Treatment of Chrysanthemum Synthetic Seeds by Air SDBD Plasma

Abstract

:1. Introduction

2. Results

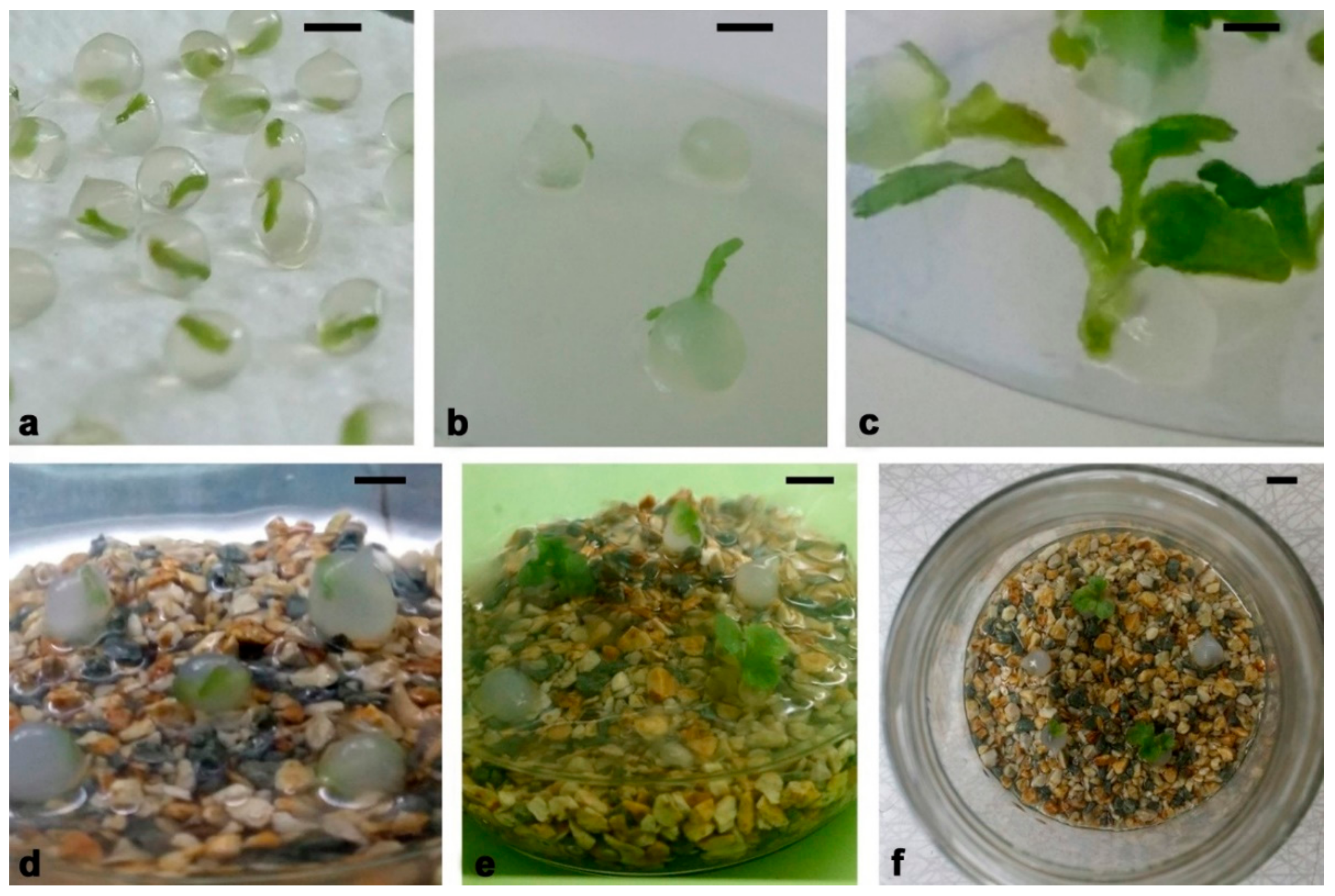

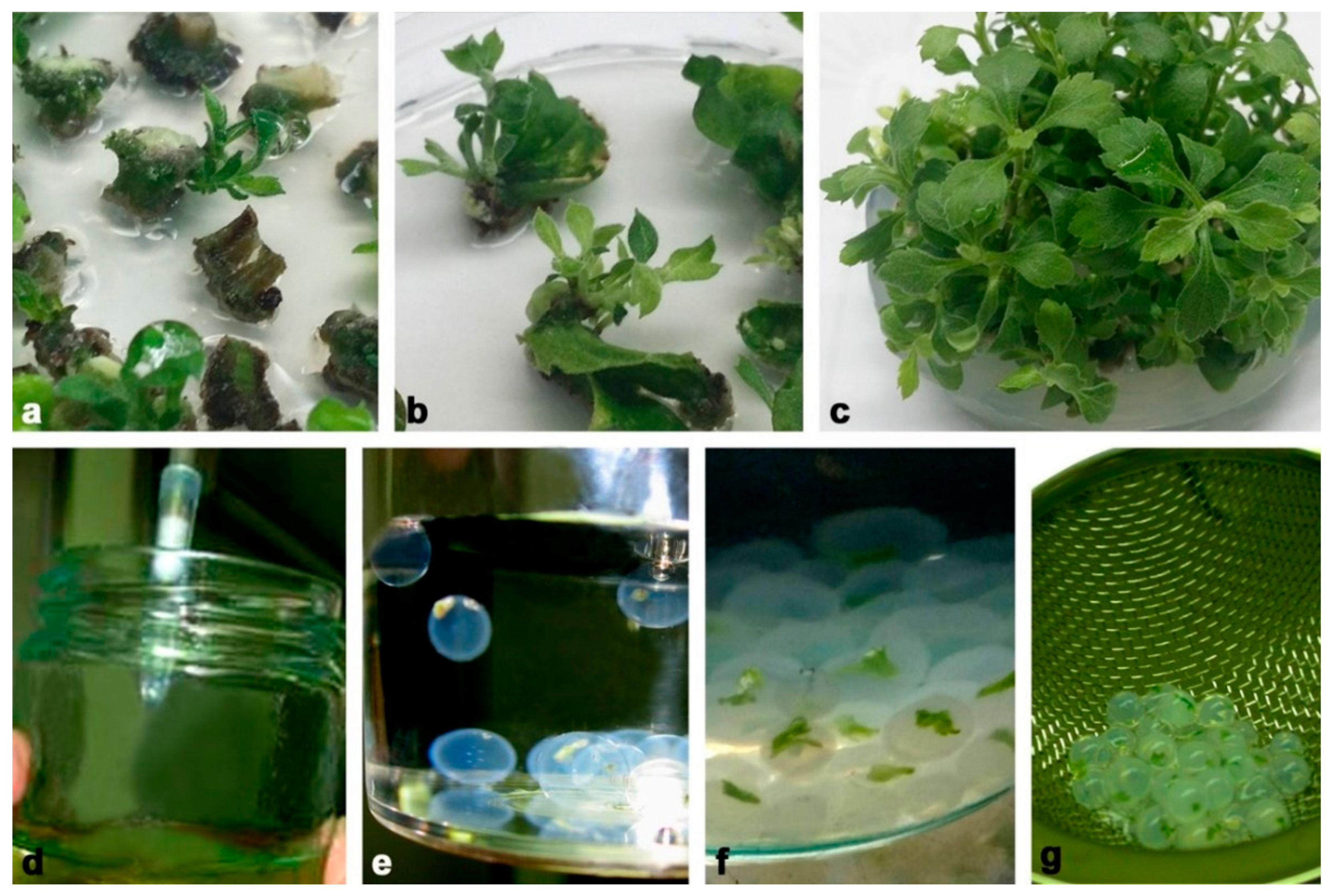

2.1. Regrowth of Plasma-Treated Synthetic Seeds under Aseptic Conditions (In Vitro)

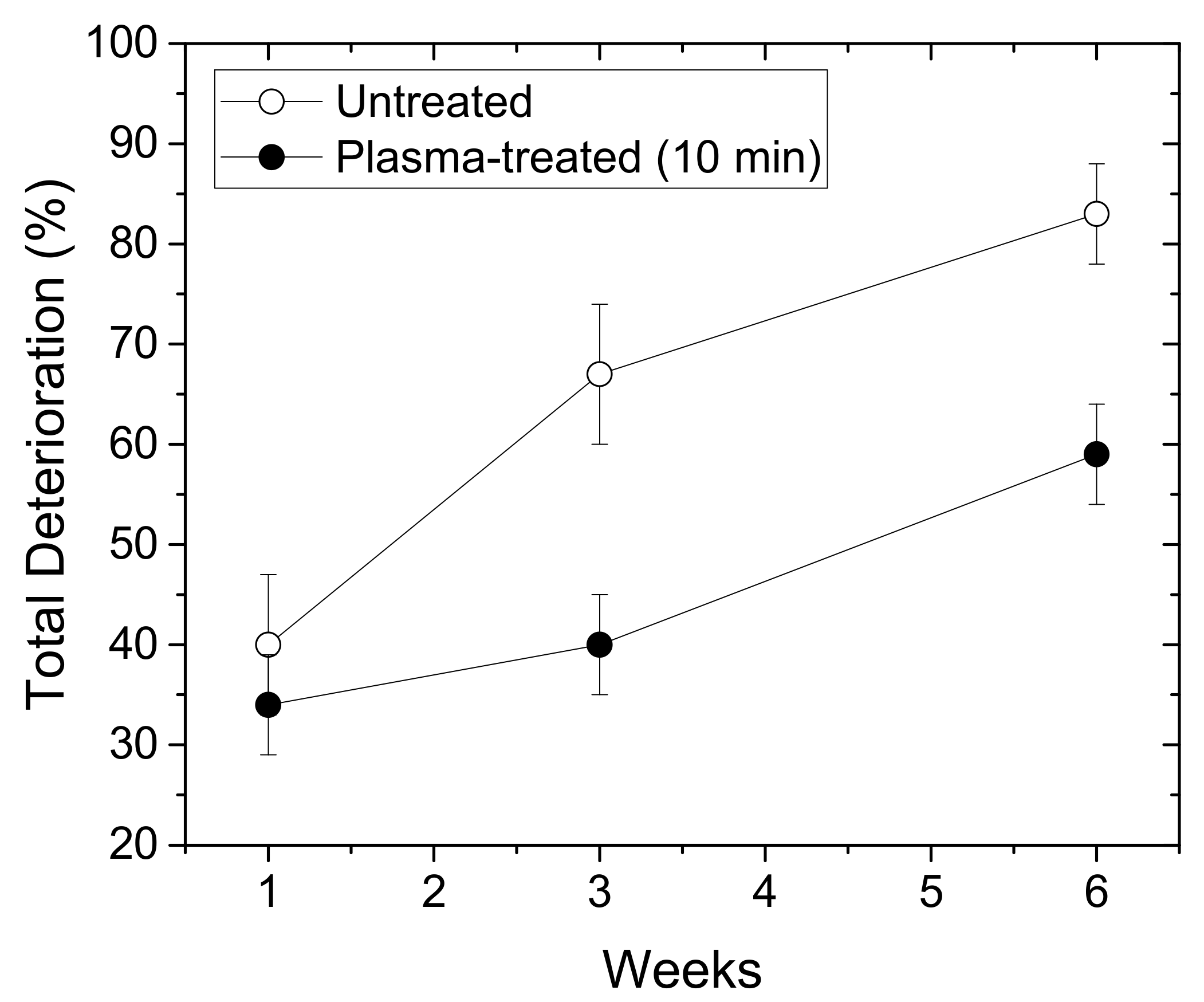

2.2. Germination of Plasma-Treated Synthetic Seeds under Non-Aseptic Conditions (Ex Vitro)

2.3. Germination of Plasma-Treated Synthetic Seeds of Different Cultivars Ex Vitro

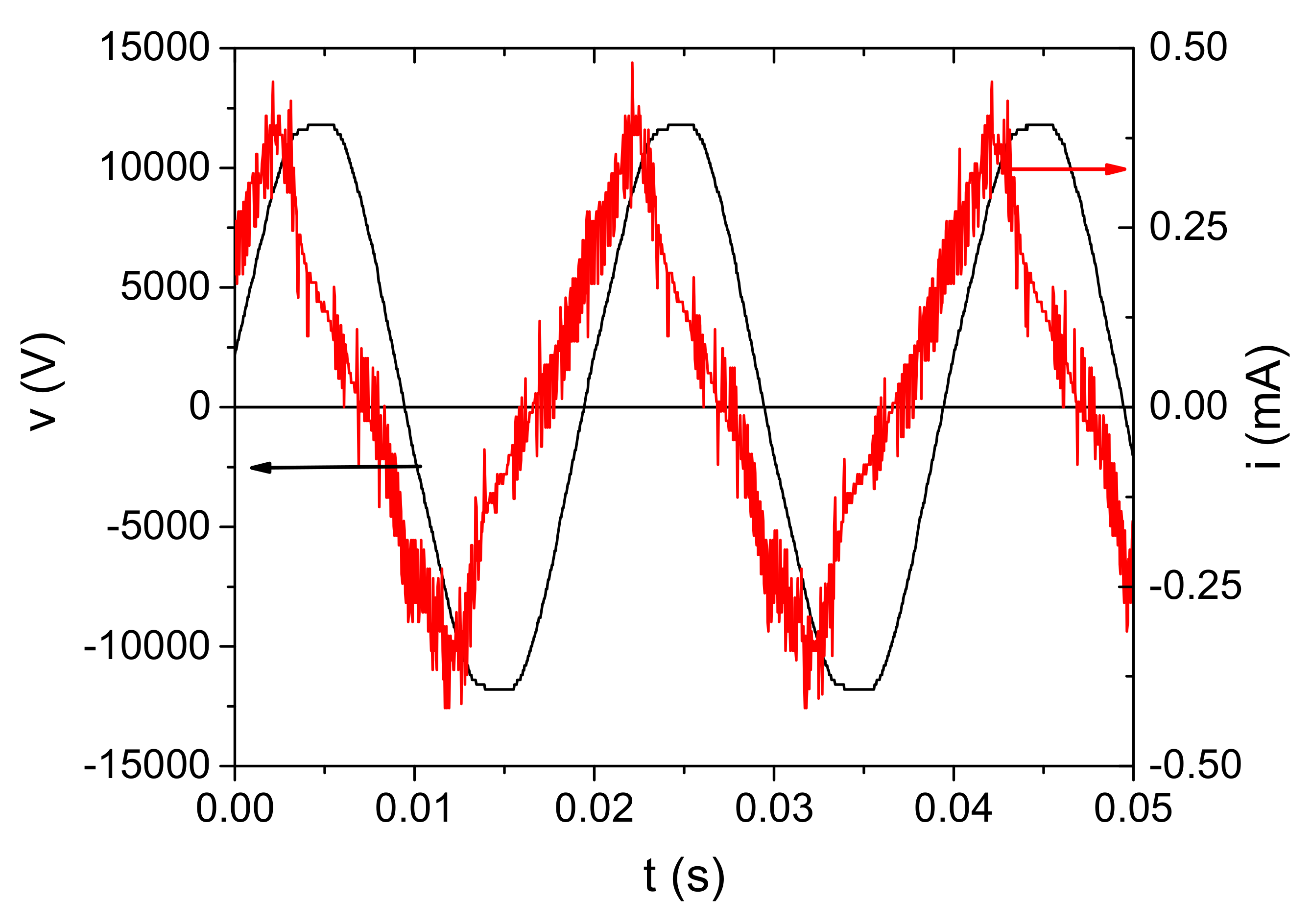

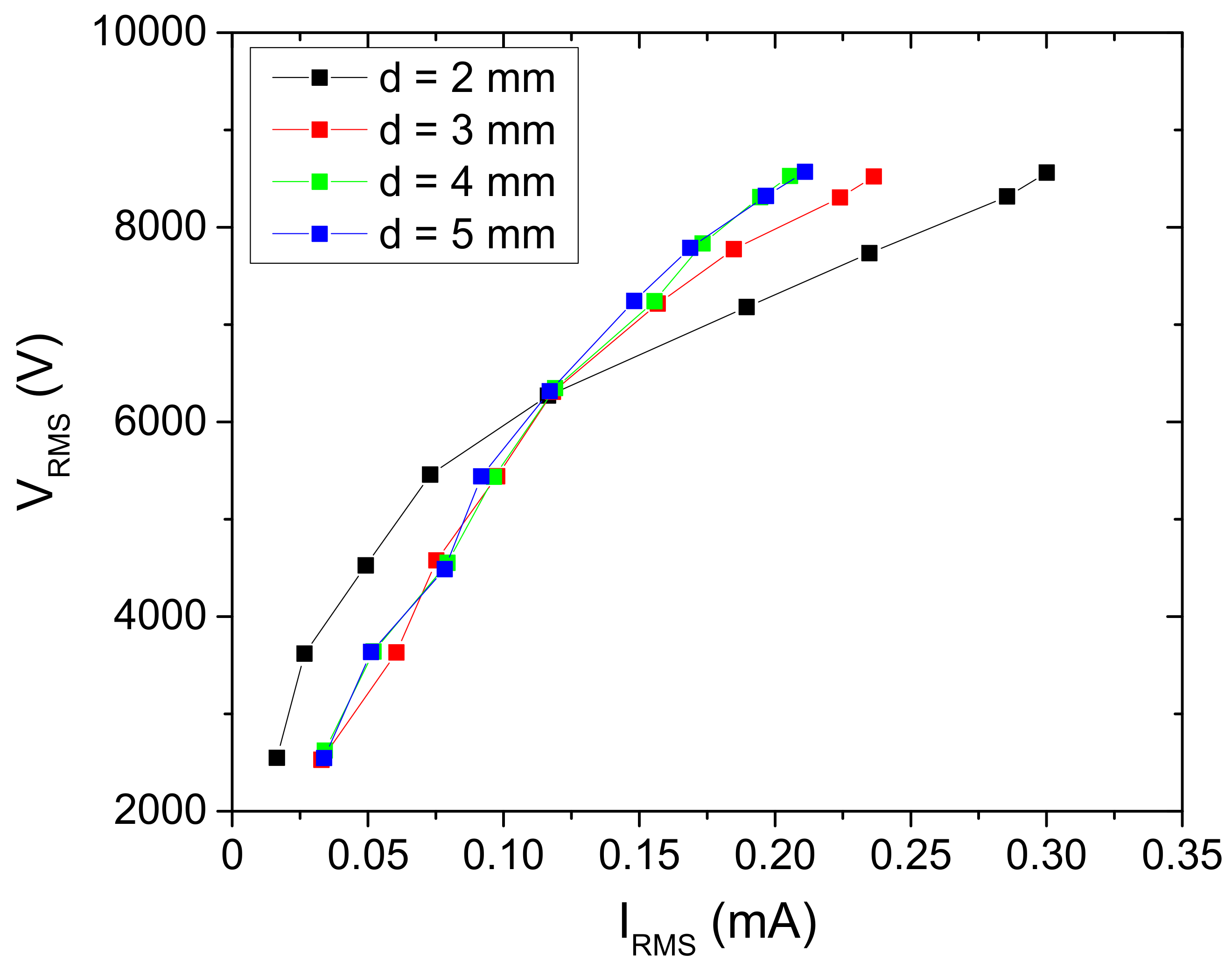

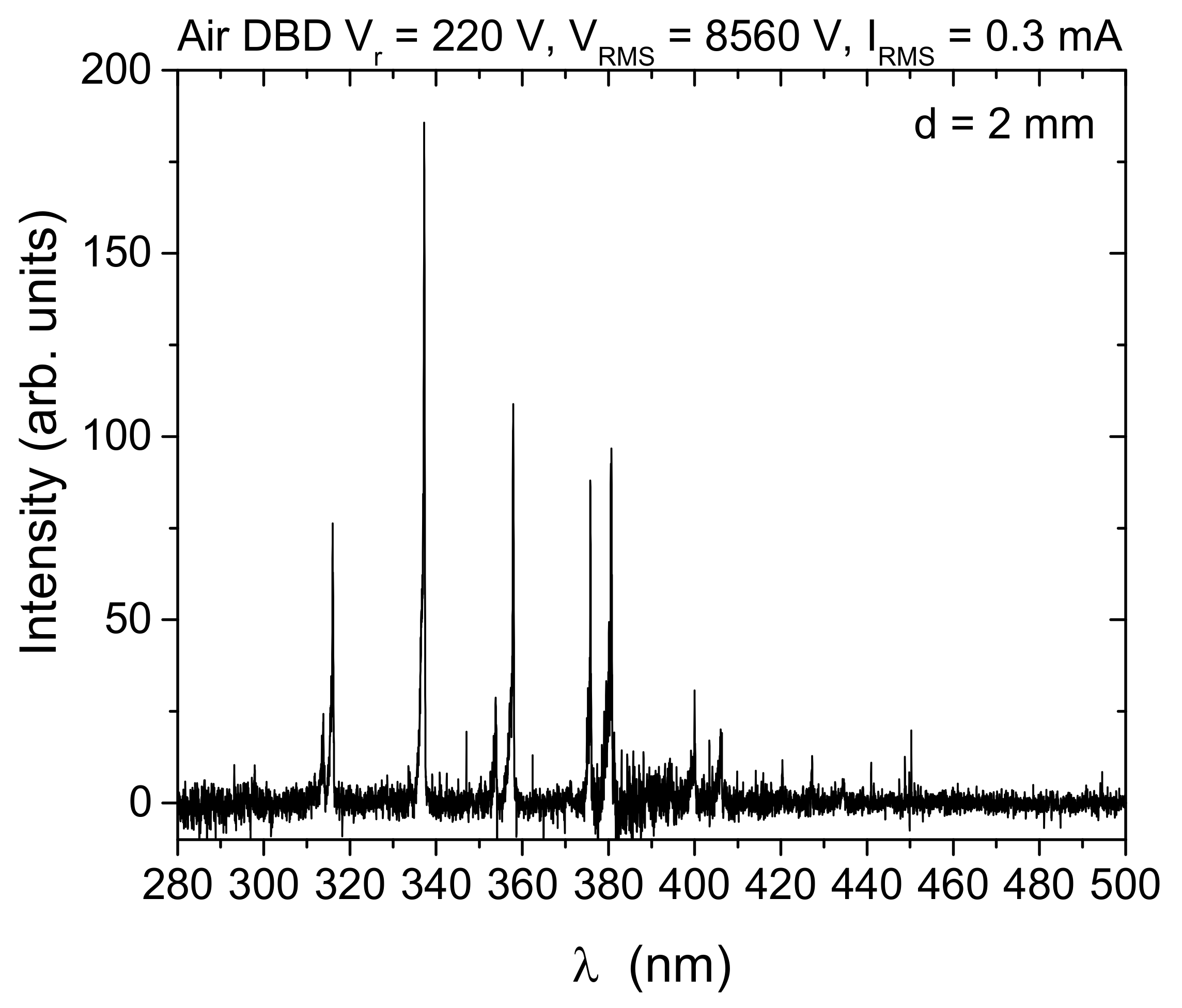

2.4. Characterization of DBD Plasma Source

3. Discussion

4. Materials and Methods

4.1. Atmospheric Pressure Plasma Source

4.2. Synthetic Seed Production

4.3. Plasma Treatment of Synthetic Seeds

4.4. Sowing of Synthetic Seeds

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rihan, H.Z.; Kareem, F.; El-Mahrouk, E.; Fuller, M.P. Artificial seeds (Principle, aspects and applications). Agronomy 2017, 7, 71. [Google Scholar] [CrossRef] [Green Version]

- Yücesan, B. Synseed: A new trend in seed technology. In Synthetic Seeds, Germplasm Regeneration, Preservation and Prospects; Faisal, M., Alatar, A.A., Eds.; Springer Nature: Cham, Switzerland, 2019; pp. 61–75. [Google Scholar] [CrossRef]

- Murashige, T. Plant cell and organ culture as horticultural practice. Acta Hortic. 1977, 78, 17–30. [Google Scholar] [CrossRef]

- Standardi, A.; Picconi, E. Recent perspectives on the synthetic seed technology using non–embryogenic in vitro-derived explants. Int. J. Plant Sci. 1998, 159, 968–978. [Google Scholar] [CrossRef]

- Ara, H.; Jaiswal, U.; Jaiswal, V.S. Synthetic seed: Prospects and limitations. Curr. Sci. 2000, 78, 1438–1444. [Google Scholar] [CrossRef]

- Benelli, C.; Micheli, M.; De Carlo, A. An improved encapsulation protocol for regrowth and conservation of four ornamental species. Acta Soc. Bot. Pol. 2017, 86, 3559. [Google Scholar] [CrossRef] [Green Version]

- Phanornchai, S.; Bodhipadma, K.; Noichnda, S.; Leung, D.W.M. Short-term storability of alginate-encapsulated Persian violet microshoots for germplasm exchange. Plants 2022, 11, 185. [Google Scholar] [CrossRef]

- Sakai, A.; Engelmann, F. Vitrification, encapsulation-vitrification and droplet-vitrification: A review. Cryo Lett. 2007, 28, 151–172. [Google Scholar]

- Sharma, S.; Shahza, A.; Teixeira da Silva, J.A. Synseed technology—A complete synthesis. Biotechnol. Adv. 2013, 31, 186–207. [Google Scholar] [CrossRef]

- Saxena, A.; Shukla, M.; Saxena, P. Synthetic seeds: Relevance to endangered germplasm conservation in vitro. In Synthetics Seeds, Germplasm Regeneration, Preservation and Prospects; Faisal, M., Alatar, A.A., Eds.; Springer Nature: Cham, Switzerland, 2019; pp. 21–59. [Google Scholar] [CrossRef]

- Szekalska, M.; Puciłowska, A.; Szymańska, E.; Ciosek, P.; Winnicka, K. Alginate: Current use and future perspectives in pharmaceutical and biomedical applications. Int. J. Polym. Sci. 2016, 2016, 7697031. [Google Scholar] [CrossRef] [Green Version]

- Wiegand, C.; Heinze, T.; Hipler, U.C. Comparative in vitro study on cytotoxicity, antimicrobial activity, and binding capacity for pathophysiological factors in chronic wounds of alginate and silver-containing alginate. Wound Repair Regen. 2009, 17, 511–521. [Google Scholar] [CrossRef]

- Poor, A.E.; Ercan, U.K.; Yost, A.; Brooks, A.D.; Joshi, S.G. Control of multi-drug-resistant pathogens with non-thermal-plasma-treated alginate wound dressing. Surg. Infect. 2014, 15, 233–243. [Google Scholar] [CrossRef] [PubMed]

- Salachna, P.; Grzeszczuk, M.; Miller, E.; Soból, M. Oligo-alginate with low molecular mass improves growth and physiological activity of Eucomisa utumnalis under salinity stress. Molecules 2018, 23, 812. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Golkar, P.; Taghizadeh, M.; Noormohammadi, A. Effect of sodium alginate on secondary metabolites and antioxidant activity of safflower genotypes under in vitro salinity stress. In Vitro Cell Dev. Biol.-Plant 2019, 55, 527–538. [Google Scholar] [CrossRef]

- Teixeira da Silva, J.A. Ornamental chrysanthemums: Improvement by biotechnology. Plant Cell Tissue Organ Cult. 2004, 79, 1–18. [Google Scholar] [CrossRef]

- Teixeira da Silva, J.A.; Kulus, D. Chrysanthemum biotechnology: Discoveries from the recent literature. Folia Hortic. 2014, 26, 67–77. [Google Scholar] [CrossRef] [Green Version]

- Zalewska, M.; Lema-Rumińska, J.; Miler, N. In vitro propagation using adventitious buds technique as a source of new variability in chrysanthemum. Sci. Hortic. 2007, 113, 70–73. [Google Scholar] [CrossRef]

- Kulus, D.; Zalewska, M. In vitro plant recovery from alginate-encapsulated chrysanthemum x grandiflorum (Ramat.) Kitam. shoot tips. Propag. Ornam. Plants 2014, 14, 3–12. [Google Scholar]

- Zalewska, M.; Tymoszuk, A.; Miler, N. New Chrysanthemum cultivars as a result of in vitro mutagenesis with the application of different explant types. Acta Sci. Pol. Hort. Cult. 2011, 10, 109–123. [Google Scholar]

- Hill, G.P. Shoot formation in tissue cultures of chrysanthemum Chrysanthemum morifolium Ramat. JPN J. Breed. 1968, 42, 386–389. [Google Scholar]

- Jevremović, S.; Radojević, L. In vitro plant regeneration from stem segments of several cultivars of chrysanthemum (Chrysanthemum morifolium Ramat. ) Bull. Inst. Jard. Bot. Univ. Belgrade 1995, 29, 107–114. [Google Scholar]

- Jevremović, S.; Subotić, A.; Miljković, D.; Trifunović, M.; Petrić, M.; Cingel, A. Clonal fidelity of chrysanthemum cultivars after long term micropropagation by stem culture. Acta Hortic. 2012, 961, 211–216. [Google Scholar] [CrossRef]

- Jevremovic, S.; Subotic, A. Micropropagation of chrysanthemum cultivars in Serbia. In Proceedings of the IX International Scientific Agriculture Symposium, Agrosym 2018, Jahorina, Bosnia and Herzegovina, 4–7 October 2018; Kovacevic, D., Ed.; University of East Sarajevo, Faculty of Agriculture: Sarajevo, Bosnia and Herzegovina, 2018; pp. 408–413. [Google Scholar]

- Teixeira da Silva, J.A.; Kim, H.; Engelmann, F. Chrysanthemum low-temperature storage and cryopreservation: A review. Plant Cell Tissue Organ Cult. 2015, 120, 423–440. [Google Scholar] [CrossRef]

- Rout, G.R.; Das, P. Recent trends in the biotechnology of Chrysanthemum: A crucial review. Sci. Hortic. 1997, 69, 239–257. [Google Scholar] [CrossRef]

- Teixeira da Silva, J.A. Chrysanthemum: Advances in tissue culture, cryopreservation, postharvest technology, genetics and transgenic biotechnology. Biotechnol. Adv. 2003, 21, 715–766. [Google Scholar] [CrossRef]

- Kulus, D. Application of synthetic seeds in propagation, storage, and preservation of Asteraceae plant species. In Synthetic Seeds, Germplasm Regeneration, Preservation and Prospects; Faisal, M., Alatar, A.A., Eds.; Springer Nature: Cham, Switzerland, 2019; pp. 155–179. [Google Scholar] [CrossRef]

- Pinker, I.; Abdel-Rahman, S.S. Artificial seeds for propagation of Dendrantema × grandiflora (Ramat.). Propag. Ornam. Plants 2005, 5, 186–191. [Google Scholar]

- Hung, C.D.; Dung, C.D. Production of chrysanthemum synthetic seeds under non-aseptic conditions for direct transfer to commercial greenhouses. Plant Cell Tissue Organ Cult. 2015, 122, 639–648. [Google Scholar] [CrossRef]

- Reddy, M.C.; Rama Murthy, K.S.; Pullaiah, T. Synthetic seeds: A review in agriculture and forestry. Afr. J. Biotechnol. 2012, 11, 14254–14275. [Google Scholar] [CrossRef]

- Rihan, H.Z.; Al-Issawi, M.; Al-Swedi, F.; Fuller, M.P. The effect of using PPM (Plant preservative mixture) on the development of cauliflower microshoots and the quality of the artificial seed produced. Sci. Hortic. 2012, 141, 47–52. [Google Scholar] [CrossRef]

- Adamovich, I.; Baalrud, S.D.; Bogaerts, A.; Bruggeman, P.J.; Cappelli, M.; Colombo, V.; Czarnetzki, U.; Ebert, U.; Eden, J.G.; Favia, P.; et al. The Plasma Roadmap: Low temperature plasma science and technology. J. Phys. D Appl. Phys. 2017, 50, 323001. [Google Scholar] [CrossRef]

- Weltmann, K.-D.; von Woedtke, T. Plasma medicine—current state of research and medical application. Plasma Phys. Control. Fusion 2017, 59, 014031. [Google Scholar] [CrossRef]

- Laroussi, M.; Kong, M.G.; Morfill, G.; Stolz, W. (Eds). Plasma Medicine Applications of Low-Temperature Gas Plasmas in Medicine and Biology; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Lazović, S.; Puač, N.; Miletić, M.; Pavlica, D.; Jovanović, M.; Bugarski, D.; Mojsilović, S.; Maletić, D.; Malović, G.; Milenković, P.; et al. The effect of a plasma needle on bacteria in planktonic samples and on peripheral blood mesenchymal stemcells. New J. Phys. 2010, 12, 083037. [Google Scholar] [CrossRef]

- Puac, N.; Gherardi, M.; Shiratani, M. Plasma agriculture: A rapidly emerging field. Plasma Proc. Polym. 2018, 15, 1700174. [Google Scholar] [CrossRef]

- Attri, P.; Ishikawa, K.; Okumura, T.; Koga, K.; Shiratani, M. Plasma agriculture from laboratory to farm: A review. Processes 2020, 8, 1002. [Google Scholar] [CrossRef]

- Živković, S.; Puač, N.; Giba, Z.; Grubišić, D.; Petrović, Z.L. The stimulatory effect of non-equilibrium (low temperature) air plasma pretreatment on light-induced germination of Paulownia tomentosa seeds. Seed Sci. Tech. 2004, 32, 693–701. [Google Scholar] [CrossRef]

- Sera, B.; Stranák, V.; Serý, M.; Tichý, M.; Spatenka, P. Germination of Chenopodium album in response to microwave plasma treatment. Plasma Sci. Technol. 2008, 10, 506. [Google Scholar] [CrossRef]

- Lu, X.; Reuter, S.; Laroussi, M.; Liu, D. Non Equilibrium Atmospheric Pressure Plasma Jets: Fundamentals, Diagnostics, and Medical Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019; pp. 1–426. [Google Scholar]

- Waskow, A.; Avino, F.; Howling, A.; Furno, I. Entering the plasma agriculture field: An attempt to standardize protocols for plasma treatment of seeds. Plasma Process Polym. 2022, 19, e2100152. [Google Scholar] [CrossRef]

- Motyka-Pomagruk, A.; Dzimitrowicz, A.; Orlowski, J.; Babinska, W.; Terefinko, D.; Rychlowski, M.; Prusinski, M.; Pohl, P.; Lojkowska, E.; Jamroz, P.; et al. Implementation of a non-thermal atmospheric pressure plasma for eradication of plant pathogens from a surface of economically important seeds. Int. J. Mol. Sci. 2021, 22, 79256. [Google Scholar] [CrossRef]

- Lu, X.; Naidis, G.V.; Laroussi, M.; Reuter, S.; Graves, D.B.; Ostrikov, K. Reactive species in non-equilibrium atmospheric-pressure plasmas: Generation, transport, and biological effects. Phys. Rep. 2016, 630, 1–84. [Google Scholar] [CrossRef] [Green Version]

- Bradu, C.; Kutasi, K.; Magureanu, M.; Puač, N.; Živković, S. Reactive nitrogen species in plasma-activated water: Generation, chemistry and application in agriculture. J. Phys. D Appl. Phys. 2020, 53, 223001. [Google Scholar] [CrossRef]

- Matthes, R.; Bender, C.; Schlüter, R.; Koban, I.; Bussiahn, R.; Reuter, S.; Lademann, J.; Weltmann, K.D.; Kramer, A. Antimicrobial efficacy of two surface barrier discharges with air plasma against in vitro biofilms. PLoS ONE 2013, 8, 70462. [Google Scholar] [CrossRef]

- Bormashenko, E.; Grynyov, R.; Bormashenko, Y.; Driori, E. Cold radiofrequency plasma treatment modifies wettability and germination speed of plant seeds. Sci. Rep. 2012, 2, 741. [Google Scholar] [CrossRef] [PubMed]

- Sivachandiran, L.; Khacef, A. Enhanced seed germination and plant growth by atmospheric pressure cold air plasma: Combined effect of seed and water treatment. RSC Adv. 2017, 7, 1822–1832. [Google Scholar] [CrossRef] [Green Version]

- Mildažienė, V.; Aleknavičiūtė, V.; Žūkienė, R.; Giedrė, P.; Naučienė, Z.; Filatova, I.; Lyushkevich, V.; Haimi, P.; Tamošiūnė, I.; Baniulis, D. Treatment of Common Sunflower (Helianthus annus L.) Seeds with radio-frequency electromagnetic field and cold plasma induces changes in seed phytohormone balance, seedling development and leaf protein expression. Sci. Rep. 2019, 9, 6437. [Google Scholar] [CrossRef] [PubMed]

- Zahoranová, A.; Henselová, M.; Hudecová, D.; Kalináková, B.; Kováčik, D.; Medvecká, V.; Černák, M. Effect of cold atmospheric pressure plasma on the wheat seedlings vigor and on the inactivation of microorganisms on the seeds surface. Plasma Chem. Plasma Process. 2016, 36, 398–414. [Google Scholar] [CrossRef]

- Waskow, A.; Betschart, J.; Butscher, D.; Oberbossel, G.; Klöti, D.; Büttner-Mainik, A.; Adamcik, J.; von Rohr, P.R.; Schuppler, M. Characterization of efficiency and mechanisms of cold atmospheric pressure plasma decontamination of seeds for sprout sroduction. Front. Microbiol. 2018, 9, 3164. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Honnorat, B.; Yang, H.; Arancibia, J.; Rajjou, L.; Rousseau, A. Non-thermal DBD plasma array on seed germination of different plant species. J. Phys. D Appl. Phys. 2019, 52, 025401. [Google Scholar] [CrossRef]

- Chen, H.H.; Chang, H.C.; Chen, Y.K.; Hung, C.L.; Lin, S.Y.; Chen, Y.S. An improved process for high nutrition of germinated brown rice production: Low-pressure plasma. Food Chem. 2016, 191, 120–127. [Google Scholar] [CrossRef]

- Brandenburg, R. Dielectric barrier discharges: Progress on plasma. Plasma Sources Sci. Technol. 2017, 26, 053001. [Google Scholar] [CrossRef]

- Winter, J.; Brandenburg, R.; Weltmann, K.D. Atmospheric pressure plasma jets: An overview of devices and new directions. Plasma Sources Sci. Technol. 2015, 24, 064001. [Google Scholar]

- Bruggeman, P.; Brandenburg, R. Atmospheric pressure discharge filaments and microplasmas: Physics, chemistry and diagnostics. J. Phys. D Appl. Phys. 2013, 46, 464001. [Google Scholar] [CrossRef]

- Janić Hajnal, E.; Vukić, M.; Pezo, L.; Orčić, D.; Puač, N.; Škoro, N.; Milidrag, A.; Šoronja Simović, D. Effect of atmospheric cold plasma treatments on reduction of alternaria toxins content in wheat flour. Toxins 2019, 11, 704. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brandenburg, R.; Navrátil, Z.; Jansky, J.; Stahel, P.; Trunec, D.; Wagner, H.E. The transition between different modes of barrier discharges at atmospheric pressure. J. Phys. D Appl. Phys. 2009, 42, 085208. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, G.; Wang, X. Comparison of discharge characteristics of a dielectric barrier discharge with different electrode structures. Vacuum 2012, 86, 960. [Google Scholar] [CrossRef]

- Sakiyama, Y.; Graves, D.B.; Chang, H.-W.; Shimizu, T.; Morfill, G.E. Plasma chemistry model of surface microdischarge in humid air and dynamics of reactive neutral species. J. Phys. D Appl. Phys. 2012, 45, 425201. [Google Scholar] [CrossRef]

- Tang, Q.; Jiang, W.; Cheng, Y.; Lin, S.; Lim, T.M.; Xiong, J. Generation of Reactive Species by Gas-Phase Dielectric Barrier Discharges. Ind. Eng. Chem. Res. 2011, 50, 9839–9846. [Google Scholar] [CrossRef]

- Kozlov, K.V.; Brandenburg, R.; Wagner, H.-E.; Morozov, A.M.; Michel, P. Investigation of the filamentary and diffuse mode of barrier discharges in N2/O2 mixtures at atmospheric pressure by cross-correlation spectroscopy. J. Phys. D Appl. Phys. 2005, 38, 518–529. [Google Scholar] [CrossRef] [Green Version]

- Shang, K.; Wang, M.; Peng, B.; Li, J.; Lu, N.; Jiang, N.; Wu, Y. Characterization of a novel volume-surface DBD reactor: Discharge characteristics, ozone production and benzene degradation. J. Phys. D Appl. Phys. 2020, 53, 065201. [Google Scholar] [CrossRef]

- Jiang, N.; Guo, L.; Qiu, C.; Zhang, Y.; Shang, K.; Lu, N.; Li, J.; Wu, Y. Reactive species distribution characteristics and toluene destruction in the three-electrode DBD reactor energized by different pulsed modes. Chem. Eng. J. 2018, 350, 12–19. [Google Scholar] [CrossRef]

- Liberatore, C.M.; Rodolfi Beghèa, D.; Fabbri, A.; Ganino, T.; Chianconea, B. Adventitious shoot organogenesis and encapsulation technology in hop (Humulus lupulus L.). Sci. Hortic. 2020, 270, 109416. [Google Scholar] [CrossRef]

- Benelli, C. Encapsulation of shoot tips and nodal segments for in vitro storage of “kober 5BB” grapevine rootstock. Horticulturae 2016, 10, 185. [Google Scholar] [CrossRef]

- Hung, C.D.; Trueman, S.J. Encapsulation technology for short term preservation and germplasm distribution of the African mahogany Khaya senegalensis. Plant Cell Tissue Organ. Cult. 2011, 107, 397–405. [Google Scholar] [CrossRef]

- Hung, C.D.; Trueman, S.J. Alginate encapsulation of shoot tips and nodal segments for short term storage and distribution of the eucalypt Corymbia torelliana × C. citriodora. Acta Physiol. Plant. 2012, 34, 117–128. [Google Scholar] [CrossRef]

- Dobrynin, D.; Fridman, G.; Friedman, G.; Fridman, A. Physical and biological mechanisms of direct plasma interaction with living tissue. New J. Phys. 2009, 11, 115020. [Google Scholar] [CrossRef]

- Murashige, T.; Skoog, F. A revised medium for rapid growth and bio assays with tobacco tissue cultures. Physiol. Plant 1962, 15, 473–497. [Google Scholar] [CrossRef]

| Cultivar | Plant Material | Beads | Sowing | Germination (%) | Flowering | References |

|---|---|---|---|---|---|---|

| Clone ‘PS 27’ | Nodal segments (in vitro) | Monolayered (3% Na-alginate + 0.1 mg/L IAA) | Sterile, water–sand | 50 | no | [29] |

| Double-layered (beads: 3% Na alginate, second layer: water) | Non-sterile, water–perlite | 45 | no | |||

| Lady group | Shoot tips (in vitro) | Monolayered (3% Na-alginate) | Sterile, agar | 52 | no | [19] |

| cv. ‘Royal Purple’ | Shoot tips (ex vitro) | Monolayered (2.5% Na-alginate, sucrose, vitamin free) | Non-sterile, vermiculite | 34 | no | [30] |

| Plasma Treatment (min) | Leaf Emergence (%) * | Shoot Regrowth (%) ** |

|---|---|---|

| 1 Week | 4 Weeks | |

| 0 | 20 ± 10 a *** | 0 ± 0 a |

| 1 | 47 ± 13 a,b | 40 ± 13 b |

| 5 | 67 ± 12 b | 47 ±13 b |

| 10 | 67 ± 13 b | 33 ± 12 b |

| Plasma Treatment (min) | Synseed Germination | ||

|---|---|---|---|

| Leaf Emergence * (%) | Shoot Regrowth * (%) | Plantlet * (%) | |

| 0 | 60 ± 7 a ** | 33 ± 7 a | 17 ± 5 a |

| 10 | 66 ± 5 a | 60 ± 5 b | 41 ± 5 b |

| Plasma Treatment (min) | Plantlet (%) | |||

|---|---|---|---|---|

| BC * | Q * | PC * | PP * | |

| 0 | 6 ± 1 a ** | 17 ± 2 a | 28 ± 1 a | 14 ± 1 a |

| 10 | 22 ± 6 b | 40 ± 3 b | 44 ± 2 b | 49 ± 3 b |

| Increment (%) | ~370 | ~230 | ~160 | ~350 |

| Electrode Distance-d [mm] | Stray Capacitance—Cp [pF] |

|---|---|

| 2 | 20 |

| 3 | 35 |

| 4 | 41 |

| 5 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Škoro, N.; Živković, S.; Jevremović, S.; Puač, N. Treatment of Chrysanthemum Synthetic Seeds by Air SDBD Plasma. Plants 2022, 11, 907. https://doi.org/10.3390/plants11070907

Škoro N, Živković S, Jevremović S, Puač N. Treatment of Chrysanthemum Synthetic Seeds by Air SDBD Plasma. Plants. 2022; 11(7):907. https://doi.org/10.3390/plants11070907

Chicago/Turabian StyleŠkoro, Nikola, Suzana Živković, Slađana Jevremović, and Nevena Puač. 2022. "Treatment of Chrysanthemum Synthetic Seeds by Air SDBD Plasma" Plants 11, no. 7: 907. https://doi.org/10.3390/plants11070907