Influence of Nanoscaled Surface Modification on the Reaction of Al/Ni Multilayers

Abstract

:1. Introduction

2. Materials and Methods

3. Results

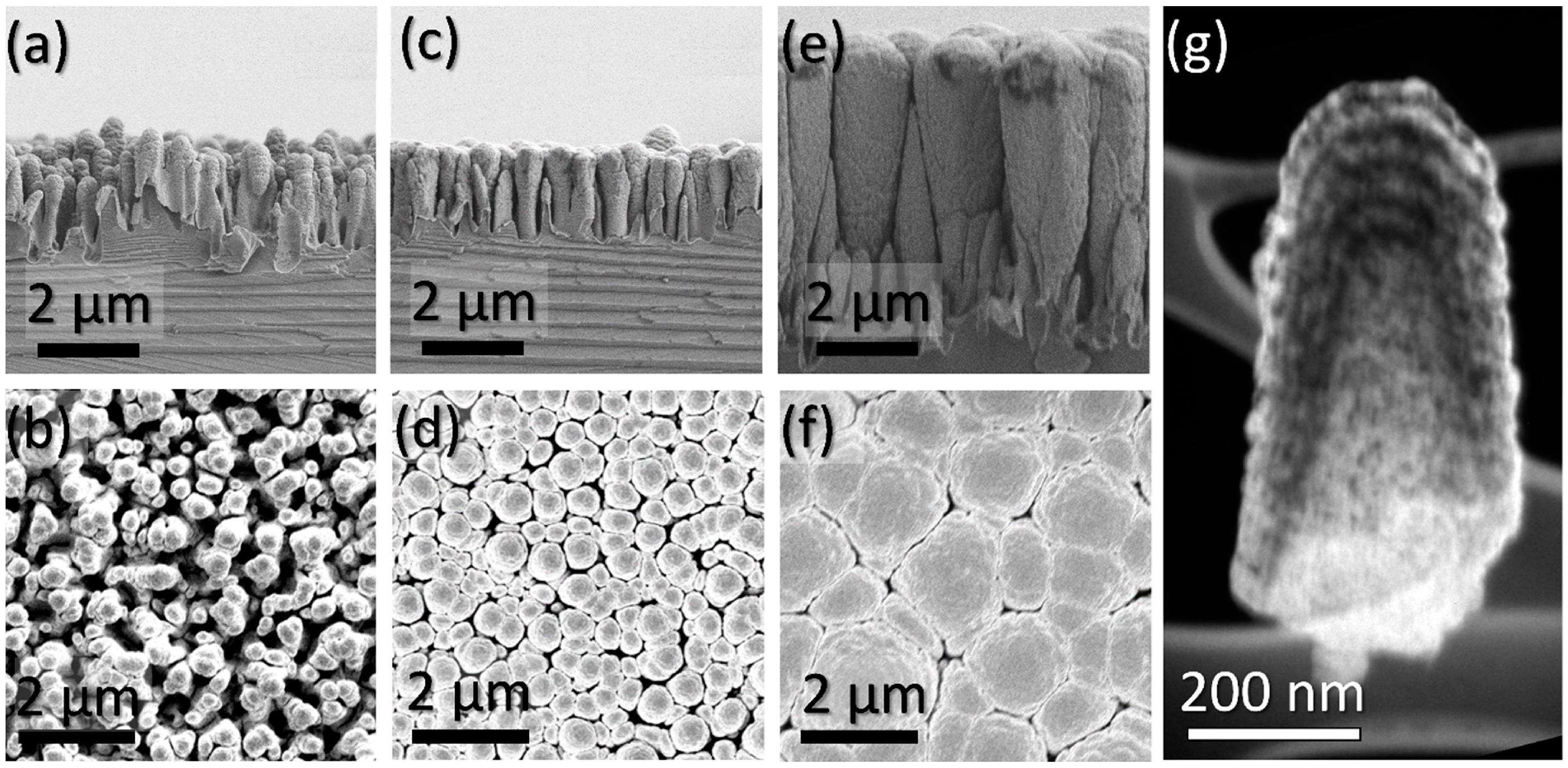

3.1. Parent Multilayer Morphology on Nanostructures

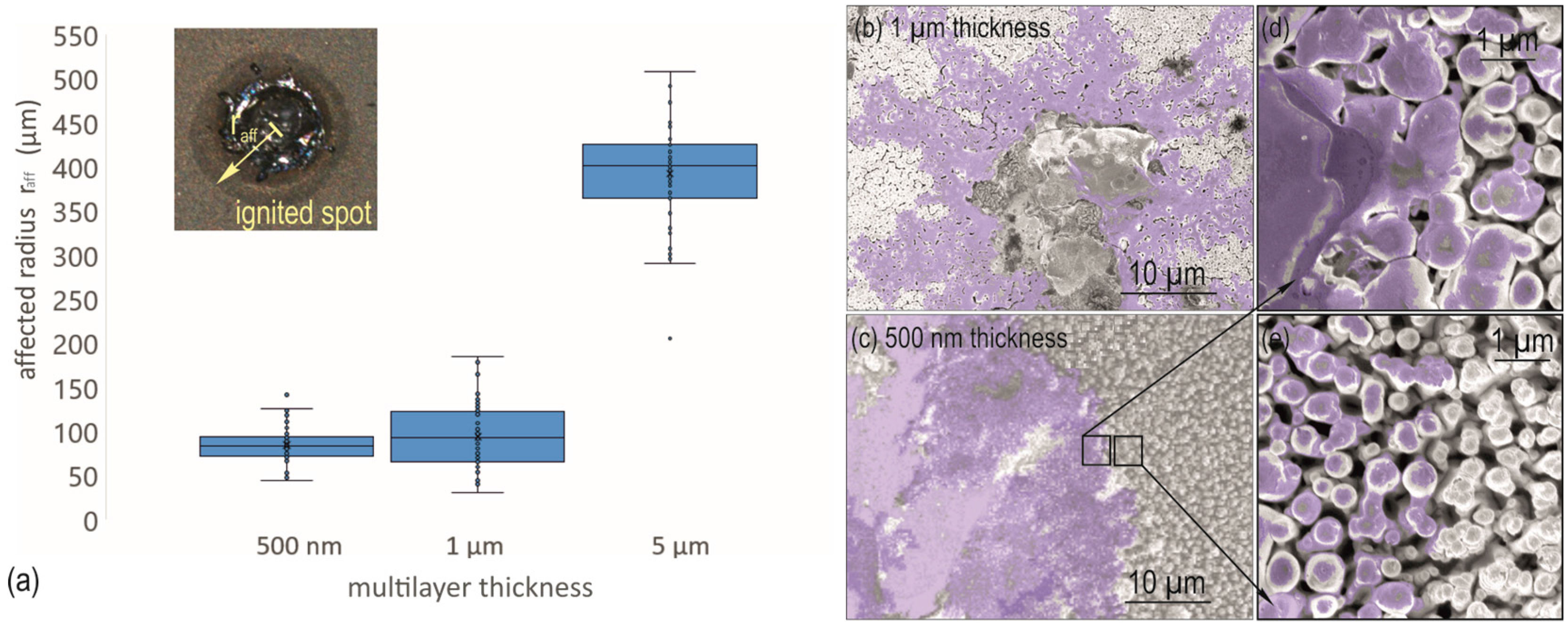

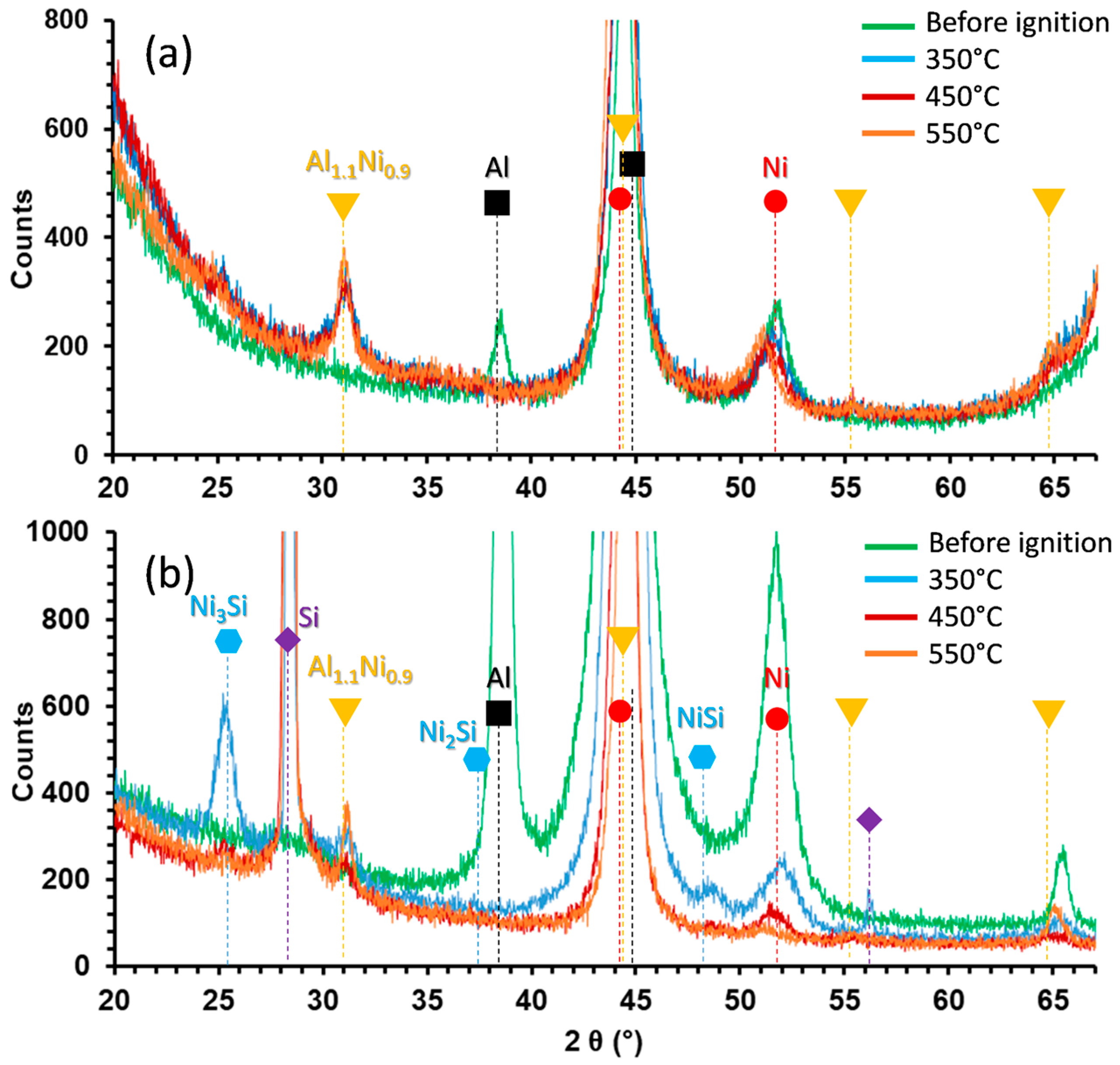

3.2. Spark Ignition

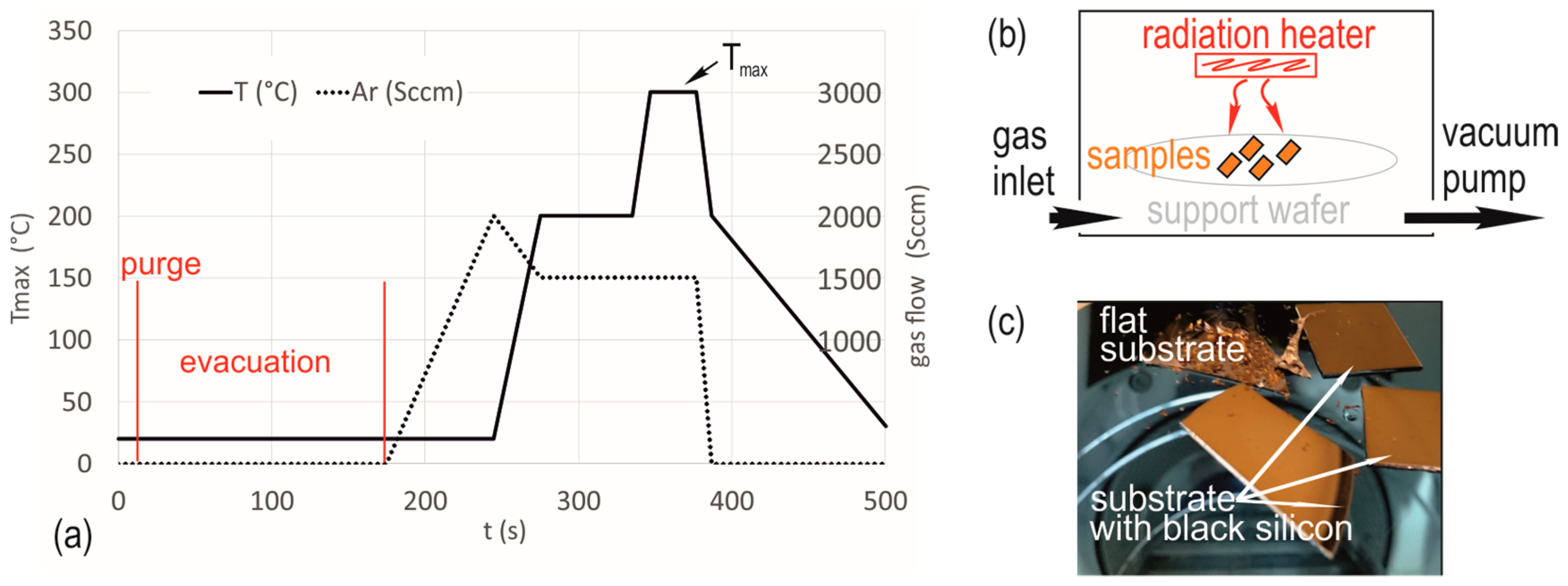

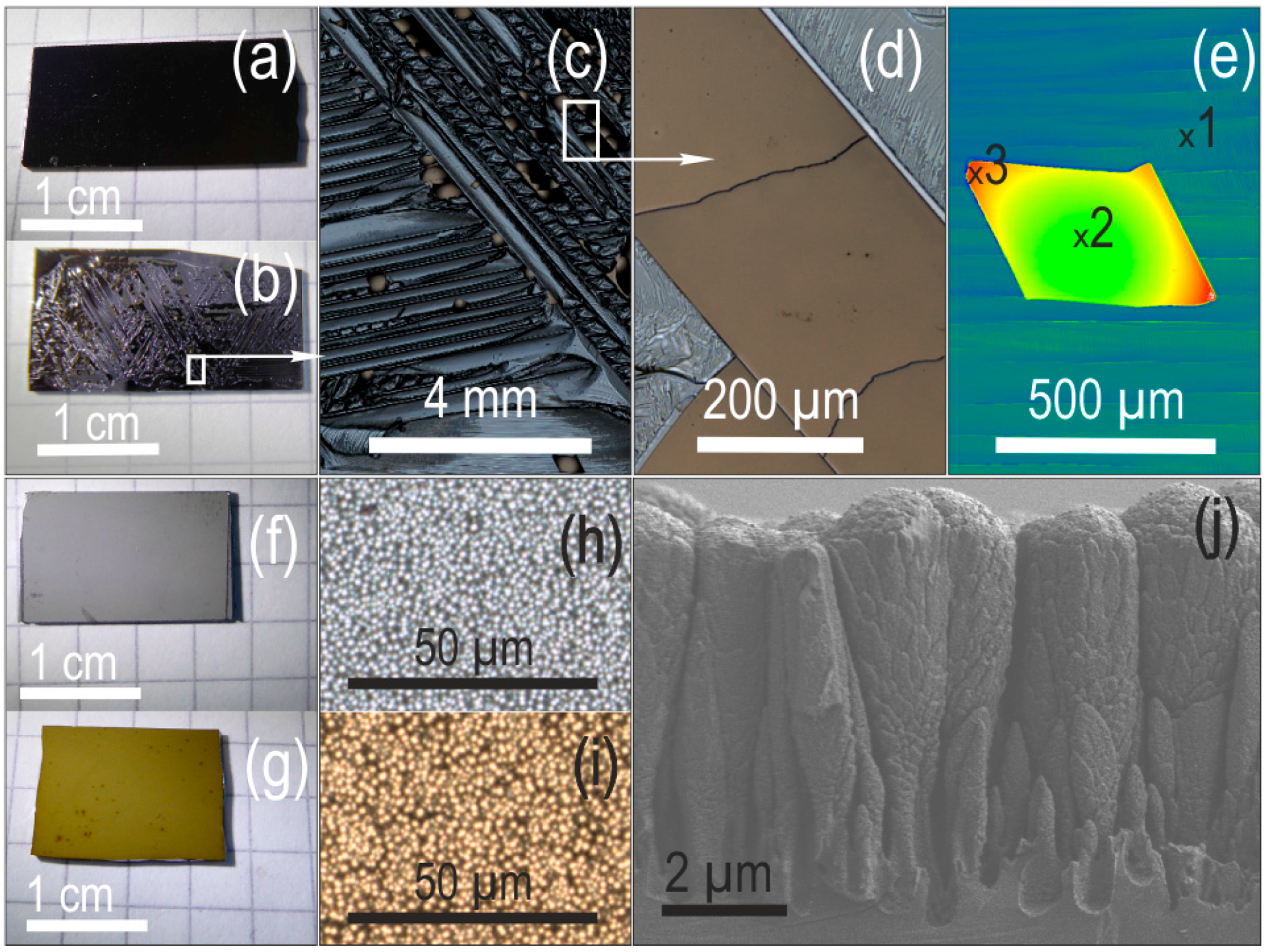

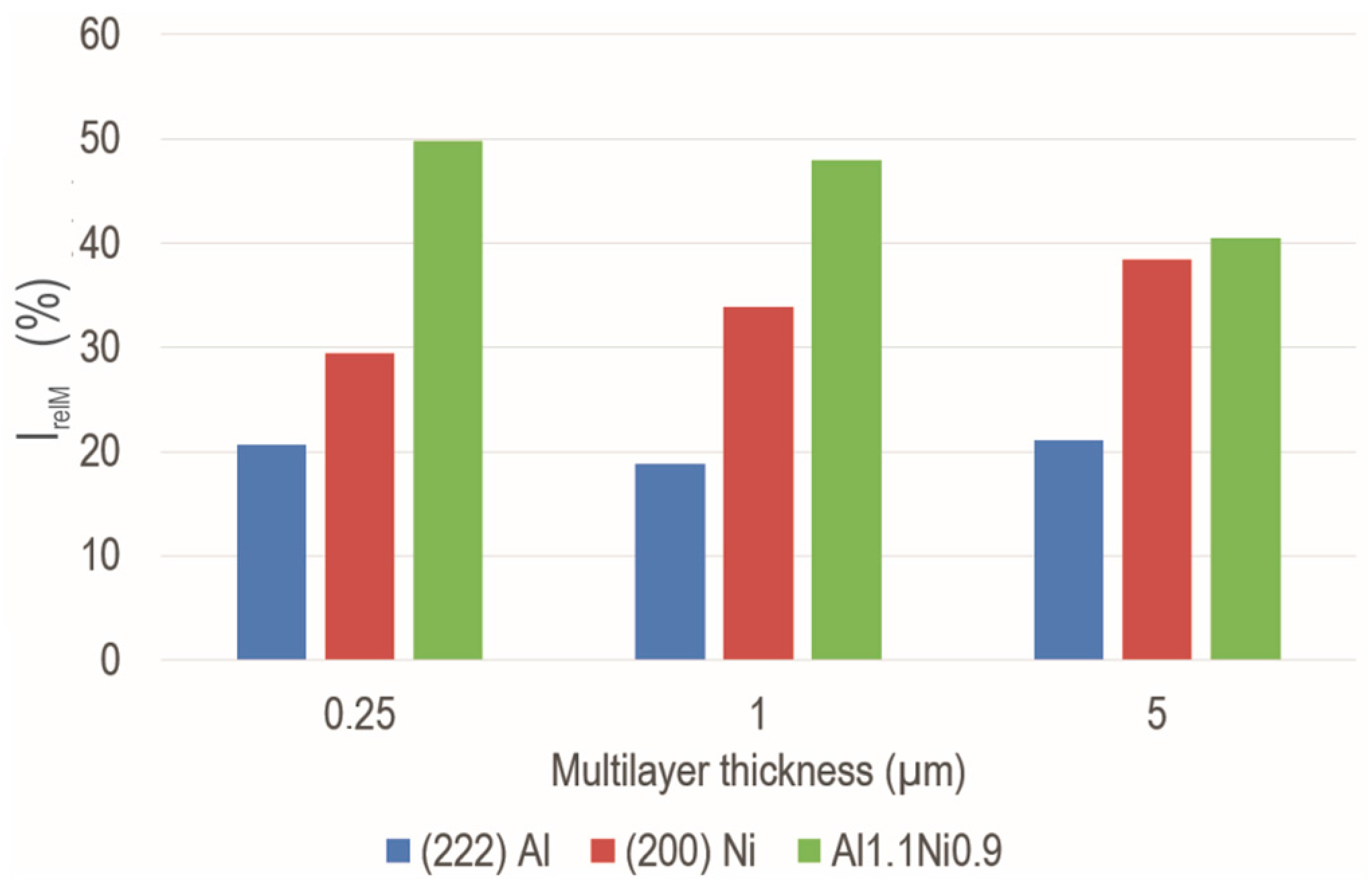

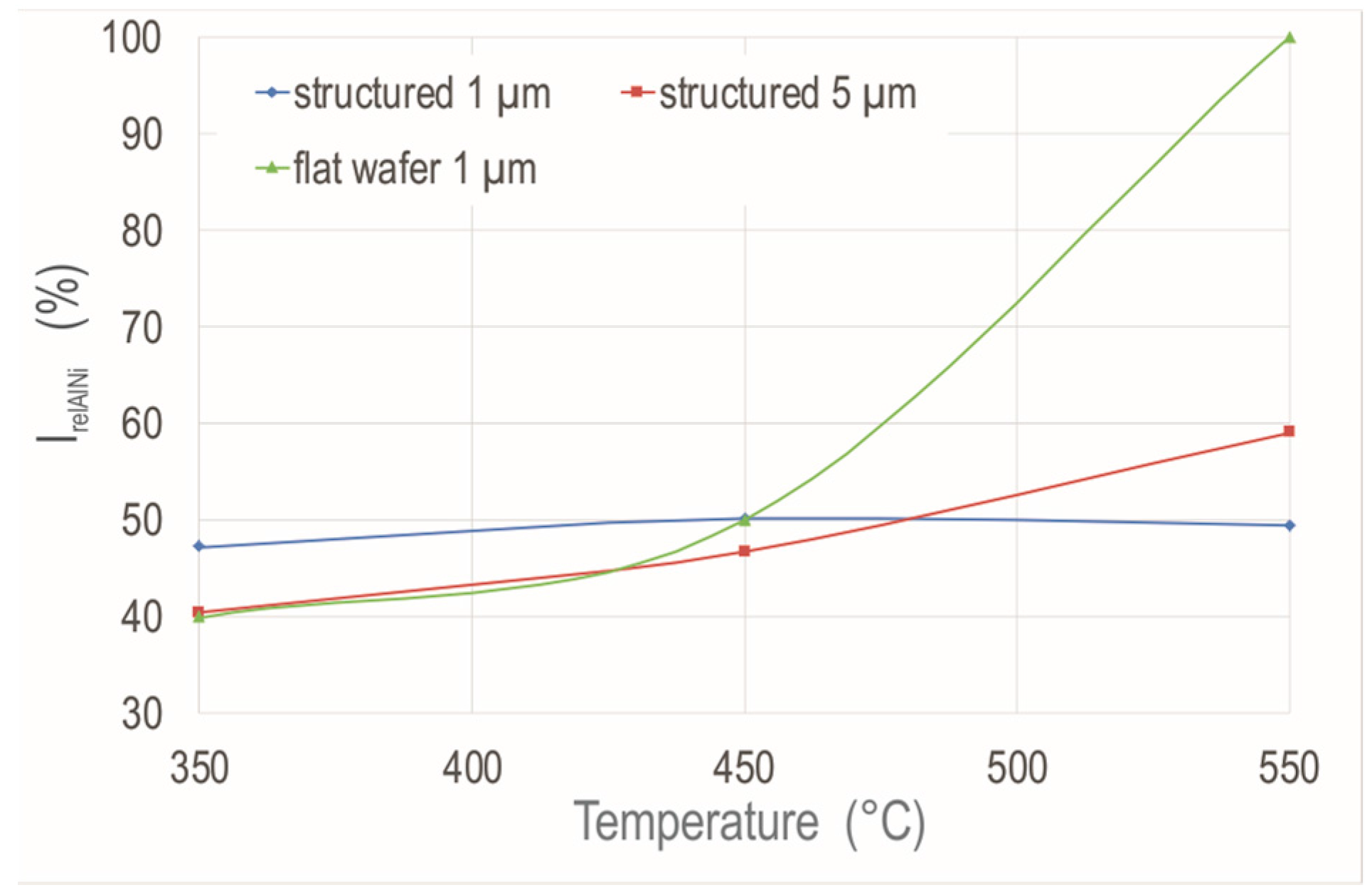

3.3. Rapid Thermal Annealing

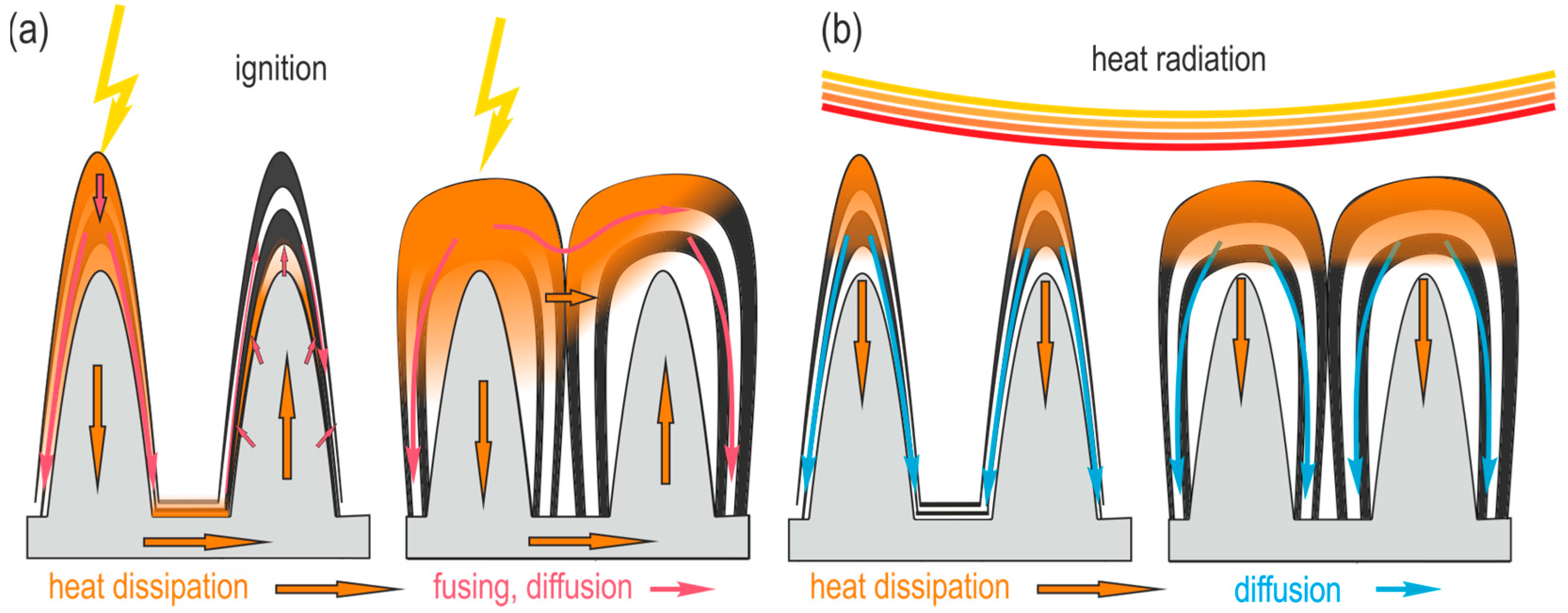

4. Discussion

4.1. Self-Propagation of the Reaction Front

4.2. Rapid Thermal Annealing Tests

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Grace O’Malley. Highlights from the iNEMI Thermal Management Technology Roadmap, Advancing in Manufacturing Technology. 2014. Available online: http://thor.inemi.org/webdownload/2014/Eurotherm_061914.pdf (accessed on 4 December 2017).

- Yeh, L.-T. Thermal Management/Roadmap and Energy Efficiency for Telecommunications Equipment. J. Comput. Intel. Electron. Syst. 2015, 4, 1–9. [Google Scholar] [CrossRef]

- Mahajan, R.; Chiu, C.-P.; Prasher, R.S. Thermal Interface Materials: A Brief Review of Design Characteristics and Materials. Electron. Cool. 2004, 10, 10–18. [Google Scholar]

- Welker, T.; Geiling, T.; Bartsch, H.; Müller, J. Design and Fabrication of Transparent and Gas-Tight Optical Windows in Low-Temperature Co-Fired Ceramics. Int. J. Appl. Ceram. Technol. 2013, 10, 405–412. [Google Scholar] [CrossRef]

- Subramanian, J.; Rodgers, P.; Newson, J.; Rude, T.R.; He, Z.; Besnoin, E.; Weihs, T.; Eveloy, V.; Pecht, M. Room Temperature Soldering of Microelectronic Components for Enhanced Performance. In Proceedings of the IEEE International Conference on Thermal, Mechanical and Multiphysics Simulation and Experience in Microelectronics and Microsystems, Berlin, Germany, 18–20 April 2006; pp. 681–686. [Google Scholar]

- Bräuer, J.; Besser, J.; Wiemer, M.; Gessner, T. A novel technique for MEMS packaging: Reactive bonding with integrated material systems. Sens. Actuators A Phys. 2012, 188, 212–219. [Google Scholar] [CrossRef]

- Bräuer, J.; Gessner, T. A hermetic and room-temperature wafer bonding technique based on integrated reactive multilayer systems. J. Micromech. Microeng. 2014, 24, 115002. [Google Scholar] [CrossRef]

- Grieseler, R.; Welker, T.; Müller, J.; Schaaf, P. Bonding of low temperature co-fired ceramics to copper and to ceramic blocks by reactive aluminum/nickel multilayers. Phys. Status Solidi A 2012, 209, 512–518. [Google Scholar] [CrossRef]

- Miyake, S.; Kanetsuki, S.; Morino, K.; Kuroishi, J.; Namazu, T. Thermal property measurement of solder joints fabricated by self-propagating exothermic reaction in Al/Ni multilayer film. Jpn. J. Appl. Phys. 2015, 54, 06FP15. [Google Scholar] [CrossRef]

- Namazu, T.; Ohtani, K.; Inoue, S.; Miyake, S. Influences of Exothermic Reactive Layer and Metal Interlayer on Fracture Behavior of Reactively Bonded Solder Joints. J. Eng. Mater. Technol. 2015, 137, 031011. [Google Scholar] [CrossRef]

- Bar-Cohen, A.; Matin, K.; Narumanchi, S. Nanothermal Interface Materials: Technology Review and Recent Results. J. Electron. Packag. 2015, 137, 040803. [Google Scholar] [CrossRef]

- Feng, B.; Cao, J.; Wang, Y.; Feng, J. Enhanced Adhesive Bonding Based on Surface Modification with Silicon Nanowire Arrays. ECS J. Solid State Sci. Technol. 2015, 5, P41–P46. [Google Scholar] [CrossRef]

- Fischer, M.; Bartsch, H.; Pawlowski, B.; Gade, R.; Barth, S.; Mach, M.; Stubenrauch, M.; Hoffmann, M.; Müller, J. Silicon on Ceramics—A New Integration Concept for Silicon Devices to LTCC. J. Microelectron. Electron. Packag. 2009, 1, 1–5. [Google Scholar] [CrossRef]

- Jansen, H.V.; de Boer, M.J.; Unnikrishnan, S.; Louwerse, M.C.; Elwenspoek, M.C. Black silicon method X: A review on high speed and selective plasma etching of silicon with profile control: An in-depth comparison between Bosch and cryostat DRIE processes as a roadmap to next generation equipment. J. Micromech. Microeng. 2009, 19, 033001. [Google Scholar] [CrossRef]

- Pezoldt, J.; Kups, T.; Stubenrauch, M.; Fischer, M. Black luminescent silicon. Phys. Status Solidi C 2011, 8, 1021–1026. [Google Scholar] [CrossRef]

- Theodossiadis, G.D.; Zaeh, M.F. Study of the kinetic and energetic reaction properties of multilayered aluminum–nickel nanofoils. Prod. Eng. Res. Devel. 2017, 11, 245–253. [Google Scholar] [CrossRef]

- Sraj, I.; Vohra, M.; Alawieh, L.; Weihs, T.P.; Knio, O.M. Self-Propagating Reactive Fronts in Compacts of Multilayered Particles. J. Nanomater. 2013, 2013, 1–11. [Google Scholar] [CrossRef]

- Fritz, G.M.; Joress, H.; Weihs, T. Enabling and controlling slow reaction velocities in low-density compacts of multilayer reactive particle. Combust. Flame 2011, 158, 1084–1088. [Google Scholar] [CrossRef]

- Politano, O.; Baras, F.; Mukasyan, A.S.; Vadchenko, S.G.; Rogachev, A.S. Microstructure development during NiAl intermetallic synthesis in reactive Ni-Al nanolayers: Numerical investigations vs. TEM observations. Surf. Coat. Technol. 2013, 215, 485–492. [Google Scholar] [CrossRef]

- Urrutia, A.; Tumminello, S.; Aricó, S.F.; Sommadossi, S. Characterization of Al-Ni intermetallics around 30–60 at % Al for TLPB application. CALPHAD Comput. Coupl. Phase Diagr. Thermochem. 2014, 44, 108–113. [Google Scholar] [CrossRef]

- Tumminello, S.; Sommadossi, S. Growth Kinetics of Intermetallic Phases in Transient Liquid Phase Bonding Process (TLPB) in Al/Ni System. Defect Diffus. Forum 2012, 323–325, 465–470. [Google Scholar] [CrossRef]

- Urrutia, A.; Tumminello, S.; Lamas, D.G.; Sommadossi, S. X-Ray Characterization of Intermetallic Phases in Al/Ni Multilayer System. Proced. Mater. Sci. 2015, 8, 1150–1159. [Google Scholar] [CrossRef]

| No. | Substrate | Bilayer Thickness (nm) | Total RML Thickness (nm) | RTA Tmax (°C) | Spark Ignition (V)/(mA) |

|---|---|---|---|---|---|

| 1 | Flat wafer | 50 | 1000 | 350/450/550 | - |

| 2 | Flat wafer | 50 | 5000 | 350/450/550 | 50/50 |

| 3 | Black silicon | 50 | 500 | 350/450/550 | 50/50 |

| 4 | Black silicon | 50 | 1000 | 350/450/550 | 50/50 |

| 5 | Black silicon | 50 | 5000 | 350/450/550 | 50/50 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartsch, H.; Mánuel, J.M.; Grieseler, R. Influence of Nanoscaled Surface Modification on the Reaction of Al/Ni Multilayers. Technologies 2017, 5, 79. https://doi.org/10.3390/technologies5040079

Bartsch H, Mánuel JM, Grieseler R. Influence of Nanoscaled Surface Modification on the Reaction of Al/Ni Multilayers. Technologies. 2017; 5(4):79. https://doi.org/10.3390/technologies5040079

Chicago/Turabian StyleBartsch, Heike, José Manuel Mánuel, and Rolf Grieseler. 2017. "Influence of Nanoscaled Surface Modification on the Reaction of Al/Ni Multilayers" Technologies 5, no. 4: 79. https://doi.org/10.3390/technologies5040079

APA StyleBartsch, H., Mánuel, J. M., & Grieseler, R. (2017). Influence of Nanoscaled Surface Modification on the Reaction of Al/Ni Multilayers. Technologies, 5(4), 79. https://doi.org/10.3390/technologies5040079