Kinetic Analysis of Additive on Plasma Electrolytic Boriding

Abstract

:1. Introduction

2. Experimental Details

2.1. Material and Preparation

2.2. Characterization of Boriding Layer

3. Results and Discussions

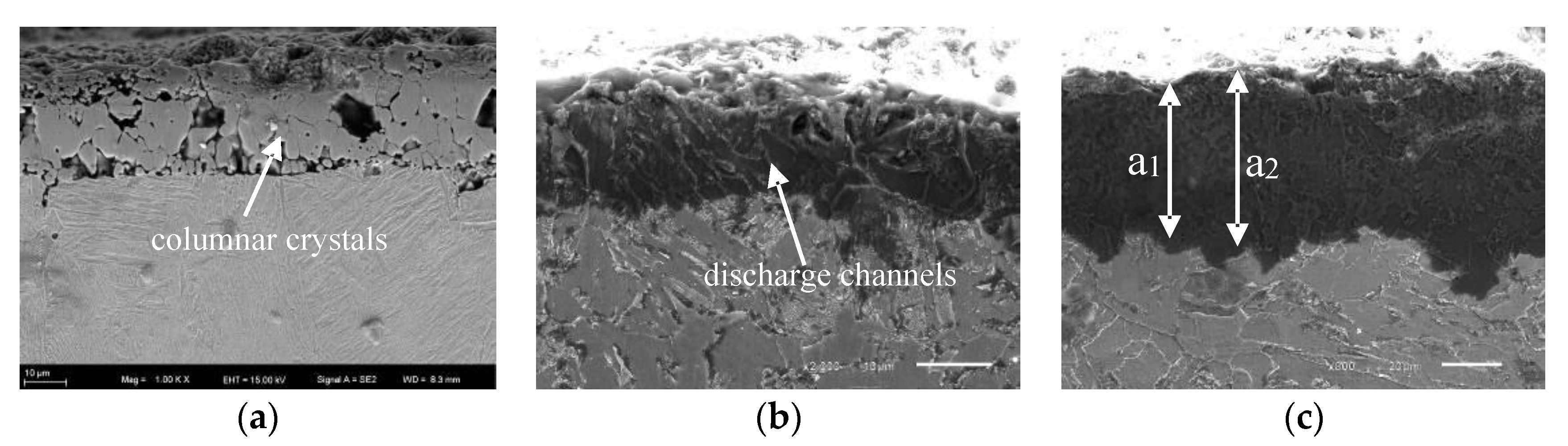

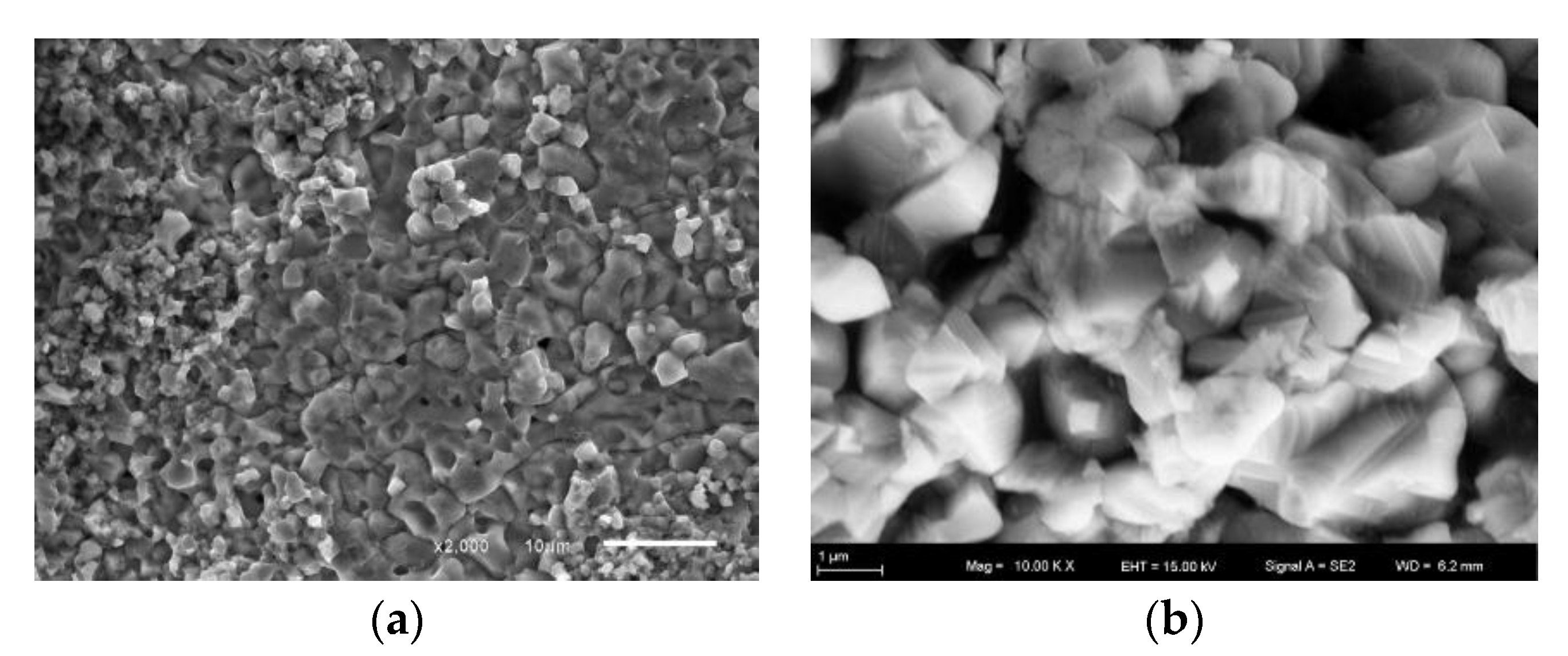

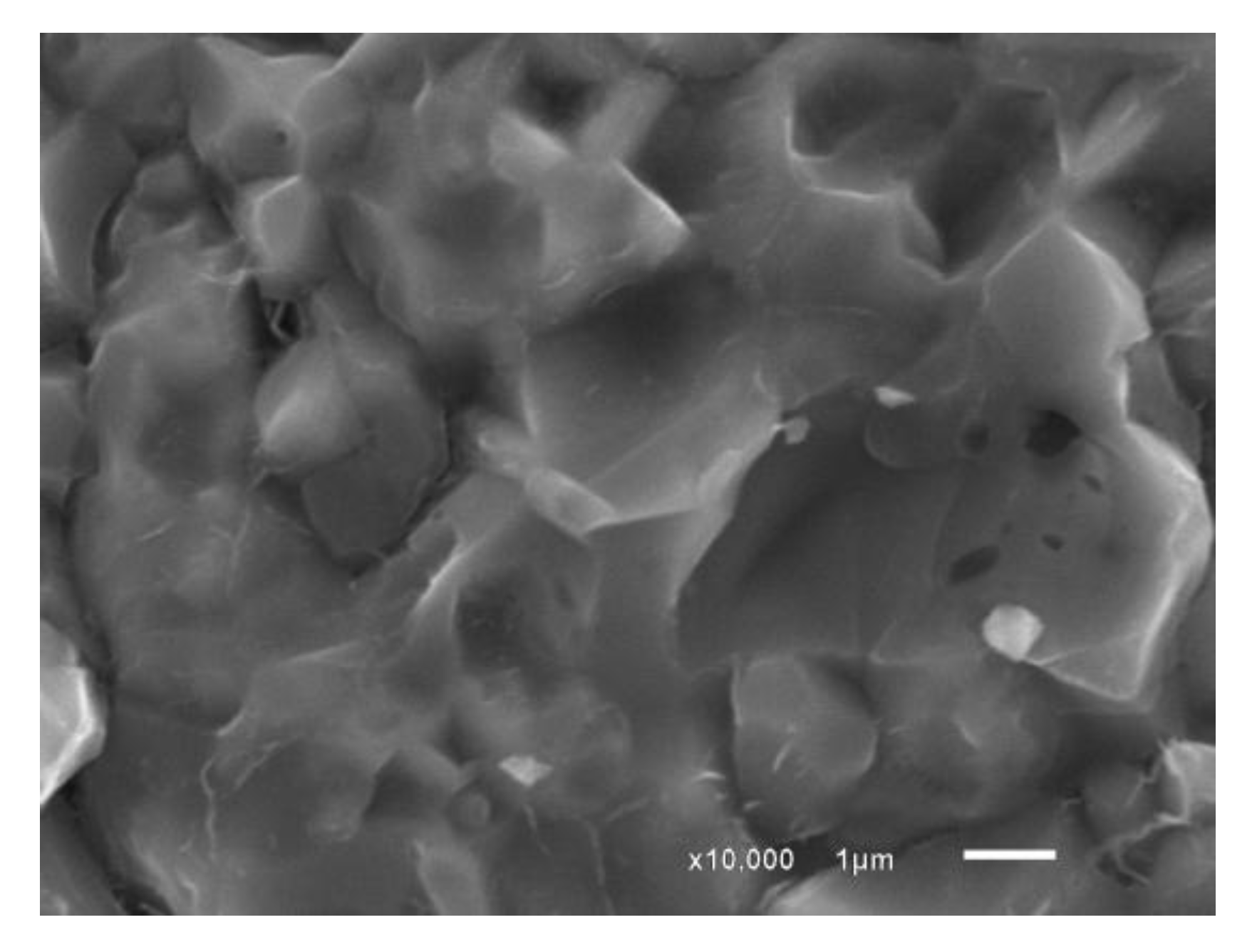

3.1. Microstructures

3.2. XRD

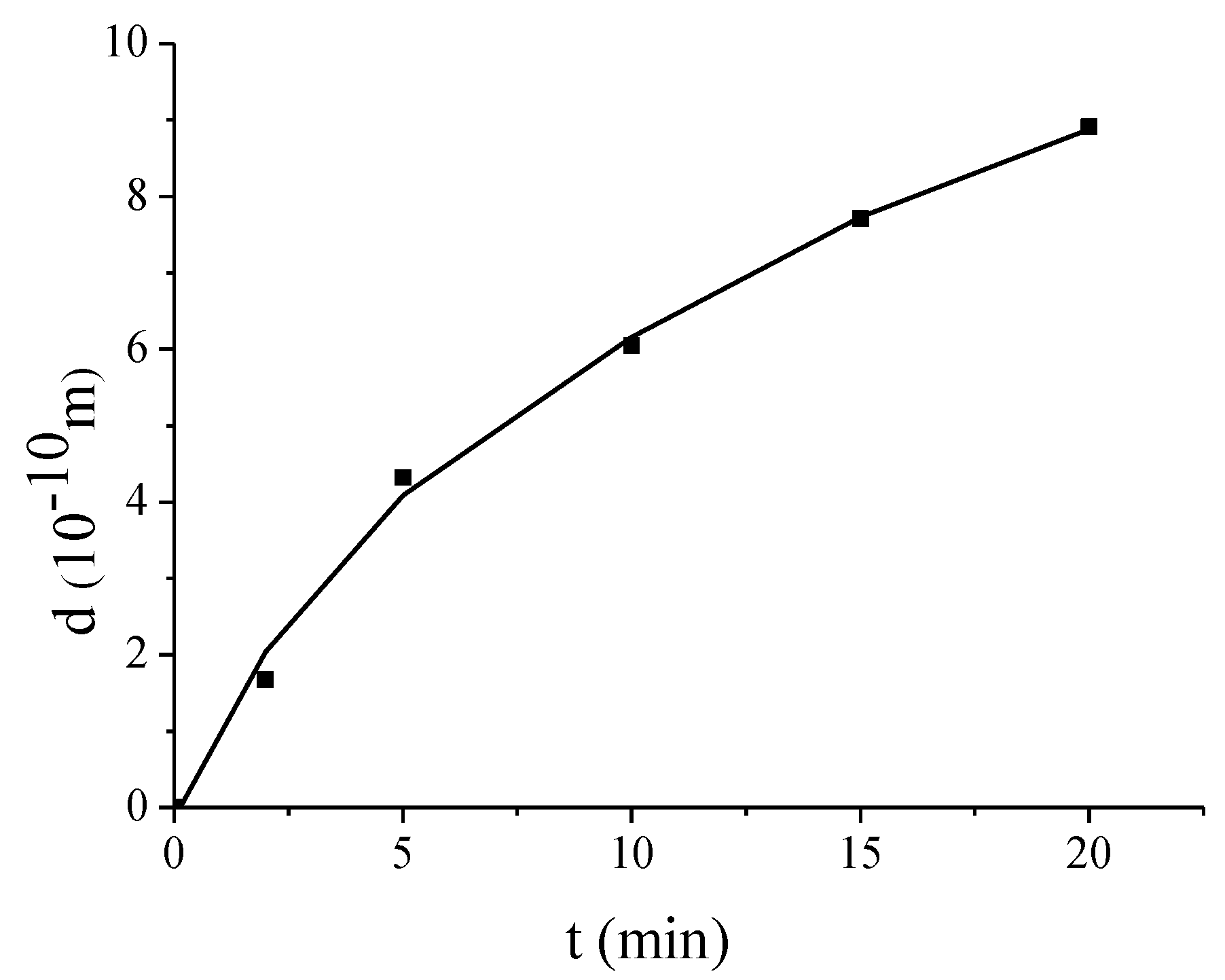

3.3. Growth Kinetics of Boriding Layer

3.4. Hardness

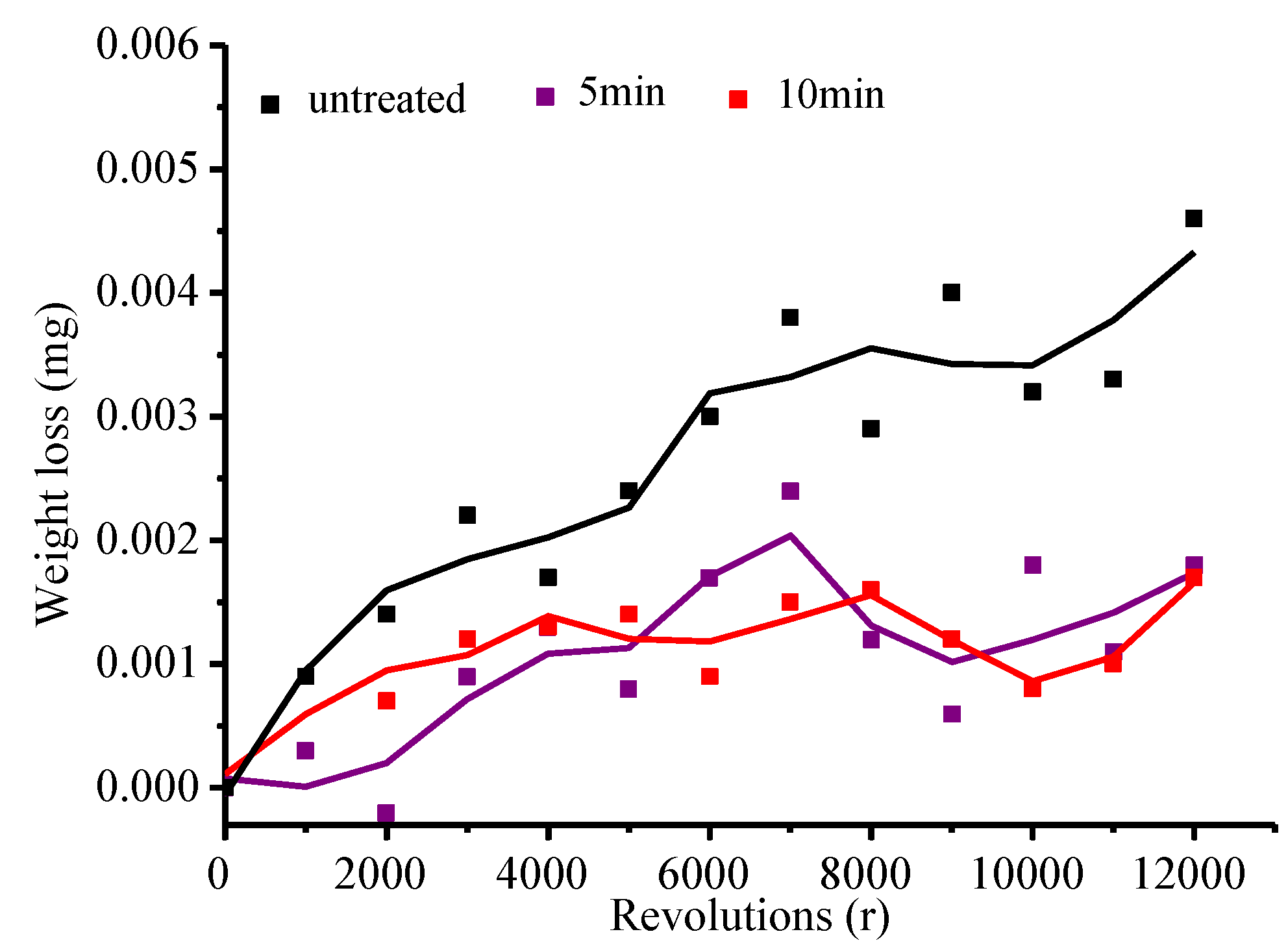

3.5. Lubrication Friction Mechamism

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Parfenov, E.V.; Yerokhin, A.L.; Nevyantseva, R.R.; Gorbatkov, M.V.; Liang, C.-J.; Matthews, A. Towards smart electrolytic plasma technologies: An overview of methodological approaches to process modelling. Surf. Coat. Technol. 2015, 269, 2–22. [Google Scholar] [CrossRef]

- Gupta, P.; Tenhundfeld, G.; Daigle, E.O. Electrolytic plasma technology: Science and engineering—An overview. Surf. Coat. Technol. 2007, 201, 8746–8760. [Google Scholar] [CrossRef]

- Kusmanov, S.A.; Tambovskiy, I.V.; Sevostyanova, V.S.; Savushkina, S.V.; Belkin, P.N. Anode plasma electrolytic boriding of medium carbon steel. Surf. Coat. Technol. 2016, 291, 334–341. [Google Scholar] [CrossRef]

- Wang, B.; Wu, J.; Zhang, Y.F.; Wu, Z.L.; Li, Y.L.; Xue, W.B. High-temperature oxidation of Q235 low-carbon steel treated by plasmaelectrolytic borocarburizing. Surf. Coat. Technol. 2015, 269, 302–307. [Google Scholar] [CrossRef]

- Cavuslu, F.; Usta, M. Kinetics and mechanical study of plasma electrolytic carburizing for pure iron. Appl. Surf. Sci. 2011, 257, 4014–4020. [Google Scholar] [CrossRef]

- Jiang, Y.F.; Geng, T.; Bao, Y.F.; Zhu, Y.H. Electrolyte–electrode interface and surface characterization of plasma electrolytic nitrocarburizing. Surf. Coat. Technol. 2013, 216, 232–236. [Google Scholar] [CrossRef]

- Nie, X.; Tsotsos, C.; Wilson, A.; Yerokhin, A.L.; Leyland, A.; Matthews, A. Characteristics of a plasma electrolytic nitrocarburising treatment for stainless steels. Surf. Coat. Technol. 2001, 139, 135–142. [Google Scholar] [CrossRef]

- Wang, B.; Xue, Y.L.; Wu, J.; Jin, X.X.; Hua, M.; Wu, Z.L. Characterization of surface hardened layers on Q235 low-carbon steel treated by plasma electrolytic borocarburizing. J. Alloys Comp. 2013, 578, 162–169. [Google Scholar] [CrossRef]

- Kong, J.H.; Okumiya, M.; Tsunekawa, Y.; Takeda, T.; Yun, K.Y.; Yoshida, M.; Kim, S.G. Surface modification of SCM420 steel by plasma electrolytic treatment. Surf. Coat. Technol. 2013, 232, 275–282. [Google Scholar] [CrossRef]

- Béjar, M.A.; Henríquez, R. Surface hardening of steel by plasma-electrolysis boronizing. Mater. Des. 2009, 30, 1726–1728. [Google Scholar] [CrossRef]

- Kartal, G.; Eryilmaz, O.L.; Krumdick, G.; Erdemir, A.; Timur, S. Kinetics of electrochemical boriding of low carbon steel. Appl. Surf. Sci. 2011, 257, 6928–6934. [Google Scholar] [CrossRef]

- Taheri, P.; Dehghanian, C.; Aliofkhazraei, M.; Rouhaghdam, A.S. Evaluation of nanocrystalline microstructure, abrasion, and corrosion properties of carbon steel treated by plasma electrolytic boriding. Plasma Process. Polym. 2007, 4, 711–716. [Google Scholar] [CrossRef]

- Badini, C.; Gianoglio, C.; Pradelli, G. The effect of carbon, chromium and nickel on the hardness of borided layers. Surf. Coat. Technol. 1987, 30, 157–180. [Google Scholar] [CrossRef]

- Campos, I.; Bautista, O.; Ramírez, G.; Islas, M.; De La Parra, J.; Zúñiga, L. Effect of boron paste thickness on the growth kinetics of Fe2B boride layers during the boriding process. Appl. Surf. Sci. 2005, 243, 429–436. [Google Scholar] [CrossRef]

- Genel, K. Boriding kinetics of H13 steel. Vacuum 2006, 80, 451–457. [Google Scholar] [CrossRef]

| Steel | C (%) | Si (%) | Mn (%) | P (%) | S (%) | Cr (%) | Ni (%) | Ti (%) | Fe (%) |

|---|---|---|---|---|---|---|---|---|---|

| Q235 | 0.14–0.22 | <0.07 | 0.30–0.60 | <0.045 | <0.05 | – | – | – | Bal. |

| 304 | <0.08 | <1.0 | <2.0 | <0.045 | <0.03 | 18–20 | 8–12 | – | Bal. |

| GCr15 | 0.95–1.05 | 0.15–0.35 | 0.2–0.4 | – | – | 1.3–1.65 | – | – | Bal. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Bao, Y.; Wang, M. Kinetic Analysis of Additive on Plasma Electrolytic Boriding. Coatings 2017, 7, 61. https://doi.org/10.3390/coatings7050061

Jiang Y, Bao Y, Wang M. Kinetic Analysis of Additive on Plasma Electrolytic Boriding. Coatings. 2017; 7(5):61. https://doi.org/10.3390/coatings7050061

Chicago/Turabian StyleJiang, Yongfeng, Yefeng Bao, and Min Wang. 2017. "Kinetic Analysis of Additive on Plasma Electrolytic Boriding" Coatings 7, no. 5: 61. https://doi.org/10.3390/coatings7050061