Evaluation of Thermal Degradation of DLC Film Using a Novel Raman Spectroscopy Technique

Abstract

:1. Introduction

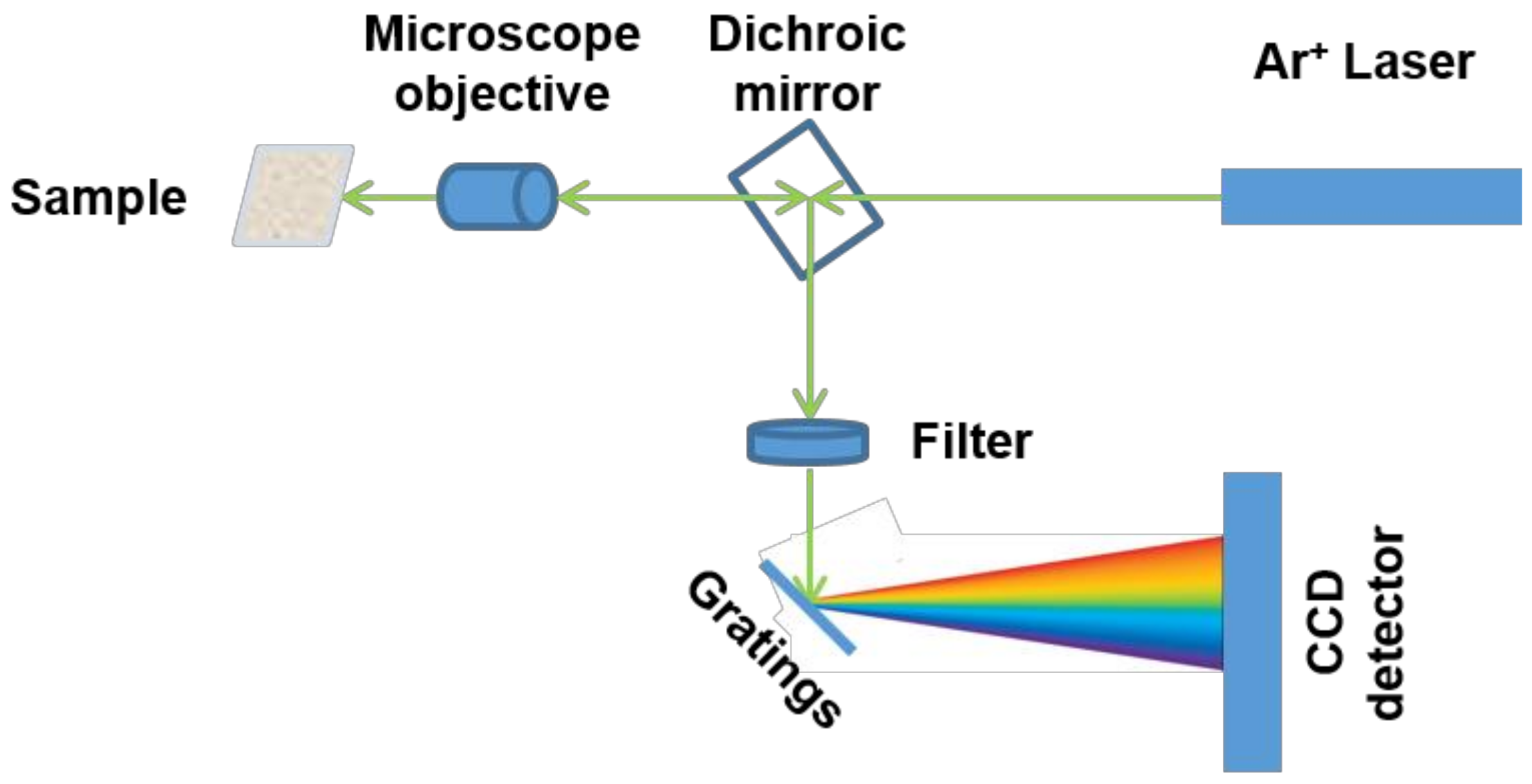

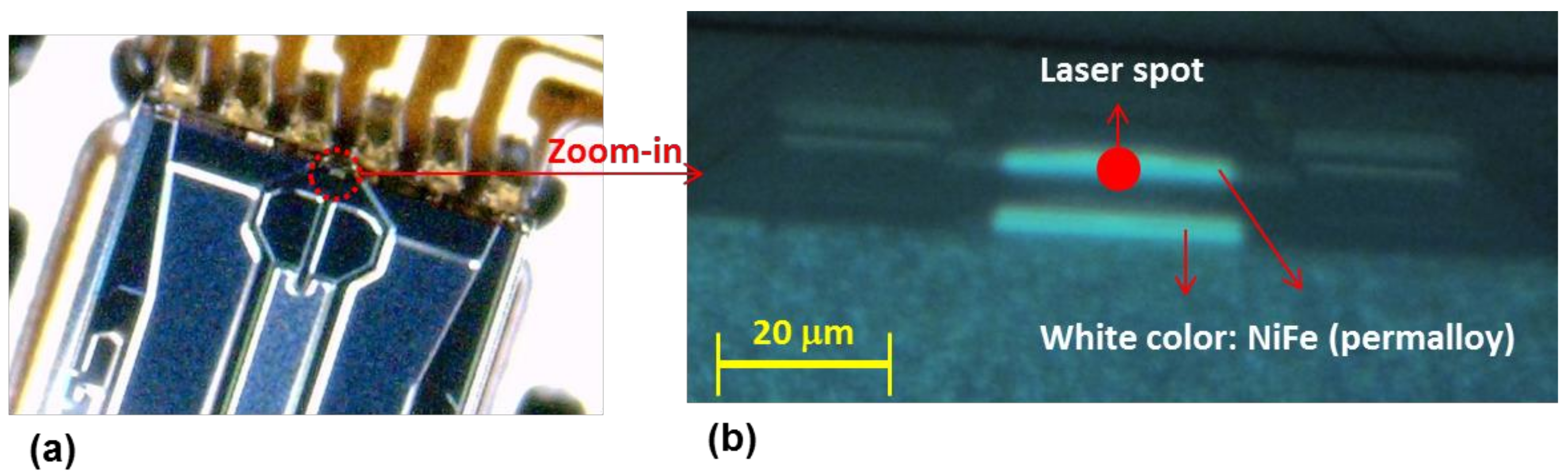

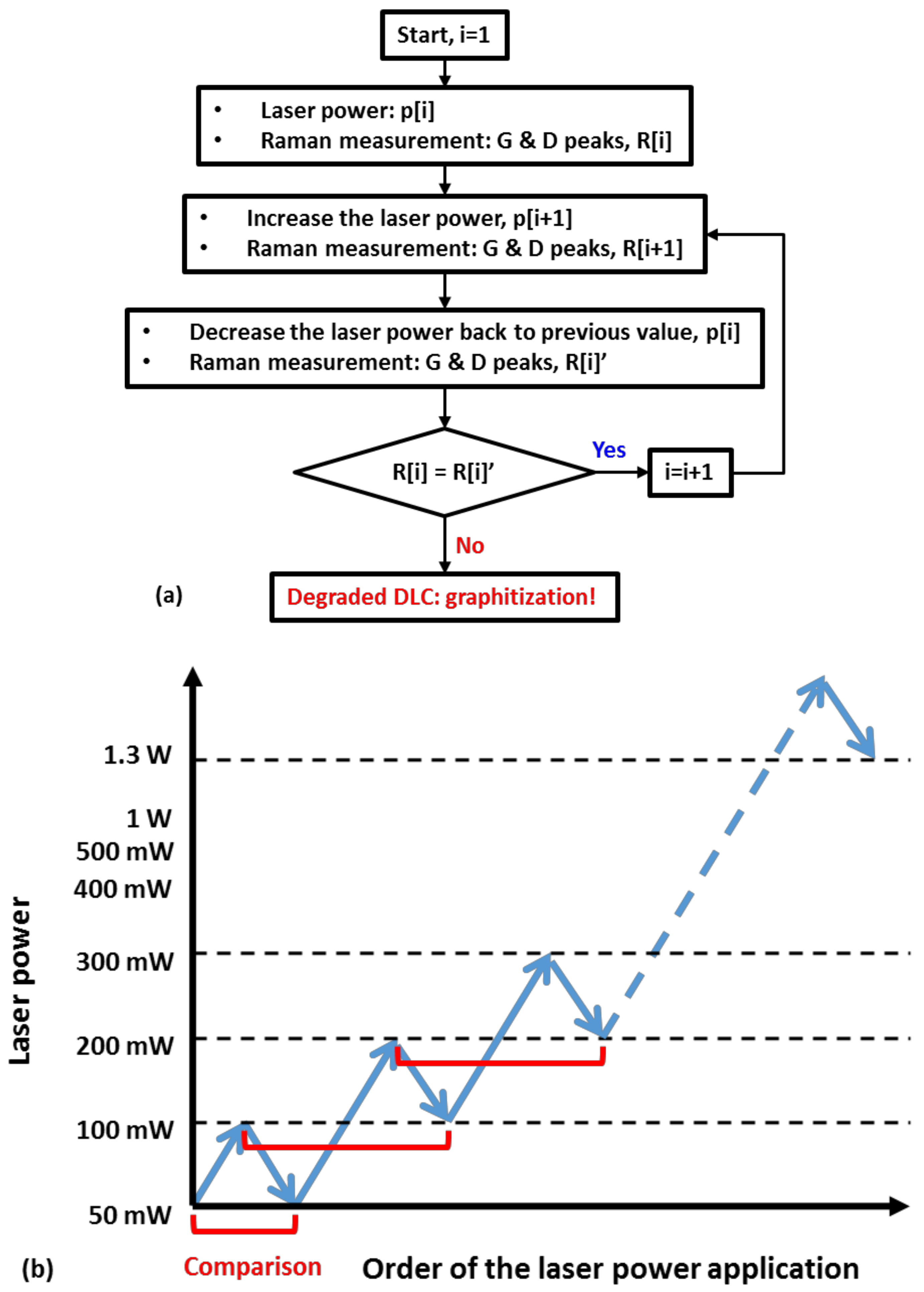

2. Materials and Methods

3. Results and Discussion

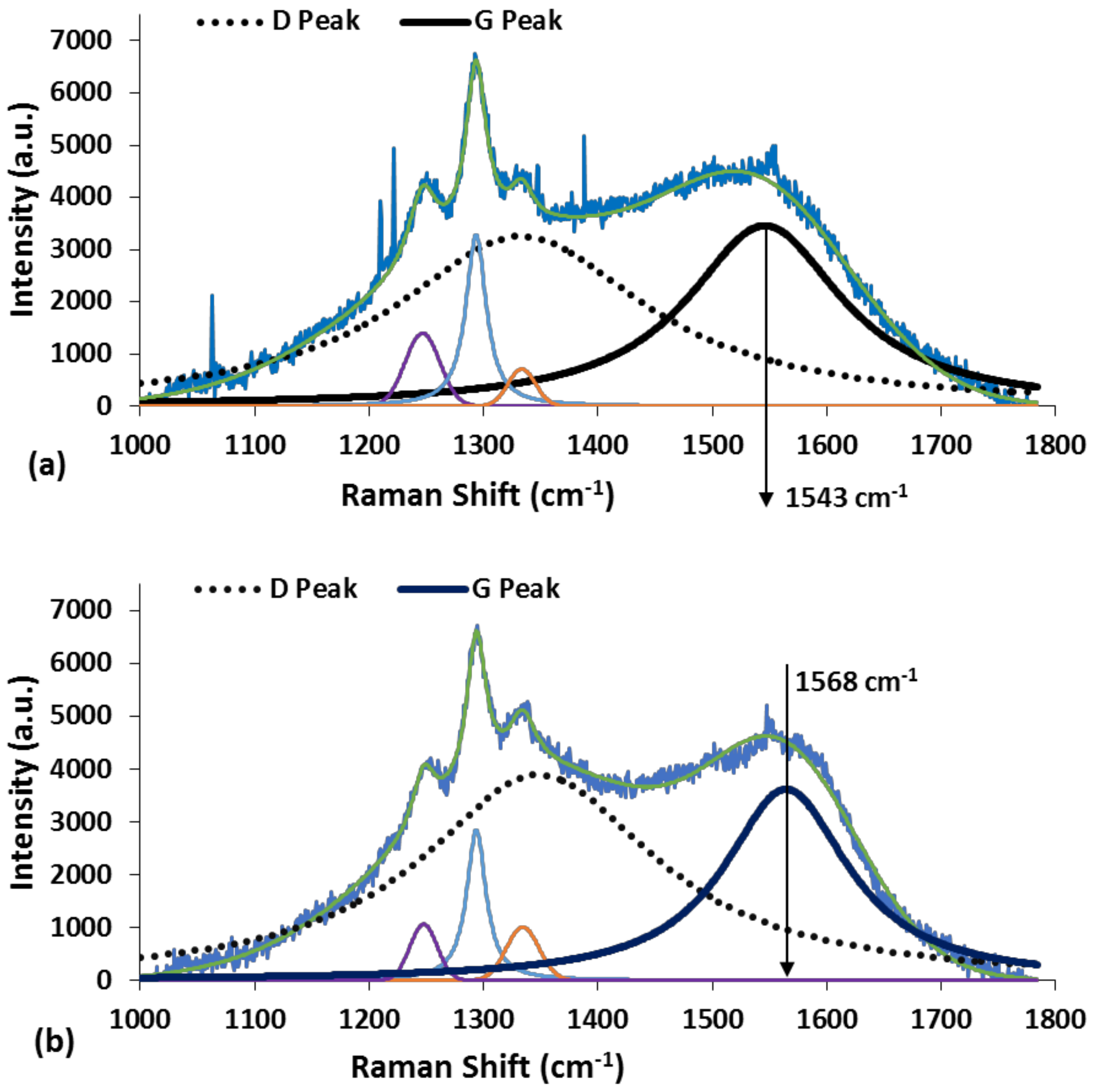

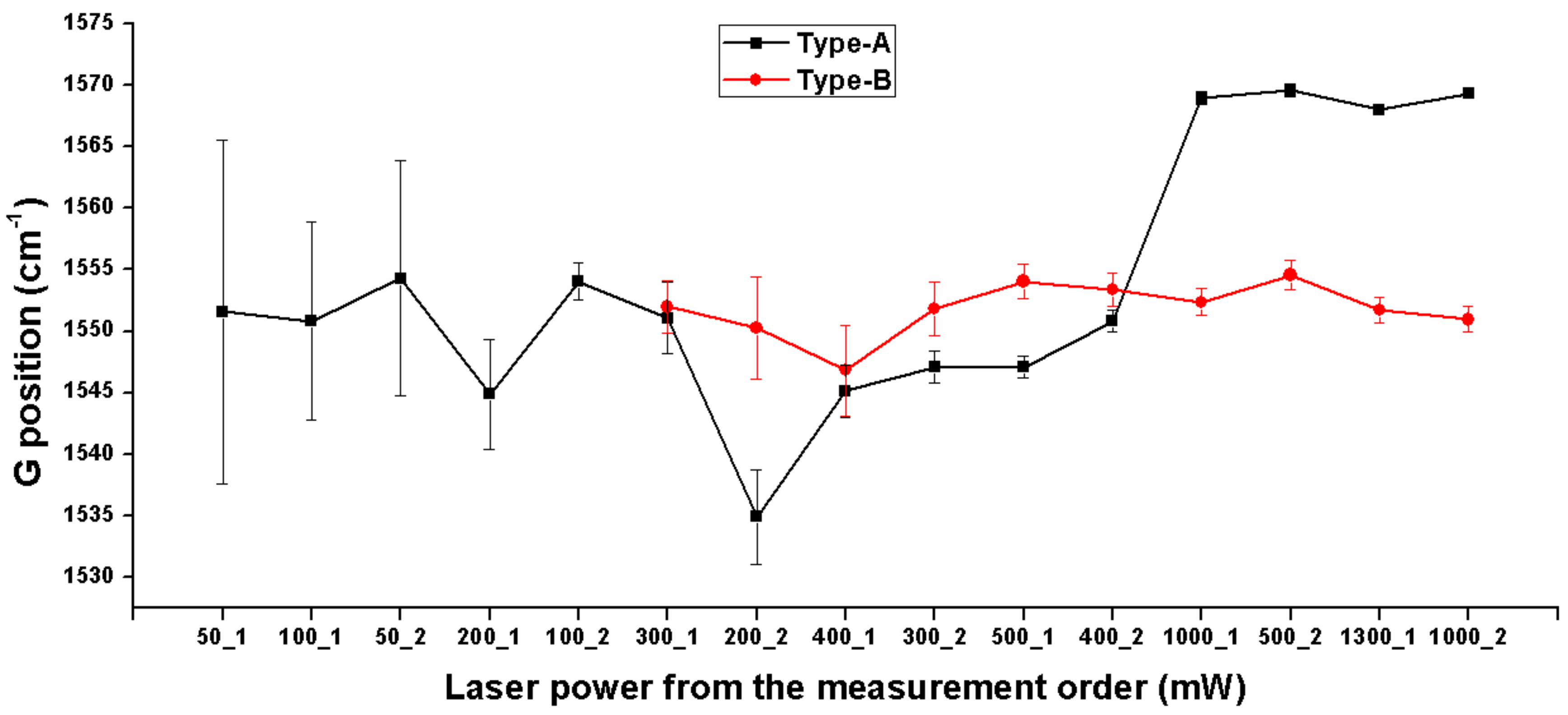

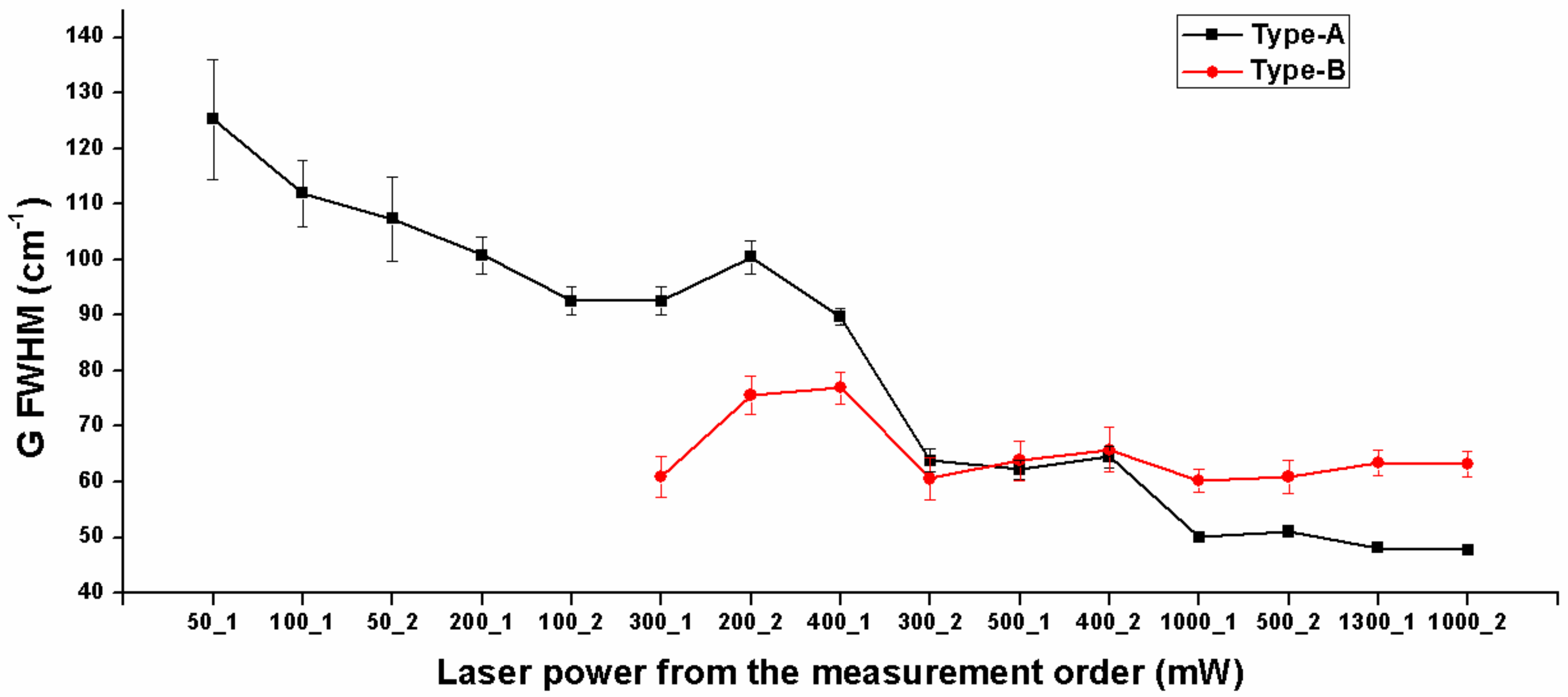

3.1. Micro-Raman Spectroscopy Characterization: G Peak Position and Width

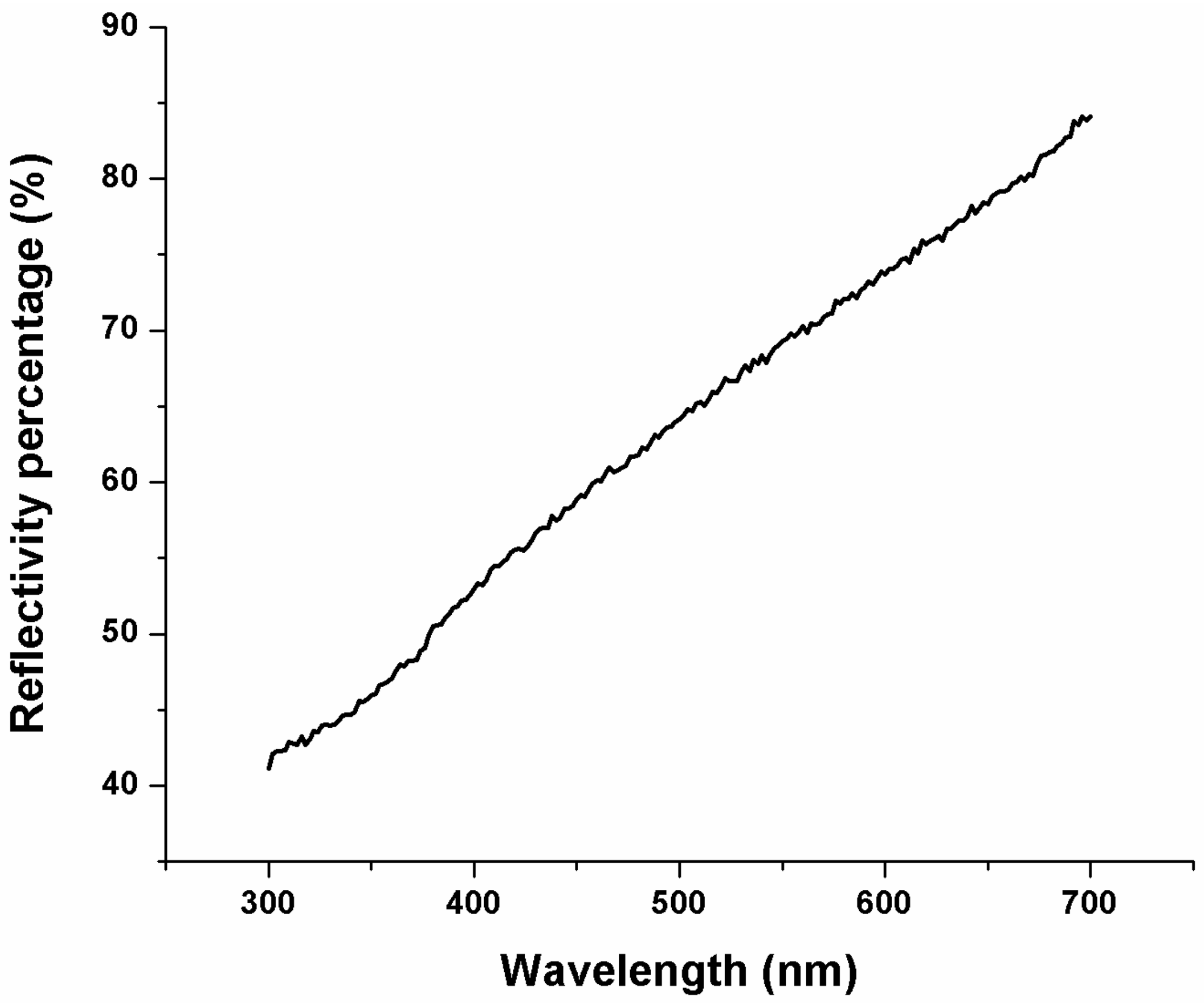

3.2. Caculation of Temperature Rise by Laser Heating

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kano, M. Super low friction of DLC applied to engine cam follower lubricated with ester-containing oil. Tribol. Int. 2006, 39, 1682–1685. [Google Scholar] [CrossRef]

- Fukui, H.; Okida, J.; Omori, N.; Moriguchi, H.; Tsuda, K. Cutting performance of DLC coated tools in dry machining aluminum alloys. Surf. Coat. Technol. 2004, 187, 70–76. [Google Scholar] [CrossRef]

- Vanhulsel, A.; Velasco, F.; Jacobs, R.; Eersels, L.; Havermans, D.; Roberts, E.W.; Sherrington, I.; Anderson, M.J.; Gaillard, L. DLC solid lubricant coatings on ball bearings for space applications. Tribol. Int. 2007, 40, 1186–1194. [Google Scholar] [CrossRef]

- Österle, W.; Klaffke, D.; Griepentrog, M.; Gross, U.; Kranz, I.; Knabe, C. Potential of wear resistant coatings on Ti-6Al-4V for artificial hip joint bearing surfaces. Wear 2008, 264, 505–517. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like carbon: state of the art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- Jung, H.; Park, H.; Sik, S.; Yeo, S. The structural and electron field emission characteristics of pulsed laser deposited diamond-like carbon films with thermal treatment. Thin Solid Films 1999, 356, 151–156. [Google Scholar] [CrossRef]

- McKenzie, D.R.; Yin, Y.; Marks, N.A.; Davis, C.A.; Pailthorpe, B.A.; Amaratunga, G.A.J.; Veerasamy, V.S. Hydrogen-free amorphous carbon preparation and properties. Diam. Relat. Mater. 1994, 3, 353–360. [Google Scholar] [CrossRef]

- Lifshitz, Y. Carbon forms structured by energetic species: Amorphous, nanotubes, and crystalline. In The Dekker Encyclopedia of Nanoscience and Nanotechnology; Nalwa, H.S., Ed.; CRC Press: New York, NY, USA, 2014; pp. 1369–1378. ISBN 978-1-4398-9134-6. [Google Scholar]

- Liu, Y.; Erdemirb, A.; Meletis, E.I. Influence of environmental parameters on the frictional behavior of DLC coatings. Surf. Coat. Technol. 1997, 94–95, 463–468. [Google Scholar] [CrossRef]

- Lee, S.; Yeo, C.-D. Microwear mechanism of head carbon film during head disk interface sliding contact. Tribol. Int. 2012, 45, 30–37. [Google Scholar] [CrossRef]

- He, M.; Lee, S.; Yeo, C.-D. Investigating atomic structure of thin carbon film under mechanical stress and frictional heat generation. Surf. Coat. Technol. 2015, 261, 79–85. [Google Scholar] [CrossRef]

- Rottmayer, R.E.; Batra, S.; Buechel, D.; Challener, W.A.; Hohlfeld, J.; Kubota, Y.; Li, L.; Lu, B.; Mihalcea, C.; Mountfield, K.; et al. Heat-Assisted Magnetic Recording. IEEE Trans. Magn. 2006, 42, 2417–2421. [Google Scholar] [CrossRef]

- Pathem, B.K.; Guo, X.C.; Rose, F.; Wang, N.; Komvopoulos, K.; Schreck, E.; Marchon, B. Carbon overcoat oxidation in heat-assisted magnetic recording. IEEE Trans. Magn. 2013, 49, 3721–3724. [Google Scholar] [CrossRef]

- Suk, M.; Miyake, K.; Kurita, M.; Tanaka, H.; Saegusa, S.; Robertson, N. Verification of thermally induced nanometer actuation of magnetic recording transducer to overcome mechanical and magnetic spacing challenges. IEEE Trans. Magn. 2005, 41, 4350–4352. [Google Scholar] [CrossRef]

- Ahmad, I.; Holtz, M.; Faleev, N.N.; Temkin, H. Dependence of the stress-temperature coefficient on dislocation density in epitaxial GaN grown on a-Al2O3 and 6H-SiC substrates. J. Appl. Phys. 2004, 95, 1692–1697. [Google Scholar] [CrossRef]

- Lewis, W.A. The use of Raman spectroscopy to monitor the quality of carbon overcoats in disk drive industry. In Handbook of Raman Spectroscopy; Lewis, I.R., Edwards, H.G.M., Eds.; Marcel Dekker, Inc.: New York, NY, USA, 2001; pp. 975–998. ISBN 0-8247-0557-2. [Google Scholar]

- Ferrari, A.C. Diamond-like carbon for magnetic storage disks. Surf. Coat. Technol. 2004, 180–181, 190–206. [Google Scholar] [CrossRef]

- Tamor, M.A.; Vassel, W.C. Raman “fingerprinting” of amorphous carbon films. J. Appl. Phys. 1994, 76, 3823–3830. [Google Scholar] [CrossRef]

- Nakahigashi, T.; Tanaka, Y.; Miyake, K.; Oohara, H. Properties of flexible DLC film deposited by amplitude-modulated RF P-CVD. Tribol. Int. 2004, 37, 907–912. [Google Scholar] [CrossRef]

- Kennedy, F.E.B. Frictional heating and contact temperatures. In Modern Tribology Handbook; Bhushan, B., Ed.; CRC Press: New York, NY, USA, 2000; Volume 1, pp. 227–264. ISBN 978-0-8493-8403-5. [Google Scholar]

| Laser Power (mW) | Ts of DLC Film (°C) |

|---|---|

| 50 | 56.6 |

| 100 | 93.2 |

| 200 | 166.4 |

| 300 | 239.6 |

| 400 | 312.8 |

| 500 | 386.1 |

| 1000 | 752.1 |

| 1300 | 971.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, M.; Yeo, C. Evaluation of Thermal Degradation of DLC Film Using a Novel Raman Spectroscopy Technique. Coatings 2018, 8, 143. https://doi.org/10.3390/coatings8040143

He M, Yeo C. Evaluation of Thermal Degradation of DLC Film Using a Novel Raman Spectroscopy Technique. Coatings. 2018; 8(4):143. https://doi.org/10.3390/coatings8040143

Chicago/Turabian StyleHe, Muyang, and Changdong Yeo. 2018. "Evaluation of Thermal Degradation of DLC Film Using a Novel Raman Spectroscopy Technique" Coatings 8, no. 4: 143. https://doi.org/10.3390/coatings8040143