Schlieren Visualization of Shaping Air during Operation of an Electrostatic Rotary Bell Sprayer: Impact of Shaping Air on Droplet Atomization and Transport

Abstract

:1. Introduction

2. Materials and Methods

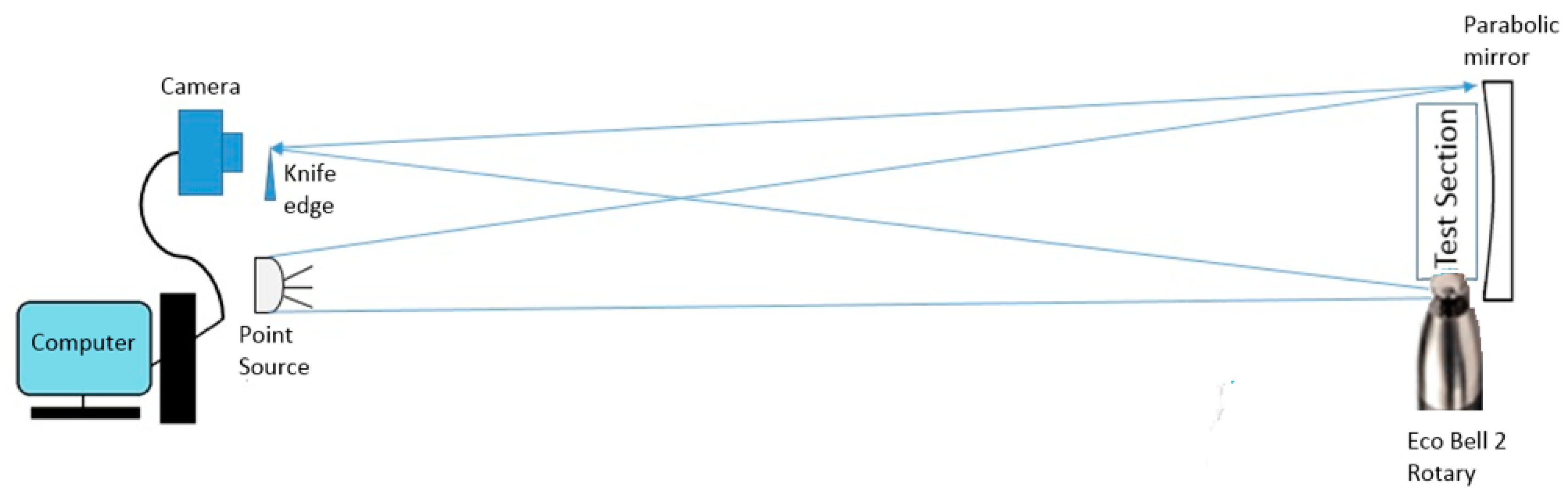

2.1. Schlieren Instrumentation for SA Visualization

2.2. Infrared Thermography for Spray Visualization

3. Results and Discussion

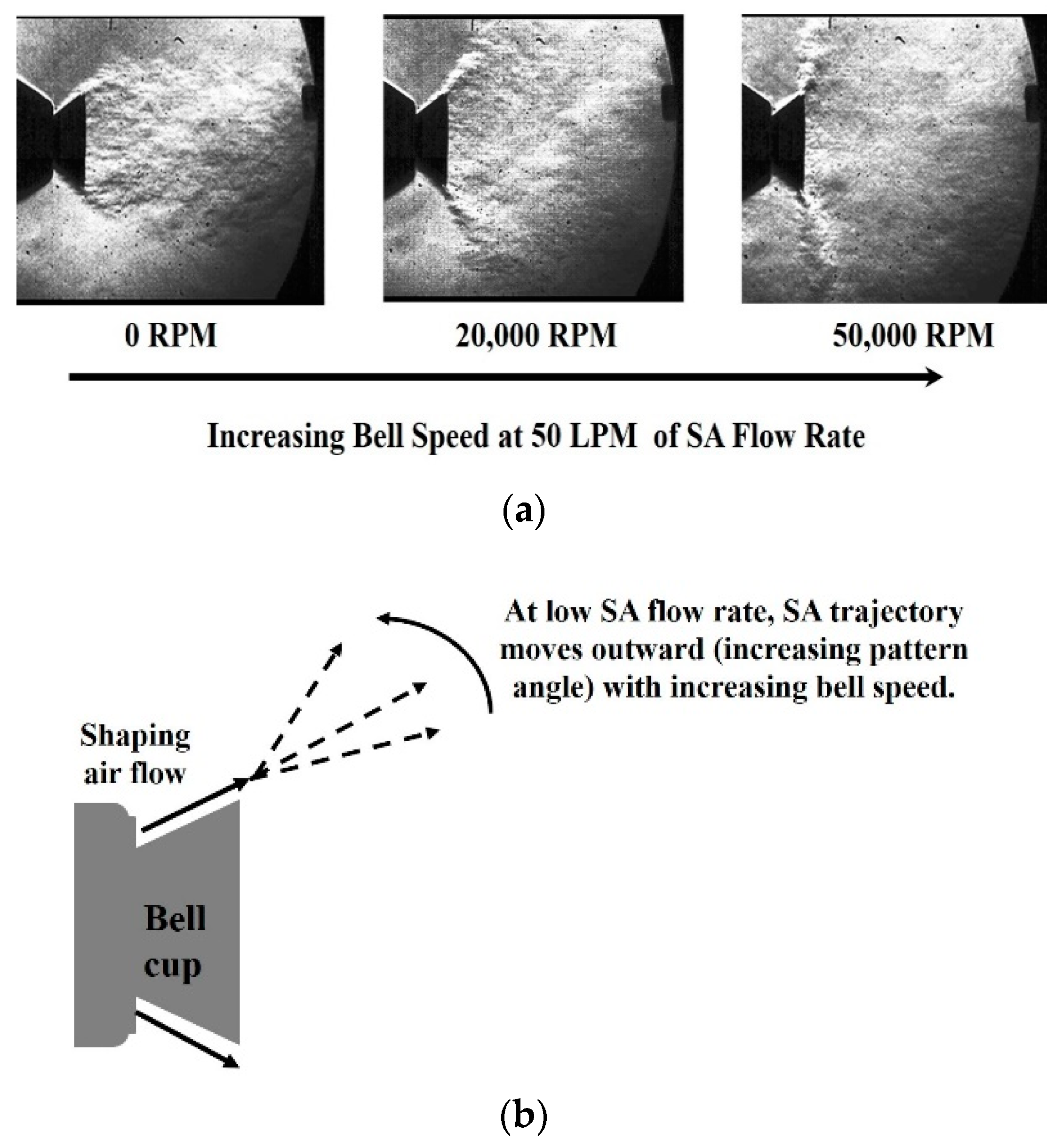

3.1. Results for Shaping Air Flow Rate of 50 LPM

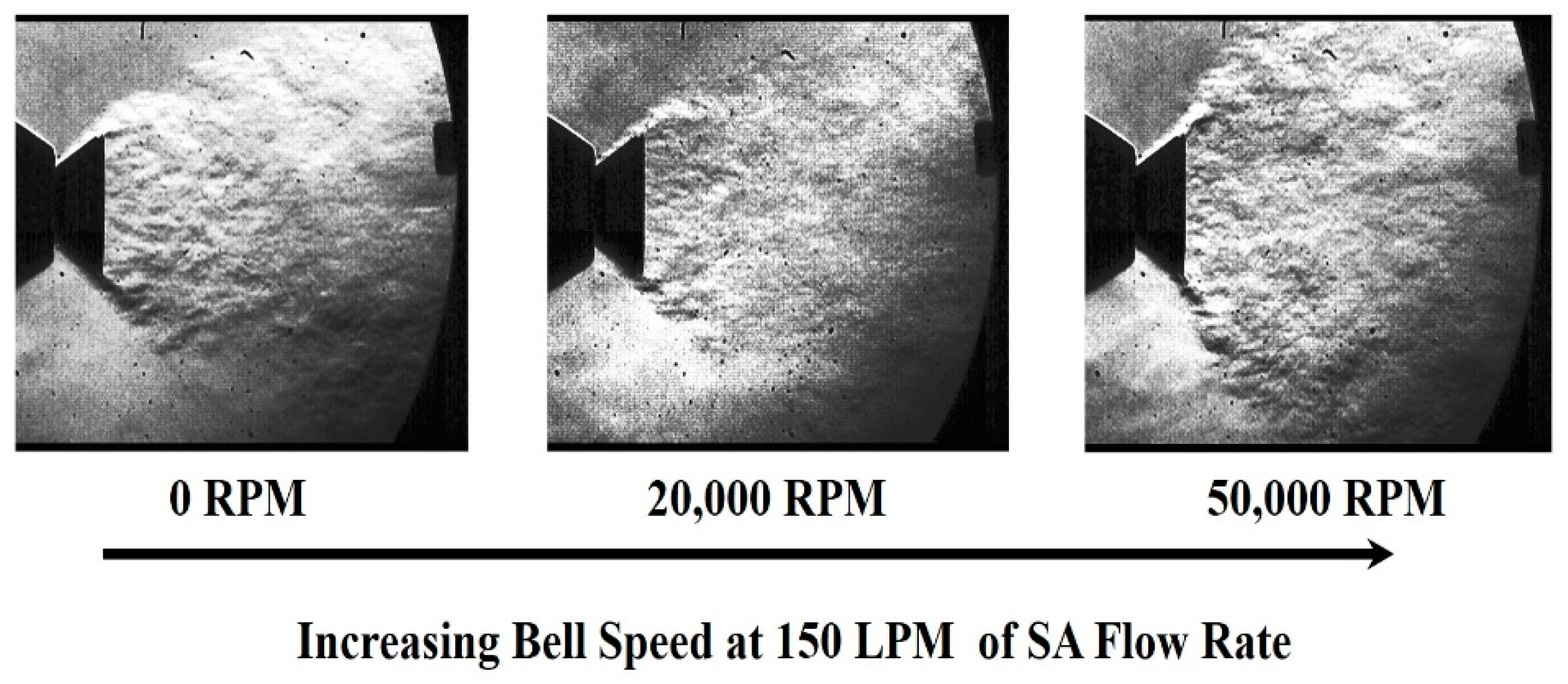

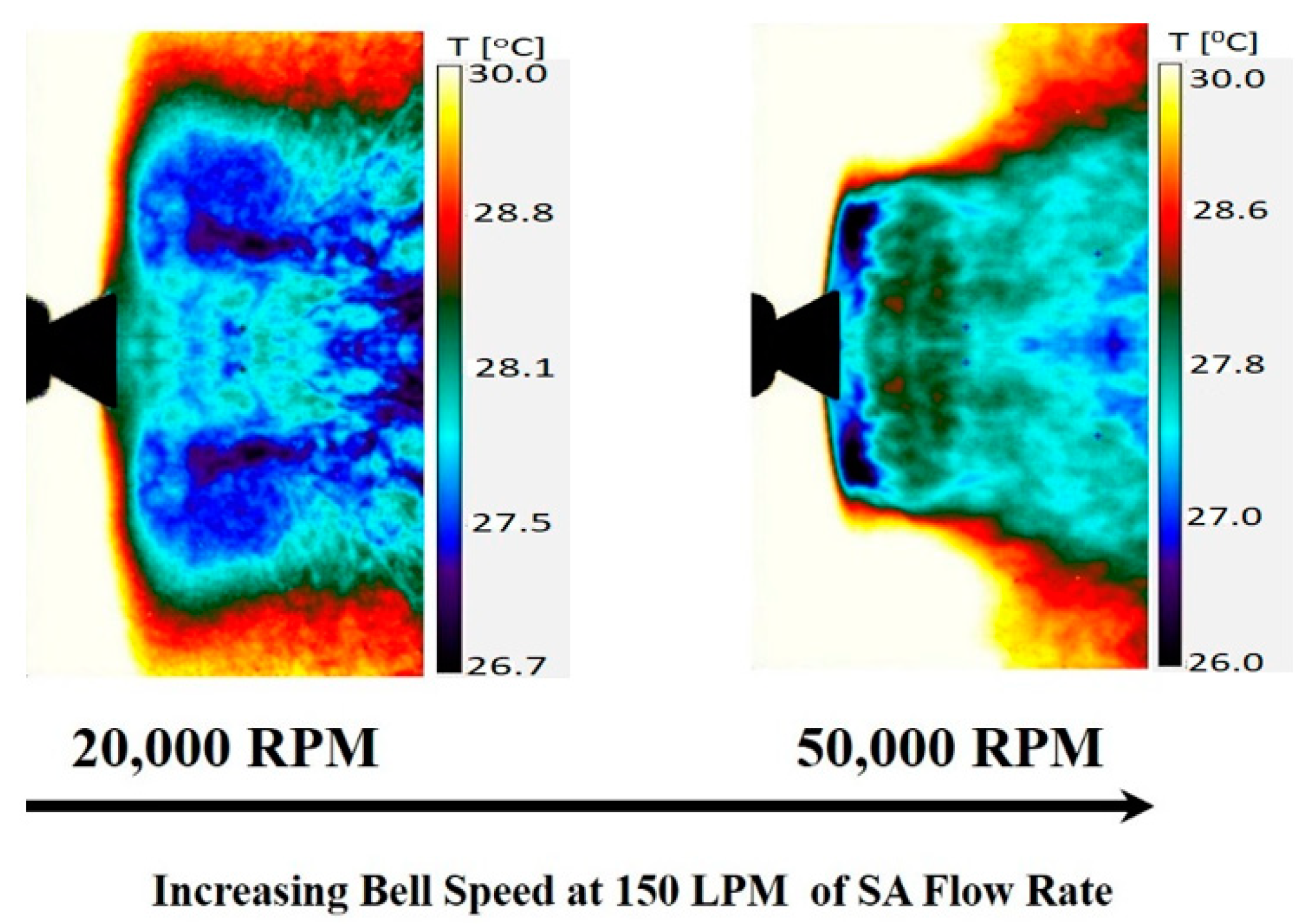

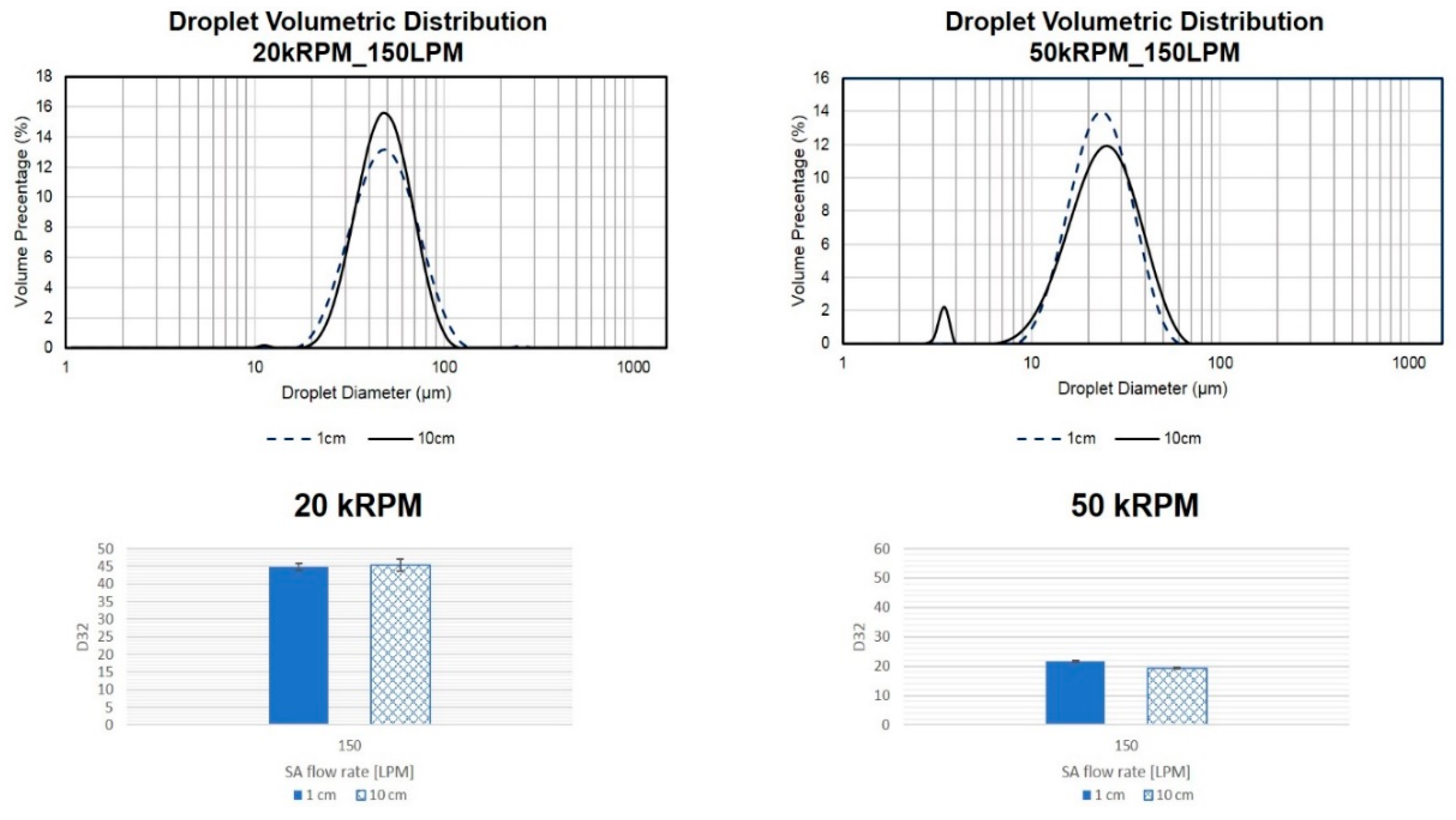

3.2. Results for Shaping Air Flow Rate of 150 LPM

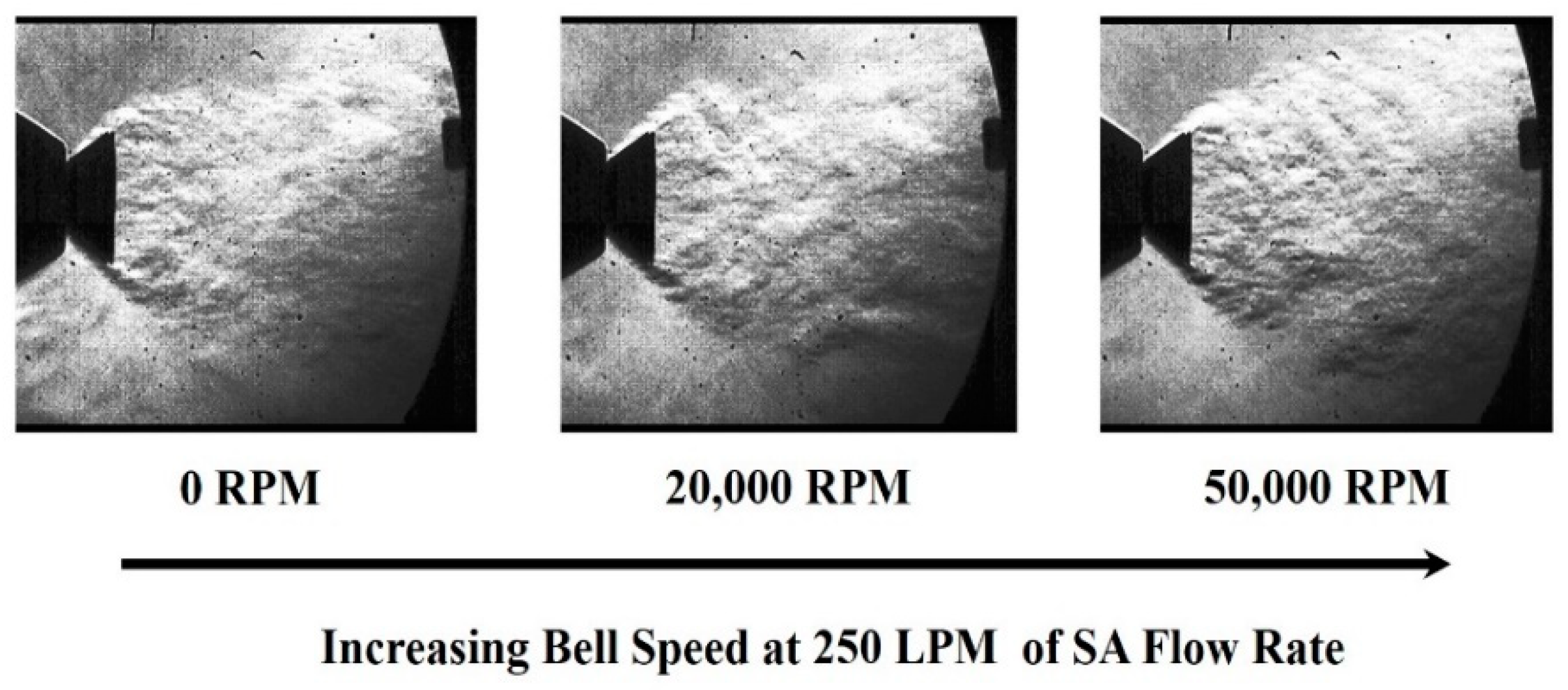

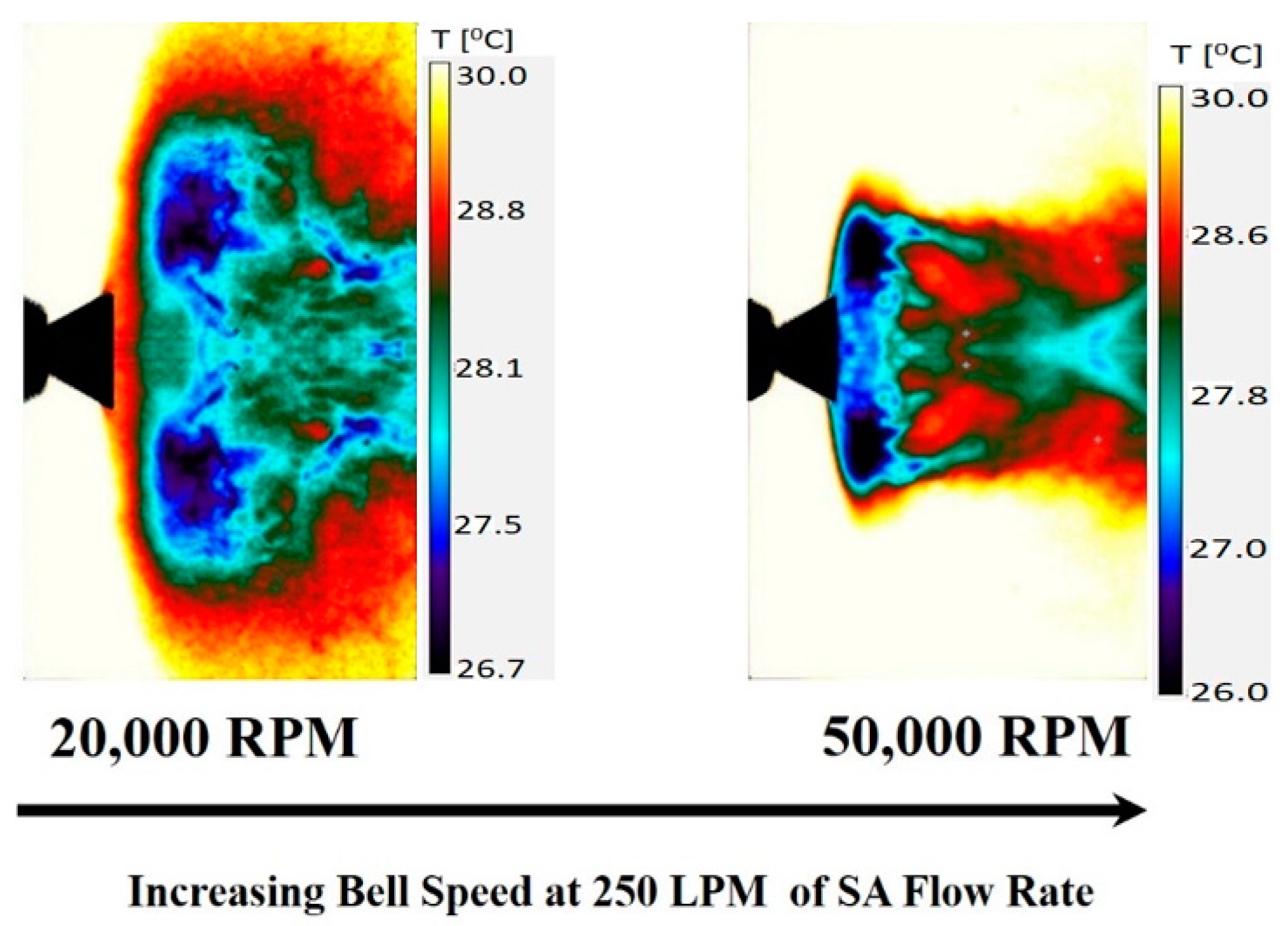

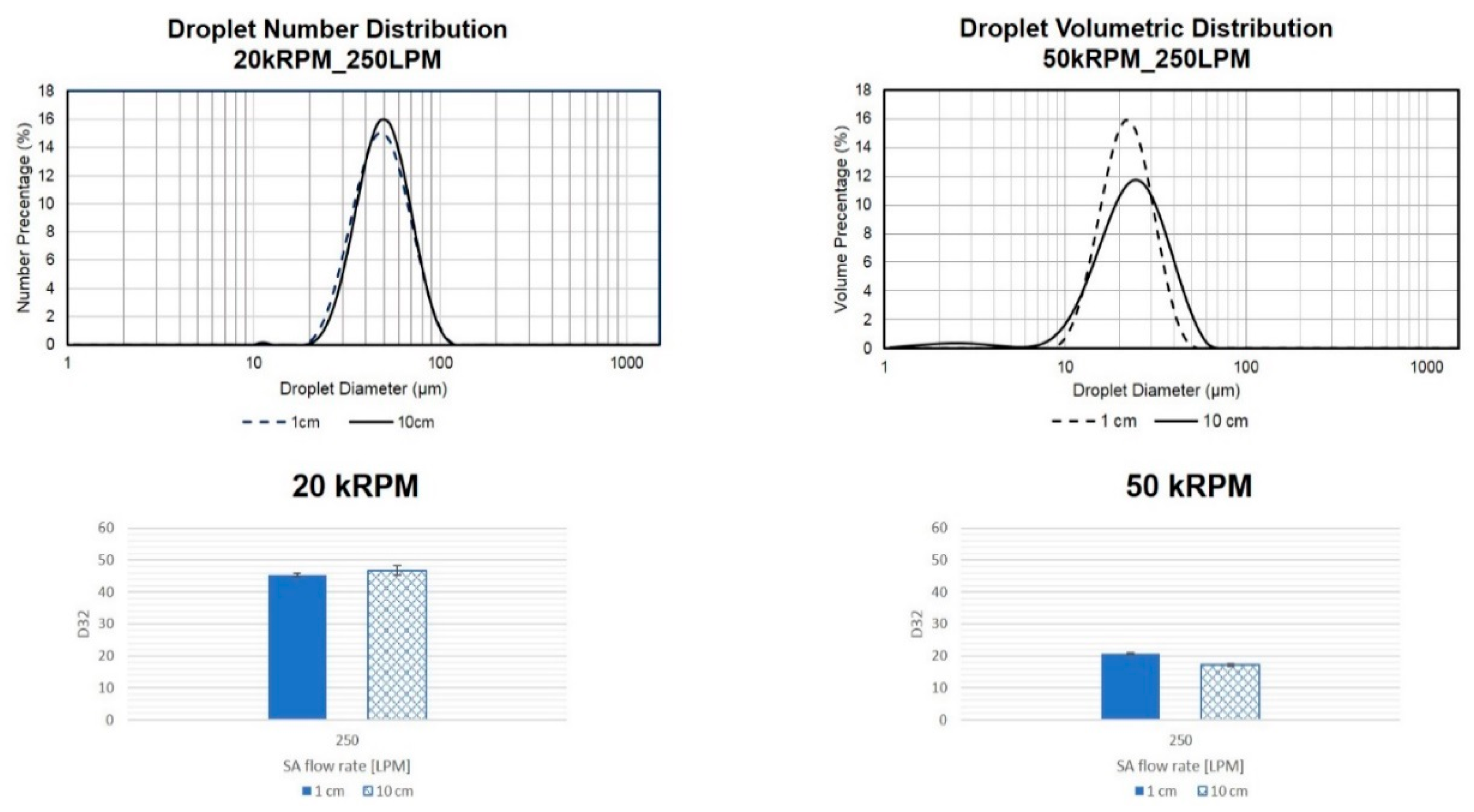

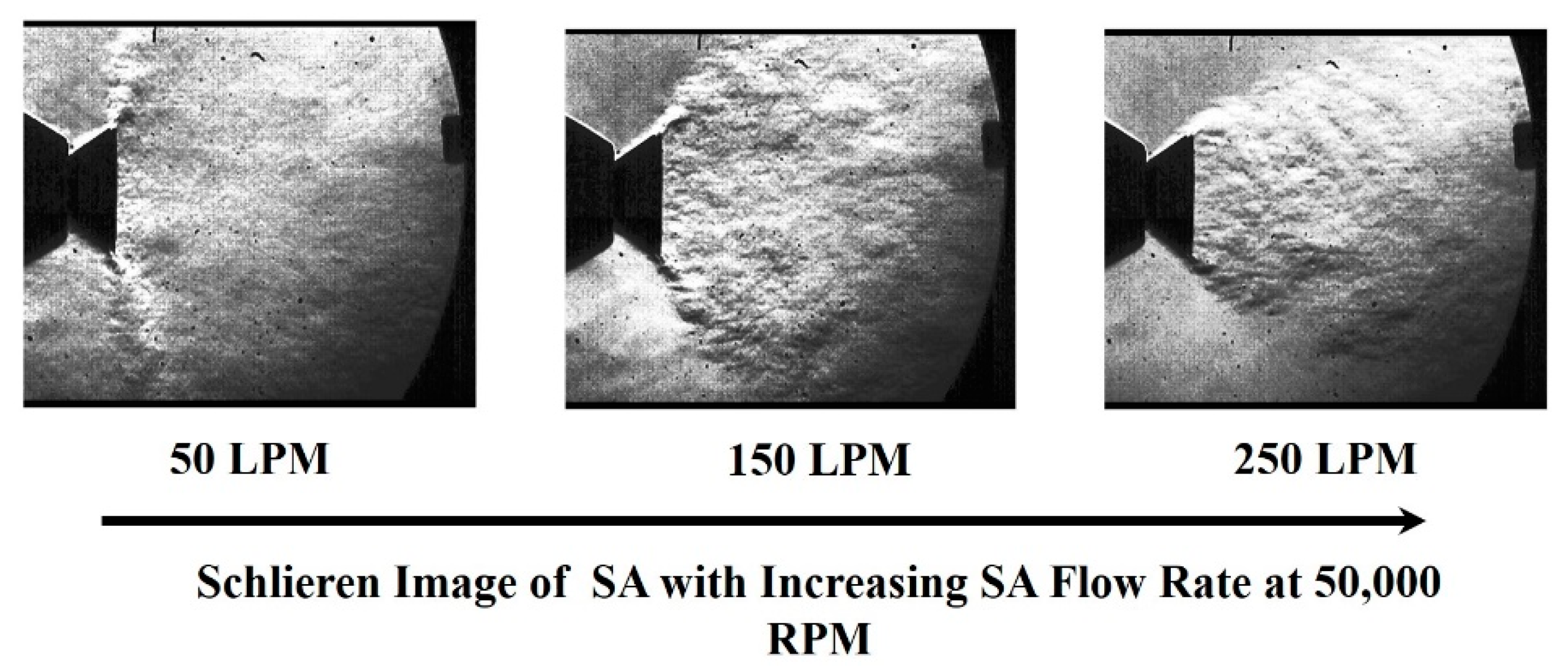

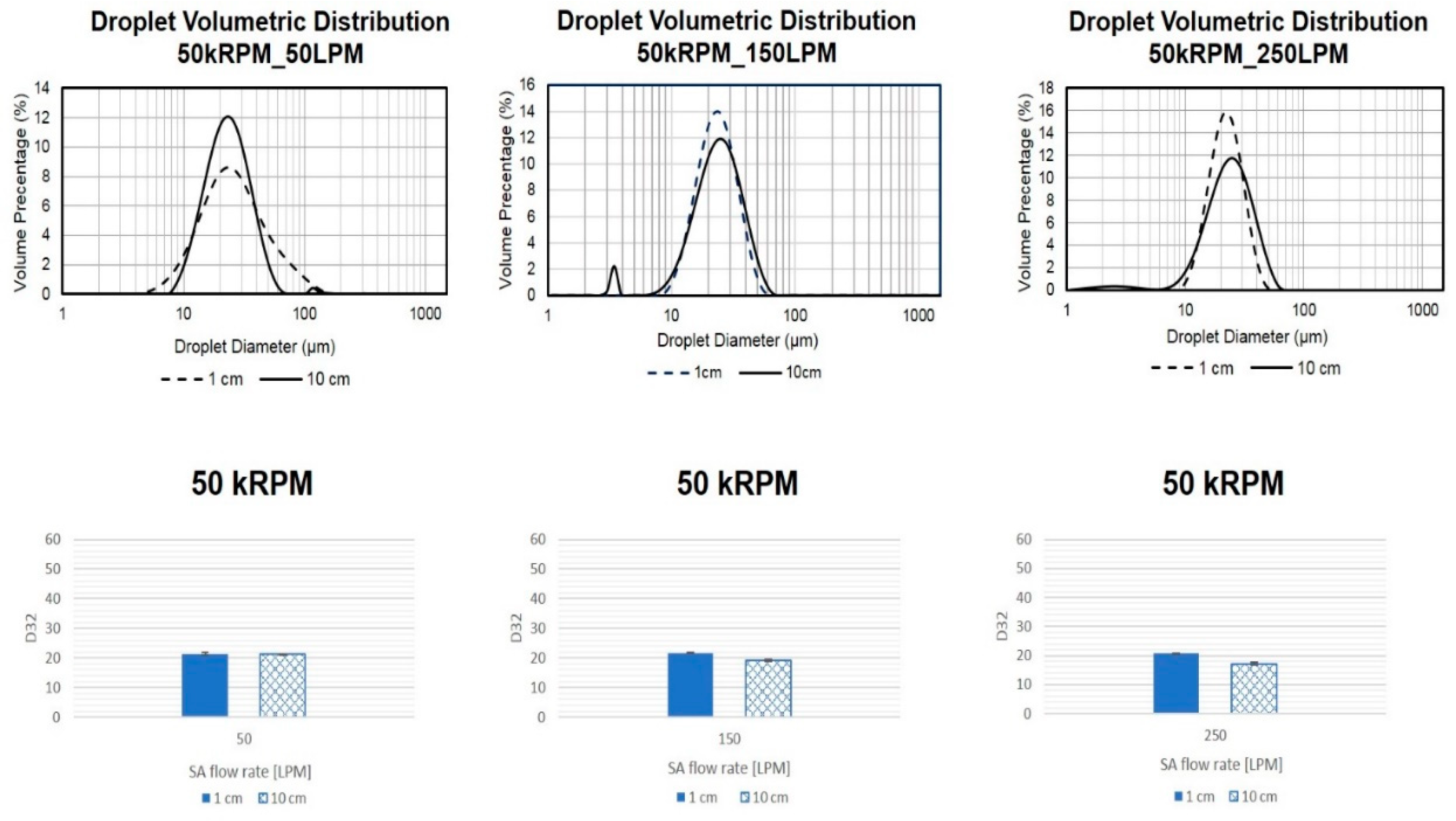

3.3. Results for Shaping Air Flow Rate of 250 LPM

3.4. Effect of Shaping Air Flow Rate on Droplet Transport and Atomization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Akafuah, N.K.; Poozesh, S.; Salaimeh, A.; Patrick, G.; Lawler, K.; Saito, K. Evolution of the automotive body coating process—A review. Coatings 2016, 6, 24. [Google Scholar] [CrossRef]

- Wilson, J.; Grib, S.; Darwish Ahmad, A.; Renfro, M.; Adams, S.; Salaimeh, A. Study of near-cup droplet breakup of an automotive electrostatic rotary bell (ESRB) atomizer using high-speed shadowgraph imaging. Coatings 2018, 8, 174. [Google Scholar] [CrossRef]

- Bailey, A.G. Electrostatic atomization of liquids. Sci. Prog. 1974, 61, 555–581. [Google Scholar]

- Frost, A. Rotary atomization in the ligament formation mode. J. Agric. Eng. Res. 1981, 26, 63–78. [Google Scholar] [CrossRef]

- Corbeels, P.; Senser, D.W.; Lefebvre, A.H. Atomization characteristics of a highspeed rotary-bell paint applicator. At. Sprays 1992, 2, 87–89. [Google Scholar] [CrossRef]

- Ahmed, M.; Youssef, M. Influence of spinning cup and disk atomizer configurations on droplet size and velocity characteristics. Chem. Eng. Sci. 2014, 107, 149–157. [Google Scholar] [CrossRef]

- Peng, H.; Wang, N.; Wang, D.; Ling, X. Experimental study on the critical characteristics of liquid atomization by a spinning disk. Ind. Eng. Chem. Res. 2016, 55, 6175–6185. [Google Scholar] [CrossRef]

- Huang, H.; Lai, M.-C.; Meredith, M. Simulation of spray transport from rotary cup atomizer using KIVA-3V. In Proceedings of the 10th International KIVA User’s Group Meeting, Detroit, MI, USA, 5 March 2000. [Google Scholar]

- Domnick, J.; Thieme, M. Atomization characteristics of high-speed rotary bell atomizers. At. Sprays 2006, 16, 857–874. [Google Scholar]

- Dombrowski, N.; Lloyd, T. Atomisation of liquids by spinning cups. Chem. Eng. J. 1974, 8, 63–81. [Google Scholar] [CrossRef]

- Fan, H.-T.; Kuo, H.; Simmer, J. Measuring paint droplet size, velocity, and charge-to-mass ratio distribution for electrostatic rotary bell spray simulation. In Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition, Denver, CO, USA, 11–17 November 2011; American Society of Mechanical Engineers: New York, NY, USA, 2011; pp. 703–709. [Google Scholar]

- Ahmed, M.; Youssef, M. Characteristics of mean droplet size produced by spinning disk atomizers. J. Fluids Eng. 2012, 134, 071103. [Google Scholar] [CrossRef]

- Im, K.-S.; Lai, M.-C.; Yu, S.-T.J.; Matheson, R.R. Simulation of spray transfer processes in electrostatic rotary bell sprayer. J. Fluids Eng. 2004, 126, 449–456. [Google Scholar] [CrossRef]

- Fukuta, K.; Murate, M.; Ohashi, Y.; Toda, K. New rotary bell for metallic paint application. Met. Finish. 1993, 91, 39–42. [Google Scholar]

- Matsuyama, K. Effect of shaping air nozzle shape on spray characteristics of rotary bell-cup atomizer. In Proceedings of the Eighteenth Symosium (ILASS-Japan) on Atomization, Fukuoka, Japan, 17–18 December 2009; pp. 57–62. [Google Scholar]

- Honma, K.; Yamasaki, I. Rotary Atomizing Electrostatic Coating Apparatus and Method. U.S. Patent 5,980,994, 9 November 1999. [Google Scholar]

- Tachi, K.; Yamada, K.; Okuda, C.; Suzuki, S. Study on paint coating by electrostatic rotary atomizer (iv)—Effects of shaping air on paint particle flow. Shikizai Kyokaishi 1987, 60, 321–327. [Google Scholar]

- Wu, J.-Z.; Ma, H.-Y.; Zhou, M.-D. Vortical Flows; Springer: New York, NY, USA, 2015. [Google Scholar]

- Im, K.-S.; Lai, M.-C.; Liu, Y.; Sankagiri, N.; Loch, T.; Nivi, H. Visualization and measurement of automotive electrostatic rotary-bell paint spray transfer processes. J. Fluids Eng. 2001, 123, 237–245. [Google Scholar] [CrossRef]

- Bauckhage, K.; Schulte, G.; Scholz, T. Atomization of water based metallic paint by means of electrostation rotary atomizers. In Proceedings of the Sixth International Conference on Liquid Atomization and Spray Systems, Rouen, France, 18–22 July 1994. [Google Scholar]

- Akafuah, N.K.; Salazar, A.J.; Saito, K. Infrared visualization of automotive paint spray transfer process. In Proceedings of the ASME 2009 Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009; American Society of Mechanical Engineers: New York, NY, USA, 2009; pp. 759–765. [Google Scholar]

- Stevenin, C.; Béreaux, Y.; Charmeau, J.Y.; Balcaen, J. Shaping air flow characteristics of a high-speed rotary-bell sprayer for automotive painting processes. J. Fluids Eng. 2015, 137, 111304–111308. [Google Scholar] [CrossRef]

- Settles, G.S. Schlieren and Shadowgraph Techniques: Visualizing Phenomena in Transparent Media; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Settles, G.S.; Hargather, M.J. A review of recent developments in schlieren and shadowgraph techniques. Meas. Sci. Technol. 2017, 28, 042001. [Google Scholar] [CrossRef]

- Settles, G.S. The penn state full-scale schlieren system. In Proceedings of the 11th International Symposium on Flow Visualization, Notre Dame, IN, USA, 9–12 August 2004. [Google Scholar]

- Settles, G.B.; Hackett, E.D.; Miller, J.M.; Weinstein, L. Full-scale schlieren flow visualization. In Proceedings of the 7th International Symposium on Flow Visualizatio, Seattle, WA, USA, 11–14 September 1995. [Google Scholar]

- Settles, G.S. Schlieren and shadowgraph imaging in the great outdoors. In Proceedings of the 2nd Pacific Symposium on Flow Visualization and Image Processing, Honolulu, HI, USA, 16–19 May 1999. [Google Scholar]

- Zhang, Z. Lda Application Methods: Laser Doppler Anemometry for Fluid Dynamics; Springer Science & Business Media: New York, NY, USA, 2010. [Google Scholar]

- Grant, I. Particle image velocimetry: A review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1997, 211, 55–76. [Google Scholar] [CrossRef]

- Akafuah, N.K.; Salazar, A.J.; Saito, K. Infrared thermography-based visualization of droplet transport in liquid sprays. Infrared Phys. Technol. 2010, 53, 218–226. [Google Scholar] [CrossRef]

- Mazumdar, A. Principles and Techniques of Schlieren Imaging Systems; Columbia University: New York, NY, USA, 2013. [Google Scholar]

- Domnick, J.; Scheibe, A.; Ye, Q. The simulation of the electrostatic spray painting process with high-speed rotary bell atomizers. Part I: Direct charging. Part. Part. Syst. Charact. 2005, 22, 141–150. [Google Scholar] [CrossRef]

- Domnick, J. Effect of bell geometry in high-speed rotary bell atomization. In Proceedings of the 23rd Annual Conference on Liquid Atomization and Spray Systems, Brno, Czech Republic, 6–8 September 2010; pp. 6–8. [Google Scholar]

- Bhandari, B.R.; Bansal, N.; Zhang, M.; Schuck, P. Handbook of Food Powders: Processes and Properties; Elsevier: Philadelphia, PA, USA, 2013. [Google Scholar]

| Bell Rotational Speed (RPM) | SA Flow Rate (L·min−1) |

|---|---|

| 0 | 50 |

| 150 | |

| 250 | |

| 20,000 | 50 |

| 150 | |

| 250 | |

| 50,000 | 50 |

| 150 | |

| 250 |

| SA Flow Rate (L·min−1) | Bell Rotational Speed (kRPM) | Angle of the SA (Degree) |

|---|---|---|

| 50 | 0 | 84 |

| 20 | 152 | |

| 50 | 166 | |

| 150 | 0 | 78 |

| 20 | 96 | |

| 50 | 136 | |

| 250 | 0 | 90 |

| 20 | 102 | |

| 50 | 110 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darwish Ahmad, A.; Abubaker, A.M.; Salaimeh, A.A.; Akafuah, N.K. Schlieren Visualization of Shaping Air during Operation of an Electrostatic Rotary Bell Sprayer: Impact of Shaping Air on Droplet Atomization and Transport. Coatings 2018, 8, 279. https://doi.org/10.3390/coatings8080279

Darwish Ahmad A, Abubaker AM, Salaimeh AA, Akafuah NK. Schlieren Visualization of Shaping Air during Operation of an Electrostatic Rotary Bell Sprayer: Impact of Shaping Air on Droplet Atomization and Transport. Coatings. 2018; 8(8):279. https://doi.org/10.3390/coatings8080279

Chicago/Turabian StyleDarwish Ahmad, Adnan, Ahmad M. Abubaker, Ahmad A. Salaimeh, and Nelson K. Akafuah. 2018. "Schlieren Visualization of Shaping Air during Operation of an Electrostatic Rotary Bell Sprayer: Impact of Shaping Air on Droplet Atomization and Transport" Coatings 8, no. 8: 279. https://doi.org/10.3390/coatings8080279