Laser-Fabricated Reduced Graphene Oxide Memristors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

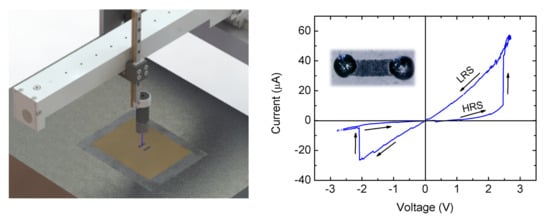

2.2. Experimental Setup

2.3. Laser-Reduced Memristor Fabrication

3. Results

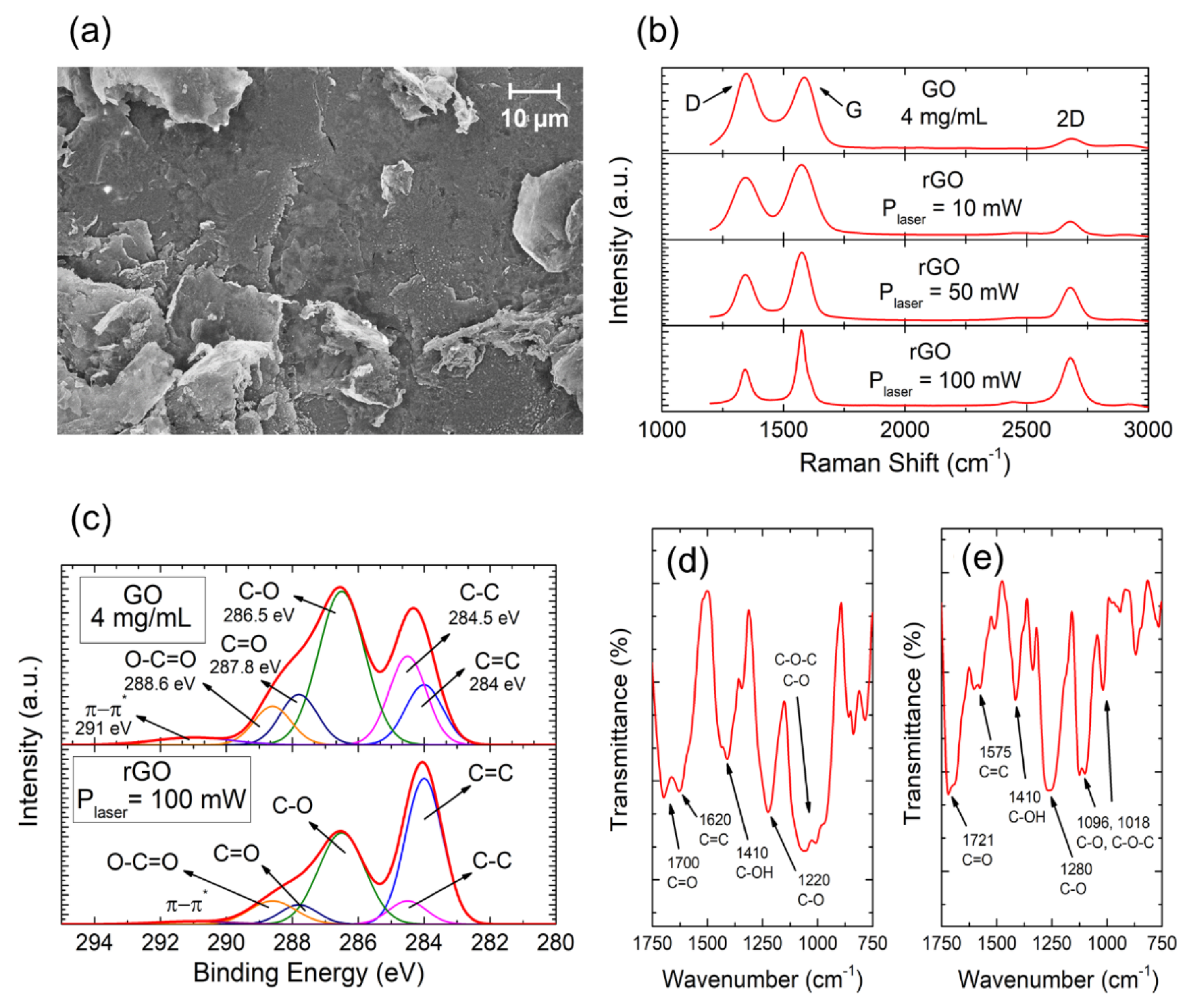

3.1. Structural Characterization

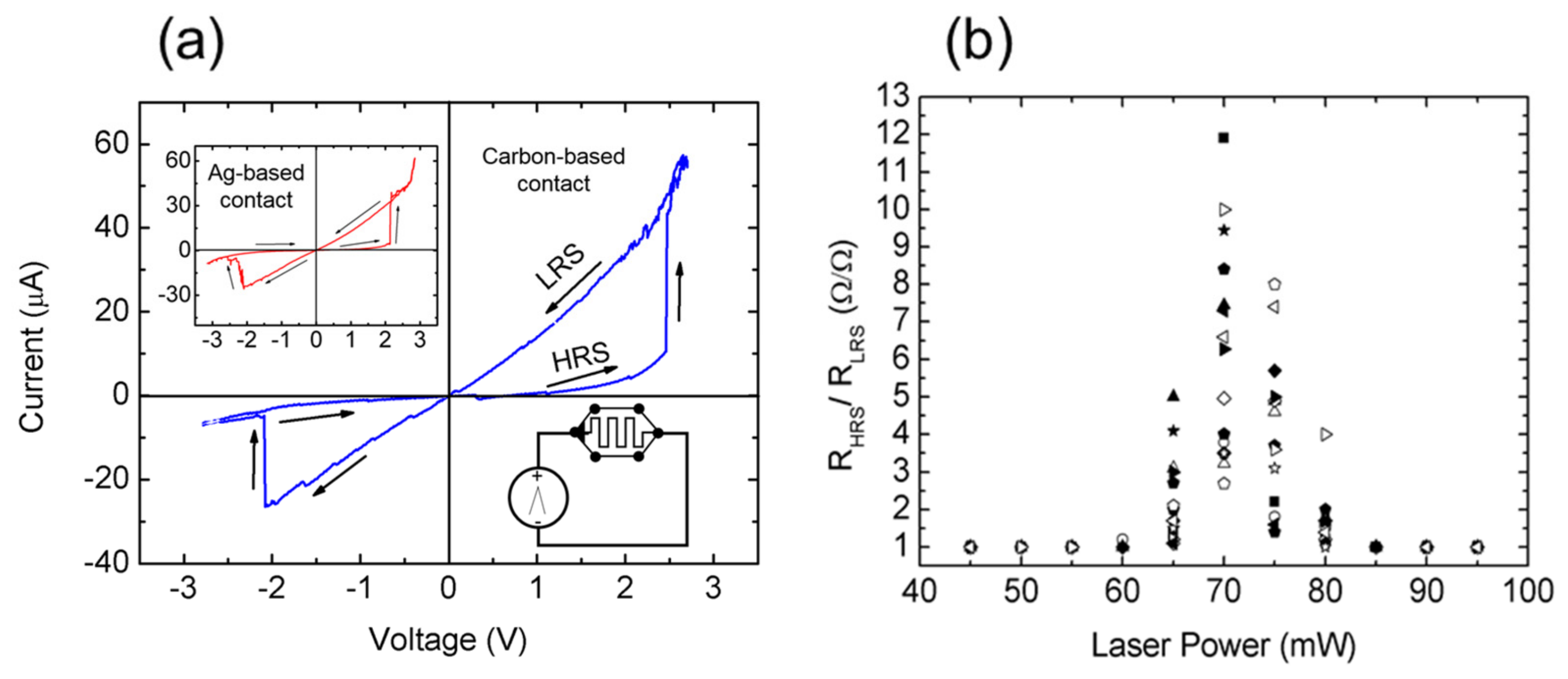

3.2. Electrical Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chua, L. Memristor-The missing circuit element. IEEE Trans. Circuit Theory 1971, 18, 507–519. [Google Scholar] [CrossRef]

- Chua, L.; Sung, M.K. Memristive devices and systems. Proc. IEEE 1976, 64, 209–223. [Google Scholar] [CrossRef]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, R.S. The Missing memristor found. Nature 2008, 453, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Tetzlaff, R. (Ed.) Memristors and Memristive, 1st ed.; Springer: New York, NY, USA, 2014; ISBN 978-1-4614-9068-5. [Google Scholar]

- Wang, L.; Yang, C.; Wen, J.; Gai, S.; Peng, Y. Overview of emerging memristor families from resistive memristor to spintronic memristor. J. Mater. Sci. Mater. Electron. 2015, 26, 4618–4628. [Google Scholar] [CrossRef] [Green Version]

- Hu, S.G.; Wu, S.; Jia, W.W.; Yu, Q.; Deng, L.J.; Fu, Y.Q.; Liu, Y.; Chen, T.P. Review of Nanostructured Resistive Switching Memristor and Its Applications. Nanosci. Nanotechnol. Lett. 2014, 6, 729–757. [Google Scholar] [CrossRef]

- Rehn, D.A.; Reed, E.J. Memristors with distorted structures. Nat. Mater. 2019, 18, 8–9. [Google Scholar] [CrossRef]

- Gonzalez-Rosillo, J.C.; Ortega-Hernandez, R.; Jareño-Cerulla, J.; Miranda, E.; Suñe, J.; Granados, X.; Obradors, X.; Palau, A.; Puig, T. Volume Resistive Switching in metallic perovskite oxides driven by the Metal-Insulator Transition. J. Electroceram. 2017, 39, 185. [Google Scholar] [CrossRef]

- Galle, E. TiO2-based Memristors and ReRAM: Materials Mechanisms and Models (a Review). Semicond. Sci. Technol. 2014, 29, 104004. [Google Scholar] [CrossRef]

- Rodriguez-Fernandez, A.; Aldana, S.; Campabadal, F.; Suñé, J.; Miranda, E.; Jiménez-Molinos, F.; Roldán, J.B.; Gonzalez, M.B. Resistive Switching with Self-Rectifying Tunability and Influence of the Oxide Layer Thickness in Ni/HfO₂/n⁺-Si RRAM Devices. IEEE Trans. Electron Devices 2017, 64, 1–8. [Google Scholar] [CrossRef]

- Lanza, M.; Wong, P.H.-S.; Pop, E.; Ielmini, D.; Strukov, D.; Regan, B.C.; Larcher, L.; Villena, M.A.; Yang, J.J.; Goux, L.; et al. Recommended Methods to Study Resistive Switching Devices. Adv. Electron. Mater. 2019, 5, 1800143. [Google Scholar] [CrossRef]

- Wang, R.; Shi, T.; Zhang, X.; Wang, W.; Wei, J.; Lu, J.; Zhao, X.; Wu, Z.; Cao, R.; Long, S.; et al. Bipolar Analog Memristors as Artificial Synapses for Neuromorphic Computing. Materials 2018, 11, 2102. [Google Scholar] [CrossRef] [PubMed]

- Jo, S.H.; Chang, T.; Ebong, I.; Bhadviya, B.B.; Mazumder, P.; Lu, W. Nanoscale Memristor Device as Synapse in Neuromorphic Systems. Nano Lett. 2010, 10, 1297–1301. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, S.; Zhao, X.; Wu, F.; Wu, Q.; Wang, W.; Cao, R.; Fang, Y.; Lv, H.; Long, S.; et al. Emulating short-term and long-term plasticity of bio-synapse based on cu/a-Si/Pt memristor. IEEE Electron Device Lett. 2017, 38, 1208–1211. [Google Scholar] [CrossRef]

- Indiveri, G.; Linares-Barranco, B.; Legenstein, R.; Deligeorgis, G.; Prodromakis, R. Integration of nanoscale memristor synapses in neuromorphic computing architectures. Nanotechnology 2014, 24, 384010. [Google Scholar] [CrossRef] [PubMed]

- 3D Xpoint Memory: Faster-Than-Flash Storage Unveiled, BBC News. Available online: https://www.bbc.com/news/technology-33675734 (accessed on 27 February 2019).

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Yao, J. Highly transparent nonvolatile resistive memory devices from silicon oxide and graphene. Nat. Commun. 2012, 3, 1101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, C.; Li, F.; Guo, T. Efficient tristable resistive memory based on single layer graphene/insulating polymer multi-stacking layer. Appl. Phys. Lett. 2014, 104, 183105. [Google Scholar] [CrossRef]

- Hui, F. Graphene and Related Materials for Resistive Random Access Memories. Adv. Electron. Mater. 2017, 3, 1600195. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef]

- Porro, S.; Ricciardi, C. Memristive behaviour in inkjet printed graphene oxide thin layers. RSC Adv. 2015, 6, 68565. [Google Scholar] [CrossRef]

- Porro, S.; Accornero, E.; Pirri, C.F.; Ricciardi, C. Memristive devices based on Graphene oxide. Carbon 2015, 85, 383–395. [Google Scholar] [CrossRef]

- Romero, F.J.; Rivadeneyra, A.; Toral, V.; Castillo, E.; García-Ruiz, F.; Morales, D.P.; Rodriguez, N. Design guidelines of laser reduced graphene oxide conformal thermistor for IoT applications. Sens. Actuators A Phys. 2018, 274, 148–154. [Google Scholar] [CrossRef]

- Tian, H. Cost-Effective, Transfer-Free, Flexible Resistive Random Access Memory Using Laser Scribed Reduced Graphene Oxide Patterning Technology. Nano Lett. 2014, 14, 3214–3219. [Google Scholar] [CrossRef] [PubMed]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1958. [Google Scholar] [CrossRef]

- Romero, F.J.; Salinas-Castillo, A.; Rivadeneyra, A.; Albrecht, A.; Godoy, A.; Morales, D.P.; Rodriguez, N. In-Depth Study of Laser Diode Ablation of Kapton Polyimide for Flexible Conductive Substrates. Nanomaterials 2018, 8, 517. [Google Scholar] [CrossRef]

- Wan, Z.; Wang, S.; Haylock, B.; Kaur, J.; Tanner, P.; Thiel, D.V.; Sang, R.T.; Cole, I.s.; Li, X.; Lobino, M.; et al. Tuning the sub-processes in laser reduction of graphene oxide by adjusting the power and scanning speed of laser. Carbon 2019, 141, 83–91. [Google Scholar] [CrossRef]

- Guan, Y.C.; Fang, Y.W.; Lim, G.C.; Zheng, H.Y.; Hong, M.H. Fabrication of Laser-reduced Graphene Oxide in Liquid Nitrogen Environment. Sci. Rep. 2016, 6, 28913. [Google Scholar] [CrossRef] [Green Version]

- Amato, G.; Milano, G.; Vignolo, U.; Vittone, E. Kinetics of defect formation in chemically vapor deposited (CVD) graphene during laser irradiation: The case of Raman investigation. Nano Res. 2015, 8, 3972–3981. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.B.; Lin, M.L.; Cong, X.; Liua, H.N.; Tan, P.H. Raman spectroscopy of graphene-based materials and its applications in related devices. Chem. Soc. Rev. 2018, 47, 1822–1873. [Google Scholar] [CrossRef] [Green Version]

- Hao, Y.; Wang, Y.; Wang, L.; Ni, Z.; Wang, Z.; Wang, R.; Koo, C.K.; Shen, Z.; Thong, J.T. Probing Layer Number and Stacking Order of Few-Layer Graphene by Raman Spectroscopy. Small 2010, 6, 195–200. [Google Scholar] [CrossRef]

- Huang, Y.L.; Tien, H.W.; Ma, C.C.M.; Yang, S.Y.; Wu, S.Y.; Liub, H.; Mai, Y.W. Effect of extended polymer chains on properties of transparent graphene nanosheets conductive film. J. Mater. Chem. 2011, 21, 18236–18241. [Google Scholar] [CrossRef]

- Bobinger, M.R.; Romero, F.J.; Salinas-Castillo, A.; Becherer, M.; Lugli, P.; Morales, D.P.; Rodríguez, N.; Rivadeneyra, A. Flexible and robust laser-induced graphene heaters photothermally scribed on bare polyimide substrates. Carbon 2019, 144, 116–126. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef]

- Mei, X.; Yan, Q.; Lu, P.; Wang, J.; Cui, Y.; Nie, Y.; Umar, A.; Wang, Q. Synthesis of Pt/K2CO3/MgAlOx–reduced graphene oxide hybrids as promising NOx storage–reduction catalysts with superior catalytic performance. Sci. Rep. 2017, 7, 42862. [Google Scholar] [CrossRef] [PubMed]

- Piovesan, J.V.; Santana, E.R.; Spinelli, A. Reduced graphene oxide/gold nanoparticles nanocomposite modified glassy carbon electrode for determination of endocrine disruptor methylparaben. J. Electroanal. Chem. 2018, 813, 163–170. [Google Scholar] [CrossRef]

- Aragaw, B.A.; Su, W.N.; Rick, J.; Hwang, B.J. Highly efficient synthesis of reduced graphene oxide–Nafion nanocomposites with strong coupling for enhanced proton and electron conduction. RSC Adv. 2013, 3, 23212. [Google Scholar] [CrossRef]

- Abdali, H.; Ajji, A. Preparation of Electrospun Nanocomposite Nanofibers of Polyaniline/Poly(methyl methacrylate) with Amino-Functionalized Graphene. Polymers 2017, 9, 453. [Google Scholar] [CrossRef]

- Sakharov, Y.V. Investigation of memristor effect on basis of thin-film oxide dielectrics modified by carbon. IOP Conf. Ser. Mater. Sci. Eng. 2019, 489, 012029. [Google Scholar] [CrossRef]

- Venugopal, G.; Kim, S. Observation of Nonvolatile Resistive Memory Switching Characteristics in Ag/Graphene-Oxide/Ag Devices. J. Nanosci. Nanotechnol. 2012, 12, 1–4. [Google Scholar] [CrossRef]

- Panin, G.N.; Kapitanova, O.O.; Leem, S.W.; Baranov, A.N.; Kang, T.W. Resistive Switching in Al/Graphene Oxide/Al Structure. Jpn. J. Appl. Phys. 2011, 50, 070110. [Google Scholar] [CrossRef]

- Cheng, P.; Hu, Y.H. Novel design for the odd-symmetric memristor from asymmetric switches. J. Mater. Chem. C 2015, 3, 2768–2772. [Google Scholar] [CrossRef]

- Lee, M.J. A fast, high-endurance and scalable non-volatile memory device made from asymmetric Ta2O5−x/TaO2−x bilayer structures. Nat. Mater. 2011, 10, 625–630. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Kim, J.E.; Kim, S.O.; Choi, S.; Cho, B.J. Flexible Resistive Switching Memory Device Based on Graphene Oxide. IEEE Electron Device Lett. 2010, 31, 1005–1007. [Google Scholar] [CrossRef]

- Goswami, S.; Matula, A.J.; Rath, S.P.; Hedström, S.; Saha, S.; Annamalai, M.; Sengupta, D.; Patra, A.; Ghosh, S.; Jani, H.; et al. Robust resistive memory devices using solution-processable metal-coordinated azo aromatics. Nat. Mater. 2017, 16, 1216–1224. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, S.K.; Xiao, B.; Mishra, S.; Killam, A.; Pradhan, A.K. Resistive switching behavior of reduced graphene oxide memory cells for low power nonvolatile device application. Sci. Rep. 2016, 6, 26763. [Google Scholar] [CrossRef] [PubMed]

- Khurana, G.; Misra, P.; Katiyara, R.S. Forming free resistive switching in graphene oxide thin film for thermally stable nonvolatile memory applications. J. Appl. Phys. 2013, 114, 124508. [Google Scholar] [CrossRef]

- Qi, M.; Bai, L.; Xu, H.; Wang, Z.; Kang, Z.; Zhao, X.; Liu, W.; Ma, J.; Liu, Y. Oxidized carbon quantum dot–graphene oxide nanocomposites for improving data retention of resistive switching memory. J. Mater. Chem. C 2018, 6, 2026–2033. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Kim, J.Y.; Kim, J.W.; Hwang, J.O.; Kim, J.E.; Lee, J.Y.; Yoon, T.H.; Cho, B.J.; Kim, S.O.; Ruoff, R.S.; et al. Graphene Oxide Thin Films for Flexible Nonvolatile Memory Applications. Nano Lett. 2010, 10, 4381–4386. [Google Scholar] [CrossRef]

- Bare Conductive Ltd. Electric Paint®: Safety Data Sheet. 2015. Available online: https://www.bareconductive.com/wp-content/uploads/2015/01/MSDS_BareConductive_ElectricPaint.pdf (accessed on 10 June 2019).

- Abunahla, H.; Mohammad, B.; Homouz, D.; Okelly, C.J. Modeling Valence Change Memristor Device: Oxide Thickness, Material Type, and Temperature Effects. IEEE Trans. Circuits Syst. I Regul. Pap. 2016, 63, 2139–2148. [Google Scholar] [CrossRef]

- Zhou, S.; Bongiorno, A. Origin of the Chemical and Kinetic Stability of Graphene Oxide. Sci. Rep. 2013, 3, 2484. [Google Scholar] [CrossRef]

- Kim, S.; Zhou, S.; Hu, Y.; Acik, M.; Chabal, Y.J.; Berger, C.; de Heer, W.; Bongiorno, A.; Riedo, E. Room-temperature metastability of multilayer graphene oxide films. Nat. Mater. 2012, 11, 544–549. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Shuang, N.; Li, Z.; Yang, J. Diffusion and desorption of oxygen atoms on graphene. J. Phys. Condens. Matter 2013, 25, 405301. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.Q.; Zhou, P.; Sun, Q.Q.; Wang, L.H.; Geng, Y.; Zhang, D.W.; Wang, X.B. The nano-scale resistive memory effect of graphene oxide. In Proceedings of the 2012 IEEE Nanotechnology Materials and Devices Conference (NMDC2012), Waikiki Beach, HI, USA, 16–19 October 2012. [Google Scholar]

- Mativetsky, J.M.; Treossi, E.; Orgiu, E.; Melucci, M.; Veronese, G.P.; Samorì, P.; Palermo, V. Local Current Mapping and Patterning of Reduced Graphene Oxide. J. Am. Chem. Soc. 2010, 132, 14130–14136. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Yang, W.; Suna, Q.; Zhoua, P.; Lu, H.; Ding, S.J.; Zhang, D.W. The mechanism of the asymmetric SET and RESET speed of graphene oxide based flexible resistive switching memories. Appl. Phys. Lett. 2012, 100, 063509. [Google Scholar] [CrossRef]

- Bizao, R.A.; Machado, L.D.; de Sousa, J.M.; Pugno, N.M.; Galvao, D.S. Scale Efects on the Ballistic Penetration of Graphene Sheets. Sci. Rep. 2018, 8, 6750. [Google Scholar] [CrossRef] [PubMed]

- He, H.Y.; Klinowski, J.; Forster, M.; Lerf, A. A new structural model for graphite oxide. Chem. Phys. Lett. 1998, 287, 53–56. [Google Scholar] [CrossRef]

- Jian, L.; Wu, B.; Liu, H.; Huang, Y.; Chen, J.; Geng, D.; Gao, H.; Liu, Y. A General Approach for Fast Detection of Charge Carrier Type and Conductivity Difference in Nanoscale Materials. Adv. Mater. 2013, 25, 7015–7019. [Google Scholar] [CrossRef]

- Loh, K.P.; Bao, Q.; Eda, G.; Chhowalla, M. Graphene oxide as a chemically tunable platform for optical applications. Nat. Chem. 2010, 23, 1015–1023. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero, F.J.; Toral-Lopez, A.; Ohata, A.; Morales, D.P.; Ruiz, F.G.; Godoy, A.; Rodriguez, N. Laser-Fabricated Reduced Graphene Oxide Memristors. Nanomaterials 2019, 9, 897. https://doi.org/10.3390/nano9060897

Romero FJ, Toral-Lopez A, Ohata A, Morales DP, Ruiz FG, Godoy A, Rodriguez N. Laser-Fabricated Reduced Graphene Oxide Memristors. Nanomaterials. 2019; 9(6):897. https://doi.org/10.3390/nano9060897

Chicago/Turabian StyleRomero, Francisco J., Alejandro Toral-Lopez, Akiko Ohata, Diego P. Morales, Francisco G. Ruiz, Andres Godoy, and Noel Rodriguez. 2019. "Laser-Fabricated Reduced Graphene Oxide Memristors" Nanomaterials 9, no. 6: 897. https://doi.org/10.3390/nano9060897