Development of Soft Composite Based Anisotropic Synthetic Skin for Biomechanical Testing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Matrix and Fiber Materials

2.2. Anisotropic Synthetic Skin Fabrication

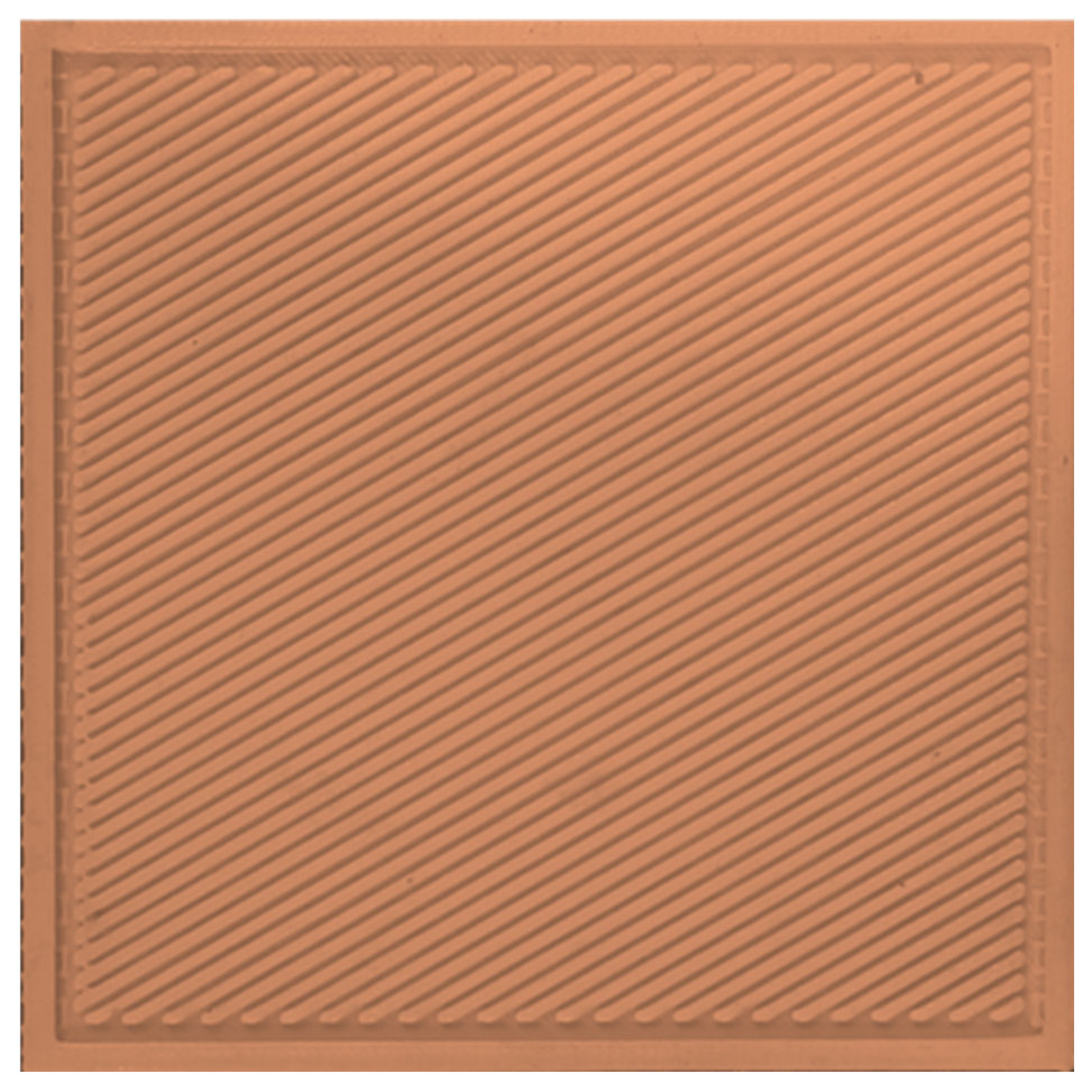

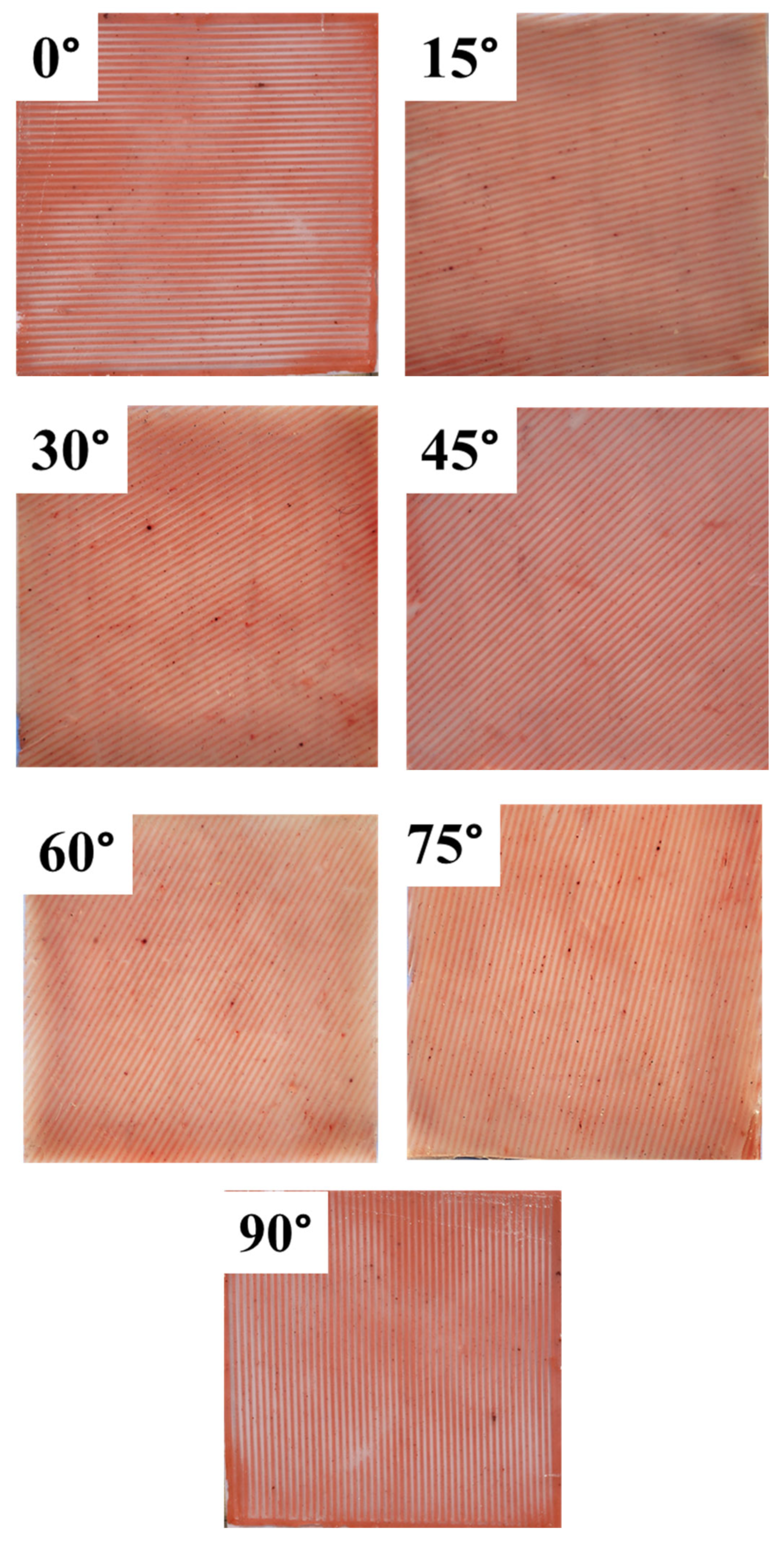

2.2.1. Development of Single-Layer Synthetic Skin

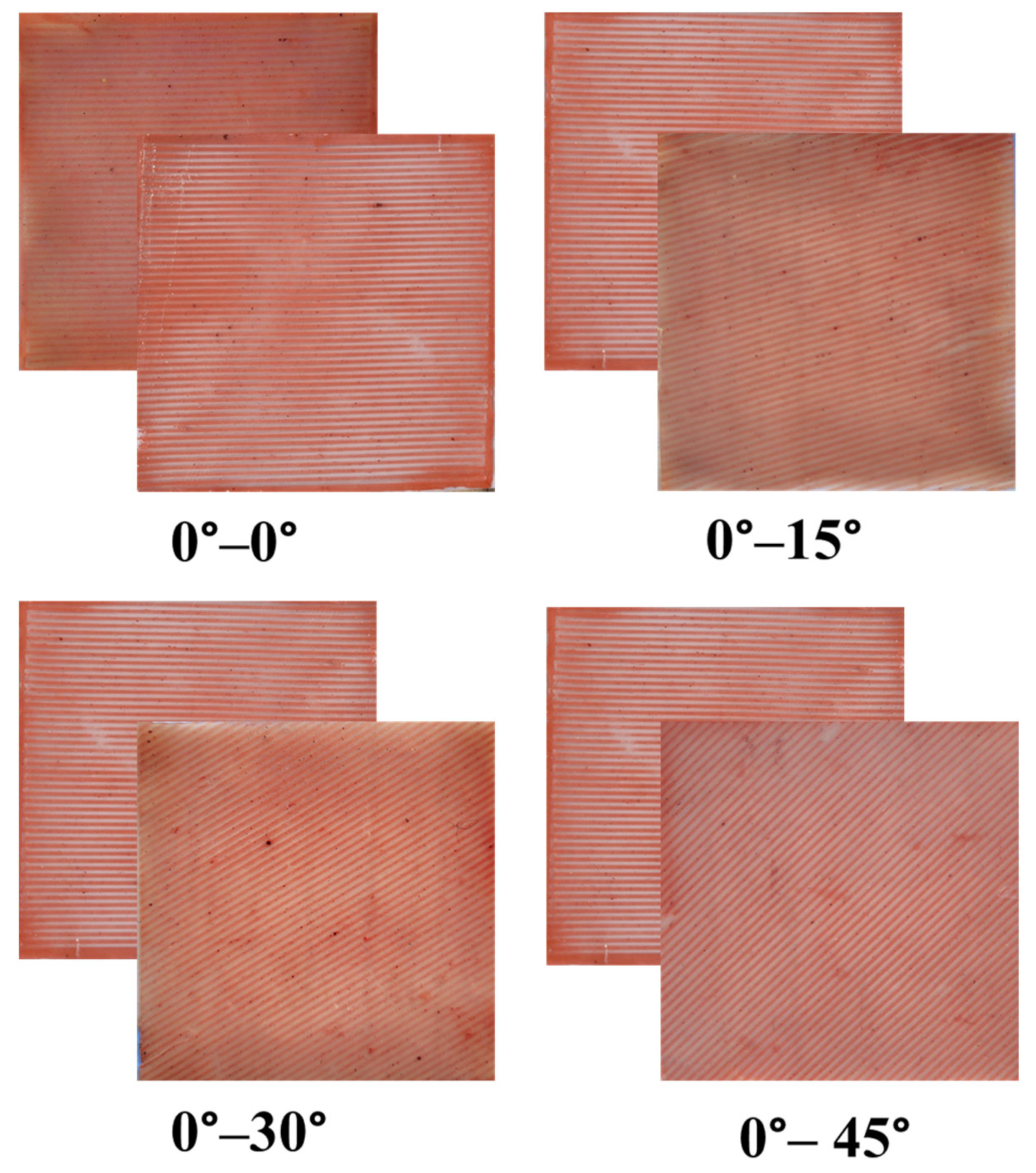

2.2.2. Development of Multi-Layer Synthetic Skin

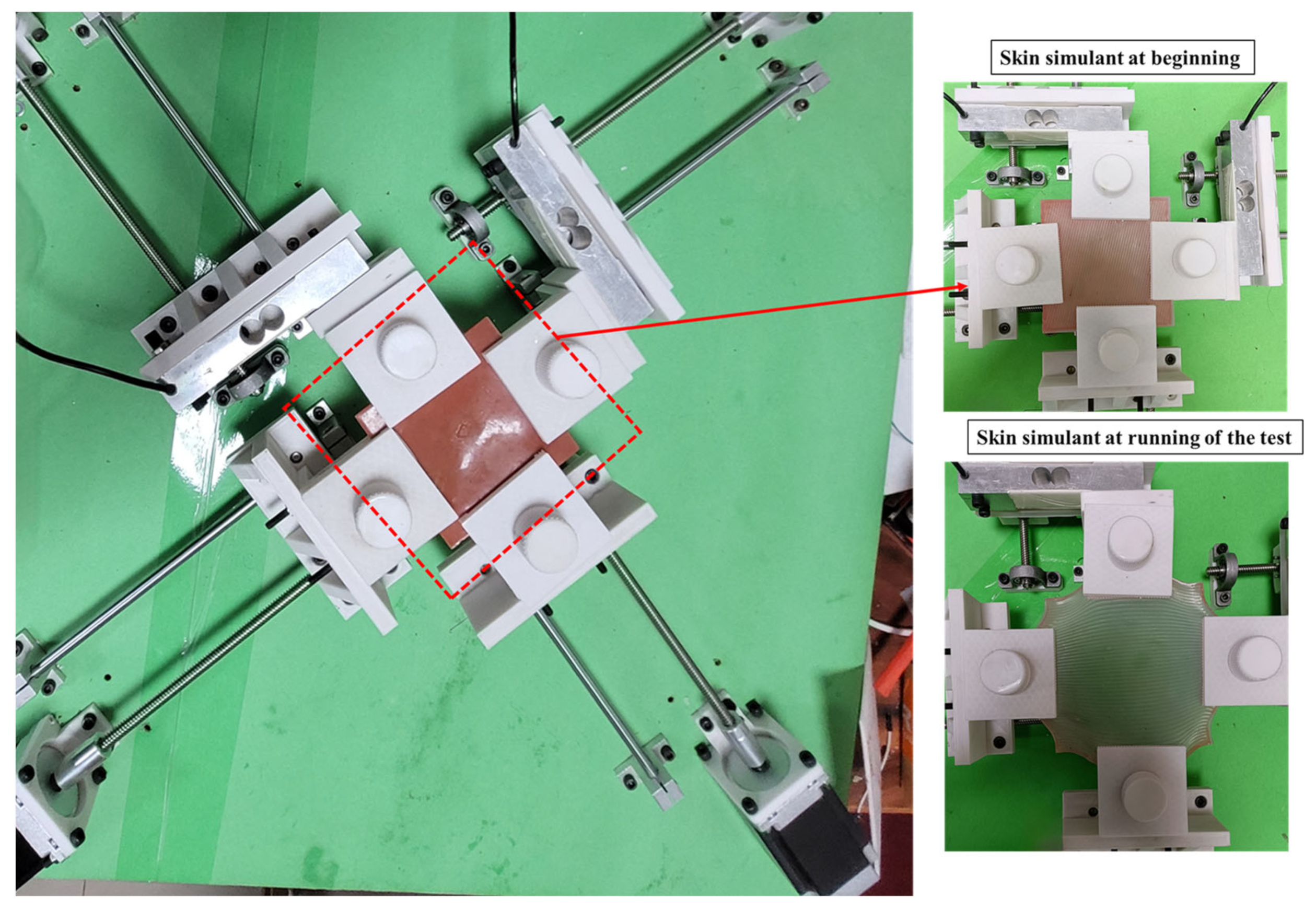

2.3. Method Parameters and Testing Setup

2.4. Anisotropic Material Characterization

3. Results and Discussion

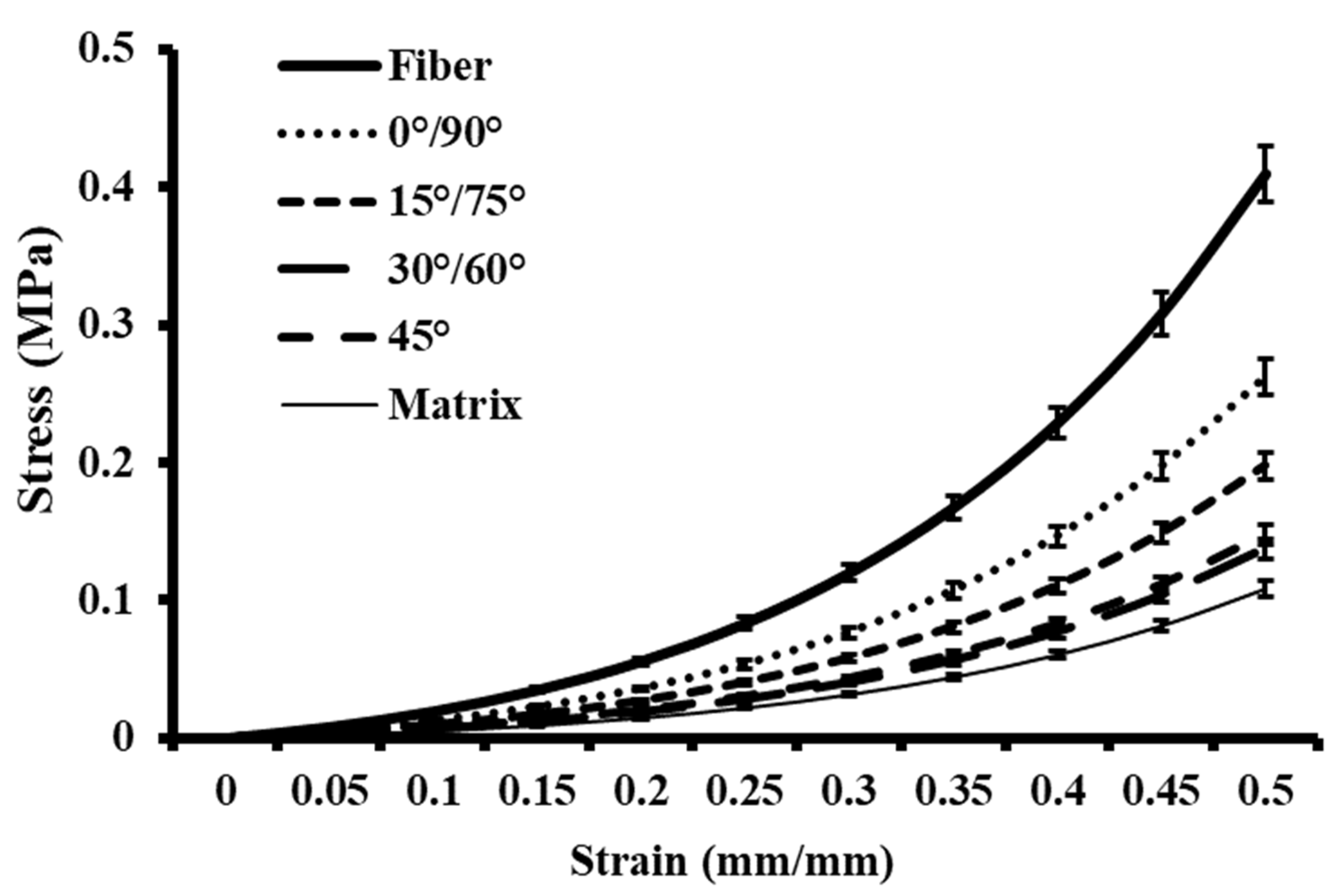

3.1. Stress Analysis of Single-Layer Synthetic Skin

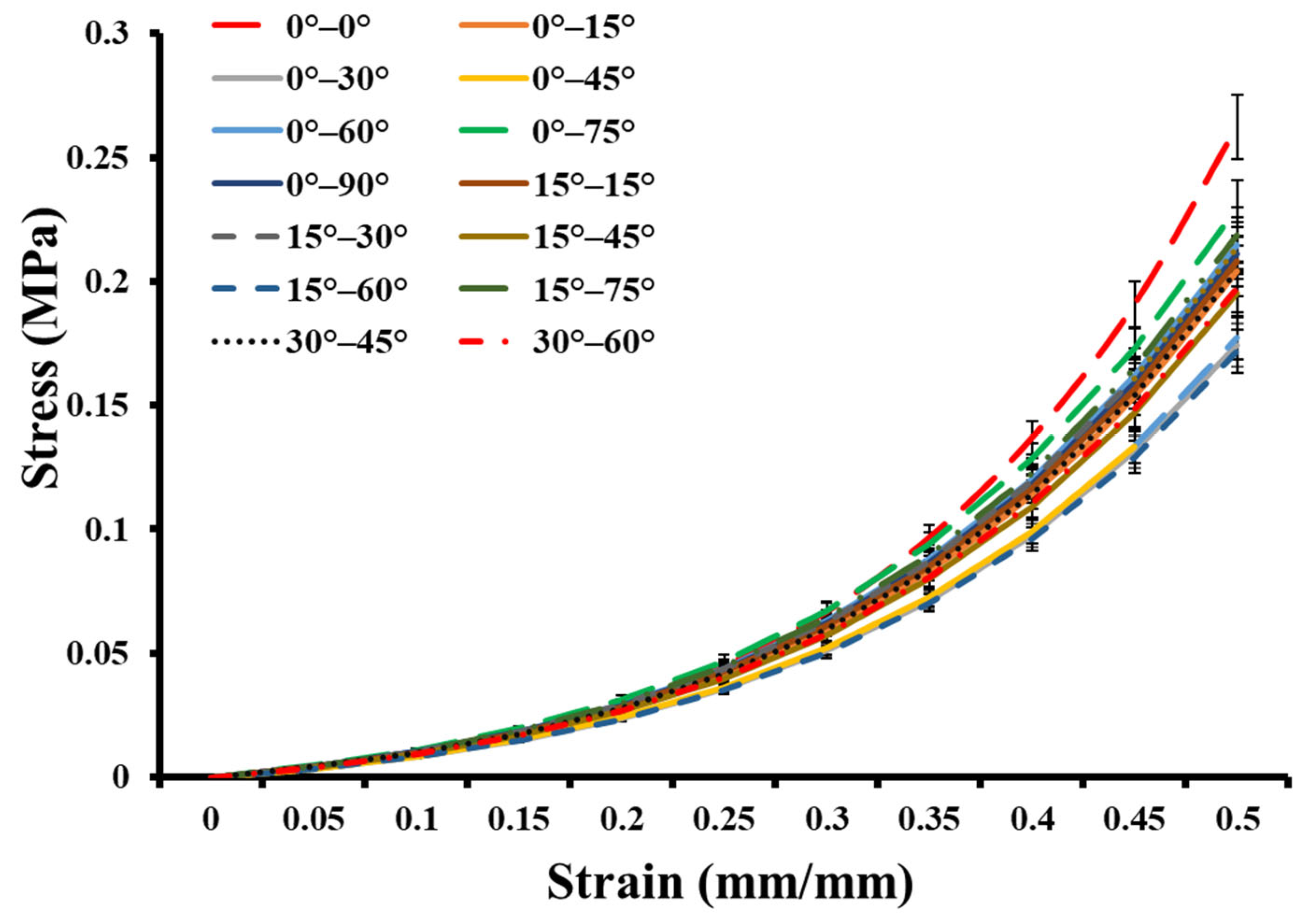

3.2. Stress Analysis of Two-Layer Synthetic Skin

3.3. Hyperelastic Modelling of Synthetic Skin

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yi, D.; Choe, Y.M.; Byun, M.S.; Sohn, B.K.; Seo, E.H.; Han, J.; Park, J.; Woo, J.I.; Lee, D.Y. Differences in functional brain connectivity alterations associated with cerebral amyloid deposition in amnestic mild cognitive impairment. Front. Aging Neurosci. 2015, 7, 15. [Google Scholar] [CrossRef] [PubMed]

- Picinbono, G.; Delingette, H.; Ayache, N. Non-linear and anisotropic elastic soft tissue models for medical simulation. In Proceedings of the IEEE International Conference on Robotics and Automation, Seoul, Republic of Korea, 21–26 May 2001; Volume 2, pp. 1370–1375. [Google Scholar] [CrossRef]

- Singh, G.; Chanda, A. Mechanical properties of whole-body soft human tissues: A review. Biomed. Mater. 2021, 16, 062004. [Google Scholar] [CrossRef] [PubMed]

- Serebrakian, A.T.; Pickrell, B.B.; Varon, D.E.; Mohamadi, A.; Grinstaff, M.W.; Rodriguez, E.K.; Nazarian, A.; Halvorson, E.G.; Sinha, I. Meta-analysis and Systematic Review of Skin Graft Donor-site Dressings with Future Guidelines. Plast. Reconstr. Surg. Glob. Open 2018, 6, e1928. [Google Scholar] [CrossRef] [PubMed]

- Wong, W.L.E.; Joyce, T.J.; Goh, K.L. Resolving the viscoelasticity and anisotropy dependence of the mechanical properties of skin from a porcine model. Biomech. Model. Mechanobiol. 2016, 15, 433–446. [Google Scholar] [CrossRef]

- Flynn, C.; Taberner, A.; Nielsen, P. Mechanical characterisation of in vivo human skin using a 3D force-sensitive micro-robot and finite element analysis. Biomech. Model. Mechanobiol. 2011, 10, 27–38. [Google Scholar] [CrossRef]

- Groves, R.B.; Coulman, S.A.; Birchall, J.C.; Evans, S.L. An anisotropic, hyperelastic model for skin: Experimental measurements, finite element modelling and identification of parameters for human and murine skin. J. Mech. Behav. Biomed. Mater. 2013, 18, 167–180. [Google Scholar] [CrossRef]

- Roberts, D.E.; Scher, A.M. Effect of tissue anisotropy on extracellular potential fields in canine myocardium in situ. Circ. Res. 1982, 50, 342–351. [Google Scholar] [CrossRef] [Green Version]

- Aslanidi, O.V.; Boyett, M.R.; Dobrzynski, H.; Li, J.; Zhang, H. Mechanisms of transition from normal to reentrant electrical activity in a model of rabbit atrial tissue: Interaction of tissue heterogeneity and anisotropy. Biophys. J. 2009, 96, 798–817. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Wang, L.; Peng, X. Testing, characterizing, and forming of glass twill fabric/polypropylene prepregs. J. Compos. Mater. 2019, 53, 3939–3950. [Google Scholar] [CrossRef]

- Mandal, B.B.; Kundu, S.C. Cell proliferation and migration in silk fibroin 3D scaffolds. Biomaterials 2009, 30, 2956–2965. [Google Scholar] [CrossRef]

- Singh, G.; Gupta, V.; Chanda, A. Artificial skin with varying biomechanical properties. Mater. Today Proc. 2022, 62, 3162–3166. [Google Scholar] [CrossRef]

- Carotenuto, F.; Politi, S.; Ul Haq, A.; De Matteis, F.; Tamburri, E.; Terranova, M.L.; Teodori, L.; Pasquo, A.; Di Nardo, P. From Soft to Hard Biomimetic Materials: Tuning Micro/Nano-Architecture of Scaffolds for Tissue Regeneration. Micromachines 2022, 13, 780. [Google Scholar] [CrossRef]

- Patel, S.; Caldwell, J.M.; Doty, S.B.; Levine, W.N.; Rodeo, S.; Soslowsky, L.J.; Thomopoulos, S.; Lu, H.H. Integrating soft and hard tissues via interface tissue engineering. J. Orthop. Res. 2018, 36, 1069–1077. [Google Scholar] [CrossRef] [Green Version]

- Michels, J.; Appel, E.; Gorb, S.N. Functional diversity of resilin in Arthropoda. Beilstein J. Nanotechnol. 2016, 7, 1241–1259. [Google Scholar] [CrossRef] [Green Version]

- Carlsen, R.W.; Daphalapurkar, N.P. The importance of structural anisotropy in computational models of traumatic brain injury. Front. Neurol. 2015, 6, 28. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Yang, X.; Lin, Y.; Shi, J.; Prominski, A.; Clayton, C.; Ostroff, E.; Tian, B. Dissecting Biological and Synthetic Soft-Hard Interfaces for Tissue-Like Systems. Chem. Rev. 2022, 122, 5233–5276. [Google Scholar] [CrossRef]

- Liu, Z.; Liao, Z.; Wang, D.; Wang, C.; Song, C.; Li, H.; Liu, Y. Recent Advances in Soft Biological Tissue Manipulating Technologies. Chin. J. Mech. Eng. 2022, 35, 89. [Google Scholar] [CrossRef]

- Famaey, N.; Sloten, J.V. Soft tissue modelling for applications in virtual surgery and surgical robotics. Comput. Methods Biomech. Biomed. Eng. 2008, 11, 351–366. [Google Scholar] [CrossRef]

- Martins, P.; Peña, E.; Calvo, B.; Doblaré, M.; Mascarenhas, T.; Jorge, R.N.; Ferreira, A. Prediction of nonlinear elastic behaviour of vaginal tissue: Experimental results and model formulation. Comput. Methods Biomech. Biomed. Eng. 2010, 13, 327–337. [Google Scholar] [CrossRef]

- Natali, A.N.; Pavan, P.G.; Carniel, E.L.; Dorow, C. A transversally isotropic elasto-damage constitutive model for the periodontal ligament. Comput. Methods Biomech. Biomed. Eng. 2003, 6, 329–336. [Google Scholar] [CrossRef]

- Ranamukhaarachchi, S.A.; Lehnert, S.; Ranamukhaarachchi, S.L.; Sprenger, L.; Schneider, T.; Mansoor, I.; Rai, K.; Häfeli, U.O.; Stoeber, B. A micromechanical comparison of human and porcine skin before and after preservation by freezing for medical device development. Sci. Rep. 2016, 6, 32074. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Blair, M.J.; Jones, J.D.; Woessner, A.E.; Quinn, K.P. Skin Structure-Function Relationships and the Wound Healing Response to Intrinsic Aging. Adv. Wound Care 2020, 9, 127–143. [Google Scholar] [CrossRef] [PubMed]

- Belkoff, S.M.; Haut, R.C. A structural model used to evaluate the changing microstructure of maturing rat skin. J. Biomech. 1991, 24, 711–720. [Google Scholar] [CrossRef] [PubMed]

- Thorpe, C.T.; Birch, H.L.; Clegg, P.D.; Screen, H.R.C. The role of the non-collagenous matrix in tendon function. Int. J. Exp. Pathol. 2013, 94, 248–259. [Google Scholar] [CrossRef]

- Li, Y.; Fessel, G.; Georgiadis, M.; Snedeker, J.G. Advanced glycation end-products diminish tendon collagen fiber sliding. Matrix Biol. 2013, 32, 169–177. [Google Scholar] [CrossRef]

- Gupta, V.; Chanda, A. Biomechanics of skin grafts: Effect of pattern size, spacing and orientation. Eng. Res. Express 2022, 4, 015006. [Google Scholar] [CrossRef]

- Payne, T.; Mitchell, S.; Bibb, R.; Waters, M. Initial validation of a relaxed human soft tissue simulant for sports impact surrogates. Procedia Eng. 2014, 72, 533–538. [Google Scholar] [CrossRef] [Green Version]

- Shergold, O.A.; Fleck, N.A.; Radford, D. The uniaxial stress versus strain response of pig skin and silicone rubber at low and high strain rates. Int. J. Impact Eng. 2006, 32, 1384–1402. [Google Scholar] [CrossRef]

- Arm, R.; Shahidi, A.; Dias, T. Mechanical behaviour of silicone membranes saturated with short strand, loose polyester fibres for prosthetic and rehabilitative surrogate skin applications. Materials 2019, 12, 3647. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.; Liao, Z. An additively manufactured silicone polymer: Thermo-viscoelastic experimental study and computational modelling. Addit. Manuf. 2020, 35, 101395. [Google Scholar] [CrossRef]

- Zhang, J.; Keith, A.N.; Sheiko, S.S.; Wang, X.; Wang, Z. To mimic mechanical properties of the skin by inducing oriented nanofiber microstructures in bottlebrush cellulose-graft-diblock copolymer elastomers. ACS Appl. Mater. Interfaces 2021, 13, 3278–3286. [Google Scholar] [CrossRef]

- MacNeil, S. Progress and opportunities for tissue-engineered skin. Nature 2007, 445, 874–880. [Google Scholar] [CrossRef]

- Chanda, A.; Callaway, C. Tissue anisotropy modeling using soft composite materials. Appl. Bionics Biomech. 2018, 2018, 4838157. [Google Scholar] [CrossRef] [Green Version]

- Ojogbo, E.; Tzoganakis, C.; Mekonnen, T.H. Effect of extrusion, batch-mixing, and co-coagulation on the dispersion of CNCs in natural rubber-CNC nanocomposites. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106580. [Google Scholar] [CrossRef]

- Mongkolsuttirat, K.; Sanponpute, T. Prototype of Depth Standard for Elastomer Hardness Tester. J. Phys. Conf. Ser. 2018, 1065, 062012. [Google Scholar] [CrossRef]

- Durban, M.M.; Lenhardt, J.M.; Wu, A.S.; Small, W.; Bryson, T.M.; Perez-Perez, L.; Nguyen, D.T.; Gammon, S.; Smay, J.E.; Duoss, E.B.; et al. Custom 3D Printable Silicones with Tunable Stiffness. Macromol. Rapid Commun. 2018, 39, 1700563. [Google Scholar] [CrossRef]

- Herzberger, J.; Sirrine, J.M.; Williams, C.B.; Long, T.E. Polymer Design for 3D Printing Elastomers: Recent Advances in Structure, Properties, and Printing. Prog. Polym. Sci. 2019, 97, 101144. [Google Scholar] [CrossRef]

- Webster, T.; Yao, C.; Hedrick, M.; Pareek, G.; Haleblian, G.; Renzulli, J. Nanostructured polyurethane-poly-lactic- co-glycolic acid scaffolds increase bladder tissue regeneration: An in vivo study. Int. J. Nanomed. 2013, 8, 3285. [Google Scholar] [CrossRef] [Green Version]

- Parikh, D.V.; Calamari, T.A.; Sawhney, A.P.S.; Blanchard, E.J.; Screen, F.J.; Myatt, J.C.; Muller, D.H.; Stryjewski, D.D. Thermoformable Automotive Composites Containing Kenaf and Other Cellulosic Fibers. Text. Res. J. 2002, 72, 668–672. [Google Scholar] [CrossRef]

- Singh, G.; Gupta, V.; Chanda, A. Mechanical Characterization of Rotating Triangle Shaped Auxetic Skin Graft Simulants. Facta Univ. Ser. Mech. Eng. 2022, 1–16. [Google Scholar] [CrossRef]

- Chanda, A.; Upchurch, W. Biomechanical Modeling of Wounded Skin. J. Compos. Sci. 2018, 2, 69. [Google Scholar] [CrossRef] [Green Version]

- Chanda, A.; Unnikrishnan, V.; Flynn, Z.; Lackey, K. Experimental study on tissue phantoms to understand the effect of injury and suturing on human skin mechanical properties. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2017, 231, 80–91. [Google Scholar] [CrossRef] [PubMed]

- Ní Annaidh, A.; Bruyère, K.; Destrade, M.; Gilchrist, M.D.; Otténio, M. Characterization of the anisotropic mechanical properties of excised human skin. J. Mech. Behav. Biomed. Mater. 2012, 5, 139–148. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Design | Matrix Volume (mm3) | Fiber Volume (mm3) | Fiber Volume Fraction | Matrix Volume Fraction |

|---|---|---|---|---|

| 0/90° | 15,180 | 4820 | 0.243 | 0.757 |

| 15/75° | 14,776 | 5224 | 0.261 | 0.739 |

| 30/60° | 15,392 | 4608 | 0.234 | 0.766 |

| 45° | 15,392 | 4608 | 0.234 | 0.766 |

| Composition | Stress Values in MPa | ||||

|---|---|---|---|---|---|

| At 0.1 mm/mm Strain | At 0.2 mm/mm Strain | At 0.3 mm/mm Strain | At 0.4 mm/mm Strain | At 0.5 mm/mm Strain | |

| 0–0° | 0.009 | 0.029 | 0.067 | 0.137 | 0.262 |

| 0–15° | 0.010 | 0.028 | 0.060 | 0.114 | 0.204 |

| 0–30° | 0.008 | 0.024 | 0.051 | 0.098 | 0.174 |

| 0–45° | 0.008 | 0.024 | 0.052 | 0.099 | 0.177 |

| 0–60° | 0.010 | 0.029 | 0.063 | 0.120 | 0.215 |

| 0–75° | 0.011 | 0.031 | 0.067 | 0.128 | 0.229 |

| 0–90° | 0.010 | 0.029 | 0.062 | 0.118 | 0.211 |

| 15–15° | 0.010 | 0.028 | 0.061 | 0.116 | 0.208 |

| 15–30° | 0.010 | 0.029 | 0.063 | 0.119 | 0.213 |

| 15–45° | 0.009 | 0.027 | 0.057 | 0.109 | 0.195 |

| 15–60° | 0.008 | 0.023 | 0.050 | 0.096 | 0.172 |

| 15–75° | 0.010 | 0.030 | 0.064 | 0.122 | 0.219 |

| 30–45° | 0.010 | 0.028 | 0.060 | 0.114 | 0.204 |

| 30–60° | 0.009 | 0.027 | 0.058 | 0.110 | 0.197 |

| Synthetic Skin | Mooney-Rivlin Model | Yeoh | |||

|---|---|---|---|---|---|

| c1 (MPa) | c2 (MPa) | c1 (MPa) | c2 (MPa) | c3 (MPa) | |

| Matrix | 0.02525 | 0.00010 | 0.00806 | 0.01825 | 0.00474 |

| Fiber | 0.09531 | 0.00010 | 0.03044 | 0.06891 | 0.01788 |

| 0° | 0.06106 | 0.00010 | 0.0195 | 0.04415 | 0.01145 |

| 15° | 0.04603 | 0.00010 | 0.0147 | 0.03328 | 0.00863 |

| 30° | 0.03199 | 0.00010 | 0.01022 | 0.02313 | 0.00600 |

| 45° | 0.03447 | 0.00010 | 0.01101 | 0.02492 | 0.00647 |

| 0–0° | 0.06971 | 0.00010 | 0.01612 | 0.06174 | 0.00586 |

| 0–15° | 0.03343 | 0.05307 | 0.01518 | 0.03436 | 0.00891 |

| 0–30° | 0.0665 | 0.00010 | 0.01518 | 0.03436 | 0.00892 |

| 0–45° | 0.05841 | 0.01731 | 0.01587 | 0.03592 | 0.00932 |

| 0–60° | 0.0527 | 0.00561 | 0.01297 | 0.02936 | 0.00762 |

| 0–75° | 0.02476 | 0.04198 | 0.01277 | 0.0289 | 0.0075 |

| 0–90° | 0.06186 | 0.01427 | 0.01571 | 0.03557 | 0.00923 |

| 15–15° | 0.00010 | 0.11194 | 0.01598 | 0.03617 | 0.00938 |

| 15–30° | 0.06663 | 0.00133 | 0.01548 | 0.03503 | 0.00909 |

| 15–45° | 4.2 × 10−6 | 0.10614 | 0.01627 | 0.03683 | 0.00956 |

| 15–60° | 0.00010 | 0.12614 | 0.01706 | 0.03862 | 0.01002 |

| 15–75° | 0.00010 | 0.09844 | 0.01468 | 0.03322 | 0.00862 |

| 30–45° | 0.05667 | 0.00010 | 0.01318 | 0.02983 | 0.00774 |

| 30–60° | 0.08760 | 0.00713 | 0.02104 | 0.04761 | 0.01235 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, V.; Singla, R.; Singh, G.; Chanda, A. Development of Soft Composite Based Anisotropic Synthetic Skin for Biomechanical Testing. Fibers 2023, 11, 55. https://doi.org/10.3390/fib11060055

Gupta V, Singla R, Singh G, Chanda A. Development of Soft Composite Based Anisotropic Synthetic Skin for Biomechanical Testing. Fibers. 2023; 11(6):55. https://doi.org/10.3390/fib11060055

Chicago/Turabian StyleGupta, Vivek, Rohan Singla, Gurpreet Singh, and Arnab Chanda. 2023. "Development of Soft Composite Based Anisotropic Synthetic Skin for Biomechanical Testing" Fibers 11, no. 6: 55. https://doi.org/10.3390/fib11060055