Evaluation of the Shearing Strength of a WC-12Co Thermal Spray Coating by the Scraping Test Method

Abstract

:1. Introduction

2. Experiments

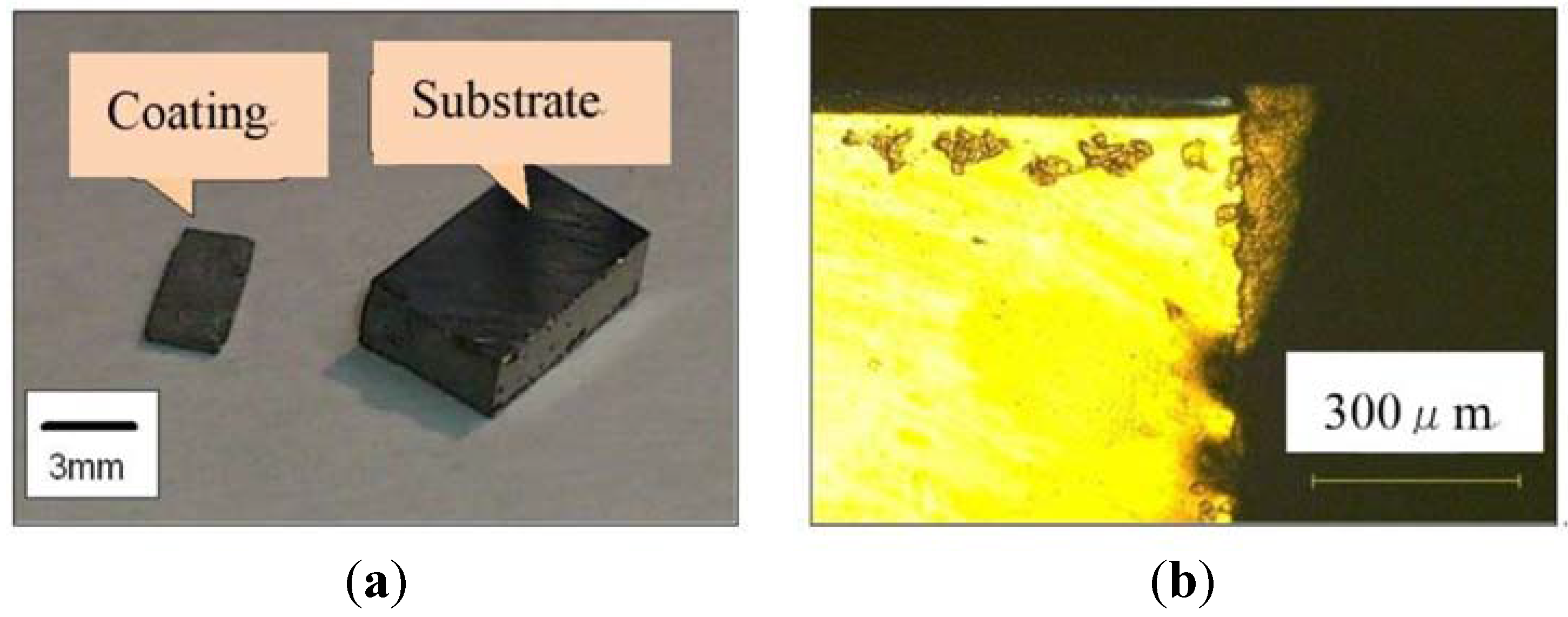

2.1. Specimen

| Items in Spraying | Materials/Conditions |

|---|---|

| Spraying Gun | TAFA/JP-5000 Gun |

| Coating material | WC-12%Co Powder (15–53 μm) |

| Blasting condition | WA#60, 0.4 MPa |

| O2 | 60 m3/h |

| Kerosene | 0.03 m3/h |

| Combustion pressure | 0.7 MPa |

| Work distance | 400 mm |

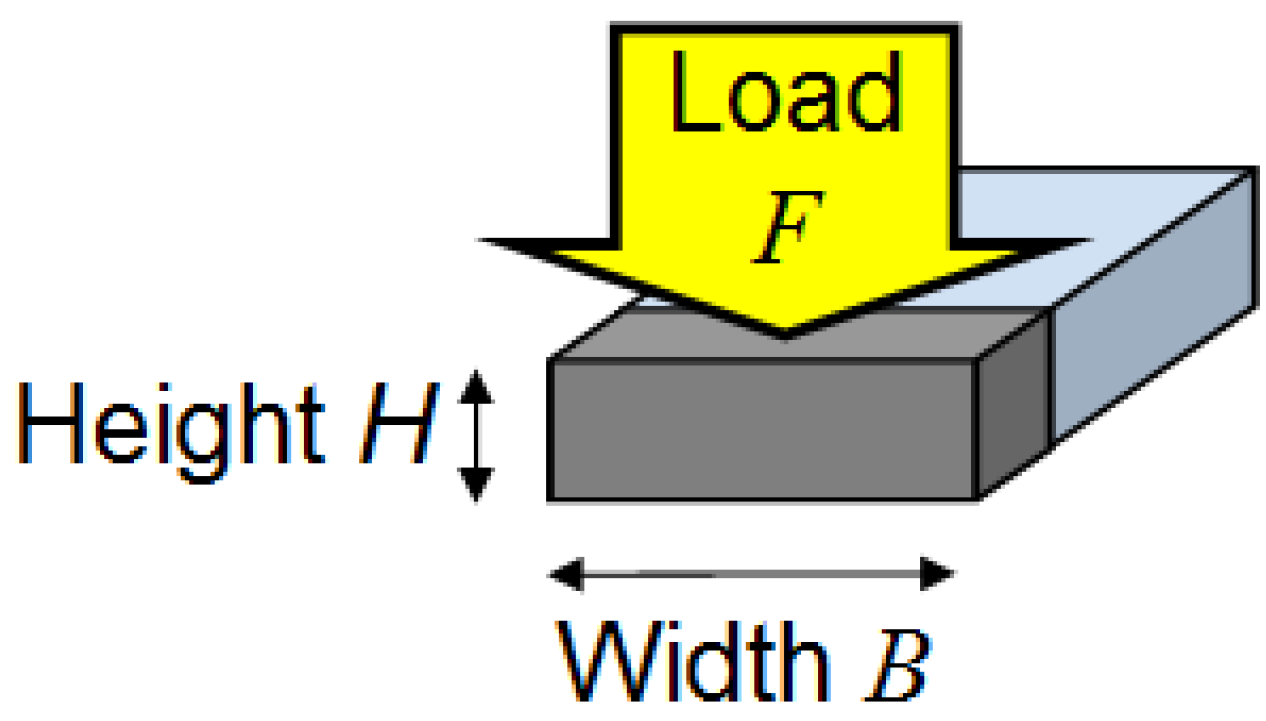

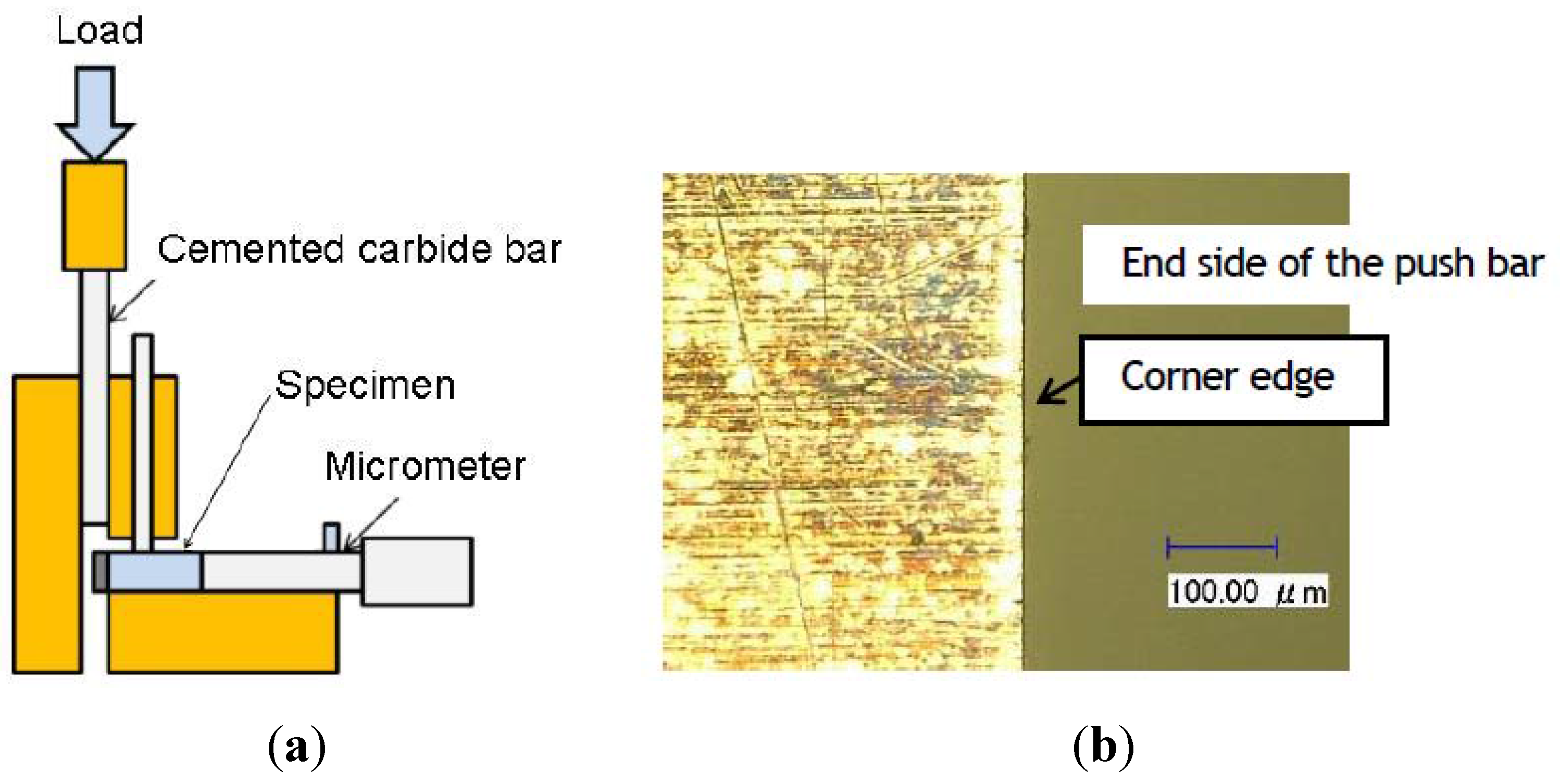

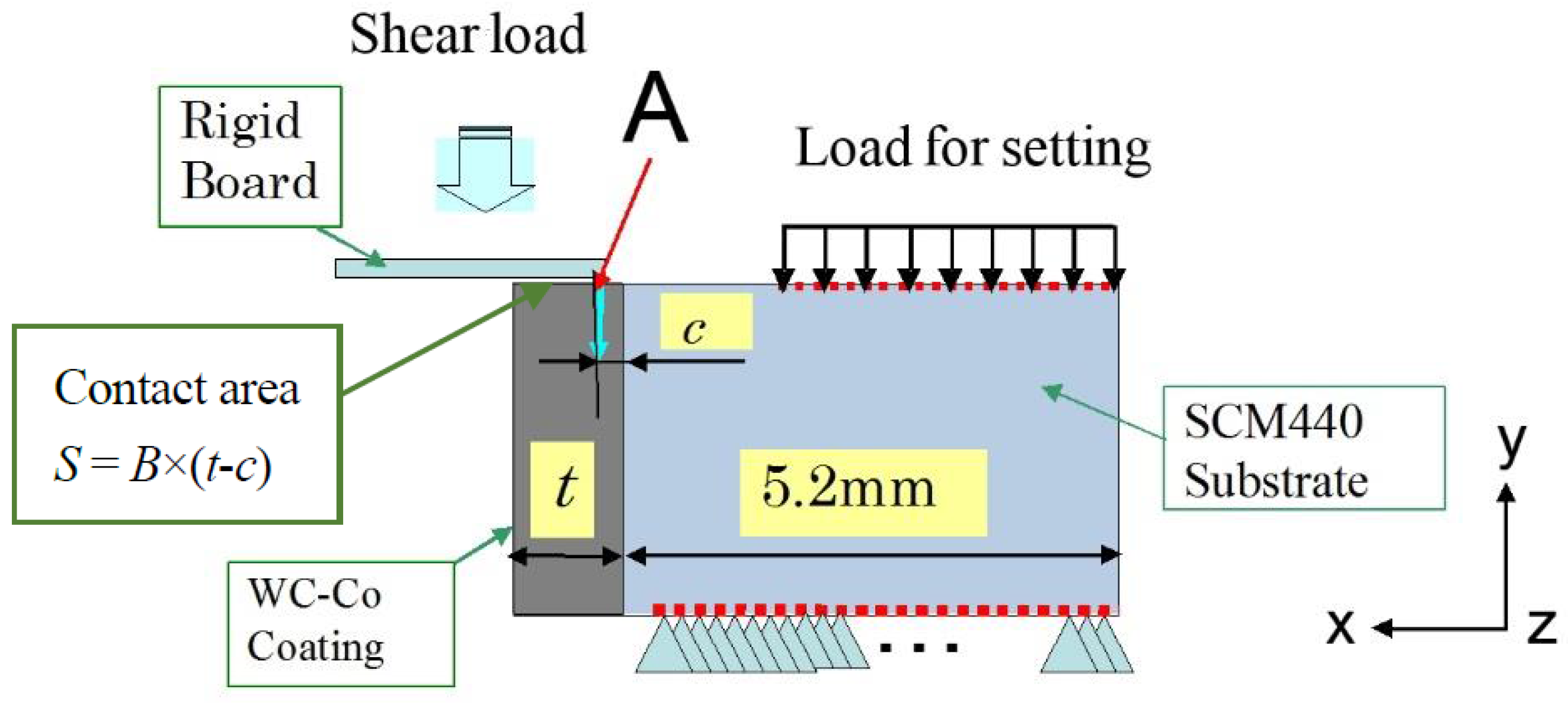

2.2. Scraping Shear Test

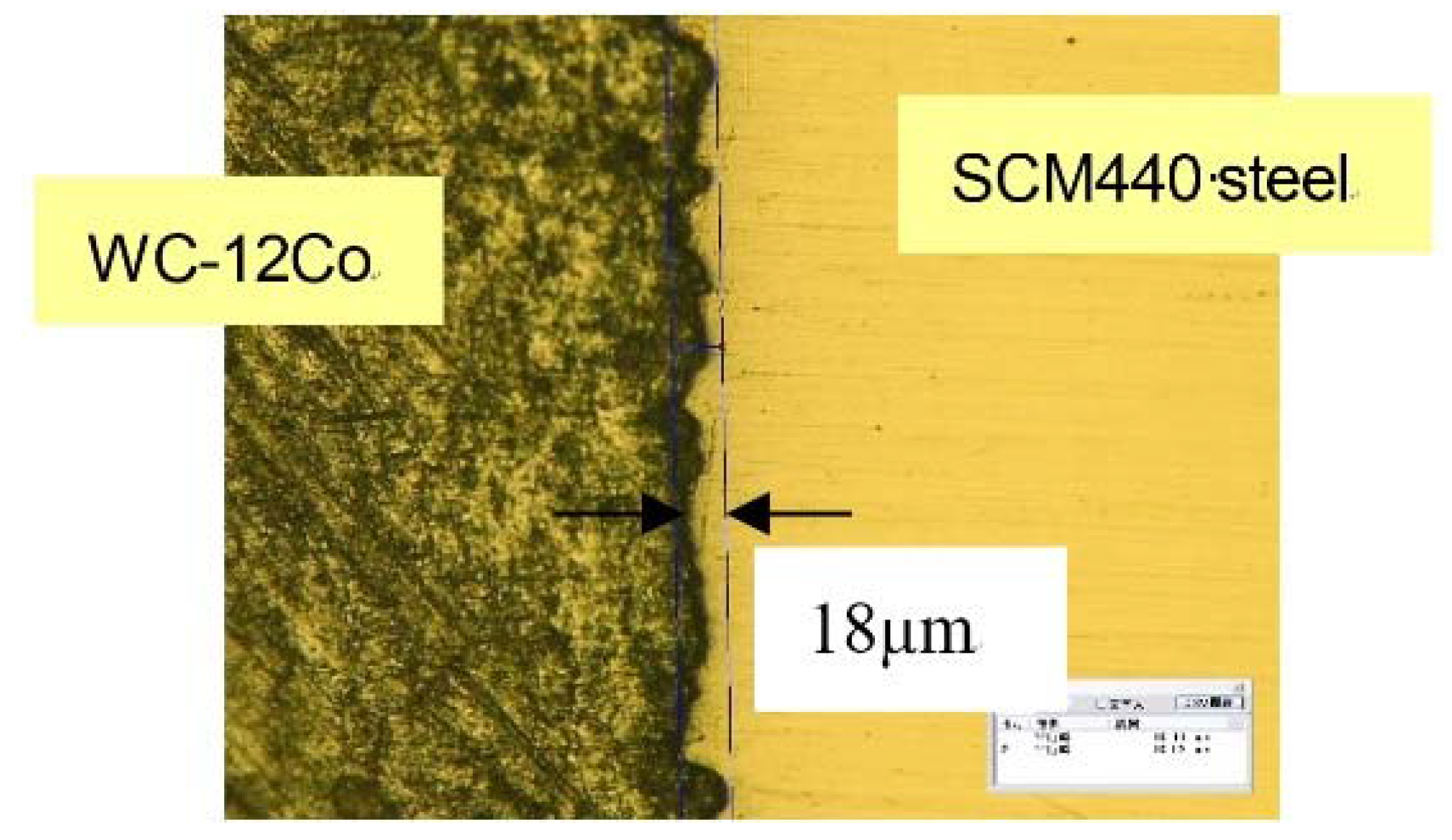

2.3. Reason and Procedure for Deciding the Shear Point to be 25 µm Offset from the Interface

3. Experimental Results and Discussion

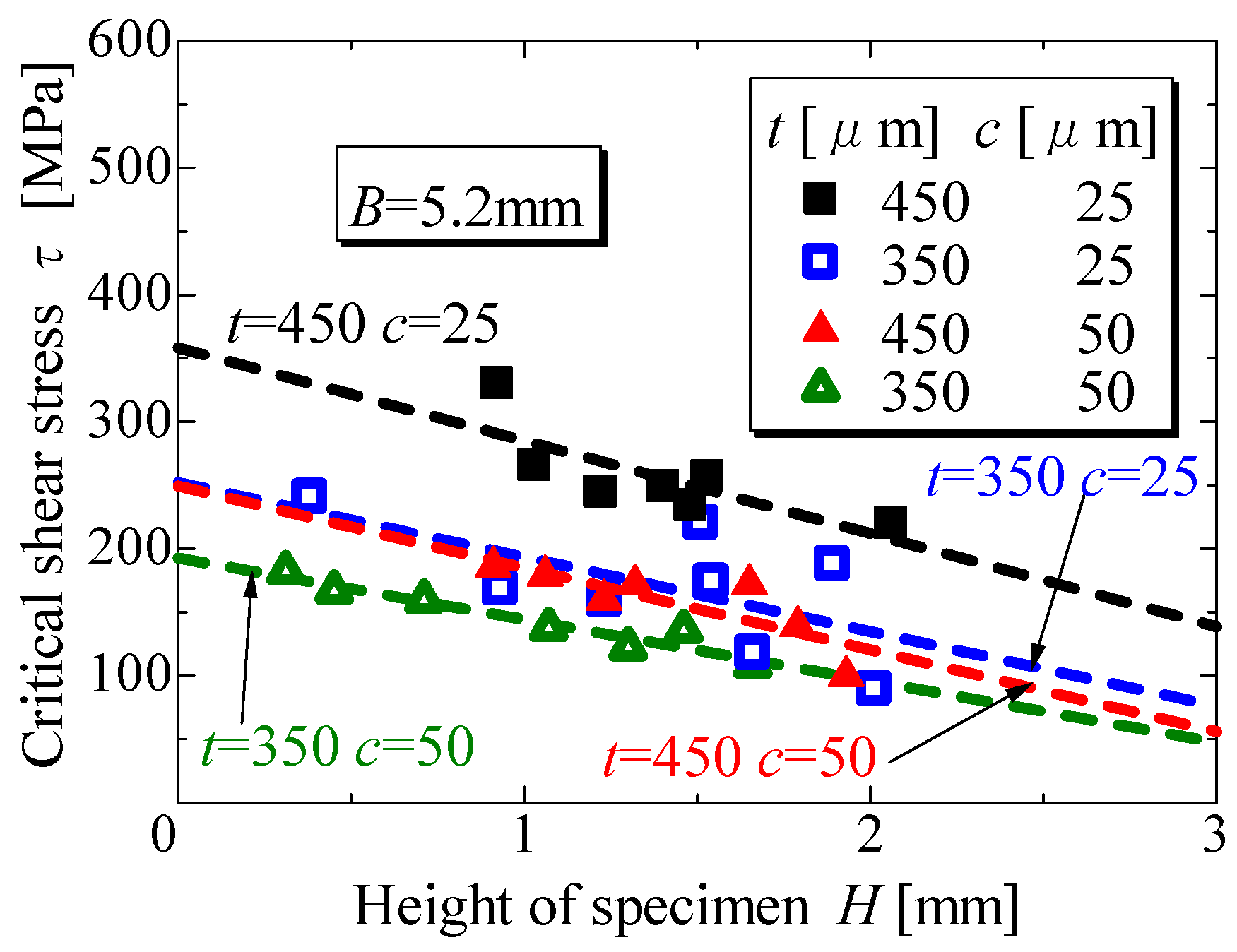

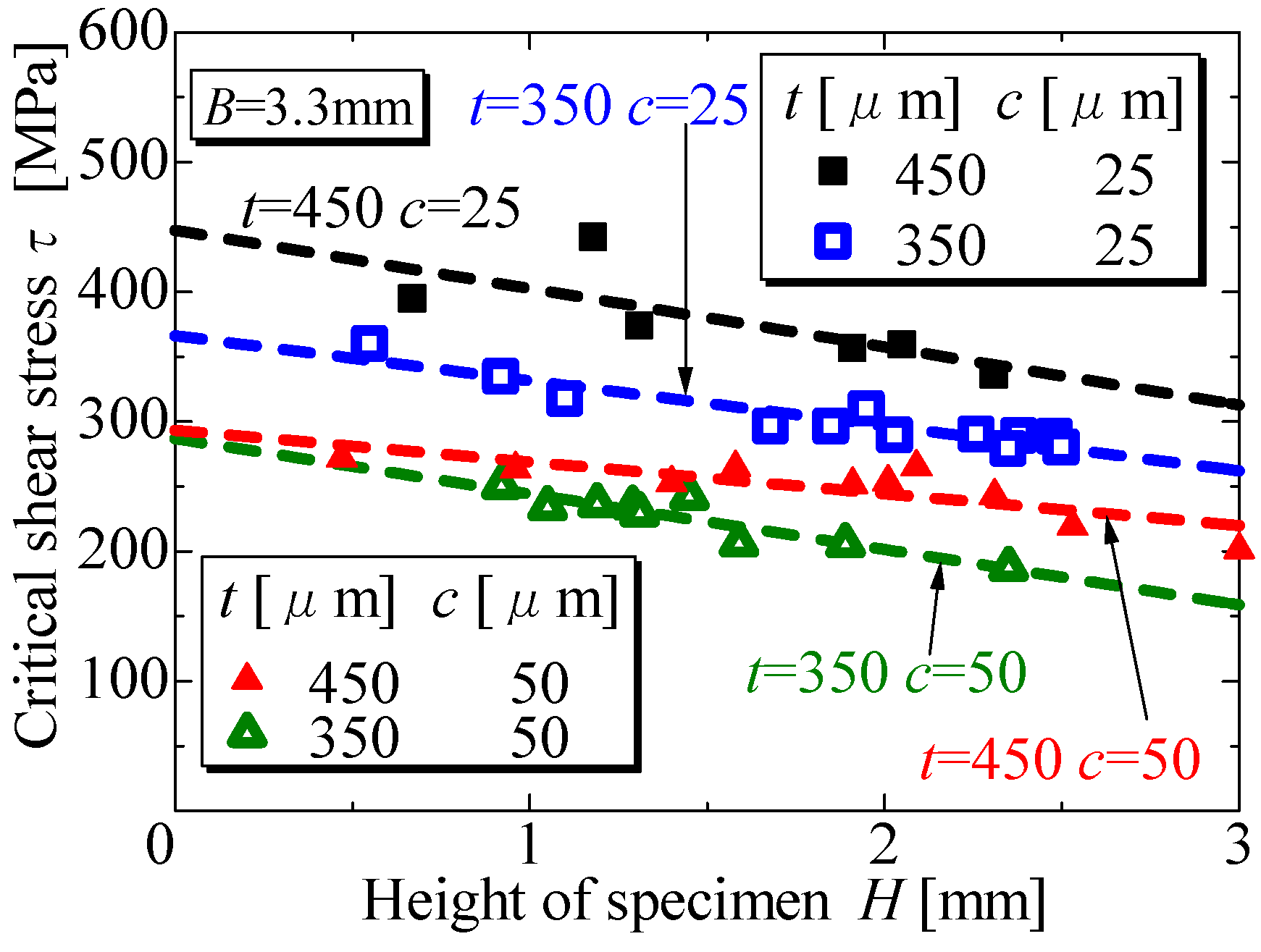

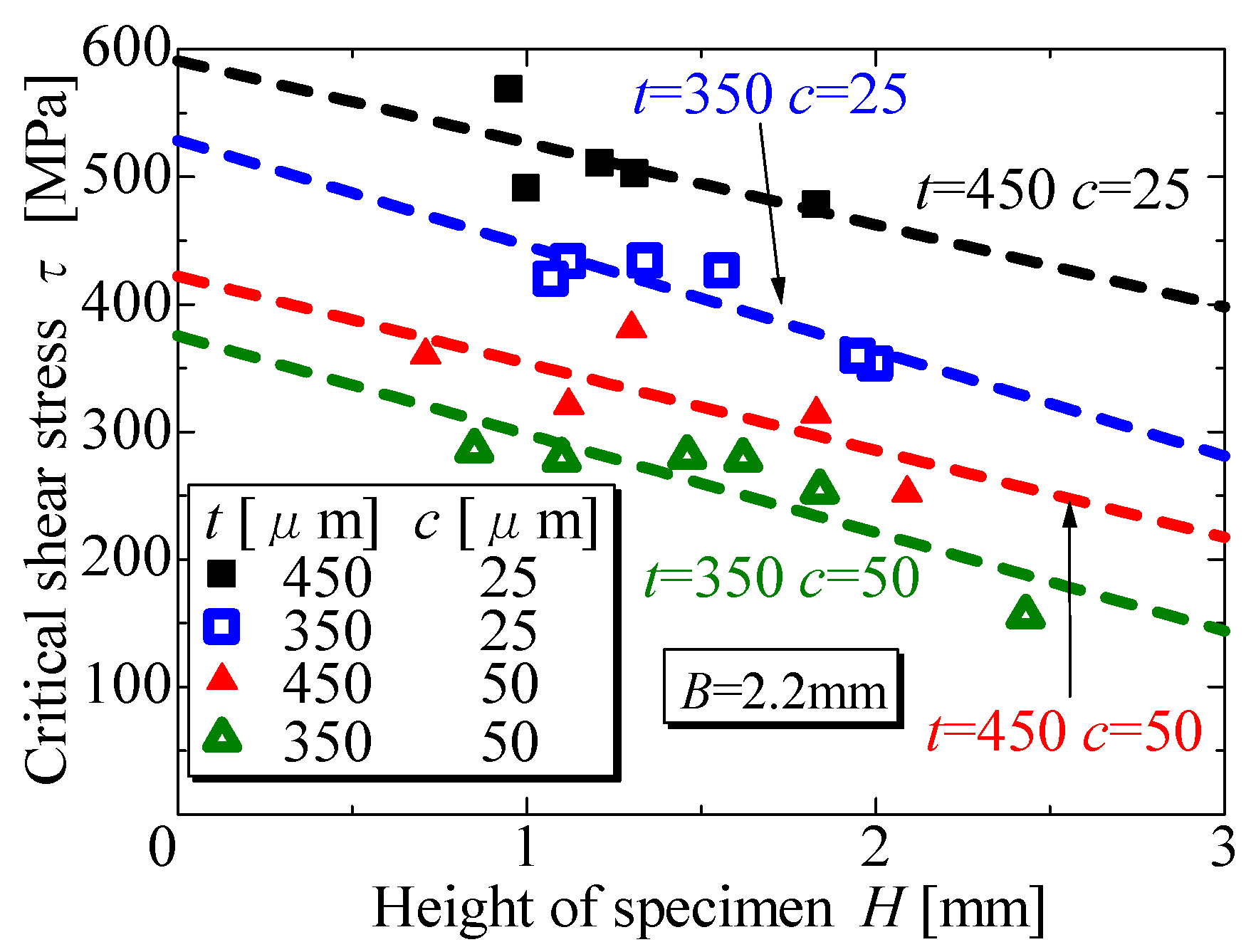

3.1. Effect of Specimen Height H on Critical Shearing Average Stress τ

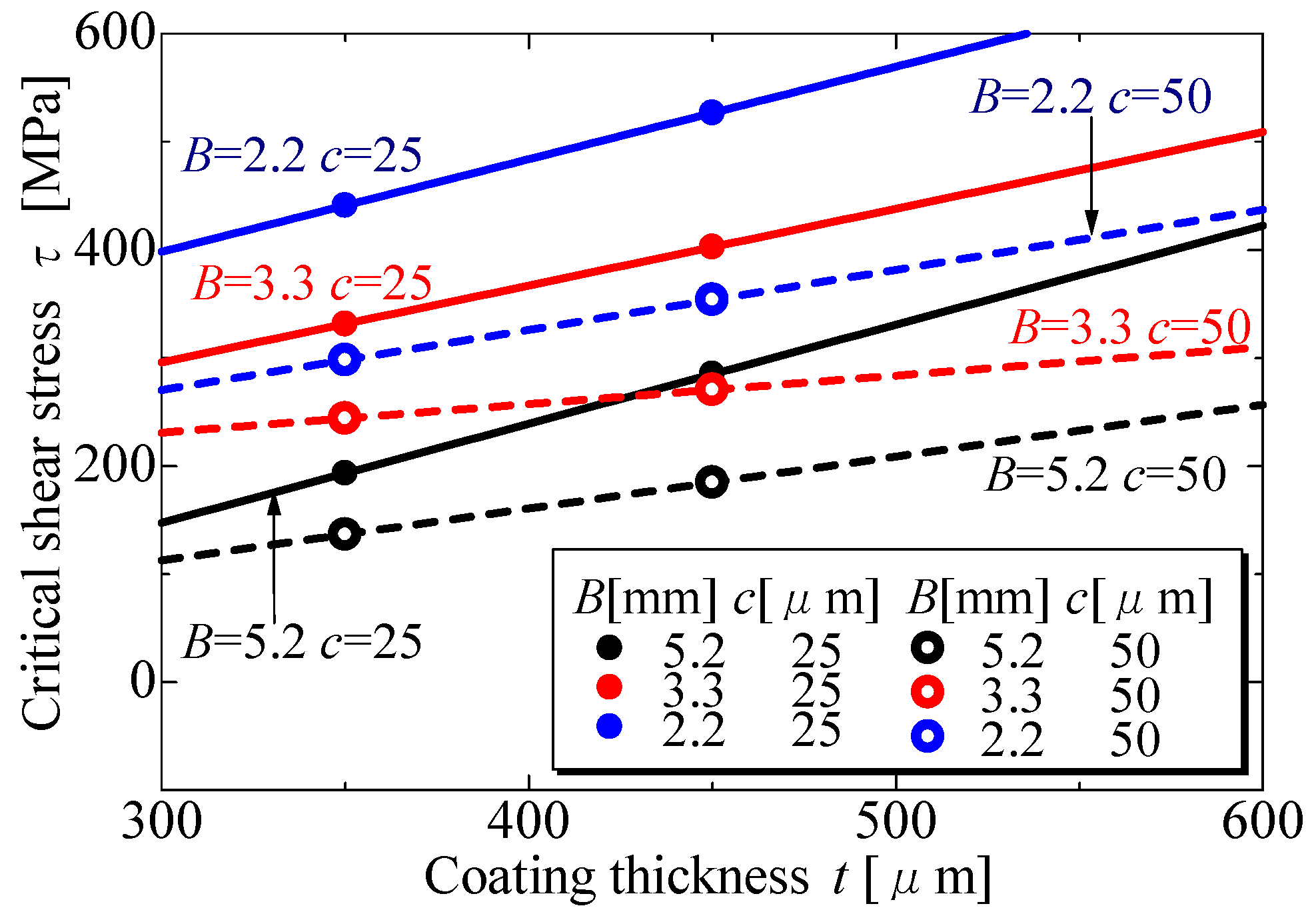

3.2. Effect of Coating Thickness t on Critical Shearing Stress τ

3.3. Effect of Shearing Point c on Critical Shearing Stress τ

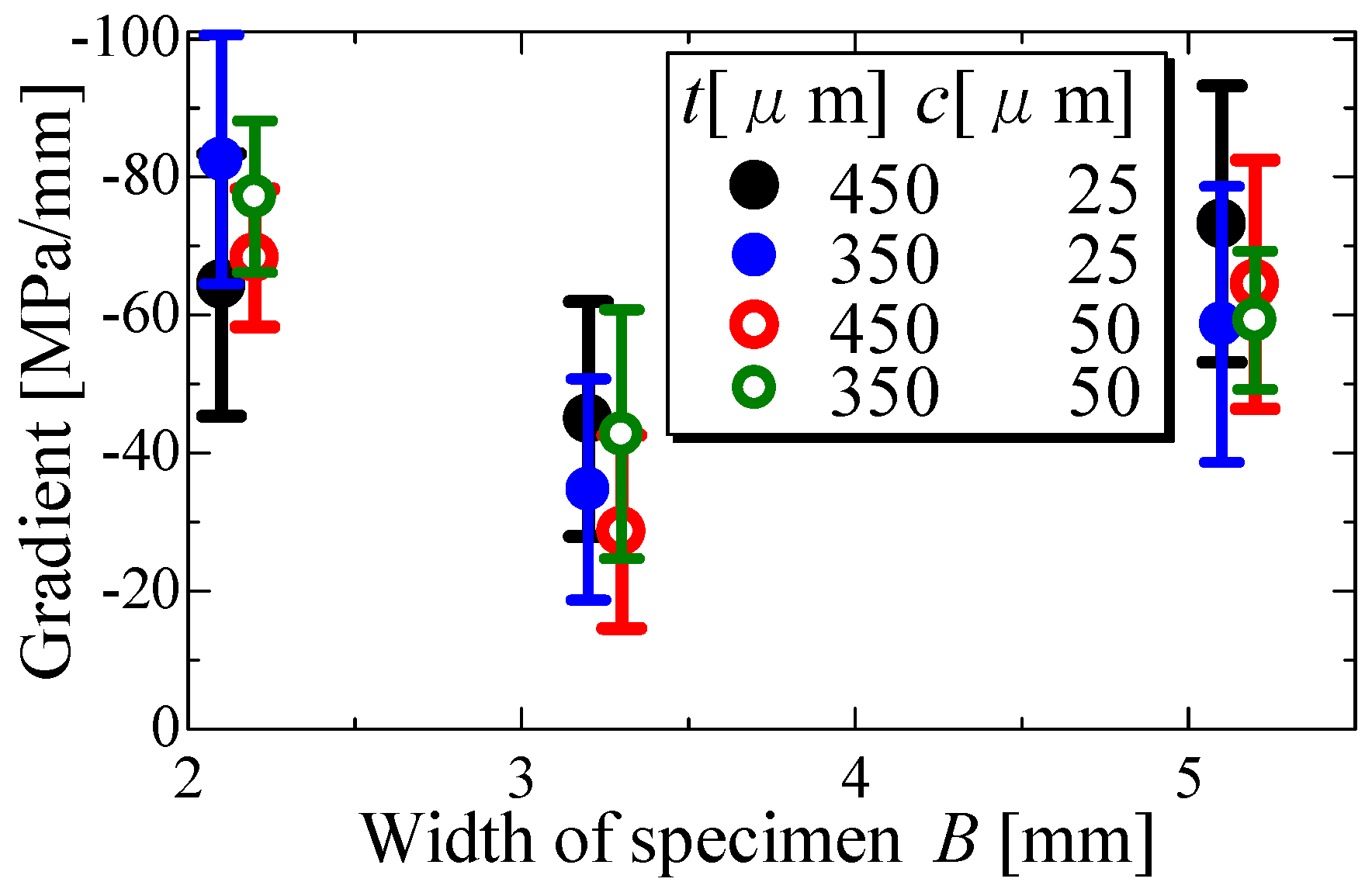

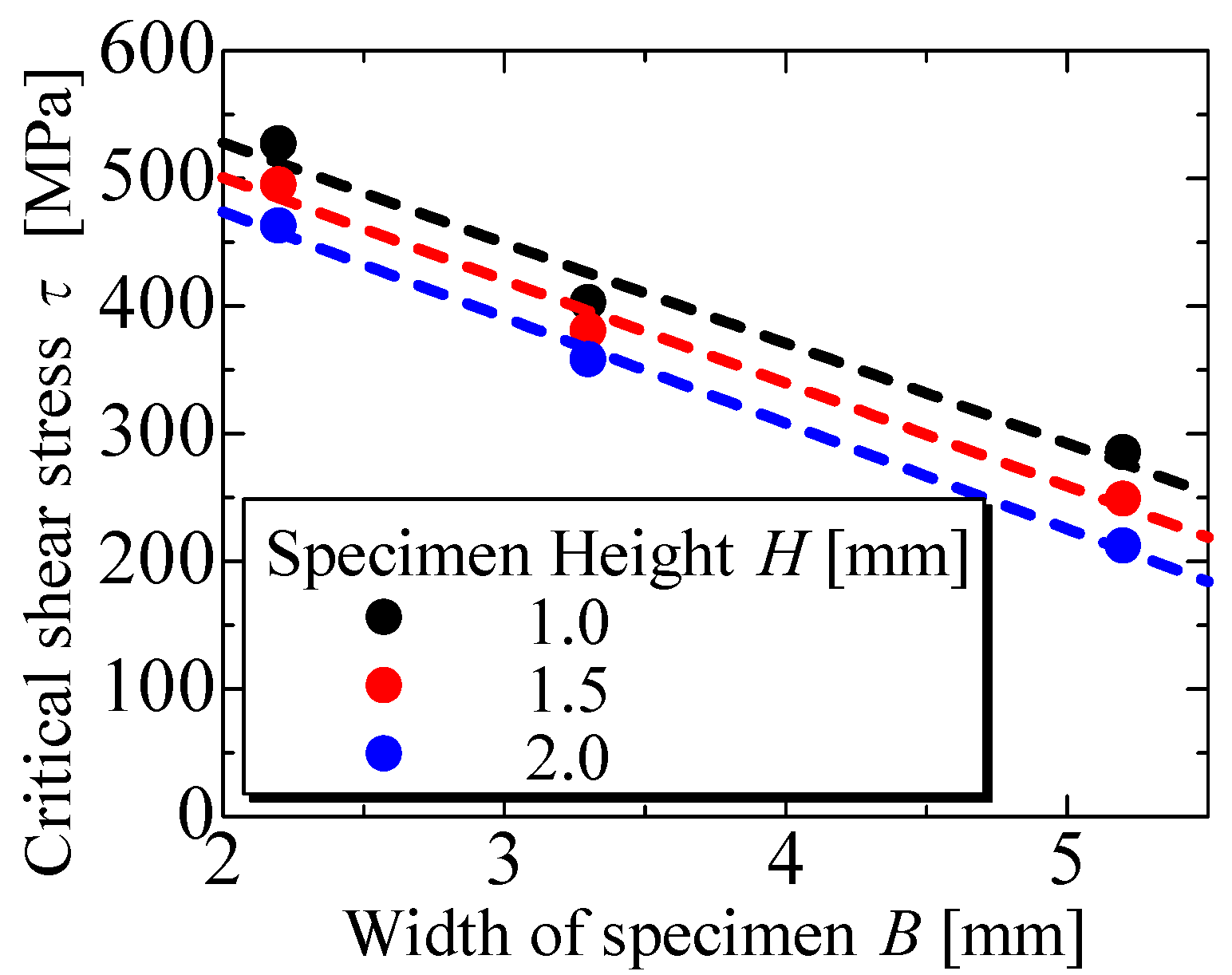

3.4. Effect of Specimen Width B on Critical Shearing Stress τ

3.5. Views of the Failed Specimens and Coatings

4. Three-Dimensional Stress Analysis by FEM

4.1. Analysis Method and Conditions

| Materials | Young’s Modulus | Poisson’s Ratio |

|---|---|---|

| SCM440 | 208GPa | 0.268 |

| WC/12Co | 154GPa | 0.230 |

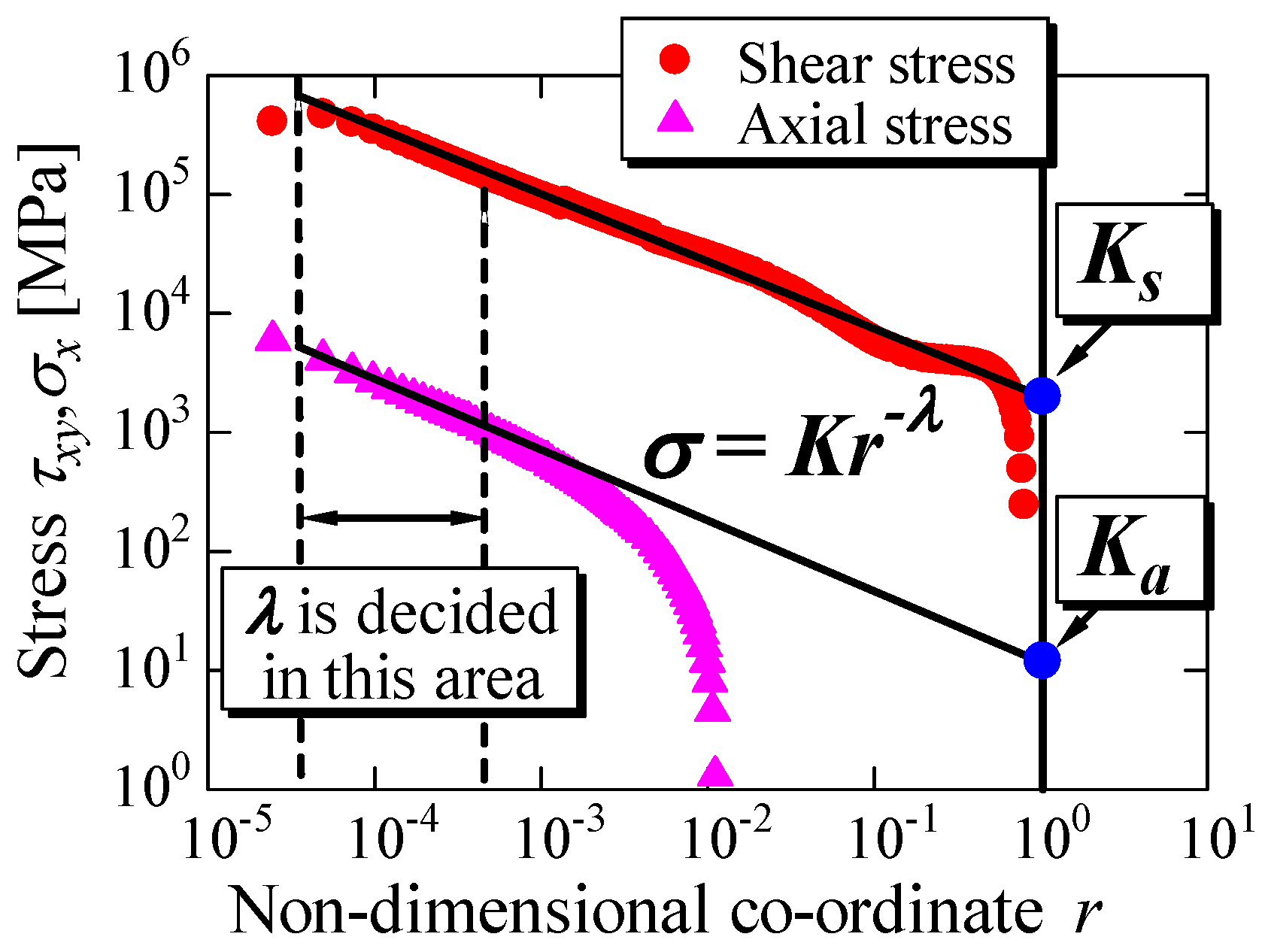

4.2. Evaluation of the Stress Singularity

5. Analytical Results and Discussions

5.1. Influences of Parameters in the Experiments on the Stress Distributions

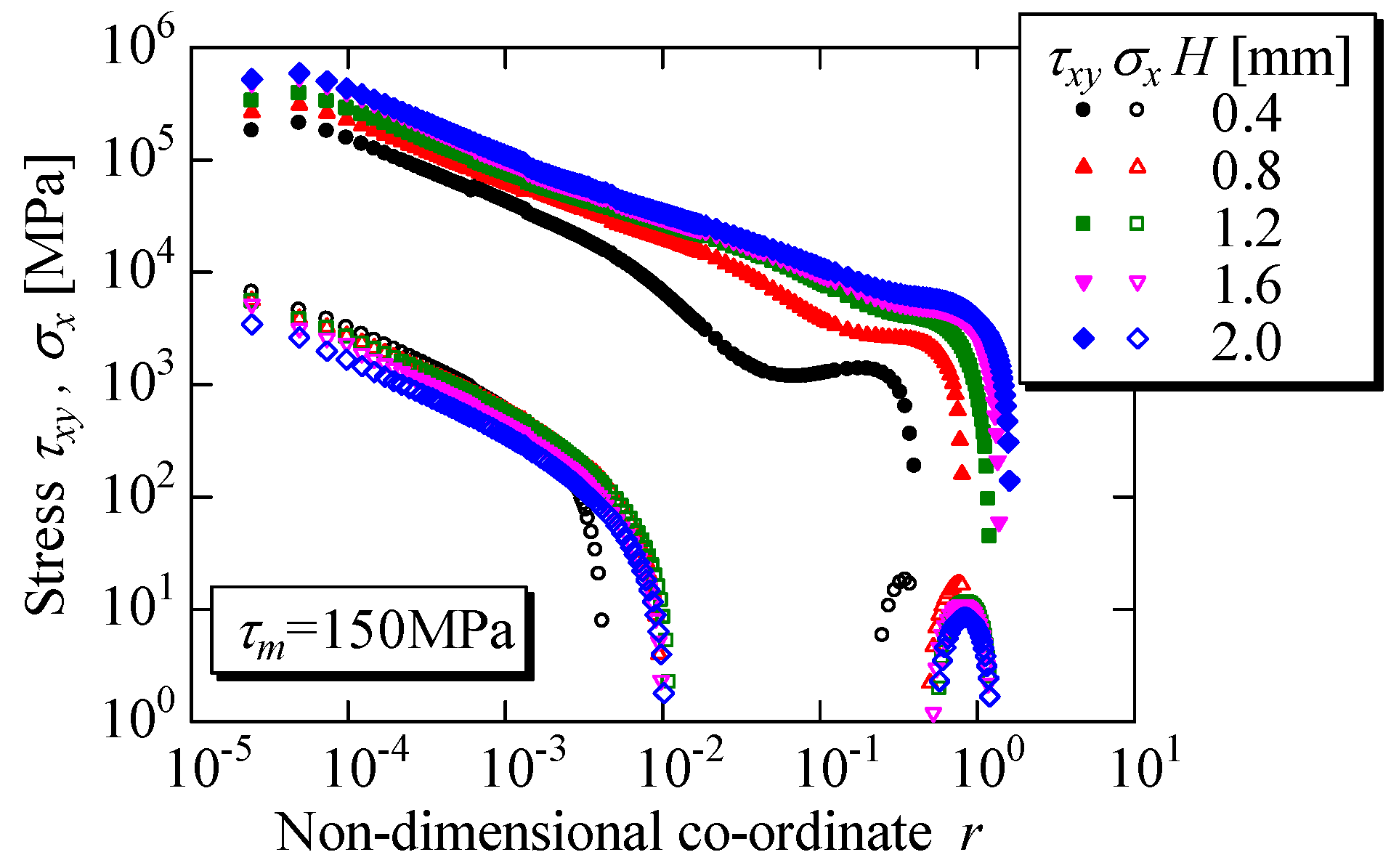

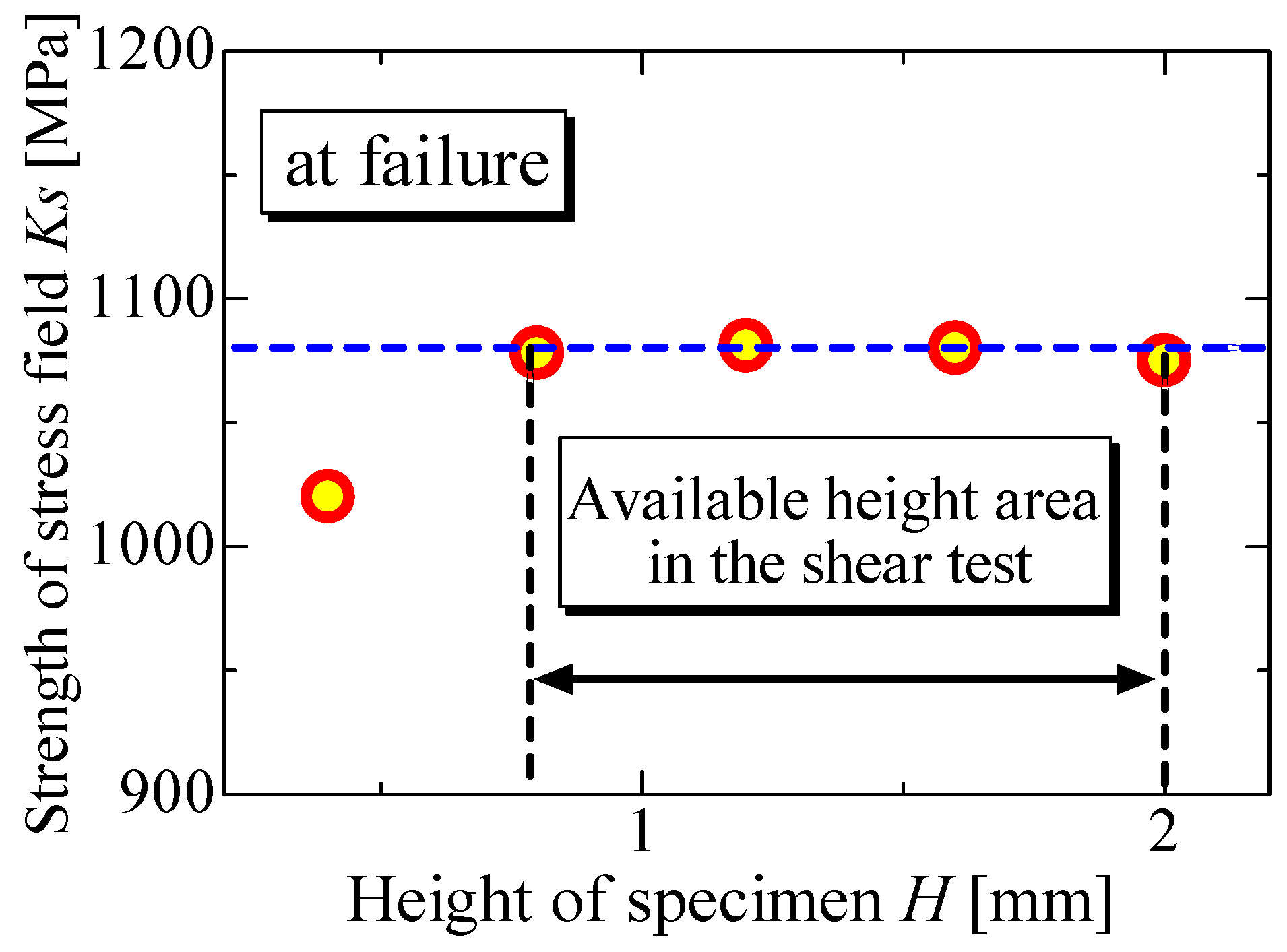

5.1.1. Influences of the Specimen Height H on the Stress Distributions

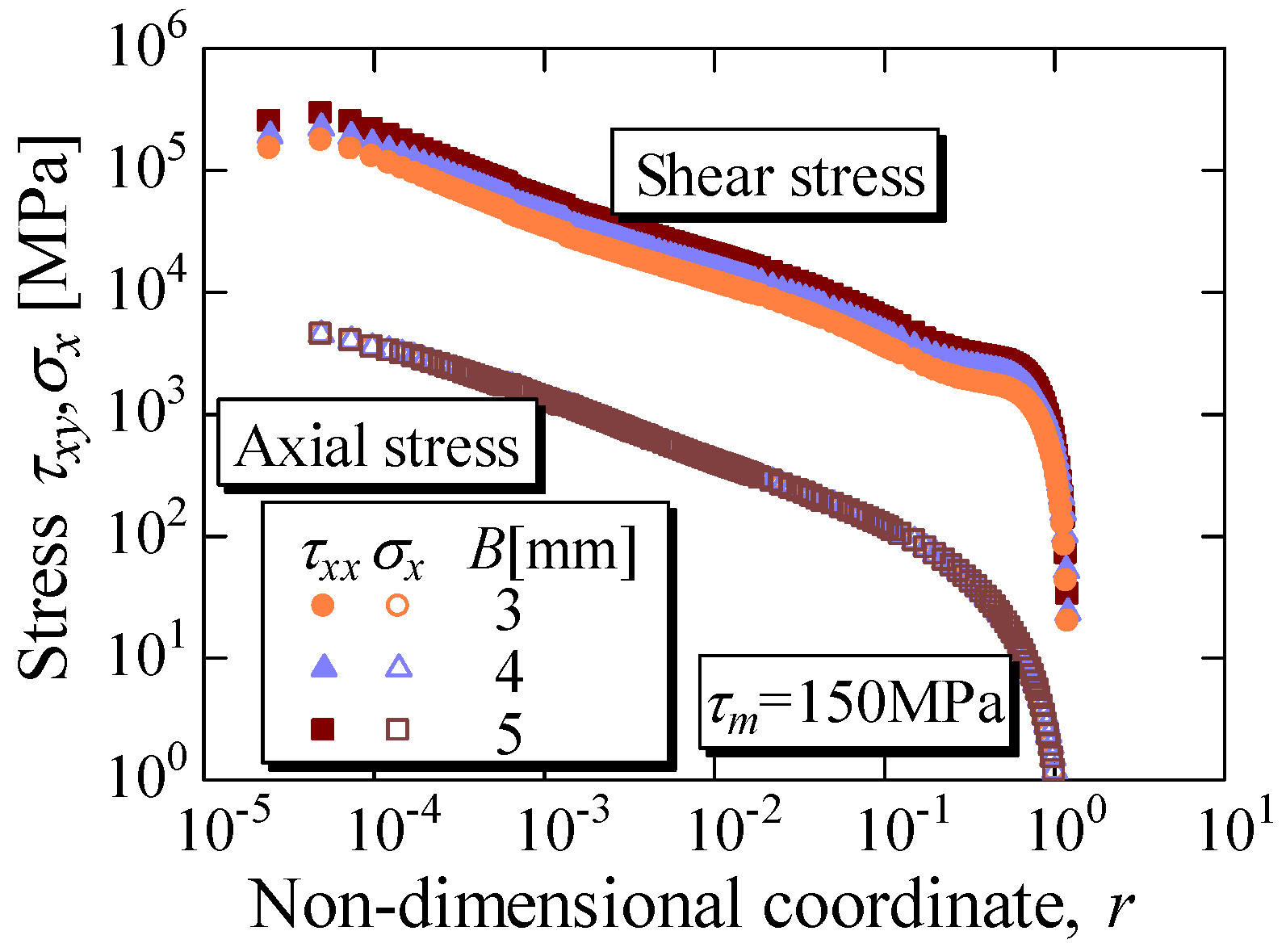

5.1.2. Influence of Specimen Width B on the Stress Distributions

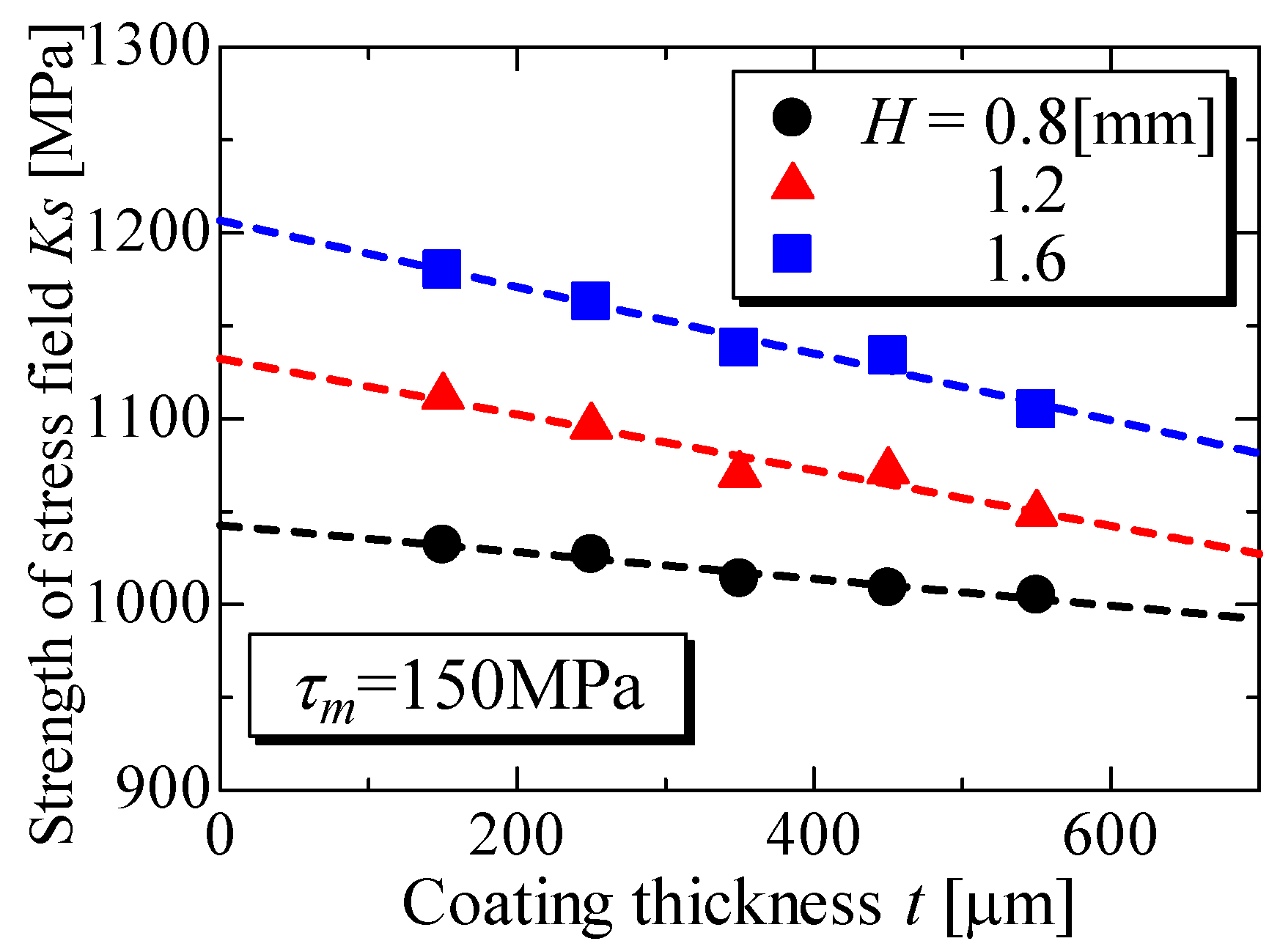

5.1.3. Influence of Coating Thickness t on the Stress Distributions

5.1.4. Influence of Shear Point c on the Stress Distributions

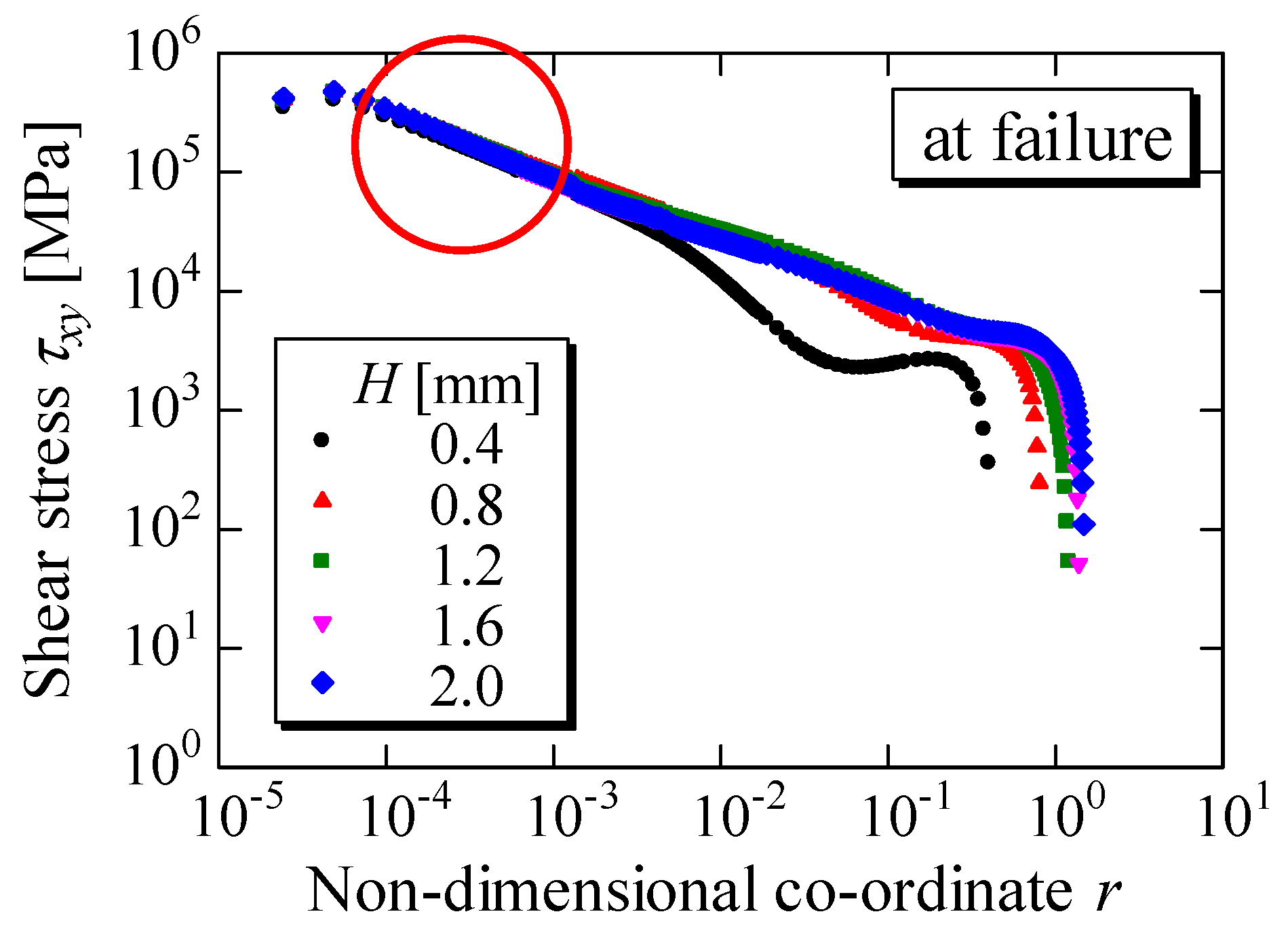

5.2. Stress Distributions Analysis around the Shearing Point at Failure

6. Conclusions

- (1)

- The critical shear average stress decreases with increasing specimen height H and width B.

- (2)

- The critical shear average stress increases with increasing coating thickness t.

- (3)

- The critical shear average stress increases with decreasing shear loading position c.

- (4)

- Thus, the apparent critical strength depends on the magnitude of the specimen and the loading position in the scraping shear test.

- (5)

- Virtually all failures are initiated at the shear loading points on the coating. Therefore, the apparent critical shear strength does not represent the adhesive strength, but rather the shear strength of the coating.

- (6)

- The local singularity stresses were found to occur at the loading point on the coating. These singularity shear and tensile stresses were approximated τ = Ksr−λ and σ = Kar−λ, respectively. It was found that the singularity parameter λ is virtually constant and the strength of the stress singularity Ks becomes constant at failure, regardless of the magnitude of the specimen. Thus, the critical strength of the stress singularity obtained here indicates the shear fracture condition of the coating.

- (7)

- The strength of the shear stress singularity at the loading point was found to increase with increasing height H and width B of the specimen, and the loading position c measured from the interface, and with decreasing coating thickness t. Thus, the reasons why the apparent critical load depends on the magnitudes of specimen become clear.

- (8)

- This paper gave an important notice that the failure initiation point as well as the loading point should be carefully checked when the scraping shear -test method was used in evaluating the strength of a coating system.

Acknowledgements

Conflicts of Interest

References

- Agrawal, D.C.; Raj, R. Measurement of ultimate shear strength of a metal-ceramic interface. Acta Metall. 1989, 37, 1265–1270. [Google Scholar] [CrossRef]

- Chen, B.F.; Hwang, J.; Chen, I.F.; Yu, G.P.; Huang, J.-H. A tensile-film-cracking model for evaluating interfacial shear strength of elastic film on ductile substrate. Surf. Coat. Tech. 2000, 126, 91–95. [Google Scholar] [CrossRef]

- Lane, M.W.; Dauskardt, R.H. Plasticity contributions to interface adhesion in thin-film interconnect structures. J. Mater. Res. 2000, 15, 2758–2769. [Google Scholar] [CrossRef]

- Tsui, Y.C.; Howard, S.J.; Clyne, T.W. The effect of residual stresses on the debonding of coatings -II. An experimental study of a thermally sprayed system. Acta Metall. Mater. 1994, 42, 2837–2844. [Google Scholar] [CrossRef]

- Li, H.; Khor, K.A.; Cheang, P. Adhesive and bending failure of thermal sprayed hydroxyapatite coatings: Effect of nanostructures at interface and crack propagation phenomenon during bending. Eng. Fract. Mech. 2007, 74, 1894–1903. [Google Scholar] [CrossRef]

- Okazaki, M.; Yamagishi, S.; Osakabe, M.; Fukanuma, H. A new testing method to evaluate adhesion strength of ceramic top coat in TBCs. J. Solid Mech. Mater. Eng. 2010, 4, 345–354. [Google Scholar] [CrossRef]

- Fukumoto, M.; Murakami, H.; Okane, I.; Harada, H. Improved ring shear test for the evaluation of adhesion strength of thermal sprayed coating. J. Jpn. Inst. Met. Mater. 1995, 59, 84–88. (In Japanese) [Google Scholar]

- Zhu, Y.L.; Mas, N.; Xub, S. Finite-element evaluation and improvement of a test procedure for coating shear bond strength determination. J. Therm. Spray Technol. 1999, 8, 328–332. [Google Scholar] [CrossRef]

- Guo, S.Q.; Mumm, D.R.; Karlsson, A.M.; Kagawa, Y. Measurement of interfacial shear mechanical properties in thermal barrier coating systems by a barb pullout method. Scr. Mater. 2005, 53, 1043–1048. [Google Scholar] [CrossRef]

- Inoue, Y.; Ono, H.; Noutomi, A.; Dewa, A.; Toyoda, M.; Tsukamoto, M. Adhesive strength evaluation of plasma sprayed coatings by tensile pin test. J. Jpn. Weld. Soc. 1991, 9, 167–173. (In Japanese) [Google Scholar] [CrossRef]

- Kaneko, K. Delamination strength of coating and fracture strength of coating’s own. Sci. Mach. 1997, 49, 450–457. (In Japanese) [Google Scholar]

- Kaneko, K. Evaluation methods of adhesive strength of thermal sprayed coating. J. High Temp. Soc. Jpn. 2004, 30, 301–307. (In Japanese) [Google Scholar]

- Nakasa, K. Interfacial Strength Evaluation Handbook; Jpn. Soc. Mater. Sci.: Kyoto, Japan, 2011. (In Japanese) [Google Scholar]

- Arai, M.; Iwata, U.; Sakuma, T.; Saito, M. Effect of a delamination initiation strength between thermal barrier coating and base metal on thermal aging. J. Soc. Mater. Sci. 2000, 49, 912–918. (In Japanese) [Google Scholar] [CrossRef]

- Arai, M.; Iwata, U.; Sakuma, T.; Saito, M. Proposal of delamination life prediction method thermal barrier coating layer under thermal cycle condition. J. Soc. Mater. Sci. 2001, 50, 651–656. (In Japanese) [Google Scholar] [CrossRef]

- Arai, M. Proposal of delamination strength evaluation method of thermal barrier coatings based on interface cohesive model with interface oxidation process. J. Soc. Mater. Sci. 2004, 53, 459–464. (In Japanese) [Google Scholar] [CrossRef]

- Arai, M.; Okajima, Y.; Kishimoto, K. Mixed-mode interfacial fracture toughness for thermal barrier coating. Eng. Fract. Mech. 2007, 74, 2055–2069. [Google Scholar] [CrossRef]

- Suzuki, K.; Kubo, T.; Tanaka, K.; Akiniwa, Y.; Okado, H. Oxidation of thermal barrier coatings and spalling stress analyzed with synchrotron X-rays. J. Soc. Mater. Sci. 2004, 53, 734–739. (In Japanese) [Google Scholar] [CrossRef]

- Kaneko, K.; Takatou, S.; Enomoto, K. Study on shear fatigue fracture and delamination mechanism of thermal barrier coatings after thermal loading. J. Solid Mech. Mater. Eng. 2010, 4, 315–324. [Google Scholar] [CrossRef]

- Kaneko, K.; Ohmori, A. Evaluations of strength of thermal sprayed coating for complex loading. J. Solid Mech. Mater. Eng. 2010, 4, 264–273. [Google Scholar] [CrossRef]

- DIN EN 15340:2007-06 EN 15340 Thermal Spraying-Determination of Shear Load Resistance of Thermally Sprayed Coatings; Beuth: Berlin, Germany, 2007.

- Marot, G.; Demareaux, P.; Lesage, J.; Hadad, M.; Siegmann, S.T.; Staia, M.H. Interfacial indentation and shear tests to determine the adhesion of thermal spray coatings. Surf. Coat. Tech. 2006, 201, 2080–2085. [Google Scholar] [CrossRef]

- Hartmann, S.; Deuerler, F.; Winkler, R. Evaluation of shear test results for determination of shear load resistance of thermally sprayed coatings. Therm. Spray 2008, 2008, 670–673. [Google Scholar]

- Kaneko, K.; Higaki, K. Delamination strength evaluation of thermal sprayed coating by torsion pin-test method. J. Solid Mech. Mater. Eng. 2011, 5, 1042–1050. [Google Scholar] [CrossRef]

- Kaneko, K.; Higaki, K. Delamination strength of WC-Co thermal-sprayed coating under combined stresses by torsion-tension pin-test method. J. Therm. Spray Technol. 2014, 23, 903–909. [Google Scholar] [CrossRef]

- Kaneko, K.; Higaki, K. Evaluation of fatigue delamination strength of WC-Co thermal sprayed coating by torsion-tension pin-test method. Trans. Jpn. Soc. Mech. Eng. 2014, 80. (In Japanese) [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaneko, K. Evaluation of the Shearing Strength of a WC-12Co Thermal Spray Coating by the Scraping Test Method. Coatings 2015, 5, 278-292. https://doi.org/10.3390/coatings5030278

Kaneko K. Evaluation of the Shearing Strength of a WC-12Co Thermal Spray Coating by the Scraping Test Method. Coatings. 2015; 5(3):278-292. https://doi.org/10.3390/coatings5030278

Chicago/Turabian StyleKaneko, Kenji. 2015. "Evaluation of the Shearing Strength of a WC-12Co Thermal Spray Coating by the Scraping Test Method" Coatings 5, no. 3: 278-292. https://doi.org/10.3390/coatings5030278