Development of a TiC/Cr23C6 Composite Coating on a 304 Stainless Steel Substrate through a Tungsten Inert Gas Process

Abstract

:1. Introduction

- Hard particles with a hardness of 4–30 GPa such as SiC, TiC, and TiN;

- Soft particles with a hardness of less than 2 GPa such as graphite, mica, and molybdenum disulfide, which acts as a lubricant.

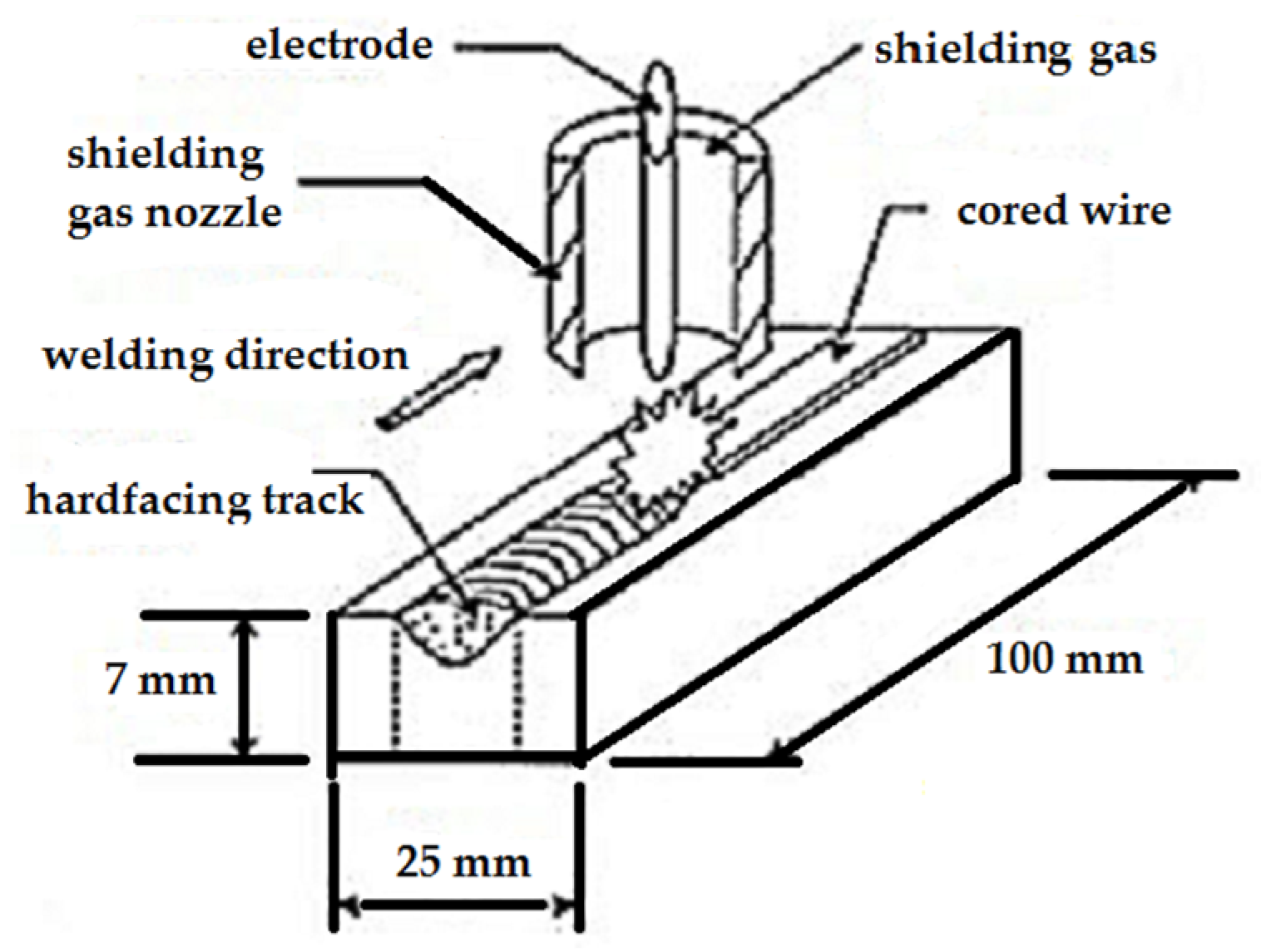

2. Experimental Procedures

3. Discussion

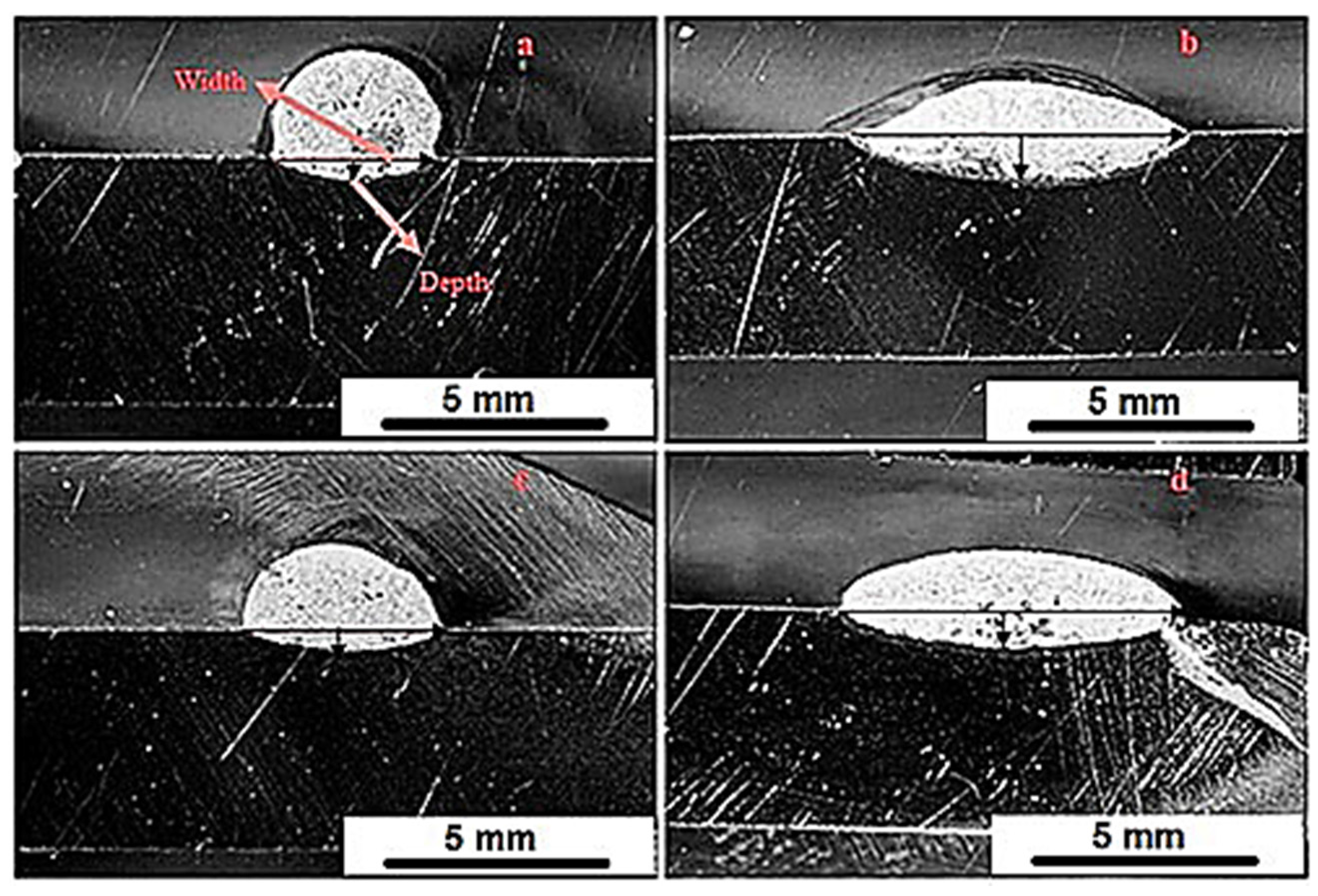

3.1. Stereo Images

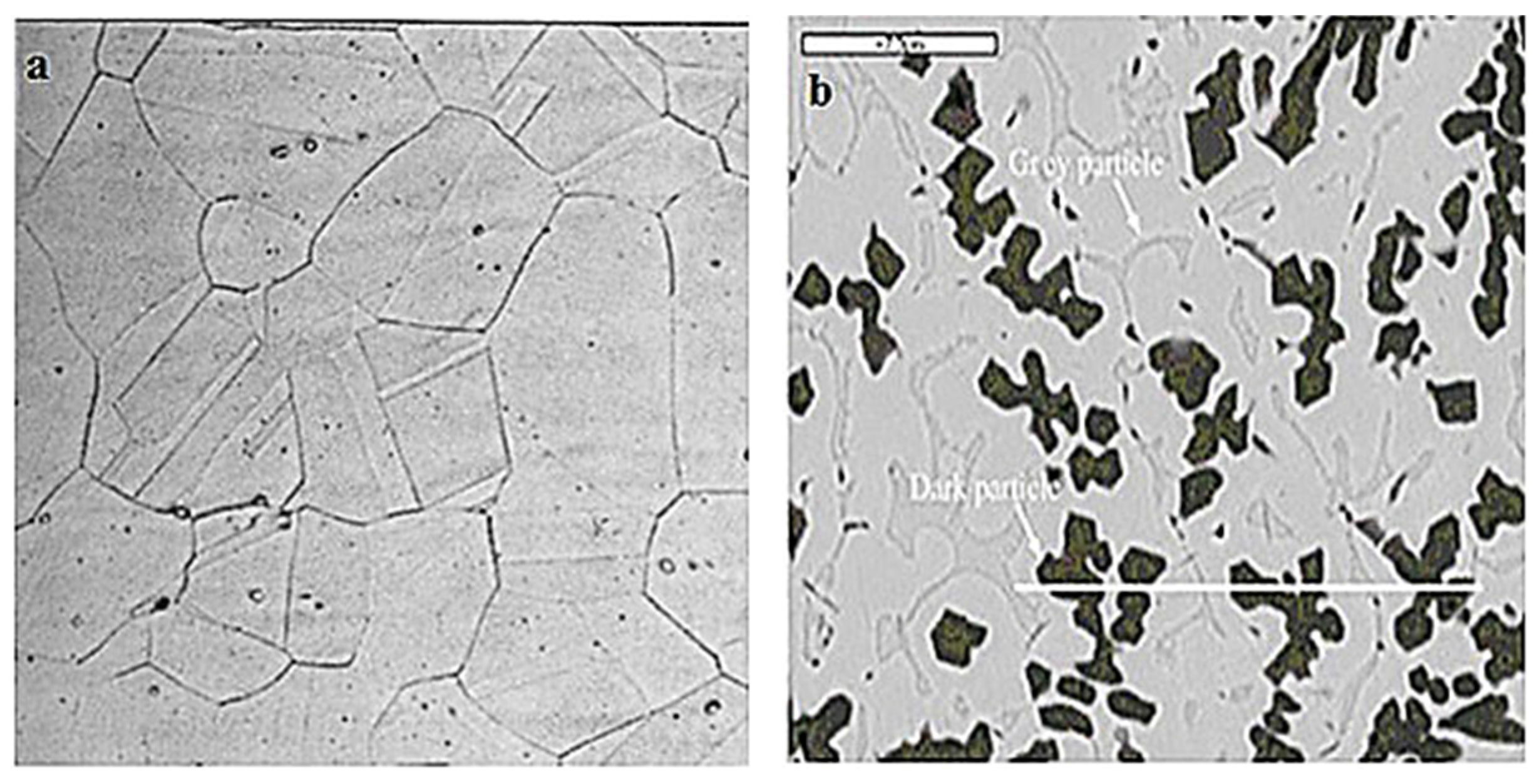

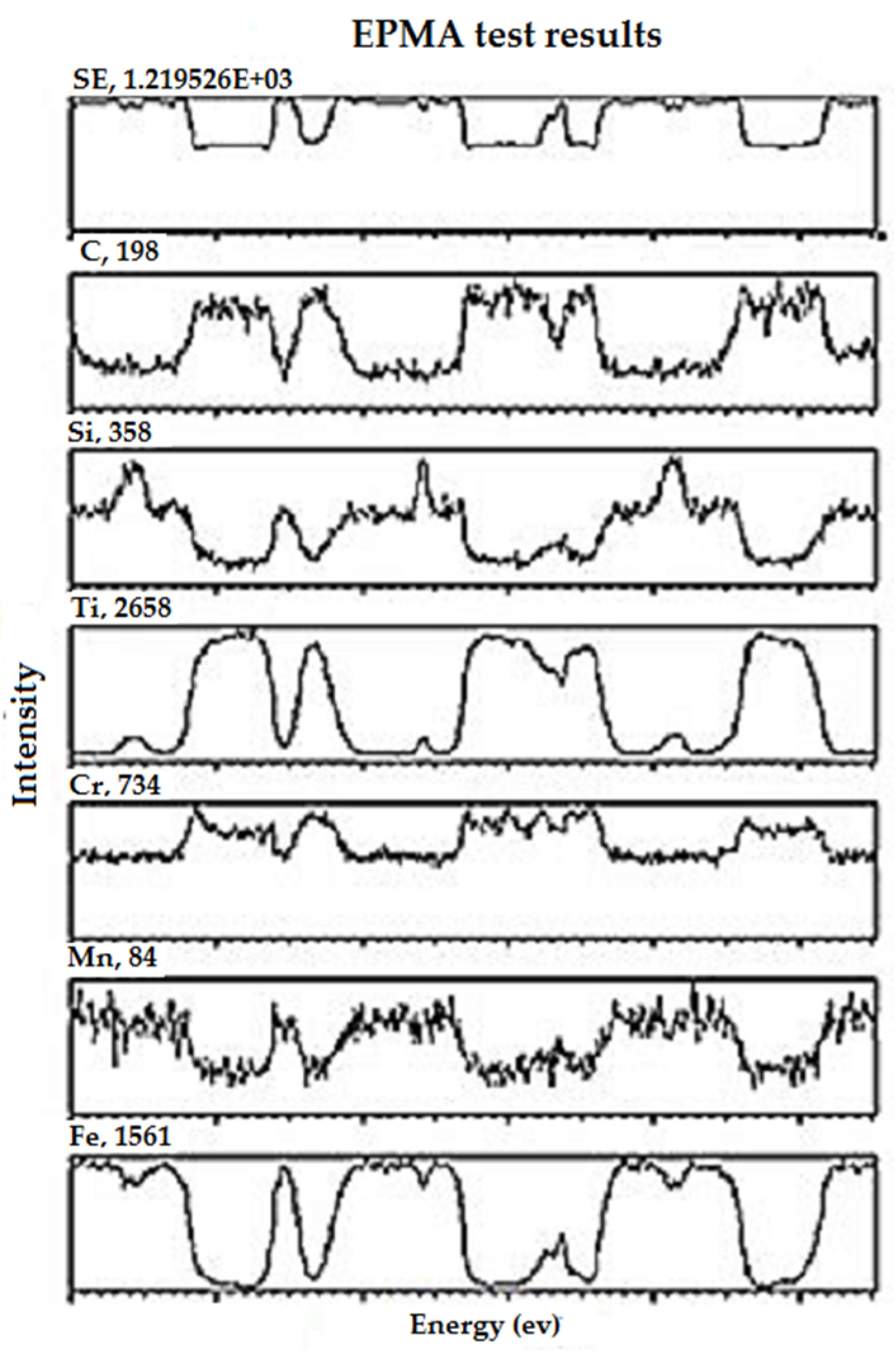

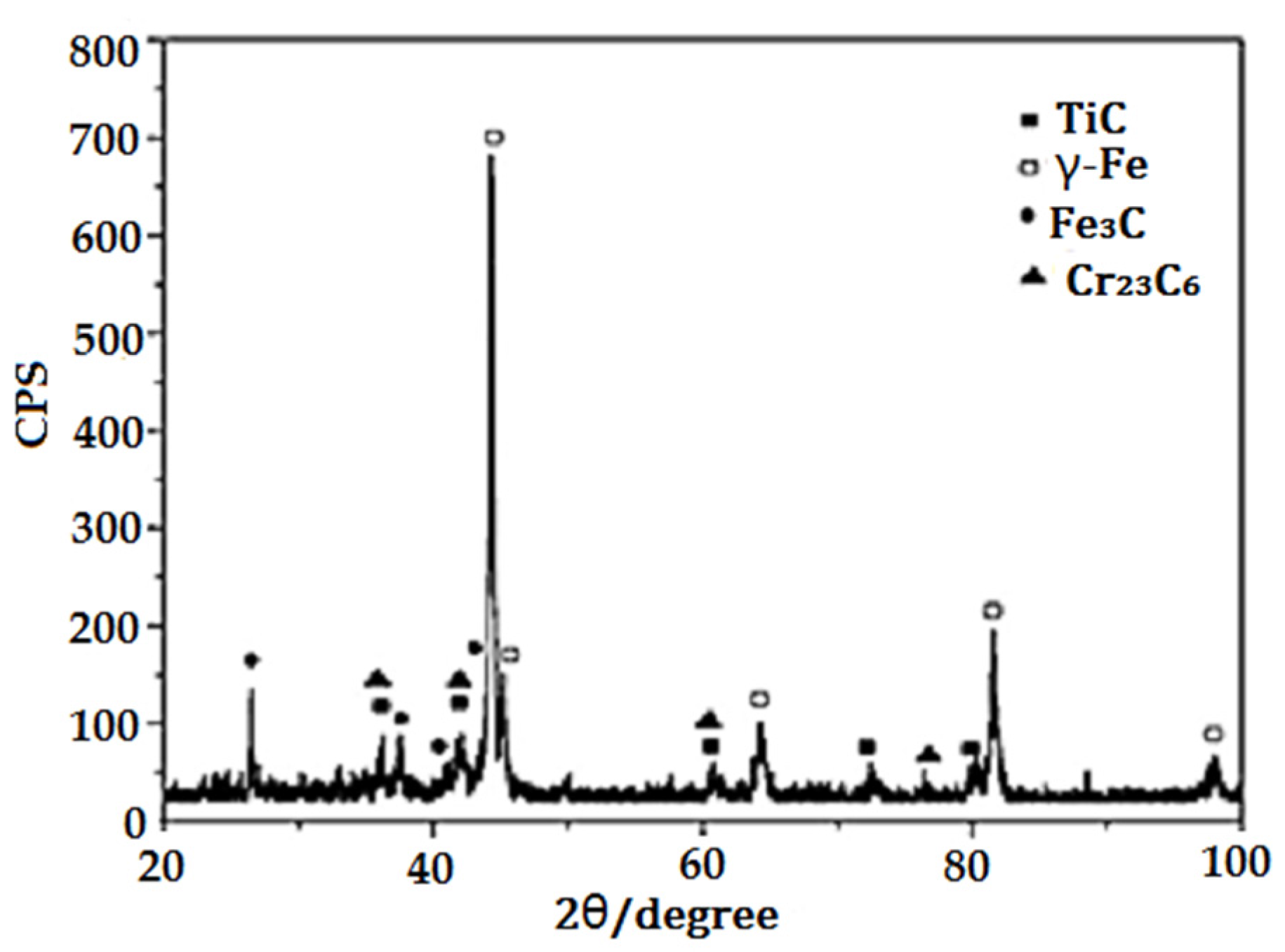

3.2. Microstructure and Composition of Coating

3.3. Micro-Hardness

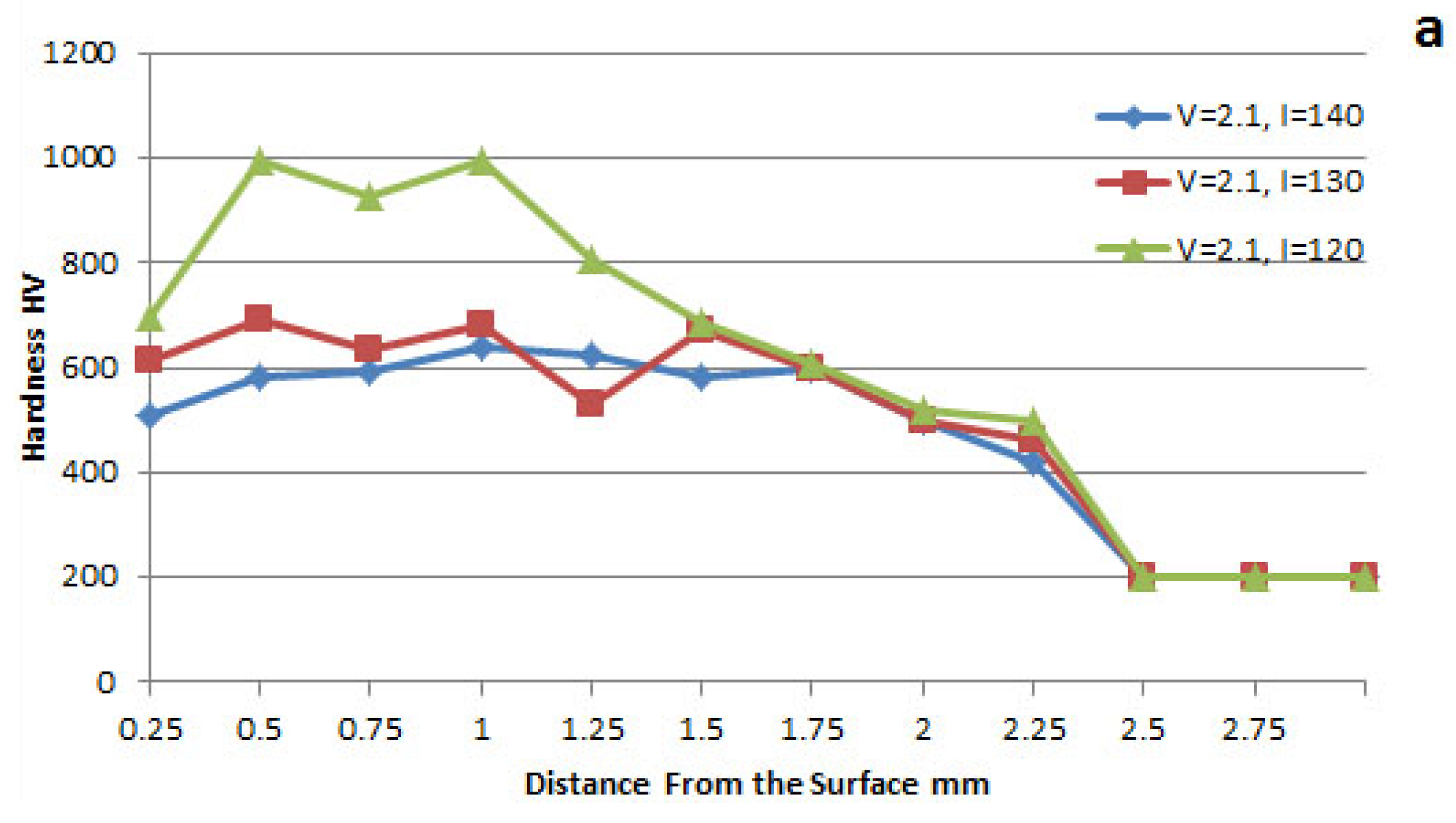

3.3.1. Variation of Microhardness with Current Density

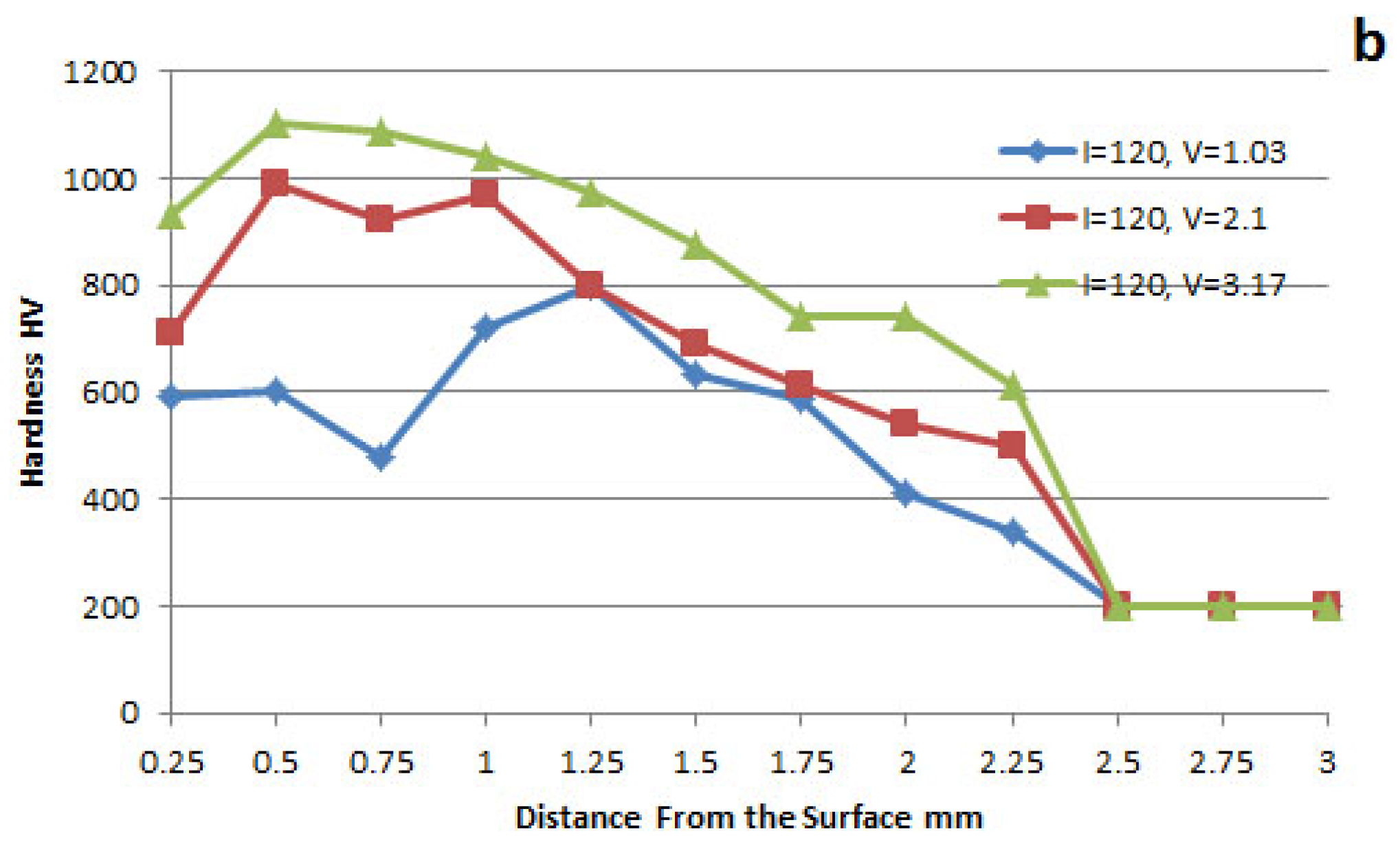

3.3.2. Variation in Microhardness with Travel Speed

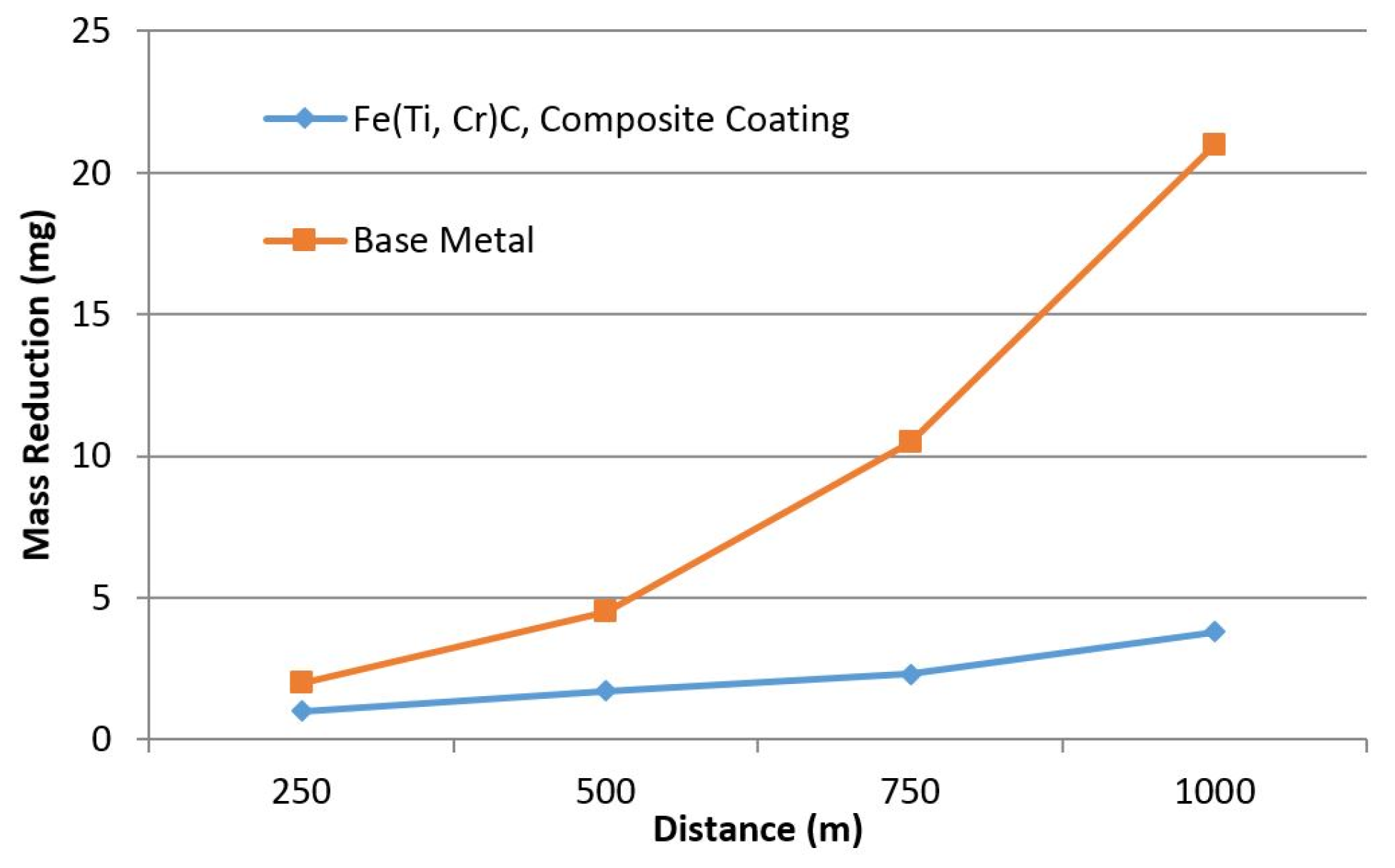

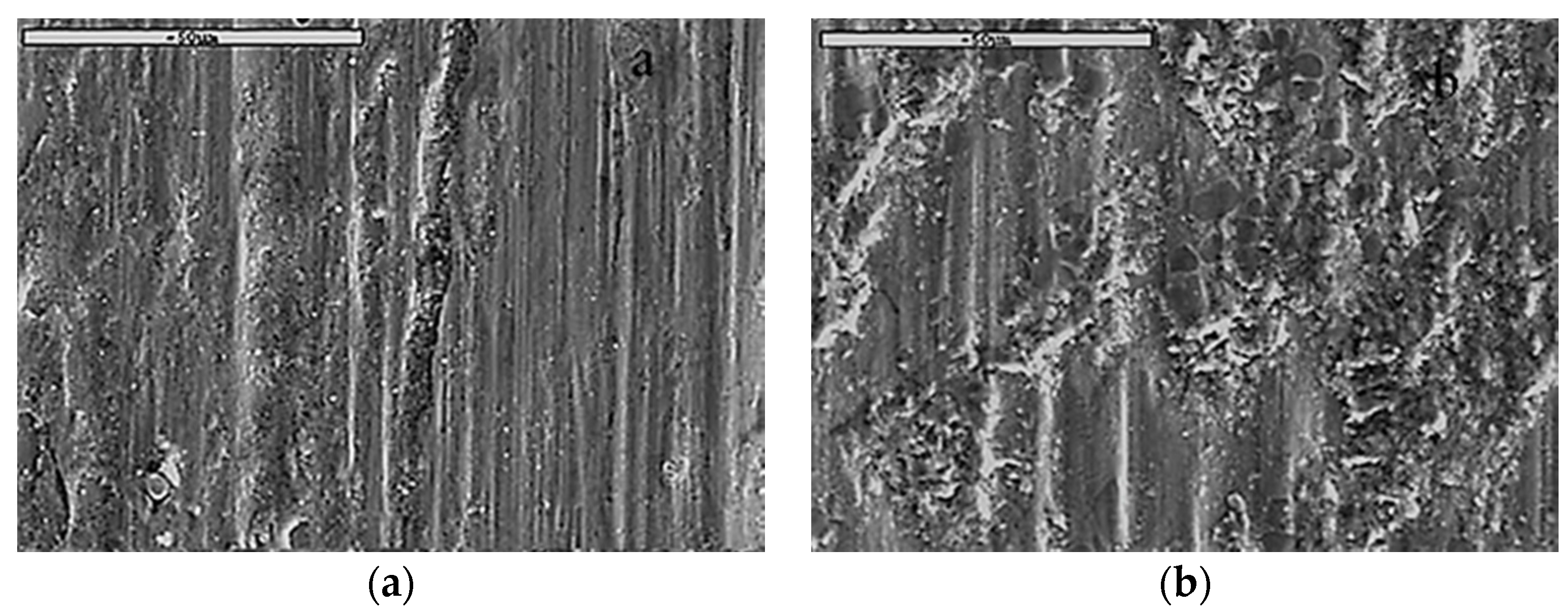

3.4. Wear

4. Conclusions

- The coating is mainly composed of TiC/Cr23C6/Fe. The microstructure of the composite layer includes TiC and Cr23C6 particles as well as traces of Fe3C in the austenitic matrix.

- Specimens coated with the composite layer are harder than the substrate. The coating hardness can be up to 1100 HV, which is almost 4.5 times higher than the hardness of 304 SS. The hardness of the deposited layer is decreased by increasing the welding current density at a constant travel speed and also by reducing the travel speed at a constant current density.

- The formation of the TiC/Cr23C6 hard phase in the coating layer is the main reason for the hardness and wear resistance enhancement and friction coefficient reduction compared with the substrate.

- The friction coefficient of the optimum coating layer is around 0.35, which is about half that of the substrate (0.56).

- The optimum parameters for the coating are as follows: A 120 current and a 3.17 mm/s travel speed.

Author Contributions

Conflicts of Interest

References

- ASM International Handbook. Properties and Selections: Iron, Steel and High Performance Alloys, ASM International; The Materials Information Company: Materials Park, OH, USA, 1990; Volume 1, pp. 1765–1827. [Google Scholar]

- Peckner, D. Handbook of Stainless Steels; Mcgraw-Hill: New York, NY, USA, 1977. [Google Scholar]

- Sedriks, A.J. Corrosion of Stainless Steel, 2; John Wiley and Sons, Inc.: New York, NY, USA, 1996. [Google Scholar]

- Kim, C.S. Thermophysical Properties of Stainless Steels; Argonne National Laboratory: Argonne, IL, USA, 1975.

- Zotova, E. Mechanical Properties of Stainless Steels. Met. Sci. Heat Treat. 1964, 5, 371–373. [Google Scholar] [CrossRef]

- Olsson, C.-O.; Landolt, D. Passive films on stainless steels—Chemistry, structure and growth. Electrochim. Acta 2003, 48, 1093–1104. [Google Scholar] [CrossRef]

- Alizadeh, H.; Hanaei, A.; Pakseresht, A.; Shahbazkhan, A.; Ahmadi, N.P.; Baniasadi, F. Effect of Ca2+ additives on morphology, composition and corrosion resistant of Zn–12% Ni phosphate coating. J. Mater. Res. Technol. 2016, 5, 327–332. [Google Scholar] [CrossRef]

- Baniasadi, F.; Bahmannezhad, B.; Nikpoor, N.; Asgari, S. Thermal stability investigation of expanded martensite. Surf. Coat. Technol. 2016, 300, 87–94. [Google Scholar] [CrossRef]

- Conrad, J.R.; Radtkeet, J.L. Plasma source ion—Implantation technique for surface modification of materials. J. Appl. Phys. 1987, 62, 4591–4596. [Google Scholar] [CrossRef]

- Liang, W. Surface modification of AISI 304 austenitic stainless steel by plasma nitriding. Appl. Surf. Sci. 2003, 211, 308–314. [Google Scholar] [CrossRef]

- Mansfield, F.; Breslin, C.B.; Pardo, A.; Pérez, F.J. Surface modification of stainless steels: Green technology for corrosion protection. Surf. Coat. Technol. 1997, 90, 224–228. [Google Scholar] [CrossRef]

- Trtica, M.S.; Gaković, B.M.; Nenadović, T.M.; Mitrović, M.M. Surface modification of stainless steels by TEA CO2 laser. Appl. Surf. Sci. 2001, 177, 48–57. [Google Scholar] [CrossRef]

- Malekzad, H.; Mirshekari, H.; Zangabad, P.S.; Basri, S.M.M.; Baniasadi, F.; Aghdam, M.S.; Karimi, M.; Hamblin, M.R. Plant protein-based hydrophobic fine and ultrafine carrier particles in drug delivery systems. Crit. Rev. Biotechnol. 2017, 24, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.-G.; Wu, J.; Zhang, S.; Rong, S.; Li, Z. High temperature erosion properties of arc-sprayed coatings using various cored wires containing Ti–Al intermetallics. Wear 2007, 262, 555–561. [Google Scholar] [CrossRef]

- Hajbagheri, F.A.; Bozorg, S.K.; Amadeh, A. Microstructure and wear assessment of TIG surface alloying of CP-titanium with silicon. J. Mater. Sci. 2008, 43, 5720–5727. [Google Scholar] [CrossRef]

- Kwok, C.; Cheng, F.; Man, H. Laser surface modification of UNS S31603 stainless steel using NiCrSiB alloy for enhancing cavitation erosion resistance. Surf. Coat. Technol. 1998, 107, 31–40. [Google Scholar] [CrossRef]

- Proskurovsky, D.I.; Rotshtein, V.P.; Ozur, G.E.; Markov, A.B.; Nazarov, D.S.; Shulov, V.A.; Ivanov, Y.F.; Buchheit, R.G. Pulsed electron-beam technology for surface modification of metallic materials. J. Vac. Sci. Technol. A: Vac. Surf. Films 1998, 16, 2480–2488. [Google Scholar] [CrossRef]

- Hao, S.; Wu, P.; Zou, J.; Grosdidier, T.; Dong, C. Microstructure evolution occurring in the modified surface of 316L stainless steel under high current pulsed electron beam treatment. Appl. Surf. Sci. 2007, 253, 5349–5354. [Google Scholar] [CrossRef]

- Karimi, M.; Solati, N.; Ghasemi, A.; Estiar, M.A.; Hashemkhani, M.; Kiani, P.; Mohamed, E.; Saeidi, A.; Taheri, M.; Avci, P.; et al. Carbon nanotubes part II: A remarkable carrier for drug and gene delivery. Expert Opin. Drug Deliv. 2015, 12, 1089–1105. [Google Scholar] [CrossRef] [PubMed]

- Mozaffari, S.; Tchoukov, P.; Mozaffari, A.; Atias, J.; Czarnecki, J.; Nazemifard, N. Capillary driven flow in nanochannels–Application to heavy oil rheology studies. Colloids Surf. A Physicochem. Eng. Asp. 2017, 513, 178–187. [Google Scholar] [CrossRef]

- Buytoz, S.; Ulutan, M. In situ synthesis of SiC reinforced MMC surface on AISI 304 stainless steel by TIG surface alloying. Surf. Coat. Technol. 2006, 200, 3698–3704. [Google Scholar] [CrossRef]

- Yang, K.; Yu, S.; Li, Y.; Li, C. Effect of carbonitride precipitates on the abrasive wear behaviour of hardfacing alloy. Appl. Surf. Sci. 2008, 254, 5023–5027. [Google Scholar] [CrossRef]

- Klimpel, A.; Dobrzański, L.A.; Lisiecki, A.; Janicki, D. The study of properties of Ni–WC wires surfaced deposits. J. Mater. Process. Technol. 2005, 164, 1046–1055. [Google Scholar] [CrossRef]

- Amushahi, M.; Ashrafizadeh, F.; Shamanian, M. Characterization of boride-rich hardfacing on carbon steel by arc spray and GMAW processes. Surf. Coat. Technol. 2010, 204, 2723–2728. [Google Scholar] [CrossRef]

- Chatterjee, S.; Pal, T. Wear behaviour of hardfacing deposits on cast iron. Wear 2003, 255, 417–425. [Google Scholar] [CrossRef]

- Watanabe, T.; Sato, T.; Nezu, A. Electrode phenomena investigation of wire arc spraying for preparation of Ti-Al intermetallic compounds. Thin Solid Films 2002, 407, 98–103. [Google Scholar] [CrossRef]

- Chang, C.; Chen, L.; Lin, C.; Chen, J.; Fan, C.; Wu, W. Microstructure and wear characteristics of hypereutectic Fe–Cr–C cladding with various carbon contents. Surf. Coat. Technol. 2010, 205, 245–250. [Google Scholar] [CrossRef]

- Oghbaei, M.; Baniasadi, F.; Asgari, S. Lithium iron silicate sol–gel synthesis and electrochemical investigation. J. Alloys Compd. 2016, 672, 93–97. [Google Scholar] [CrossRef]

- Keshmiri, K.; Mozaffari, S.; Tchoukov, P.; Huang, H.; Nazemifard, N. Using Microfluidic Device to Study Rheological Properties of Heavy Oil. In Proceedings of the 2016 AIChE Annual Meeting, San Francisco, CA, USA, 13–18 November 2016. [Google Scholar]

- Zhanga, S.H.; Li, M.X.; Yoon, J.H.; Cho, T.Y. Characterization on the coatings of Ni-base alloy with nano-and micron-size Sm2O3 addition prepared by laser deposition. Mater. Chem. Phys. 2008, 112, 668–674. [Google Scholar] [CrossRef]

- Xinhong, W.; Zengda, Z.; Sili, S.; Shiyao, Q. Microstructure and wear properties of in situ TiC/FeCrBSi composite coating prepared by gas tungsten arc welding. Wear 2006, 260, 25–29. [Google Scholar] [CrossRef]

- Wang, X.H.; Song, S.L.; Zou, Z.D.; Qu, S.Y. Fabricating TiC particles reinforced Fe-based composite coatings produced by GTAW multi-layers melting process. Mater. Sci. Eng. A 2006, 441, 60–67. [Google Scholar] [CrossRef]

- Amirsadeghi, A.; Sohi, M.H. Comparison of the influence of molybdenum and chromium TIG surface alloying on the microstructure, hardness and wear resistance of ADI. J. Mater. Process. Technol. 2008, 201, 673–677. [Google Scholar] [CrossRef]

- Buytoz, S.; Ulutan, M.; Yildirim, M.M. Dry sliding wear behavior of TIG welding clad WC composite coatings. Appl. Surf. Sci. 2005, 252, 1313–1323. [Google Scholar] [CrossRef]

| Elements | Percent, % | Elements | Percent, % | Elements | Percent, % |

|---|---|---|---|---|---|

| Fe | 70.99 | C | 0.08 | N | 0.10 |

| Cr | 18.00 | Si | 0.75 | S | 0.03 |

| Ni | 8.00 | Mn | 2.00 | P | 0.05 |

| Speed (mm/s) | Current (A) | Width (mm) | Depth (mm) |

|---|---|---|---|

| 2.1 | 120 | 7 | 0.65 |

| 3.17 | 120 | 8.1 | 1.6 |

| 3.17 | 140 | 1.6 | 0.75 |

| 2.1 | 110 | 1.65 | 1.1 |

| Speed (mm/s) | Current (A) | Dilution Amount |

|---|---|---|

| 2.1 | 120 | 53% |

| 3.17 | 120 | 21% |

| 3.17 | 140 | 42% |

| 2.1 | 110 | 17% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heidarshenas, B.; Hussain, G.; Asmael, M.B.A. Development of a TiC/Cr23C6 Composite Coating on a 304 Stainless Steel Substrate through a Tungsten Inert Gas Process. Coatings 2017, 7, 80. https://doi.org/10.3390/coatings7060080

Heidarshenas B, Hussain G, Asmael MBA. Development of a TiC/Cr23C6 Composite Coating on a 304 Stainless Steel Substrate through a Tungsten Inert Gas Process. Coatings. 2017; 7(6):80. https://doi.org/10.3390/coatings7060080

Chicago/Turabian StyleHeidarshenas, Behzad, Ghulam Hussain, and Mohammed. Bsher. A. Asmael. 2017. "Development of a TiC/Cr23C6 Composite Coating on a 304 Stainless Steel Substrate through a Tungsten Inert Gas Process" Coatings 7, no. 6: 80. https://doi.org/10.3390/coatings7060080