Detoxification of Copper and Chromium via Dark Hydrogen Fermentation of Potato Waste by Clostridium butyricum Strain 92

Abstract

:1. Introduction

2. Materials and Methods

2.1. Isolation and Identification of the Hydrogen-Synthesizing Strain

2.2. Preparation of Chromium and Copper Solutions and Their Analytical Determination

2.3. The Process of Fermentation and Metals Insertion

2.4. Data Analysis

3. Results

3.1. Characteristic of the Strict Hydrogen-Synthesizing Anaerobic Strain

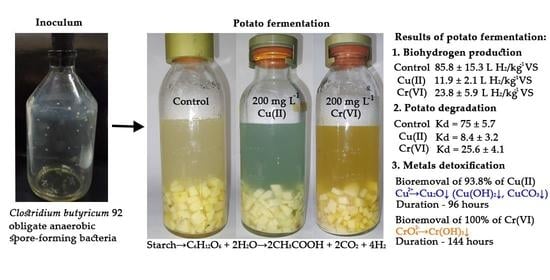

3.2. The Influence of Metals on the Gas Synthesis and the Efficiency of Potato Fermentation Process by Clostridium butyricum Strain 92

3.3. The Influence of Metals on Metabolic Parameters of the Potato Fermentation Process

3.4. Bioremoval of Metals from a Medium by Clostridium butyricum Strain 92

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, D.M.-C.; Bodirsky, B.L.; Krueger, T.; Mishra, A.; Popp, A. The World’s Growing Municipal Solid Waste: Trends and Impacts. Environ. Res. Lett. 2020, 15, 074021. [Google Scholar] [CrossRef]

- Wijekoon, P.; Koliyabandara, P.A.; Cooray, A.T.; Lam, S.S.; Athapattu, B.C.; Vithanage, M. Progress and Prospects in Mitigation of Landfill Leachate Pollution: Risk, Pollution Potential, Treatment and Challenges. J. Hazard. Mater. 2022, 421, 126627. [Google Scholar] [CrossRef] [PubMed]

- Igiri, B.E.; Okoduwa, S.I.; Idoko, G.O.; Akabuogu, E.P.; Adeyi, A.O.; Ejiogu, I.K. Toxicity and Bioremediation of Heavy Metals Contaminated Ecosystem from Tannery Wastewater: A Review. J. Toxicol. 2018, 2018, 2568038. [Google Scholar] [CrossRef] [PubMed]

- Hoxha, I.; Shala, N.; Xhabiri, G.Q. Concentration of Heavy Metals in Edible Plants Potatoes: The Health Effects in the Human Organism. Rasayan J. Chem. 2018, 11, 682–687. [Google Scholar] [CrossRef]

- Milyutina, N.O.; Smyatskaya, Y.A.; Politaeva, N.A.; Zelenkovsky, P.S. MSW Landfill Leachate: Formation, Characterization and Treatment. Butl. Commun. 2020, 61, 79–85. [Google Scholar] [CrossRef]

- Keskin, T.; Abubackar, H.N.; Arslan, K.; Azbar, N. Biohydrogen Production from Solid Wastes. In Biohydrogen; Elsevier: Amsterdam, The Netherlands, 2019; pp. 321–346. [Google Scholar] [CrossRef]

- Arain, M.; Mahar, R.B.; Sahtio, A.R. Biohydrogen Production from Co-Digestion of High Carbohydrate Containing Food Waste and Combined Primary and Secondary Sewage Sludge. Mehran. Univ. Res. J. Eng. Technol. 2018, 37, 139–148. [Google Scholar] [CrossRef] [Green Version]

- Hovorukha, V.; Havryliuk, O.; Gladka, G.; Tashyrev, O.; Kalinichenko, A.; Sporek, M.; Dołhańczuk-Śródka, A. Hydrogen Dark Fermentation for Degradation of Solid and Liquid Food Waste. Energies 2021, 14, 1831. [Google Scholar] [CrossRef]

- Maroušek, J.; Rowland, Z.; Valášková, K.; Král, P. Techno-Economic Assessment of Potato Waste Management in Developing Economies. Clean Technol. Environ. Policy 2020, 22, 937–944. [Google Scholar] [CrossRef]

- Káš, M.; Matějková, Š.; Diviš, J. Effect of Preceding Crops on Potato Yield in Organic and Conventional Farming. J. Agrobiol. 2009, 26, 61–67. [Google Scholar] [CrossRef] [Green Version]

- Schieber, A.; Aranda Saldaña, M.D. Potato Peels: A Source of Nutritionally and Pharmacologically Interesting Compounds—A Review. Food 2009, 3, 23–29. [Google Scholar] [CrossRef]

- Sabathé, F.; Croux, C.; Cornillot, E.; Soucaille, P. AmyP, a Reporter Gene to Study Strain Degeneration in Clostridium acetobutylicum ATCC 824. FEMS Microbiol. Lett. 2002, 210, 93–98. [Google Scholar] [CrossRef]

- Bahl, H.; Burchhardt, G.; Spreinat, A.; Haeckel, K.; Wienecke, A.; Schmidt, B.; Antranikian, G. Alpha-Amylase of Clostridium thermosulfurogenes EM1: Nucleotide Sequence of the Gene, Processing of the Enzyme, and Comparison of Other Alpha-Amylases. Appl. Environ. Microbiol. 1991, 57, 1554–1559. [Google Scholar] [CrossRef] [Green Version]

- Duan, Y.; Liu, T.; Zhou, Y.; Dou, T.; Yang, Q. Glycoside Hydrolase Family 18 and 20 Enzymes Are Novel Targets of the Traditional Medicine Berberine. J. Biol. Chem. 2018, 293, 15429–15438. [Google Scholar] [CrossRef] [Green Version]

- Song, K.-M.; Okuyama, M.; Kobayashi, K.; Mori, H.; Kimura, A. Characterization of a Glycoside Hydrolase Family 31 α-Glucosidase Involved in Starch Utilization in Podospora anserina. Biosci. Biotechnol. Biochem. 2013, 77, 2117–2124. [Google Scholar] [CrossRef]

- De Amorim, E.L.C.; Barros, A.R.; Damianovic, M.H.R.Z.; Silva, E.L. Anaerobic Fluidized Bed Reactor with Expanded Clay as Support for Hydrogen Production through Dark Fermentation of Glucose. Int. J. Hydrogen Energy 2009, 34, 783–790. [Google Scholar] [CrossRef]

- Vongdala, N.; Tran, H.-D.; Xuan, T.D.; Teschke, R.; Khanh, T.D. Heavy Metal Accumulation in Water, Soil, and Plants of Municipal Solid Waste Landfill in Vientiane, Laos. Int. J. Environ. Res. Public Health 2019, 16, 22. [Google Scholar] [CrossRef] [Green Version]

- Fryzova, R.; Pohanka, M.; Martinkova, P.; Cihlarova, H.; Brtnicky, M.; Hladky, J.; Kynicky, J. Oxidative Stress and Heavy Metals in Plants. In Reviews of Environmental Contamination and Toxicology; de Voogt, P., Ed.; Springer International Publishing: Cham, Switzerland, 2018; Volume 245, pp. 129–156. ISBN 978-3-319-75037-8. [Google Scholar]

- Rathnayake, I.V.N.; Megharaj, M.; Krishnamurti, G.S.R.; Bolan, N.S.; Naidu, R. Heavy Metal Toxicity to Bacteria—Are the Existing Growth Media Accurate Enough to Determine Heavy Metal Toxicity? Chemosphere 2013, 90, 1195–1200. [Google Scholar] [CrossRef]

- Mohammadi, A.A.; Zarei, A.; Majidi, S.; Ghaderpoury, A.; Hashempour, Y.; Saghi, M.H.; Alinejad, A.; Yousefi, M.; Hosseingholizadeh, N.; Ghaderpoori, M. Carcinogenic and Non-Carcinogenic Health Risk Assessment of Heavy Metals in Drinking Water of Khorramabad, Iran. MethodsX 2019, 6, 1642–1651. [Google Scholar] [CrossRef]

- Semu, E.; Singh, B.R. Accumulation of Heavy Metals in Soils and Plants after Long-Term Use of Fertilizers and Fungicides in Tanzania. Fertil. Res. 1995, 44, 241–248. [Google Scholar] [CrossRef]

- Renu, K.; Chakraborty, R.; Myakala, H.; Koti, R.; Famurewa, A.C.; Madhyastha, H.; Vellingiri, B.; George, A.; Valsala Gopalakrishnan, A. Molecular Mechanism of Heavy Metals (Lead, Chromium, Arsenic, Mercury, Nickel and Cadmium)—Induced Hepatotoxicity—A Review. Chemosphere 2021, 271, 129735. [Google Scholar] [CrossRef]

- Ertani, A.; Mietto, A.; Borin, M.; Nardi, S. Chromium in Agricultural Soils and Crops: A Review. Water Air Soil Pollut. 2017, 228, 190. [Google Scholar] [CrossRef]

- Cao, R.; Zhang, Y.; Ju, Y.; Wang, W.; Xi, C.; Liu, W.; Liu, K. Exacerbation of Copper Pollution Toxicity from Ocean Acidification: A Comparative Analysis of Two Bivalve Species with Distinct Sensitivities. Environ. Pollut. 2022, 293, 118525. [Google Scholar] [CrossRef]

- Lund, B.M.; Knox, M.R.; Sims, A.P. The Effect of Oxygen and Redox Potential on Growth of Clostridium Botulinum Type E from a Spore Inoculum. Food Microbiol. 1984, 1, 277–287. [Google Scholar] [CrossRef]

- Hovorukha, V.; Havryliuk, O.; Tashyreva, H.; Tashyrev, O.; Sioma, I. Thermodynamic Substantiation of Integral Mechanisms of Microbial Interaction with Metals. Ecol. Eng. Environ. Prot. 2018, 55–63. [Google Scholar] [CrossRef]

- Boyle, J. Lehninger Principles of Biochemistry, 4th ed.: Nelson, D., and Cox, M. Biochem. Mol. Biol. Educ. 2005, 33, 74–75. [Google Scholar] [CrossRef]

- Taylor, J. The Estimation of Numbers of Bacteria by Tenfold Dilution Series. J. Appl. Bacteriol. 1962, 25, 54–61. [Google Scholar] [CrossRef]

- Hungate, R.E. A Roll Tube Method for Cultivation of Strict Anaerobes. In Methods in Microbiology; Norris, J.R., Ribbons, D.W., Eds.; Academic Press: Cambridge, MS, USA, 1969; Volume 3, pp. 117–132. ISBN 0580-9517. [Google Scholar] [CrossRef]

- Nübel, U.; Garcia-Pichel, F.; Muyzer, G. PCR Primers to Amplify 16S RRNA Genes from Cyanobacteria. Appl. Environ. Microbiol. 1997, 63, 3327–3332. [Google Scholar] [CrossRef] [Green Version]

- Havryliuk, O.; Hovorukha, V.; Gladka, G.; Tashyrev, O. Bioremoval of Copper(Ii) Via Hydrogen Fermentation of Ecologically Hazardous Multicomponent Food Waste. Ecol. Eng. Environ. Prot. 2020, 13, 5–14. [Google Scholar] [CrossRef]

- Lace, A.; Ryan, D.; Bowkett, M.; Cleary, J. Chromium Monitoring in Water by Colorimetry Using Optimised 1,5-Diphenylcarbazide Method. Int. J. Environ. Res. Public Health 2019, 16, 1803. [Google Scholar] [CrossRef] [Green Version]

- Acree, W.E. Basic Gas Chromatography (McNair, Harold M.; Miller, James, M.). J. Chem. Educ. 1998, 75, 1094. [Google Scholar] [CrossRef] [Green Version]

- Havryliuk, O.; Hovorukha, V.; Savitsky, O.; Trilis, V.; Kalinichenko, A.; Dołhańczuk-Śródka, A.; Janecki, D.; Tashyrev, O. Anaerobic Degradation of Environmentally Hazardous Aquatic Plant Pistia stratiotes and Soluble Cu(II) Detoxification by Methanogenic Granular Microbial Preparation. Energies 2021, 14, 3849. [Google Scholar] [CrossRef]

- Suslova, O.; Govorukha, V.; Brovarskaya, O.; Matveeva, N.; Tashyreva, H.; Tashyrev, O. Method for Determining Organic Compound Concentration in Biological Systems by Permanganate Redox Titration. Int. J. Bioautom. 2014, 18, 45–52. Available online: https://www.researchgate.net/publication/290006934_Method_for_Determining_Organic_Compound_Concentration_in_Biological_Systems_by_Permanganate_Redox_Titration (accessed on 17 December 2021).

- Zhang, C.; Li, T.; Su, G.; He, J. Enhanced Direct Fermentation from Food Waste to Butanol and Hydrogen by an Amylolytic Clostridium. Renew. Energy 2020, 153, 522–529. [Google Scholar] [CrossRef]

- Mahato, R.K.; Kumar, D.; Rajagopalan, G. Biohydrogen Production from Fruit Waste by Clostridium Strain BOH3. Renew. Energy 2020, 153, 1368–1377. [Google Scholar] [CrossRef]

- Rambabu, K.; Show, P.-L.; Bharath, G.; Banat, F.; Naushad, M.; Chang, J.-S. Enhanced Biohydrogen Production from Date Seeds by Clostridium thermocellum ATCC 27405. Int. J. Hydrogen Energy 2020, 45, 22271–22280. [Google Scholar] [CrossRef]

- Valles, A.; Álvarez-Hornos, F.J.; Martínez-Soria, V.; Marzal, P.; Gabaldón, C. Comparison of Simultaneous Saccharification and Fermentation and Separate Hydrolysis and Fermentation Processes for Butanol Production from Rice Straw. Fuel 2020, 282, 118831. [Google Scholar] [CrossRef]

- Wang, J.; Yin, Y. Clostridium Species for Fermentative Hydrogen Production: An Overview. Int. J. Hydrogen Energy 2021, 46, 34599–34625. [Google Scholar] [CrossRef]

- Yan, B.H.; Selvam, A.; Wong, J.W. Bio-Hydrogen and Methane Production from Two-Phase Anaerobic Digestion of Food Waste under the Scheme of Acidogenic off-Gas Reuse. Bioresour. Technol. 2020, 297, 122400. [Google Scholar] [CrossRef]

- An, Q.; Bu, J.; Cheng, J.-R.; Hu, B.-B.; Wang, Y.-T.; Zhu, M.-J. Biological Saccharification by Clostridium thermocellum and Two-Stage Hydrogen and Methane Production from Hydrogen Peroxide-Acetic Acid Pretreated Sugarcane Bagasse. Int. J. Hydrogen Energy 2020, 45, 30211–30221. [Google Scholar] [CrossRef]

- Tang, X.; Huang, Y.; Li, Y.; Wang, L.; Pei, X.; Zhou, D.; He, P.; Hughes, S.S. Study on Detoxification and Removal Mechanisms of Hexavalent Chromium by Microorganisms. Ecotoxicol. Environ. Saf. 2021, 208, 111699. [Google Scholar] [CrossRef]

- Elahi, A.; Arooj, I.; Bukhari, D.A.; Rehman, A. Successive Use of Microorganisms to Remove Chromium from Wastewater. Appl. Microbiol. Biotechnol. 2020, 104, 3729–3743. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, M.; Zhou, D.; Fan, W.; Wang, X.; Huo, M. Bioremoval of Cu2+ from CMP Wastewater by a Novel Copper-Resistant Bacterium Cupriavidus gilardii CR3: Characteristics and Mechanisms. RSC Adv. 2017, 7, 18793–18802. [Google Scholar] [CrossRef] [Green Version]

- Huang, F.; Wang, Z.-H.; Cai, Y.-X.; Chen, S.-H.; Tian, J.-H.; Cai, K.-Z. Heavy Metal Bioaccumulation and Cation Release by Growing Bacillus cereus RC-1 under Culture Conditions. Ecotoxicol. Environ. Saf. 2018, 157, 216–226. [Google Scholar] [CrossRef]

- Zheng, X.; Yuan, D.; Li, Y.; Liu, C. Exploration of the Reduction Mechanism of Cr(VI) in Anaerobic Hydrogen Fermenter. Environ. Pollut. 2019, 254, 113042. [Google Scholar] [CrossRef]

- Vernans, A.; Iswanto, B.; Rinanti, A. Removal of Heavy Metal (Cu2+) by Thiobacillus Sp. and Clostridium sp. at Various Temperatures and Concentration of Pollutant in Liquid Media; IOP Publishing: Bristol, UK, 2019; Volume 1402, p. 022102. [Google Scholar] [CrossRef]

- Havryliuk, O.; Hovorukha, V.; Patrauchan, M.; Youssef, N.H.; Tashyrev, O. Draft Whole Genome Sequence for Four Highly Copper Resistant Soil Isolates Pseudomonas lactis strain UKR1, Pseudomonas panacis strain UKR2, and Pseudomonas veronii strains UKR3 and UKR4. Curr. Res. Microb. Sci. 2020, 1, 44–52. [Google Scholar] [CrossRef]

- Havryliuk, O.; Hovorukha, V.; Sachko, A.; Gladka, G.; Bida, I.; Tashyrev, O. Bioremoval of Hazardous Cobalt, Nickel, Chromium, Copper and Cadmium Compounds from Contaminated Soil by Nicotiana tabacum Plants and Associated Microbiome. Biosyst. Divers. 2021, 29, 88–93. [Google Scholar] [CrossRef]

| Treatments (mg L−1) | H2max (vol.%) * | H2 yield (L kg−1 VSpotato) | CO2 yield (L kg−1 VSpotato) | Kd (times) |

|---|---|---|---|---|

| Control | 38.4 ± 1.9 | 85.8 ± 15.3 a | 123.8 ± 14.5 a | 75 ± 5.7 a |

| 50 Cu(II) | 37.0 ± 1.9 | 77.1 ± 16.1 ab | 112.8 ± 17.1 a | 71 ± 10.2 a |

| 50 Cr(VI) | 34.2 ± 2.5 | 79.2 ± 5.6 ad | 127 ± 21.5 a | 77.4 ± 12.1 a |

| 100 Cu(II) | 34.2 ± 1.7 | 12.5 ± 3.5 c | 34 ± 15.1 b | 32.1 ± 5.6 b |

| 100 Cr(VI) | 33.2 ± 6.2 | 45.3 ± 3.9 be | 108 ± 9.8 a | 62.7 ± 7.2 a |

| 200 Cu(II) | 32 ± 2.6 | 11.9 ± 2.1 c | 32 ± 4.1 b | 8.4 ± 3.2 c |

| 200 Cr(VI) | 32.3 ± 3.1 | 23.8 ± 5.9 cf | 6.1 ± 2.2 c | 25.6 ± 4.1 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hovorukha, V.; Havryliuk, O.; Gladka, G.; Kalinichenko, A.; Sporek, M.; Stebila, J.; Mavrodi, D.; Mariychuk, R.; Tashyrev, O. Detoxification of Copper and Chromium via Dark Hydrogen Fermentation of Potato Waste by Clostridium butyricum Strain 92. Processes 2022, 10, 170. https://doi.org/10.3390/pr10010170

Hovorukha V, Havryliuk O, Gladka G, Kalinichenko A, Sporek M, Stebila J, Mavrodi D, Mariychuk R, Tashyrev O. Detoxification of Copper and Chromium via Dark Hydrogen Fermentation of Potato Waste by Clostridium butyricum Strain 92. Processes. 2022; 10(1):170. https://doi.org/10.3390/pr10010170

Chicago/Turabian StyleHovorukha, Vira, Olesia Havryliuk, Galina Gladka, Antonina Kalinichenko, Monika Sporek, Jan Stebila, Dmitri Mavrodi, Ruslan Mariychuk, and Oleksandr Tashyrev. 2022. "Detoxification of Copper and Chromium via Dark Hydrogen Fermentation of Potato Waste by Clostridium butyricum Strain 92" Processes 10, no. 1: 170. https://doi.org/10.3390/pr10010170