3.1. Nut and Kernel Size Distribution

The Rolek nutcracker cracks palm nuts to produce a cracked mixture consisting of more than 35 wt % whole kernel, less than 12 wt % broken kernel, less than 1 wt % uncracked nuts and less than 2 wt % half-cracked nuts. Conventional nutcrackers used at POMs, such as ripple mill and super cracker, often crack both the nuts and the kernel; the cracked mixture then consists of a high broken kernel of

ca. 15–25 wt % [

19]. Rolek nutcracker differs from other commercial crackers in terms of its principle of operation, which relies on dynamic interactions of adjustable rods varied to break all sizes of nuts without causing high kernel breakage [

13,

19].

Currently, there is no established method to measure nut and kernel size. Nut and kernel are not perfectly round in shape; thus, the horizontal cross-section of the nut and kernel, as shown in

Figure 4 (right), is deemed appropriate to represent the size of the nut and kernel. To determine the size distribution of the collective samples, the sizes are generally grouped into the acceptable range of nut and kernel size, ranging from 5–25 mm. A perforated metal plate consisting of holes with different sizes ranging from 5–25 mm was therefore developed to facilitate size measurement of the collective samples, as shown in

Figure 4 (left). This method of measurement is common in POMs in Malaysia but has not been properly documented elsewhere.

Measurement of nut and kernel size distribution prior to cracking was carried out to determine the exact composition of nut type processed in the mill, such as

Dura,

Pisifera and

Tenera.

Pisifera is a pollen-type nut, while

Dura has a thicker shell and a lower oil content compared to

Tenera, which is a hybrid between

Pisifera and

Dura.

Tenera has a high oil content with a thin shell.

Figure 5 shows nut size distribution prior to cracking and kernel size distribution after separation. It shows that Air Tawar POM processed about 96.7%

Tenera nuts and 3.3%

Dura nuts. Typical

Tenera nuts may be 20 mm or less in length, and

Dura nuts may be 20 to 30 mm in length. In terms of horizontal cross-sectional diameter,

Tenera nut size is less than 16 mm, while

Dura nuts are often more than 16 mm. The size distribution of nuts ranged from 10 to 18 mm in diameter; the largest nut sizes ranged from 13 to 16 mm with kernel sizes between 10 and 12 mm. Determination of the nut and kernel size distribution was important prior to optimization of kernel separation using the five-stage winnowing column system.

3.2. Kernel Throughput and Separation Efficiency

The determination of the kernel and shell throughput was carried out at three kernel-discharge points and three shell-discharge outlets.

Table 1 shows the optimized setup for the five-stage winnowing column system for the dry kernel separation process in terms of airflow rate, damper opening and column height to achieve the desired 45 wt % of total kernel throughput. The cracked mixture fed into the system contained

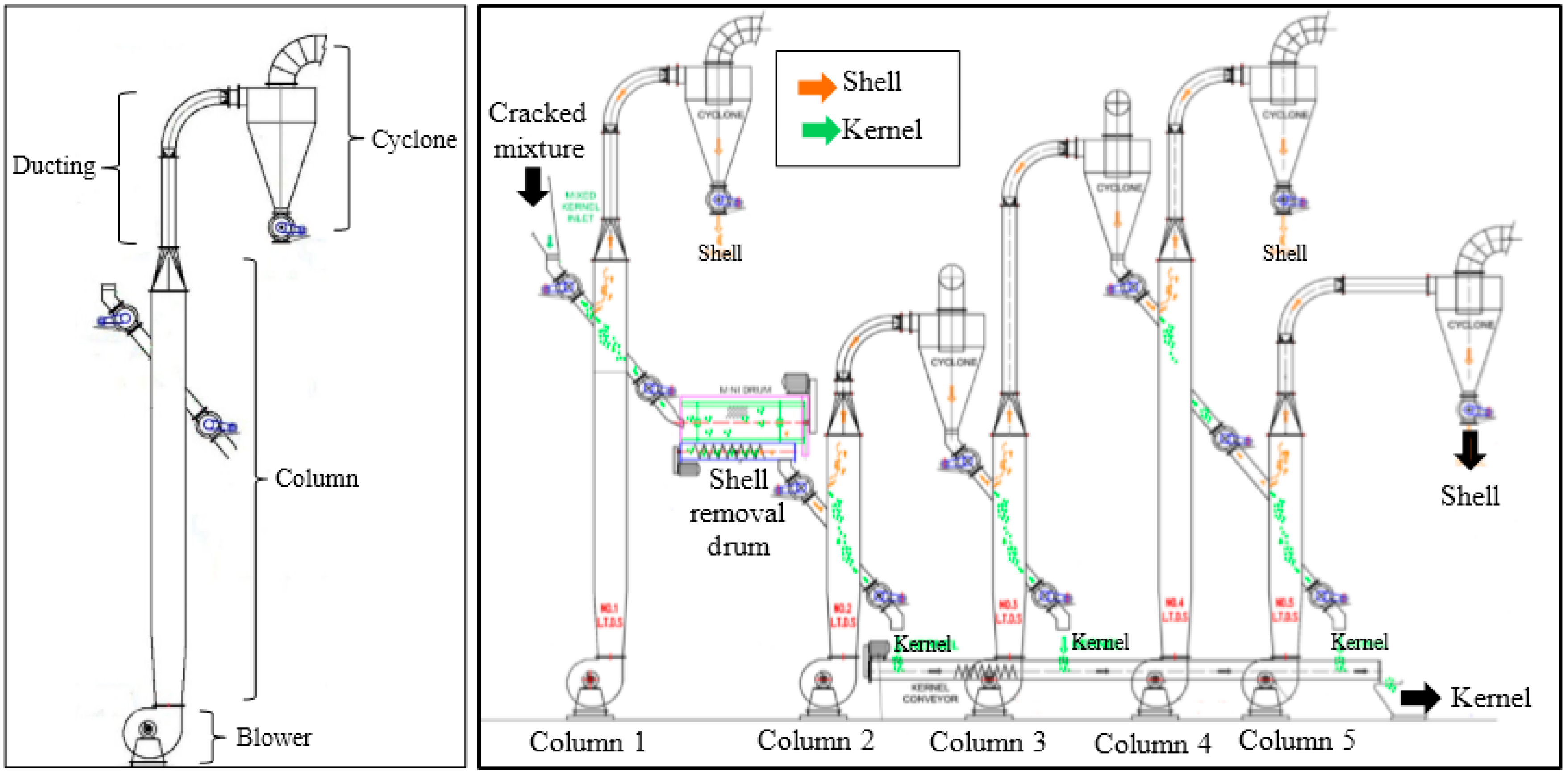

ca. 55 wt % shells and 45 wt % kernels; thus, the maximum recovery of kernel was at 45 wt % and maximum shell removal at 55 wt %. As mentioned previously, the system was designed so that shell and kernel would be discharged at Stages 1, 4, and 5 and Stages 2, 3, and 5, respectively. Separation of shell and kernel in a column is driven by the specific gravity differential of materials and in the presence of high velocity airflow blown by an electrical fan. Furthermore, different openings of the damper drive the variation in air velocity to suit the characteristic of the feed material.

We found most of the small shells (30–35 wt %) were successfully discharged at the first stage. Large and thin shells (10–12 wt %) were discharged at the fourth stage, whereas large and thick shells (5–8 wt %) were discharged at the fifth stage. Overall, the system showed excellent shell removal efficiency by more than 82 wt % (min

. 45 wt % shell throughput), as shown in

Table 1.

The highest removal of shells in the first stage was due to the highest airflow rate utilized at 257 m

3/min in the first column compared to 202, 196, 173 and 173 m

3/min in the second, third, fourth, and fifth columns, respectively. Technically, a high airflow rate blows the small light shells upwards and leaves the heavy kernels and thick shell fraction deposited at the bottom of the column. However, due to the high air velocity, this is also associated with a loss of light broken kernel that is blown away with the small shells, amounting to 0.1–0.2 wt % (kernel to FFB) (

Table 2). For comparison, this loss is higher than the kernel losses at the fourth and the fifth stage, which are both in the range of 0.06–0.08 wt % (kernel to FFB) (

Table 2). This stage makes use of a high column height (8.64 m) to allow longer separation time in order to effectively push up most of the small shells (

Table 1). A similar case was also observed at the fourth stage where a high column design enables good removal of shells in the range of 10–12 wt % from the total throughput.

For the separation and recovery of the kernel, 20–28 wt % large whole kernels and large broken kernels were discharged at the second stage. The remaining 5–8 wt % and 5–7 wt % small whole kernels and small broken kernels were recovered at the third and fifth stages, respectively. In general, the system showed excellent kernel recovery efficiency by more than 67% (min. 30 wt % kernel throughput), as shown in

Table 1.

The system was intentionally designed for the second stage to carry out most of the separation of large whole kernels. The discharge at the second-stage fraction was kept as clean as possible by using a high separating velocity in the separating column, represented by the highest airflow rate (202 m

3/min) compared to the airflow rate at the third and fifth columns where kernel was also discharged (196 m

3/min and 173 m

3/min, respectively). This was achieved through the opening of the damper to 50% at the second stage, which provides a higher air velocity compared to opening the damper at the third and fifth columns to 40% and 30%, respectively. Nevertheless, we found that the recovered kernel from the second stage was contaminated with 1–2 wt % of free shells, which was still within the acceptable limit (

Table 2). We note that the second and the third stages, which both accounted for almost 84% of the kernel recovery (max. 36 wt % of total throughput), had a lower column height at 5.03 m compared to 8.64 m for the first and fourth stages, which are meant for shell removal. In contrast to the shell removal principle, which requires a high column to allow a sufficient floating duration of shells, recovery of the kernel requires a short column to avoid kernel from being lifted to the upper end of the column.

The third stage, also designed for kernel recovery, used a lower separating velocity represented by a lower airflow rate (from 202 to 196 m

3/min) by reducing the damper opening from 50% to 40% (

Table 1). As the separation column throat area remained the same as for the first stage, the lower separating velocity was able to separate out the light kernel fraction in the form of small whole kernel and large broken kernel, both having almost the same specific gravity. About 5–8 wt % kernels (small whole and large broken kernels) were successfully discharged through the bottom outlet. Consequently, the remaining broken kernel and shell were lifted and deposited in the third-stage discharge cyclone for further separation. In addition to the optimum separating velocity, the height of the circular ducting from the column is much higher (

Figure 1 (right)) to prevent kernel from being lifted to the cyclone. The height of the circular ducting was in the order of: third column > fourth column = first column > fifth column > second column (

Figure 1 (right)). Results obtained confirm that kernel loss in the third-stage shell discharge outlet was in the range of 0.06–0.08 wt %, which was less than in the shell discharge outlet at the first stage (

Table 2).

Small kernels and shells from the third-stage cyclone were then transferred by a screw conveyor to the feed inlet of the fourth-stage separating column where the large and thin shells (10–12 wt %) and smashed kernels (0.06–0.08 wt %) were lifted and delivered to the discharge cyclone for discharging into the boiler as fuel. The airflow rate here was further reduced from 196 to 173 m3/min by adjusting the setting of the damper position from 40% to 30%–35% opening. Apart from the designated air velocity, the reduced height of the cyclone from the column also cut-short the travelling distance of the lightweight shell along the ducting, therefore lifted almost all the shell and deposited it in the cyclone.

The fifth stage recovered the remaining 5–7 wt % small kernel and removed another 5–8 wt % large and thick shells. The fifth column also served a cleaning purpose, which helps the system to maximize kernel recovery, achieve a dry kernel separation process and generates zero effluent waste. The predecessor of this system that uses a four-stage separation technique still requires a wet separation process using claybath and hydrocyclone, indicating the remarkable concept and performance improvement of our design [

14].

Another work reported by Olasumboye and Koya [

17] demonstrated a separation technique using a rotary separator that employs a multi-cyclic-separation process for the dry mixture. The work reports the highest kernel recovery over feeding cracked mixture of 92%. The kernel purity was 73%, which indicates contamination of other foreign materials of up to 27% [

17]. Our study, however, as presented in

Table 2, showed better separation efficiency with maximum kernel losses over FFB processed of 0.36 wt %, equivalent to 97.5% of kernel recovery over feeding cracked mixture. In a later section, we discuss the KER over FFB processed instead of feeding cracked mixture. This is because the KER is a parameter commonly used among millers and therefore provides convenient data to actual end users. In addition to kernel recovery, purity of the recovered kernel in this study was much higher, ranging from 92 to 95 wt % (5–8 wt % shell contaminated in the kernel fraction), as shown in

Table 2.

3.3. Kernel Recovery Rate

KER is commonly used to measure the kernel recovery performance of a POM calculated over the processed FFB. The palm oil milling sector makes use of this parameter to evaluate the production performance of POMs in addition to its main CPO production. In this study, the system performance in terms of KER and kernel losses between three commercial mills using different kernel separation system was evaluated on a monthly basis.

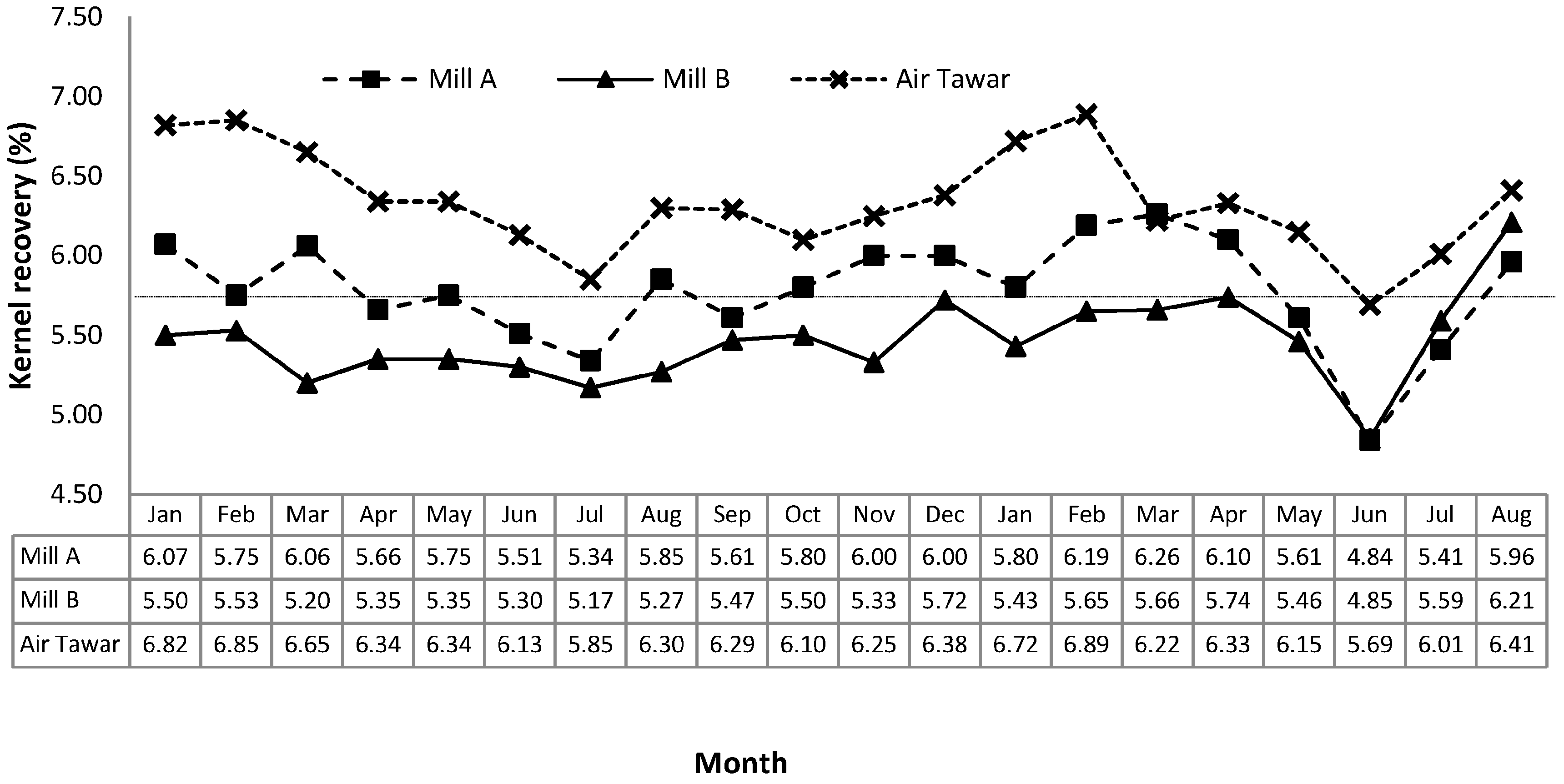

Figure 6 illustrates a comparison of the trend of KER in Air Tawar POM with other sister mills in the Johor region over a period of 20 months. Air Tawar POM, mill A and mill B show their KER values in the range of 5.69–6.89 wt %, 4.84–6.26 wt % and 4.85–6.21 wt %, respectively. In general, Air Tawar POM, which adopted a totally dry kernel separation process using the five-stage winnowing column system, showed a higher KER with an average KER of 6.34 ± 0.30 wt % compared to mill A and mill B, which had average KERs of 5.78 ± 0.34 wt % and 5.46 ± 0.28 wt %, respectively. Air Tawar POM maintained its KER values above 6.00 wt % at a 90% consistency rate, whereas the other two mills were only able to maintain their KER above the targeted limit of 6.00 wt % at a 35% and 5% consistency rate, respectively. In an attempt to reduce the effluent generated from the kernel separation system, mill A and mill B improved their system by using a combination of a two-stage winnowing column with a wet separation system using either hydrocyclone or claybath. However, as shown in

Figure 6, their KER values were still below 6.00 wt % in most cases.

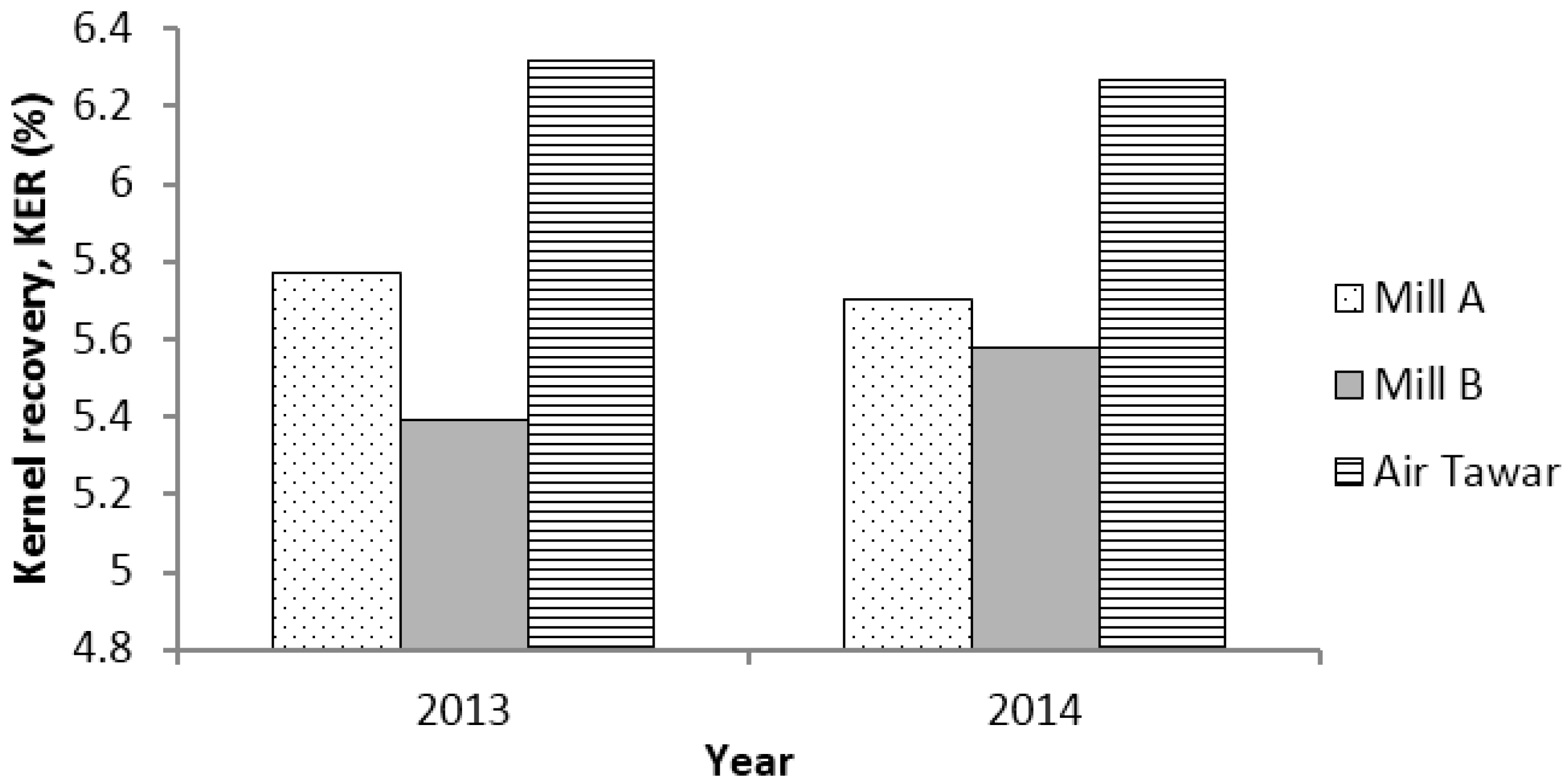

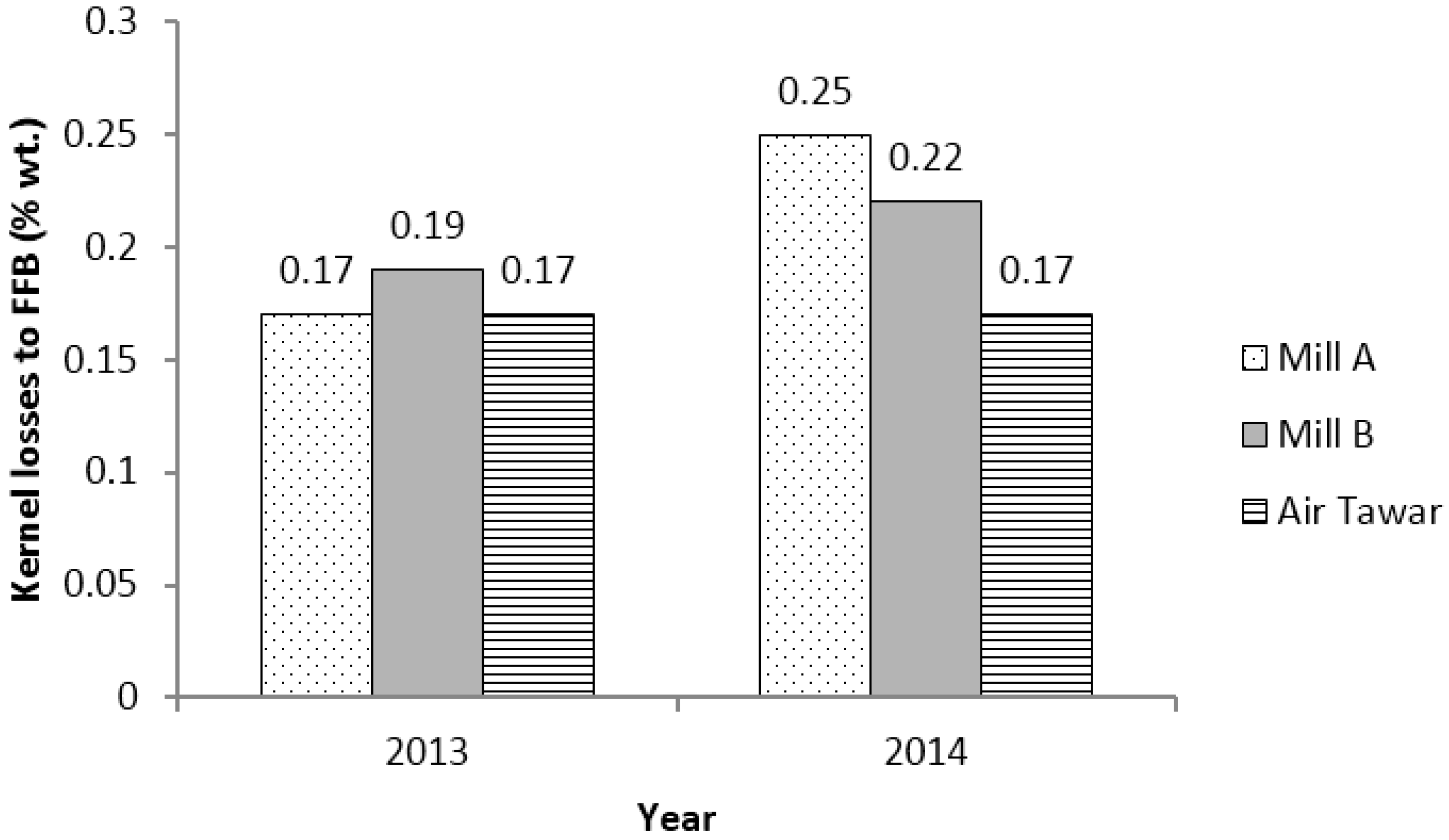

On a yearly basis for two consecutive years, Air Tawar POM recorded the highest average KER of 6.32 wt % and 6.27 wt % compared to mill A (5.77 wt % and 5.70 wt %) and mill B (5.39 wt % and 5.58 wt %) (

Figure 7).

These results imply better KER associated with the five-stage winnowing column system for the kernel separation evaluated in this study. The conventional wet separation system, e.g., the claybath, comprises a cylindrical tank with an inverted cone shape to allow settlement of the heavy phase. A clay solution with a relative density of 1.12 is maintained in the claybath and slowly facilitates the sinking of denser shells and the floating of lighter kernels, both having a relative density in the range of 1.15 to 1.20 and about 1.07, respectively [

16]. While the claybath separation is subjected to, and limited to, the density of the clay solution used, the five-stage winnowing column system optimizes the separation mechanism at each column based on the characteristics of the feed into the column, thereby reducing kernel losses and improving kernel recovery.

3.5. Maintenance Activity and Its Effect on Dirt Content

Maintenance activity is scheduled for every 2500 h and 5000 h of operation, equivalent to once for every 5–6-month interval. For every 2400 to 2600 h operation, the system required minor services and parts replacement, including the carbon steel liner plate for the cyclone and transfer trunking of the first and second columns. The replacement of the trunking column was due to the wearing from blown shells that hit the trunking.

There is a major service and parts replacement after 5000 h of operation, including replacement of the liner plate for the cyclone and trunking of all columns as well as servicing of the motor, bearing and impeller of the fan. The system eases the maintenance needs and requires less supervision in order to promote a user-friendly technology concept.

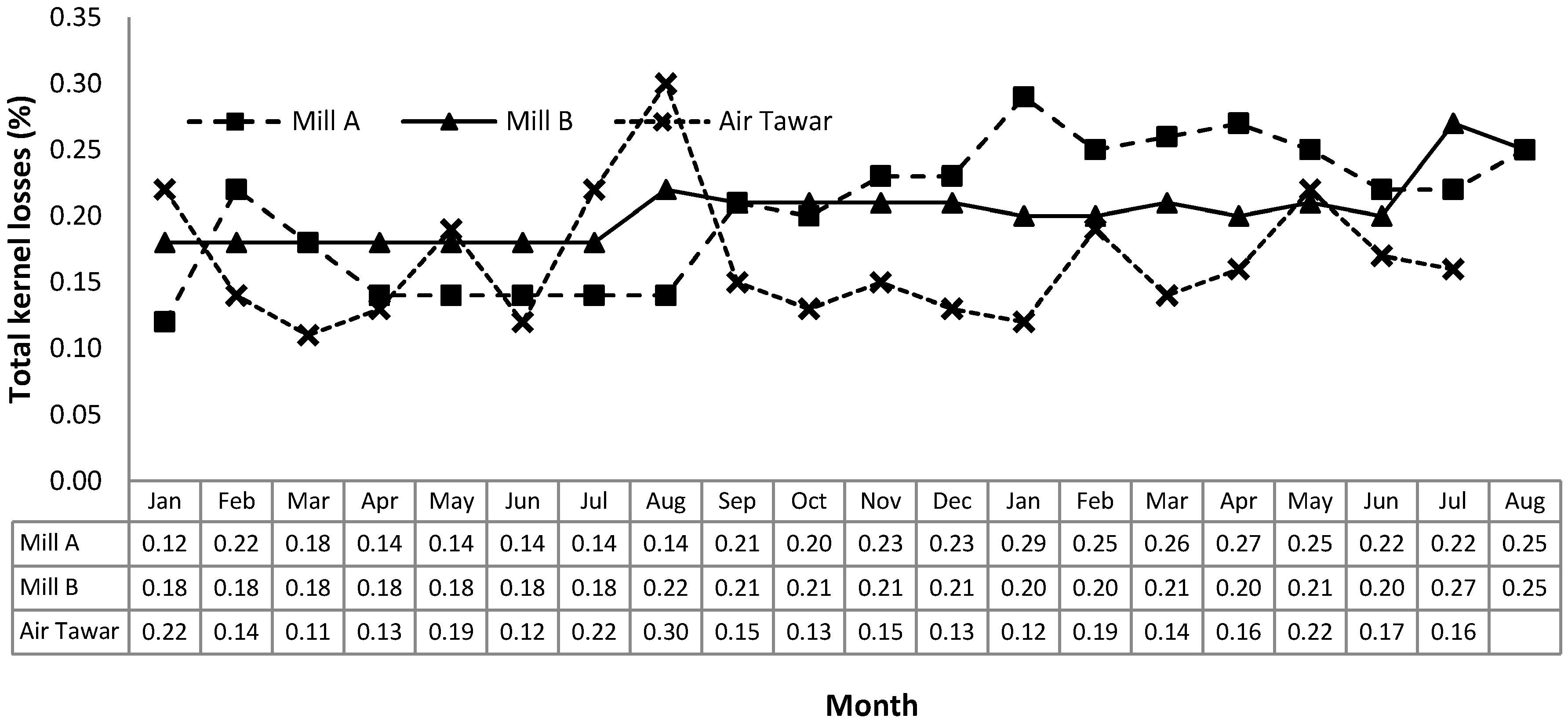

The wear and tear of the system’s parts influences its performance in terms of the dirt content in the recovered kernel.

Figure 10 shows the trends of dirt content in the recovered kernel for the three mills over the 20 months of evaluation. For the Air Tawar POM, which utilized the five-stage dry kernel separation system, the total dirt and shell content in the kernel sampled at the end of the kernel conveyor varied from 4.56 to 6.03 wt %, and in most cases (80% consistency rate) the dirt content was below the set limit of 5.5 wt %. The high dirt content was observed for three different months as 5.82 wt %, 6.03 wt % and 5.97 wt %. In the first six months, during which the system starts its operation, the dirt content slowly increased from 4.68 wt % in the first month to 5.82 wt % in the sixth month. Maintenance was done gradually from Month 7 until Month 10, resulting in better (reduced) dirt content but still fluctuations. From Month 11 until Month 15, the system retained its dirt content below 5.5 wt % because of the new parts from maintenance. This trend was repeated for the next six-month cycle, thus justifying the need to undertake maintenance every 2500 h and 5000 h of operation.

Air Tawar POM experienced slightly lower average dirt content compared to other mills even with a totally dry separation system to separate kernel and shell. As shown in

Figure 10, Air Tawar POM experienced an average dirt content of 5.24 ± 0.40 wt %, slightly lower than the dirt content experienced by Mill A and Mill B at 5.27 ± 0.22 wt % and 5.44 ± 0.36 wt %, respectively. Generally, thick shell could be separated efficiently by the wet separation system with either claybath or hydrocyclone, but the use of a shell removal drum in the five-stage winnowing column system eliminates the presence of thick shell and contaminant carryover as the dirt in the production kernel.

Over two successive years, the average dirt content in Air Tawar POM was 5.33 wt % and 5.12 wt %, whereas the dirt content in Mill A was 5.38 and 5.05 wt % and Mill B was 5.39 wt % and 5.65 wt % (

Figure 11).

3.6. Power Consumption and Economic Analysis

The five-stage winnowing column system requires about 245 HP or 170 kW of power consumption, as tabulated in

Table 3. The use of five columns to enhance the separation process and to maximize kernel recovery resulted in high power consumption, with nearly half the power (130 HP) for the operation of the columns, namely to blow air.

The cost of maintenance was calculated for an eight-month period over which the total FFB processed was 122,890 t in 2889 running hours. Two units of impeller for the first and third stages with a total cost of MYR9000 were replaced, and the cost of maintenance was less than MYR 0.10/t FFB processed. An additional cost incurred in the second year of operation is expected since more parts will be replaced after more operational hours. However, this cost will be very low compared to the conventional separation system. The only drawback of the five-stage winnowing column system is that it requires a higher capital cost of nearly MYR one million compare to the wet conventional system, which costs less than MYR500,000.

The kernel plant in Air Tawar POM has been in operation for nearly two years and has recorded an average of an additional min. of 0.3 wt % KER. With the actual FFB processed of 184,335 t/year, this will generate an additional production of palm kernel of 533 t/year. Calculated at the average price of palm kernel in 2015 at MYR1564 per tonne of palm kernel, an additional revenue of MYR844,560 per year could be generated [

20]. Therefore, the expected payback period for the capital investment of MYR950,000 is less than two years.