.; Gao, F.; Ju, Y.; Xue, Y. How moisture loss affects coal porosity and permeability during gas recovery in wet reservoirs. Int. J. Min. Sci. Technol. 2017, 27, 899–906. [Google Scholar] [CrossRef]

- Wen, S.; Zhou, K.; Lu, Q. A discussion on CBM development strategies in China: A case study of PetroChina Coalbed Methane Co., Ltd. Nat. Gas Ind. B 2019, 6, 610–618. [Google Scholar] [CrossRef]

- Raza, S.; Ghasali, E.; Raza, M.; Chen, C.; Li, B.; Orooji, Y.; Lin, H.; Karaman, C.; Maleh, H.K.; Erk, N. Advances in technology and utilization of natural resources for achieving carbon neutrality and a sustainable solution to neutral environment. Environ. Res. 2022, 220, 115135. [Google Scholar] [CrossRef]

- Liu, D.; Jia, Q.; Cai, Y.; Gao, C.; Qiu, F.; Zhao, Z.; Chen, S. A new insight into coalbed methane occurrence and accumulation in the Qinshui Basin, China. Gondwana Res. 2022, 111, 280–297. [Google Scholar] [CrossRef]

- Gao, C.; Liu, D.; Vandeginste, V.; Cai, Y.; Sun, F. Thermodynamic energy change and occurrence mechanism of multiple fluids in coal reservoirs. Energy 2023, 283, 129089. [Google Scholar] [CrossRef]

- Fu, X.; Qin, Y.; Wang, G.G.; Rudolph, V. Evaluation of gas content of coalbed methane reservoirs with the aid of geophysical logging technology. Fuel 2009, 88, 2269–2277. [Google Scholar] [CrossRef]

- Wang, S.; Elsworth, D.; Liu, J. Permeability evolution in fractured coal: The roles of fracture geometry and water-content. Int. J. Coal Geol. 2011, 87, 13–25. [Google Scholar] [CrossRef]

- Weniger, S.; Weniger, P.; Littke, R. Characterizing coal cleats from optical measurements for CBM evaluation. Int. J. Coal Geol. 2016, 154, 176–192. [Google Scholar] [CrossRef]

- Wang, X.; Pan, J.; Deng, Z.; Xu, Q.; Cheng, N.; Wang, Z.; Li, Y. Comparison of fracture and permeability between tectonically deformed coal and briquette coal using x-ray computer tomography and the lattice Boltzmann method. Nat. Resour. Res. 2023, 32, 2223–2241. [Google Scholar] [CrossRef]

- Diamond, W.P.; Schatzel, S.J. Measuring the gas content of coal: A review. Int. J. Coal Geol. 1998, 35, 311–331. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, L.-B.; Cheng, Y.-P.; Liu, S.; Guo, P.-K.; Jin, K.; Jiang, H.-N. A new method for accurate and rapid measurement of underground coal seam gas content. J. Nat. Gas Sci. Eng. 2015, 26, 1388–1398. [Google Scholar] [CrossRef]

- Wang, X.; Pan, J.; Wang, K.; Ge, T.; Wei, J.; Wu, W. Characterizing the shape, size, and distribution heterogeneity of pore-fractures in high rank coal based on X-ray CT image analysis and mercury intrusion porosimetry. Fuel 2020, 282, 118754. [Google Scholar] [CrossRef]

- Ramandi, H.L.; Mostaghimi, P.; Armstrong, R.T.; Saadatfar, M.; Pinczewski, W.V. Porosity and permeability characterization of coal: A micro-computed tomography study. Int. J. Coal Geol. 2016, 154, 57–68. [Google Scholar] [CrossRef]

- Karacan, C.O.; Okandan, E. Adsorption and gas transport in coal microstructure: Investigation and evaluation by quantitative X-ray CT imaging. Fuel 2001, 80, 509–520. [Google Scholar] [CrossRef]

- Giffin, S.; Littke, R.; Klaver, J.; Urai, J. Application of BIB–SEM technology to characterize macropore morphology in coal. Int. J. Coal Geol. 2013, 114, 85–95. [Google Scholar] [CrossRef]

- Zhou, S.; Yan, G.; Xue, H.; Guo, W.; Li, X. 2D and 3D nanopore characterization of gas shale in Longmaxi formation based on FIB-SEM. Mar. Pet. Geol. 2016, 73, 174–180. [Google Scholar] [CrossRef]

- Zelenka, T. Adsorption and desorption of nitrogen at 77 K on micro-and meso-porous materials: Study of transport kinetics. Microporous Mesoporous Mater. 2016, 227, 202–209. [Google Scholar] [CrossRef]

- Raut, U.; Famá, M.; Teolis, B.D.; Baragiola, R.A. Characterization of porosity in vapor-deposited amorphous solid water from methane adsorption. J. Chem. Phys. 2007, 127, 204713. [Google Scholar] [CrossRef] [PubMed]

- Chalmers, G.R.; Bustin, R.M. Lower Cretaceous gas shales in northeastern British Columbia, Part I: Geological controls on methane sorption capacity. Bull. Can. Pet. Geol. 2008, 56, 1–21. [Google Scholar] [CrossRef]

- Wang, Z.; Fu, X.; Pan, J.; Deng, Z. Effect of N2/CO2 injection and alternate injection on volume swelling/shrinkage strain of coal. Energy 2023, 275, 127377. [Google Scholar] [CrossRef]

- Sarrazin, P.; Blake, D.; Feldman, S.; Chipera, S.; Vaniman, D.; Bish, D. Field deployment of a portable X-ray diffraction/X-ray flourescence instrument on Mars analog terrain. Powder Diffr. 2005, 20, 128–133. [Google Scholar] [CrossRef]

- ISO 15901-1:2016; Evaluation of Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption-Part 1: Mercury Porosimetry. ISO: Geneva, Switzerland, 2016.

- Chinese Standard GB/T 19560-2008; Experimental Method of High-Pressureisothermal Adsorption to Coal. GB Standards: Shenzhen, China, 2008. (In Chinese)

- Chinese Standard GB/T 19559-2021; Method of Determining Coalbed Methane Content. GB Standards: Shenzhen, China, 2021. (In Chinese)

- Guo, S. Experimental study on isothermal adsorption of methane gas on three shale samples from Upper Paleozoic strata of the Ordos Basin. J. Pet. Sci. Eng. 2013, 110, 132–138. [Google Scholar] [CrossRef]

- Su, X.B.; Zhang, L.P.; Lin, X.Y. Influence of coal rank on coal adsorption capacity. Nat. Gas Ind. 2005, 25, 19–21. [Google Scholar]

- Gao, Z.; Liang, Z.; Hu, Q.; Jiang, Z.; Xuan, Q. A new and integrated imaging and compositional method to investigate the contributions of organic matter and inorganic minerals to the pore spaces of lacustrine shale in China. Mar. Pet. Geol. 2021, 127, 104962. [Google Scholar] [CrossRef]

- Roslin, A.; Pokrajac, D.; Wu, K.; Zhou, Y. 3D pore system reconstruction using nano-scale 2D SEM images and pore size distribution analysis for intermediate rank coal matrix. Fuel 2020, 275, 117934. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Liu, W.; Wang, G.; Han, D.; Xu, H.; Chu, X. Accurate characterization of coal pore and fracture structure based on CT 3D reconstruction and NMR. J. Nat. Gas Sci. Eng. 2021, 96, 104242. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Schieber, J. Common themes in the formation and preservation of intrinsic porosity in shales and mudstones–illustrated with examples across the Phanerozoic. In Proceedings of the SPE Unconventional Gas Conference; OnePetro: Richardson, TX, USA, 2010. [Google Scholar]

- Zhang, H.; Jin, X.; Wu, J.; Yang, Q.; Hao, L. Nano-pores of organic matter in Longmaxi Formation shale in Sichuan Basin. Coal Geol. Explor. 2018, 46, 47–53. [Google Scholar]

- Zhang, J.; Wang, H.; Vandeginste, V.; Miao, H.; Guo, Y.; Ji, Y.; Liu, P.; Peng, Y. Effect of litho-facies on nano-pore structure of continental shale in shuinan formation of Jiaolai Basin. Geoenergy Sci. Eng. 2023, 228, 212020. [Google Scholar] [CrossRef]

- Wang, J.; Wu, W.; Huang, X.-F. Micropore structure characteristics of shale in the Paleogene Sha-4 Member, Dongying Sag. J. Electron Microsc. 2017, 36, 368–375. [Google Scholar]

- Yu, B.S. Classification and characterization of gas shale pore system. Earth Sci. Front. 2013, 20, 211–220. [Google Scholar]

- Qin, S.; Wang, R.; Shi, W.; Liu, K.; Zhang, W.; Xu, X.; Qi, R.; Yi, Z. Diverse effects of intragranular fractures on reservoir properties, diagenesis, and gas migration: Insight from Permian tight sandstone in the Hangjinqi area, north Ordos Basin. Mar. Pet. Geol. 2022, 137, 105526. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.; Liu, S.; Zhang, R. Pore characterization and its impact on methane adsorption capacity for organic-rich marine shales. Fuel 2016, 181, 227–237. [Google Scholar] [CrossRef]

- Jinling, L. The Analysis of Coal Reservoir Physical Propertiesand Geological Factors in Southern Qinshui Basin; China University of Geosciences: Beijing, China, 2011. [Google Scholar]

- Guihong, L.; Hong, Z.; Hui, Z.; Xiaozhong, S. Characteristics of fractures and pores of anthracite in Jincheng by SEM. Min. Sci. Technol. 2010, 20, 789–793. [Google Scholar]

- Liu, Y.; Liu, A.; Liu, S.; Kang, Y. Nano-scale mechanical properties of constituent minerals in shales investigated by combined nanoindentation statistical analyses and SEM-EDS-XRD techniques. Int. J. Rock Mech. Min. Sci. 2022, 159, 105187. [Google Scholar] [CrossRef]

- Li, J.; Lu, S.; Zhang, P.; Cai, J.; Li, W.; Wang, S.; Feng, W. Estimation of gas-in-place content in coal and shale reservoirs: A process analysis method and its preliminary application. Fuel 2020, 259, 116266. [Google Scholar] [CrossRef]

- Song, L.; Dazhen, T.; Hao, X.; Shu, T. Progress in geological researches on the deep coalbed methane reservoirs. Earth Sci. Front. 2016, 23, 10. [Google Scholar]

- Meng, Y.; Li, Z. Experimental study on diffusion property of methane gas in coal and its influencing factors. Fuel 2016, 185, 219–228. [Google Scholar] [CrossRef]

- Meng, Z.; Yan, J.; Li, G. Controls on gas content and carbon isotopic abundance of methane in Qinnan-East coal bed methane block, Qinshui Basin, China. Energy Fuels 2017, 31, 1502–1511. [Google Scholar] [CrossRef]

- Wei, Q.; Li, X.; Hu, B.; Zhang, X.; Zhang, J.; He, Y.; Zhang, Y.; Zhu, W. Reservoir characteristics and coalbed methane resource evaluation of deep-buried coals: A case study of the No. 13–1 coal seam from the Panji Deep Area in Huainan Coalfield, Southern North China. J. Pet. Sci. Eng. 2019, 179, 867–884. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Zhang, K.; Elsworth, D.; Yao, Y.; Tang, D. Preliminary evaluation of gas content of the No. 2 coal seam in the Yanchuannan area, southeast Ordos basin, China. J. Pet. Sci. Eng. 2014, 122, 675–689. [Google Scholar] [CrossRef]

- Fu, S.; Wang, L.; Li, S.; Zheng, S.; Li, J. The effect of organic matter fraction extracted on micropores development degree and CH4 adsorption capacity of coal. Gas Sci. Eng. 2023, 110, 204870. [Google Scholar] [CrossRef]

- Song, D.; Ji, X.; Li, Y.; Zhao, H.; Song, B.; He, K. Heterogeneous development of micropores in medium-high rank coal and its relationship with adsorption capacity. Int. J. Coal Geol. 2020, 226, 103497. [Google Scholar] [CrossRef]

- Wang, Z.; Hao, C.; Wang, X.; Wang, G.; Ni, G.; Cheng, Y. Effects of micro-mesopore structure characteristics on methane adsorption capacity of medium rank coal. Fuel 2023, 351, 128910. [Google Scholar] [CrossRef]

- Guanghui, Y.U.; Yingchang, C.A.; Kelai, X.I.; Yanzhong, W.A.; Xiaoyan, L.I.; Tian, Y.A. Feldspar dissolution and its impact on physical properties of Paleogene clastic reservoirs in the northern slope zone of the Dongying sag. Acta Pet. Sin. 2013, 34, 853. [Google Scholar]

- Yuan, G.; Cao, Y.; Gluyas, J.; Li, X.; Xi, K.; Wang, Y.; Jia, Z.; Sun, P.; Oxtoby, N.H. Feldspar dissolution, authigenic clays, and quartz cements in open and closed sandstone geochemical systems during diagenesis: Typical examples from two sags in Bohai Bay Basin, East China. AAPG Bull. 2015, 99, 2121–2154. [Google Scholar] [CrossRef]

- Ma, B.; Lu, Y.; Eriksson, K.A.; Peng, L.; Xing, F.; Li, X. Multiple organic–inorganic interactions and influences on heterogeneous carbonate-cementation patterns: Example from Silurian deeply buried sandstones, central Tarim Basin, north-western China. Sedimentology 2021, 68, 670–696. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Z.; She, Y.; Lin, S.; Lin, M.; Zhang, C. Mineral characteristic of rocks and its impact on the reservoir quality of He 8 tight sandstone of Tianhuan area, Ordos Basin, China. J. Nat. Gas Geosci. 2019, 4, 205–214. [Google Scholar] [CrossRef]

- Jiu, B.; Huang, W.; Li, Y.; He, M. Influence of clay minerals and cementation on pore throat of tight sandstone gas reservoir in the eastern Ordos Basin, China. J. Nat. Gas Sci. Eng. 2021, 87, 103762. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Cao, J.; Xiao, C.; Wang, S.; Pang, X.; Dai, Q.; He, Z.; Fan, X.; Yang, L.; et al. Investigation of pore structure and petrophysical property in tight sandstones. Mar. Pet. Geol. 2018, 91, 179–189. [Google Scholar] [CrossRef]

- Ye, Y.; Tang, S.; Xi, Z.; Jiang, D.; Duan, Y. Quartz types in the Wufeng-Longmaxi Formations in southern China: Implications for porosity evolution and shale brittleness. Mar. Pet. Geol. 2022, 137, 105479. [Google Scholar] [CrossRef]

| Sample ID | Maceral | |||

|---|---|---|---|---|

| Vitrinite | Inertinite | Exinite | Inorganic Mineral Component | |

| SK21 | 82.17 | 9.42 | - | 8.41 |

| SK42#1 | 68.53 | 19.42 | 4.70 | 7.35 |

| SK42#2 | 68.53 | 19.42 | 4.70 | 7.35 |

| SK43#1 | 68.53 | 19.42 | 4.70 | 7.35 |

| SK43#2 | 68.53 | 19.42 | 4.70 | 7.35 |

| Sample ID | Moisture/% | Ash/% | Air-Dried Basis | ||

|---|---|---|---|---|---|

| Langmuir Volumetric VL/m3·t−1 | Langmuir Pressure PL/MPa | R2 | |||

| SK21 | 1.91 | 10.57 | 13.82 | 0.44 | 0.9927 |

| SK42#1 | 0.93 | 11.67 | 13.18 | 1.07 | 0.9904 |

| SK42#2 | 1.49 | 12.59 | 10.25 | 1.01 | 0.9935 |

| SK43#1 | 0.68 | 23.99 | 9.71 | 1.21 | 0.9957 |

| SK43#2 | 0.72 | 20.06 | 8.36 | 0.69 | 0.9823 |

| Sample ID | Macropore (>1000 nm) | Mesopore (100–1000) | Transitional Pore (10–100) | Micropore (<10) |

|---|---|---|---|---|

| SK21 | 0.65% | 2.36% | 26.39% | 70.60% |

| SK42#1 | 0.08% | 0.23% | 30.28% | 69.42% |

| SK42#2 | 0.08% | 0.34% | 26.19% | 73.39% |

| SK43#1 | 0.14% | 0.36% | 20.33% | 79.17% |

| SK43#2 | 0.13% | 0.36% | 26.28% | 73.24% |

| Sample ID | Quartz | Kaolinite | Calcite | Siderite | Dolomite | Pyrite | Anatase | Muscovite |

|---|---|---|---|---|---|---|---|---|

| SK21 | 15.2 | 81.8 | 3 | — | — | — | — | — |

| SK42#1 | — | 86 | 11 | — | 3 | — | — | — |

| SK42#2 | 41 | 52 | — | 4 | 3 | — | — | — |

| SK43#1 | 46 | 52 | — | — | — | — | 2 | — |

| SK43#2 | 49 | 44 | — | — | — | 5 | 2 | — |

| Sample ID | Depth/m | Total Gas Content (daf)/m3·t−1 | Methane Content (daf)/m3·t−1 | Gas Composition/% (Normalized after Deducting Air) | Adsorption Time/d | |||

|---|---|---|---|---|---|---|---|---|

| CH4 | CO2 | N2 | C2H6 | |||||

| SK21#1 | 872.22–872.52 | 2.08 | 1.16 | 55.94 | 4.72 | 37.72 | 1.62 | 3.46 |

| SK21#2 | 873.43–873.73 | 3.73 | 2.88 | 77.25 | 10.51 | 9.49 | 2.75 | 1.30 |

| SK21#3 | 874.73–875.03 | 2.85 | 2.29 | 80.30 | 8.70 | 8.06 | 2.94 | 1.54 |

| SK21#4 | 875.73–876.03 | 3.01 | 2.48 | 82.22 | 9.30 | 4.79 | 3.70 | 0.94 |

| SK21#5 | 876.68–876.98 | 1.58 | 0.75 | 47.50 | 4.26 | 46.23 | 2.01 | 0.98 |

| SK21#6 | 877.69–877.99 | 0.37 | 0.20 | 55.20 | 2.59 | 40.70 | 1.51 | 0.29 |

| SK42#1 | 699.36–699.66 | 7.07 | 6.64 | 93.99 | 1.18 | 4.81 | 0.02 | 4.26 |

| SK42#2 | 699.99–700.29 | 8.61 | 8.19 | 95.16 | 0.97 | 3.85 | 0.01 | 3.19 |

| SK42#3 | 701.00–701.30 | 6.49 | 5.99 | 92.32 | 0.97 | 6.69 | 0.02 | 3.07 |

| SK43#1 | 692.02–692.32 | 7.03 | 6.60 | 93.89 | 1.62 | 4.47 | 0.02 | 2.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, D.; Wang, J.; Wang, B.; Gao, D.; Zhao, J. Physical Characteristics and Controlling Factors of Coal Gas Reservoir in Pingdingshan No. 10 Coal Mine. Processes 2023, 11, 3130. https://doi.org/10.3390/pr11113130

Zhou D, Wang J, Wang B, Gao D, Zhao J. Physical Characteristics and Controlling Factors of Coal Gas Reservoir in Pingdingshan No. 10 Coal Mine. Processes. 2023; 11(11):3130. https://doi.org/10.3390/pr11113130

Chicago/Turabian StyleZhou, Dejie, Juan Wang, Baoyu Wang, Di Gao, and Junjie Zhao. 2023. "Physical Characteristics and Controlling Factors of Coal Gas Reservoir in Pingdingshan No. 10 Coal Mine" Processes 11, no. 11: 3130. https://doi.org/10.3390/pr11113130