Effects of the Oxide Coating Thickness on the Small Flaw Sizing Using an Ultrasonic Test Technique

Abstract

:1. Introduction

2. Theory

2.1. Ultrasonic Measurement Model

2.2. Effects of the Coating Thickness

3. Experiments

3.1. Materials

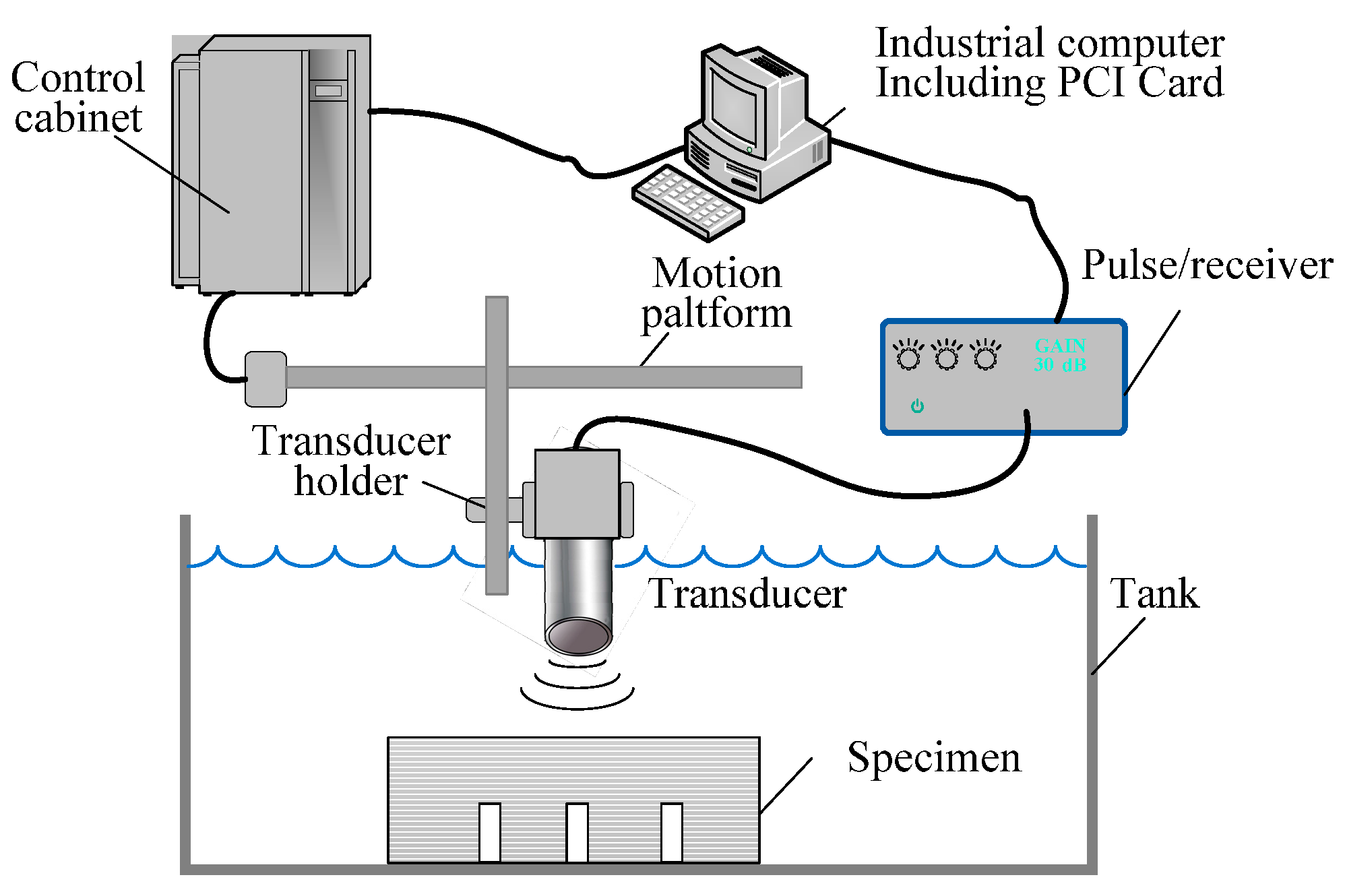

3.2. Experimental Process

4. Results and Discussions

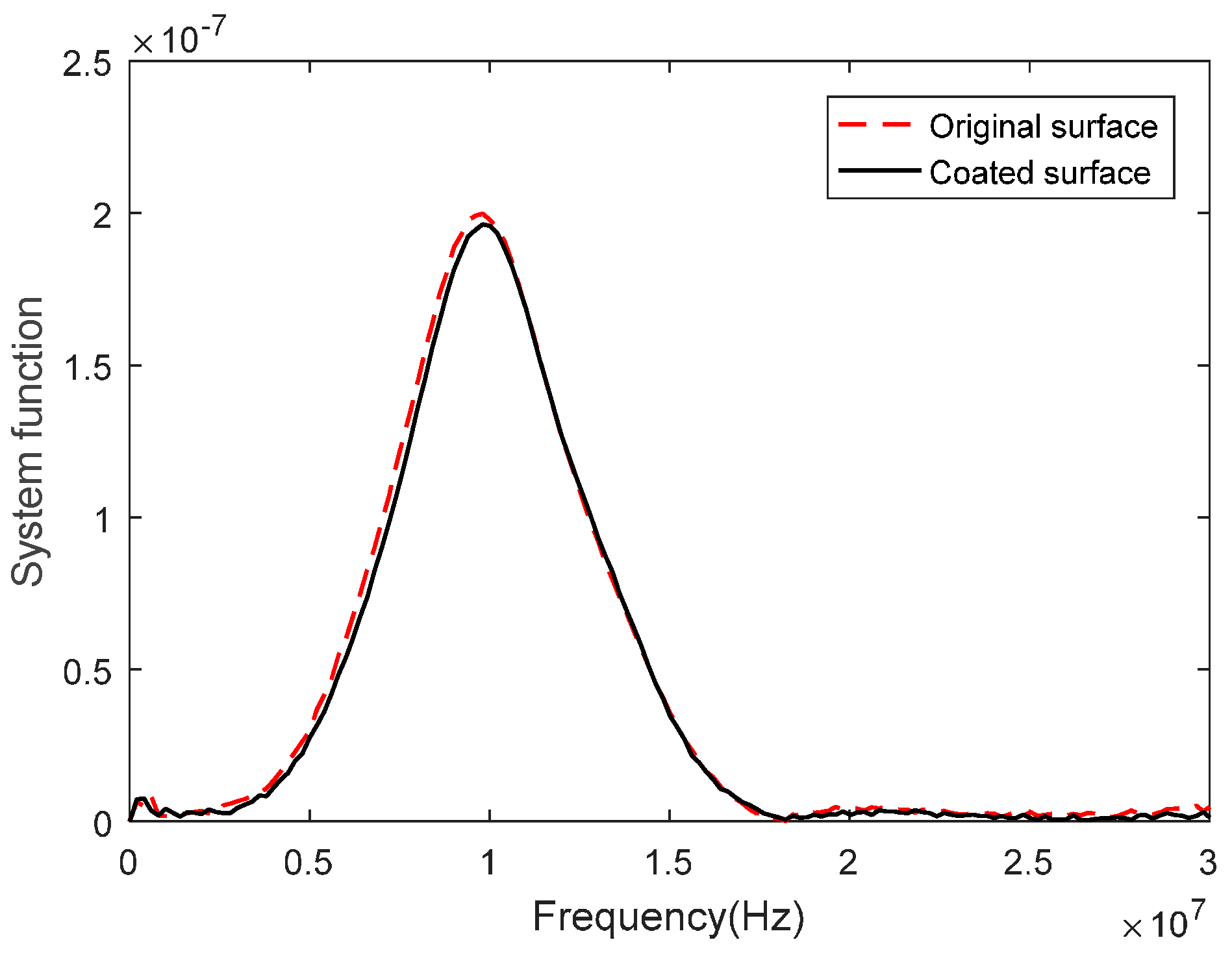

4.1. System Functions

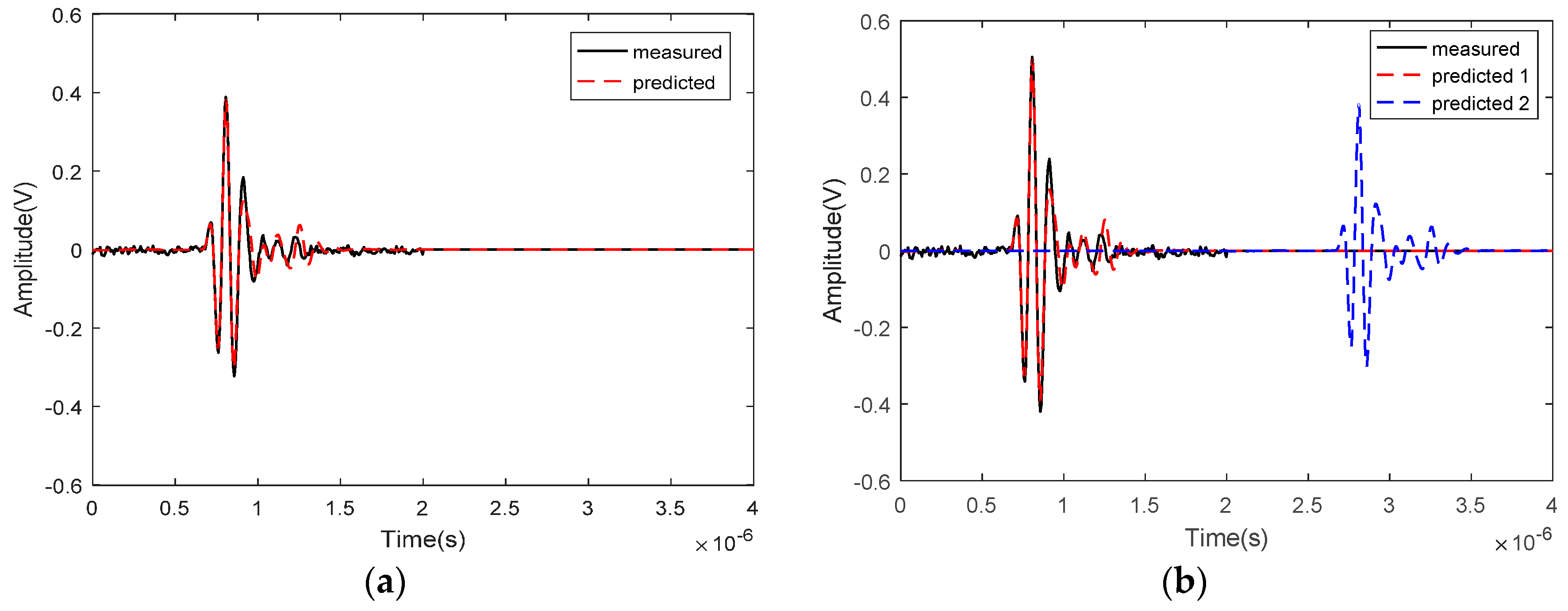

4.2. Flaw Responses

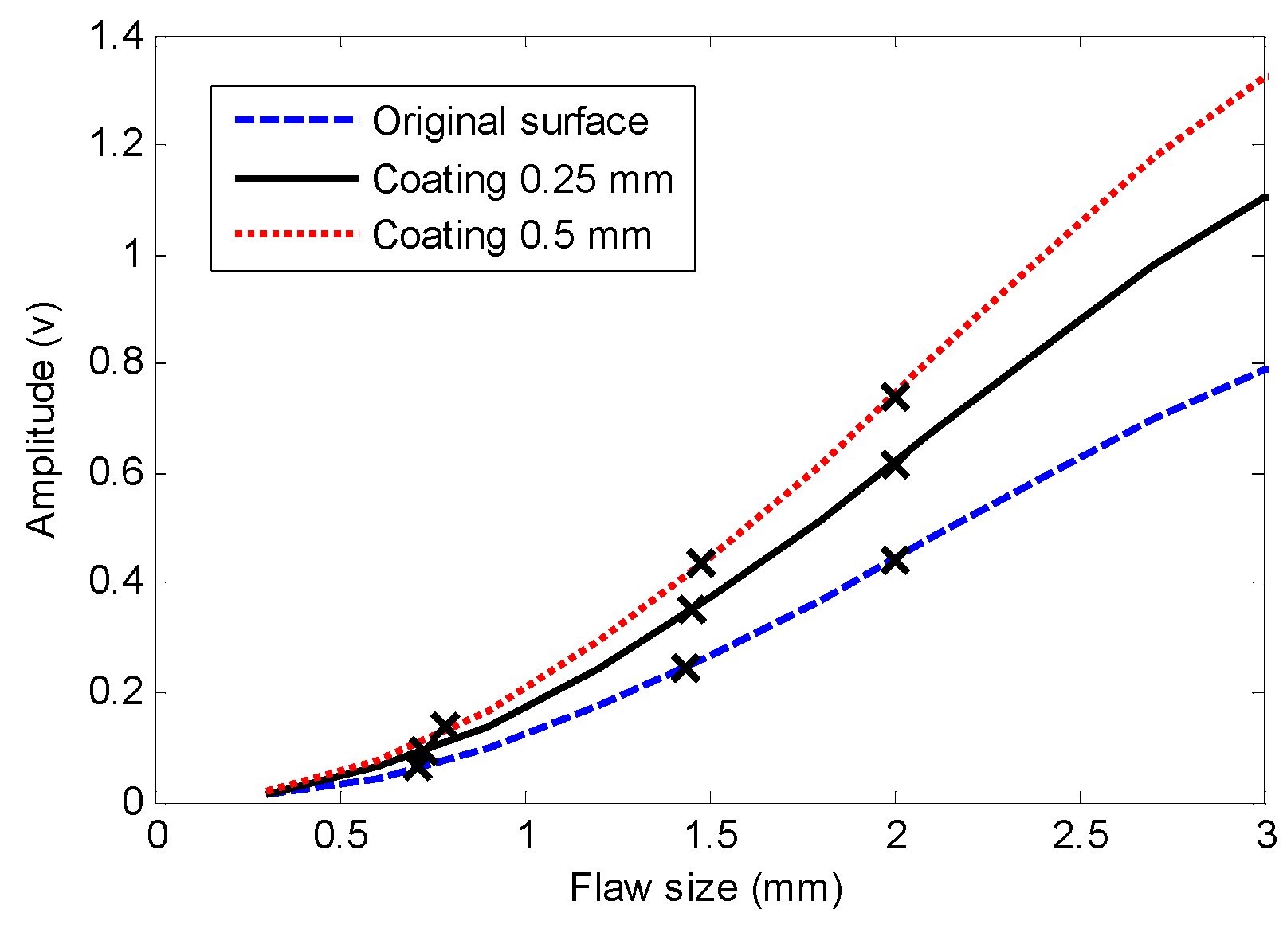

4.3. Flaw-Sizing Problems

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, W.J.; An, C.W.; Kim, Y.S.; Hong, S.I. Mechanical properties and microstructures of an AZ61 Mg alloy produced by equal channel angular pressing. Scr. Mater. 2002, 47, 39–44. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, L.; Li, X.M.; Lei, M.K. Simultaneous determination of the coating thickness and its longitudinal velocity by ultrasonic nondestructive method. NDT E Int. 2010, 43, 579–585. [Google Scholar] [CrossRef]

- He, J.; Ran, Y.; Liu, B.; Yang, J.; Guan, X. A Fatigue Crack Size Evaluation Method Based on Lamb Wave Simulation and Limited Experimental Data. Sensors 2017, 17, 2097. [Google Scholar] [CrossRef] [PubMed]

- Rose, J.L. Ultrasonic Waves in Solid Media, 2nd ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Schmerr, L.W.; Song, S.-J.; Sedov, A. Ultrasonic flaw sizing inverse problems. Inverse Probl. 2002, 18, 1775–1793. [Google Scholar] [CrossRef]

- Sodev, A.; Schmerr, L.W.; Song, S.J. Ultrasonic scattering by a flat-bottom hold in immersion testing: An analytical model. J. Acoust. Soc. Am. 1992, 92, 478–486. [Google Scholar] [CrossRef]

- Achenbach, J.D. Quantitative nondestructive evaluation. Int. J. Solids Struct. 2000, 37, 13–27. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Ni, P.; Hu, H.; Song, Y. Flaw sizing using ultrasonic c-scan imaging with dynamic thresholds. Insight 2017, 59, 603–608. [Google Scholar] [CrossRef]

- Schmerr, L.W. Fundamentals of Ultrasonic Nondestructive Evaluation: A Modeling Approach; Springer: New York, NY, USA, 1998. [Google Scholar]

- Thompson, R.B.; Gray, T.A. A model relating ultrasonic scattering measurements through liquid-solid interfaces to unbounded medium scattering amplitudes. J. Acoust. Soc. Am. 1983, 74, 1279–1290. [Google Scholar] [CrossRef]

- Zhao, X.; Gnag, T.; Xu, C. Prediction of side-drilled hole signals captured by a dual crystal contact probe. J. Nondestruct. Eval. 2010, 29, 105–110. [Google Scholar] [CrossRef]

- Rogers, P.H.; Van Buren, A.L. An exact expression for the Lommel diffraction correction integral. J. Acoust. Soc. Am. 1974, 55, 724–728. [Google Scholar] [CrossRef]

- Kim, H.J.; Schmerr, L.W.; Sedov, A. Generation of the basis sets for multi-Gaussian ultrasonic beam models—An overview. J. Acoust. Soc. Am. 2006, 119, 1971–1978. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Kube, C.M.; Song, Y.; Li, X. A self-reciprocity calibration method for broadband focused transducers. J. Acoust. Soc. Am. 2016, 140, EL236–EL241. [Google Scholar] [CrossRef] [PubMed]

- Brekhovskikh, L.M. Waves in Layered Media; Academic: New York, NY, USA, 1960. [Google Scholar]

| Material | Density (kg/m3) | Velocity (m/s) | Attenuation (Np/m) |

|---|---|---|---|

| water | 1000 | 1482 | 25.3 × 10−15 f2 |

| oxide coating | 3500 | 5400 | – |

| Mg alloys | 1800 | 5740 | 45 × 10−15 f2 |

| Coating Thickness | 0.8 mm Flaw (mm) | 1.5 mm Flaw (mm) | 2 mm Flaw (mm) | |||

|---|---|---|---|---|---|---|

| Actual Size | Measured Size | Actual Size | Measured Size | Actual Size | Measured Size | |

| – | 0.8 | 0.72 | 1.5 | 1.44 | 2 | 1.97 |

| 0.25 mm | 0.8 | 0.73 | 1.5 | 1.45 | 2 | 1.97 |

| 0.5 m | 0.8 | 0.78 | 1.5 | 1.48 | 2 | 1.98 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, X.; Li, X.; Hu, H.; Gao, G.; Zhang, S. Effects of the Oxide Coating Thickness on the Small Flaw Sizing Using an Ultrasonic Test Technique. Coatings 2018, 8, 69. https://doi.org/10.3390/coatings8020069

Miao X, Li X, Hu H, Gao G, Zhang S. Effects of the Oxide Coating Thickness on the Small Flaw Sizing Using an Ultrasonic Test Technique. Coatings. 2018; 8(2):69. https://doi.org/10.3390/coatings8020069

Chicago/Turabian StyleMiao, Xiujuan, Xiongbing Li, Hongwei Hu, Guangjun Gao, and Shuzeng Zhang. 2018. "Effects of the Oxide Coating Thickness on the Small Flaw Sizing Using an Ultrasonic Test Technique" Coatings 8, no. 2: 69. https://doi.org/10.3390/coatings8020069

APA StyleMiao, X., Li, X., Hu, H., Gao, G., & Zhang, S. (2018). Effects of the Oxide Coating Thickness on the Small Flaw Sizing Using an Ultrasonic Test Technique. Coatings, 8(2), 69. https://doi.org/10.3390/coatings8020069