Embedded Fuzzy Logic Controller and Wireless Communication for Home Energy Management Systems

Abstract

1. Introduction

2. Proposed System

2.1. Architecture of Electrical System

- Non-shiftable loads: lighting and refrigerator;

- Time shiftable loads: washing machine and iron;

- Power shiftable load: fan,

- Non-essential load: TV.

2.2. Fuzzy Logic Controller (FLC)

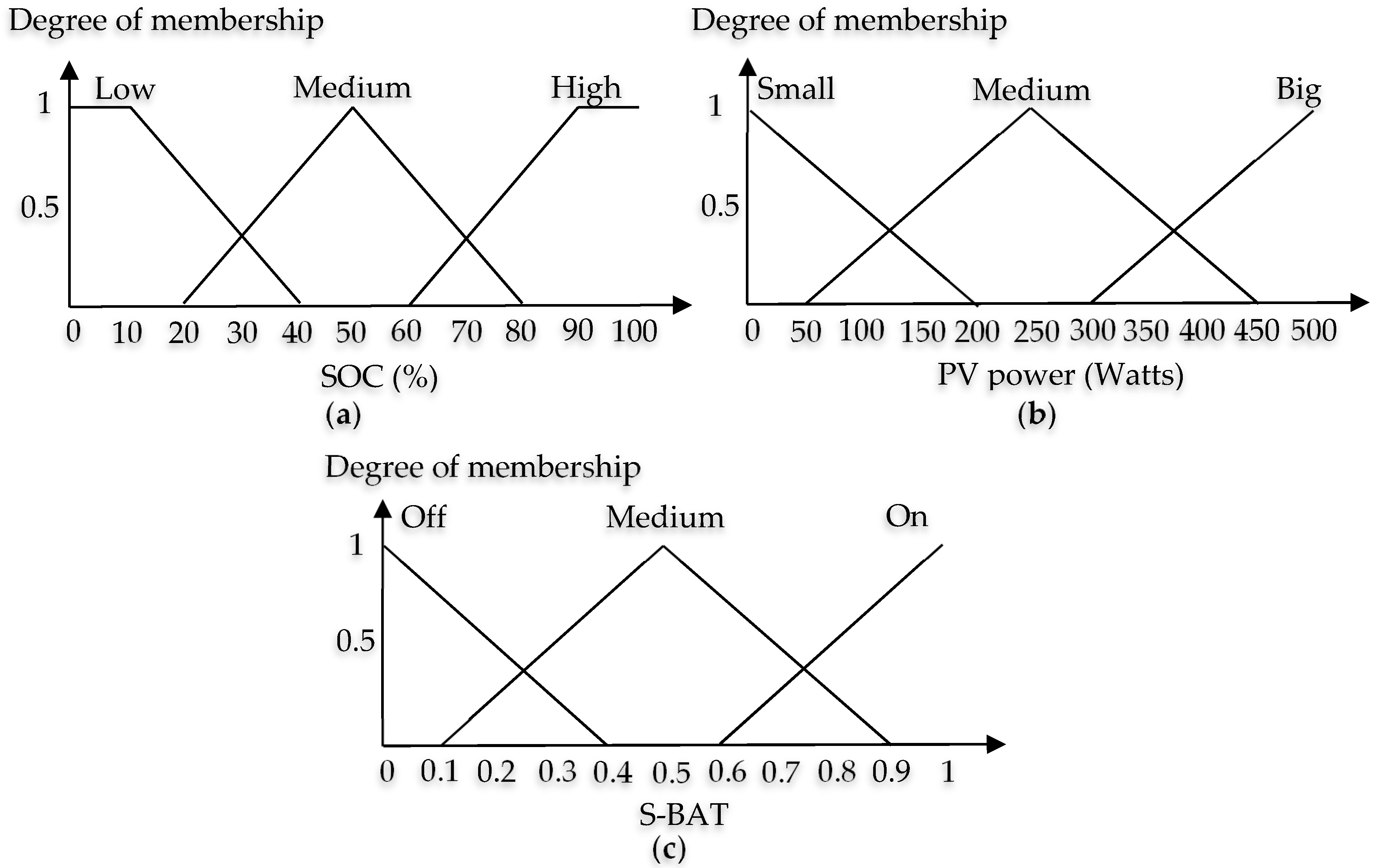

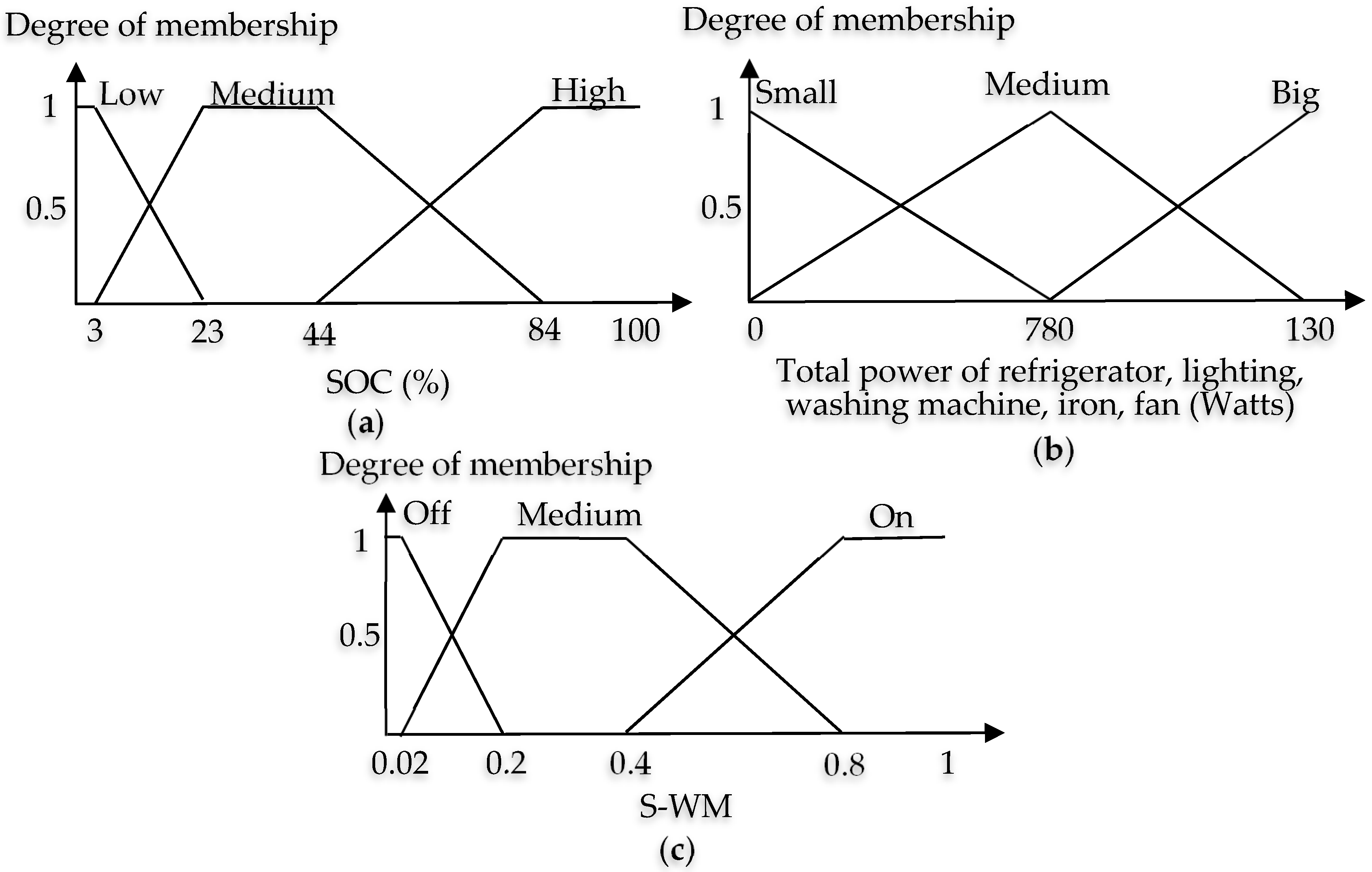

2.2.1. Fuzzy Membership Functions

2.2.2. Fuzzy Rules

- IF PV power is Small AND SOC is Low THEN S-BAT is Off.This means that when the energy from PV is small and the battery is empty (the capacity is low), then there is a high probability that the power switch will be off.

- IF PV power is Small AND SOC is High THEN S-BAT is On.This means that even though the energy from PV is small, if the battery is full (the capacity if high), then there is a high probability that the power switch will be on.

- IF PV power is Big AND SOC is High THEN S-BAT is On.

- IF total load power is Small AND SOC is Low THEN S-WM is Off.This means that when the total load power is small and the battery is empty (the capacity is low), then there is a high probability that the power switch will be off.

- IF total load power is Big AND SOC is Low THEN S-WM is Off.This means that even though the battery is full, since total load power is big, it is better to switch off the load; thus, there is a low probability that the power switch will be on.

- IF total load power is Small AND SOC is High THEN S-WM is On.This means that when the battery is full and total load power is small, the load will be switched on.

2.3. Tuning of Fuzzy Membership Function Using Genetic Algorithm

- Initialize the GA;

- Model the proposed FLC with Load Simulink;

- Encode the membership functions into the GA chromosomes;

- Run the GA;

- Decode the GA chromosomes;

- Run the Simulink model of the proposed FLC;

- Calculate the fitness function;

- Repeat for N-generations.

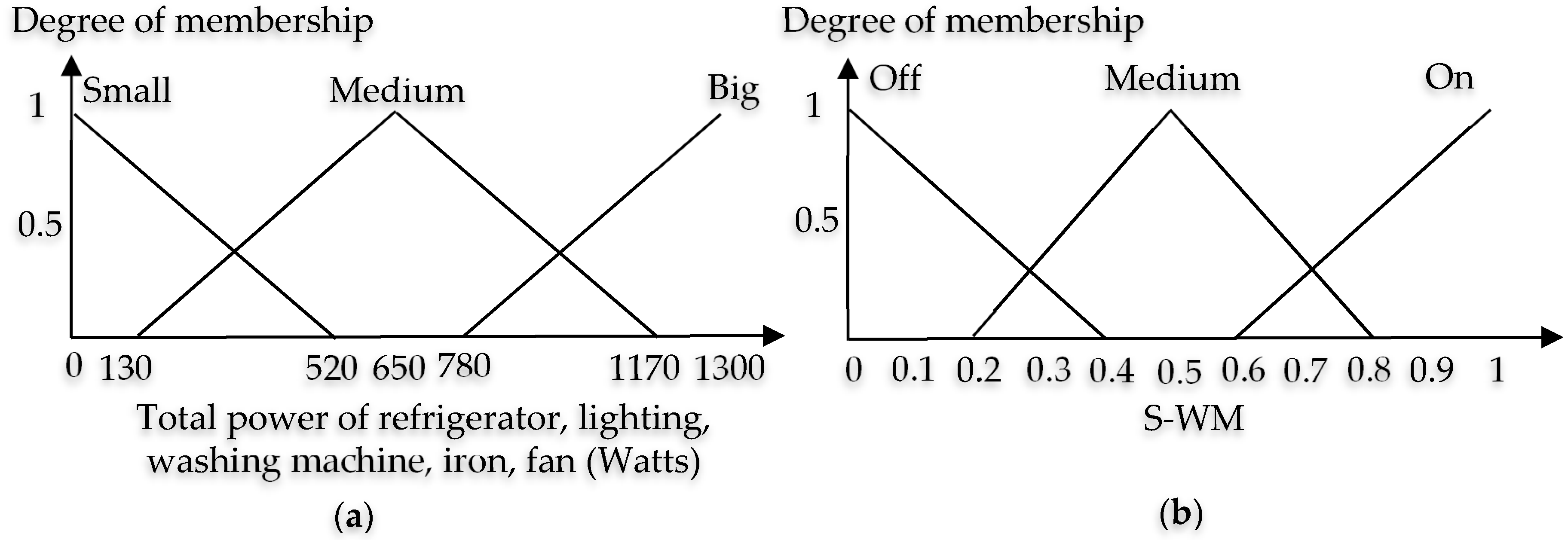

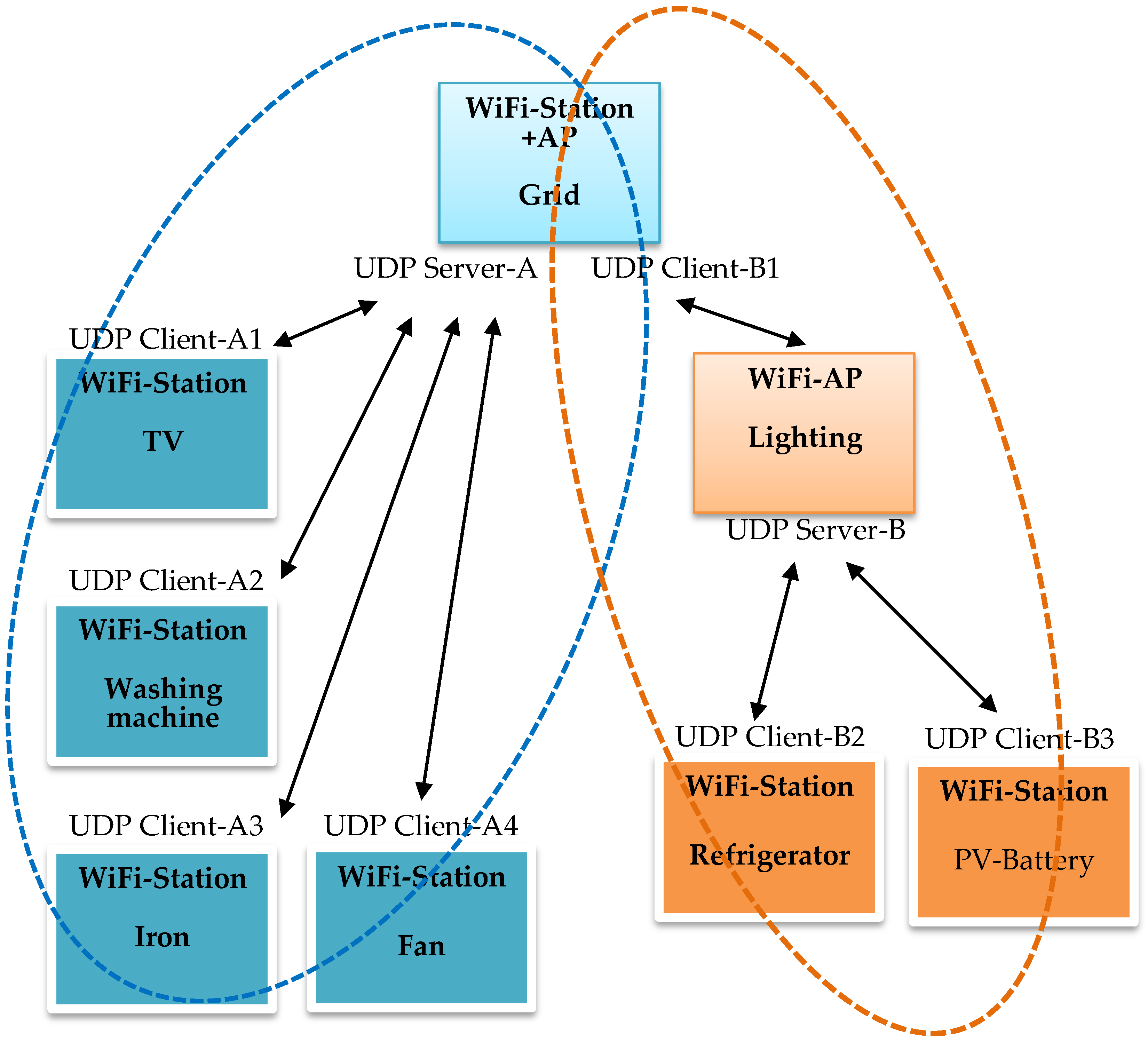

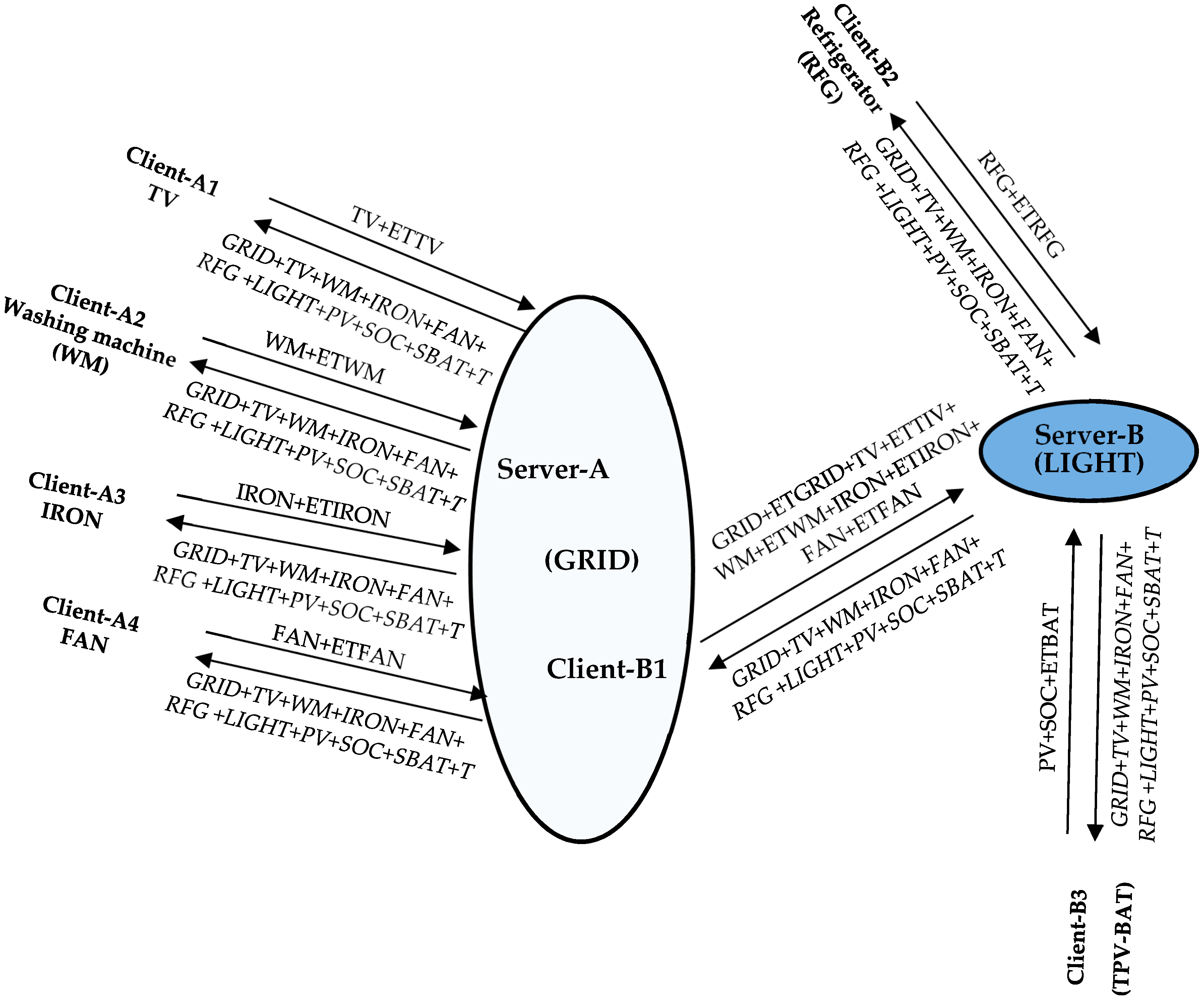

2.4. Wireless Communication Configuration

3. Experimental Results and Discussion

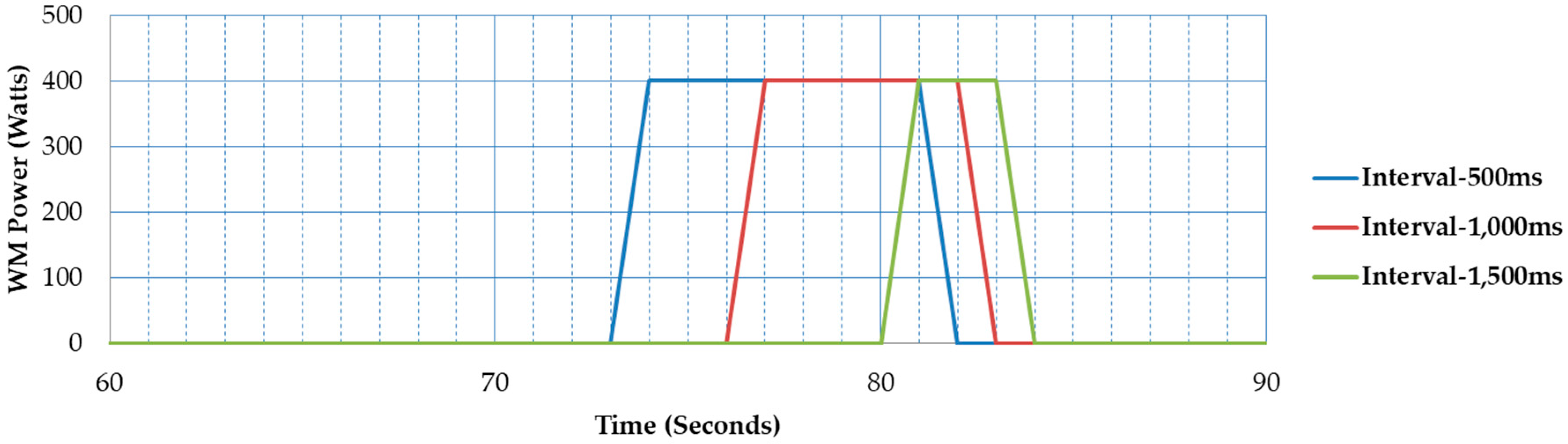

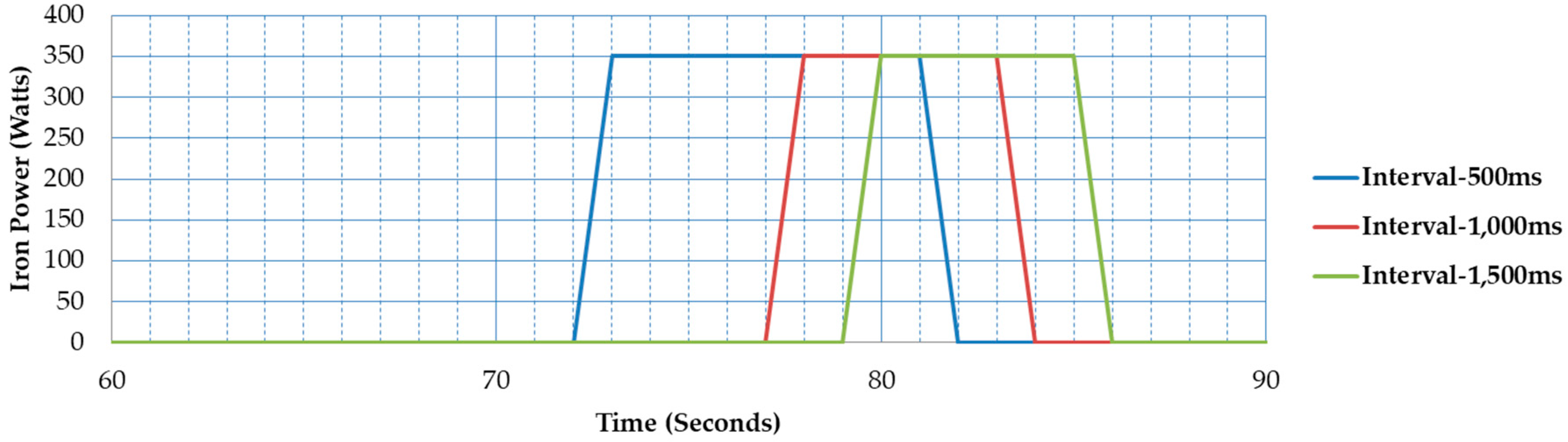

3.1. Execution Time and Data Transmission Time Interval

- Data communication only: The lighting (LIGHT), grid (GRID), and refrigerator (RFG) modules.

- Data communication and FLC: The washing machine (WM), the iron (IRON), the TV (TV), the fan (FAN), and PV-Battery system (PV-BAT) modules.

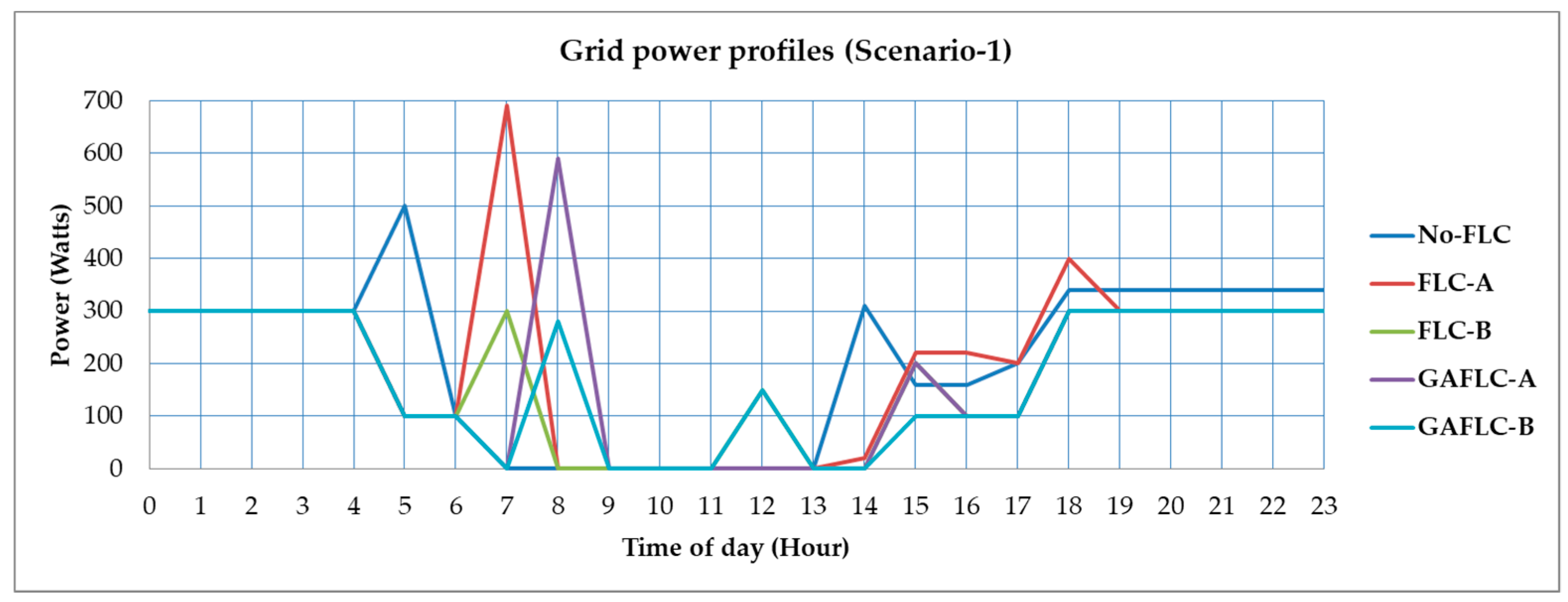

3.2. FLC-Based HEMS Effectiveness

- Number of generations = 10

- Population size = 30

- Chromosome size = 42 bits

- Crossover rate = 0.7

- Mutation rate = 0.001

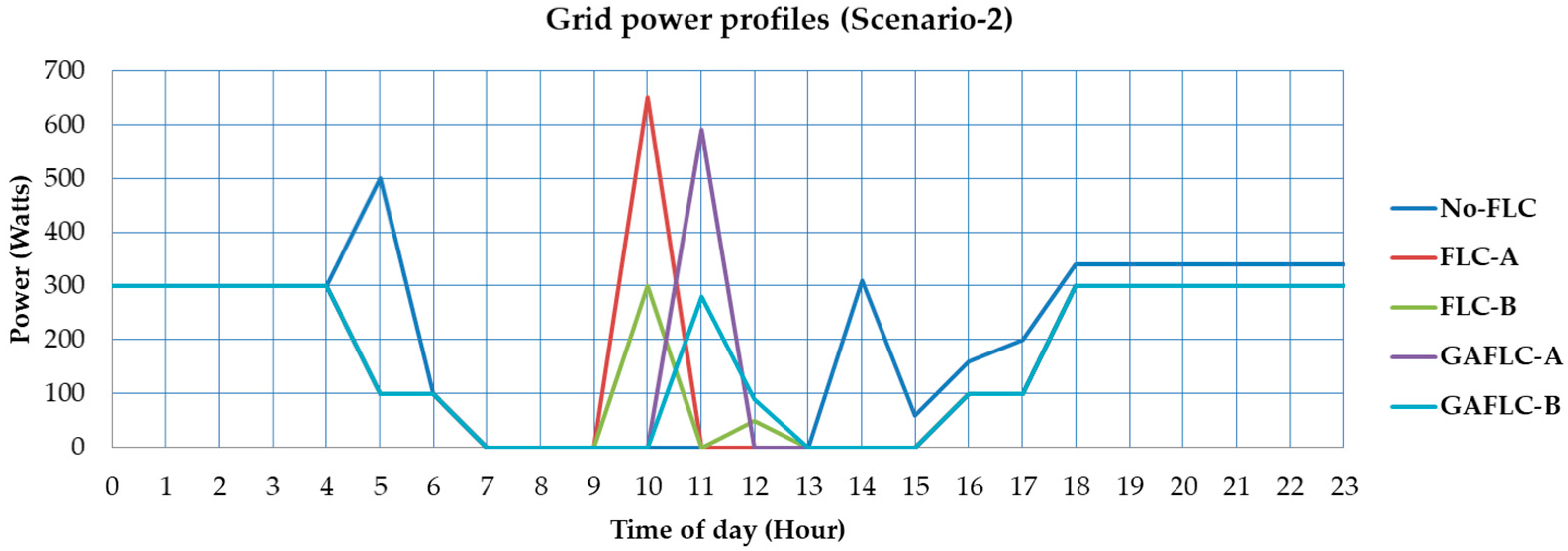

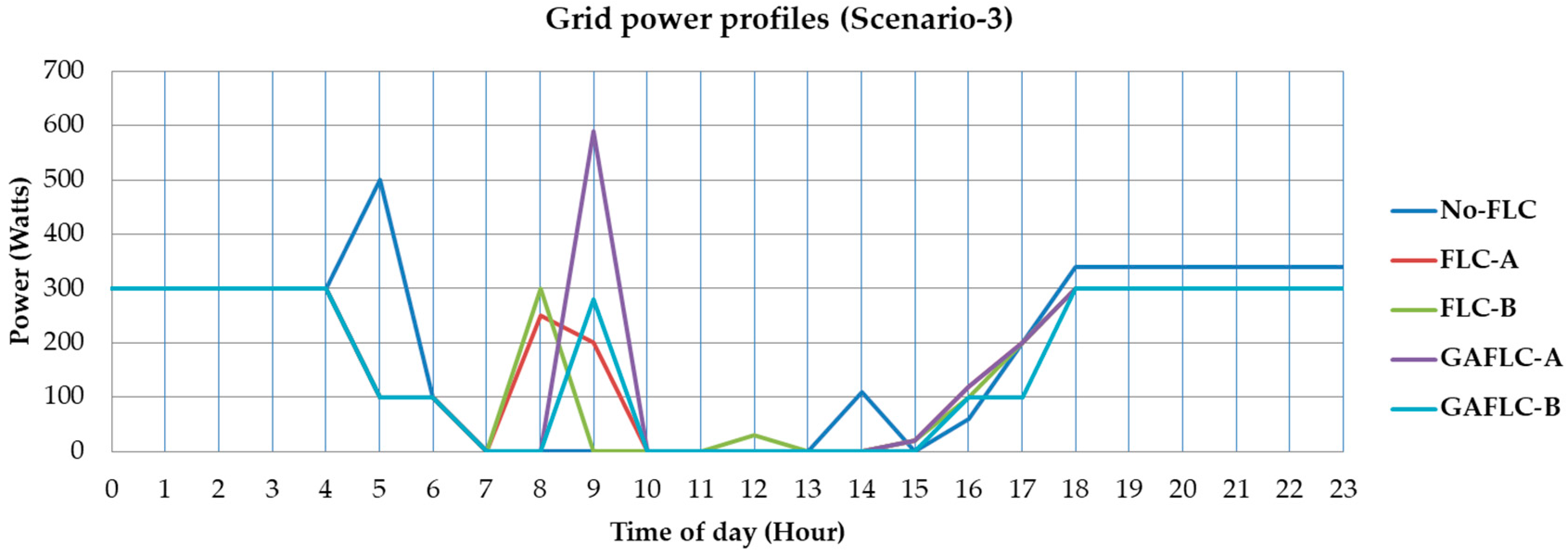

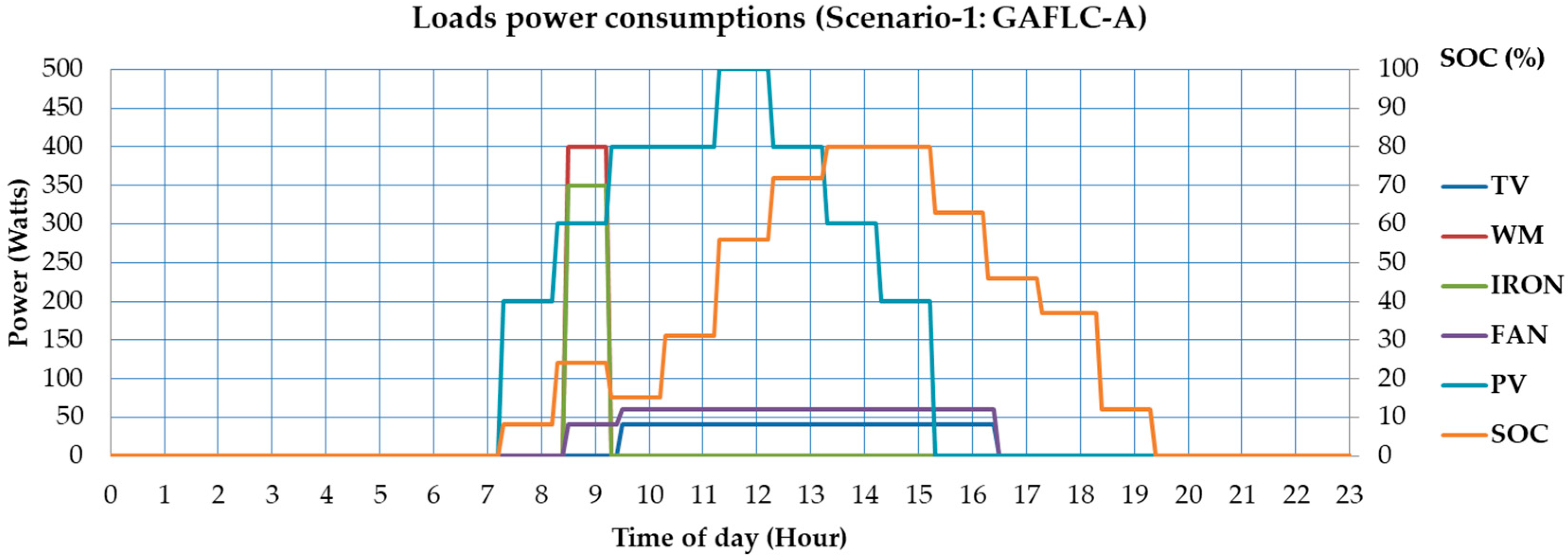

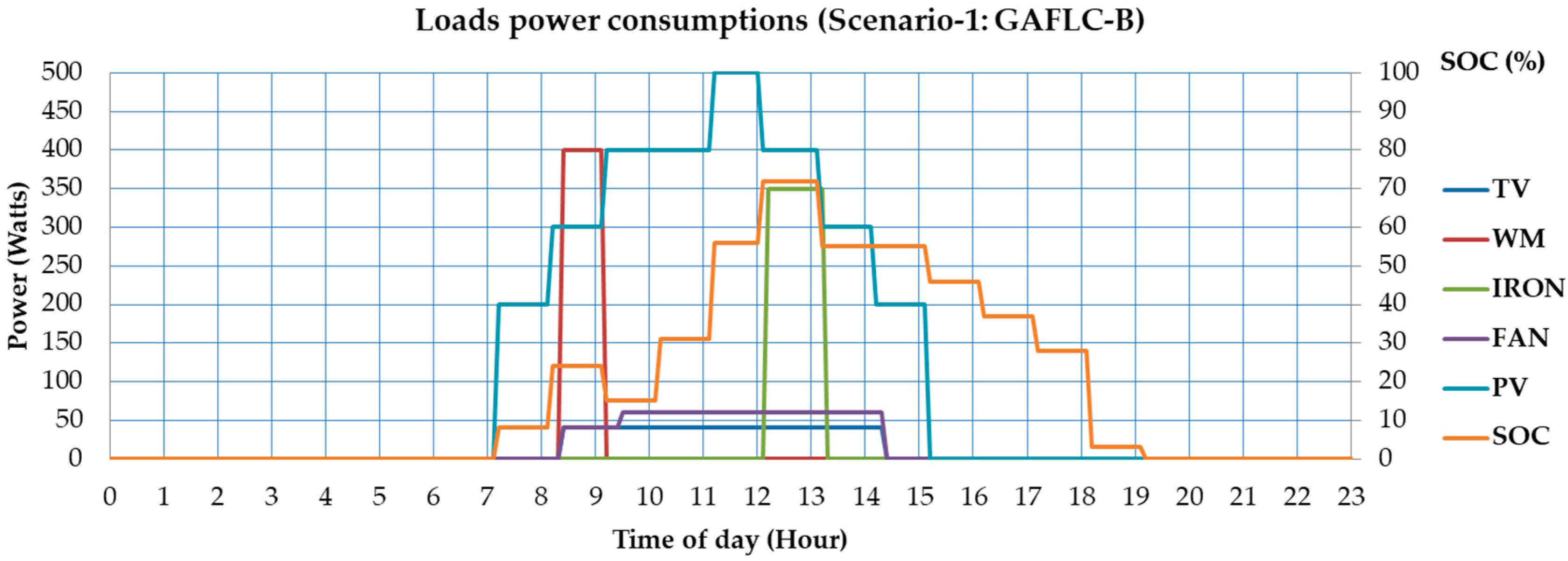

- The electricity costs of both the FLC method and the GAFLC method were lower than the No-FLC method. The average cost reduction of the four scenarios was from 3.865% to 12.493%. By examining Figure 13, it is interesting to analyse when the peak power levels occurred (i.e., when the WM and/or the IRON was switched on). In the No-FLC, they occurred at 05:00 h (the WM was switched on) and 14:00 h (the IRON was switched on). The total power drawn from the grid was 500 + 300 = 800 Watts. In FLC-A, this occurred at 7:00 h, when the total power drawn from the grid was 690 Watt. In FLC-B, this occurred at 7:00 h and 12:00 h, when the total power drawn from the grid was 300 + 150 = 450 Watt. In GAFLC-A, this occurred at 8:00 h, when the total power drawn from the grid was 590 Watt. In the GAFLC-B, this occurred at 8:00 h and 12:00 h, when the total power drawn from the grid was 280 + 150 = 430 Watts. Similar conditions also occurred in Figure 14, Figure 15 and Figure 16. Since the peak power levels of the FLC and the GAFLC methods were lower than that of the No-FLC, it is clear that the FLC and GAFLC methods reduce the electricity cost.It is noted here that in Scenario 4, the electricity cost of FLC-A was slightly higher than that of No-FLC. However, the GAFLC-A in Scenario-4 was able to reduce the electricity cost, even though only slightly. This strange result may have been caused by improper membership functions which were determined manually).

- In both the FLC and GAFLC methods, the electricity cost of Case B was lower than that of Case A. Thus, by shifting the operation starting time of the iron to the afternoon, the excessive power from PV was consumed by the iron, thereby reducing the electricity usage from the grid. This is shown by Figure 13 and Figure 19, where the GAFLC-A operates the washing machine and the iron at 08:00 h and obtains 590 Watt of power from the grid, while Figure 13 and Figure 20 show that the GAFLC-B operates the washing machine at 08:00 h and the iron at 12:00 h. Thus, it obtains 280 + 150 = 430 Watts of power from the grid. Similar situations occurred in FLC-A and FLC-B. The average cost reduction increased from 3.875% (Case A) to 10.933% (Case B) in the FLC-method and from 6.189% (Case A) to 12.493% (Case B) in the GAFLC method.

- In both Cases A and B, the average cost reduction of the GAFLC method was lower than that of the FLC method. In Case A, the average cost reduction increased from 3.875% (FLC method) to 6.180% (GAFLC method), while in Case B, the average cost reduction increased from 10.933% (FLC method) to 12.493% (GAFLC method). This shows that the automated tuning of the membership functions using the GA effectively improved the performance of FLC, i.e., increased the cost reduction.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shareef, H.; Ahmed, M.S.; Mohamed, A.; Al Hassan, E. Review on Home Energy Management System Considering Demand Responses, Smart Technologies, and Intelligent Controllers. IEEE Access 2018, 6, 24498–24509. [Google Scholar] [CrossRef]

- Batchu, R.; Pindoriya, N.M. Residential Demand Response Algorithms: State-of-the-Art, Key Issues and Challenges. In Wireless and Satellite Systems; Pillai, P., Hu, Y., Otung, I., Giambene, G., Eds.; Springer: Cham, Switzerland, 2015; Volume 154, pp. 18–32. ISBN 978-3-319-25479-1. [Google Scholar]

- Asare-Bediako, B.; Kling, W.L.; Ribeiro, P.F. Home energy management systems: Evolution, trends and frameworks. In Proceedings of the 2012 47th International Universities Power Engineering Conference (UPEC), London, UK, 4–7 September 2012; pp. 1–5. [Google Scholar]

- Pilloni, V.; Floris, A.; Meloni, A.; Atzori, L. Smart Home Energy Management Including Renewable Sources: A QoE-Driven Approach. IEEE Trans. Smart Grid 2018, 9, 2006–2018. [Google Scholar] [CrossRef]

- Arikiez, M.; Alotaibi, F.; Rehan, S.; Rohouma, W. Minimizing the electricity cost of coordinating houses on microgrids. In Proceedings of the 2016 IEEE PES Innovative Smart Grid Technologies Conference Europe (ISGT-Europe), Ljubljana, Slovenia, 9–12 October 2016; pp. 1–6. [Google Scholar]

- Anvari-Moghaddam, A.; Monsef, H.; Rahimi-Kian, A. Optimal Smart Home Energy Management Considering Energy Saving and a Comfortable Lifestyle. IEEE Trans. Smart Grid 2015, 6, 324–332. [Google Scholar] [CrossRef]

- Baig, F.; Mahmood, A.; Javaid, N.; Razzaq, S.; Khan, N.; Saleem, Z. Smart Home Energy Management System for Monitoring and Scheduling of Home Appliances Using Zigbee. J. Basic App. Sci. Res. 2013, 3, 880–891. [Google Scholar]

- Pipattanasomporn, M.; Kuzlu, M.; Rahman, S. An Algorithm for Intelligent Home Energy Management and Demand Response Analysis. IEEE Trans. Smart Grid 2012, 3, 2166–2173. [Google Scholar] [CrossRef]

- Kuzlu, M.; Pipattanasomporn, M.; Rahman, S. Hardware Demonstration of a Home Energy Management System for Demand Response Applications. IEEE Trans. Smart Grid 2012, 3, 1704–1711. [Google Scholar] [CrossRef]

- Cagnetti, M.; Leccese, F.; Proietti, A. Energy saving project for heating system with ZigBee wireless control network. In Proceedings of the 2012 11th International Conference on Environment and Electrical Engineering, Venice, Italy, 18–25 May 2012; pp. 580–585. [Google Scholar]

- Soetedjo, A.; Lomi, A.; Nakhoda, Y.I. Implementation of optimization technique on the embedded systems and wireless sensor networks for home energy management in smart grid. In Proceedings of the 2016 IEEE Conference on Wireless Sensors (ICWiSE), Langkawi, Malaysia, 10–12 October 2016; pp. 26–31. [Google Scholar]

- Byun, J.; Hong, I.; Hwang, Z.; Park, S. An Intelligent Cloud-based Home Energy Management System Based on Machine to Machine Communication in Future Energy Environments. In Proceedings of the Eight International Conference on Systems, Seville, Spain, 27 January–1 February 2013; pp. 40–45. [Google Scholar]

- Collotta, M.; Pau, G. A Solution Based on Bluetooth Low Energy for Smart Home Energy Management. Energies 2015, 8, 11916–11938. [Google Scholar] [CrossRef]

- Chekired, F.; Mahrane, A.; Samara, Z.; Chikh, M.; Guenounou, A.; Meflah, A. Fuzzy logic energy management for a photovoltaic solar home. Energy Procedia 2017, 134, 723–730. [Google Scholar] [CrossRef]

- Ruban, A.A.M.; Selvakumar, K.; Hemavathi, N.; Rajeswari, N. Hardware Realization of Two Level Fuzzy Based Energy Management System Using Wireless Sensor Network. Int. J. Latest Eng. Man Res. 2017, 2, 46–54. [Google Scholar]

- Yao, L.; Lai, C.; Lim, W.H. Home Energy Management System Based on Photovoltaic System. In Proceedings of the 2015 IEEE International Conference on Data Science and Data Intensive Systems, Sydney, NSW, Autralia, 11–13 December 2015; pp. 644–650. [Google Scholar]

- Chehri, A.; Chehri, H.T. FEMAN: Fuzzy-Based Energy Management System for Green Houses Using Hybrid Grid Solar Power. J. Renew. Energy 2013, 2013. [Google Scholar] [CrossRef]

- Bissey, S.; Jacques, S.; Le Bunetel, J.-C. The Fuzzy Logic Method to Efficiently Optimize Electricity Consumption in Individual Housing. Energies 2017, 10, 1701. [Google Scholar] [CrossRef]

- Zhou, S.; Wu, Z.; Li, J.; Zhang, X.P. Real-time Energy Control Approach for Smart Home Energy Management System. Electr. Power Compon. Syst. 2014, 42, 315–326. [Google Scholar] [CrossRef]

- Ameur, K.; Hadjaissa, A.; Ait Cheikh, M.S.; Cheknane, A.; Essounbouli, N. Fuzzy energy management of hybrid renewable power system with the aim to extend component lifetime. Int. J. Energy Res. 2017, 41, 1867–1879. [Google Scholar] [CrossRef]

- Soetedjo, A.; Nakhoda, Y.I.; Saleh, C. Simulation of Fuzzy Logic Based Energy Management for the Home with Grid Connected PV-Battery System. In Proceedings of the 2018 3rd Asia-Pacific Conference on Intelligent Robot Systems (ACIRS 2018), Singapore, 21–23 July 2018. In press. [Google Scholar]

- Yao, L.; Lim, W.H.; Lai, C. Self-Learning Fuzzy Controller-Based Energy Management for Smart Home. In Proceedings of the 2016 IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Chengdu, China, 15–18 December 2016; pp. 87–93. [Google Scholar]

- Mudhokar, R.R.; Somnatti, U.V. Genetic Tuning of Fuzzy Inference System for Furnace Temperature Controller. Int. J. Comput. Sci. Inf. Technol. 2015, 6, 3496–3500. [Google Scholar]

- Byrne, J.P. GA-Optimization of a Fuzzy Logic Controller. Master’s Thesis, School of Electronic Engineering, Dublin City University, Dublin, Ireland, August 2003. [Google Scholar]

- Mendes, J.; Araujo, R.; Matias, T.; Seco, R.; Belchior, C. Automatic extraction of the fuzzy control system by a hierarchical genetic algorithm. Eng. Appl. Artif. Intell. 2014, 29, 70–78. [Google Scholar] [CrossRef]

- Lu, X.; Liu, M. A fuzzy logic controller tuned with PSO for delta robot trajectory control. In Proceedings of the IECON 2015—41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 004345–004351. [Google Scholar]

- Castillo, O.; Lizarraga, E.; Soria, J.; Melin, P.; Valdez, F. New approach using ant colony optimization with ant set partition for fuzzy control design applied to the ball and beam system. Inf. Sci. 2015, 294, 203–215. [Google Scholar] [CrossRef]

- Chaiyatham, T.; Ngamroo, I. A bee colony optimization based-fuzzy logic-PID control design of electrolyzer for microgrid stabilization. Int. J. Innov. Comput. Inf. Control. 2012, 8, 6049–6066. [Google Scholar]

- An Arduino UNO Compatible WIFI Board Based on ESP8266EX. Available online: https://wiki.wemos.cc/products:d1:d1 (accessed on 1 August 2018).

| Reference | Input Variables | Output Variable (s) | Objective | Hardware/Software Implementation |

|---|---|---|---|---|

| [13] | Scheduled time Consumer feedback | New scheduled time | Reduce peak load | PC, Network simulator (NS-2), Bluetooth |

| [14] | PV power–consumed power State of charge (SOC) of battery | Probability of starting the load | Manage energy from PV | PC, Matlab-Simulink |

| [15] | Generated power SOC of battery Load demand | Amount of power sold to the grid | Maximize the efficiency of power production | PIC microcontroller, Zigbee |

| [16] | Electricity price SOC of battery Load demand | Amount of power purchased from the grid | Manage energy flow from energy resources to loads | Embedded system, C++, Modbus RTU(TCP/IP) |

| [17] | Electricity price Load demand | Signal control to switch on/off the grid and PV | Maximize the use of PV power | Computer simulation |

| [18] | Day, time electricity consumption Inside temperature Outside temperature Predicted temperature. | Short term load consumption | Minimize electricity cost | Computer simulation |

| [19] | Electricity price SOC of battery | Battery power | Optimize charging/discharging time | Computer laptop, C#, Matlab, Zigbee, Hardware simulator |

| [20] | PV power–load power SOC battery–desired SOC of battery Hydrogen level–desired hydrogen level of fuel cell | PV control Battery control Fuel cell control | Control energy flow from hybrid energy resources | Computer simulation |

| [21] | SOC of battery Load demand | Probability to start the load | Minimize electricity cost | PC, Matlab-Simulink |

| [22] | Net load demand SOC of battery Electricity price | Grid power | Minimize electricity cost | Linux embedded system |

| SOC | ||||

|---|---|---|---|---|

| Low | Medium | High | ||

| PV power | Small | Off | Medium | On |

| Medium | Medium | Medium | On | |

| Big | Medium | On | On | |

| SOC | ||||

|---|---|---|---|---|

| Low | Medium | High | ||

| Total power of refrigerator, lighting, washing machine, iron, fan | Small | Off | Medium | On |

| Medium | Off | Medium | Medium | |

| Big | Off | Off | Medium | |

| Embedded Module | Execution Time (ms) | Remark |

|---|---|---|

| GRID | 26.98 | Data communication (server + client) |

| TV | 19.50 | FLC + Data communication (client) |

| WM | 19.66 | FLC + Data communication (client) |

| IRON | 19.35 | FLC + Data communication (client) |

| FAN | 19.66 | FLC + Data communication (client) |

| RFG | 6.40 | Data communication (client) |

| LIGHT | 0.14 | Data communication (server) |

| PV-BAT | 20.09 | FLC + Data communication (client) |

| Time (h) | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|

| 00:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 01:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 02:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 03:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 04:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 05:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 06:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 07:00 | 200 Watts | 100 Watts | 100 Watts | 300 Watts |

| 08:00 | 300 Watts | 100 Watts | 200 Watts | 400 Watts |

| 09:00 | 400 Watts | 100 Watts | 300 Watts | 500 Watts |

| 10:00 | 400 Watts | 200 Watts | 300 Watts | 500 Watts |

| 11:00 | 500 Watts | 300 Watts | 400 Watts | 500 Watts |

| 12:00 | 400 Watts | 400 Watts | 500 Watts | 500 Watts |

| 13:00 | 300 Watts | 300 Watts | 500 Watts | 500 Watts |

| 14:00 | 200 Watts | 200 Watts | 400 Watts | 500 Watts |

| 15:00 | 0 Watts | 100 Watts | 200 Watts | 400 Watts |

| 16:00 | 0 Watts | 0 Watts | 100 Watts | 300 Watts |

| 17:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 18:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 19:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 20:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 21:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 22:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| 23:00 | 0 Watts | 0 Watts | 0 Watts | 0 Watts |

| Load Name | Operation Time (h) | Operation Duration | Consumption Power |

|---|---|---|---|

| Refrigerator (RFG) | 00:00–24:00 | 24 h | 100 Watts |

| Lighting (LIGHT) | 18:00–05:00 | 11 h | 200 Watts |

| Washing machine (WM) | 05:00–21:00 | 1 h | 400 Watts |

| Iron (IRON)–Case A | 05:00–21:00 | 1 h | 350 Watts |

| Iron (IRON)–Case B | 12:00–21:00 | 1 h | 350 Watts |

| Fan (FAN) | 00:00–24:00 | NA | 40, 60, 80 Watts |

| TV (TV) | 00:00–24:00 | NA | 40 Watts |

| Energy Consumption from the Grid per Day (Wh) | Energy Consumption from the Grid per Month (Wh) | Total Cost per Month (IDR) | Cost Reduction (%) | ||

|---|---|---|---|---|---|

| Scenario 1 | No-FLC | 4970 | 149,100 | 218,729.7 | - |

| FLC-A | 4950 | 148,500 | 217,849.5 | 0.40 | |

| FLC-B | 4350 | 130,500 | 191,443.5 | 12.47 | |

| GAFLC-A | 4490 | 134,700 | 197,604.9 | 9.66 | |

| GAFLC-B | 4230 | 126,900 | 186,162.3 | 14.89 | |

| Scenario 2 | No-FLC | 4870 | 146,100 | 214,328.7 | - |

| FLC-A | 4350 | 130,500 | 191,443.5 | 10.68 | |

| FLC-B | 4050 | 121,500 | 178,240.5 | 16.84 | |

| GAFLC-A | 4290 | 128,700 | 188,802.9 | 11.91 | |

| GAFLC-B | 4070 | 122,100 | 179,120.7 | 16.43 | |

| Scenario 3 | No-FLC | 4510 | 135,300 | 198,485.1 | - |

| FLC-A | 4290 | 128,700 | 188,802.9 | 4.88 | |

| FLC-B | 4150 | 124,500 | 182,641.5 | 7.98 | |

| GAFLC-A | 4430 | 132,900 | 194,964.3 | 1.77 | |

| GAFLC-B | 3980 | 119,400 | 175,159.8 | 11.75 | |

| Scenario 4 | No-FLC | 4350 | 130,500 | 191,443.5 | - |

| FLC-A | 4370 | 131,100 | 192,323.7 | −0.46 | |

| FLC-B | 4070 | 122,100 | 179,120.7 | 6.44 | |

| GAFLC-A | 4290 | 128,700 | 188,802.9 | 1.38 | |

| GAFLC-B | 4050 | 121,500 | 178,240.5 | 6.90 |

| Method | Cost Reduction (%) | Average Cost Reduction (%) | |||

|---|---|---|---|---|---|

| Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | ||

| FLC-A | 0.4 | 10.68 | 4.88 | -0.46 | 3.875 |

| FLC-B | 12.47 | 16.84 | 7.98 | 6.44 | 10.933 |

| GAFLC-A | 9.66 | 11.91 | 1.77 | 1.38 | 6.180 |

| GAFLC-B | 14.89 | 16.43 | 11.75 | 6.9 | 12.493 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soetedjo, A.; Nakhoda, Y.I.; Saleh, C. Embedded Fuzzy Logic Controller and Wireless Communication for Home Energy Management Systems. Electronics 2018, 7, 189. https://doi.org/10.3390/electronics7090189

Soetedjo A, Nakhoda YI, Saleh C. Embedded Fuzzy Logic Controller and Wireless Communication for Home Energy Management Systems. Electronics. 2018; 7(9):189. https://doi.org/10.3390/electronics7090189

Chicago/Turabian StyleSoetedjo, Aryuanto, Yusuf Ismail Nakhoda, and Choirul Saleh. 2018. "Embedded Fuzzy Logic Controller and Wireless Communication for Home Energy Management Systems" Electronics 7, no. 9: 189. https://doi.org/10.3390/electronics7090189

APA StyleSoetedjo, A., Nakhoda, Y. I., & Saleh, C. (2018). Embedded Fuzzy Logic Controller and Wireless Communication for Home Energy Management Systems. Electronics, 7(9), 189. https://doi.org/10.3390/electronics7090189