Material Application of a Transformer Box: A Study on the Electromagnetic Shielding Characteristics of Al–Ta Coating Film with Plasma-Spray Process

Abstract

:1. Introduction

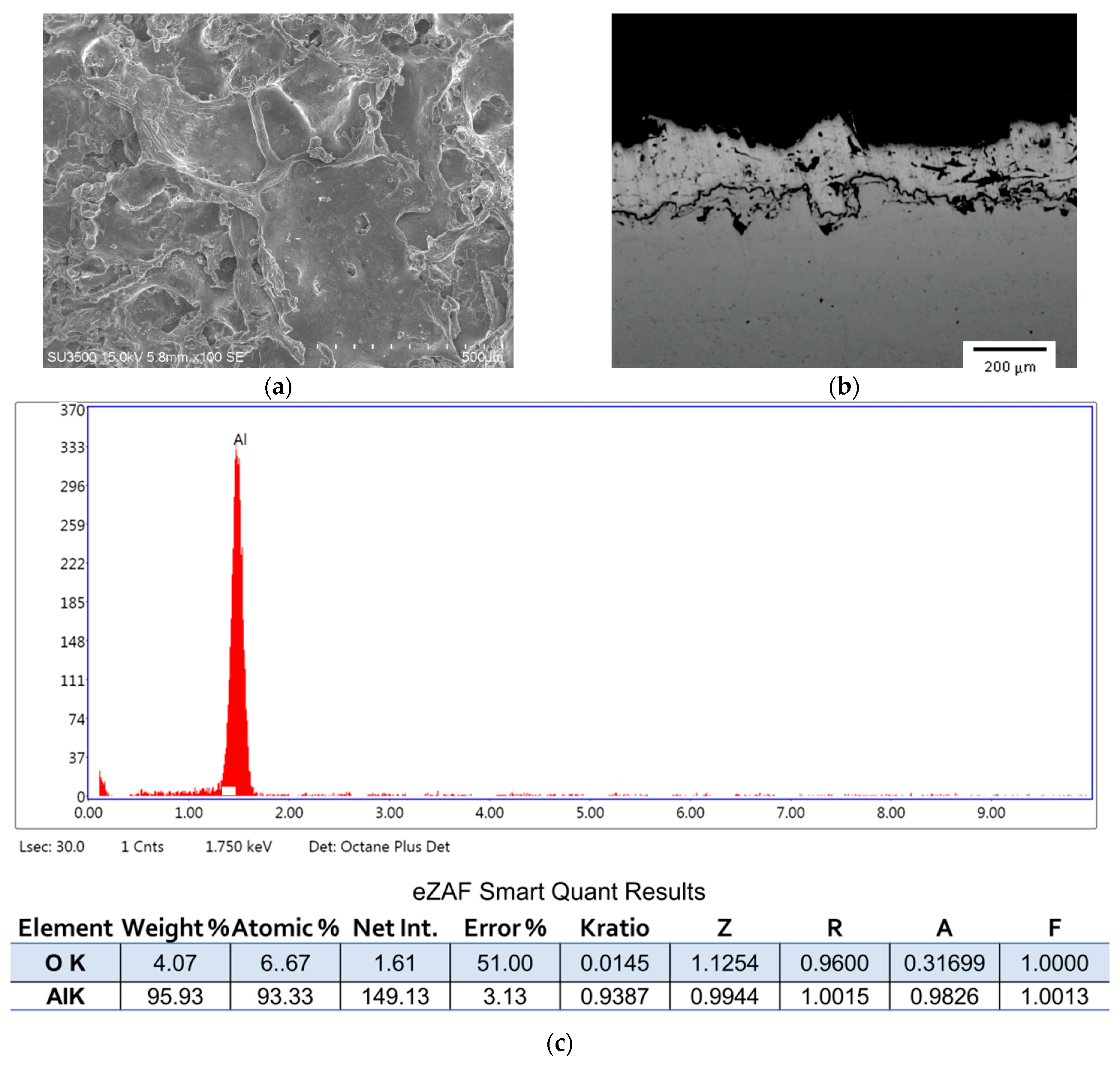

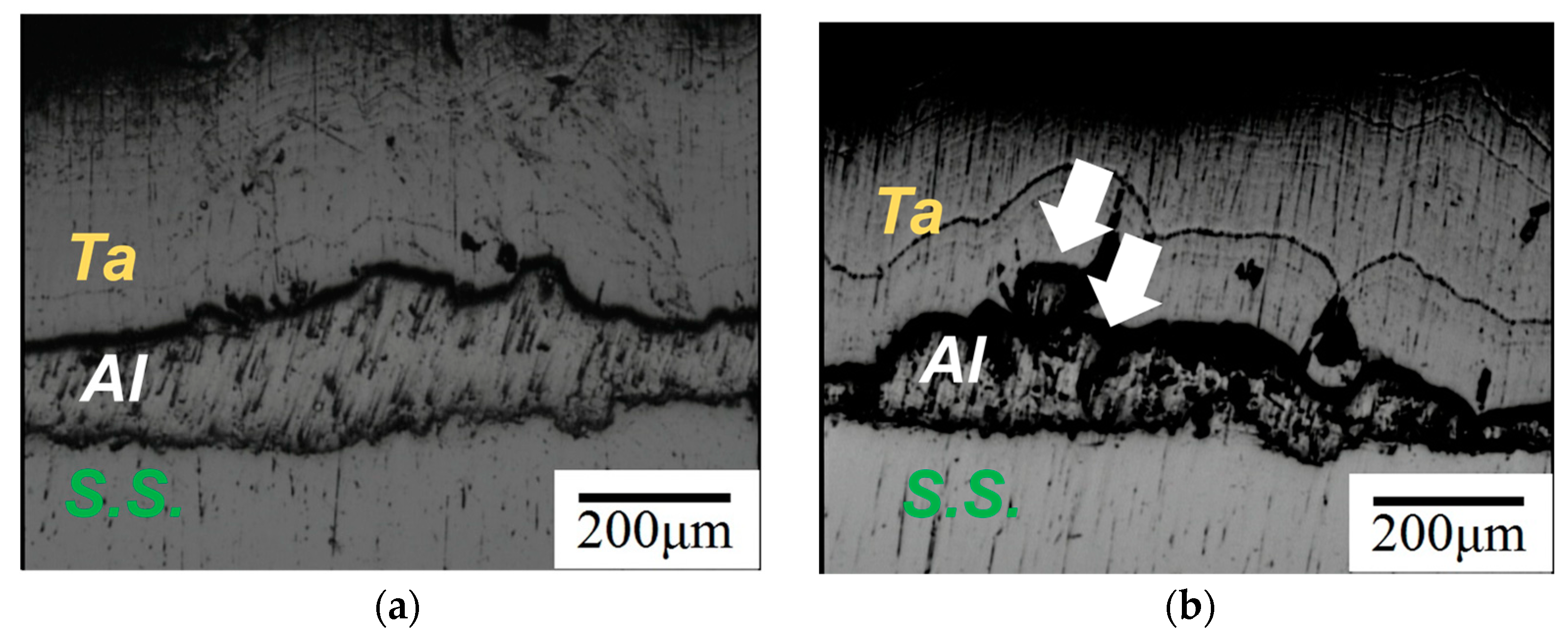

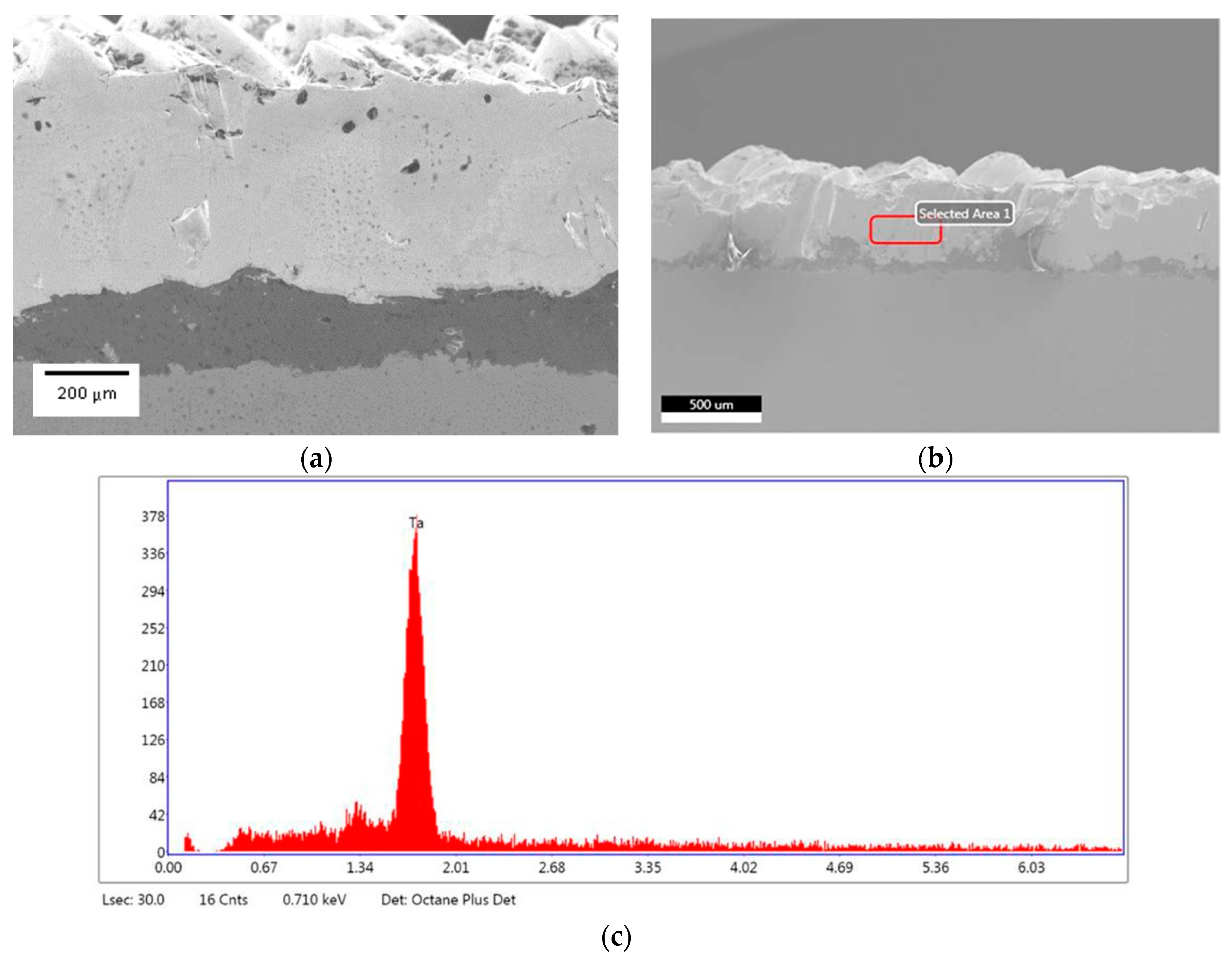

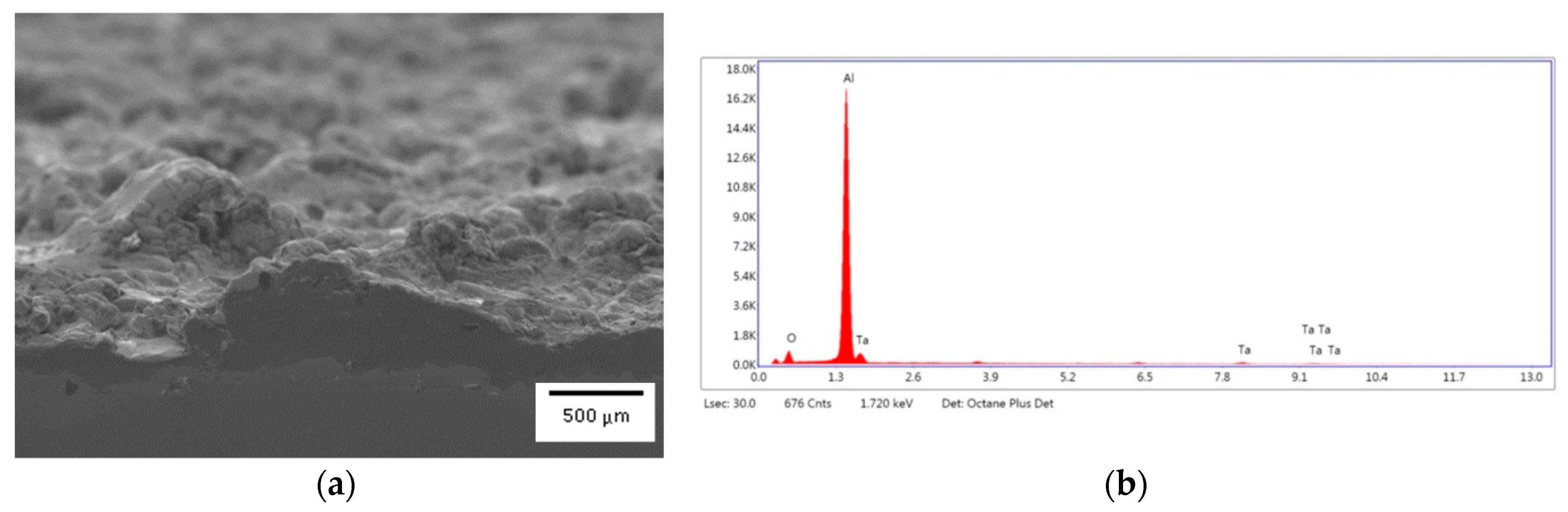

2. Experimental Procedure

2.1. Plasma Spraying Ta/Al/SS Multilayer Structure Preparation

2.2. Electromagnetic Wave Shielding Test

3. Results and Discussion

4. Conclusions

- The Ta/Al/SS multilayer structure can improve the mechanical properties and interfacial adhesion of stainless steel plates. The Al–Ta–O compound layer interface can improve the thermal insulation effect and reduce the thermal conductivity, which were confirmed to achieve explosion-proof and heat-resisting effects.

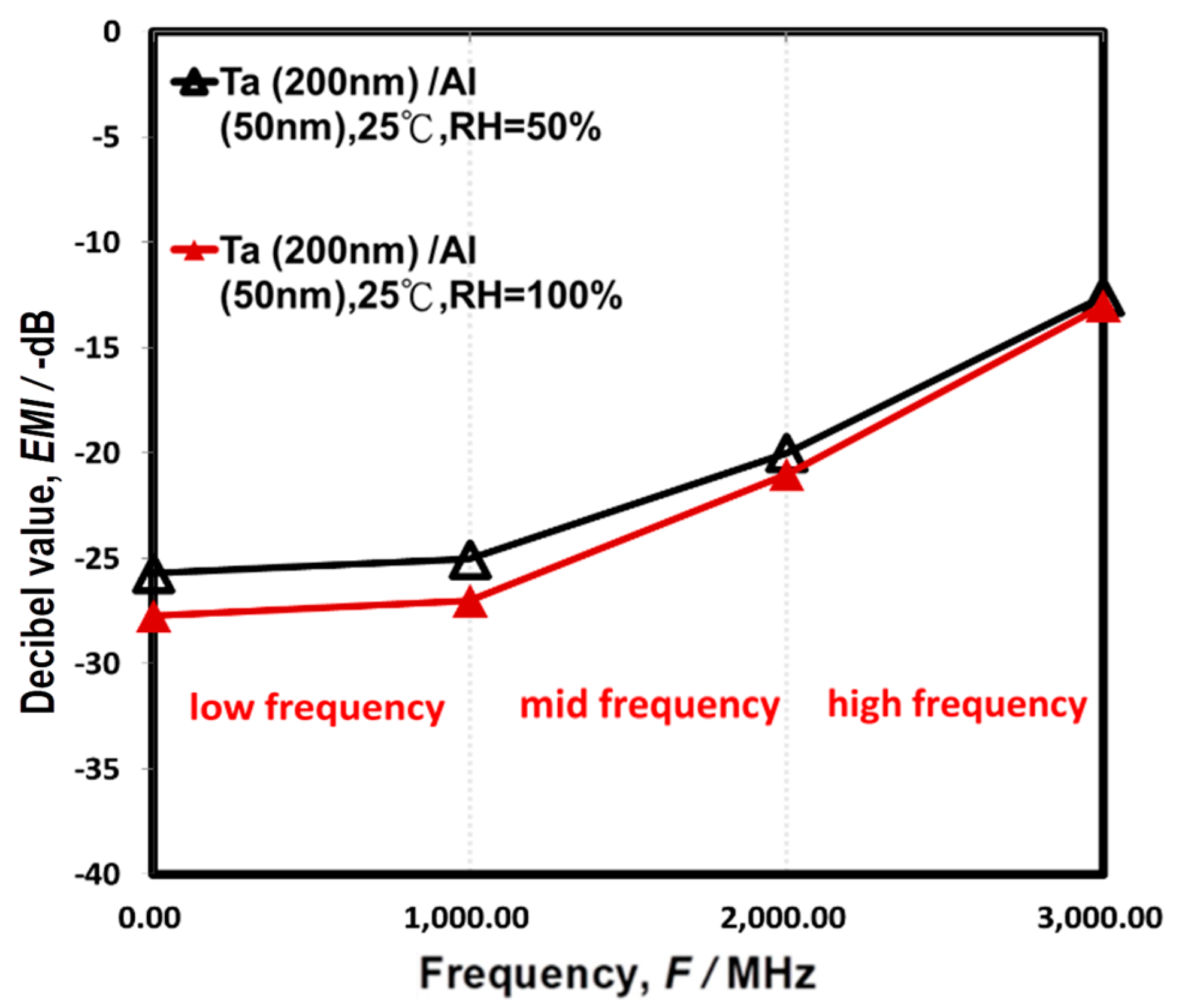

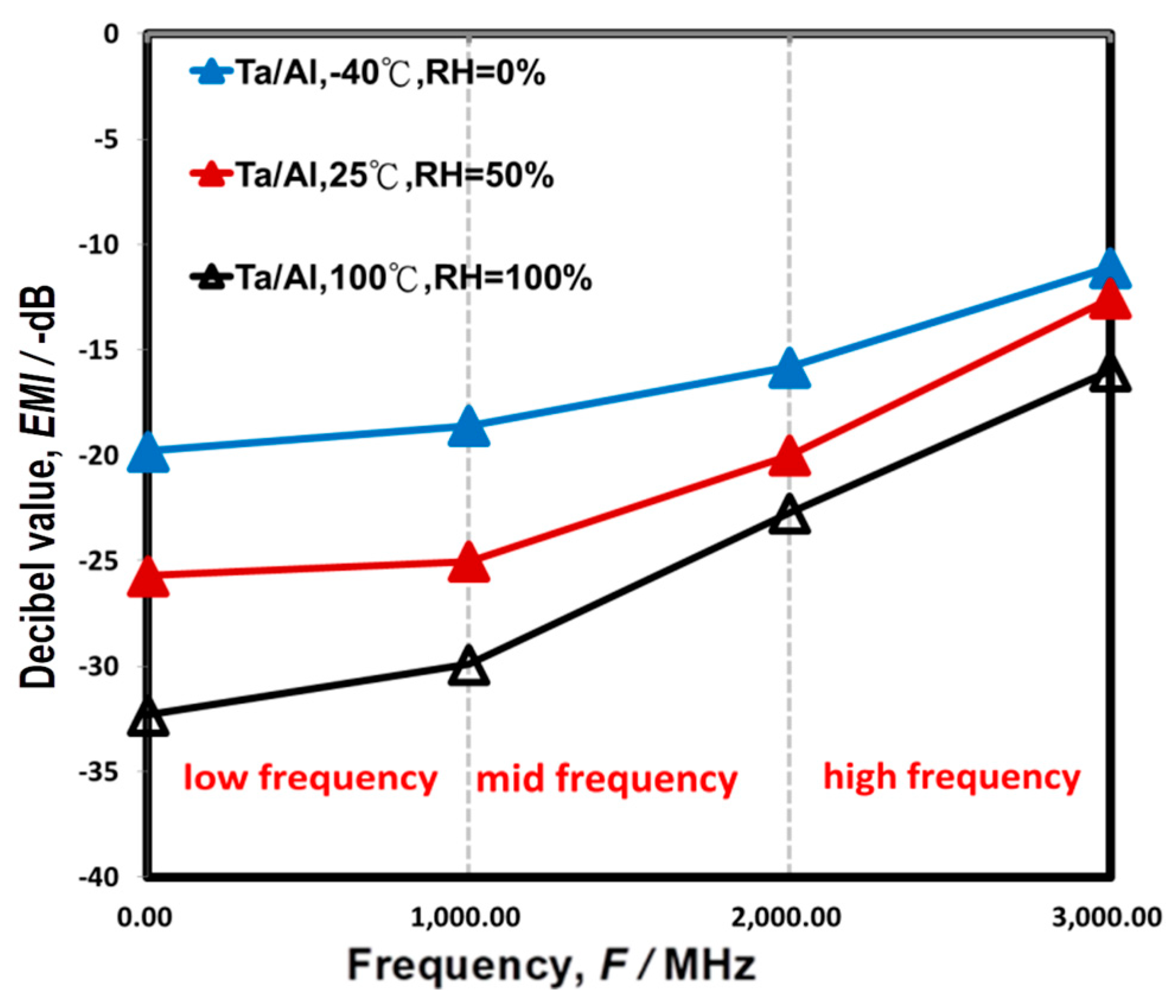

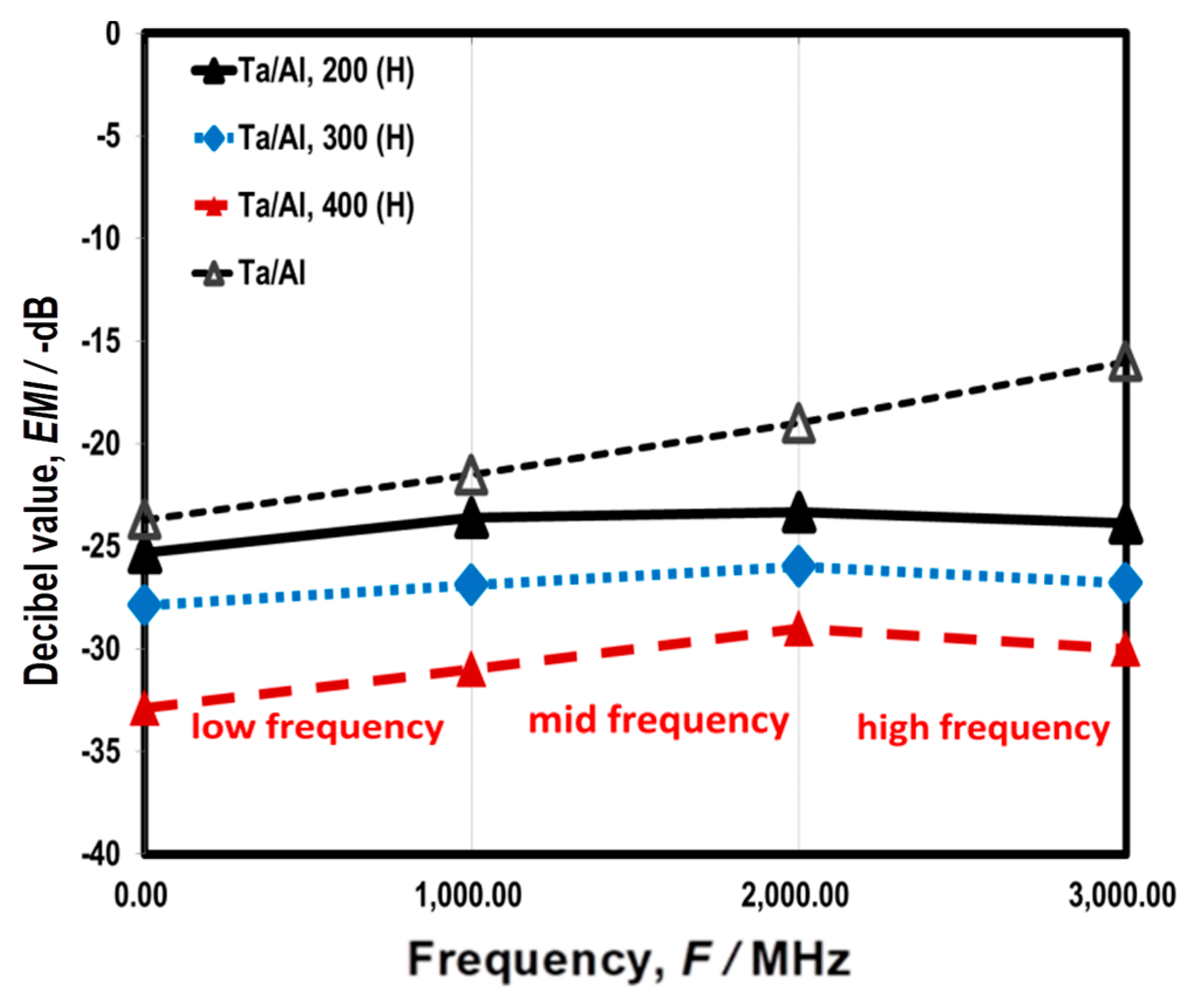

- Increasing the Ta layer thickness can improve EMI shielding effectively at low and middle frequency conditions. For the Ta (200 nm)/Al (50 nm) structure, EMI shielding increased with increasing temperature. After annealing, it had significant positive effects at high-frequency condition.

Funding

Acknowledgments

Conflicts of Interest

References

- Chiang, C.M.; Lai, C.M. A study on the comprehensive indicator of indoor environment assessment for occupants’ health in Taiwan. Build. Environ. 2002, 37, 387–392. [Google Scholar] [CrossRef]

- Wang, C.; Wu, T. TiO2 nanoparticles with efficient photocatalytic activity towards gaseous benzene degradation. Ceram. Int. 2015, 41, 2836–2839. [Google Scholar] [CrossRef]

- Hung, F.S. Adding effects of Ni and Mn on electromagnetic interference (EMI) shield of Sn-based architectural materials. Trans. Nonferrous Met. Soc. China 2013, 23, 2633–2637. [Google Scholar] [CrossRef]

- Liu, H.Y.; Sun, W.C.; Wei, S.Y.; Yu, S.M. Characterization of TiO2-based MISIM ultraviolet photodetectors by ultrasonic spray pyrolysis. IEEE Photonics Technol. Lett. 2016, 28, 637–640. [Google Scholar] [CrossRef]

- Liu, D.; Deng, S. The study of metal meshes on electromagnetic interference shielding effectiveness. In Proceedings of the Asia-Pacific Conference on Environmental Electromagnetics, Shanghai, China, 7 May 2000; pp. 326–332. [Google Scholar]

- Liboff, A.R. Geomagnetic cyclotron resonance in living cells. J. Biolog. Phys. 1985, 13, 99–102. [Google Scholar] [CrossRef]

- Liu, J.C.; Ho, S.S.; Bor, S.S.; Lu, P.C. Tchebyshev approximation method for Salisbury screen design. IEE Proc. H Microwav. Antennas Propag. 1993, 140, 414–416. [Google Scholar] [CrossRef]

- Mcleod, B.R.; Liboff, A.R. Dynamic characteristics of membrane ions in multifield configurations of low-frequency electromagnetic radiation. Bioelectromagnetics 1986, 7, 177–189. [Google Scholar] [CrossRef]

- Merchant, C.J.; Renew, D.C.; Swanson, J. Exposures to power frequency magnetic field in the home. J. Radiol. Prot. 1994, 14, 77–87. [Google Scholar] [CrossRef]

- Wu, C.H.; Hung, F.Y.; Lui, T.S.; Chen, L.H. Microstructural characteristics and the charge-discharge characteristics of Sn–Cu thin film materials. Mater. Trans. 2009, 50, 381–387. [Google Scholar] [CrossRef]

- Tenforde, T.S.; Kaune, W.T. Interaction of extremely low frequency electric and magnetic fields with humans. Health Phys. 1987, 53, 585–606. [Google Scholar] [CrossRef]

- Ubeda, A.; Leaf, J.; Trillo, M.A.; Jimenez, M.A.; Delgado, J.M. Pulse shape of magnetic fields influences chick embryogenesis. J. Anat. 1982, 37, 513–536. [Google Scholar]

- Vossen, J.L. Transparent Conducting Films. In Physics of Thin Films; Hass, G., Francombe, M.H., Hoffman, R.W., Eds.; Academic Press: New York, NY, USA, 1977; pp. 1–71. [Google Scholar]

- Wenderoth, K.; Petermann, J. Synergism on electromagnetic inductance (EMI)-shielding in metal- and ferroelectric-particle filled polymers. Polym. Composite 1989, 10, 52–56. [Google Scholar] [CrossRef]

- Wertheimer, N.; Leeper, E. Electrical wiring configurations and childhood cancer. Am. J. Epidemiol. 1979, 109, 273–284. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Chen, G.; Wu, C.; Wu, D. Study on the graphite nanosheets/resin shielding coatings. Prog. Org. Coat. 2007, 59, 101–105. [Google Scholar] [CrossRef]

- Vardelle, A.; Vardelle, M.; Fauchais, P. Influence of velocity and surface temperature of alumina particles on the properties of plasma-sprayed coatings. Plasma Chem. Plasma Process. 1982, 2, 255–291. [Google Scholar] [CrossRef]

- Yu, D.Q.; Xie, H.P.; Wang, L. Investigation of interfacial microstructure and wetting property of newly developed Sn–Zn–Cu solders with Cu substrate. J. Alloy. Compd. 2004, 385, 119–125. [Google Scholar] [CrossRef]

- Faria, D.R.; Vieira, M.; Faria, F.C.; Premebida, C. Affective facial expressions recognition for human-robot interaction. In Proceedings of the 2017 26th IEEE International Symposium on Robot and Human Interactive Communication (RO-MAN), Lisbon, Portugal, 28 August–1 September 2017; pp. 805–810. [Google Scholar]

- Perini, K.; Ottele, M.; Fraaij, A.L.A.; Haas, E.M.; Raiteri, R. Vertical greening systems and the effect on air flow and temperature on the building envelope. Build. Environ. 2011, 46, 2287–2294. [Google Scholar] [CrossRef]

- Barroca, N.; Borges, L.M.; Velez, F.J.; Monteiro, F.; Górski, M.; Castro-Gomes, J. Wireless sensor networks for temperature and humidity monitoring within concrete structures. Constr. Build. Mater. 2013, 40, 1156–1166. [Google Scholar] [CrossRef] [Green Version]

- Hung, F.S.; Hung, F.Y.; Chiang, C.M. Crystallization and annealing effects of sputtered tin alloy films on electromagnetic interference shielding. Appl. Surf. Sci. 2011, 257, 3733–3738. [Google Scholar] [CrossRef]

- Juan, P.R.; Camacho, N.; Barberis, E.; Palma, S.D. Challenges and opportunities related to health promotion in community pharmacies: Obstacles and professional perspectives. J. 3D Print. Med. 2018, 2, 313–320. [Google Scholar]

- Hung, F.S.; Hung, F.Y.; Chiang, C.M.; Lui, T.S. Electromagnetic interference shielding characteristics of Sn-Al powder coating layers. Mater. Trans. 2008, 49, 655–660. [Google Scholar] [CrossRef]

- Tipler, P.A.; Mosca, G. Physics for Scientists and Engineers: Electricity, Magnetism, Light, and Elementary Modern Physics, 5th ed.; W.H. Freeman: London, UK, 2003. [Google Scholar]

| Specimen | Resistivity |

|---|---|

| Ta (100 nm)/Al (50 nm) | 68.07 × 10−8 |

| Ta (200 nm)/Al (50 nm) | 52.38 × 10−8 |

| Ta (400 nm)/Al (50 nm) | 26.82 × 10−8 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, F.-S. Material Application of a Transformer Box: A Study on the Electromagnetic Shielding Characteristics of Al–Ta Coating Film with Plasma-Spray Process. Coatings 2019, 9, 495. https://doi.org/10.3390/coatings9080495

Hung F-S. Material Application of a Transformer Box: A Study on the Electromagnetic Shielding Characteristics of Al–Ta Coating Film with Plasma-Spray Process. Coatings. 2019; 9(8):495. https://doi.org/10.3390/coatings9080495

Chicago/Turabian StyleHung, Fei-Shuo. 2019. "Material Application of a Transformer Box: A Study on the Electromagnetic Shielding Characteristics of Al–Ta Coating Film with Plasma-Spray Process" Coatings 9, no. 8: 495. https://doi.org/10.3390/coatings9080495