Machining Performance of Sputter-Deposited (Al0.34Cr0.22Nb0.11Si0.11Ti0.22)50N50 High-Entropy Nitride Coatings

Abstract

:1. Introduction

2. Materials and Methods

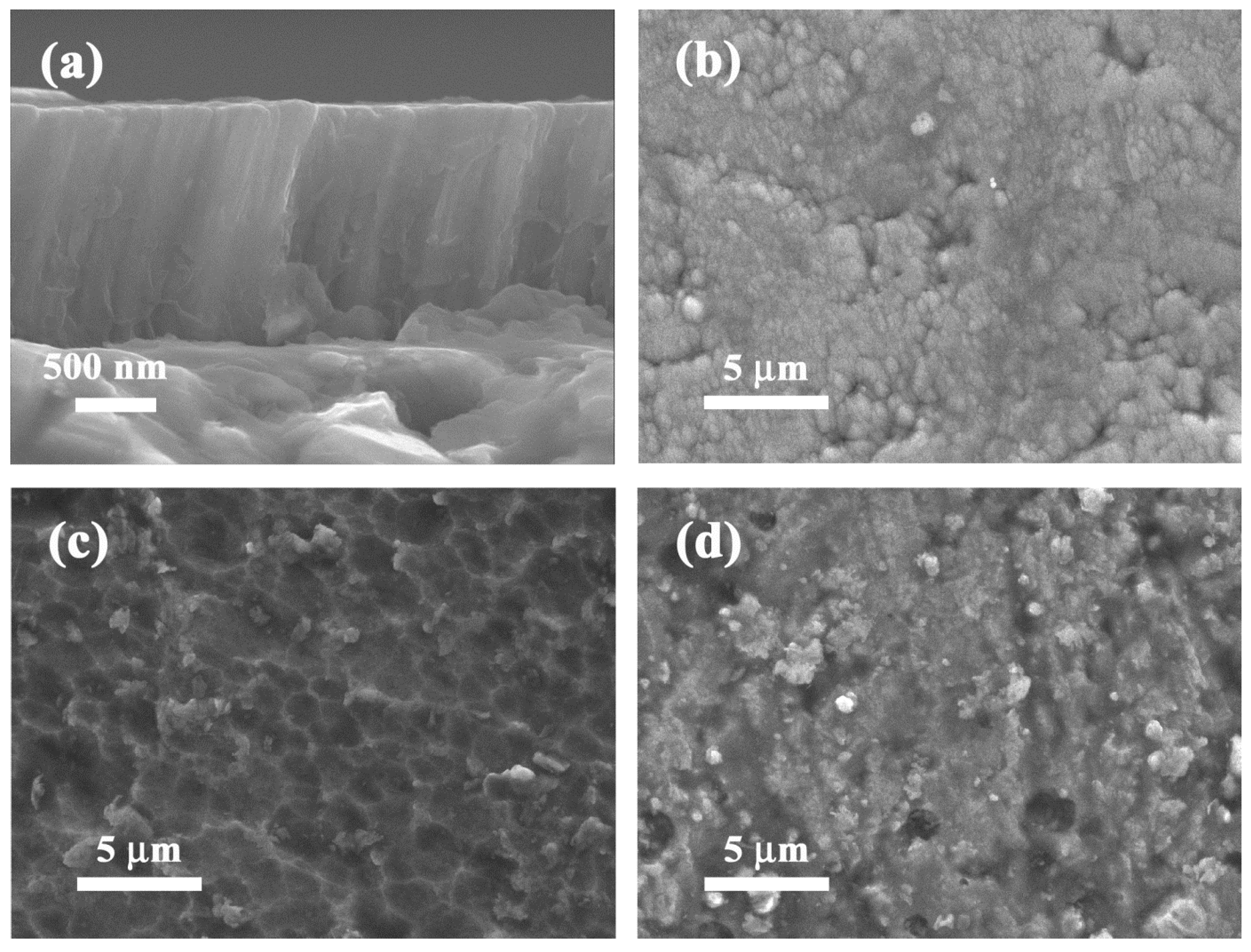

2.1. Target and Film Preparation

2.2. Film Characterization

2.3. Adhesion Test

2.4. Milling Test

3. Results and Discussion

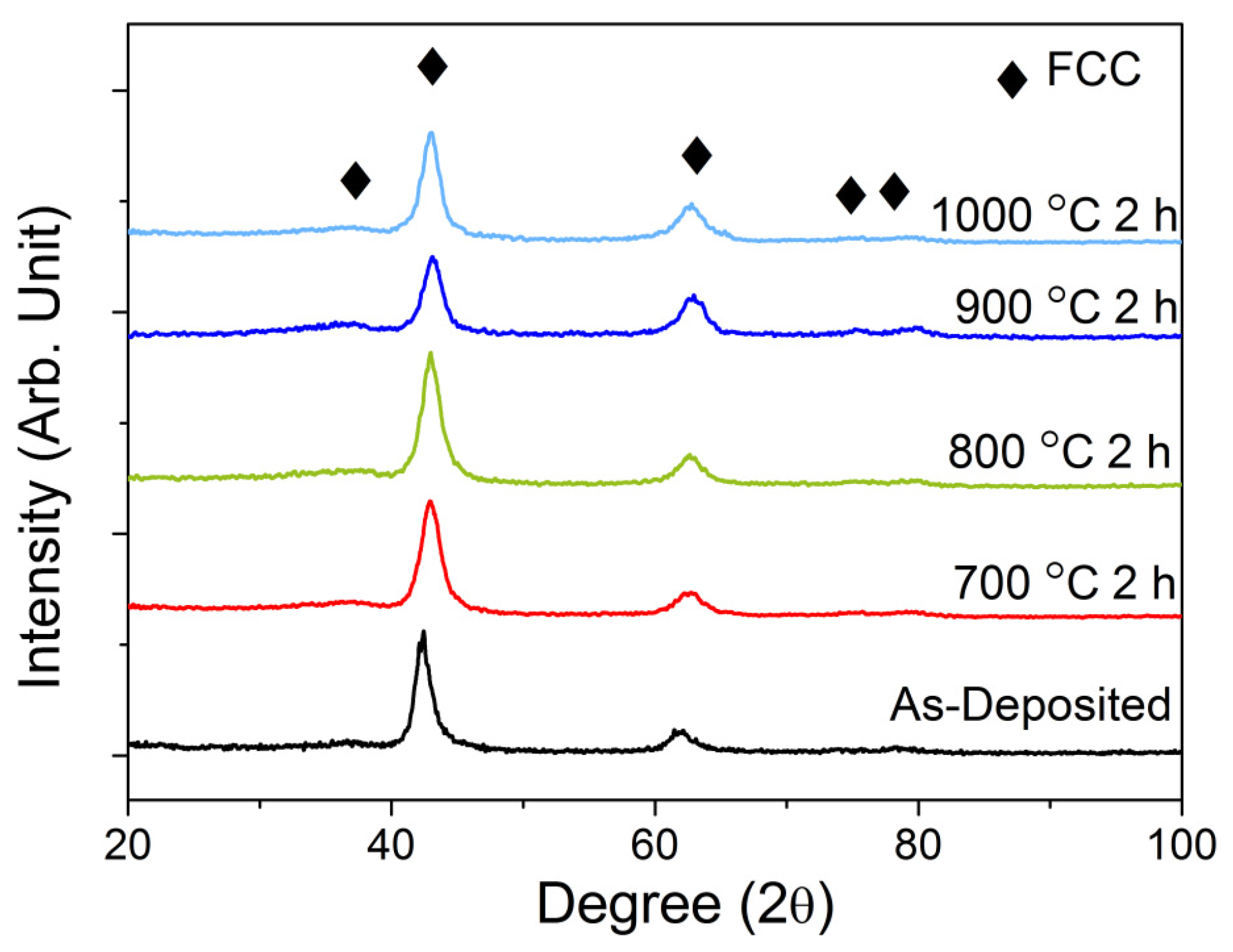

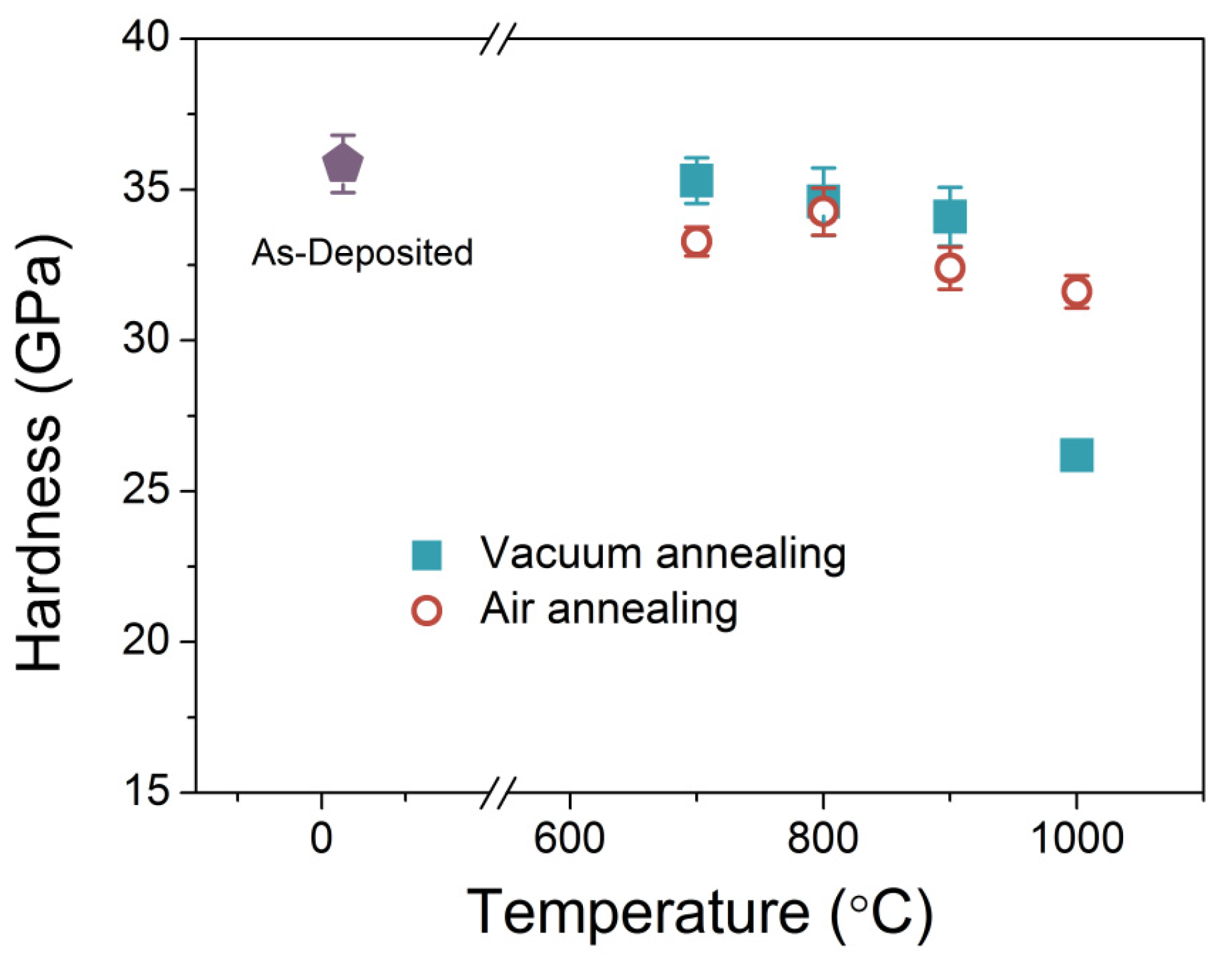

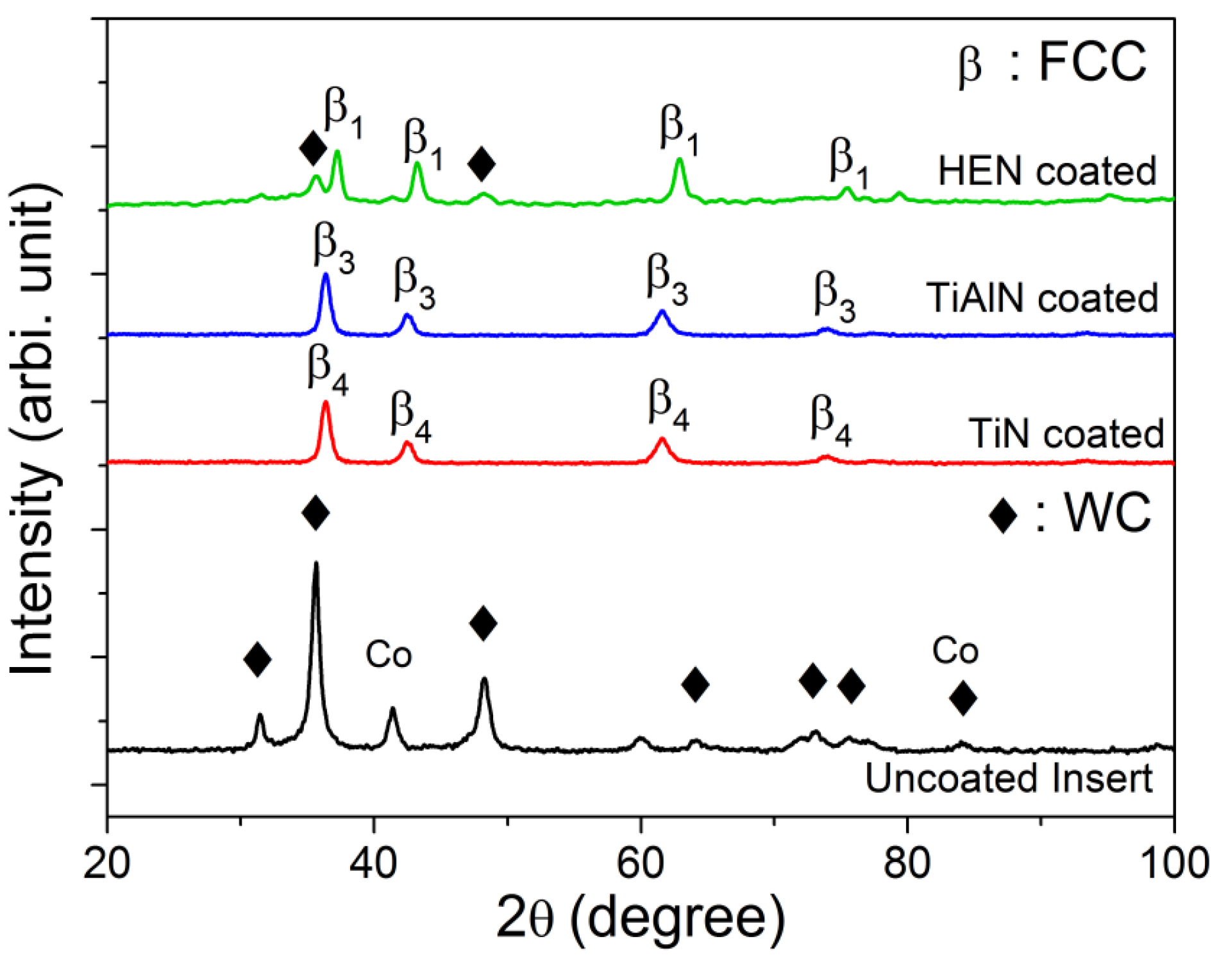

3.1. Thermal Stability and Film Hardness

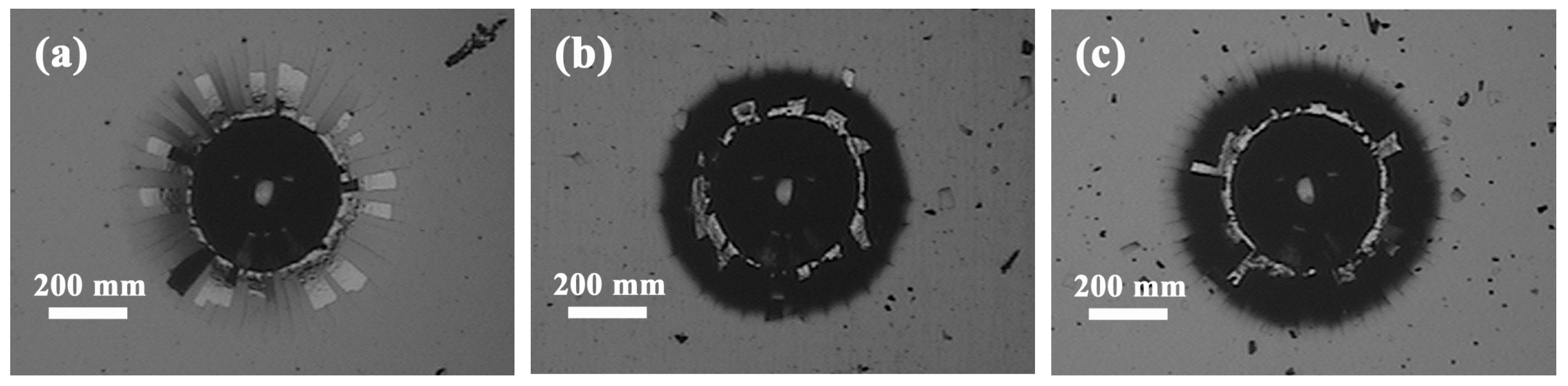

3.2. Adhesion Test

| Interlayer | LC3 | LC4 | Rockwell C (150 kg) |

|---|---|---|---|

| Cr | 2 ± 0.2 N | 14 ± 4 N | HF5 |

| Al0.34Cr0.22Nb0.11Si0.11Ti0.22 | 47 ± 4 N | 55 ± 2.9 N | HF4 |

| Ti | >100 N | >100 N | HF4 |

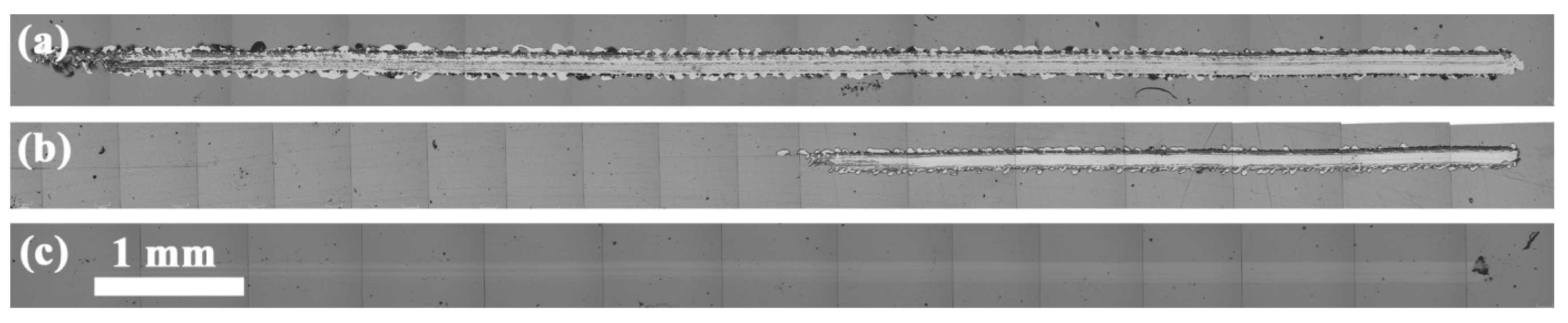

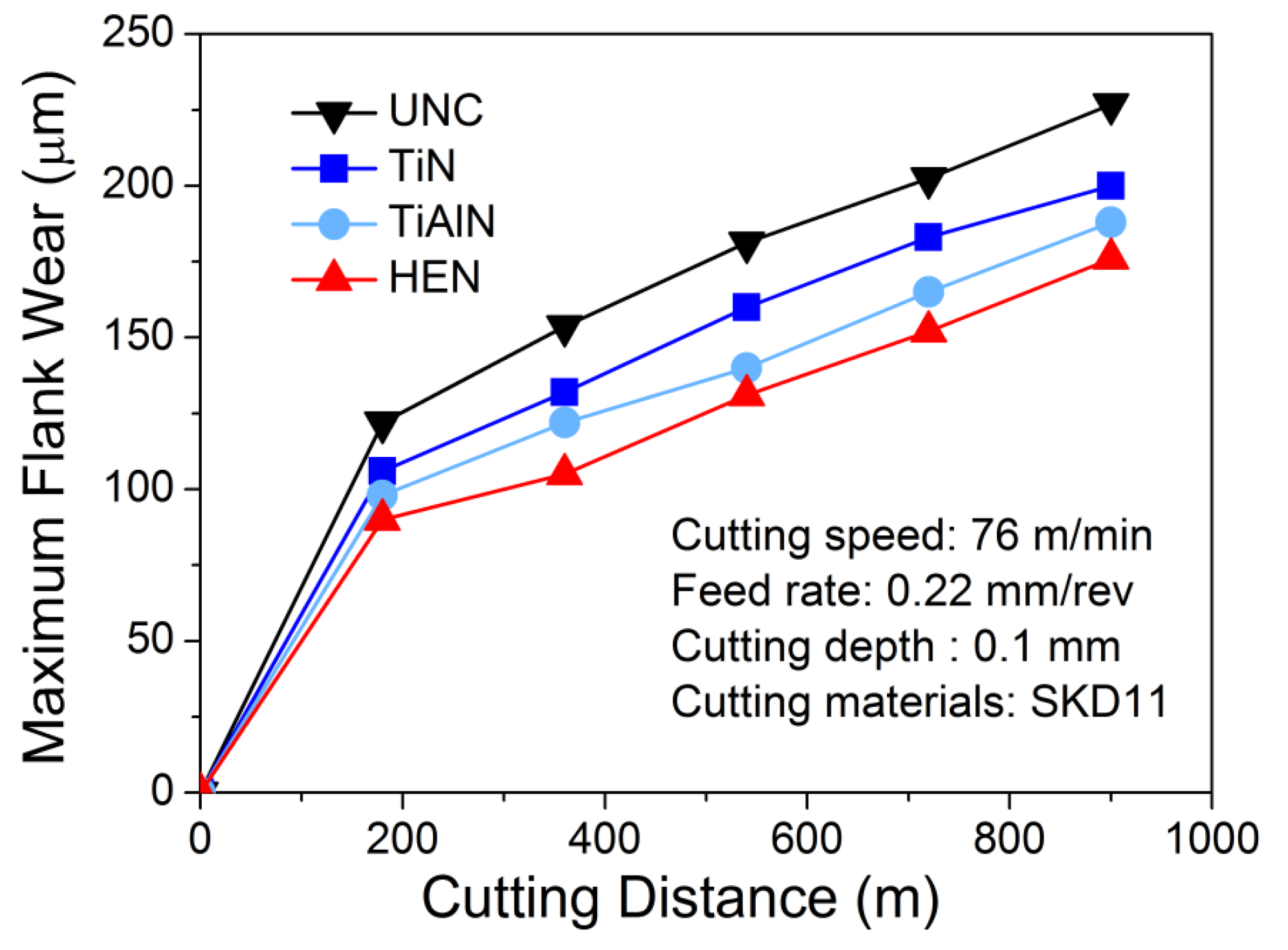

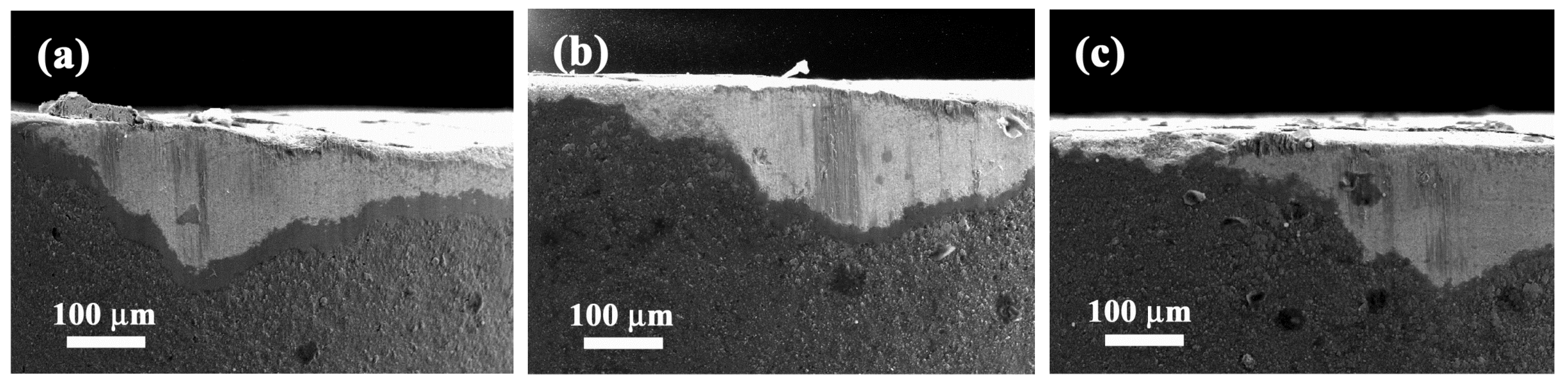

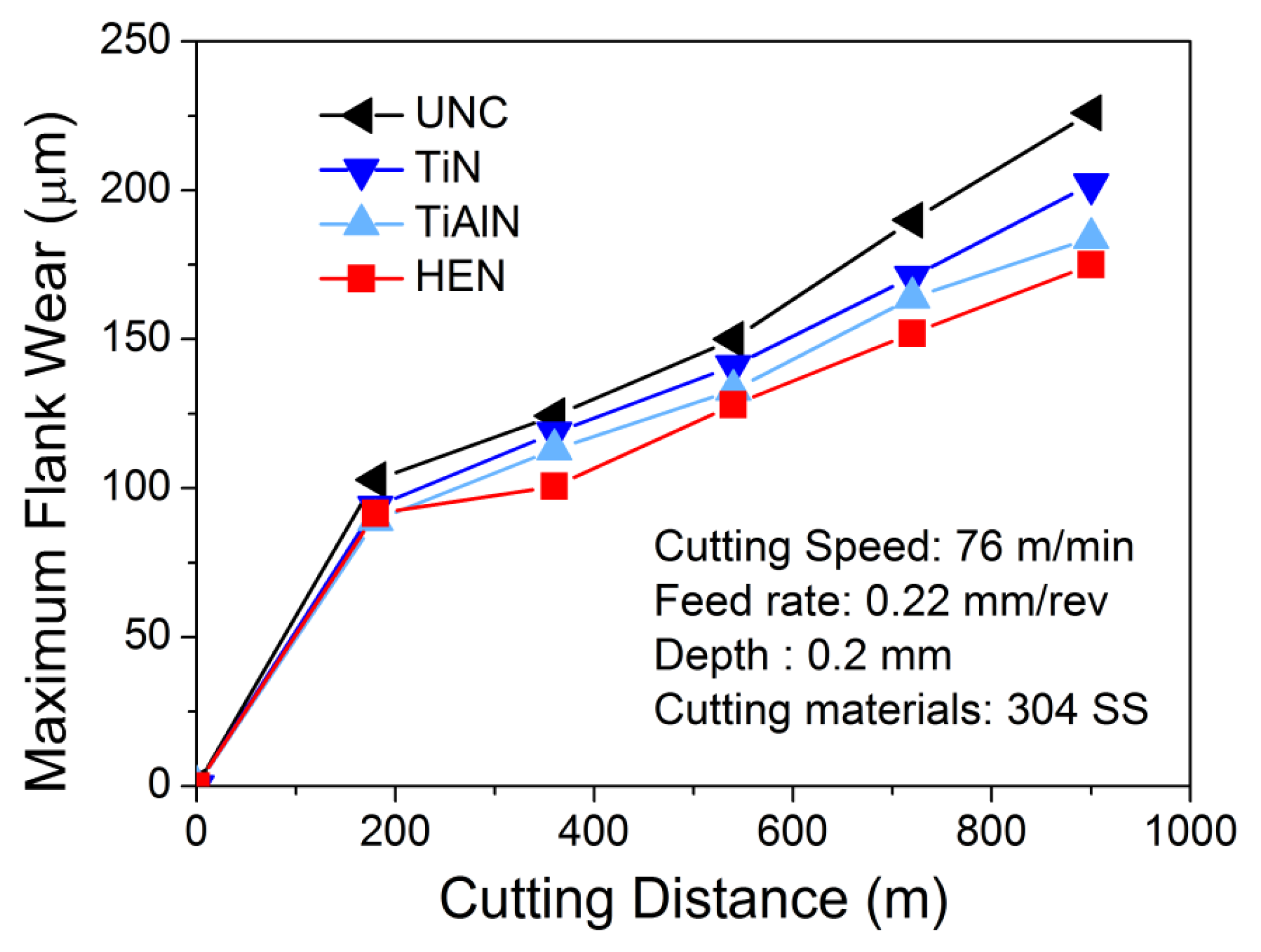

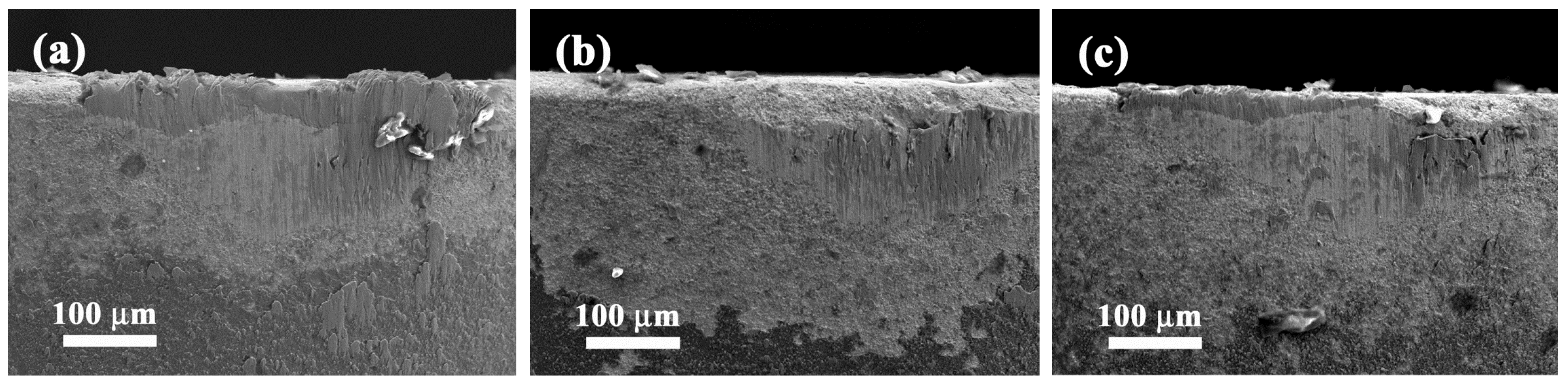

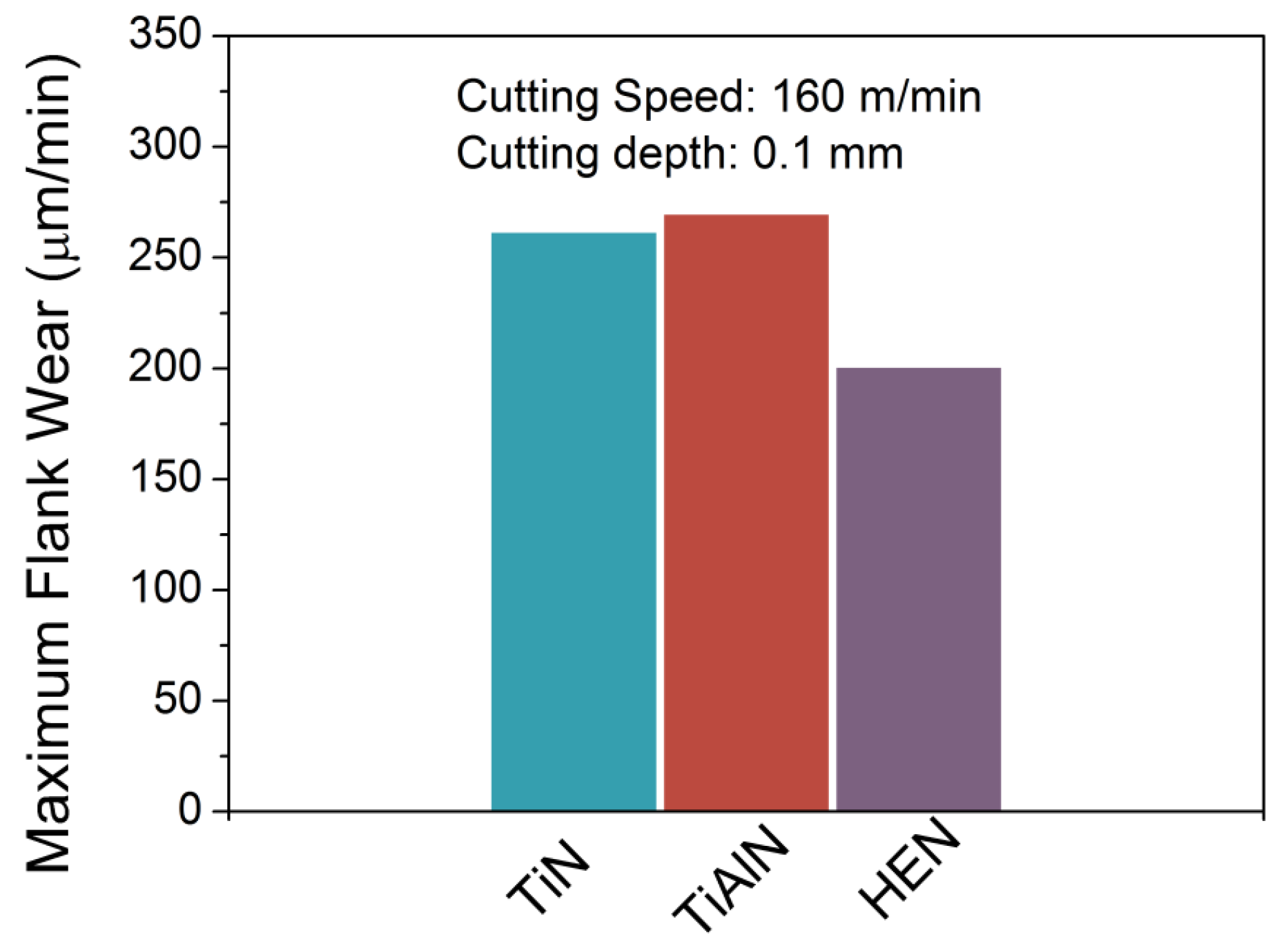

3.3. Milling Test

4. Conclusion

Acknowledgement

Author Contributions

Conflicts of Interest

References

- Derflinger, V.; Brandle, H.; Zimmermann, H. New hard/lubricant coating for dry machining. Surf. Coat. Technol. 1999, 113, 286–292. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.J.G. Industrial applications of superhard nanocomposite coatings. Surf. Coat. Technol. 2008, 202, 5063–5073. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Kathrein, M.; Michotte, C.; Penoy, M.; Polcik, P.; Mitterer, C. Multifunctional multi-component PVD coatings for cutting tools. Surf. Coat. Technol. 2005, 200, 1867–1871. [Google Scholar] [CrossRef]

- Knotek, O.; Löffler, F.; Krämer, G. Applications to cutting tools. In Handbook of Hard Coatings; Bunshah, R.F., Ed.; Noyes Publications: New York, NY, USA, 2001; pp. 370–410. [Google Scholar]

- Knotek, O.; Lugscheider, E.; Loffler, F.; Kramer, G.; Zimmermann, H. Abrasive wear-resistance and cutting performance of complex PVD coatings. Surf. Coat. Technol. 1994, 68, 489–493. [Google Scholar] [CrossRef]

- Wittmer, M.; Noser, J.; Melchior, H. Oxidation-kinetics of tin thin-films. J. Appl. Phys. 1981, 52, 6659–6664. [Google Scholar] [CrossRef]

- Zhou, M.; Makino, Y.; Nose, M.; Nogi, K. Phase transition and properties of Ti-Al-N thin films prepared by RF-plasma assisted magnetron sputtering. Thin Solid Films 1999, 339, 203–208. [Google Scholar] [CrossRef]

- Vancoille, E.; Celis, J.P.; Roos, J.R. Dry sliding wear of tin based ternary PVD coatings. Wear 1993, 165, 41–49. [Google Scholar] [CrossRef]

- Polcar, T.; Novak, R.; Siroky, P. The tribological characteristics of TiCN coating at elevated temperatures. Wear 2006, 260, 40–49. [Google Scholar] [CrossRef]

- Knotek, O.; Loffler, F.; Kramer, G. Acr deposition of Ti-C and Ti-C-N using acetylene as a reactive gas. Vacuum 1992, 43, 645–648. [Google Scholar] [CrossRef]

- Erturk, E.; Knotek, O.; Burgmer, W.; Prengel, H.G.; Heuvel, H.J.; Dederichs, H.G.; Stossel, C. Ti(C,N) coatings using the arc process. Surf. Coat. Technol. 1991, 46, 39–46. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Kawate, M.; Hashimoto, A.K.; Suzuki, T. Oxidation resistance of Cr1−xAlxN and Ti1−xAlxN films. Surf. Coat. Technol. 2003, 165, 163–167. [Google Scholar] [CrossRef]

- McIntyre, D.; Greene, J.E.; Hakansson, G.; Sundgren, J.E.; Münz, W.D. Oxidation of metastable single-phase polycrystalline Ti0.5Al0.5N films: Kinetics and mechanisms. J. Appl. Phys. 1990, 67, 1542–1553. [Google Scholar] [CrossRef]

- Jindal, P.C.; Santhanam, A.T.; Schleinkofer, U.; Shuster, A.F. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Munz, W.D. Titanium aluminum nitride films—A new alternative to TiN coatings. J. Vac. Sci. Technol. A 1986, 4, 2717–2725. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Lai, C.H.; Cheng, K.H.; Lin, S.J.; Yeh, J.W. Mechanical and tribological properties of multi-element (AlCrTaTiZr)N coatings. Surf. Coat. Technol. 2008, 202, 3732–3738. [Google Scholar] [CrossRef]

- Lai, C.H.; Lin, S.J.; Yeh, J.W.; Davison, A. Effect of substrate bias on the structure and properties of multi-element (AlCrTaTiZr)N coatings. J. Phys. D Appl. Phys. 2006, 39, 4628–4633. [Google Scholar] [CrossRef]

- Lin, C.H.; Duh, J.G.; Yeh, J.W. Multi-component nitride coatings derived from Ti-Al-Cr-Si-V target in rf magnetron sputter. Surf. Coat. Technol. 2007, 201, 6304–6308. [Google Scholar] [CrossRef]

- Chang, H.W.; Huang, P.K.; Yeh, J.W.; Davison, A.; Tsau, C.H.; Yang, C.C. Influence of substrate bias, deposition temperature and post-deposition annealing on the structure and properties of multi-principal-component (AlCrMoSiTi)N coatings. Surf. Coat. Technol. 2008, 202, 3360–3366. [Google Scholar] [CrossRef]

- Tsai, M.H.; Lai, C.H.; Yeh, J.W.; Gan, J.Y. Effects of nitrogen flow ratio on the structure and properties of reactively sputtered (AlMoNbSiTaTiVZr)Nx coatings. J. Phys. D Appl. Phys. 2008, 41. [Google Scholar] [CrossRef]

- Tsai, D.C.; Chang, Z.C.; Kuo, L.Y.; Lin, T.J.; Lin, T.N.; Shieu, F.S. Solid solution coating of (TiVCrZrHf)N with unusual structural evolution. Surf. Coat. Technol. 2013, 217, 84–87. [Google Scholar] [CrossRef]

- Braic, V.; Vladescu, A.; Balaceanu, M.; Luculescu, C.R.; Braic, M. Nanostructured multi-element (TiZrNbHfTa)N and (TiZrNbHfTa)C hard coatings. Surf. Coat. Technol. 2012, 211, 117–121. [Google Scholar] [CrossRef]

- Huang, P.K.; Yeh, J.W. Inhibition of grain coarsening up to 1000 °C in (AlCrNbSiTiV)N superhard coatings. Scr. Mater. 2010, 62, 105–108. [Google Scholar] [CrossRef]

- Huang, P.K.; Yeh, J.W. Effects of substrate bias on structure and mechanical properties of (AlCrNbSiTiV)N coatings. J. Phys. D Appl. Phys. 2009, 42. [Google Scholar] [CrossRef]

- Shen, W.J.; Tsai, M.H.; Chang, Y.S.; Yeh, J.W. Effects of substrate bias on the structure and mechanical properties of (Al1.5CrNb0.5Si0.5Ti)Nx coatings. Thin Solid Films 2012, 520, 6183–6188. [Google Scholar] [CrossRef]

- Shen, W.J.; Tsai, M.H.; Tsai, K.Y.; Juan, C.C.; Tsai, C.W.; Yeh, J.W.; Chang, Y.S. Superior oxidation resistance of (Al0.34Cr0.22Nb0.11Si0.11Ti0.22)50N50 high-entropy nitride. J. Electrochem. Soc. 2013, 160, C531–C535. [Google Scholar] [CrossRef]

- Chang, S.Y.; Chen, M.K.; Chen, D.S. Multiprincipal-element AlCrTaTiZr-nitride nanocomposite film of extremely high thermal stability as diffusion barrier for Cu metallization. J. Electrochem. Soc. 2009, 156, G37–G42. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determing hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Cohen, M.L. Calculation of bulk moduli of diamond and zincblende solid. Phys. Rev. B 1985, 32, 7988–7991. [Google Scholar] [CrossRef]

- Stallard, J.; Poulat, S.; Teer, D.G. The study of the adhesion of a TiN coating on steel and titanium alloy substrates using a multi-mode scratch tester. Tribol. Int. 2006, 39, 159–166. [Google Scholar] [CrossRef]

- Lai, S.W. A study on nitride films of AlBCrSiTi high-entropy alloy by reactive dc sputtering. Master Thesis, National Tsing Hua University, Hsinchu, Taiwan, 2006. [Google Scholar]

- Chang, S.Y.; Chen, D.S. 10-nm-thick quinary (AlCrTaTiZr)N film as effective diffusion barrier for Cu interconnects at 900 °C. Appl. Phys. Lett. 2009, 94. [Google Scholar] [CrossRef]

- Sundgren, J.E. Structure and properties of tin coatings. Thin Solid Films 1985, 128, 21–44. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, W.-J.; Tsai, M.-H.; Yeh, J.-W. Machining Performance of Sputter-Deposited (Al0.34Cr0.22Nb0.11Si0.11Ti0.22)50N50 High-Entropy Nitride Coatings. Coatings 2015, 5, 312-325. https://doi.org/10.3390/coatings5030312

Shen W-J, Tsai M-H, Yeh J-W. Machining Performance of Sputter-Deposited (Al0.34Cr0.22Nb0.11Si0.11Ti0.22)50N50 High-Entropy Nitride Coatings. Coatings. 2015; 5(3):312-325. https://doi.org/10.3390/coatings5030312

Chicago/Turabian StyleShen, Wan-Jui, Ming-Hung Tsai, and Jien-Wei Yeh. 2015. "Machining Performance of Sputter-Deposited (Al0.34Cr0.22Nb0.11Si0.11Ti0.22)50N50 High-Entropy Nitride Coatings" Coatings 5, no. 3: 312-325. https://doi.org/10.3390/coatings5030312