Influence of Surface Roughness and Agitation on the Morphology of Magnetite Films Electrodeposited on Carbon Steel Substrates

Abstract

:1. Introduction

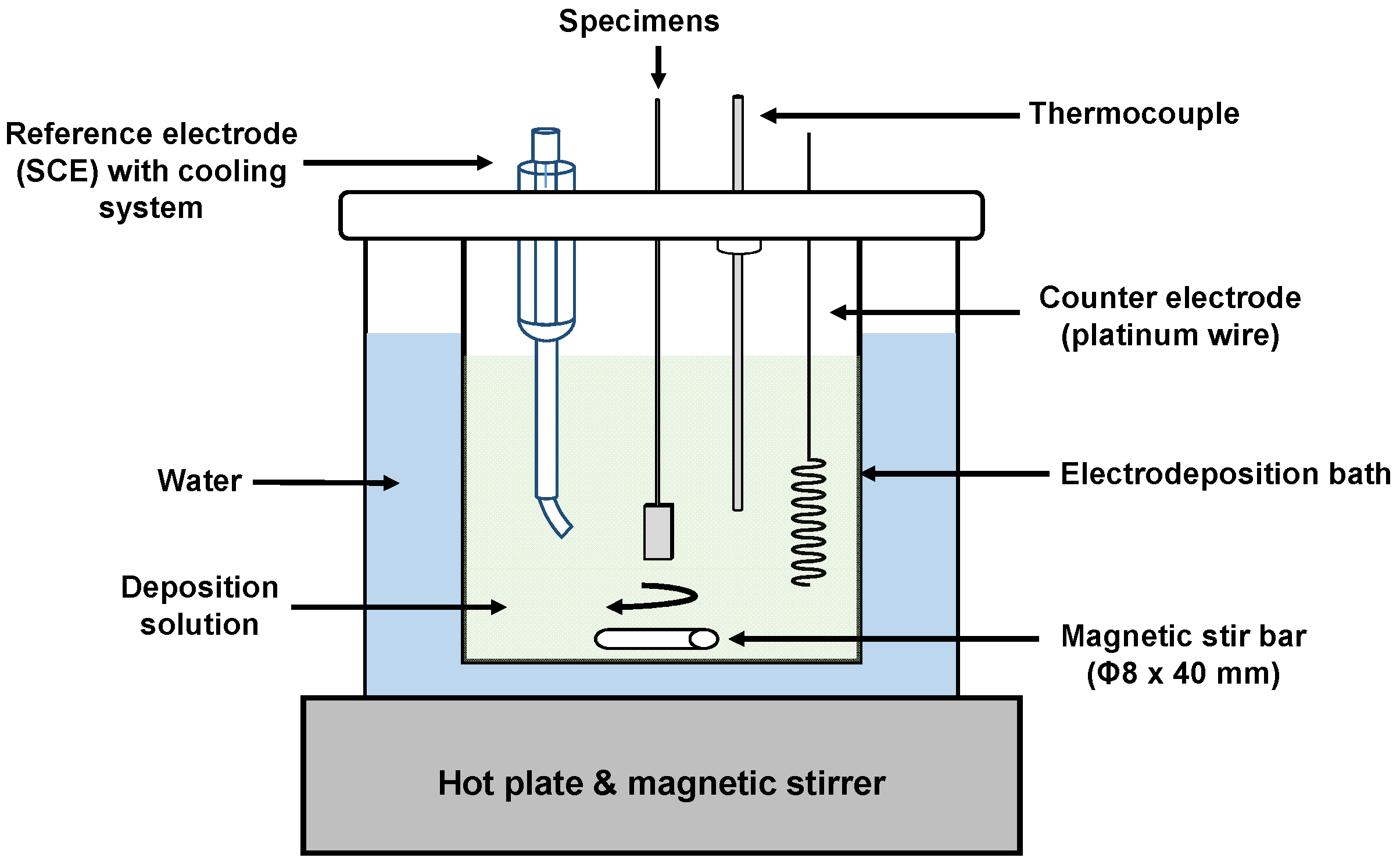

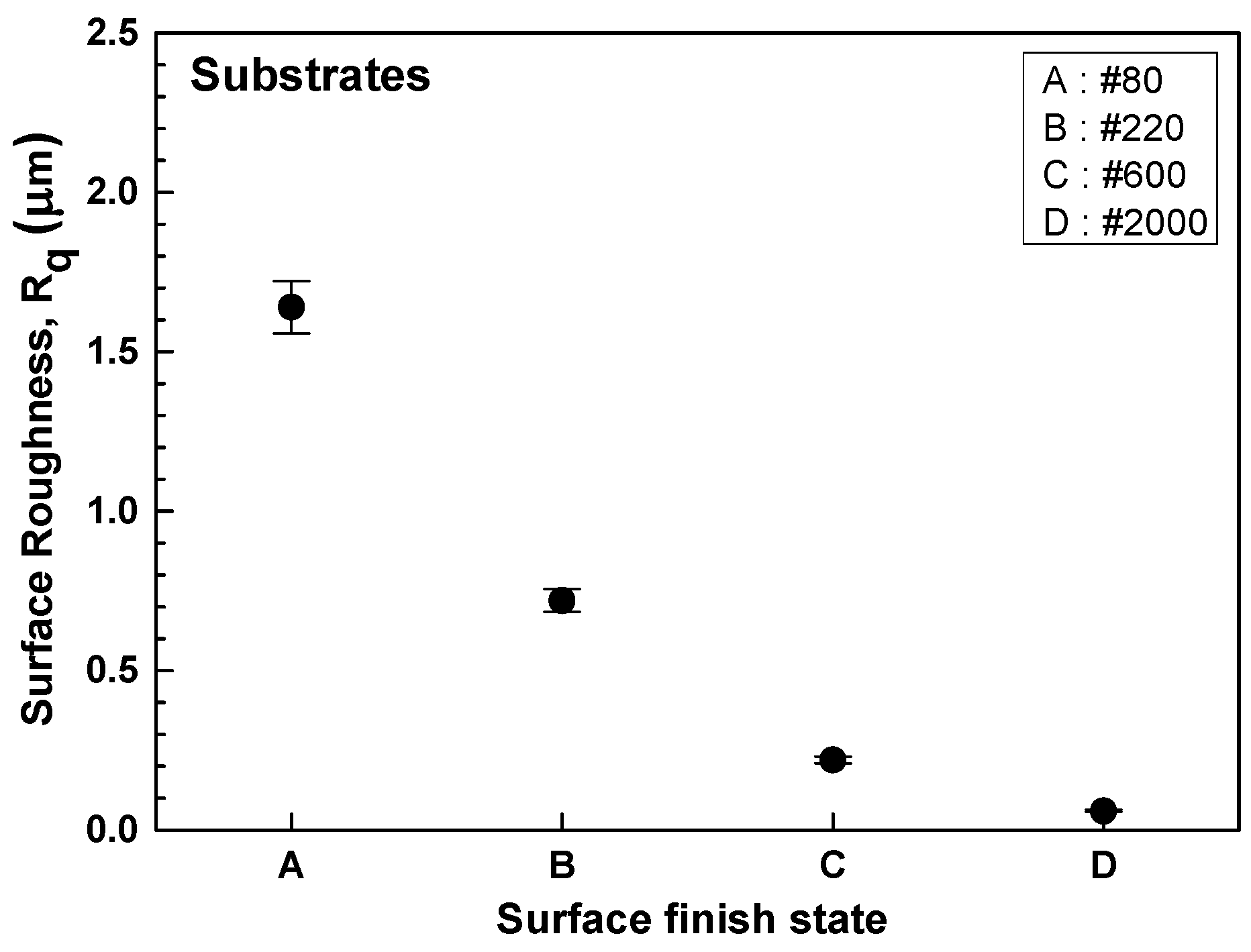

2. Materials and Methods

3. Results

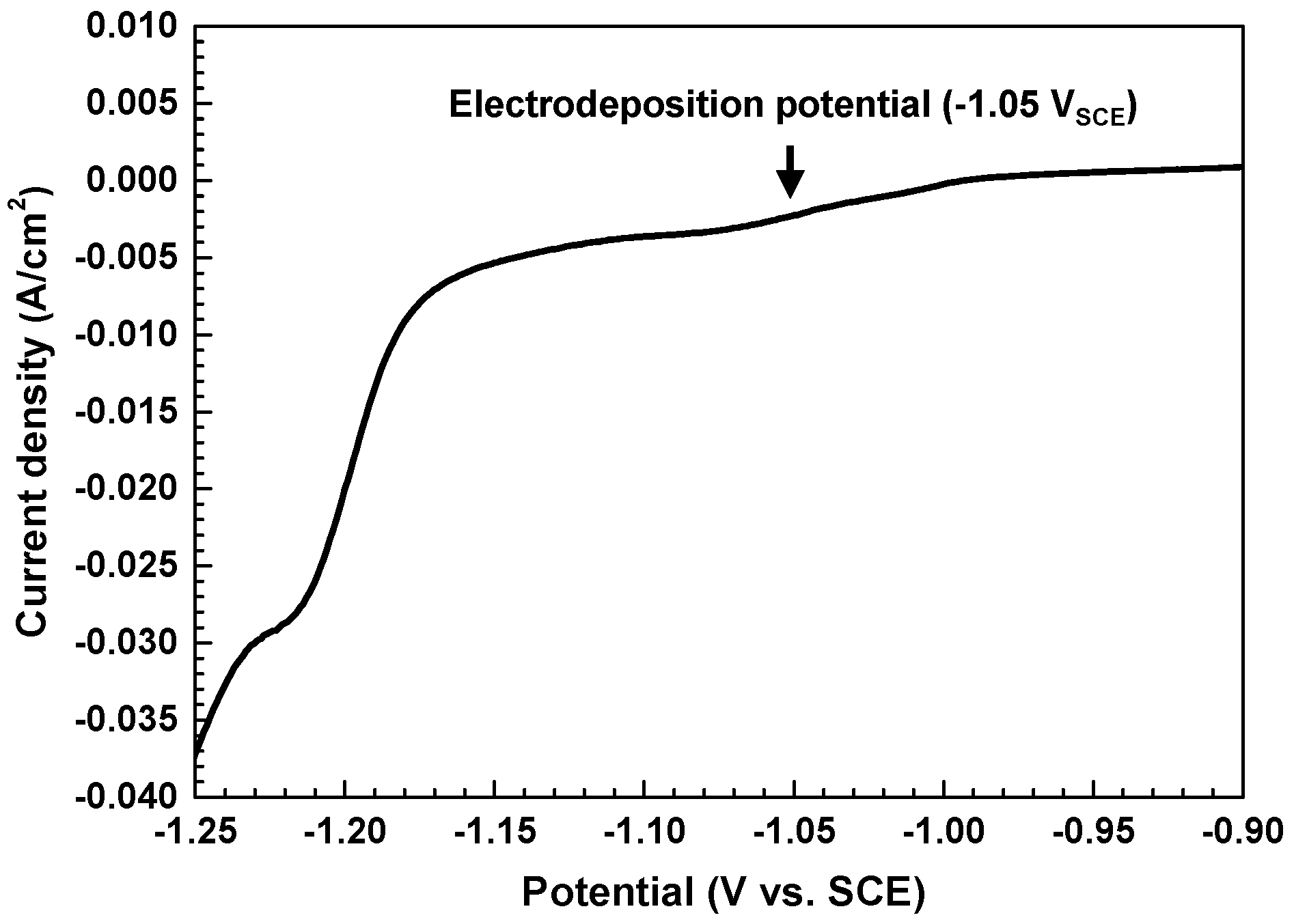

3.1. Electrodeposition of Magnetite Films

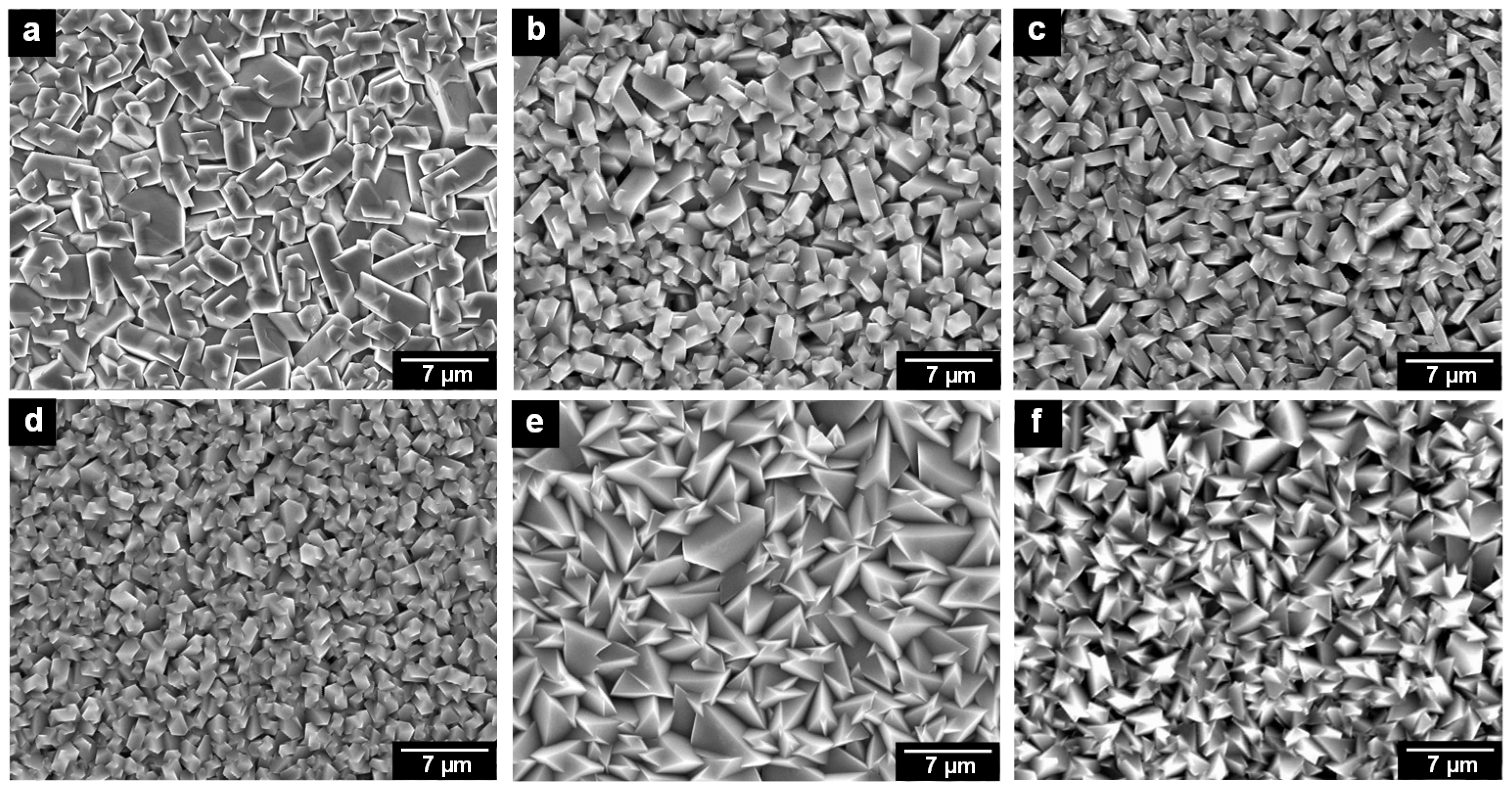

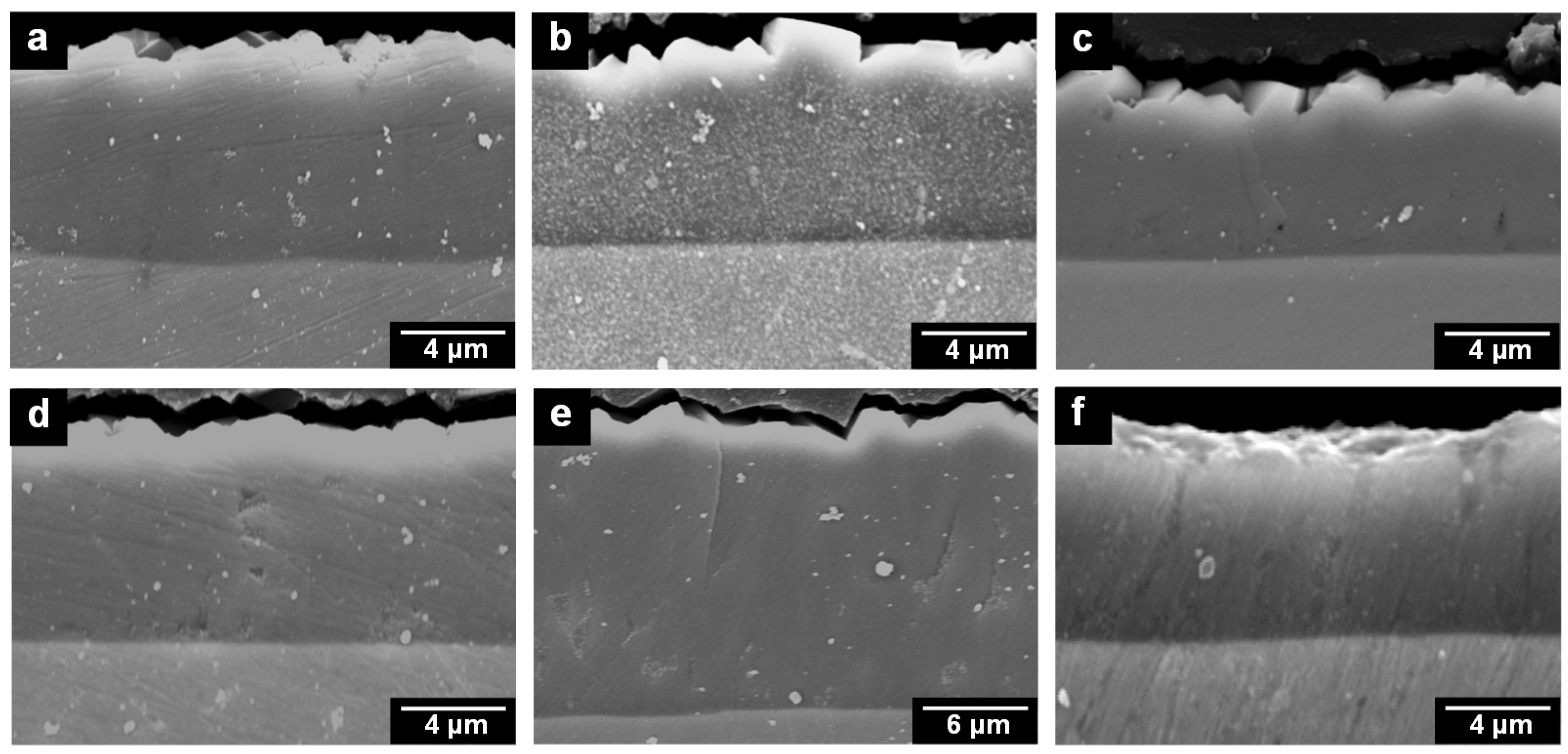

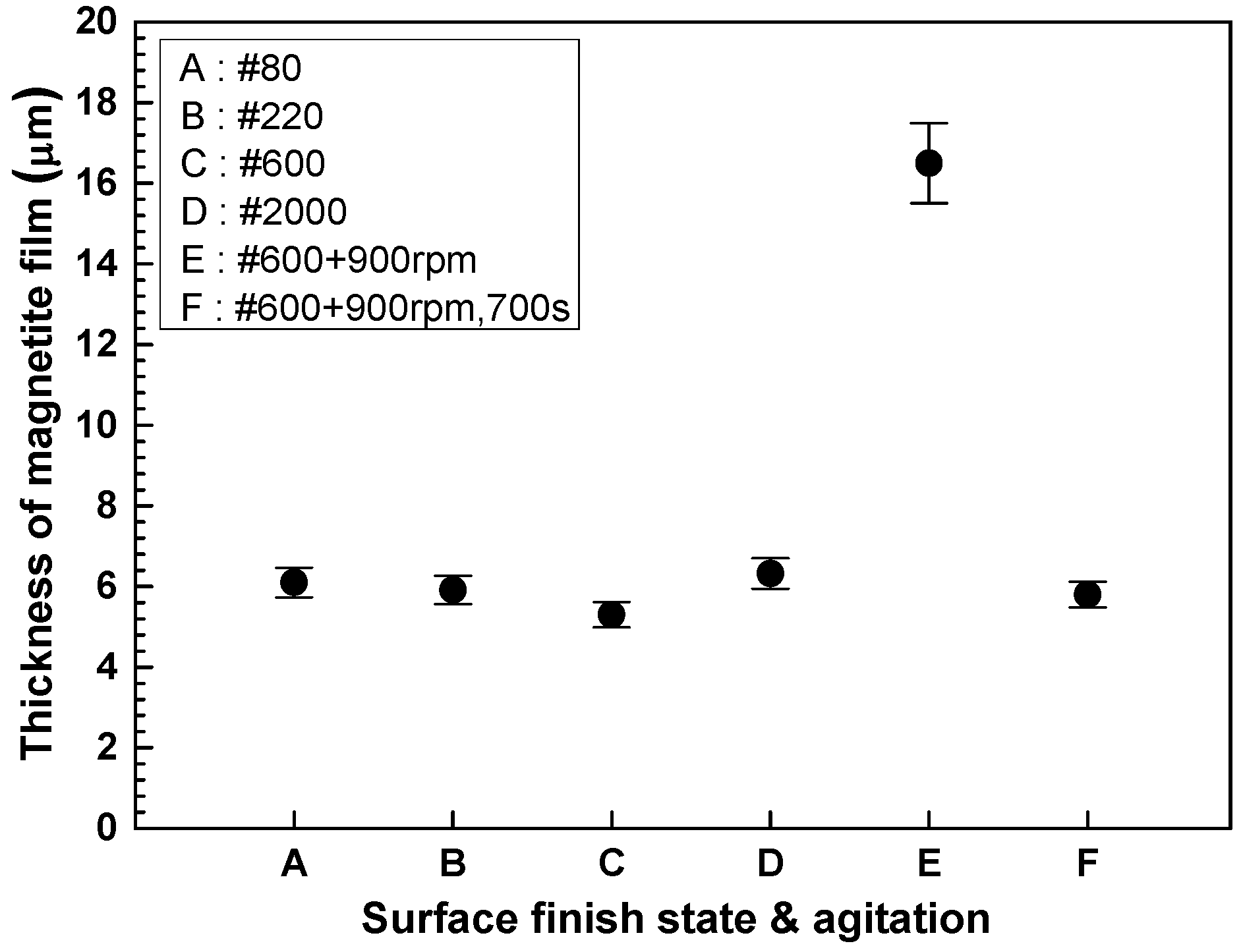

3.2. Morphology of the Magnetite Films

3.3. X-ray Diffraction of Magnetite Films

3.4. Surface Roughness of Magnetite Films

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Verwey, E.J.W. Electronic conduction of magnetite (Fe3O4) and its transition point at low temperature. Nature 1939, 144, 327–328. [Google Scholar] [CrossRef]

- Walz, F. The Verwey transition-a topical review. J. Phys. Condens. Matter 2002, 14, R285–R340. [Google Scholar] [CrossRef]

- Burrill, K.A.; Cheluget, E.L. Corrosion of CANDU Outlet Feeder Pipes. In Proceedings of the International Conference on Water Chemistry in Nuclear Power Plants, Nigata, Japan, 13–16 October 1998.

- Cook, W.G.; Lister, D.H. Some Aspects of Electrochemistry and Corrosion Mechanisms Influencing Flow Assisted Corrosion in CANDU Outlet Feeder Pipes. In Proceedings of the International Conference on Water Chemistry of Nuclear Reactor Systems, San Francisco, CA, USA, 11–14 October 2004.

- Jung, K.S.; Sung, K.W. Magnetite: Electrochemical Properties and Its Role on Flow Accelerated Corrosion. In Magnetite: Structure, Properties and Applications; Nova Science Publishers: New York, NY, USA, 2010; pp. 261–298. [Google Scholar]

- Shah, V.N. Flow-Accelerated Corrosion of PWR Carbon Steel Components. In Presented at Symposium on Life Extension and Aging Management of Nuclear Power Plant Components in Korea, Taejon, Korea, July 1999.

- Accident at the Kansai Electric’s Mihama-3 NPS. JAIF Focus, Japan Atomic Industrial Forum, Inc.: Tokyo, Japan, 2004.

- Jeon, S.H.; Song, G.D.; Hur, D.H. Electrodeposition of magnetite on carbon steel in Fe(III)-triethanolamine solution and its corrosion behavior. Mater. Trans. 2015, 56, 1107–1111. [Google Scholar] [CrossRef]

- Song, G.D.; Jeon, S.H.; Hur, D.H. Effect of polyacrylic acid on the corrosion behavior of carbon steel and magnetite in alkaline aqueous solutions. Corrosion 2016, 72, 1010–1020. [Google Scholar] [CrossRef]

- Carlier, D.; Terrier, C.; Arm, C.; Anserment, J.P. Preparation and magnetic properties of Fe3O4 nanostructures grown by electrodeposition. Electrochem. Solid State Lett. 2005, 8, 43–46. [Google Scholar] [CrossRef]

- Peulon, S.; Antony, H.; Legrand, L.; Chausse, A. Thin layers of iron corrosion products electrochemically deposited on inert substrates: synthesis and behavior. Electrochim. Acta 2004, 49, 2891–2899. [Google Scholar] [CrossRef]

- Wang, S.Y.; Ho, K.C.; Kuo, S.L.; Wu, N.L. Investigation on capacitance mechanisms of Fe3O4 electrochemical capacitors. Electrochem. Soc. 2006, 153, A75–A80. [Google Scholar] [CrossRef]

- Teng, C.L.; Ryan, M.P. A morphological study of nanocrystalline magnetite electrodeposited onto polycrystalline copper substrates. Electrochem. Solid State Lett. 2007, 10, D108–D112. [Google Scholar] [CrossRef]

- Sapieszko, R.S.; Matijevic, E. Preparation of well-defined colloidal particles by thermal decomposition of metal chelates. I. Iron oxides. J. Colloid Interface Sci. 1980, 74, 405–422. [Google Scholar] [CrossRef]

- Mitra, S.; Poizot, P.; Finke, A.; Tarascon, J.M. Growth and electrochemical characterization versus lithium of Fe3O4 electrodes made by electrodeposition. Adv. Funct. Mater. 2006, 16, 2281–2287. [Google Scholar] [CrossRef]

- Taberna, P.L.; Mitra, S.; Poizit, P.; Tarascon, J.M. High rate capabilities Fe3O4-based Cu nano-architectured electrodes for lithium-ion battery applications. Net. Mater. 2006, 5, 567–573. [Google Scholar] [CrossRef] [PubMed]

- Kothari, H.M.; Kulp, E.A.; Limmer, S.J.; Poizot, P.; Bohannan, E.W.; Switzer, J.A. Electrochemical deposition and characterization of Fe3O4 films produced by the reduction of Fe(III)-triethanolamine. J. Mater. Res. 2006, 21, 293–301. [Google Scholar] [CrossRef]

- Kulp, E.A.; Kothari, H.M.; Limmer, S.J.; Yang, J.; Gudavarthy, R.V.; Bohannan, E.W.; Switzer, J.A. Electrodeposition of epitaxial magnetite films and ferrihydritenanoribbons on single-crystal gold. Chem. Mater. 2009, 21, 5022–5031. [Google Scholar] [CrossRef]

- Gudavarthy, R.V.; Gorantla, S.; Mu, G.; Kulp, E.A.; Gemming, T.; Eckert, J.; Switzer, J.A. Epitaxial electrodeposition of Fe3O4 on single-crystal Ni(111). Chem. Mater. 2011, 23, 2017–2019. [Google Scholar] [CrossRef]

- Goujon, C.; Pauporté, T.; Mansour, C.; Delaunary, S.; Bretelle, J.L. Fouling of Steam Generator Tubes in Nuclear Power Plants: Laboratory Tests to Reproduce Oxides Deposition. In Proceedings of the International Conference on Heat Exchanger Fouling and Cleaning, Budapest, Hungary, 9–14 June 2013; pp. 101–107.

- Goujon, C.; Pauporté, T.; Mansour, C.; Delaunary, S.; Bretelle, J.L. Electrochemical deposition of thick iron oxide films on nickel based superalloy substrates. Electrochim. Acta 2015, 176, 230–239. [Google Scholar] [CrossRef]

- Duan, H.; Chen, X.; Li, B.; Liang, J. Growth morphology study of cathodically electrodeposited Fe3O4thin films at elevated temperatures. Mater. Res. Bull. 2010, 45, 1696–1702. [Google Scholar] [CrossRef]

- Huang, X.J.; Yarimaga, O.; Kim, J.H.; Choi, Y.K. Substrate surface roughness-dependent 3-D complex nanoarchitectures of gold particles from directed electrodeposition. J. Mater. Chem. 2009, 19, 478–483. [Google Scholar] [CrossRef]

- Gunawardena, G.; Hills, G.; Montenegrom, I.; Scharifker, B. Electrochemical nucleation: Part I. General considerations. J. Electroanal. Chem. 1982, 138, 225–239. [Google Scholar] [CrossRef]

- Leopoldes, J.; Damman, P. From a two-dimensional chemical pattern to a three-dimensional topology through selective inversion of a liquid-liquid bilayer. Nat. Mater. 2006, 5, 957–961. [Google Scholar] [CrossRef] [PubMed]

- Squires, T.M.; Quake, S.R. Microfluidics: Fluid physics at the nanoliter scale. Rev. Mod. Phys. 2005, 77, 977–1026. [Google Scholar] [CrossRef]

- Castro-Rodriguez, R.; Oliva, A.I.; Sosa, V.; Caballero-Briones, F.; Pena, J.L. Effect of indium tin oxide substrate roughness on the morphology, structural and optical properties of CdS thin films. Appl. Surf. Sci. 2000, 161, 340–346. [Google Scholar] [CrossRef]

- Depestel, L.M.; Strubbe, K. Electrodeposition of gold from cyanide dolution on different n-GaAs crystal faces. J. Electroanal. Chem. 2004, 572, 195–201. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Ahmed, Z. The effect of current density on properties of electrodeposited nanocrystalline nockel. J. Appl. Electrochem. 2003, 33, 733–739. [Google Scholar] [CrossRef]

- Zamanzad-Ghavidel, M.R.; Raeissi, K.; Saatchi, A. Effect of substrate texture and deposition current density on properties of Ni nanocrystalline electrodeposition. Iran. J. Mater. Sci. Eng. 2012, 9, 1–14. [Google Scholar]

- Haug, K.; Jenkins, T. Effect of Hydrogen on the Three-Dimensional Epitaxial Growth of Ni(100), (110), and (111). J. Phys. Chem. B 2000, 104, 10017–10023. [Google Scholar] [CrossRef]

- Kim, T.H.; Dulal, S.M.S.I.; Park, C.H.; Chae, H.; Kim, C.K. Optimisation of process parameters for electroless plating of Co-W-P capping layers from an alkali-metal-free bath. Surf. Coat. Technol. 2008, 202, 4861–4867. [Google Scholar] [CrossRef]

- Bulasara, V.K.; Thakuria, H.; Uppaluri, R.; Purkait, M.K. Combination performance characteristics of agitated nickel hypophosphite electroless plating baths. J. Mater. Proc. Technol. 2011, 211, 1488–1499. [Google Scholar] [CrossRef]

- Inoue, M.; Hirasawa, I. The relationship between crystal morphology and XRD peak intensity on CaSO4·2H2O. J. Cryst. Growth 2013, 380, 169–175. [Google Scholar] [CrossRef]

- Tapping, R.L.; Turner, C.W.; Thompson, R.H. Steam generator deposits-a detailed analysis and some inferences. Corrosion 1991, 47, 489–495. [Google Scholar] [CrossRef]

| Composition | wt.% | Composition | wt.% |

|---|---|---|---|

| C | 0.19 | Cu | 0.1 |

| Cr | 0.4 | Mn | 1.05 |

| Ni | 0.2 | S | 0.005 |

| Mo | 0.1 | P | 0.012 |

| Si | 0.23 | Fe | Bal. |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, S.-H.; Choi, W.-I.; Song, G.-D.; Son, Y.-H.; Hur, D.H. Influence of Surface Roughness and Agitation on the Morphology of Magnetite Films Electrodeposited on Carbon Steel Substrates. Coatings 2016, 6, 62. https://doi.org/10.3390/coatings6040062

Jeon S-H, Choi W-I, Song G-D, Son Y-H, Hur DH. Influence of Surface Roughness and Agitation on the Morphology of Magnetite Films Electrodeposited on Carbon Steel Substrates. Coatings. 2016; 6(4):62. https://doi.org/10.3390/coatings6040062

Chicago/Turabian StyleJeon, Soon-Hyeok, Won-Ik Choi, Geun-Dong Song, Yeong-Ho Son, and Do Haeng Hur. 2016. "Influence of Surface Roughness and Agitation on the Morphology of Magnetite Films Electrodeposited on Carbon Steel Substrates" Coatings 6, no. 4: 62. https://doi.org/10.3390/coatings6040062