Investigation of Coated Cutting Tool Performance during Machining of Super Duplex Stainless Steels through 3D Wear Evaluations

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Workpiece Material

2.2. Cutting Tools Characteristic and Cutting Fluid

2.3. Experimental Machine Techniques

3. Results and Discussion

3.1. Tool Life Measurements

3.2. Chip Characteristics

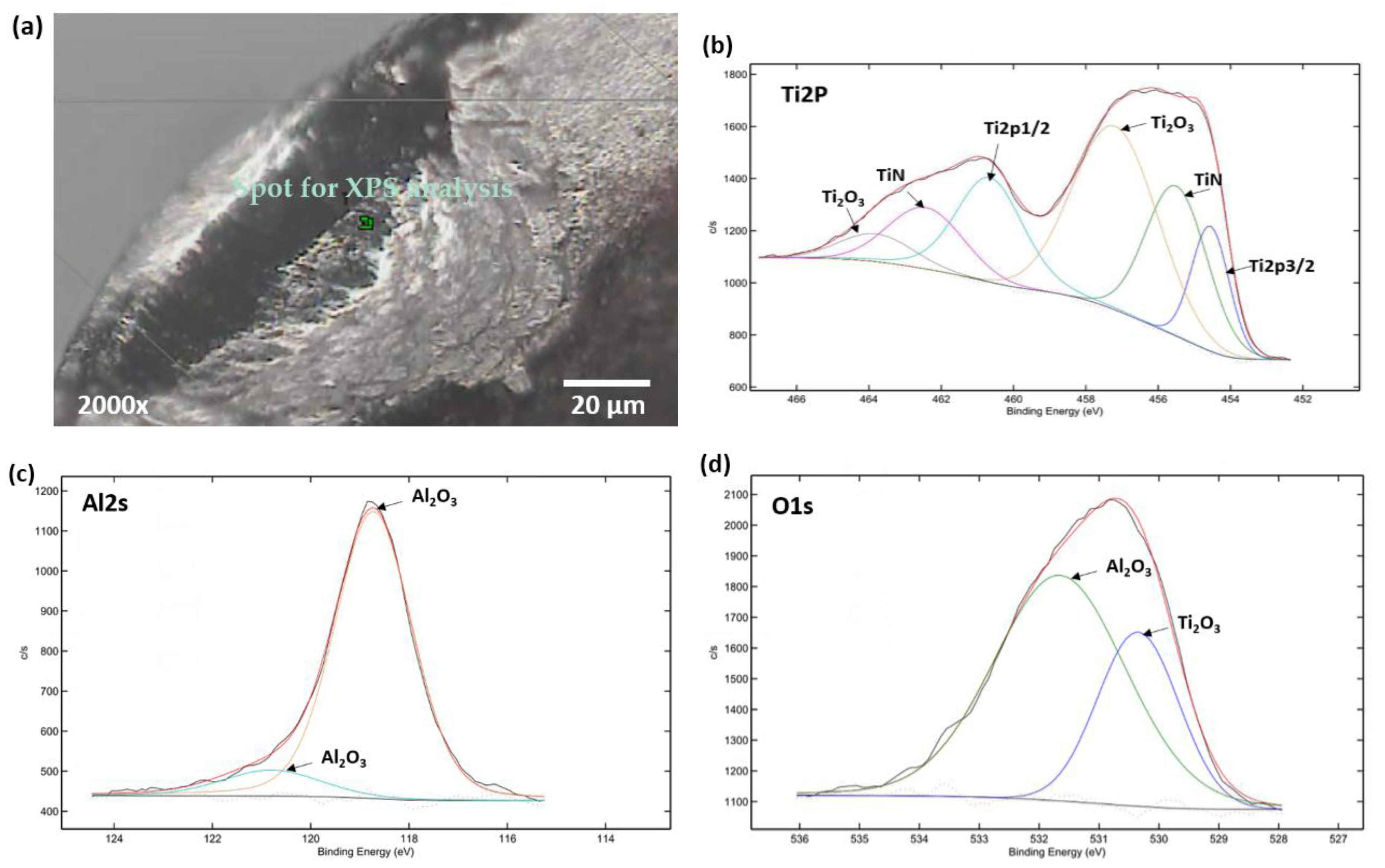

3.3. The Composition of Tribo Films and Frictional Conditions

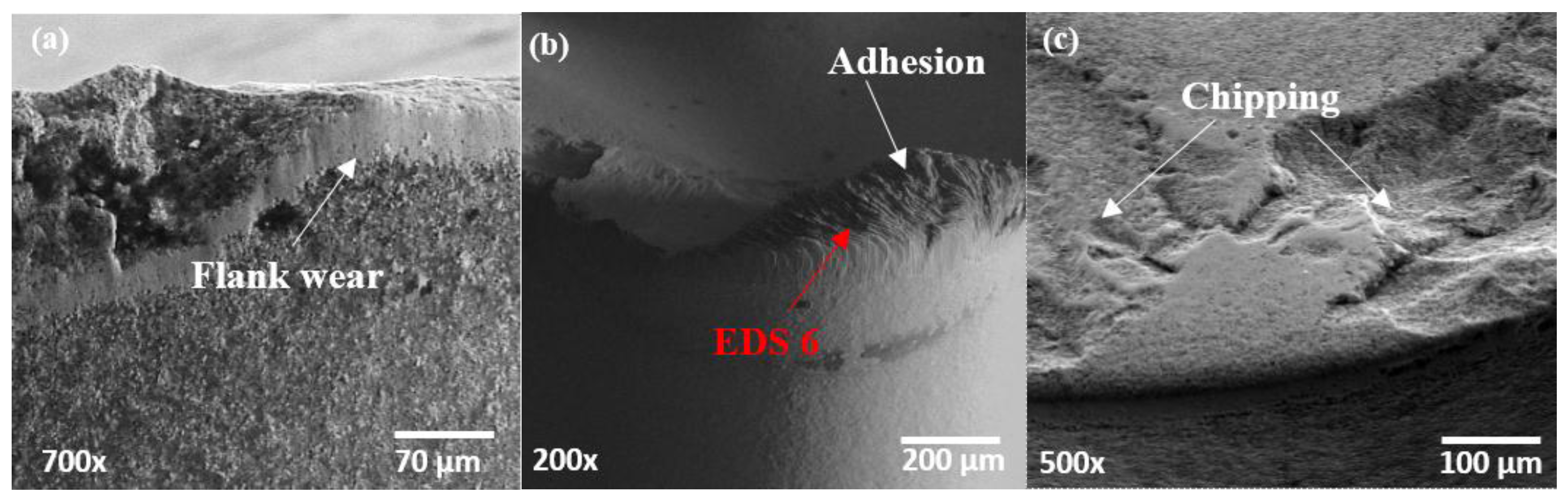

3.4. Tool Wear Analysis

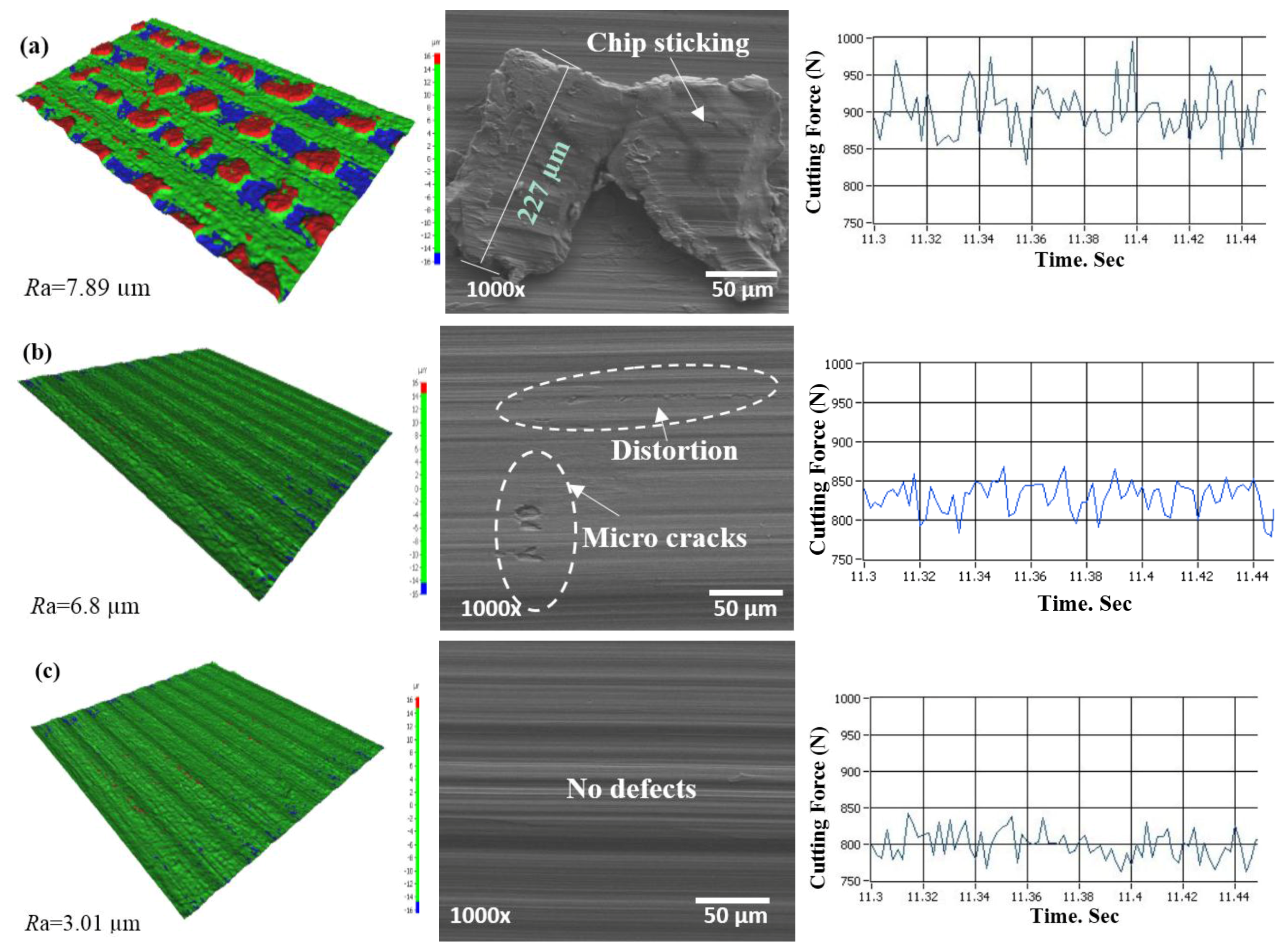

3.5. Machined Workpiece Characteristics

4. Conclusions

- Substantial improvement in tool life was achieved with the AlTiN coated insert: Tool life was approximately twice that of the CVD TiCN + Al2O3 coated insert and three times than uncoated insert.

- The chip thickness, chip compression ratio and shear angle values are better for the AlTiN coated tool, compared to the CVD TiCN + Al2O3 coated and uncoated tools, and the chip undersurface is smoother without any defects, indicating lower friction between the chip and tool rake face, which results in a constant chip flow over the tool rake surface.

- XPS analysis revealed that the underlying cause of the high performance of the AlTiN coating is the formation of aluminum oxide tribo-films at the tool-chip interface.

- The AlTiN coated tool had the lowest value for both BUE and total wear volume compared with the CVD TiCN + Al2O3 coated and uncoated tools, indicating that PVD AlTiN coated tool performs very well with SDSS.

- Adhesion wear and chipping are the predominant wear mechanism for all the cutting tools studied. When turning with the PVD AlTiN coated tool, adhesion and diffusion were present in different places on the worn area of the tools. Machining with the CVD TiCN + Al2O3 coated tool shows diffusion, abrasion, chipping and adhesion wear mechanisms while sever adhesion wear and chipping were the main wear mechanism with the uncoated insert.

- The machined surface obtained using the AlTiN coated tool had the lowest surface roughness value. The machined surfaces obtained with the CVD TiCN + Al2O3 coated and uncoated inserts show minor cracks and distortions, and there is some chip sticking on the machined workpiece obtained by the uncoated insert, as a result of intensive BUE formation and high friction generated during cutting. Spikes in cutting forces at the beginning of the cutting process were highest for the uncoated cutting tool, which is directly related to chip sticking on the surface of the workpiece.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bordinassi, E.C.; Stipkovic, M.F.; Batalha, G.F.; Delijaicov, S.; Lima, N.B. Superficial integrity analysis in a super-duplex stainless steel after turning. J. Achiev. Mater. Manuf. Eng. 2006, 18, 335–338. [Google Scholar]

- Biksa, A.; Yamamoto, K.; Dosbaeva, G.; Veldhuis, S.C.; Fox-rabinovich, G.S.; Elfizy, A.; Wagg, T.; Shuster, L.S. Wear behavior of adaptive nano-multilayered AlTiN/MexN PVD coatings during machining of aerospace alloys. Tribol. Int. 2010, 43, 1491–1499. [Google Scholar] [CrossRef]

- Paro, J.; Hänninen, H.; Kauppinen, V. Tool wear and machinability of HIPed P/M and conventional cast duplex stainless steels. Wear 2001, 249, 279–284. [Google Scholar] [CrossRef]

- Nilsson, J.-O.; Kangas, P.; Wilson, A.; Karlsson, T. Mechanical properties, microstructural stability and kinetics of σ phase formation in 29Cr–6Ni–2Mo–0.38N in super duplex stainless steel. Metall. Mater. Trans. 2000, 31, 35–45. [Google Scholar] [CrossRef]

- Nilsson, J.-O. Overview superduplex stainless steels. Mater. Sci. Technol. 1992, 8, 685–700. [Google Scholar] [CrossRef]

- Corrêa, J.G.; Schroeterb, R.B.; Machadoa, A.R. Tool life and wear mechanism analysis of carbide tools used in the machining of martensitic and supermartensitic stainless steels. Tribol. Int. 2017, 105, 102–117. [Google Scholar] [CrossRef]

- Paiva, J.M.; Torres, R.D.; Amorim, F.L.; Covelli, D.; Tauhiduzzaman, M.; Veldhuis, S.C.; Dosbaeva, G.; Fox-Rabinovich, G. Frictional and wear performance of hard coatings during machining of superduplex stainless steel. Int. J. Adv. Manuf. Technol. 2017, 24, 1–10. [Google Scholar] [CrossRef]

- Endrino, J.L.; Fox-rabinovich, G.S.; Gey, C. Hard AlTiN-AlCrN PVD coatings for machining of austenitic stainless steel. Surf. Coat. Technol. 2006, 200, 6840–6845. [Google Scholar] [CrossRef]

- Ciftci, I. Machining of austenitic stainless steels using CVD multi-layer coated cemented carbide tools. Tribol. Int. 2006, 39, 565–569. [Google Scholar] [CrossRef]

- Sik, I.; Amanov, A.; Kim, J.D. The effects of AlCrN coating, surface modification and their combination on the tribological properties of high speed steel under dry conditions. Tribol. Int. 2015, 81, 61–72. [Google Scholar]

- Fox-Rabinovich, G.S.; Paiva, J.M.; Gershman, I.; Aramesh, M.; Cavelli, D.; Yamamoto, K.; Dosbaeva, G.; Veldhuis, S.C. Control of self-organized criticality through adaptive behavior of nano-structured thin film coatings. Entropy 2016, 18, 290. [Google Scholar] [CrossRef]

- Krolczyk, G.; Legutko, S.; Gajek, M. Predicting the surface roughness in the dry machining of duplex stainless steel DSS. Metalurgija 2013, 52, 259–262. [Google Scholar]

- Selvaraj, P.D.; Chandramohan, P.; Mohanraj, M. Optimization of surface roughness, cutting force and tool wear of nitrogen alloyed duplex stainless steel in a dry turning process using Taguchi method. Measurement 2014, 49, 205–215. [Google Scholar] [CrossRef]

- Carlos, O.J.; Anaelmo, E.D.; Rodnei, B. Correlating tool wear, surface roughness and corrosion resistance in the turning process of super duplex stainless steel. J. Braz. Soc. Mech. Sci. Eng. 2014, 36, 775–785. [Google Scholar]

- Jawaid, A.; Olajire, K.; Ezugwu, O. Machining of martensitic stainless steels (JETHETE) with coated carbides. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2001, 215, 769–779. [Google Scholar] [CrossRef]

- Aihua, L; Jianxin, D.; Haibing, C.; Yang, C.; Jun, Z. Friction and wear properties of TiN, TiAlN, AlTiN and CrAlN PVD nitride coatings. Int. J. Refract. Met. Hard Mater. 2012, 31, 82–88. [Google Scholar] [CrossRef]

- Dobrzański, L.A; Pakuła, D.; Křiž, A. Tribological properties of the PVD andCVD coatings put down onto the nitride tool ceramics. In Proceedings of the 12th International Scientific Conference: Achievements in Mechanical& Materials Engineering, Podgorica, Montenegro, 2–5 April 2003; pp. 267–270. [Google Scholar]

- ISO 3685:1993–Tool Life Testing with Single-Point Turning Tools; International Organization for Standardization: Geneva, Switzerland, 1993.

- Shaw, M. Metal Cutting Principles, 2nd ed.; Oxford University Press: New York, NY, USA, 2005. [Google Scholar]

- ISO 25178–2–Geometrical Product Specifications (GPS)—Surface Texture: Areal Part 2: Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Geneva, Switzerland, 2012.

- Fox-Rabinovich, G.; Totten, G.E. Self-Organization during Friction: Advanced Surface-Engineered Materials and Systems Design; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Jacobson, S.; Hogmark, S. Tribofilms—On the crucial importance of tribologically induced surface modification. In Recent Developments in Wear Prevention, Friction and Lubrication; Nikas, G.K., Ed.; Research Signpost: Kerala, India, 2010. [Google Scholar]

- Fox-Rabinovich, G.; Kovalev, A.; Veldhuis, S.; Yamamoto, K.; Endrino, J.L.; Gershman, I.S.; Rashkovskiy, A.; Aguirre, M.H.; Wainstein, D.L. Spatio-temporal behaviour of atomic-scale tribo-ceramic films in adaptive surface engineered nano-materials. Sci. Rep. 2015, 5, 8780. [Google Scholar] [CrossRef] [PubMed]

- Kalss, W.; Reiter, A.; Derflinger, V.; Gey, C.; EndrinoInt, J.L. Study of PVD AlCrN coating for reducing carbide cutting tool deterioration in the machining of titanium alloys. J. Refract. Metal. Hard Mater. 2006, 24, 399. [Google Scholar] [CrossRef]

- Bershadsky, L.I.B.I. Kostetsky and the general concept in tribology. Trenie I Iznos (Russ. Frict. Wear) 1993, 14, 6–18. [Google Scholar]

- Takago, S.; Gotoh, M.; Sasaki, T.; Hirose, Y. The residual stress measurements of TiCN PVD films. Adv. X-ray Anal. 2002, 45, 365–370. [Google Scholar]

- Ho, W.Y.; Huang, D.H.; Hsu, C.H.; Wang, D.Y. Corrosion behaviors of Cr(N,O)/CrN double-layered coatings by cathodic arc deposition. Surf. Coat. Technol. 2004, 172, 177–178. [Google Scholar] [CrossRef]

- Joseph, R.D. ASM Specialty Handbook: Tool Material-Technology and Engineering; ASM International: Almere, The Netherlands, 1 January 1995; pp. 67–77. [Google Scholar]

- Noordin, M.Y.; Venkatesh, V.C.; Sharif, S. Dry turning of tempered martensitic stainless tool steel using coated cermet and coated carbide tools. J. Mater. Proc. Technol. 2007, 185, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Junior, A.B.; Diniz, A.E.; Teixeira Filho, F. Tool wear and tool life in end milling of 15–5 PH stainless steel under different cooling and lubrication conditions. Int. J. Adv. Manuf. Technol. 2009, 43, 756–764. [Google Scholar] [CrossRef]

- Trent, E.; Wright, P. Metal Cutting, 4th ed.; Butterworth–Heinemann: London, UK, 2000; p. 464. [Google Scholar]

- Melo, A.C.; Milan, J.C.G.; Silva, M.B.; Machado, A.R. Some observations on wear and damage in cemented carbide tools. J. Braz. Soc. Mech. Sci. Eng. 2006, 28, 269–277. [Google Scholar] [CrossRef]

- Diniz, A.E.; Marcondes, F.C.; Coppini, N.L. The performance evaluation of ceramic and carbide cutting tools in machining of stainless steels. In Tecnologia da Usinagem dos Materiais, 5th ed.; Artliber Editora: São Paulo, Brazil, 2006. [Google Scholar]

- ASTM G40-15–Standard Terminology Relating to Wear and Erosion; ASTM: West Conshohocken, PA, USA, 1987; Volume 03.02, pp. 243–250.

- Choi, J.P.; Lee, S.L. Efficient chip breaker design by predicting the chip breaking performance. Int. J. Adv. Manuf. Technol. 2001, 17, 489–497. [Google Scholar] [CrossRef]

- Fahrion, M.E.; Brown, J.C.; Hassell, J.C. Technical Basis For Improved Reliability Of 347H Stainless Steel Heavy Wall Piping in Hydrogen Service; NACE International: San Diego, CA, USA, 2003. [Google Scholar]

- Zhou, J.; Bushlya, V.; Avdovic, P.; Stahl, J.E. Study of surface quality in high speed turning of Inconel 718 with uncoated and coated CBN tools. Int. J. Adv. Manuf. Technol. 2012, 58, 141–151. [Google Scholar] [CrossRef]

- Alabdullah, M.; Polishetty, A.; Littlefair, G. Microstructural and surface texture analysis due to machining in super austenitic stainless steel. J. Metall. 2016, 2016, 3685312. [Google Scholar] [CrossRef]

| Elements | Chemical Composition (%) | Proof Strength (0.2% Yield) (Mpa) | Tensile Strength (Mpa) | Elongation | Hardness (HRC) |

|---|---|---|---|---|---|

| C | 0.03 | 550 | 800–1000 | 15 | 32 |

| Si | 0.80 | ||||

| Mn | 1.2 | ||||

| P | 0.035 | ||||

| S | 0.02 | ||||

| Cr | 25 | ||||

| Ni | 7 | ||||

| Mo | 4 | ||||

| N | 0.24 |

| Coating | Process | Layer | Structure | Residual Stresses (MPa) | Hardness (GPa) | Thickness (µm) | Roughness, Ra (µm) |

|---|---|---|---|---|---|---|---|

| AlTiN | PVD | Monolayer | Columnar nano-crystalline [16] | 293 ± 88 | 35 [16] | 1.8 | 0.039 |

| TiCN + Al2O3 | CVD | Bi layer | Columnar micro-crystalline [17] | 439 ± 20 | 31 [17] | Sublayer 5, Toplayer 3 | 0.038 |

| Type of Coating | Chip Thickness (mm) | Chip Compression Ratio | Shear Angle (°) | Coefficient of Friction | Tool Chip Contact Length (mm) |

|---|---|---|---|---|---|

| AlTiN | 0.433 | 0.69 | 36 | 0.267 | 0.682 |

| TiCN + Al2O3 | 0.560 | 0.54 | 29 | 0.404 | 0.797 |

| Uncoated | 0.653 | 0.46 | 27 | 0.445 | 0.903 |

| EDS | Chemical Composition % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fe | W | O | Cr | Ni | C | Ti | N | Al | |

| 1 | 26.3 | 7.55 | 30.37 | 16.04 | 4.25 | 23.49 | 0.54 | – | 1.41 |

| 2 | 0.11 | 2.10 | 20.2 | 1.20 | 0.30 | 14.00 | 2.54 | 12.50 | 49.20 |

| 3 | 34.06 | 1.37 | 13.12 | 15.9 | 3.92 | 24.95 | 3.00 | – | 0.75 |

| 4 | 0.11 | 0.92 | 54.45 | – | 0.10 | 28.7 | 0.56 | – | 29.13 |

| 5 | 0.11 | 66.4 | 13.00 | 1.13 | – | 23.00 | 0.1 | – | 0.50 |

| 6 | 44.2 | 0.8 | 15.00 | 18.0 | 8415 | 18.2 | 0.48 | – | 0.42 |

| Cutting Tool | Wear Mechanism | Main Causes | Suggested Solutions |

|---|---|---|---|

| PVD AlTiN | Adhesive wear (Attrition) | High strain hardening High ductility | Use very low or very high cutting speeds to decrease the formation of BUE [19] |

| Chipping | BUE formation | ||

| Diffusion | High cutting temperature | Increase the flow and pressure of the coolant to reduce the cutting temperature | |

| CVD TiCN + Al2O3 | Cracks | BUE formation | Use very low or very high cutting speeds to decrease the formation of BUE [19] |

| Abrasive wear | BUE fragments | ||

| Adhesive wear (Attrition) | High strain hardening High ductility | ||

| Coating dissipation | High tensile residual stresses | Use PVD coated tools | |

| Chipping | Coating dissipation | ||

| Diffusion | High cutting temperature | Increase the flow and pressure of the coolant to reduce the cutting temperature | |

| Uncoated | Adhesive wear (Attrition) | High strain hardening High ductility | Use very low or very high cutting speeds to decrease the formation of BUE [19] |

| Chipping | Chip jamming | Use cutting tool with a proper chip breaker to be able to break chips [35] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seid Ahmed, Y.; Paiva, J.M.; Covelli, D.; Veldhuis, S.C. Investigation of Coated Cutting Tool Performance during Machining of Super Duplex Stainless Steels through 3D Wear Evaluations. Coatings 2017, 7, 127. https://doi.org/10.3390/coatings7080127

Seid Ahmed Y, Paiva JM, Covelli D, Veldhuis SC. Investigation of Coated Cutting Tool Performance during Machining of Super Duplex Stainless Steels through 3D Wear Evaluations. Coatings. 2017; 7(8):127. https://doi.org/10.3390/coatings7080127

Chicago/Turabian StyleSeid Ahmed, Yassmin, Jose Mario Paiva, Danielle Covelli, and Stephen Clarence Veldhuis. 2017. "Investigation of Coated Cutting Tool Performance during Machining of Super Duplex Stainless Steels through 3D Wear Evaluations" Coatings 7, no. 8: 127. https://doi.org/10.3390/coatings7080127