Recent Advances in Graphene-Based Humidity Sensors

Abstract

:1. Introduction

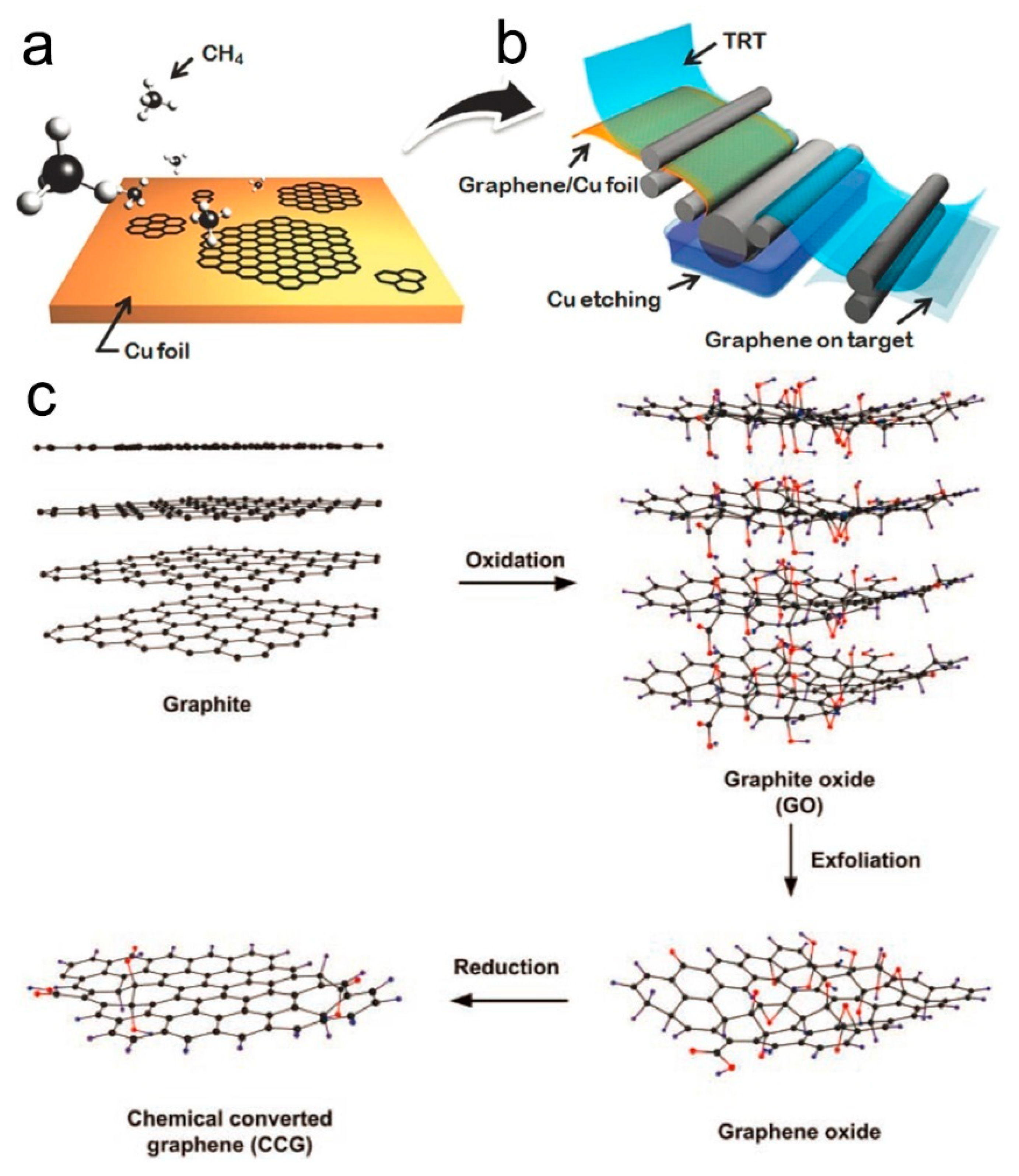

2. Preparation and Properties of Graphene

2.1. Preparation of Graphene

2.2. Properties of Graphene

3. Mechanisms of Graphene-Based Humidity Sensors

3.1. Field-Effect Transistor (FET) Humidity Sensors

3.2. Resistive Humidity Sensors

3.3. Impedance Humidity Sensors

3.4. Capacitive Humidity Sensors

3.5. Surface Acoustic Wave (SAW) Humidity Sensors

3.6. Quartz Crystal Microbalance (QCM) Humidity Sensors

3.7. Optical Fiber Humidity Sensors

4. Humidity Sensors Based on Graphene Materials

4.1. Humidity Sensors Based on Pristine Graphene

4.2. Humidity Sensors Based on Graphene Oxide

4.3. Humidity Sensors Based on Reduced Graphene Oxide

4.4. Humidity Sensors Based on Graphene Quantum Dots

4.5. Humidity Sensors Based on Chemical Modified Graphene

4.6. Humidity Sensors Based on Graphene/Polymer Composites

4.7. Humidity Sensors Based on Graphene/Metal or Metal Oxide Composites

4.8. Humidity Sensors Based on Graphene/2D Materials

5. Summary and Perspective

Author Contributions

Funding

Conflicts of Interest

References

- Seiyama, T.; Yamazoe, N.; Arai, H. Ceramic humidity sensors. Sens. Actuat. 1983, 4, 85–96. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, C. Humidity Sensors: A Review of Materials and Mechanisms. Sens. Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

- Blank, T.A.; Eksperiandova, L.P.; Belikov, K.N. Recent Trends of Ceramic Humidity Sensors Development: A Review. Sens. Actuat. B Chem. 2016, 228, 416–442. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, Y.; Chen, M.-Q.; Xia, F. Research Advances in Microfiber Humidity Sensors. Small 2018, 14, 1800524. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Zhang, H.; Zheng, W.; Wang, W.; Huang, H.; Wang, C.; MacDiarmid, A.G.; Wei, Y. Highly Sensitive and Stable Humidity Nanosensors Based on LiCl Doped TiO2 Electrospun Nanofibers. J. Am. Chem. Soc. 2008, 130, 5036–5037. [Google Scholar] [CrossRef] [PubMed]

- Sun, A.; Huang, L.; Li, Y. Study on humidity sensing property based on TiO2 porous film and polystyrene sulfonic sodium. Sens. Actuat. B Chem. 2009, 139, 543–547. [Google Scholar] [CrossRef]

- Kuang, Q.; Lao, C.; Wang, Z.L.; Xie, Z.; Zheng, L. High-Sensitivity Humidity Sensor Based on a Single SnO2 Nanowire. J. Am. Chem. Soc. 2007, 129, 6070–6071. [Google Scholar] [CrossRef]

- Feng, H.; Li, C.; Li, T.; Diao, F.; Xin, T.; Liu, B.; Wang, Y. Three-dimensional hierarchical SnO2 dodecahedral nanocrystals with enhanced humidity sensing properties. Sens. Actuat. B Chem. 2017, 243, 704–714. [Google Scholar] [CrossRef]

- Li, W.; Liu, J.; Ding, C.; Bai, G.; Xu, J.; Ren, Q.; Li, J. Fabrication of Ordered SnO2 Nanostructures with Enhanced Humidity Sensing Performance. Sensors 2017, 17, 2392. [Google Scholar] [CrossRef]

- Malik, R.; Tomer, V.K.; Chaudhary, V.; Dahiya, M.S.; Sharma, A.; Nehra, S.P.; Duhan, S.; Kailasam, K. An excellent humidity sensor based on In–SnO2 loaded mesoporous graphitic carbon nitride. J. Mater. Chem. A 2017, 5, 14134–14143. [Google Scholar] [CrossRef]

- Gu, L.; Zheng, K.; Zhou, Y.; Li, J.; Mo, X.; Patzke, G.R.; Chen, G. Humidity sensors based on ZnO/TiO2 core/shell nanorod arrays with enhanced sensitivity. Sens. Actuat. B Chem. 2011, 159, 1–7. [Google Scholar] [CrossRef]

- Ates, T.; Tatar, C.; Yakuphanoglu, F. Preparation of semiconductor ZnO powders by sol–gel method: Humidity sensors. Sens. Actuat. A Phys 2013, 190, 153–160. [Google Scholar] [CrossRef]

- Jagtap, S.; Priolkar, K.R. Evaluation of ZnO nanoparticles and study of ZnO–TiO2 composites for lead free humidity sensors. Sens. Actuat. B Chem. 2013, 183, 411–418. [Google Scholar] [CrossRef]

- Narimani, K.; Nayeri, F.D.; Kolahdouz, M.; Ebrahimi, P. Fabrication, modeling and simulation of high sensitivity capacitive humidity sensors based on ZnO nanorods. Sens. Actuat. B Chem. 2016, 224, 338–343. [Google Scholar] [CrossRef]

- Kano, S.; Kim, K.; Fujii, M. Fast-Response and Flexible Nanocrystal-Based Humidity Sensor for Monitoring Human Respiration and Water Evaporation on Skin. ACS Sens. 2017, 2, 828–833. [Google Scholar] [CrossRef] [PubMed]

- Manikandan, V.; Sikarwar, S.; Yadav, B.C.; Mane, R.S. Fabrication of tin substituted nickel ferrite (Sn-NiFe2O4) thin film and its application as opto-electronic humidity sensor. Sens. Actuat. A Phys. 2018, 272, 267–273. [Google Scholar] [CrossRef]

- Tripathy, A.; Pramanik, S.; Manna, A.; Bhuyan, S.; Azrin Shah, F.N.; Radzi, Z.; Abu Osman, A.N. Design and Development for Capacitive Humidity Sensor Applications of Lead-Free Ca,Mg,Fe,Ti-Oxides-Based Electro-Ceramics with Improved Sensing Properties via Physisorption. Sensors 2016, 16, 1135. [Google Scholar] [CrossRef]

- Yao, Y.; Ma, W. Self-Assembly of Polyelectrolytic/Graphene Oxide Multilayer Thin Films on Quartz Crystal Microbalance for Humidity Detection. IEEE Sens. J. 2014, 14, 4078–4084. [Google Scholar] [CrossRef]

- Su, P.-G.; Li, W.-C.; Tseng, J.-Y.; Ho, C.-J. Fully transparent and flexible humidity sensors fabricated by layer-by-layer self-assembly of thin film of poly(2-acrylamido-2-methylpropane sulfonate) and its salt complex. Sens. Actuat. B Chem. 2011, 153, 29–36. [Google Scholar] [CrossRef]

- Morais, R.M.; dos Santos Klem, M.; Nogueira, G.L.; Gomes, T.C.; Alves, N. Low Cost Humidity Sensor Based on PANI/PEDOT:PSS Printed on Paper. IEEE Sens. J. 2018, 18, 2647–2651. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, Q.-J.; He, J.-H.; Xu, Q.-F.; Li, H.; Li, N.-J.; Chen, D.-Y.; Lu, J.-M. Polysquaraines: Novel humidity sensor materials with ultra-high sensitivity and good reversibility. Sens. Actuat. B Chem. 2018, 255, 1147–1152. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.; Jeong, H.S.; Jung, H.U.; Park, K.; Lee, G.M.; Kim, S.; Lee, J. Enhanced Moisture-Reactive Hydrophilic-PTFE-Based Flexible Humidity Sensor for Real-Time Monitoring. Sensors 2018, 18, 921. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, Z.; Qi, D.; Ru, C.; Pan, J.; Zhao, C.; Na, H. Fast response and highly sensitive humidity sensors based on CaCl2-doped sulfonated poly (ether ether ketone)s. Sens. Actuat. B Chem. 2017, 253, 666–676. [Google Scholar] [CrossRef]

- Sajid, M.; Siddiqui, G.U.; Kim, S.W.; Na, K.H.; Choi, Y.S.; Choi, K.H. Thermally modified amorphous polyethylene oxide thin films as highly sensitive linear humidity sensors. Sens. Actuat. A Phys. 2017, 265, 102–110. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, K.; Yang, T.; Zhang, Q.; Cong, W.; Yin, H.; Zhang, Z.; Chen, Y.; Zhu, Z. The combinations of hollow MoS2 micro@nano-spheres: One-step synthesis, excellent photocatalytic and humidity sensing properties. J. Mater. Chem. C 2014, 2, 5422–5430. [Google Scholar] [CrossRef]

- Zhao, J.; Li, N.; Yu, H.; Wei, Z.; Liao, M.; Chen, P.; Wang, S.; Shi, D.; Sun, Q.; Zhang, G. Highly Sensitive MoS2 Humidity Sensors Array for Noncontact Sensation. Adv. Mater. 2017, 29, 1702076. [Google Scholar] [CrossRef]

- Debasree, B.; Sumita, S.; Panchanan, P.; Prasanta Kumar, G. Pt decorated MoS2 nanoflakes for ultrasensitive resistive humidity sensor. Nanotechnology 2018, 29, 115504. [Google Scholar]

- Ravindra Kumar, J.; Prasanta Kumar, G. Liquid exfoliated pristine WS2 nanosheets for ultrasensitive and highly stable chemiresistive humidity sensors. Nanotechnology 2016, 27, 475503. [Google Scholar]

- Guo, H.; Lan, C.; Zhou, Z.; Sun, P.; Wei, D.; Li, C. Transparent, flexible, and stretchable WS2 based humidity sensors for electronic skin. Nanoscale 2017, 9, 6246–6253. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Cao, Y.; Li, P.; Wu, J.; Zong, X. Humidity-sensing performance of layer-by-layer self-assembled tungsten disulfide/tin dioxide nanocomposite. Sens. Actuat. B Chem. 2018, 265, 529–538. [Google Scholar] [CrossRef]

- Yasaei, P.; Behranginia, A.; Foroozan, T.; Asadi, M.; Kim, K.; Khalili-Araghi, F.; Salehi-Khojin, A. Stable and Selective Humidity Sensing Using Stacked Black Phosphorus Flakes. ACS Nano 2015, 9, 9898–9905. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.-Y.; Lee, Y.; Koh, H.-J.; Jung, H.; Kim, J.-S.; Yoo, H.-W.; Kim, J.; Jung, H.-T. Superior Chemical Sensing Performance of Black Phosphorus: Comparison with MoS2 and Graphene. Adv. Mater. 2016, 28, 7020–7028. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Xu, F.; Zhang, L.; Li, M.; Chen, J.; Xu, S.; Huang, G.; Chen, W.; Sun, L. Ultrafast Preparation of Black Phosphorus Quantum Dots for Efficient Humidity Sensing. Chem.-Eur. J. 2016, 22, 7357–7362. [Google Scholar] [CrossRef] [PubMed]

- Miao, J.; Cai, L.; Zhang, S.; Nah, J.; Yeom, J.; Wang, C. Air-Stable Humidity Sensor Using Few-Layer Black Phosphorus. ACS Appl. Mater. Interfaces 2017, 9, 10019–10026. [Google Scholar] [CrossRef]

- Afify, A.S.; Ahmad, S.; Khushnood, R.A.; Jagdale, P.; Tulliani, J.-M. Elaboration and characterization of novel humidity sensor based on micro-carbonized bamboo particles. Sens. Actuat. B Chem. 2017, 239, 1251–1256. [Google Scholar] [CrossRef]

- Zhou, G.; Byun, J.-H.; Oh, Y.; Jung, B.-M.; Cha, H.-J.; Seong, D.-G.; Um, M.-K.; Hyun, S.; Chou, T.-W. Highly Sensitive Wearable Textile-Based Humidity Sensor Made of High-Strength, Single-Walled Carbon Nanotube/Poly(vinyl alcohol) Filaments. ACS Appl. Mater. Interfaces 2017, 9, 4788–4797. [Google Scholar] [CrossRef] [PubMed]

- Yeow, J.T.W.; She, J.P.M. Carbon nanotube-enhanced capillary condensation for a capacitive humidity sensor. Nanotechnology 2006, 17, 5441. [Google Scholar] [CrossRef]

- Varghese, S.S.; Lonkar, S.; Singh, K.K.; Swaminathan, S.; Abdala, A. Recent advances in graphene based gas sensors. Sens. Actuat. B Chem. 2015, 218, 160–183. [Google Scholar] [CrossRef]

- Singh, E.; Meyyappan, M.; Nalwa, H.S. Flexible Graphene-Based Wearable Gas and Chemical Sensors. ACS Appl. Mater. Interfaces 2017, 9, 34544–34586. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Feng, H.; Li, J. Graphene Oxide: Preparation, Functionalization, and Electrochemical Applications. Chem. Rev. 2012, 112, 6027–6053. [Google Scholar] [CrossRef]

- Wang, H.; Maiyalagan, T.; Wang, X. Review on Recent Progress in Nitrogen-Doped Graphene: Synthesis, Characterization, and Its Potential Applications. ACS Catal. 2012, 2, 781–794. [Google Scholar] [CrossRef] [Green Version]

- Jang, H.; Park, Y.J.; Chen, X.; Das, T.; Kim, M.-S.; Ahn, J.-H. Graphene-Based Flexible and Stretchable Electronics. Adv. Mater. 2016, 28, 4184–4202. [Google Scholar] [CrossRef] [PubMed]

- Ji, L.; Meduri, P.; Agubra, V.; Xiao, X.; Alcoutlabi, M. Graphene-Based Nanocomposites for Energy Storage. Adv. Energy Mater. 2016, 6, 1502159. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Ahn, J.-H. Graphene for flexible and wearable device applications. Carbon 2017, 120, 244–257. [Google Scholar] [CrossRef]

- Yu, X.; Cheng, H.; Zhang, M.; Zhao, Y.; Qu, L.; Shi, G. Graphene-based smart materials. Nat. Rev. Mater. 2017, 2, 17046. [Google Scholar] [CrossRef]

- Nag, A.; Mitra, A.; Mukhopadhyay, S.C. Graphene and its sensor-based applications: A review. Sens. Actuat. A Phys 2018, 270, 177–194. [Google Scholar] [CrossRef]

- Yao, Y.; Ping, J. Recent advances in graphene-based freestanding paper-like materials for sensing applications. TrAC Trend. Anal. Chem. 2018, 105, 75–88. [Google Scholar] [CrossRef]

- Yavari, F.; Koratkar, N. Graphene-Based Chemical Sensors. J. Phys. Chem. Lett. 2012, 3, 1746–1753. [Google Scholar] [CrossRef]

- Park, S.; An, J.; Suk, J.W.; Ruoff, R.S. Graphene-Based Actuators. Small 2010, 6, 210–212. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, J.; Wu, H.; Liu, J.; Aksay, I.A.; Lin, Y. Graphene Based Electrochemical Sensors and Biosensors: A Review. Electroanalysis 2010, 22, 1027–1036. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Dong, X.; Chen, P. Biological and chemical sensors based on graphene materials. Chem. Soc. Rev. 2012, 41, 2283–2307. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.; Shi, G. Graphene-based gas sensors. J. Mater. Chem. A 2013, 1, 10078–10091. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, K.; Lou, Z.; Chen, D.; Shen, G. Recent Developments in Graphene-Based Tactile Sensors and E-Skins. Adv. Mater. Technol. 2017, 3, 1700248. [Google Scholar] [CrossRef]

- Tung, T.T.; Nine, M.J.; Krebsz, M.; Pasinszki, T.; Coghlan, C.J.; Tran, D.N.H.; Losic, D. Recent Advances in Sensing Applications of Graphene Assemblies and Their Composites. Adv. Funct. Mater. 2017, 27, 1702891. [Google Scholar] [CrossRef]

- Farahani, H.; Wagiran, R.; Hamidon, M. Humidity Sensors Principle, Mechanism, and Fabrication Technologies: A Comprehensive Review. Sensors 2014, 14, 7881. [Google Scholar] [CrossRef]

- Sikarwar, S.; Yadav, B.C. Opto-electronic humidity sensor: A review. Sens. Actuat A Phys 2015, 233, 54–70. [Google Scholar] [CrossRef]

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 2007, 6, 652–655. [Google Scholar] [CrossRef] [Green Version]

- Yi, M.; Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.; Zhang, L.; Zhou, C. Review of Chemical Vapor Deposition of Graphene and Related Applications. Acc. Chem. Res. 2013, 46, 2329–2339. [Google Scholar] [CrossRef]

- Kim, K.-S.; Lee, H.-J.; Lee, C.; Lee, S.-K.; Jang, H.; Ahn, J.-H.; Kim, J.-H.; Lee, H.-J. Chemical Vapor Deposition-Grown Graphene: The Thinnest Solid Lubricant. ACS Nano 2011, 5, 5107–5114. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.; Park, J.-S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Ri Kim, H.; Song, Y.I.; et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bai, H.; Li, C.; Shi, G. Functional Composite Materials Based on Chemically Converted Graphene. Adv. Mater. 2011, 23, 1089–1115. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Soldano, C.; Mahmood, A.; Dujardin, E. Production, properties and potential of graphene. Carbon 2010, 48, 2127–2150. [Google Scholar] [CrossRef]

- Abergel, D.S.L.; Apalkov, V.; Berashevich, J.; Ziegler, K.; Chakraborty, T. Properties of graphene: A theoretical perspective. Adv. Phys. 2010, 59, 261–482. [Google Scholar]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Wu, S.; Yin, Z.; Zhang, H. Graphene-based electronic sensors. Chem. Sci. 2012, 3, 1764–1772. [Google Scholar] [CrossRef]

- Yang, S.; Jiang, C.; Wei, S.-H. Gas sensing in 2D materials. Appl. Phys. Rev. 2017, 4, 021304. [Google Scholar] [CrossRef]

- Meng, F.-L.; Guo, Z.; Huang, X.-J. Graphene-based hybrids for chemiresistive gas sensors. TrAC Trends Anal. Chem. 2015, 68, 37–47. [Google Scholar] [CrossRef]

- Shafiei, M.; Bradford, J.; Khan, H.; Piloto, C.; Wlodarski, W.; Li, Y.; Motta, N. Low-operating temperature NO2 gas sensors based on hybrid two-dimensional SnS2-reduced graphene oxide. Appl. Surf. Sci. 2018, 462, 330–336. [Google Scholar] [CrossRef]

- Piloto, C.; Shafiei, M.; Khan, H.; Gupta, B.; Tesfamichael, T.; Motta, N. Sensing performance of reduced graphene oxide-Fe doped WO3 hybrids to NO2 and humidity at room temperature. Appl. Surf. Sci. 2018, 434, 126–133. [Google Scholar] [CrossRef]

- Rheaume, J.M.; Pisano, A.P. A review of recent progress in sensing of gas concentration by impedance change. Ionics 2011, 17, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Borini, S.; White, R.; Wei, D.; Astley, M.; Haque, S.; Spigone, E.; Harris, N.; Kivioja, J.; Ryhänen, T. Ultrafast Graphene Oxide Humidity Sensors. ACS Nano 2013, 7, 11166–11173. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Singh, N.; Song, L.; Liu, Z.; Reddy, A.L.M.; Ci, L.; Vajtai, R.; Zhang, Q.; Wei, B.; Ajayan, P.M. Direct Laser Writing of Micro-Supercapacitors on Hydrated Graphite Oxide Films. Nat. Nanotechnol. 2011, 6, 496–500. [Google Scholar] [CrossRef] [PubMed]

- Bi, H.; Yin, K.; Xie, X.; Ji, J.; Wan, S.; Sun, L.; Terrones, M.; Dresselhaus, M.S. Ultrahigh Humidity Sensitivity of Graphene Oxide. Sci. Rep. 2013, 3, 2714. [Google Scholar] [CrossRef]

- Zhang, D.; Chang, H.; Li, P.; Liu, R.; Xue, Q. Fabrication and characterization of an ultrasensitive humidity sensor based on metal oxide/graphene hybrid nanocomposite. Sens. Actuat. B Chem. 2016, 225, 233–240. [Google Scholar] [CrossRef]

- Balashov, S.M.; Balachova, O.V.; Filho, A.P.; Bazetto, M.C.Q.; de Almeida, M.G. Surface Acoustic Wave Humidity Sensors Based on Graphene Oxide Thin Films Deposited with the Surface Acoustic Wave Atomizer. ECS Trans. 2012, 49, 445–450. [Google Scholar] [CrossRef]

- Le, X.; Wang, X.; Pang, J.; Liu, Y.; Fang, B.; Xu, Z.; Gao, C.; Xu, Y.; Xie, J. A high performance humidity sensor based on surface acoustic wave and graphene oxide on AlN/Si layered structure. Sens. Actuat. B Chem. 2018, 255, 2454–2461. [Google Scholar] [CrossRef]

- Wohltjen, H. Mechanism of operation and design considerations for surface acoustic wave device vapour sensors. Sens. Actuat. 1984, 5, 307–325. [Google Scholar] [CrossRef]

- Guo, Y.J.; Zhang, J.; Zhao, C.; Hu, P.A.; Zu, X.T.; Fu, Y.Q. Graphene/LiNbO3 surface acoustic wave device based relative humidity sensor. Optik 2014, 125, 5800–5802. [Google Scholar] [CrossRef]

- Kuznetsova, I.E.; Anisimkin, V.I.; Gubin, S.P.; Tkachev, S.V.; Kolesov, V.V.; Kashin, V.V.; Zaitsev, B.D.; Shikhabudinov, A.M.; Verona, E.; Sun, S. Super high sensitive plate acoustic wave humidity sensor based on graphene oxide film. Ultrasonics 2017, 81, 135–139. [Google Scholar] [CrossRef] [PubMed]

- Xuan, W.; He, M.; Meng, N.; He, X.; Wang, W.; Chen, J.; Shi, T.; Hasan, T.; Xu, Z.; Xu, Y.; et al. Fast Response and High Sensitivity ZnO/glass Surface Acoustic Wave Humidity Sensors Using Graphene Oxide Sensing Layer. Sci. Rep. 2014, 4, 7206. [Google Scholar] [CrossRef] [PubMed]

- Xuan, W.; He, X.; Chen, J.; Wang, W.; Wang, X.; Xu, Y.; Xu, Z.; Fu, Y.Q.; Luo, J.K. High Sensitivity Flexible Lamb-Wave Humidity Sensors with a Graphene Oxide Sensing Layer. Nanoscale 2015, 7, 7430–7436. [Google Scholar] [CrossRef] [PubMed]

- Kuznetsova, I.E.; Anisimkin, V.I.; Kolesov, V.V.; Kashin, V.V.; Osipenko, V.A.; Gubin, S.P.; Tkachev, S.V.; Verona, E.; Sun, S.; Kuznetsova, A.S. Sezawa wave acoustic humidity sensor based on graphene oxide sensitive film with enhanced sensitivity. Sens. Actuat. B Chem. 2018, 272, 236–242. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, D.; Li, P.; Zhou, X.; Zong, X.; Dong, G. Facile fabrication of high-performance QCM humidity sensor based on layer-by-layer self-assembled polyaniline/graphene oxide nanocomposite film. Sens. Actuat. B Chem. 2018, 255, 1869–1877. [Google Scholar] [CrossRef]

- Ding, X.; Chen, X.; Chen, X.; Zhao, X.; Li, N. A QCM humidity sensor based on fullerene/graphene oxide nanocomposites with high quality factor. Sens. Actuat. B Chem. 2018, 266, 534–542. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, X.; Guo, H.; Wu, Z. Graphene oxide thin film coated quartz crystal microbalance for humidity detection. Appl. Surf. Sci. 2011, 257, 7778–7782. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, X.; Li, X.; Chen, X.; Li, N. Investigation of the stability of QCM humidity sensor using graphene oxide as sensing films. Sens. Actuat. B Chem. 2014, 191, 779–783. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Yao, Y.; Li, N.; Chen, X.; Bi, X. Multi-Walled Carbon Nanotubes/Graphene Oxide Composites for Humidity Sensing. IEEE Sens. J. 2013, 13, 4749–4756. [Google Scholar] [CrossRef]

- Yao, Y.; Xue, Y. Impedance analysis of quartz crystal microbalance humidity sensors based on nanodiamond/graphene oxide nanocomposite film. Sens. Actuat. B Chem. 2015, 211, 52–58. [Google Scholar] [CrossRef]

- Tai, H.; Zhen, Y.; Liu, C.; Ye, Z.; Xie, G.; Du, X.; Jiang, Y. Facile development of high performance QCM humidity sensor based on protonated polyethylenimine-graphene oxide nanocomposite thin film. Sens. Actuat. B Chem. 2016, 230, 501–509. [Google Scholar] [CrossRef]

- Yuan, Z.; Tai, H.; Ye, Z.; Liu, C.; Xie, G.; Du, X.; Jiang, Y. Novel highly sensitive QCM humidity sensor with low hysteresis based on graphene oxide (GO)/poly(ethyleneimine) layered film. Sens. Actuat. B Chem. 2016, 234, 145–154. [Google Scholar] [CrossRef]

- Wang, S.; Xie, G.; Su, Y.; Su, L.; Zhang, Q.; Du, H.; Tai, H.; Jiang, Y. Reduced graphene oxide-polyethylene oxide composite films for humidity sensing via quartz crystal microbalance. Sens. Actuat. B Chem. 2018, 255, 2203–2210. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, D.; Zong, X.; Dong, G.; Zhang, Y. High-performance QCM humidity sensor based on graphene oxide/tin oxide/polyaniline ternary nanocomposite prepared by in-situ oxidative polymerization method. Sens. Actuat. B Chem. 2018, 262, 531–541. [Google Scholar] [CrossRef]

- Yuan, Z.; Tai, H.; Bao, X.; Liu, C.; Ye, Z.; Jiang, Y. Enhanced humidity-sensing properties of novel graphene oxide/zinc oxide nanoparticles layered thin film QCM sensor. Mater. Lett. 2016, 174, 28–31. [Google Scholar] [CrossRef]

- Su, P.-G.; Lin, Y.-T. Low-humidity sensing properties of diamine- and β-cyclodextrin-functionalized graphene oxide films measured using a quartz-crystal microbalance. Sens. Actuat. A Phys. 2016, 238, 344–350. [Google Scholar] [CrossRef]

- Ascorbe, J.; Corres, M.J.; Arregui, J.F.; Matias, R.I. Recent Developments in Fiber Optics Humidity Sensors. Sensors 2017, 17, 893. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, J.; Cai, X.; Tan, S.; Yu, J.; Lu, H.; Luo, Y.; Liao, G.; Li, S.; Tang, J.; et al. Reduced graphene oxide for fiber-optic humidity sensing. Opt. Express 2014, 22, 31555–31567. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, W.; Li, Z.; Chen, G.; Chen, L.; Zhou, J.; Lin, H.; Guan, J.; Fang, W.; Liu, X.; et al. High-performance fibre-optic humidity sensor based on a side-polished fibre wavelength selectively coupled with graphene oxide film. Sens. Actuat. B Chem. 2018, 255, 57–69. [Google Scholar] [CrossRef]

- Lim, H.W.; Yap, K.Y.; Chong, Y.W.; Ahmad, H. All-Optical Graphene Oxide Humidity Sensors. Sensors 2014, 14, 24329–24337. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Shen, C.; Lou, W.; Shentu, F.; Zhong, C.; Dong, X.; Tong, L. Fiber optic relative humidity sensor based on the tilted fiber Bragg grating coated with graphene oxide. Appl. Phys. Lett. 2016, 109, 031107. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, C.; Lou, W.; Shentu, F. Polarization-dependent humidity sensor based on an in-fiber Mach-Zehnder interferometer coated with graphene oxide. Sens. Actuat. B Chem. 2016, 234, 503–509. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, C.; Lou, W.; Shentu, F. Fiber optic humidity sensor based on the graphene oxide/PVA composite film. Opt. Commun. 2016, 372, 229–234. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.-F.; Cheng, J.; Jiang, Y.; Jiang, L.; Qi, Z.-M. Humidity sensor based on power leakage at resonance wavelengths of a hollow core fiber coated with reduced graphene oxide. Sens. Actuat. B Chem. 2016, 222, 618–624. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X.-G.; Zhou, X.; Zhang, Y.-N. Review on the graphene based optical fiber chemical and biological sensors. Sens. Actuat. B Chem. 2016, 231, 324–340. [Google Scholar] [CrossRef]

- Yavari, F.; Kritzinger, C.; Gaire, C.; Song, L.; Gulapalli, H.; Borca-Tasciuc, T.; Ajayan, P.M.; Koratkar, N. Tunable Bandgap in Graphene by the Controlled Adsorption of Water Molecules. Small 2010, 6, 2535–2538. [Google Scholar] [CrossRef]

- Smith, A.D.; Elgammal, K.; Niklaus, F.; Delin, A.; Fischer, A.C.; Vaziri, S.; Forsberg, F.; Rasander, M.; Hugosson, H.; Bergqvist, L.; et al. Resistive graphene humidity sensors with rapid and direct electrical readout. Nanoscale 2015, 7, 19099–19109. [Google Scholar] [CrossRef]

- Popov, V.I.; Nikolaev, D.V.; Timofeev, V.B.; Smagulova, S.A.; Antonova, I.V. Graphene-based humidity sensors: The origin of alternating resistance change. Nanotechnology 2017, 28, 355501. [Google Scholar] [CrossRef]

- Son, Y.J.; Chun, K.-Y.; Kim, J.-S.; Lee, J.-H.; Han, C.-S. Effects of chemical and physical defects on the humidity sensitivity of graphene surface. Chem. Phys. Lett. 2017, 689, 206–211. [Google Scholar] [CrossRef]

- Shehzad, K.; Shi, T.; Qadir, A.; Wan, X.; Guo, H.; Ali, A.; Xuan, W.; Xu, H.; Gu, Z.; Peng, X.; et al. Designing an Efficient Multimode Environmental Sensor Based on Graphene–Silicon Heterojunction. Adv. Mater. Technol. 2017, 2, 1600262. [Google Scholar] [CrossRef]

- Fan, X.; Elgammal, K.; Smith, A.D.; Östling, M.; Delin, A.; Lemme, M.C.; Niklaus, F. Humidity and CO2 gas sensing properties of double-layer graphene. Carbon 2018, 127, 576–587. [Google Scholar] [CrossRef]

- Zhen, Z.; Li, Z.; Zhao, X.; Zhong, Y.; Zhang, L.; Chen, Q.; Yang, T.; Zhu, H. Formation of Uniform Water Microdroplets on Wrinkled Graphene for Ultrafast Humidity Sensing. Small 2018, 14, 1703848. [Google Scholar] [CrossRef]

- Zhao, X.; Long, Y.; Yang, T.; Li, J.; Zhu, H. Simultaneous High Sensitivity Sensing of Temperature and Humidity with Graphene Woven Fabrics. ACS Appl. Mater. Interfaces 2017, 9, 30171–30176. [Google Scholar] [CrossRef]

- Qadir, A.; Sun, Y.W.; Liu, W.; Oppenheimer, P.G.; Xu, Y.; Humphreys, C.J.; Dunstan, D.J. Effect of humidity on the interlayer interaction of bilayer graphene. Phys. Rev. B 2019, 99, 045402. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, X.; Zhu, J.; Zeng, B.; Wu, Z.; Li, X. The effect of ambient humidity on the electrical properties of graphene oxide films. Nanoscale Res. Lett. 2012, 7, 363. [Google Scholar] [CrossRef] [Green Version]

- Jiawei, S.; Xiao, X.; Hengchang, B.; Haiyang, J.; Chongyang, Z.; Neng, W.; Jianqiu, H.; Meng, N.; Dan, L.; Litao, S. Solution-assisted ultrafast transfer of graphene-based thin films for solar cells and humidity sensors. Nanotechnology 2017, 28, 134004. [Google Scholar]

- Ho, D.H.; Sun, Q.; Kim, S.Y.; Han, J.T.; Kim, D.H.; Cho, J.H. Stretchable and Multimodal All Graphene Electronic Skin. Adv. Mater. 2016, 28, 2601–2608. [Google Scholar] [CrossRef]

- Park, E.U.; Choi, B.I.; Kim, J.C.; Woo, S.-B.; Kim, Y.-G.; Choi, Y.; Lee, S.-W. Correlation between the sensitivity and the hysteresis of humidity sensors based on graphene oxides. Sens. Actuat. B Chem. 2018, 258, 255–262. [Google Scholar] [CrossRef]

- Feng, X.; Chen, W.; Yan, L. Free-standing dried foam films of graphene oxide for humidity sensing. Sens. Actuat. B Chem. 2015, 215, 316–322. [Google Scholar] [CrossRef]

- Wee, B.-H.; Khoh, W.-H.; Sarker, A.K.; Lee, C.-H.; Hong, J.-D. A high-performance moisture sensor based on ultralarge graphene oxide. Nanoscale 2015, 7, 17805–17811. [Google Scholar] [CrossRef] [PubMed]

- Han, I.K.; Kim, S.; Lee, G.I.; Kim, P.J.; Kim, J.-H.; Hong, W.S.; Cho, J.B.; Hwang, S.W. Compliment Graphene Oxide Coating on Silk Fiber Surface via Electrostatic Force for Capacitive Humidity Sensor Applications. Sensors 2017, 17, 407. [Google Scholar] [CrossRef]

- Guo, R.; Tang, W.; Shen, C.; Wang, X. High sensitivity and fast response graphene oxide capacitive humidity sensor with computer-aided design. Comput. Mater. Sci. 2016, 111, 289–293. [Google Scholar] [CrossRef]

- Leng, X.; Li, W.; Luo, D.; Wang, F. Differential Structure With Graphene Oxide for Both Humidity and Temperature Sensing. IEEE Sens. J. 2017, 17, 4357–4364. [Google Scholar] [CrossRef]

- Rathi, K.; Pal, K. Impact of Doping on GO: Fast Response–Recovery Humidity Sensor. ACS Omega 2017, 2, 842–851. [Google Scholar] [CrossRef]

- Wan, N.; Wang, T.; Tan, X.-Y.; Lu, S.; Zhou, L.-L.; Huang, J.-Q.; Pan, W.; Yang, Y.-M.; Shao, Z.-Y. Microstructure Related Synergic Sensoring Mechanism in Graphene Oxide Humidity Sensor. J. Phys. Chem. C 2018, 122, 830–838. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Watanabe, A. Cost-Effective Fabrication of High-Performance Flexible All-Solid-State Carbon Micro-Supercapacitors by Blue-Violet Laser Direct Writing and Further Surface Treatment. J. Mater. Chem. A 2016, 4, 1671–1679. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Watanabe, A. Laser Direct Writing of High-Performance Flexible All-Solid-State Carbon Micro-Supercapacitors for an On-Chip Self-Powered Photodetection System. Nano Energy 2016, 30, 790–800. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Watanabe, A. High-Performance All-Solid-State Flexible Carbon/TiO2 Micro-Supercapacitors with Photo-Rechargeable Capability. RSC Adv. 2017, 7, 415–422. [Google Scholar] [CrossRef]

- Watanabe, A.; Cai, J. On Demand Process Based on Laser Direct Writing and the Sensor Application. J. Photopolym. Sci. Tec. 2017, 30, 341–343. [Google Scholar] [CrossRef] [Green Version]

- Cai, J.; Lv, C.; Aoyagi, E.; Ogawa, S.; Watanabe, A. Laser Direct Writing of a High-Performance All-Graphene Humidity Sensor Working in a Novel Sensing Mode for Portable Electronics. ACS Appl. Mater. Interfaces 2018, 10, 23987–23996. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Watanabe, A. Laser Direct Writing and Selective Metallization of Metallic Circuits for Integrated Wireless Devices. ACS Appl. Mater. Interfaces 2018, 10, 915–924. [Google Scholar] [CrossRef]

- Cai, J.; Watanabe, A.; Lv, C. Laser direct writing of carbon-based micro-supercapacitors and electronic devices. J. Laser Appl. 2018, 30, 032603. [Google Scholar] [CrossRef]

- Park, R.; Kim, H.; Lone, S.; Jeon, S.; Kwon, W.Y.; Shin, B.; Hong, W.S. One-Step Laser Patterned Highly Uniform Reduced Graphene Oxide Thin Films for Circuit-Enabled Tattoo and Flexible Humidity Sensor Application. Sensors 2018, 18, 1857. [Google Scholar] [CrossRef]

- An, J.; Le, T.-S.D.; Huang, Y.; Zhan, Z.; Li, Y.; Zheng, L.; Huang, W.; Sun, G.; Kim, Y.-J. All-Graphene-Based Highly Flexible Noncontact Electronic Skin. ACS Appl. Mater. Interfaces 2017, 9, 44593–44601. [Google Scholar] [CrossRef]

- Guo, L.; Jiang, H.-B.; Shao, R.-Q.; Zhang, Y.-L.; Xie, S.-Y.; Wang, J.-N.; Li, X.-B.; Jiang, F.; Chen, Q.-D.; Zhang, T.; et al. Two-beam-laser interference mediated reduction, patterning and nanostructuring of graphene oxide for the production of a flexible humidity sensing device. Carbon 2012, 50, 1667–1673. [Google Scholar] [CrossRef]

- Su, P.-G.; Chiou, C.-F. Electrical and humidity-sensing properties of reduced graphene oxide thin film fabricated by layer-by-layer with covalent anchoring on flexible substrate. Sens. Actuat. B Chem. 2014, 200, 9–18. [Google Scholar] [CrossRef]

- Phan, D.-T.; Chung, G.-S. Effects of rapid thermal annealing on humidity sensor based on graphene oxide thin films. Sens. Actuat. B Chem. 2015, 220, 1050–1055. [Google Scholar] [CrossRef]

- Shojaee, M.; Nasresfahani, S.; Dordane, M.K.; Sheikhi, M.H. Fully integrated wearable humidity sensor based on hydrothermally synthesized partially reduced graphene oxide. Sens. Actuat A Phys 2018, 279, 448–456. [Google Scholar] [CrossRef]

- Zaharie-Butucel, D.; Digianantonio, L.; Leordean, C.; Ressier, L.; Astilean, S.; Farcau, C. Flexible transparent sensors from reduced graphene oxide micro-stripes fabricated by convective self-assembly. Carbon 2017, 113, 361–370. [Google Scholar] [CrossRef]

- Han, D.-D.; Zhang, Y.-L.; Ma, J.-N.; Liu, Y.; Mao, J.-W.; Han, C.-H.; Jiang, K.; Zhao, H.-R.; Zhang, T.; Xu, H.-L.; et al. Sunlight-Reduced Graphene Oxides as Sensitive Moisture Sensors for Smart Device Design. Adv. Mater. Technol. 2017, 2, 1700045. [Google Scholar] [CrossRef]

- He, Y.; Liu, Y.; Ma, J.; Han, D.; Mao, J.; Han, C.; Zhang, Y. Facile Fabrication of High-Performance Humidity Sensors by Flash Reduction of GO. IEEE Sens. J. 2017, 17, 5285–5289. [Google Scholar] [CrossRef]

- Papazoglou, S.; Petridis, C.; Kymakis, E.; Kennou, S.; Raptis, Y.S.; Chatzandroulis, S.; Zergioti, I. In-situ sequential laser transfer and laser reduction of graphene oxide films. Appl. Phys. Lett. 2018, 112, 183301. [Google Scholar] [CrossRef] [Green Version]

- Zhao, F.; Zhao, Y.; Cheng, H.; Qu, L. A Graphene Fibriform Responsor for Sensing Heat, Humidity, and Mechanical Changes. Angew. Chem. 2015, 127, 15164–15168. [Google Scholar] [CrossRef]

- Choi, S.-J.; Yu, H.; Jang, J.-S.; Kim, M.-H.; Kim, S.-J.; Jeong, H.S.; Kim, I.-D. Nitrogen-Doped Single Graphene Fiber with Platinum Water Dissociation Catalyst for Wearable Humidity Sensor. Small 2018, 14, 1703934. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Xiao, G.; Liu, F.; Qiao, Y.; Li, C.M.; Lu, Z. A flexible humidity sensor based on silk fabrics for human respiration monitoring. J. Mater. Chem. C 2018, 6, 4549–4554. [Google Scholar] [CrossRef]

- Li, X.; Zong, L.; Wu, X.; You, J.; Li, M.; Li, C. Biomimetic engineering of spider silk fibres with graphene for electric devices with humidity and motion sensitivity. J. Mater. Chem. C 2018, 6, 3212–3219. [Google Scholar] [CrossRef]

- Ma, R.; Tsukruk, V.V. Seriography-Guided Reduction of Graphene Oxide Biopapers for Wearable Sensory Electronics. Adv. Funct. Mater. 2017, 27, 1604802. [Google Scholar] [CrossRef]

- Wang, X.; Xiong, Z.; Liu, Z.; Zhang, T. Exfoliation at the Liquid/Air Interface to Assemble Reduced Graphene Oxide Ultrathin Films for a Flexible Noncontact Sensing Device. Adv. Mater. 2015, 27, 1370–1375. [Google Scholar] [CrossRef]

- Pang, Y.; Jian, J.; Tu, T.; Yang, Z.; Ling, J.; Li, Y.; Wang, X.; Qiao, Y.; Tian, H.; Yang, Y.; et al. Wearable humidity sensor based on porous graphene network for respiration monitoring. Biosens. Bioelectron. 2018, 116, 123–129. [Google Scholar] [CrossRef]

- Hosseini, Z.S.; Iraji zad, A.; Ghiass, M.A.; Fardindoost, S.; Hatamie, S. A New Approach to Flexible Humidity Sensors Using Graphene Quantum Dots. J. Mater. Chem. C 2017, 5, 8966–8973. [Google Scholar] [CrossRef]

- Ruiz, V.; Fernández, I.; Carrasco, P.; Cabañero, G.; Grande, H.J.; Herrán, J. Graphene quantum dots as a novel sensing material for low-cost resistive and fast-response humidity sensors. Sens. Actuat. B Chem. 2015, 218, 73–77. [Google Scholar] [CrossRef]

- Sreeprasad, T.S.; Rodriguez, A.A.; Colston, J.; Graham, A.; Shishkin, E.; Pallem, V.; Berry, V. Electron-Tunneling Modulation in Percolating Network of Graphene Quantum Dots: Fabrication, Phenomenological Understanding, and Humidity/Pressure Sensing Applications. Nano Lett. 2013, 13, 1757–1763. [Google Scholar] [CrossRef]

- Huang, Q.; Zeng, D.; Tian, S.; Xie, C. Synthesis of defect graphene and its application for room temperature humidity sensing. Mater. Lett. 2012, 83, 76–79. [Google Scholar] [CrossRef]

- Ben Aziza, Z.; Zhang, K.; Baillargeat, D.; Zhang, Q. Enhancement of Humidity Sensitivity of Graphene through Functionalization with Polyethylenimine. Appl. Phys. Lett. 2015, 107, 134102. [Google Scholar] [CrossRef]

- Chen, L.; Li, Z.; Wu, G.; Wang, Y.; Wang, T.; Ma, Y.; Fei, B. Ultra-strong polyethyleneimine-graphene oxide nanocomposite film via synergistic interactions and its use for humidity sensing. Compos. Part A Appl. Sci. Manuf. 2018, 115, 341–347. [Google Scholar] [CrossRef]

- Su, P.-G.; Lu, Z.-M. Flexibility and electrical and humidity-sensing properties of diamine-functionalized graphene oxide films. Sens. Actuat. B Chem. 2015, 211, 157–163. [Google Scholar] [CrossRef]

- Lee, S.-W.; Choi, B.I.; Kim, J.C.; Woo, S.-B.; Kim, Y.-G.; Kwon, S.; Yoo, J.; Seo, Y.-S. Sorption/desorption hysteresis of thin-film humidity sensors based on graphene oxide and its derivative. Sens. Actuat. B Chem. 2016, 237, 575–580. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Z.; Umar, A.; Wang, Y.; Tian, T.; Shang, Y.; Fan, Y.; Qi, Q.; Xu, D. Supramolecularly Modified Graphene for Ultrafast Responsive and Highly Stable Humidity Sensor. J. Phys. Chem. C 2015, 119, 28640–28647. [Google Scholar] [CrossRef]

- Teradal, N.L.; Marx, S.; Morag, A.; Jelinek, R. Porous graphene oxide chemi-capacitor vapor sensor array. J. Mater. Chem. C 2017, 5, 1128–1135. [Google Scholar] [CrossRef]

- Ali, S.; Hassan, A.; Hassan, G.; Bae, J.; Lee, C.H. All-Printed Humidity Sensor Based on Graphene/Methyl-red Composite with High Sensitivity. Carbon 2016, 105, 23–32. [Google Scholar] [CrossRef]

- Tao, J.; Wang, Y.; Xiao, Y.; Yao, P.; Chen, C.; Zhang, D.; Pang, W.; Yang, H.; Sun, D.; Wang, Z.; et al. One-Step Exfoliation and Functionalization of Graphene by Hydrophobin for High Performance Water Molecular Sensing. Carbon 2017, 116, 695–702. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Y.; Shang, Y.; Umar, A.; Xie, P.; Qi, Q.; Zhou, G. One-Step Fabrication of Pyranine Modified- Reduced Graphene Oxide with Ultrafast and Ultrahigh Humidity Response. Sci. Rep. 2017, 7, 2713. [Google Scholar] [CrossRef] [PubMed]

- Lim, M.-Y.; Shin, H.; Shin, D.M.; Lee, S.-S.; Lee, J.-C. Poly(vinyl alcohol) nanocomposites containing reduced graphene oxide coated with tannic acid for humidity sensor. Polymer 2016, 84, 89–98. [Google Scholar] [CrossRef]

- Wen, Z.; Siyu, M.; Hui, W.; Yongning, H. Metal organic frameworks enhanced graphene oxide electrode for humidity sensor. J. Phys. Conf. Ser. 2018, 986, 012013. [Google Scholar] [Green Version]

- Sadasivuni, K.K.; Kafy, A.; Zhai, L.; Ko, H.-U.; Mun, S.; Kim, J. Transparent and Flexible Cellulose Nanocrystal/Reduced Graphene Oxide Film for Proximity Sensing. Small 2014, 11, 994–1002. [Google Scholar] [CrossRef]

- Kafy, A.; Akther, A.; Shishir, M.I.R.; Kim, H.C.; Yun, Y.; Kim, J. Cellulose nanocrystal/graphene oxide composite film as humidity sensor. Sens. Actuat. A Phys 2016, 247, 221–226. [Google Scholar] [CrossRef]

- Xu, S.; Yu, W.; Yao, X.; Zhang, Q.; Fu, Q. Nanocellulose-assisted dispersion of graphene to fabricate poly(vinyl alcohol)/graphene nanocomposite for humidity sensing. Compos. Sci. Technol. 2016, 131, 67–76. [Google Scholar] [CrossRef]

- Chen, Y.; Pötschke, P.; Pionteck, J.; Voit, B.; Qi, H. Smart cellulose/graphene composites fabricated by in situ chemical reduction of graphene oxide for multiple sensing applications. J. Mater. Chem. A 2018, 6, 7777–7785. [Google Scholar] [CrossRef]

- Chen, C.; Wang, X.; Li, M.; Fan, Y.; Sun, R. Humidity Sensor Based on Reduced Graphene Oxide/Lignosulfonate Composite Thin-Film. Sens. Actuat. B Chem. 2018, 255, 1569–1576. [Google Scholar] [CrossRef]

- Li, Y.; Deng, C.; Yang, M. Facilely prepared composites of polyelectrolytes and graphene as the sensing materials for the detection of very low humidity. Sens. Actuat. B Chem. 2014, 194, 51–58. [Google Scholar] [CrossRef]

- Li, Y.; Fan, K.; Ban, H.; Yang, M. Detection of Very Low Humidity Using Polyelectrolyte/Graphene Bilayer Humidity Sensors. Sens. Actuat. B Chem. 2016, 222, 151–158. [Google Scholar] [CrossRef]

- Zhang, D.; Tong, J.; Xia, B. Humidity-sensing properties of chemically reduced graphene oxide/polymer nanocomposite film sensor based on layer-by-layer nano self-assembly. Sens. Actuat. B Chem. 2014, 197, 66–72. [Google Scholar] [CrossRef]

- Zhang, D.; Tong, J.; Xia, B.; Xue, Q. Ultrahigh performance humidity sensor based on layer-by-layer self-assembly of graphene oxide/polyelectrolyte nanocomposite film. Sens. Actuat. B Chem. 2014, 203, 263–270. [Google Scholar] [CrossRef]

- Hwang, S.-H.; Kang, D.; Ruoff, R.S.; Shin, H.S.; Park, Y.-B. Poly(vinyl alcohol) Reinforced and Toughened with Poly(dopamine)-Treated Graphene Oxide, and Its Use for Humidity Sensing. ACS Nano 2014, 8, 6739–6747. [Google Scholar] [CrossRef]

- He, J.; Xiao, P.; Shi, J.; Liang, Y.; Lu, W.; Chen, Y.; Wang, W.; Théato, P.; Kuo, S.-W.; Chen, T. High Performance Humidity Fluctuation Sensor for Wearable Devices via a Bioinspired Atomic-Precise Tunable Graphene-Polymer Heterogeneous Sensing Junction. Chem. Mater. 2018, 30, 4343–4354. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, G.; Wang, W.; Zhou, X.; Guo, S. Individual nanocomposite sheets of chemically reduced graphene oxide and poly(N-vinyl pyrrolidone): Preparation and humidity sensing characteristics. J. Mater. Chem. 2010, 20, 10824–10828. [Google Scholar] [CrossRef]

- Santra, S.; Hu, G.; Howe, R.C.T.; De Luca, A.; Ali, S.Z.; Udrea, F.; Gardner, J.W.; Ray, S.K.; Guha, P.K.; Hasan, T. CMOS integration of inkjet-printed graphene for humidity sensing. Sci. Rep. 2015, 5, 17374. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Su, Y.; Xie, G.; Wang, S.; Tai, H.; Zhang, Q.; Du, H.; Zhang, H.; Du, X.; Jiang, Y. Novel high-performance self-powered humidity detection enabled by triboelectric effect. Sens. Actuat. B Chem. 2017, 251, 144–152. [Google Scholar] [CrossRef]

- Hernández-Rivera, D.; Rodríguez-Roldán, G.; Mora-Martínez, R.; Suaste-Gómez, E. A Capacitive Humidity Sensor Based on an Electrospun PVDF/Graphene Membrane. Sensors 2017, 17, 1009. [Google Scholar] [CrossRef]

- Lin, W.-D.; Chang, H.-M.; Wu, R.-J. Applied Novel Sensing Material Graphene/Polypyrrole for Humidity Sensor. Sens. Actuat. B Chem. 2013, 181, 326–331. [Google Scholar] [CrossRef]

- Trung, T.Q.; Duy, L.T.; Ramasundaram, S.; Lee, N.-E. Transparent, Stretchable, and Rapid-Response Humidity Sensor for Body-Attachable Wearable Electronics. Nano Res. 2017, 10, 2021–2033. [Google Scholar] [CrossRef]

- Leng, X.; Luo, D.; Xu, Z.; Wang, F. Modified Graphene Oxide/Nafion Composite Humidity Sensor and Its Linear Response to the Relative Humidity. Sens. Actuat. B Chem. 2018, 257, 372–381. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Yu, X.; Chen, X.; Ding, X.; Zhao, X. A High-Sensitive Humidity Sensor Based on Water-Soluble Composite Material of Fullerene and Graphene Oxide. IEEE Sens. J. 2018, 18, 962–966. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Chen, X.; Ding, X.; Zhao, X. High-sensitive humidity sensor based on graphene oxide with evenly dispersed multiwalled carbon nanotubes. Mater. Chem. Phys. 2018, 207, 135–140. [Google Scholar] [CrossRef]

- Fu, T.; Zhu, J.; Zhuo, M.; Guan, B.; Li, J.; Xu, Z.; Li, Q. Humidity sensors based on graphene/SnOx/CF nanocomposites. J. Mater. Chem. C 2014, 2, 4861–4866. [Google Scholar] [CrossRef]

- Xu, J.; Gu, S.; Lu, B. Graphene and graphene oxide double decorated SnO2 nanofibers with enhanced humidity sensing performance. RSC Adv. 2015, 5, 72046–72050. [Google Scholar] [CrossRef]

- Zhang, D.; Chang, H.; Liu, R. Humidity-Sensing Properties of One-Step Hydrothermally Synthesized Tin Dioxide-Decorated Graphene Nanocomposite on Polyimide Substrate. J. Electron. Mater. 2016, 45, 4275–4281. [Google Scholar] [CrossRef]

- Toloman, D.; Popa, A.; Stan, M.; Socaci, C.; Biris, A.R.; Katona, G.; Tudorache, F.; Petrila, I.; Iacomi, F. Reduced graphene oxide decorated with Fe doped SnO2 nanoparticles for humidity sensor. Appl. Surf. Sci. 2017, 402, 410–417. [Google Scholar] [CrossRef]

- Wang, Z.; Xiao, Y.; Cui, X.; Cheng, P.; Wang, B.; Gao, Y.; Li, X.; Yang, T.; Zhang, T.; Lu, G. Humidity-Sensing Properties of Urchinlike CuO Nanostructures Modified by Reduced Graphene Oxide. ACS Appl. Mater. Interfaces 2014, 6, 3888–3895. [Google Scholar] [CrossRef]

- Lin, W.-D.; Liao, C.-T.; Chang, T.-C.; Chen, S.-H.; Wu, R.-J. Humidity sensing properties of novel graphene/TiO2 composites by sol–gel process. Sens. Actuat. B Chem. 2015, 209, 555–561. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, J.; Xia, B. Layer-by-Layer Self-Assembly of Zinc Oxide/Graphene Oxide Hybrid Toward Ultrasensitive Humidity Sensing. IEEE Electron Device Lett. 2016, 37, 916–919. [Google Scholar] [CrossRef]

- Hassan, G.; Bae, J.; Lee, C.H.; Hassan, A. Wide range and stable ink-jet printed humidity sensor based on graphene and zinc oxide nanocomposite. J. Mater. Sci. Mater. Electron. 2018, 29, 5806–5813. [Google Scholar] [CrossRef]

- Sun, L.; Haidry, A.A.; Fatima, Q.; Li, Z.; Yao, Z. Improving the humidity sensing below 30% RH of TiO2 with GO modification. Mater. Res. Bull. 2018, 99, 124–131. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Zhang, H.; Ran, F.; Yang, P.; Li, H. Graphene oxide scroll meshes encapsulated Ag nanoparticles for humidity sensing. RSC Adv. 2017, 7, 40119–40123. [Google Scholar] [CrossRef] [Green Version]

- Su, P.-G.; Shiu, W.-L.; Tsai, M.-S. Flexible humidity sensor based on Au nanoparticles/graphene oxide/thiolated silica sol–gel film. Sens. Actuat. B Chem. 2015, 216, 467–475. [Google Scholar] [CrossRef]

- Yeo, C.S.; Kim, H.; Lim, T.; Kim, H.J.; Cho, S.; Cho, K.R.; Kim, Y.S.; Shin, M.K.; Yoo, J.; Ju, S.; et al. Copper-embedded reduced graphene oxide fibers for multi-sensors. J. Mater. Chem. C 2017, 5, 12825–12832. [Google Scholar] [CrossRef]

- Burman, D.; Ghosh, R.; Santra, S.; Guha, P.K. Highly proton conducting MoS2/graphene oxide nanocomposite based chemoresistive humidity sensor. RSC Adv. 2016, 6, 57424–57433. [Google Scholar] [CrossRef]

- Park, S.Y.; Kim, Y.H.; Lee, S.Y.; Sohn, W.; Lee, J.E.; Kim, D.H.; Shim, Y.-S.; Kwon, K.C.; Choi, K.S.; Yoo, H.J.; et al. Highly selective and sensitive chemoresistive humidity sensors based on rGO/MoS2 van der Waals composites. J. Mater. Chem. A 2018, 6, 5016–5024. [Google Scholar] [CrossRef]

- Park, S.Y.; Lee, J.E.; Kim, Y.H.; Kim, J.J.; Shim, Y.-S.; Kim, S.Y.; Lee, M.H.; Jang, H.W. Room temperature humidity sensors based on rGO/MoS2 hybrid composites synthesized by hydrothermal method. Sens. Actuat. B Chem. 2018, 258, 775–782. [Google Scholar] [CrossRef]

- Jha, R.K.; Burman, D.; Santra, S.; Guha, P.K. WS2/GO Nanohybrids for Enhanced Relative Humidity Sensing at Room Temperature. IEEE Sens. J. 2017, 17, 7340–7347. [Google Scholar] [CrossRef]

- Phan, D.-T.; Park, I.; Park, A.-R.; Park, C.-M.; Jeon, K.-J. Black P/graphene hybrid: A fast response humidity sensor with good reversibility and stability. Sci. Rep. 2017, 7, 10561. [Google Scholar] [CrossRef]

- Goldsmith, B.R.; Locascio, L.; Gao, Y.; Lerner, M.; Walker, A.; Lerner, J.; Kyaw, J.; Shue, A.; Afsahi, S.; Pan, D.; et al. Digital Biosensing by Foundry-Fabricated Graphene Sensors. Sci. Rep. 2019, 9, 434. [Google Scholar] [CrossRef]

| Material | Preparation Method | Type | Operating Temperature | Sensitivity | Selectivity | Humidity Range | Response/Recovery Time | Stability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Graphene | micromechanical cleavage of graphite | FET | R.T. | — | Low (NH3, CO, NO2) | 1 ppm | Hundreds of seconds | — | [57] |

| Graphene | CVD | Resistive | R.T. | 0.31% | High (Ar, N2, O2) | 1–96% | 0.6 s/0.4 s | — | [108] |

| Multilayer graphene | CVD | Resistive | 25 °C | 10–17% | — | 15–80% | <1 s | — | [109] |

| Graphene/Si Schottky junction | CVD | Resistive Capacitive | 10–90 °C | 45% 32% | High (N2, O2, Ar, CO2) | 10–90% | 8 s/19 s 4 s/10 s | — | [111] |

| Double-layer graphene | CVD | Resistive | 25 °C | ~0.784–0.933% | Low (CO2) | 20–100% | Hundreds of milliseconds | — | [112] |

| Wrinkled graphene | CVD | Resistive | 20–80 °C | — | — | 11–95% | 12.5 ms | — | [113] |

| Material | Preparation Method | Type | Operating Temperature | Sensitivity/Response | Selectivity | Humidity Range | Response/Recovery Time | Long-Term Stability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| GO | Drop casting | Capacitive | 25 °C | 37,800% | — | 15–95% | 10.5 s/41 s | 30 days | [76] |

| GO | Drop casting | Impedance | 10–40 °C | — | — | 10–90% | ~30 ms | 72 h | [74] |

| GO | Spary coating | Capacitive | 22–90 °C | — | — | 20–90% | — | 500 cycles | [118] |

| GO | Drop casting | Conductance | 25 °C | 12.3 ± 2.2 μS/%RH (pH 3.3) 12.3 ± 2.2 μS/%RH (pH 9.5) | — | 10–90% | 2.2 s/1.6 s (pH 2.8) 91.8 s/11.3 s (pH 9.3) | — | [119] |

| GO foam | Dry in a frame | Impedance | 25 °C | 33,254% | — | 11–95% | 50 s/79 s | — | [120] |

| Ultralarge GO | Drop casting | Conductance | 20 °C | 4339 ± 433 | — | 7–100% | 0.2s /0.7 s | 5 days | [121] |

| GO | Simulation | Capacitive | 25 °C | 7680 pF/%RH | — | 0–100% | <0.5 s | — | [123] |

| Li-doped GO | Drop casting | Resistive | 25 °C | 3038% | — | 11–97% | 4 s/25 s | — | [125] |

| GO | Spary coating | Capacitive | R.T. | — | — | 12–97% | <0.1 s | — | [126] |

| rGO/GO/rGO | Laser direct writing | Impedance | 23 °C | — | — | 11–95% | 1.8 s/11.5 s | 30 days | [135] |

| rGO/GO/rGO | Laser direct writing | Voltage | R.T. | 142.5 | High (H2, hexane, ethanol) | 6.3–100% | 1.9 s/3.9 s | > 1 year | [131] |

| Material | Preparation Method | Type | Operating Temperature | Sensitivity/Response | Selectivity | Humidity Range | Response/Recovery Time | Long-Term Stability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| rGO | Two-beam-laser interference reduction | Capacitive | 25 °C | — | — | 11–95% | 3 s/10 s | — | [136] |

| rGO | LBL-anchored and chemical reduction | Impedance | 15–35 °C | 0.0423 log Z/%RH | — | 30–90% | 28 s/48 s | 42 days | [137] |

| rGO | Rapid thermal annealing | Resistive | 25 °C | 35.3–0.075% | High (Acetone, ethanol, toluene, NH3, H2, CO, NO2, C2H2) | 20–95% | — | 5 weeks | [138] |

| partially reduced GO | Hydrothermal reduction | Resistive | R.T. | 3.3–105% | — | 20–85% | 4.2 s/3.6 s | 14 days | [139] |

| rGO | Chemical reduction | Resistive | 25 °C | 17.6 | — | 10–70% | — | — | [140] |

| rGO | Sunlight reduction | Impedance | 25 °C | three orders of magnitude | — | 11–95% | 16 s/47 s | 30 days | [141] |

| rGO | Flash reduction | Impedance | 20 °C | — | — | 11–95% | 1 s/24 s | 30 days | [142] |

| N-doped rGO fiber | Thermal annealing | Resistive | R.T. | 0.32–4.51% | — | 6.1–99.9% | — | 30 cycles | [145] |

| rGO-silk | Seriography-guided reduction | Resistive | 25 °C | — | — | ~20–97% | 3 s/~1 min | — | [148] |

| rGO | Exfoliation at liquid/air interface | Resistive | R.T. | ~6% | — | 4.3–75.7% | 4 s/10 s | — | [149] |

| GQDs | Hydrothermal | Resistive | 24 °C | ~390 | High (CO, H2, CH4, CO2) | 1–100% | 12 s/43 s | — | [151] |

| GQDs | Pyrolysis of citric acid | Resistive | R.T. | — | — | 15–80% | ~5 s | — | [152] |

| Material | Preparation Method | Type | Operating Temperature | Sensitivity/Response | Selectivity | Humidity Range | Response/Recovery Time | Stability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Graphene/methyl red | Electro-hydrodynamic | Resistive Capacitive | R.T. | 96.36% (R) 2,869,500% (C) | — | 5–95% | 0.251 s/0.35 s | — | [161] |

| HFBI-rGO | Drop casting | Resistive | R.T. | 2.24/RH | Medium (Ethanol, acetone, hexane) | 2–50% | 130 s/200 s | — | [162] |

| Pyranine-rGO | Supramolecular assembly | Impedance | 25 °C | 6000 | — | 11–95% | <2 s/<6 s | 100 cycles | [163] |

| PEI-GO | Solution casting | Impedance | 30 °C | — | — | 40–90% | — | — | [156] |

| Diamine-GO | Brush coating | Impedance | 15–35 °C | 0.0545 log Z/% RH | — | 20–90% | 52 s/72 s | 54 days | [157] |

| GO-NH2 | Drop casting | Conductance | 25 °C | 870 ± 90 | — | 5–95% | — | — | [158] |

| Ag-NA-rGO | Drop casting | Impedance | 25 °C | 600 | — | 11–95% | 1 s/1 s | 110 days | [159] |

| Material | Preparation Method | Type | Operating Temperature | Sensitivity/Response | Selectivity | Humidity Range | Response/Recovery Time | Stability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| m-r(CNC/GO) | Layer-by-layer spraying | Resistive | 25 °C | ~55 | — | 20–100% | ~10 s/~5 s | — | [166] |

| CNC/GO | Pour drying | Capacitive | 25–45 °C | 547 | — | 25–90% | — | — | [167] |

| PVA/NFC/rGO | Pour drying | Resistive | R.T. | 0.347/%RH | — | 30–98% | <2 min | — | [168] |

| rGO/cellulose | Pour casting | Resistive | 23 °C | ~40% | — | 35–90% | — | — | [169] |

| rGO/LS | Vacuum filtration | Resistive | 25 °C | 298% | — | 22–97% | 100 s/100 s | 30 days | [170] |

| PDA/rGO | Drop casting | Resistive | 25 °C | 20,000 | — | 0–97% | 20 ms/17 ms | 60 days | [176] |

| PDA/PVA/rGO | Pour drying | Resistive | 30 °C | — | — | 40–100% | — | — | [175] |

| PDDA/rGO PSSNa/rGO | Dip coating | Impedance | 22–25 °C | 1000% (0.2–30%) 300% (0.2–30%) | — | 0.2–90% | 16 s/24 s 38 s/70 s | — | [171] |

| QC-P4VP/rGO | Dip-coating | Impedance | 20–40 °C | 500% (0.18–2.1%) | — | 0.18–98% | 21 s/78 s | — | [172] |

| PDDA/rGO | Layer-by-layer self-assembly | Resistive | 25 °C | 8.69–37.43% | — | 11–97% | 108–147 s/ 94–133 s | 60 days | [173] |

| PDDA/GO | Layer-by-layer self-assembly | Capacitive | 25 °C | 1552.3 pF/% RH | — | 11–97% | 1 s/1 s | 60 days | [174] |

| rGO/PVP | Spin coating | Resistive | R.T. | — | — | 30–90% | 3 s/3 s | — | [177] |

| Graphene/PVP | Ink-jet printing | Resistive | R.T. | 0.3–0.21%/%RH | — | 10–80% | 6–16 s/ 60–300 s | 28 days | [178] |

| rGO/PVP | Spary coating | Resistive | 20–60 °C | ~7 | High (HCHO, H2S, NH3, acetone, H2) | 7.0–97.3% | 2.8s/3.5s | 28 days | [179] |

| PVDF/graphene | Electro-spinning | Capacitive | 25 °C | 0.0463pF/% RH | — | 40–90% | ~1000 s/21.3 s | — | [180] |

| Graphene/PPy | Dip coating | Impedance | R.T. | 138 | — | 12–90% | 15 s/20 s | — | [181] |

| rGO/PU | Spin coating | Resistive | R.T. | — | — | 10–70% | 3.5 s/7 s | — | [182] |

| MGO/Nafion | Drop casting | Impedance | R.T. | — | — | 11–97% | 100–300 s/ 100–300 s | 2 months | [183] |

| GO/C60 | Drop casting | Capacitive | R.T. | 2770% | — | 11–97% | 8 s/7 s | 21 days | [184] |

| GO/MWCNT | Drop casting | Capacitive | 25 °C | 7980 pF/% RH | — | 11–97% | 5 s/2.5 s | — | [185] |

| Material | Preparation Method | Type | Operating Temperature | Sensitivity/Response | Selectivity | Humidity Range | Response/Recovery Time | Stability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Graphene/SnOx/CF | Electro-spinning | Resistive | 20.5 °C | 6.22 | — | 30–80% | 8 s/6 s | — | [186] |

| SnO2@G-GO | Electro-spinning | Impedance | 20 °C | 32 MΩ/% RH | — | 30–90% | 1 s/1 s | 3 cycles | [187] |

| SnO2/rGO | Hydrothermal | Resistive | R.T. | 15.19–45.02% | — | 11–97% | <100 s/<100 s | 60 days | [188] |

| SnO2/rGO | Hydrothermal | Capacitive | 25 °C | 1604.89 pF/%RH | — | 11–97% | 6–102 s/6–9 s | — | [77] |

| rGO/Fe:SnO2 | Electrostatic interaction | Resistive | R.T. | 3.23 | — | 0–100% | — | — | [189] |

| CuO/rGO | Hydrothermal | Impedance | 25 °C | 22,700 | — | 11–98% | 2 s/17 s | — | [190] |

| Graphene/TiO2 | Sol–gel | Impedance | 25 °C | 151 | High (NH3, NO2, NO, CO) | 12–90% | 128 s/68 s | — | [191] |

| ZnO/GO | Layer-by-layer self-assembly | Capacitive | R.T. | 17785.6 pF/%RH | — | 0–97% | ~50 s/~20 s | 30 days | [192] |

| Graphene/ZnO | Spin coating | Impedance | R.T. | — | — | 0–85% | 1 s/2 s | — | [193] |

| TiO2/GO | Drop casting | Resistive | R.T. | > 106 | High (H2, CO, CH4, NO2) | 9–90% | ~70 s | 2 months | [194] |

| rGO–Ag scroll | Molecular combing | Resistive | R.T. | 908–1243 | — | 11–97% | 50 s/13 s | 30 days | [195] |

| Au/GO/silica | Sol-gel | Impedance | 15–35 °C | −0.0281 log Z/%RH | — | 20–90% | 119 s/125 s | 15 days | [196] |

| Cu-embeded rGO fiber | Wet spinning | Resistive | 20 °C | 0.94 | — | 34–75% | — | — | [197] |

| rGO/MoS2 | Mixing and drop casting | Resistive | 27 °C | 2494.25% | High (H2, CH3COCH3, NO2, NH3) | 5–85% | 6.3 s/30.8 s | 20 months | [199] |

| MoS2/GO | Mixing and drop casting | Resistive | R.T. | 1600 | — | 25–85% | 43 s/37 s | 90 days | [198] |

| rGO/MoS2 | Hydrothermal | Resistive | R.T. | ~25% | High (NO2, NH3, H2, C2H5OH) | 10–90% | 30 s/253 s | — | [200] |

| WS2/GO | Mixing and drop casting | Resistive | 25 °C | 590 0.044/%RH | — | 40–80% | 25 s/29 s | 28 days | [201] |

| Black P/ graphene | CVD-G electrospray BP | Resistive | R.T. | 43.4% | — | 15–70% | 9 s/30 s | 2 weeks | [202] |

| Material | Type | Response | Selectivity | Humidity Range | Limit of Detection | Response Time | Recovery Time | Stability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| GO | Impedance | ~102 (1) | — | 10–90% | 10% (2) | ~30 ms | ~30 ms | 72h | [74] |

| Ultralarge GO | Conductance | 4339 ± 433 | — | 7–100% | 7% (2) | 0.2 s | 0.7 s | 5 days | [121] |

| rGO/GO/rGO | Voltage | 142.5 | High (H2, hexane, ethanol) | 6.3–100% | 6.3% (2) | 1.9 s | 3.9 s | > 1 year | [131] |

| rGO | Impedance | ~103 (1) | — | 11–95% | 11% (2) | 1 s | 24 s | 30 days | [142] |

| Graphene/methyl red | Resistive Capacitive | 96.36% (R) 2869500% (C) | — | 5–95% | 5% (2) | 0.251 s | 0.35 s | — | [161] |

| PDA/rGO | Resistive | 20000 | — | 0–97% | 10% (1) | 20 ms | 17 ms | 60 days | [176] |

| rGO/MoS2 | Resistive | 2494.25% | High (H2, CH3COCH3, NO2, NH3) | 5–85% | 5% (2) | 6.3 s | 30.8 s | 20 months | [199] |

| PDDA/rGO PSSNa/rGO | Impedance | 1000% (0.2–30%) 300% (0.2–30%) | — | 0.2–90% | 0.2% | 16 s 38 s | 24 s 70 s | — | [171] |

| QC-P4VP/rGO | Impedance | 500% (0.18–2.1%) | — | 0.18–98% | 0.18% | 21 s | 78 s | — | [172] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, C.; Hu, C.; Luo, J.; Liu, S.; Qiao, Y.; Zhang, Z.; Song, J.; Shi, Y.; Cai, J.; Watanabe, A. Recent Advances in Graphene-Based Humidity Sensors. Nanomaterials 2019, 9, 422. https://doi.org/10.3390/nano9030422

Lv C, Hu C, Luo J, Liu S, Qiao Y, Zhang Z, Song J, Shi Y, Cai J, Watanabe A. Recent Advances in Graphene-Based Humidity Sensors. Nanomaterials. 2019; 9(3):422. https://doi.org/10.3390/nano9030422

Chicago/Turabian StyleLv, Chao, Cun Hu, Junhong Luo, Shuai Liu, Yan Qiao, Zhi Zhang, Jiangfeng Song, Yan Shi, Jinguang Cai, and Akira Watanabe. 2019. "Recent Advances in Graphene-Based Humidity Sensors" Nanomaterials 9, no. 3: 422. https://doi.org/10.3390/nano9030422