A Raspberry Pi Based Portable Endoscopic 3D Measurement System

Abstract

:1. Introduction

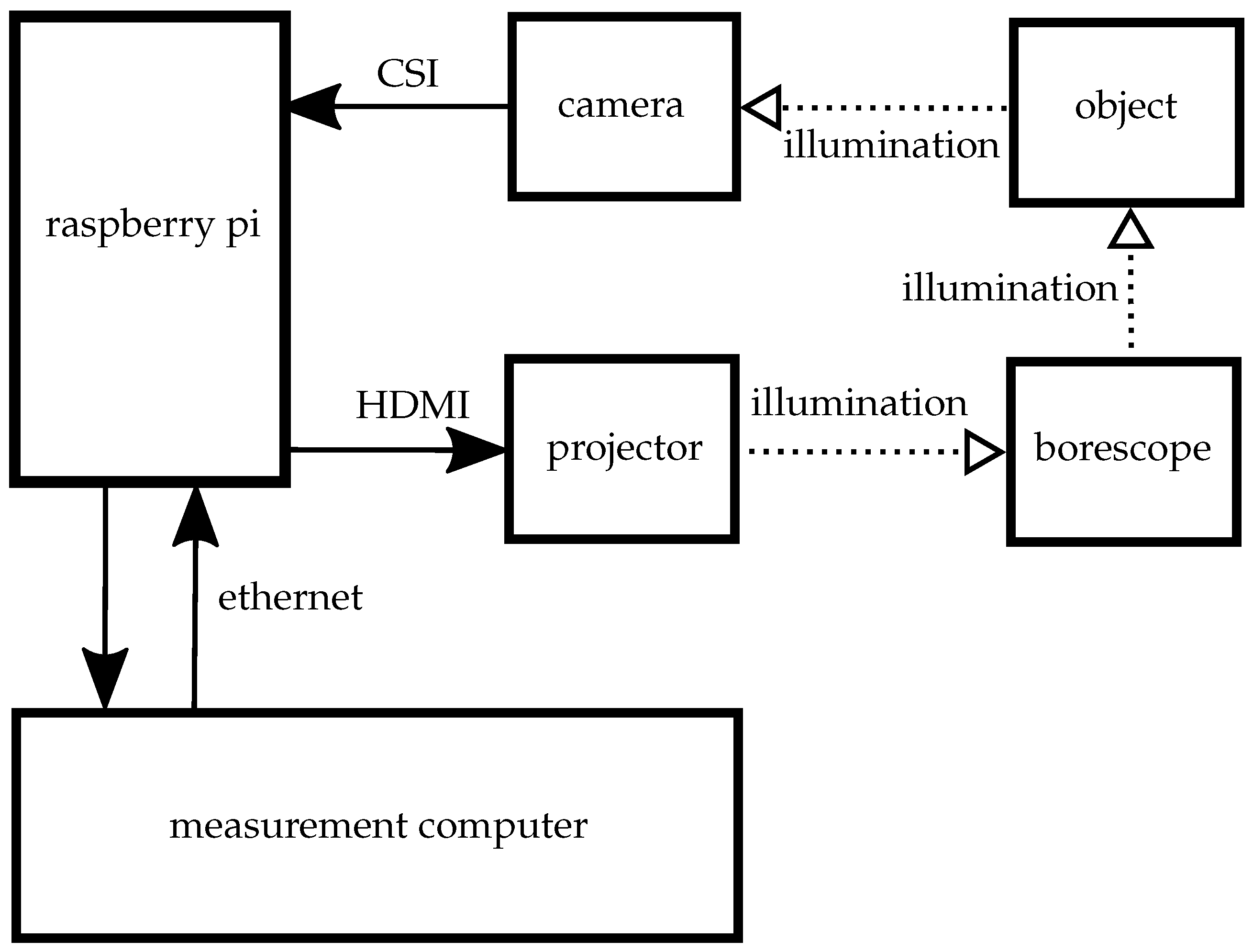

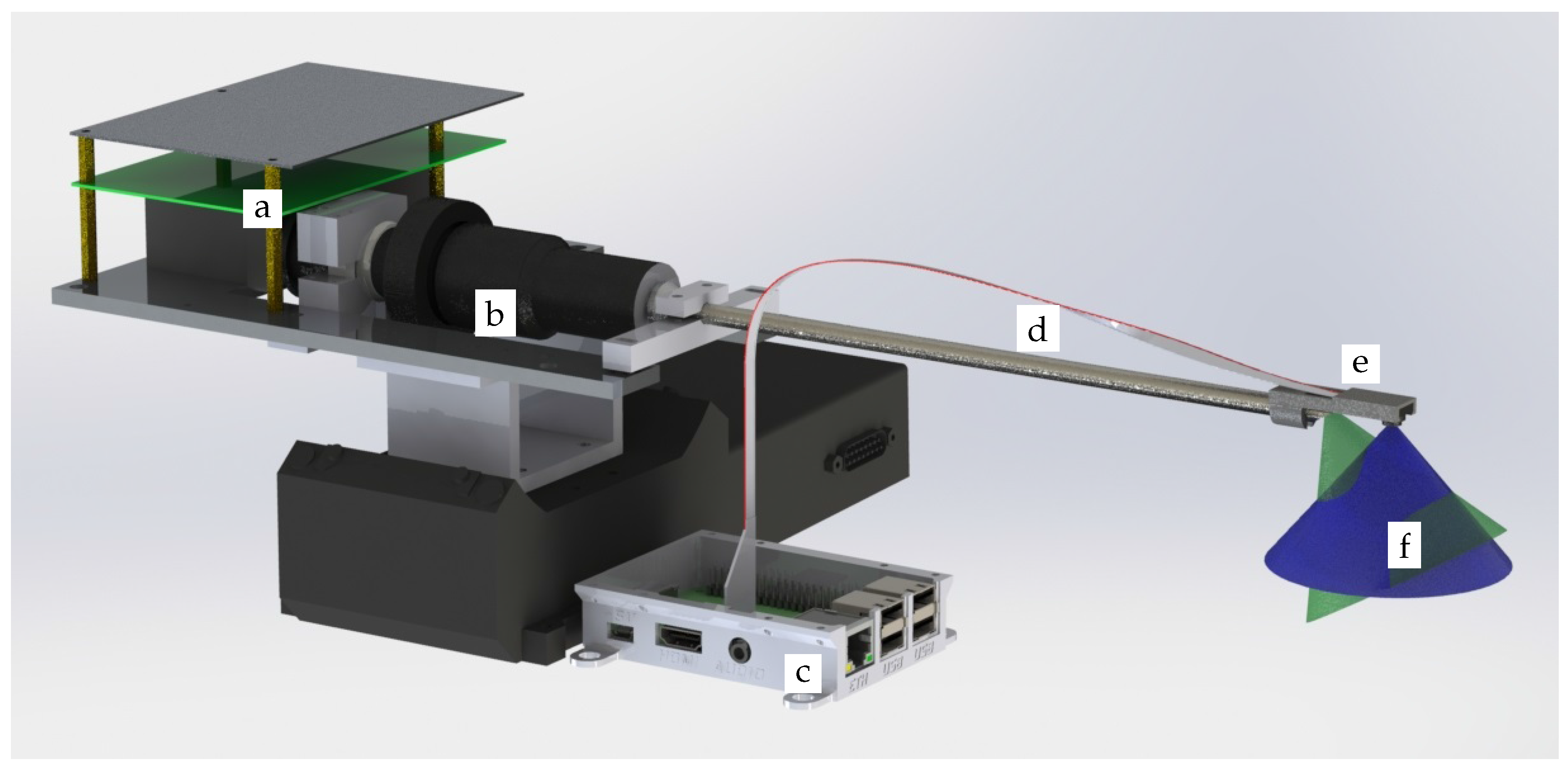

2. The Measurement System

2.1. Image Acquisition

2.2. Calibration

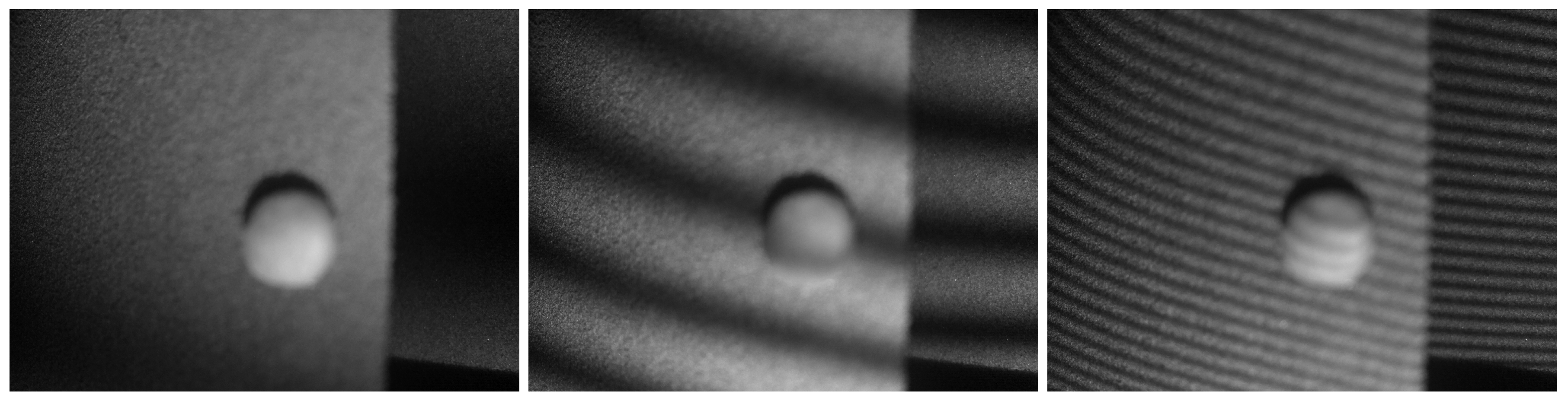

2.3. Pattern Projection and Reconstruction

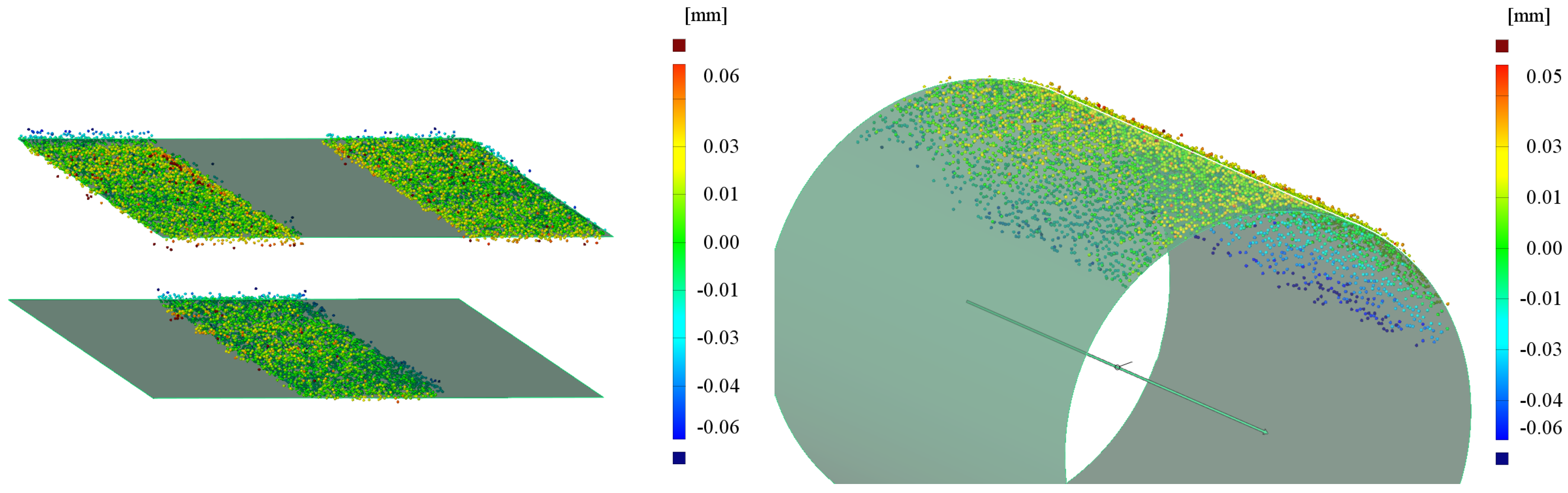

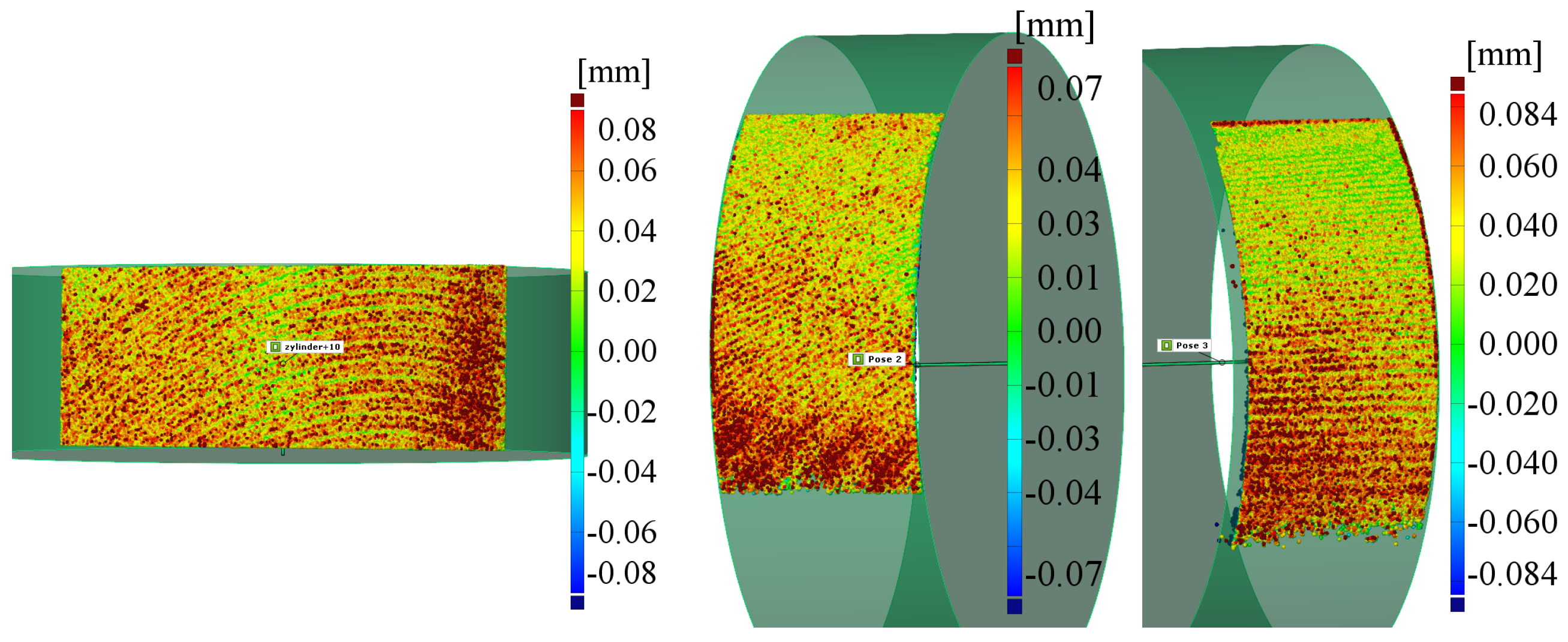

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| GUM | Guide to the expression of uncertainty in measurement |

| HDMI | High-definition multimedia interface |

| CSI | Camera serial interface |

| LED | Light emitting diode |

References

- Kästner, M. Optische Geometrieüberprüfung präzisionsgeschmiedeter Hochleistungsbauteile. Ph.D Thesis, Leibniz Universität Hannover, Hannover, Germany, 2008. [Google Scholar]

- Chen, L.; Huang, C. Miniaturized 3D surface profilometer using digital fringe projection. Meas. Sci. Technol. 2005, 16, 1061. [Google Scholar] [CrossRef]

- Karlstorz, MULTIPOINT, webpage. Available online: https://www.karlstorz.com/be/en/neues-multipoint-mess-videoendoskop.htm (accessed on 20 June 2016).

- General Electric, XLG3, webpage. Available online: https://www.gemeasurement.com/download/xlg3-videoprobe-brochure (accessed on 20 June 2016).

- Matthias, S.; Loderer, A.; Koch, S.; Gröne, M.; Kästner, M.; Hübner, S.; Krimm, R.; Reithmeier, E.; Hausotte, T.; Behrens, B.-A. Metrological solutions for an adapted inspection of parts and tools of a sheet-bulk metal forming process. Product. Eng. 2016, 10, 51–61. [Google Scholar] [CrossRef]

- Zhang, Z. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef]

- Peng, T. Algorithms and Models for 3-D Shape Measurement Using Digital Fringe Projections. Ph.D Thesis, University of Maryland, College Park, MD, USA, 2006. [Google Scholar]

| Gap with Depth 1 | Cylinder with Radius 1 | |

|---|---|---|

| calibrated value | 1000.5 ± 0.4 μ | 1001.5 ± 0.7 μ |

| measured value | 992.6 ± 0.5 μ | 935.4 ± 1.1 μ |

| deviation | 7.9 μ | 66.1 μ |

| single point distance (σ) | 16.7 μ | 18.6 μ |

| Cylinder with Radius 6 | Cylinder with Radius 10 | |

|---|---|---|

| calibrated value | 5994.0 ± 1.2 μ | 10002.1 ± 0.9 μ |

| pose one | ||

| measured value | 6037.4 ± 1.6 μ | 9945.1 ± 1.1 μ |

| deviation | 43.4 μ | 57.0 μ |

| single point distance (σ) | 83.4 μ | 100.0 μ |

| pose two | ||

| measured value | 5971.5 ± 4.4 μ | 9851.0 ± 4.0 μ |

| deviation | 22.4 μ | 151.1 μ |

| single point distance (σ) | 29.3 μ | 23.1 μ |

| pose three | ||

| measured value | 5911.7 ± 2.8 μ | 9905.1 ± 4.3 μ |

| deviation | 82.3 μ | 97.0 μ |

| single point distance (σ) | 71.0 μ | 35.0 μ |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schlobohm, J.; Pösch, A.; Reithmeier, E. A Raspberry Pi Based Portable Endoscopic 3D Measurement System. Electronics 2016, 5, 43. https://doi.org/10.3390/electronics5030043

Schlobohm J, Pösch A, Reithmeier E. A Raspberry Pi Based Portable Endoscopic 3D Measurement System. Electronics. 2016; 5(3):43. https://doi.org/10.3390/electronics5030043

Chicago/Turabian StyleSchlobohm, Jochen, Andreas Pösch, and Eduard Reithmeier. 2016. "A Raspberry Pi Based Portable Endoscopic 3D Measurement System" Electronics 5, no. 3: 43. https://doi.org/10.3390/electronics5030043