1. Introduction

Road roughness is an important issue for the assessment of road pavement condition [

1,

2], and an important aspect to be included in any Pavement Management System (

PMS) [

3,

4,

5,

6]. Road roughness evaluation can be carried out using a number of different approaches. Among these, the most common ones are based on the assessment of detrimental effects induced by irregularities on road surfaces, like the dynamic increment of loads transmitted to pavements [

7], road users’ comfort [

8] and noise generated due to road traffic [

9].

The International Roughness Index (

IRI) is the most used method worldwide and it was developed to take into account general effects (both on pavements and users) induced by irregularities of road pavement surface [

10]. Some authors, like Kropáč and Múčka [

11] and Loizos and Plati [

12], have highlighted some limits of the applicability of IRI as a method for the evaluation of road roughness. In particular, in [

13], the inability of

IRI to describe car body vertical vibration due to the presence of certain wavelengths (i.e., >20 m) of road profile was described. In recent decades, several indices have been developed as alternative methods to consider various effects [

14]. Particular attention has been paid to the assessment of the influence of road unevenness on vehicles and passenger vibrations [

15,

16], and the evaluation of possible correlations between existing roughness indicators and vehicles vibration response [

17].

Cantisani and Loprencipe [

18] proposed calculating the whole body vibration induced on passengers inside road vehicles, by means of the process described in the ISO 2631 standard [

19], to assess ride quality. In this way, it would be possible to reflect the comfort perceived by road users. Many authors have analyzed existing relations between

IRI and vertical accelerations measured on driver and/or passenger seats, considering different types of vehicles and different velocities [

17,

20,

21,

22]. Most of these studies found a linear regression with

R2 values within the range from 0.76 to 0.99. Other indicators, like the Ride Number (

RN) and the Michigan and Minnesota Ride Quality Index (

RQI), have been developed through Mean Panel Rating (

MPR) tests, in order to take into account road customers’ opinions.

In the literature, to the best of our knowledge, no relationships or comparisons between the latter indices are present. In some studies, on the other hand, it is possible to find some relationships between each of the aforementioned ride quality indices and

IRI. In particular, Sayers and Karamihas [

2] found a relationship between

IRI and Profile Index (

PI), which is a parameter at the base of

RN calculations, having an

R2 value of 0.82. In this case, the

IRI range considered was from 0.5 to 7 m/km. A similar range was also considered in [

23] where, in addition to the comparison between

IRI and

PI (

R2 variable 0.96–0.98), a direct relationship between

IRI and

RN (

R2 = 0.98) was provided, although related to a narrower range of

IRI values (from 0.5 to 1.6 m/km).

In [

24], relationships between Michigan

RQI (

RQIMich) and

IRI for different types of pavement (i.e., flexible, rigid, composite) are depicted, although corresponding equations and

R2 values are not reported (but the result seems to be good). The calculation of the Minnesota

RQI (

RQIMn) is instead, as will be described in the following section, based on

IRI values.

In this paper, a comparison of the

RN,

RQIMich and

RQIMn was carried out, applying them to a set of 3905 samples of real road (asphalt pavement) profiles, having section lengths equal to 100 m. These indices were selected because they are based on

MPR and the corresponding threshold values currently adopted in certain countries are available in literature. The final purpose is to compare the different ride quality thresholds defined for each method, also evaluating the existence of possible correlations between them. Furthermore, the capability of the ISO 2631 [

19] approach as a road unevenness indicator was investigated, comparing the results with those obtained using the consolidated methods (

RN,

RQIMich and

RQIMn). Finally, all the aforementioned approaches were compared with

IRI, which is the most-used road roughness evaluation method worldwide, as stated in [

25], where

IRI specifications around the world are reported. In this way, this work intends to highlight the need of standardizing mean panel tests, adopting also homogeneous speed-related threshold values to be used for ride quality evaluation.

4. Results and Discussion

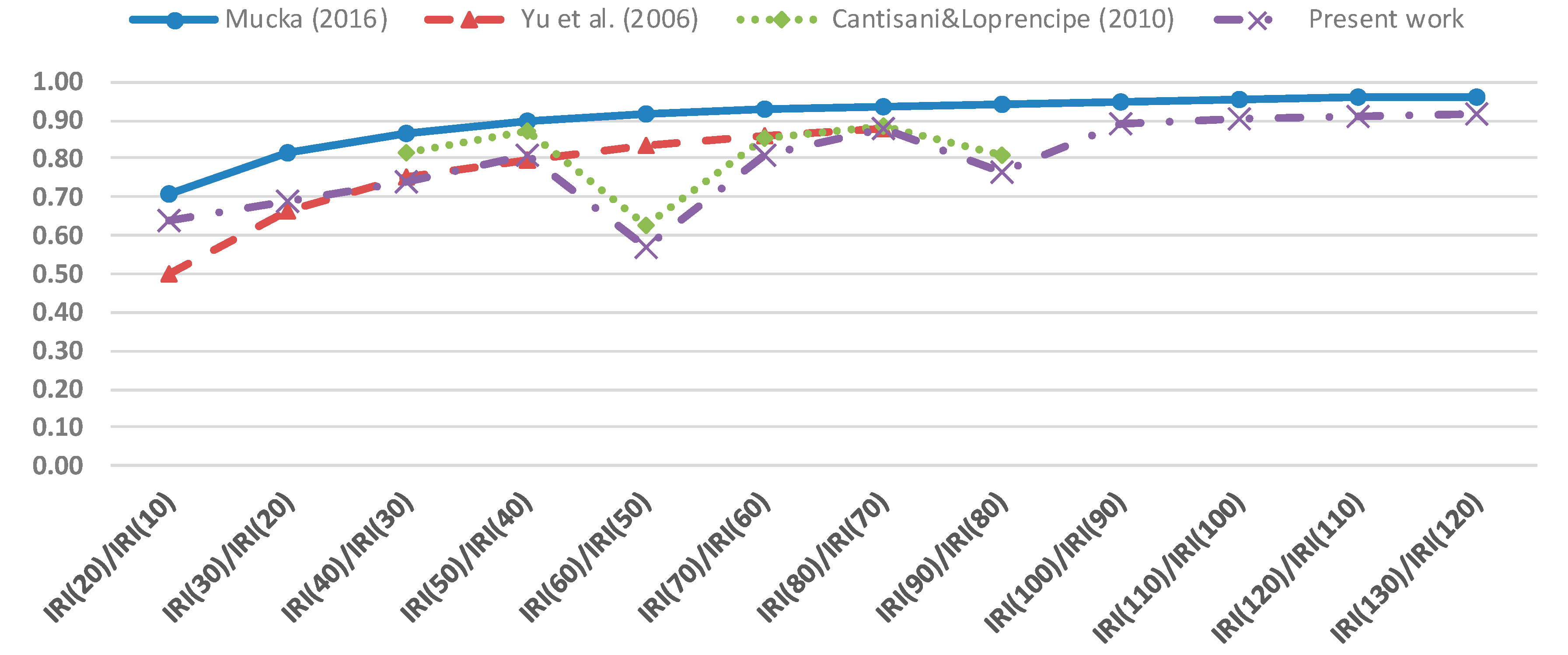

A preliminary study concerning the analysis of the

IRI relation reported in Equation (9), which was introduced by Múčka [

25], talking about international

IRI specifications for new/reconstructed roads. Specifically, it was decided to compare the ratio between

IRI thresholds at two adjacent velocities (e.g.,

IRI(30)/

IRI(20) or

IRI(80)/

IRI(70)), calculated using Equation (9), and obtained by employing both the threshold values suggested by Yu et al. [

35] and those suggested by Cantisani and Loprencipe [

18] with regard to very good ride quality level. It can be supposed, in fact, that this ride quality level characterizes new or reconstructed roads. The results of the above-mentioned comparison are then depicted in

Figure 1, where the results obtained by applying the procedure described by Cantisani and Loprencipe [

18] to the real profile samples considered in the present work and taking into account a segment length of 100 m are also reported.

As can be seen, similar trends are found for all of the examined studies and, in particular, values very close to the ones presented in [

18] are found in the present work, where the same simulation model but different road profile samples were used. Furthermore, some anomalies in both of the latter approaches’ trends can be noted to correspondend to the

IRI thresholds ratio between speeds of 60 and 50 km/h, and between 90 and 80 km/h. This unexpected behavior was probably due to the mechanical parameters considered in the simulation model at these speeds (i.e., the mechanical properties were defined as a function of the traveling velocity).

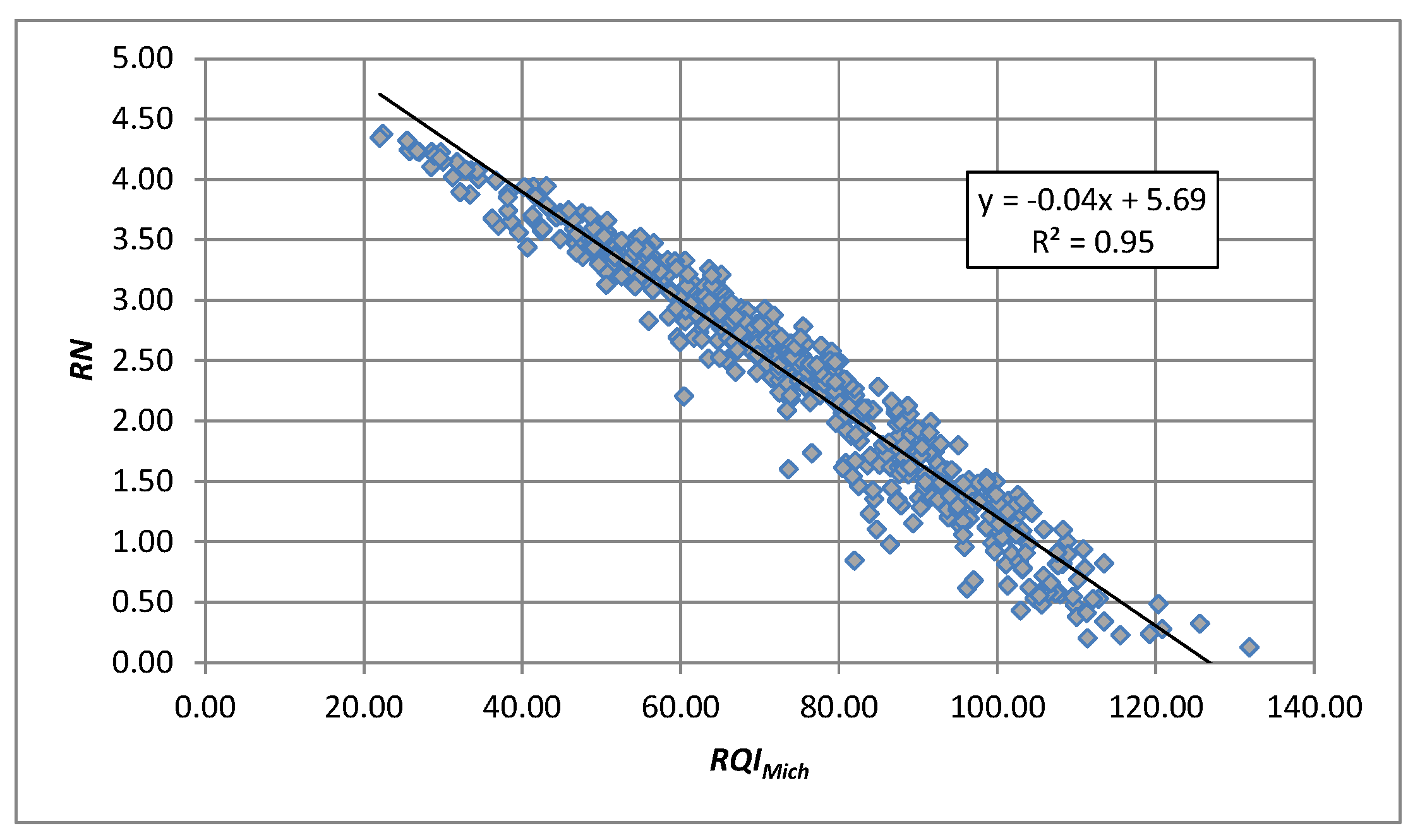

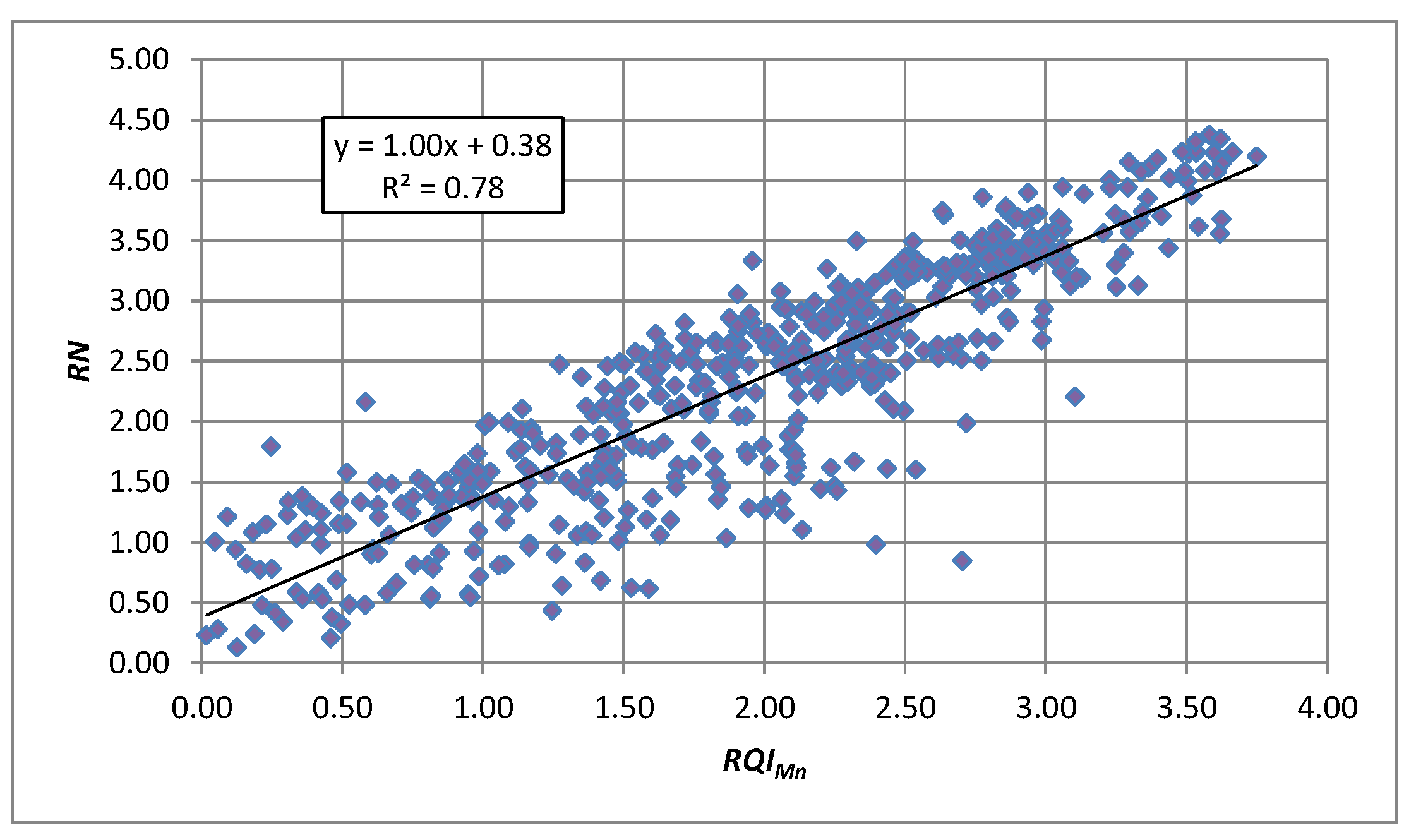

Before proceeding with the analysis of the

awz values at different speeds, a comparison between the results obtained for the other three users’ comfort evaluation methods was performed. Because no indications were found about section length to be used for their calculation, it was decided to consider the same length of 100 m as commonly adopted for

IRI calculation. In this way, all the wavelengths’ contents of interest for the various examined ride quality methods are taken into account. In particular, pretty good correlations between them were found, as can be seen in

Figure 2,

Figure 3 and

Figure 4 where

R2 values within 0.78–0.95 are shown. The highest

R2 value (0.95) was obtained for

RQIMich-

RN regression equation (

Figure 2).

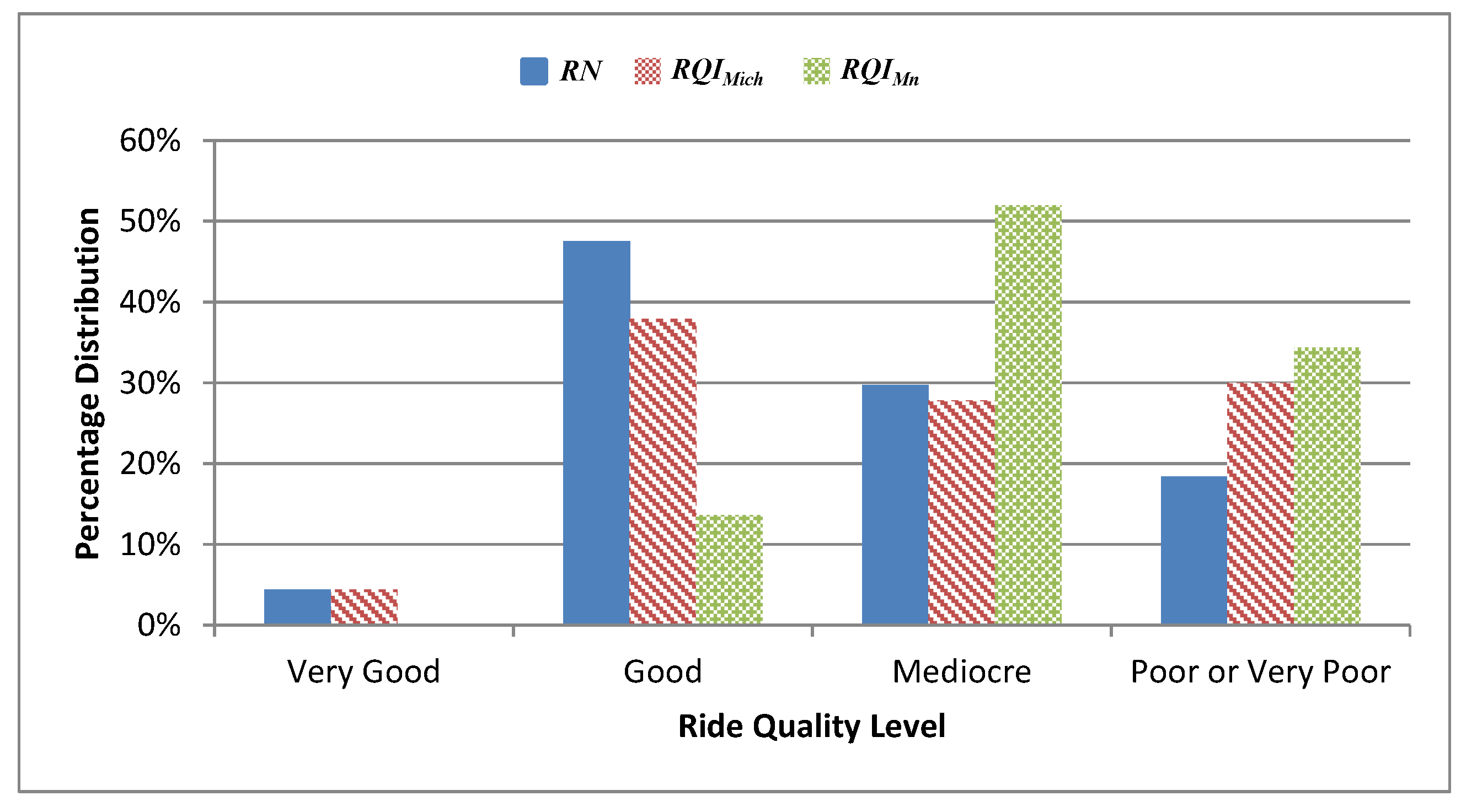

Although quite good correlations were found between these indices, each index presents a specific scale rating based on the performed panel rating tests, for which a standardization does not exist.

In fact, different distributions of the real profile samples among the four ride quality levels were obtained, based on the method that was being considered, as can be seen in

Figure 5. Thus, the choice of road ride quality evaluation method meaningfully influences the maintenance actions planning.

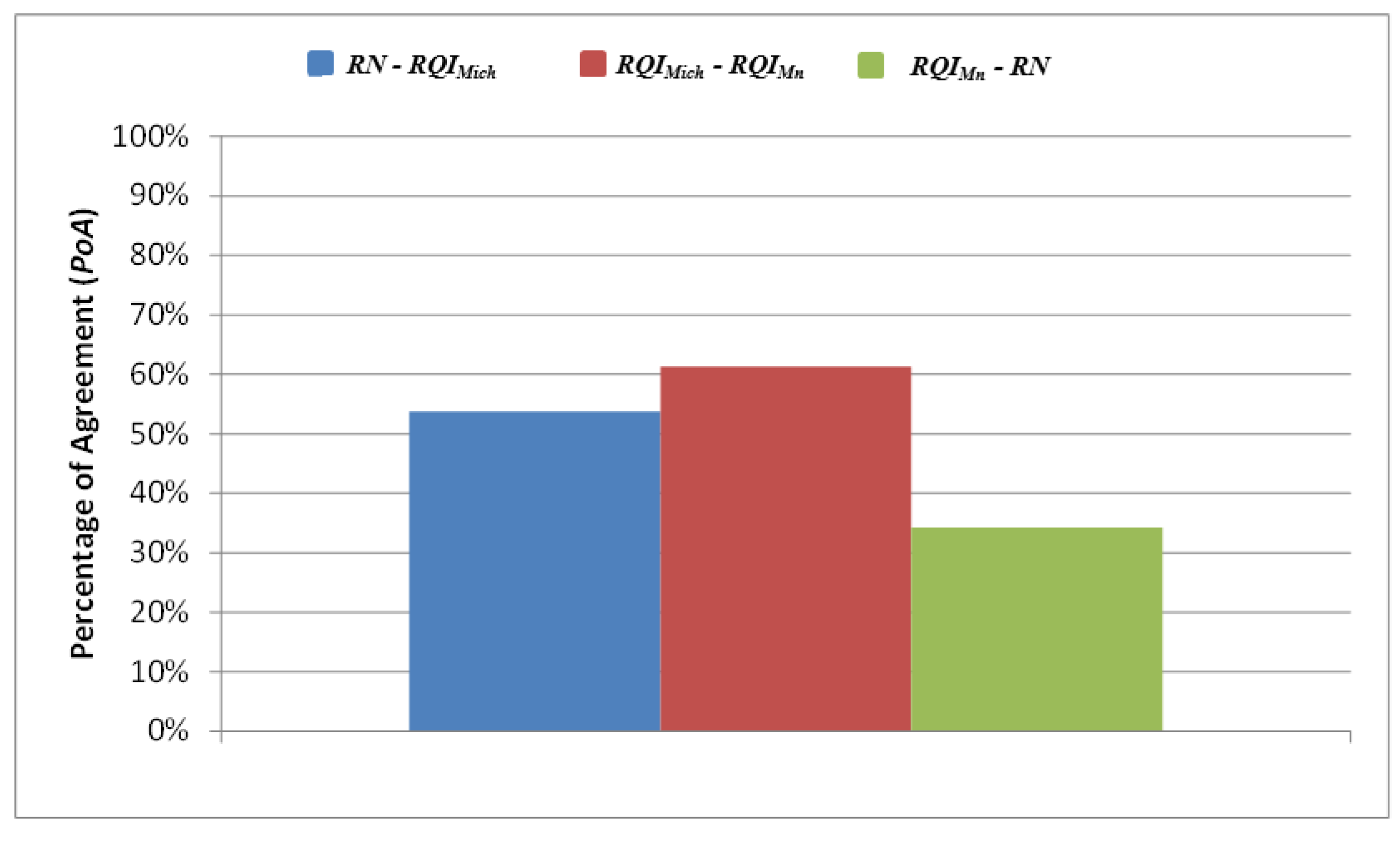

Counting the amount of profiles evaluated in the same way by the different indicators, a percentage of agreement (

PoA, calculated according to Equation (7) for each pair of indices) greater than 60% was obtained just for

RQIMich and

RQIMn comparison (see

Figure 6). The worst agreement, instead, was found between

RN and

RQIMn. This result could be expected by looking at

Figure 3. In fact, both these indices have the same rating scale (from 0 to 5.0) and ride quality categories (see

Table 4), but the linear regression equation found presents an intercept value equal to 0.38; which means that a switch between the rating scales of the two methods exists. In particular, the

RQIMn provides a more severe evaluation of road profiles, as highlighted by the results shown in

Figure 5.

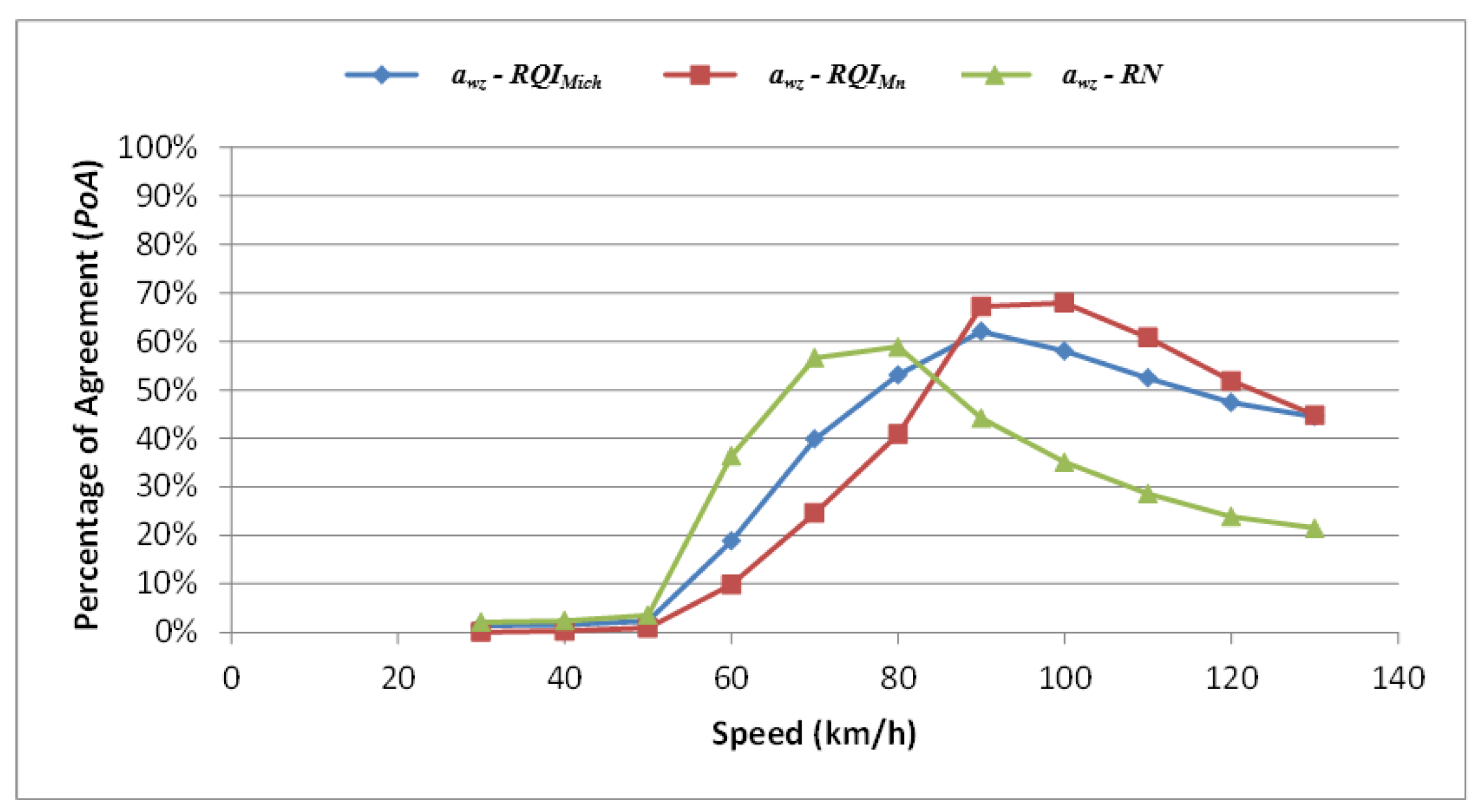

As already stated in

Section 2.4, the results obtained for

RN,

RQIMich and

RQIMn were also compared with the vertical frequency-weighted acceleration

awz calculated at several speeds (from 30 to 130 km/h). By analogy with the study of profile evaluation percentage agreement (

PoA), calculated according to Equation (7), reported above, the same analysis was also carried out for the

awz method, using the thresholds shown in

Table 4, defined as the middle point of the overlapping zone provided by ISO 2631 for two adjacent comfort levels.

As can be seen in

Figure 7, varying the traveling speed of the simulation vehicle, significant changes in the percentage agreement were found for all three methods with regards to

awz index values.

The highest values of the percentage agreement between awz and each of the other three ride quality evaluation methods were found to be within the range 55%–70%. Although these results are not too high, due to the fact that the panel rating tests have been performed using different vehicles, general considerations can be deduced. The best percentage agreement for the three ride quality evaluation methods, in fact, was found to correspond to different velocities. In particular, for RN it was found for a vehicle traveling at 80 km/h, while for RQIMich at 90 km/h. For RQIMn, the greatest percentage was found for simulation speeds equal to 100 km/h. These results could be an explanation of the different correlations found between the three indices (RN, RQIMn and RQIMich), which were in all cases lower than 65%. In fact, the ride quality thresholds of the aforementioned methods seem to be calibrated for different speeds of reference. A confirmation of the goodness of the results obtained can be found in the algorithm for the calculation of the RN, where a parameter similar to the velocity used in IRI calculation is set at 80 km/h, which is the value of the speed found for the maximum percentage agreement.

Looking at

Figure 7, it can be noted that none of the three consolidated indices (

RN,

RQIMich and

RQIMn) seem to be adequate for evaluating users’ comfort on urban roads or, in general, on roads having maximum legal speed limits lower than 50 km/h.

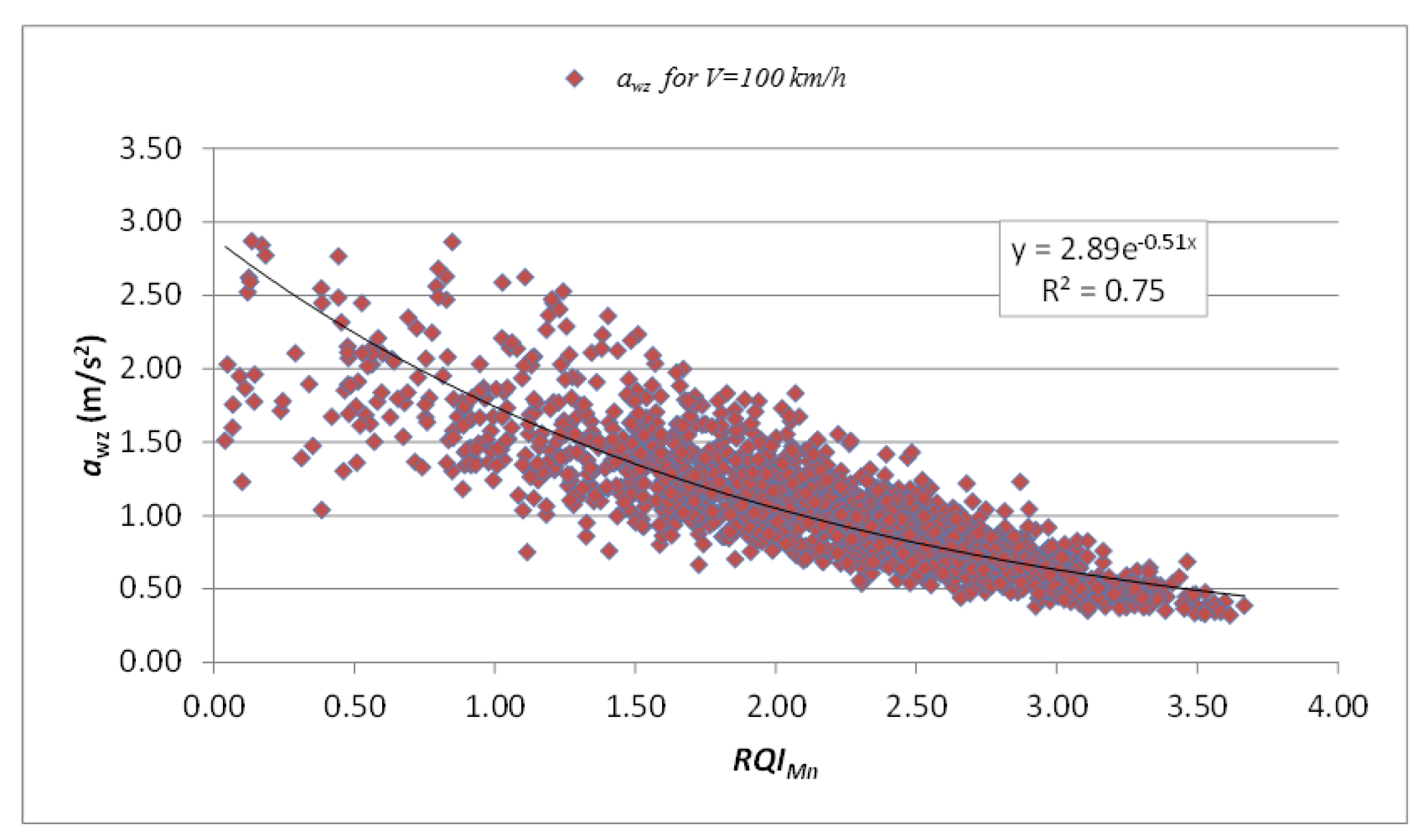

In addition to the profile evaluation agreement study, the correlations between the three consolidated ride quality evaluation methods and

awz were investigated. The

R2 values found in correspondence of the speeds at which the highest profile assessment agreements varies from 0.66 (

RN-

awz) to 0.75 (

RQIMn-

awz); as can be noted in

Figure 8,

Figure 9 and

Figure 10.

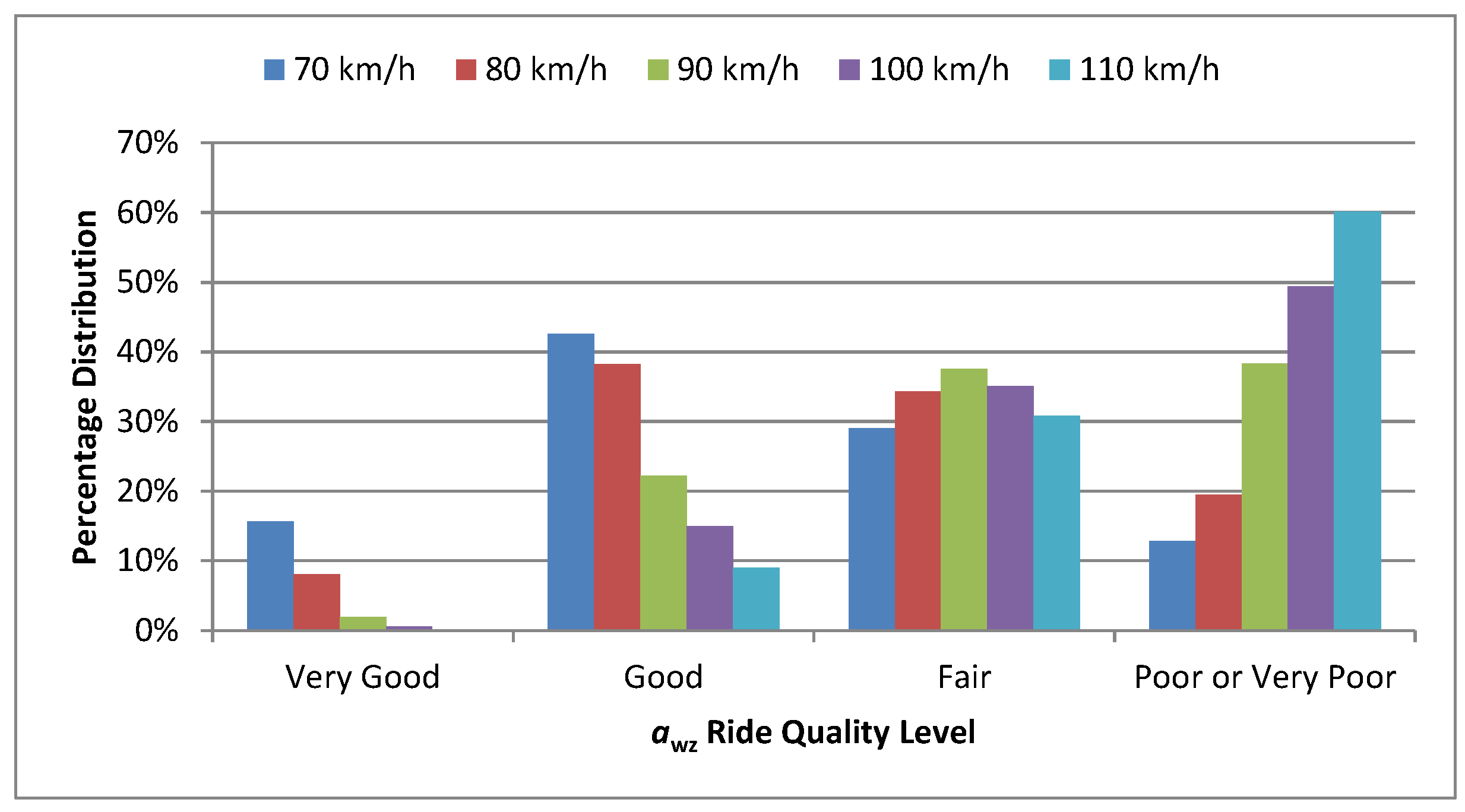

Unlike for the other methods, the use of the

awz allows the taking into account of the different users’ perceptions of road conditions based on the traveling speed, as can be noted in

Figure 11, where the distribution among the four ride quality levels of the real profiles set is reported for different velocities. To simplify the vision of the plot, not the whole range of speed considered (30–130 km/h), but just speeds within the range from 70 up to 110 km/h are represented. As can be seen, significant variation in ride quality judgement is obtained.

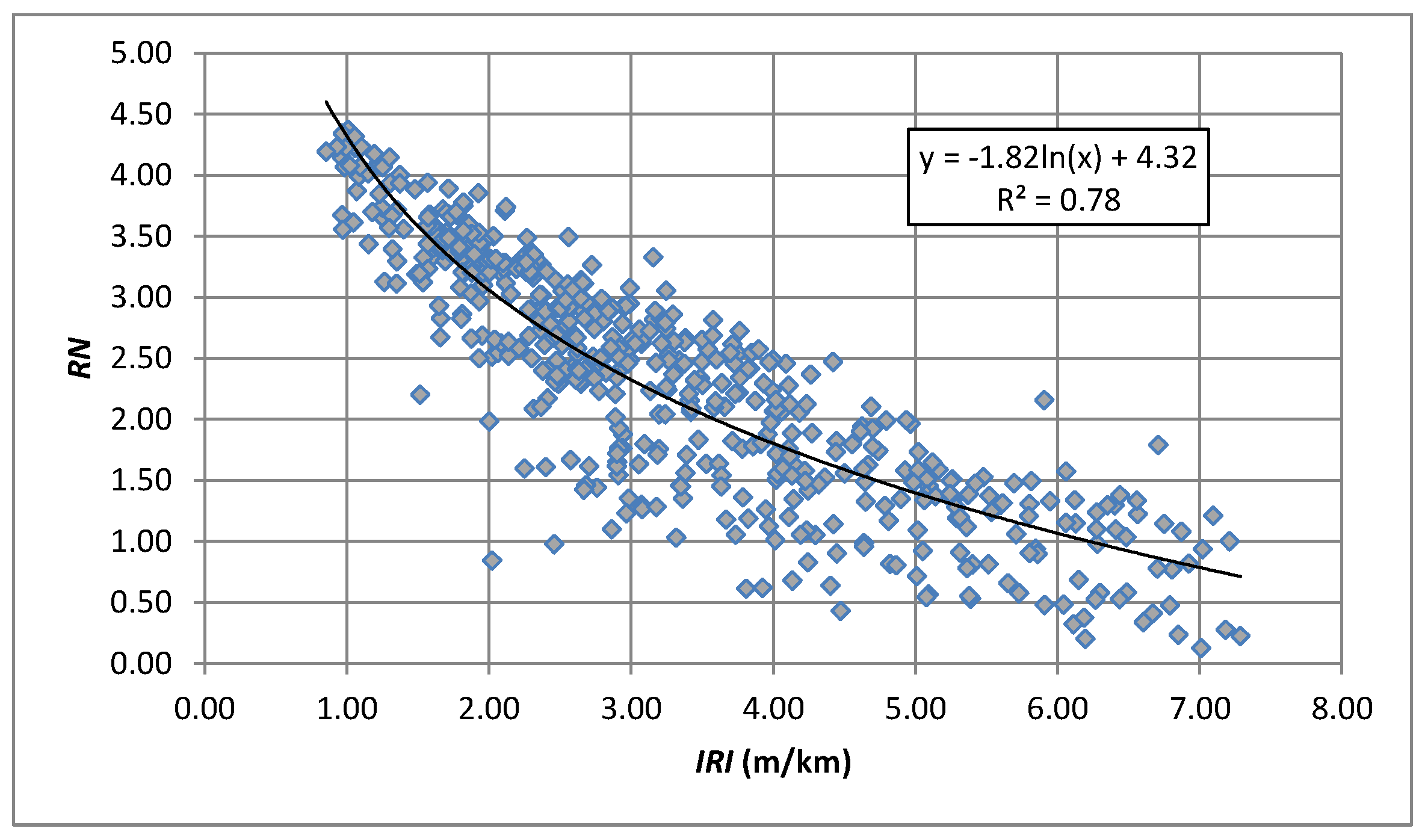

Evaluating the correlation between the various ride quality methods considered in this paper with

IRI,

R2 values of 0.78 and 0.85 were found respectively, for

RN (

Figure 12) and

RQIMich (

Figure 13).

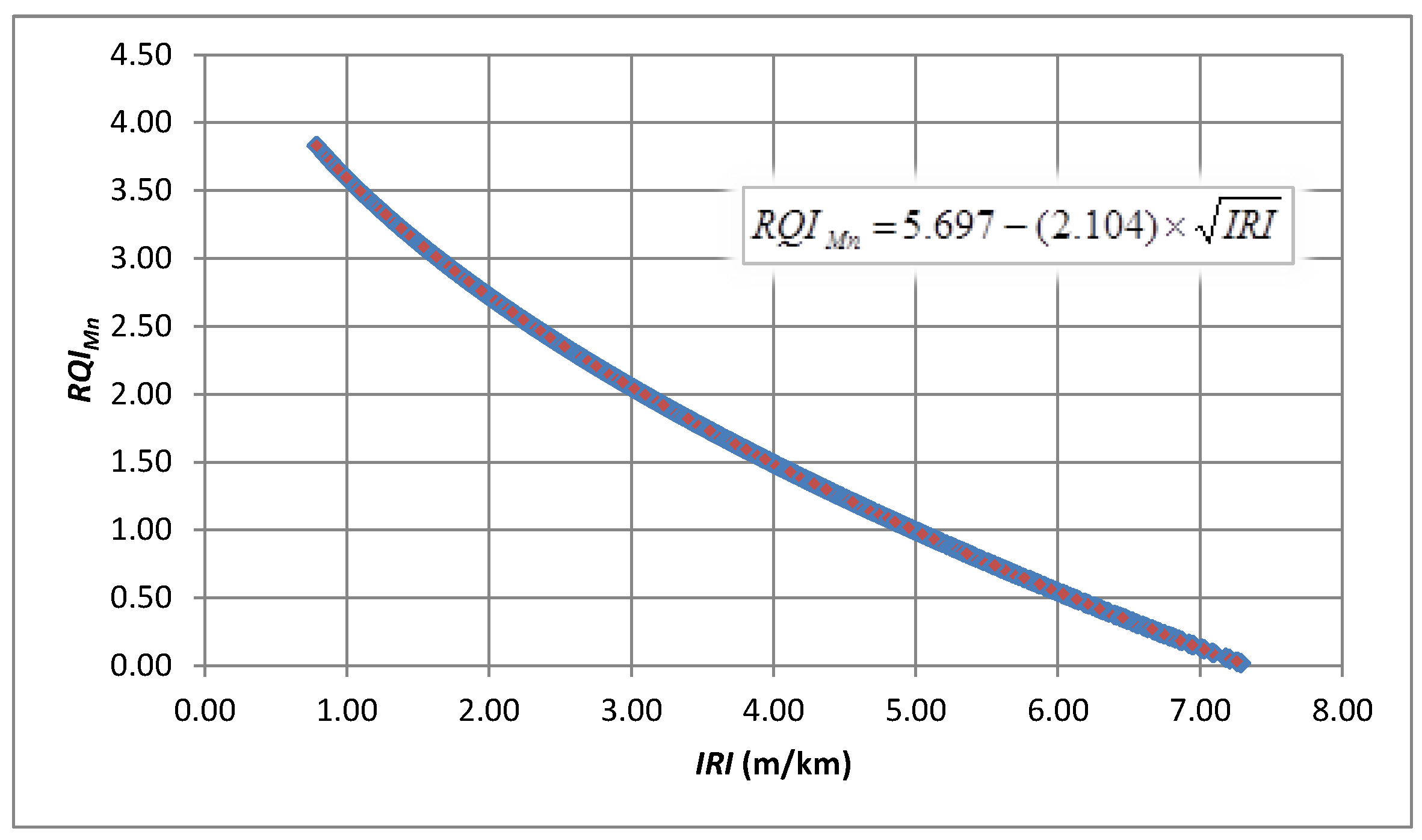

Obviously, a perfect correlation (

R2 = 1) was found between

RQIMn and

IRI (

Figure 14), since the calculation of the first one is based on

IRI values using Equation (4) previously described.

Starting from the regression equation found for each ride quality evaluation index and the thresholds reported in

Table 4 for the different ride quality levels (very good, good, mediocre and poor), it is possible to determine the corresponding

IRI limit values. The results are then reported in

Table 7.

As can be seen, looking at the thresholds related to the very good ride quality level the

RQIMn was confirmed to be the more conservative approach, while the

RN represents a less conservative approach. Although there is not perfect matching between the

IRI thresholds calculated from each method and the limit values suggested by Yu et al. [

35] and/or Cantisani and Loprencipe [

18] corresponding to all ride quality levels, it is nevertheless possible to note that all aforementioned ride quality evaluation methods were mainly developed to be used on roads characterized by speed limits within the range from 80 to 120 km/h.

Considering, then, the

IRI specifications suggested by the two aforementioned studies, already reported in

Table 5 and

Table 6, the percentage agreement in the evaluation of the examined real profile samples between

IRI and

awz approaches at various speeds was evaluated. As can be seen in

Figure 15, in this case for all the considered velocities percentages greater than 50% were always found.

These results highlight the chance of using the awz approach for road ride quality evaluation for a wide range of traveling speeds as an alternative method to IRI, mainly for velocities lower than 50 km/h, where the percentage agreement is greater than 80%. Of course, the proposed approach will need calibration and validation phases in order to be correctly used; in fact, the awz is strongly affected by the type of vehicle considered for the measurement.

In addition, Kirbaş and Karaşahin [

36] found a good correlation between

awz and Pavement Condition Index (

PCI). Therefore, using the

awz approach at a preliminary step in order to locate priorities along road networks seems to be possible, although some distresses (e.g., crack distress) do not meaningfully affect this index. Once critical sections have been located, it would be then possible to plan adequate inspections and surveys in order to understand the causes of the distresses, and then select the most appropriate maintenance actions.

All of the analyses related to the IRI method have also underlined the need to homogenize its threshold values by defining appropriate speed-related limits to be adopted by road agencies.