Spatio-Temporal Risk Assessment Process Modeling for Urban Hazard Events in Sensor Web Environment

Abstract

:1. Introduction

2. Method

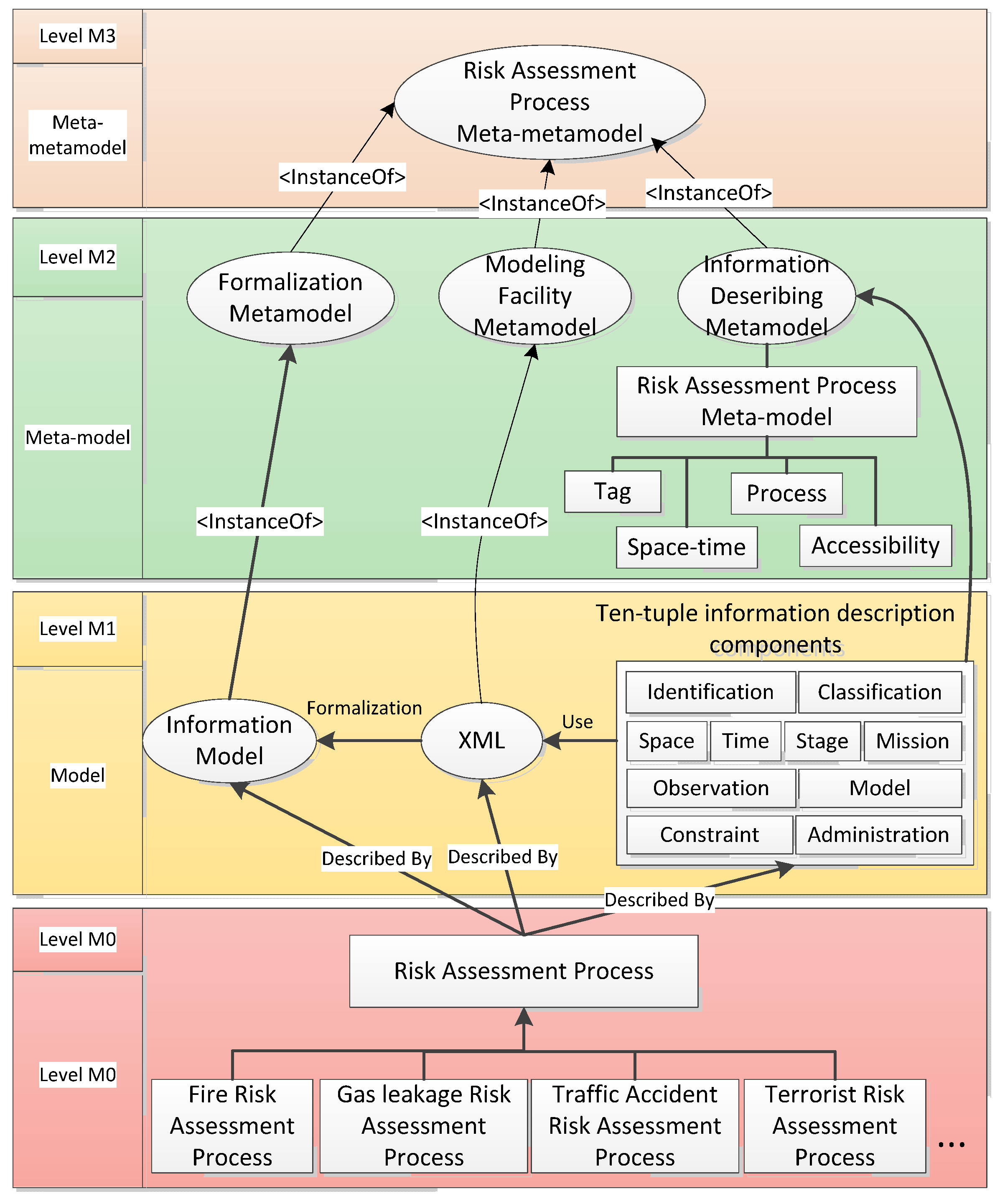

2.1. Meta-Modeling for a RAP

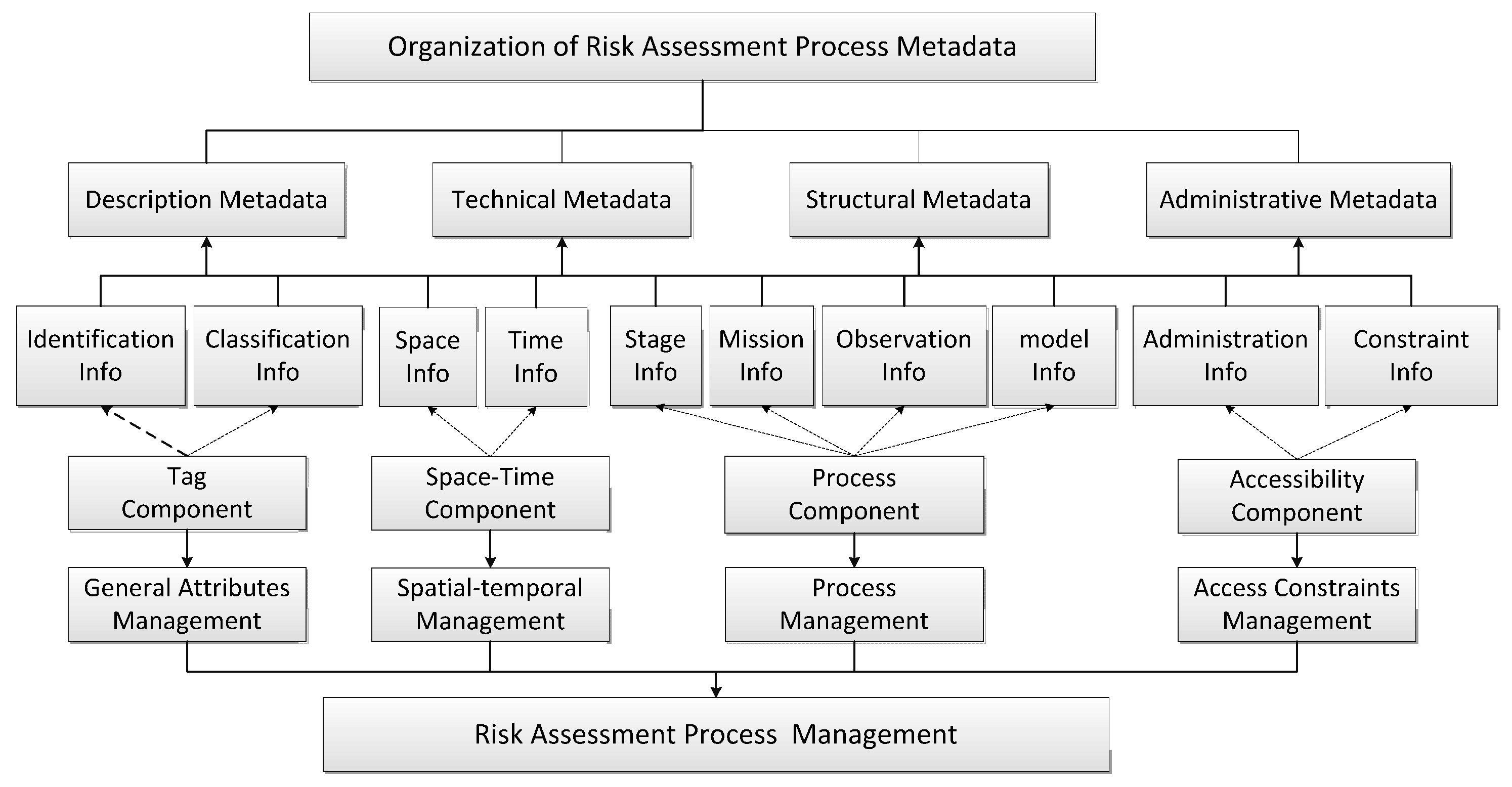

2.2. Basic Information Components of a RAP

- Tag: Such information is composed of identification information and classification information. Identification information is used to describe the RAP name, ID, and other identifying elements. Classification information describes various UHEs under different classification criteria and is useful for RAP inquiry and discovery based on the related UHE.

- Space-time: Such information represents the time and space information of the RAP. The RAP is based on spatio-temporal observations that provide the spatio-temporal range to risk assessment with the occurrence of abnormal observations.

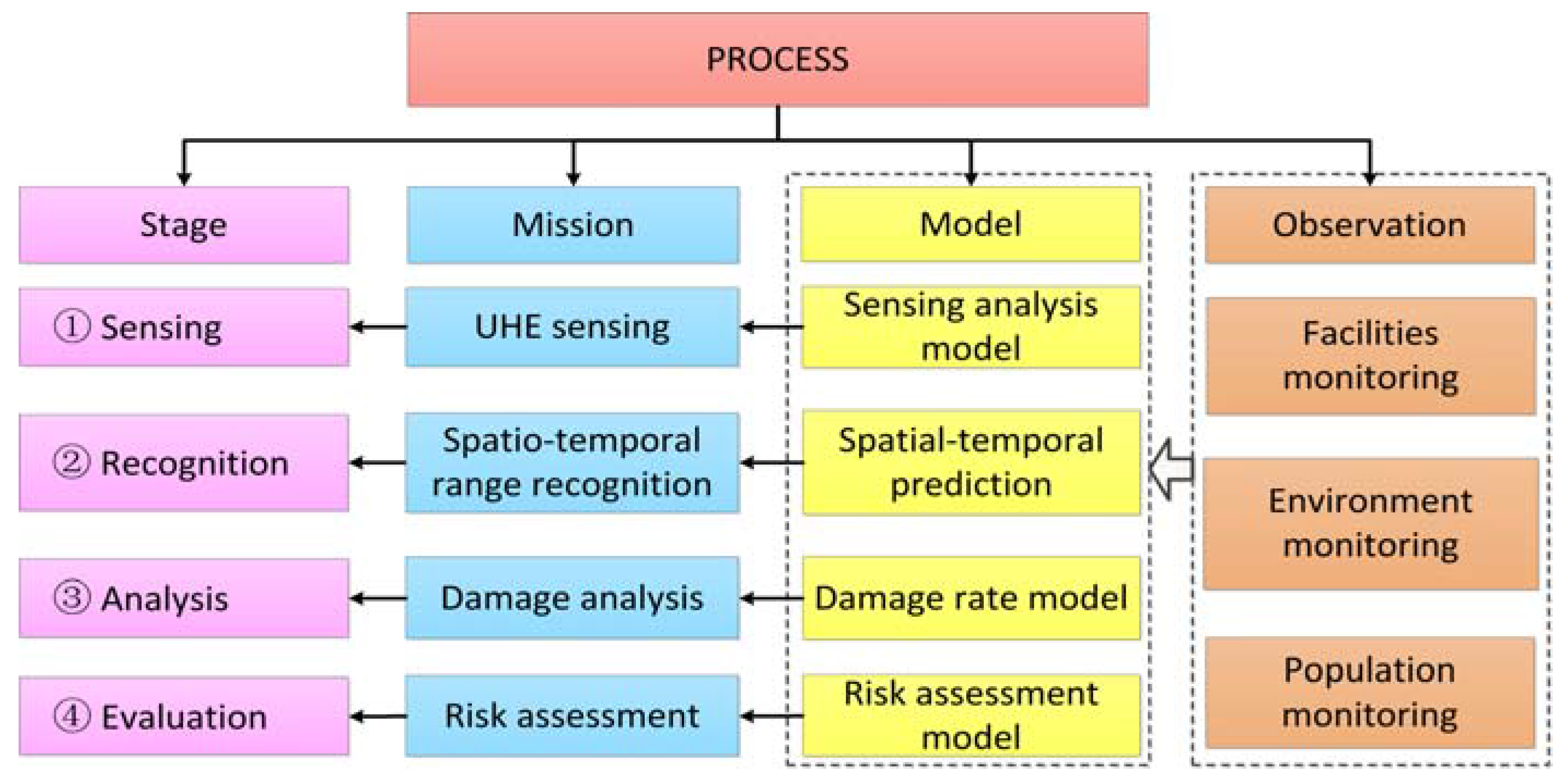

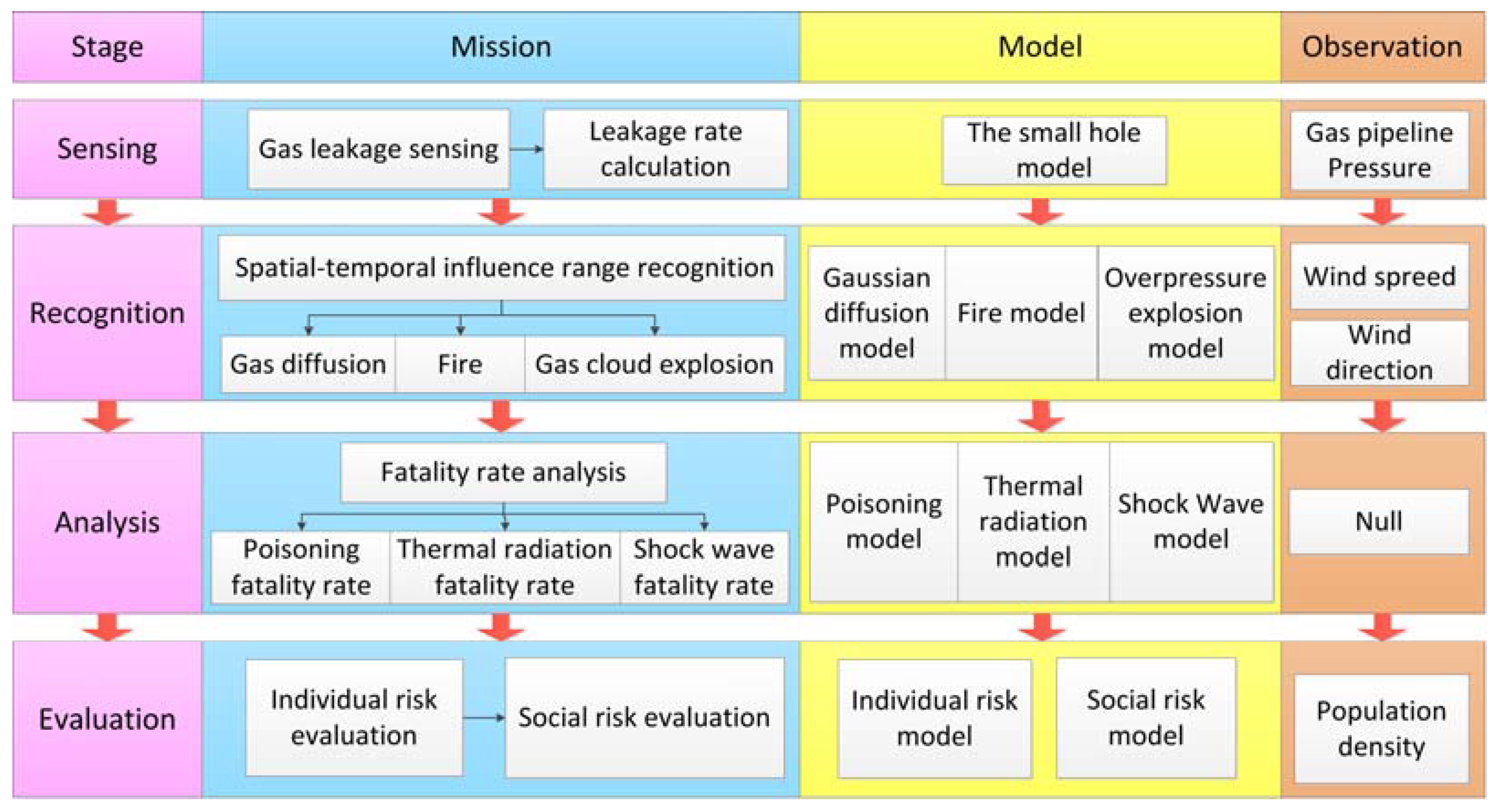

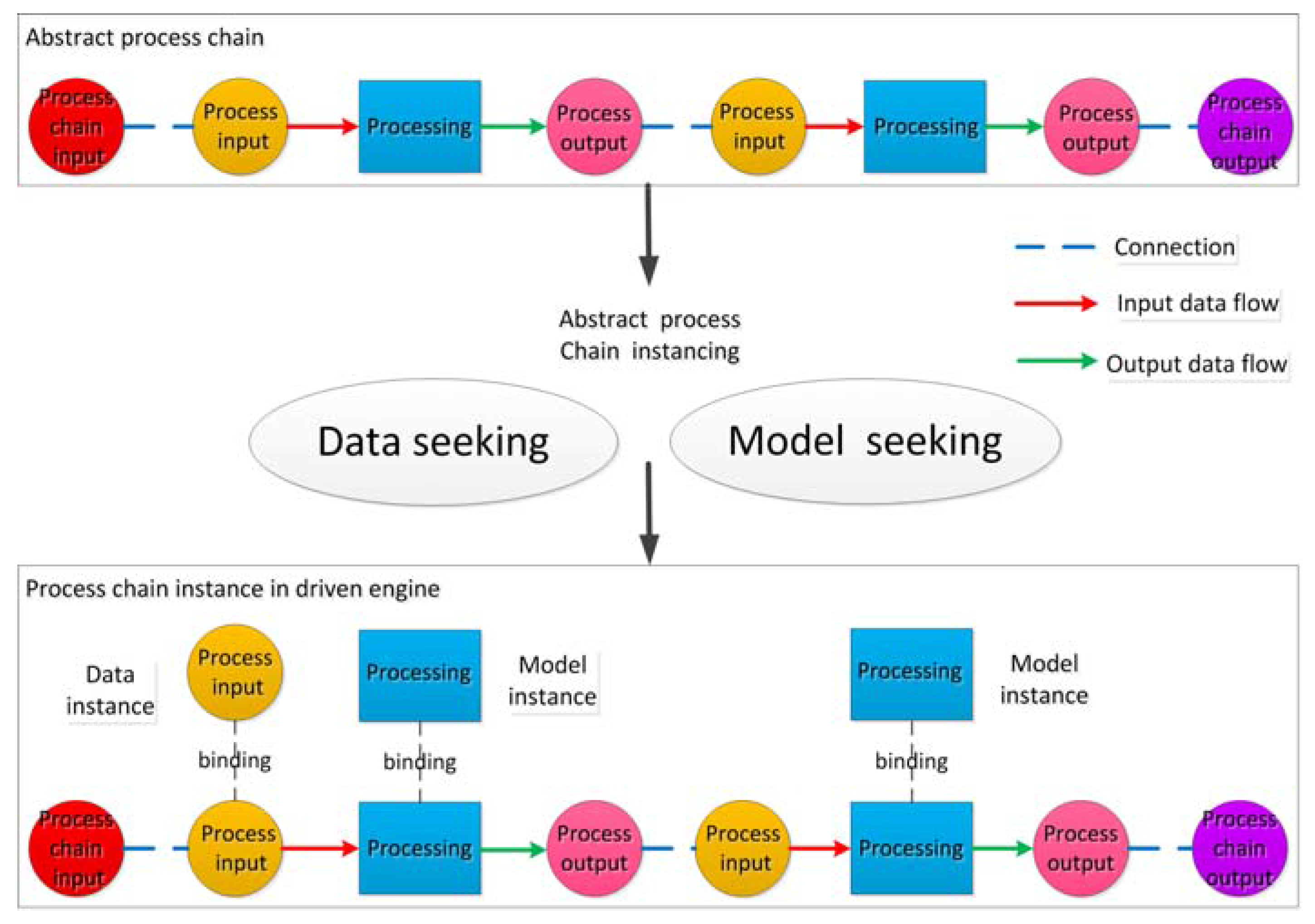

- Process: Process represents the abstract description of a workflow, which describes the execution sequence of observations and models in four stages: sensing, recognition, analysis, and evaluation.

- Accessibility: Accessibility information includes administration information and constraint information. Administration reflects an association or organization that is responsible for a UHE. Constraint information includes several legal and security restrictions that are critical for users to efficiently organize the data resource information that a RAP requires for UHEs.

- Identification information includes the keywords, name, type, and characteristics of a RAP that describe the common process information to uniquely recognize a process.

- Classification information describes mapping from a variety of RAPs to UHEs. When monitoring sensors receive abnormal values, one can quickly determine the RAP that matches the UHE based on the mapping, which makes quick discovery of UHEs and immediate risk assessment possible.

- Space information covers the spatial extent and spatial reference information used to describe the locations of UHEs. The spatial extent of a RAP is two-dimensional (2D) because UHE risk assessment focuses primarily on 2D spatial analysis.

- Time information can describe the progress of the UHE, and it provides a basis for an immediate RAP.

- Stage information describes the different required missions, models, and observations in each stage. Stage information can also describe the input, output, and parameter information for each stage. Additionally, temporal uncertainty problems occur that may be caused by delay sensor data or network problems during RAP execution time. The designed stage information can describe the execution state, stage, and incoming time of the sensor data. Stage information abstracts the time threshold range. When the execution time exceeds the threshold range, the error will be returned.

- Mission information represents specific assessment missions for each assessment stage. It describes the connection sequence for service resources, including the sensor observations and model services in a RAP.

- Observation information represents the binding of sensor observations according to mission information. Different types of sensors are often required in different assessment stages. This information contains basic information on the binding sensor observations.

- Model (service) information represents distributed models according to the mission information requirements for each assessment stage. The service name, service address and service type are provided to mission information.

- Administration information represents contacts, history, documents, and other data that play important roles in the administration and improvement of RAPs.

- Constraint information describes the access permissions, security rules and legal constraints of a RAP.

2.3. Construction of a RAP Based on Stages

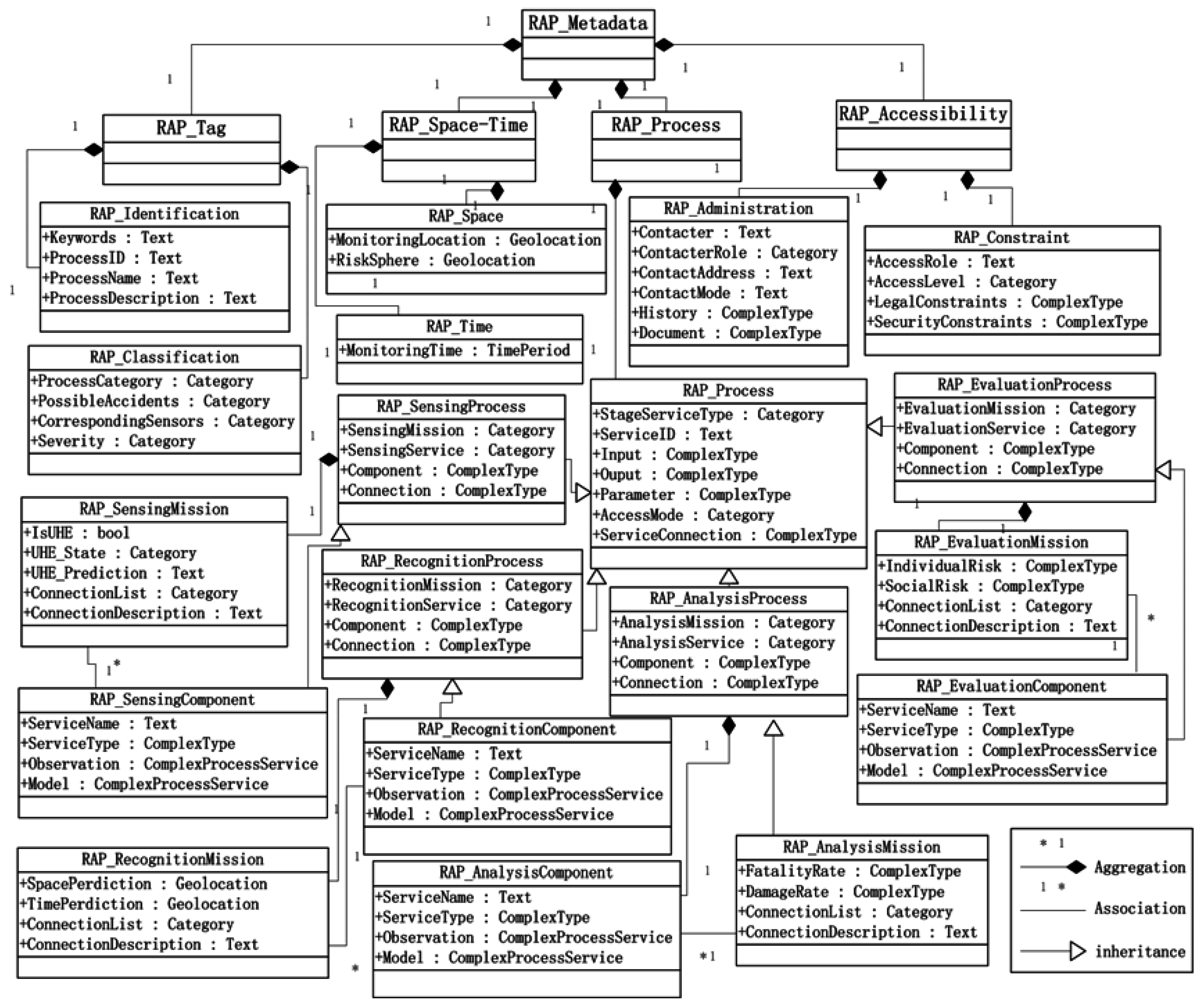

2.4. Formalization of a RAP Meta-Model

3. Case Studies Based on Gas Leakage

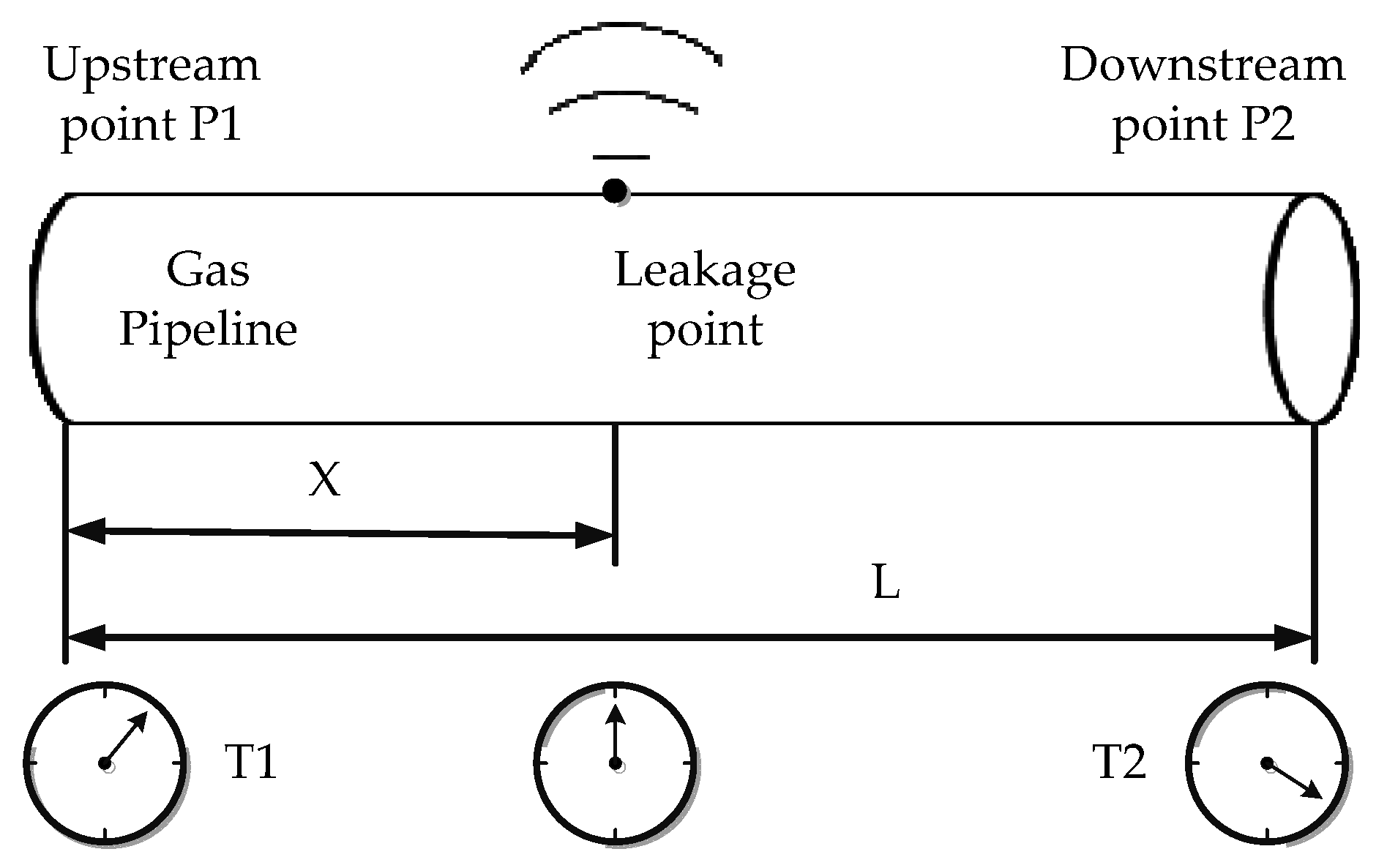

3.1. Risk Sensing for Gas Leakage

- Small hole model: Gas leakage states are often divided into two types: sonic speed and subsonic speed. To simplify the calculation, a uniform model is adopted to calculate the leak rate caused by small or medium-sized hole failure. The model is shown in Equation (2):where is the gas leakage rate in kg/s; is the area of the leak opening in m2; is the molecular weight of the gas in kg/mol; is the gas constant (8.314 J/mol·K); is the temperature of the gas inside the pipeline in °K; is the adiabatic index or the ratio of the isobaric heat capacity to the isochoric heat capacity (1.28 for natural gas); is the environmental pressure outside the gas pipeline in Pa; and is the pressure inside the gas pipeline in Pa.

3.2. Risk Recognition for Gas Leakage

- Gaussian diffusion model: A Gaussian diffusion model is divided into plume and puff types. The plume diffusion model is suitable for partial continuous leak diffusion, and the puff model is used for instantaneous gas leak diffusion. The former is more appropriate for a gas leak event. The concentration distribution of the Gaussian diffusion model is shown in Equation (3):where is the concentration near the source of the gas leakage in kg/m3; is the mass flow rate of gas leakage in kg/s, which is determined by the output of the small hole model in the sensing stage; is the height of the leak source in m; are the coordinates of any point in the downwind region; is the average wind speed in m/s, which is determined by the observation result of wind speed sensors; and , , and are the diffusivities of downwind, cross wind, and vertical wind in m, respectively, which are calculated on the basis of the observation results of the wind direction sensors and the level of atmospheric stability.

- Fire model: Fire can affect the surrounding environment through thermal radiation. Surrounding objects can be burned and deformed in a radiation environment of high intensity. High-temperature radiation may burn equipment and even cause casualties. The existing fire models are divided by fire types and include the fireball model, the jet fire model, and the flash fire model; their usage depends on the potential concerns based on the released material and context. In this paper, the fireball model, described in Equation (4), is used as an example:where is the radiative heat flux at the specific position in W/m2; is the leakage gas mass in kg, which is determined by the leakage time and the output of the small hole model in the sensing stage; is the thermal conductivity; and is the distance between the center of the flame zone and the target point.

- Vapor cloud explosion model [35]: A vapor cloud is formed when a large number of gas leaks quickly spread into the air. If a vapor cloud is ignited at an explosion limit density, an explosion will be generated with a shock wave. The vapor cloud explosion model is shown in Equation (5):where is the incident overpressure of the blast wave; is the distance from a certain point in the explosion field to the explosion source; and is calculated by Equation (6):where is the trinitrotoluene (TNT) equivalent in kg in the center of the explosion; is the mass of the gas participating in the explosion in kg, which is determined by the leakage time and the output of the small hole model in the sensing stage; is the explosion heat of the gas in J/kg; and is the calorific value of a standard TNT explosion source (4.2 MJ/kg).

3.3. Risk Analysis for Gas Leakage

3.4. Risk Evaluation for Gas Leakage

- Individual risk model [36]: An individual risk model is defined as the frequency of injuries and, in particular, deaths of people caused by a specific hazard excluding protective measures. For a gas leakage event, individual risk can be represented as the integration of the gas pipeline failure probability and the fatality rate of the people in the specific location of the event. The individual risk is given by Equation (8):where is the assumed fault type; is the pipeline failure rate per unit length; is the length of the pipeline in m; is the fatality rate of the failure accident, which is determined by the output in the analysis stage; and is the failure mode of the pipeline.

- Social risk model [37]: The social risk model is used to describe the relationship between the probability an accident and the number of casualties caused by the accident. Social risk refers to the risk of catastrophic accidents that affect many people simultaneously. Social risk is related not only to individual risk but also to the population density near the leakage region. Social risk can be calculated by Equation (9):where is the affected area of the assumed failure accident; is the population density in the region, which is determined by the calculation of the mobile base station data; and is the fatality rate of a certain accident type, , which is different from the three secondary events. A frequency and number (F–N) curve is used to formally express social risk.

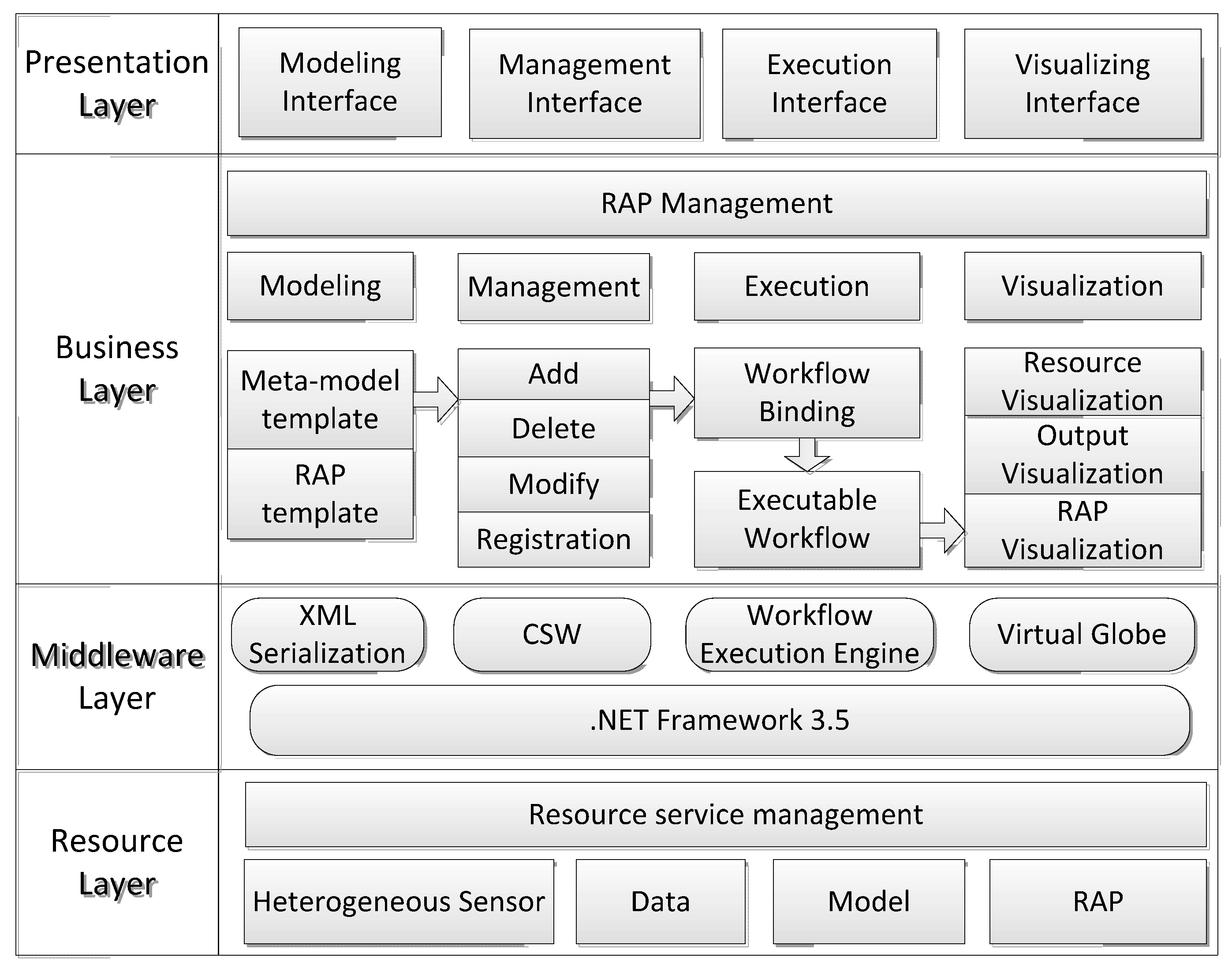

4. System Implementation

4.1. System Architecture and Components

4.2. RAP Modeling for Gas Leakage

4.2.1. RAP Modeling Based on Observations

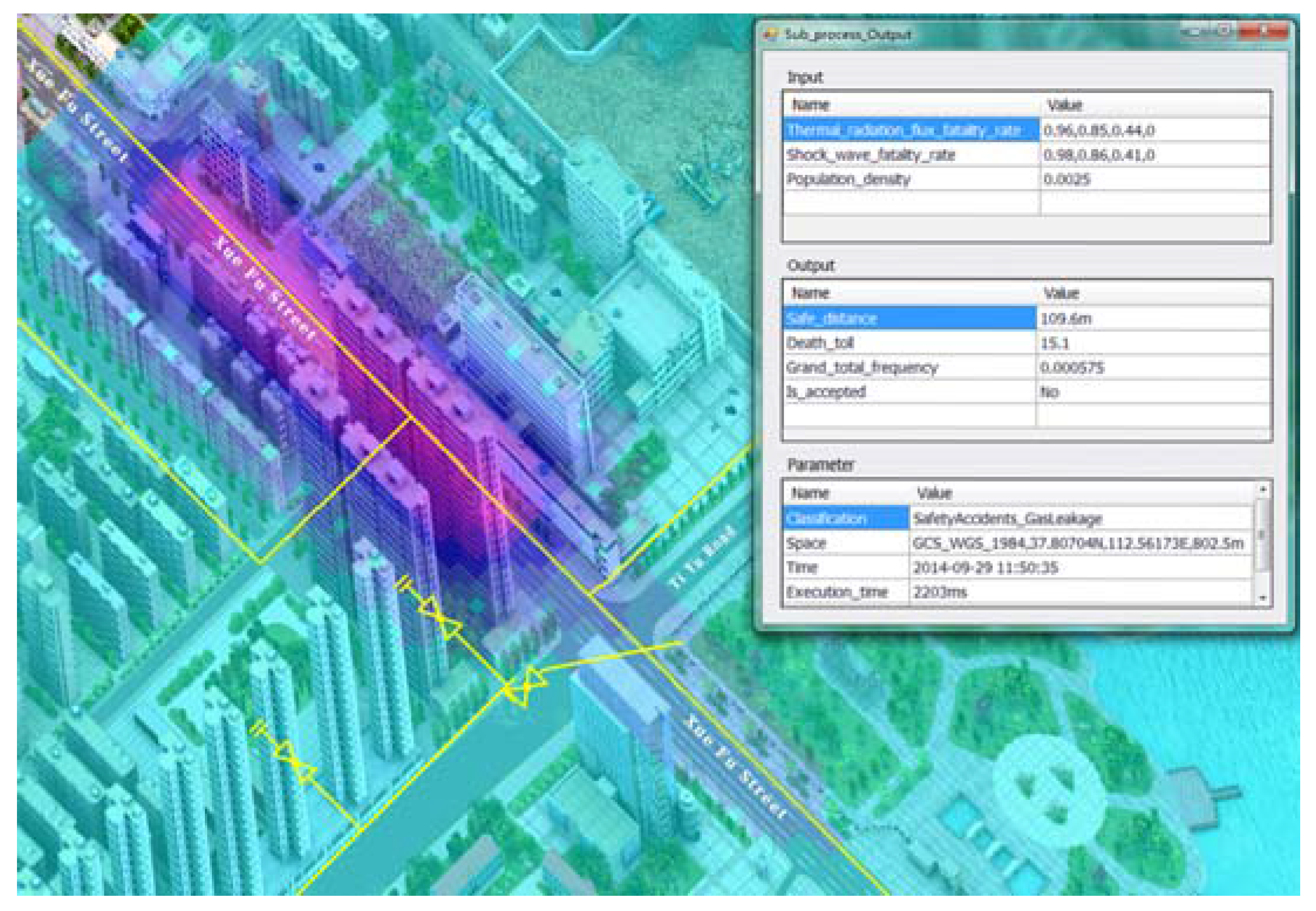

4.2.2. RAP Execution

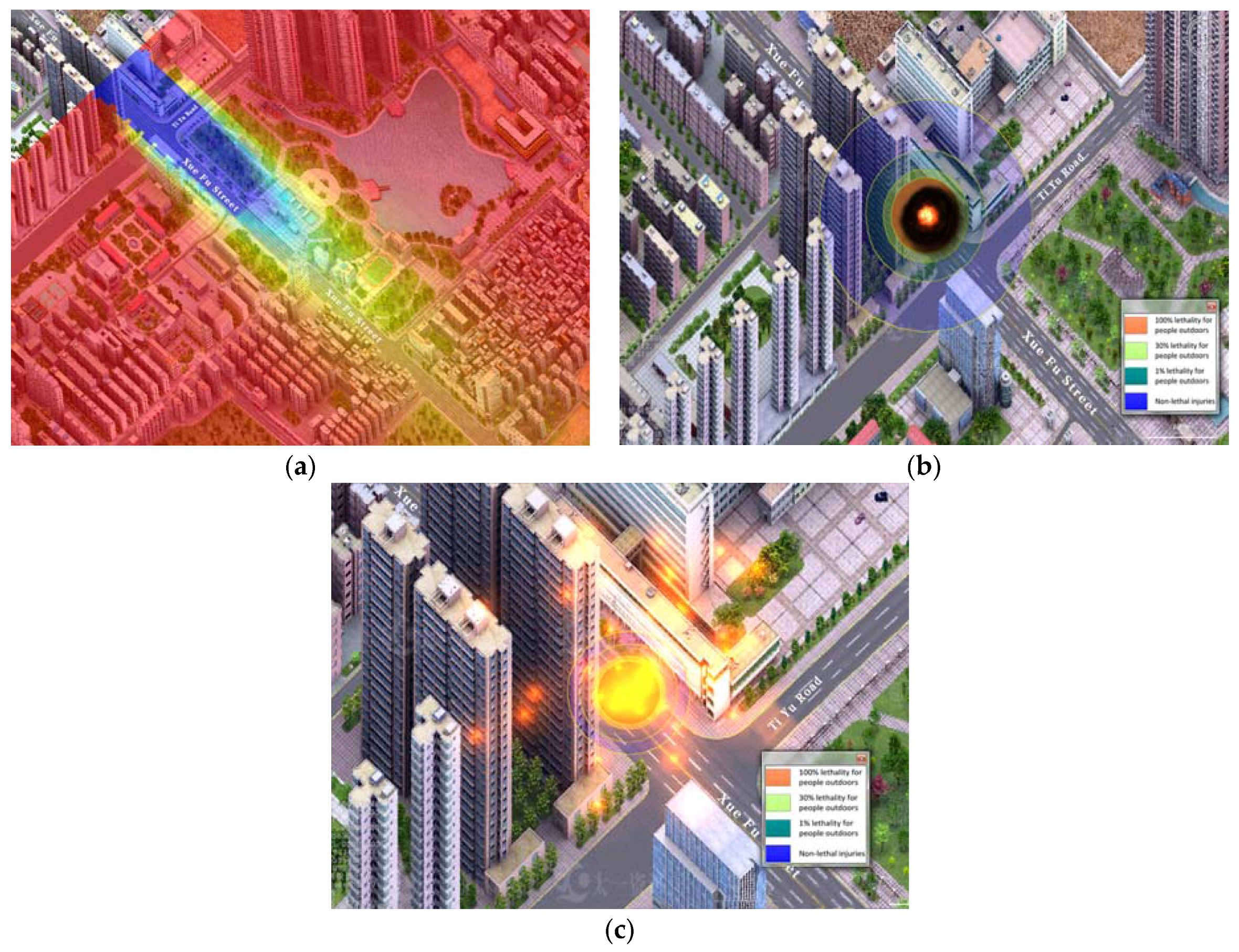

4.2.3. RAP Visualization

5. Discussion

5.1. Risk Assessment Process Based on Sensor Web Environment

5.2. Risk Assessment Process Chains for Comprehensive Integration of Urban Information Resources

5.3. Expandability of the Risk Assessment Process

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| UHE | Urban Hazard Events |

| RAP | Risk Assessment Process |

| MOF | Meta Object Facility |

| OGC | Open Geospatial Consortium |

| SOS | Sensor Observation Service |

| WPS | Web Processing Service |

| WFS | Web Feature Service |

| WCS | Web Coverage Service |

| CSW | Catalogue Services for Web |

| WMS | Web Map Service |

| IEM | Integrated Environmental Modeling |

| SDI | Spatial Data Infrastructure |

| MaaS | Model as a Service |

| SensorML | Sensor Model Language |

| RAPM | Risk Assessment Process Management |

References

- Gowland, R. The accidental risk assessment methodology for industries (ARAMIS)/layer of protection analysis (LOPA) methodology: A step forward towards convergent practices in risk assessment. J. Hazard. Mater. 2006, 130, 307–310. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Du, W.; Song, F.; Chen, Z. FLCNDEMF: An Event Metamodel for Flood Process Information Management under the Sensor Web Environment. Remote Sens. 2015, 7, 7231–7256. [Google Scholar] [CrossRef]

- Purdy, G. ISO 31000: 2009—Setting a new standard for risk management. Risk Anal. 2010, 30, 881–886. [Google Scholar] [CrossRef] [PubMed]

- Luko, S.N. Risk management principles and guidelines. Qual. Eng. 2013, 25, 451–454. [Google Scholar] [CrossRef]

- Aven, T. On the new ISO guide on risk management terminology. Reliab. Eng. Syst. Saf. 2011, 96, 719–726. [Google Scholar] [CrossRef]

- Salvi, O.; Debray, B. A global view on ARAMIS, a risk assessment methodology for industries in the framework of the SEVESO II directive. J. Hazard. Mater. 2006, 130, 187–199. [Google Scholar] [CrossRef] [PubMed]

- Antonioni, G.; Spadoni, G.; Cozzani, V. A methodology for the quantitative risk assessment of major accidents triggered by seismic events. J. Hazard. Mater. 2007, 147, 48–59. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Wang, P.; Lung, W.S.; Guo, L.; Li, M. A GIS-based generic real-time risk assessment framework and decision tools for chemical spills in the river basin. J. Hazard. Mater. 2012, 227, 280–291. [Google Scholar] [CrossRef] [PubMed]

- Calkin, D.E.; Thompson, M.P.; Finney, M.A.; Hyde, K.D. A real-time risk assessment tool supporting wildland fire decisionmaking. J. For. 2011, 109, 274–280. [Google Scholar]

- D’Alessandro, A.; Ubertini, F.; Laflamme, S.; Materazzi, A.L. Towards smart concrete for smart cities: Recent results and future application of strain-sensing nanocomposites. J. Smart Cities 2015, 1, 1–12. [Google Scholar] [CrossRef]

- Komninos, N.; Bratsas, C.; Kakderi, C.; Tsarchopoulos, P. Smart City Ontologies: Improving the effectiveness of smart city applications. J. Smart Cities 2015, 1, 1–16. [Google Scholar] [CrossRef]

- Kakderi, C.; Komninos, N.; Tsarchopoulos, P. Smart cities and cloud computing: Lessons from the STORM CLOUDS experiment. J. Smart Cities 2016, 2, 4–13. [Google Scholar] [CrossRef]

- Chen, J.; Sheng, H.; Li, C.; Xiong, Z. PSTG-based multi-label optimization for multi-target tracking. Comput. Vis. Image Underst. 2016, 144, 217–227. [Google Scholar] [CrossRef]

- Panori, A.; González-Quel, A.; Tavares, M.; Simitopoulos, D.; Arroyo, J. Migration of applications to the Cloud: A user-driven approach. J. Smart Cities 2016, 2, 41–52. [Google Scholar] [CrossRef]

- Delin, K.A.; Jackson, S.P. Sensor web: A new instrument concept. In Proceedings of the SPIE 4284, Functional Integration of Opto-Electro-Mechanical Devices and Systems, San Jose, CA, USA, 15 May 2001; pp. 1–9.

- Botts, M.; Percivall, G.; Reed, C.; Davidson, J. OGC sensor web enablement: Overview and high level architecture. In International Conference on GeoSensor Networks; Springer: Berlin/Heidelberg, Germany, 2006; pp. 175–190. [Google Scholar]

- Chen, N.; Hu, C.; Chen, Y.; Wang, C.; Gong, J. Using SensorML to construct a geoprocessing e-Science workflow model under a sensor web environment. Comput. Geosci. 2012, 47, 119–129. [Google Scholar] [CrossRef]

- Wang, W.; Hu, C.; Chen, N.; Xiao, C.; Wang, C.; Chen, Z. Spatio-temporal enabled urban decision-making process modeling and visualization under the cyber-physical environment. Sci. China Inf. Sci. 2015, 58, 1–17. [Google Scholar] [CrossRef]

- Liu, Y.; Gupta, H.; Springer, E.; Wagener, T. Linking science with environmental decision making: Experiences from an integrated modeling approach to supporting sustainable water resources management. Environ. Model. Softw. 2008, 23, 846–858. [Google Scholar] [CrossRef]

- Aspinall, R.; Pearson, D. Integrated geographical assessment of environmental condition in water catchments: Linking landscape ecology, environmental modelling and GIS. J. Environ. Manag. 2000, 59, 299–319. [Google Scholar] [CrossRef]

- Bastin, L.; Cornford, D.; Jones, R. Managing uncertainty in integrated environmental modelling: The UncertWeb framework. Environ. Model. Softw. 2013, 39, 116–134. [Google Scholar] [CrossRef]

- Wang, X.; Chen, N.; Chen, Z.; Yang, X.; Li, J. Earth observation metadata ontology model for spatiotemporal-spectral semantic-enhanced satellite observation discovery: A case study of soil moisture monitoring. GISci. Remote Sens. 2016, 53, 22–44. [Google Scholar] [CrossRef]

- Geller, G.N.; Turner, W. The model web: A concept for ecological forecasting. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium, Barcelona, Spain, 23–28 July 2007; pp. 2469–2472.

- Nativi, S.; Mazzetti, P.; Geller, G.N. Environmental model access and interoperability: The GEO Model Web initiative. Environ. Model. Softw. 2013, 39, 214–228. [Google Scholar] [CrossRef]

- Dubois, G.; Skøien, J.O.; de Jesus, J.; Peedell, S.; Hartley, A.; Nativi, S.; Santoro, M.; Geller, G. eHabitat: A contribution to the model web for habitat assessments and ecological forecasting. In Proceedings of the 34th International Symposium on Remote Sensing of Environment, Sydney, Australia, 10–15 April 2011; pp. 1–4.

- Chen, N.; Wang, X.; Yang, X. A direct registry service method for sensors and algorithms based on the process model. Comput. Geosci. 2013, 56, 45–55. [Google Scholar] [CrossRef]

- Auynirundronkool, K.; Chen, N.; Peng, C.; Yang, C.; Gong, J.; Silapathong, C. Flood detection and mapping of the Thailand Central plain using RADARSAT and MODIS under a sensor web environment. Int. J. Appl. Earth Obs. 2012, 14, 245–255. [Google Scholar] [CrossRef]

- Chen, N.; Hu, C. A Sharable and interoperable meta-model for atmospheric satellite sensors and observations. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2012, 5, 1519–1530. [Google Scholar] [CrossRef]

- Atkinson, C.; Kuhne, T. Model-driven development: A metamodeling foundation. IEEE Softw. 2003, 20, 36–41. [Google Scholar] [CrossRef]

- Jo, Y.D.; Crowl, D.A. Individual risk analysis of high-pressure natural gas pipelines. J. Loss Prev. Proc. 2008, 21, 589–595. [Google Scholar] [CrossRef]

- Si, H.; Ji, H.; Zeng, X. Quantitative risk assessment model of hazardous chemicals leakage and application. Saf. Sci. 2012, 50, 1452–1461. [Google Scholar] [CrossRef]

- Ma, L.; Li, Y.; Liang, L.; Li, M.; Cheng, L. A novel method of quantitative risk assessment based on grid difference of pipeline sections. Saf. Sci. 2013, 59, 219–226. [Google Scholar] [CrossRef]

- Dong, Y.; Gao, H.; Zhou, J.; Feng, Y. Evaluation of gas release rate through holes in pipelines. J. Loss Prev. Proc. 2002, 15, 423–428. [Google Scholar]

- Lines, I.G.; Deaves, D.M.; Atkins, W.S. Practical modelling of gas dispersion in low wind speed conditions, for application in risk assessment. J. Hazard. Mater. 1997, 54, 201–226. [Google Scholar] [CrossRef]

- Ma, L.; Cheng, L.; Li, M. Quantitative risk analysis of urban natural gas pipeline networks using geographical information systems. J. Loss Prev. Proc. 2013, 26, 1183–1192. [Google Scholar] [CrossRef]

- Jo, Y.D.; Ahn, B.J. A method of quantitative risk assessment for transmission pipeline carrying natural gas. J. Hazard. Mater. 2005, 123, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Jonkman, S.N.; van Gelder, P.H.; Vrijling, J.K. An overview of quantitative risk measures for loss of life and economic damage. J. Hazard. Mater. 2003, 99, 1–30. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Hu, C.; Chen, N.; Xiao, C.; Jia, S. Spatio-Temporal Risk Assessment Process Modeling for Urban Hazard Events in Sensor Web Environment. ISPRS Int. J. Geo-Inf. 2016, 5, 203. https://doi.org/10.3390/ijgi5110203

Wang W, Hu C, Chen N, Xiao C, Jia S. Spatio-Temporal Risk Assessment Process Modeling for Urban Hazard Events in Sensor Web Environment. ISPRS International Journal of Geo-Information. 2016; 5(11):203. https://doi.org/10.3390/ijgi5110203

Chicago/Turabian StyleWang, Wei, Chuanbo Hu, Nengcheng Chen, Changjiang Xiao, and Shan Jia. 2016. "Spatio-Temporal Risk Assessment Process Modeling for Urban Hazard Events in Sensor Web Environment" ISPRS International Journal of Geo-Information 5, no. 11: 203. https://doi.org/10.3390/ijgi5110203