Antibacterial Silicon Oxide Thin Films Doped with Zinc and Copper Grown by Atmospheric Pressure Plasma Chemical Vapor Deposition

Abstract

:1. Introduction

2. Materials and Methods

3. Results

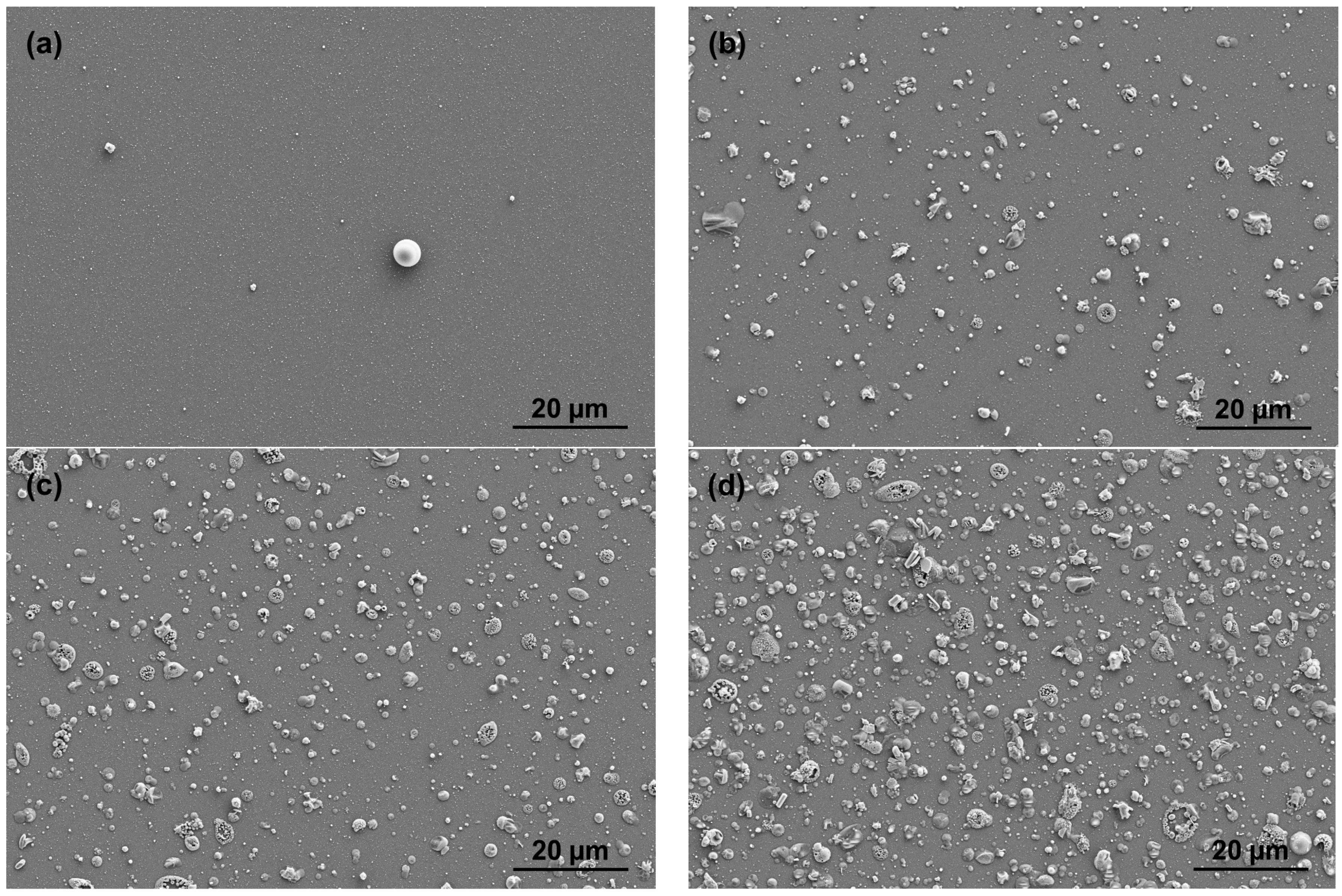

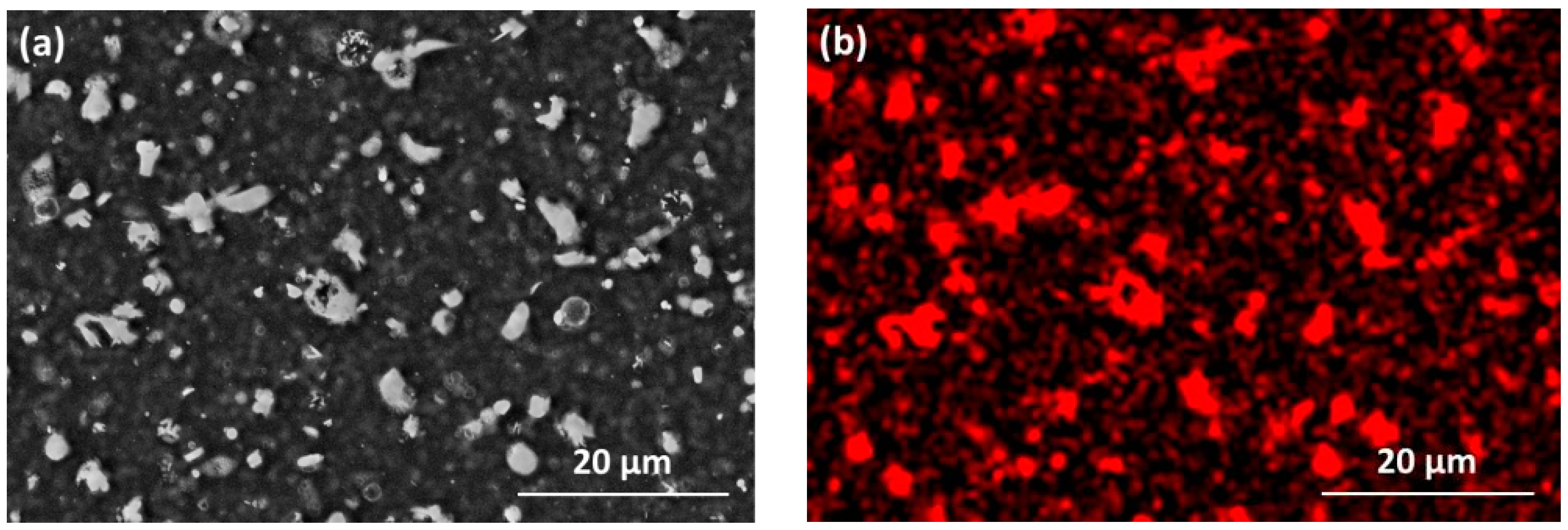

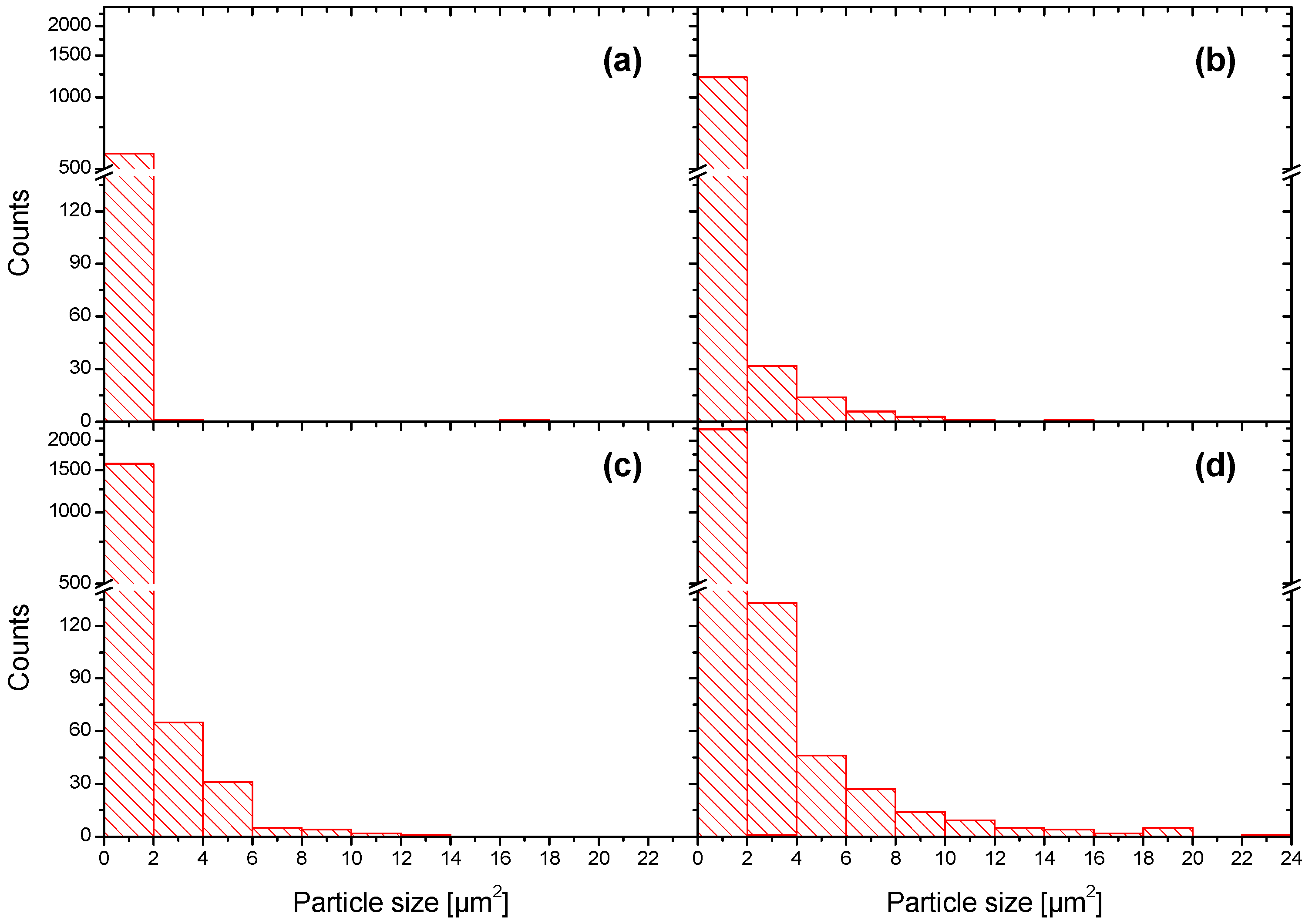

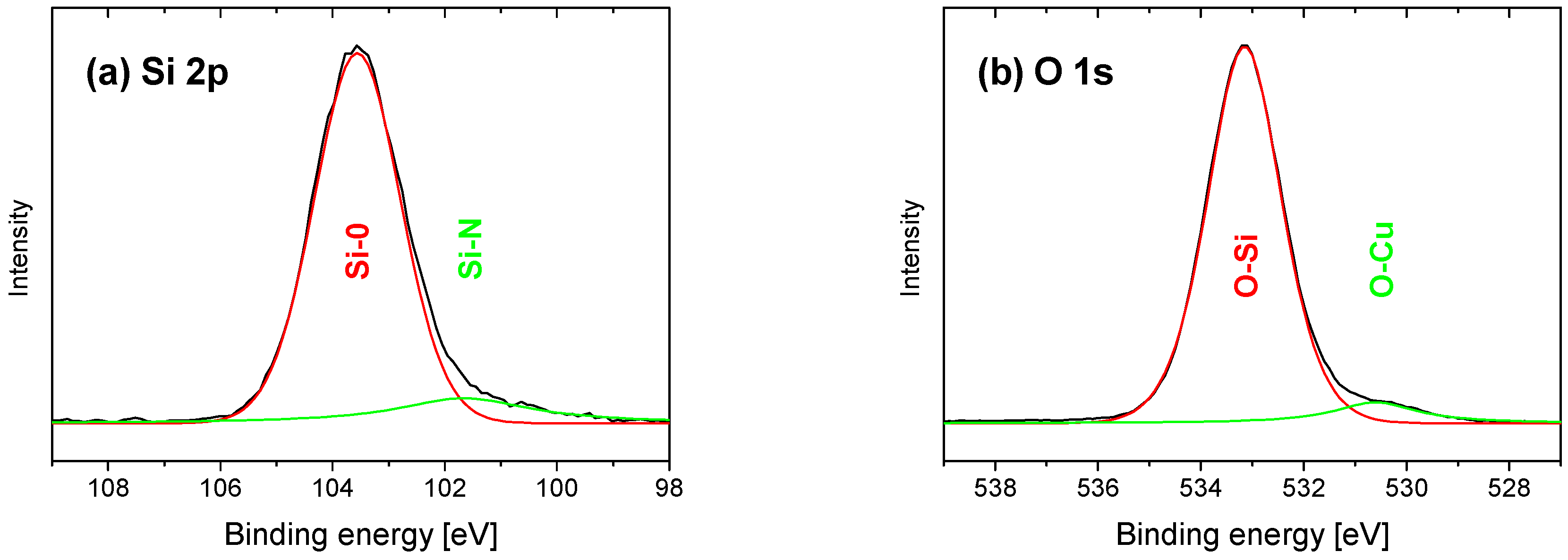

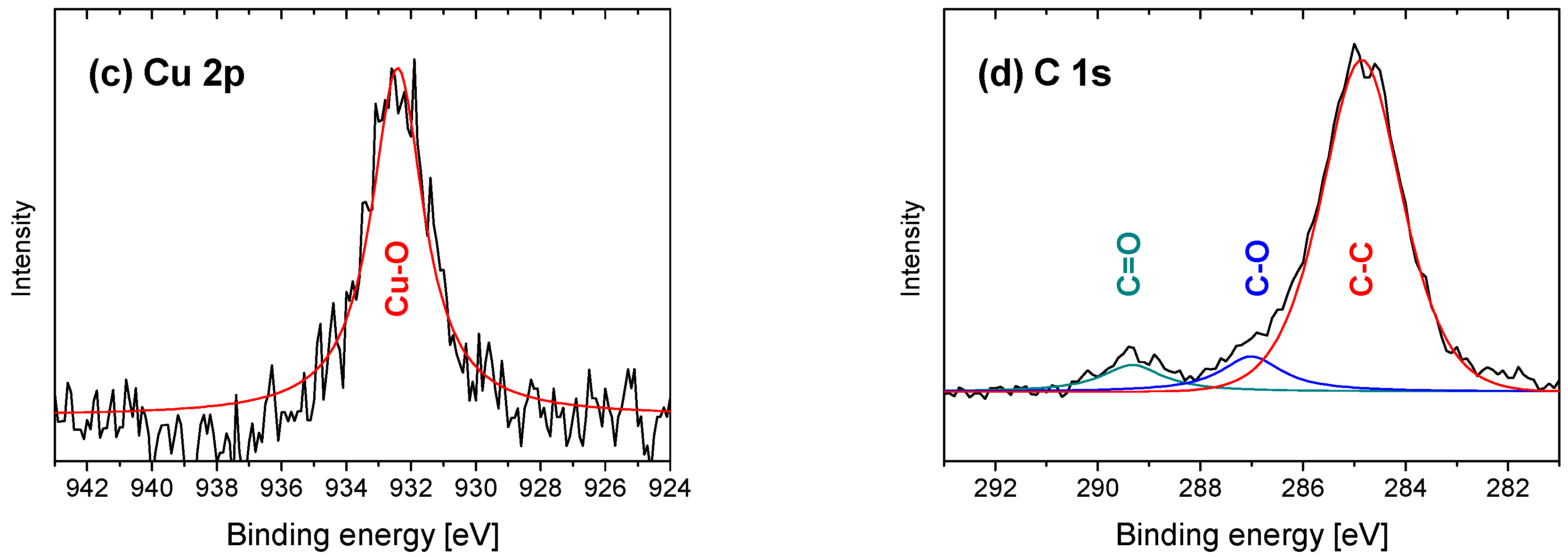

3.1. Film Morphology and Chemical Composition

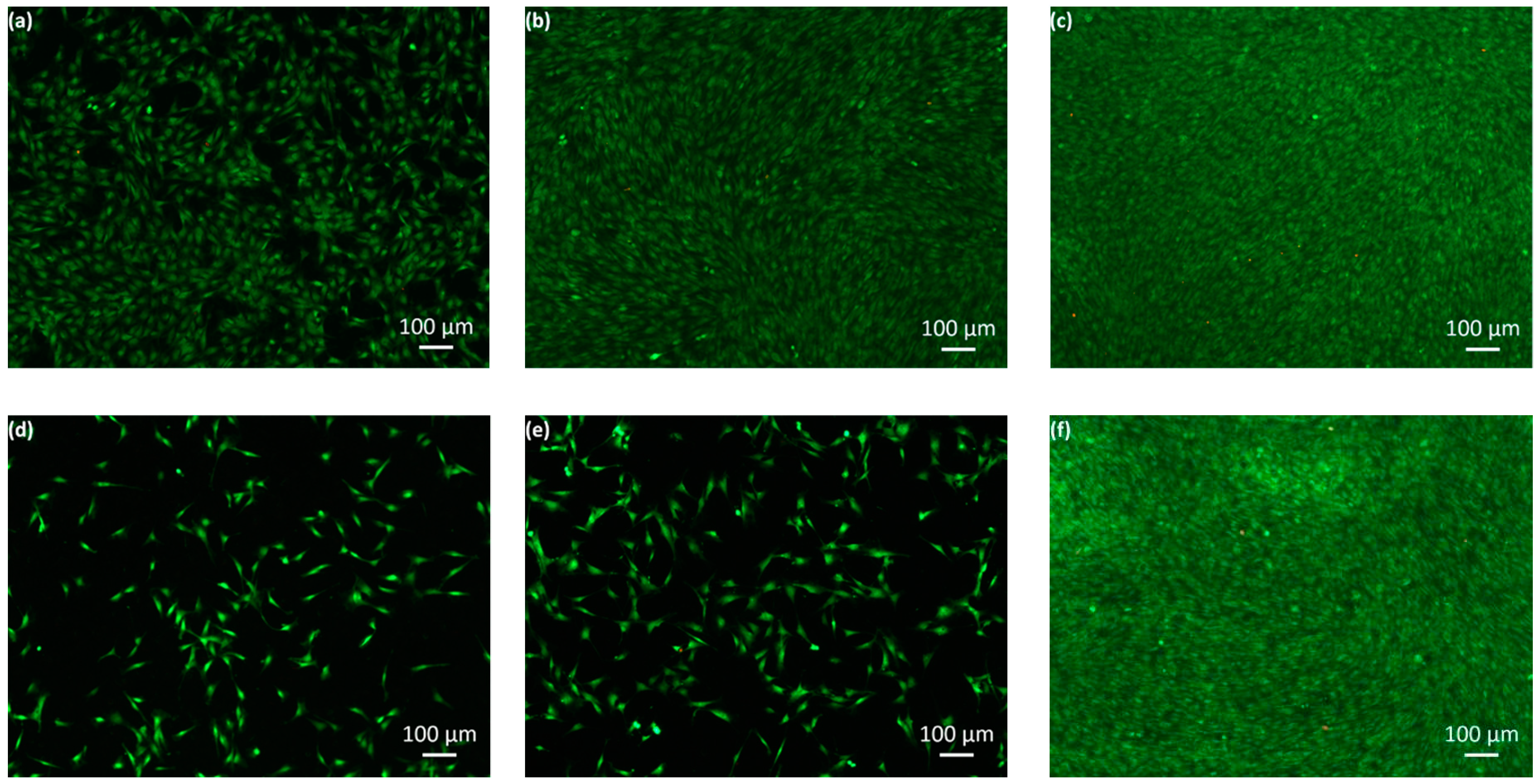

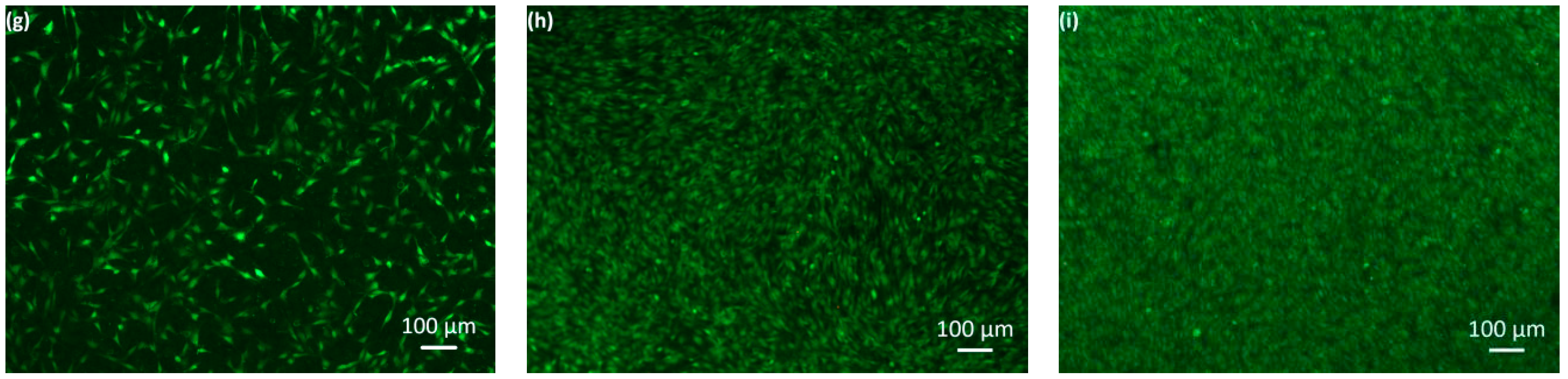

3.2. Cytotoxic Effect

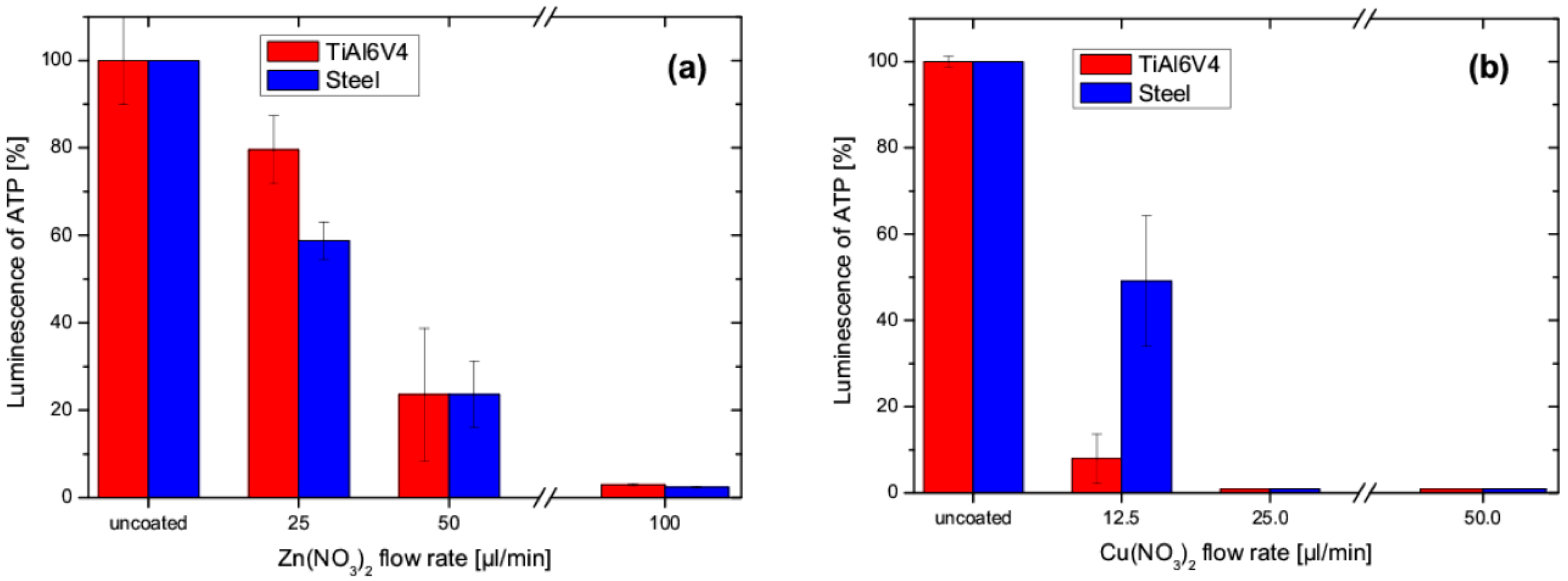

3.3. Antibacterial Activity

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Diegelmann, R.F.; Evans, M.C. Wound healing: An overview of acute, fibrotic and delayed healing. Front. Biosci. 2004, 9, 283–289. [Google Scholar] [CrossRef] [PubMed]

- Klevens, R.M.; Edwards, J.R.; Richards, C.L.; Horan, T.C.; Gaynes, R.P.; Pollock, D.A.; Cardo, D.M. Estimating health care-associated infections and deaths in U.S. hospitals, 2002. Public Health Rep. 2007, 122, 160–166. [Google Scholar] [CrossRef] [PubMed]

- Cloutier, M.; Mantovani, D.; Rosei, F. Antibacterial coatings: Challenges, perspectives, and opportunities. Trends Biotechnol. 2015, 33, 637–653. [Google Scholar] [CrossRef]

- Heidenau, F.; Mittelmeier, W.; Detsch, R.; Haenle, M.; Stenzel, F.; Ziegler, G.; Gollwitzer, H. A novel antibacterial titania coating: Metal ion toxicity and in vitro surface colonization. J. Mater. Sci. Mater. Med. 2005, 16, 883–888. [Google Scholar] [CrossRef] [PubMed]

- Velasco, S.C.; Cavaleiro, A.; Carvalho, S. Functional properties of ceramic-Ag nanocomposite coatings produced by magnetron sputtering. Prog. Mater. Sci. 2016, 84, 158–191. [Google Scholar] [CrossRef] [Green Version]

- Zimmermann, R.; Pfuch, A.; Horn, K.; Weisser, J.; Heft, A.; Röder, M.; Linke, R.; Schnabelrauch, M.; Schimanski, A. An approach to create silver containing antibacterial coatings by use of atmospheric pressure plasma chemical vapour deposition (APCVD) and combustion chemical vapour deposition (CCVD) in an economic way. Plasma Process. Polym. 2011, 8, 295–304. [Google Scholar] [CrossRef]

- Stranak, V.; Wulff, H.; Rebl, H.; Zietz, C.; Arndt, K.; Bogdanowicz, R.; Nebe, B.; Bader, R.; Podbielski, A.; Hubicka, Z.; et al. Deposition of thin titanium–copper films with antimicrobial effect by advanced magnetron sputtering methods. Mater. Sci. Eng. C 2011, 31, 1512–1519. [Google Scholar] [CrossRef]

- Ewald, A.; Glückermann, S.K.; Thull, R.; Gbureck, U. Antimicrobial titanium/silver PVD coatings on titanium. Biomed. Eng. Online 2006, 5, 22. [Google Scholar] [CrossRef] [PubMed]

- Silva-Ichante, M.; Reyes-Vidal, Y.; Bácama-Valenzuela, F.J.; Ballesteros, J.C.; Arciga, E.; Ţălu, Ş.; Méndez-Albores, A.; Trejo, G. Electrodeposition of antibacterial Zn-Cu/silver nanoparticle (AgNP) composite coatings from an alkaline solution containing glycine and AgNPs. J. Electroanal. Chem. 2018, 823, 328–334. [Google Scholar] [CrossRef]

- Shu, Z.; Zhang, Y.; Huaming, Y. Halloysite nanotubes supported Ag and ZnO nanoparticles with syntergistically enhanced antibacterial activity. Nanoscale Res. Lett. 2017, 12, 135. [Google Scholar] [CrossRef] [PubMed]

- Costa, S.M.; Ferreira, D.P.; Ferreira, A.; Vaz, F.; Fangueiro, R. Multifunctional flax fibres based on the combined effect of silver and zinc oxide (Ag/ZnO) nanostructures. Nanomaterials 2018, 8, 1069. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.-H.; Gao, Q.-L.; Qi, C.; Ma, M.-G.; Li, J.-F. Microwave-hydrothermal rapid synthesis of cellulose/Ag nanocomposites and their antibacterial activity. Nanomaterials 2018, 8, 978. [Google Scholar] [CrossRef] [PubMed]

- Diez-Pascual, A.M. Antibacterial activity of nanomaterials. Nanomaterials 2018, 8, 359. [Google Scholar] [CrossRef] [PubMed]

- Gassner, M.; Rebelo de Figueiredo, M.; Schalk, N.; Franz, R.; Weiß, C.; Rudigier, H.; Holzschuh, H.; Bürgin, W.; Pohler, M.; Czettl, C.; et al. Energy consumption and material fluxes in hard coating deposition processes. Surf. Coat. Technol. 2016, 299, 49–55. [Google Scholar] [CrossRef]

- Burduşel, A.-C.; Gherasim, O.; Grumuzescu, A.M.; Mogoantă, L.; Ficau, A.; Andonescu, E. Biomedical applications of silver nanoparticles: An up-to-date overview. Nanomaterials 2018, 8, 681. [Google Scholar] [CrossRef]

- Marimbio-Jones, C.; Hoek, E.M.V. A review of the antibacterial effects of silver nanomaterials and potential implications for human health and the environment. J. Nanoparticle Res. 2010, 12, 1531–1551. [Google Scholar] [CrossRef]

- Beier, O.; Pfuch, A.; Horn, K.; Weisser, J.; Schnabelrauch, M.; Schimanski, A. Low temperature deposition of antibacterially active silicon oxide layers containing silver nanoparticles, prepared by atmospheric pressure plasma chemical vapor deposition. Plasma Process. Polym. 2013, 10, 77–87. [Google Scholar] [CrossRef]

- Pfuch, A.; Horn, K.; Mix, R.; Ramm, M.; Heft, A.; Schimanski, A. Direct and remote plasma assisted CVD at atmospheric pressure for the preparation of oxide thin films. Galvanotechnik 2012, 103, 814–824. [Google Scholar]

- Abràmoff, M.D.; Magalhāes, P.J.; Ram, S.J. Image processing with ImageJ. Biophoton. Int. 2004, 11, 36–41. [Google Scholar]

- Wagner, C.D.; Riggs, W.M.; Davis, L.E.; Moulder, J.F.; Muilenberg, G.E. Handbook of X-ray Photoelectron Spectroscopy; Physical Electronics Division, Perkin Elmer Corporation: Eden Prairie, Minnesota, MN, USA, 1979. [Google Scholar]

- Al-Ghaashani, R.; Radiman, S.; Daud, A.R.; Tabet, N.; Al-Douri, Y. XPS and optical studies of different morphologies of ZnO nanostructures prepared by microwave methods. Ceram. Int. 2013, 39, 2283–2292. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Kusumoto, K.; Li, C.-J. XPS analysis of SiC films prepared by radio frequency plasma sputtering. Phys. Proc. 2012, 32, 95–102. [Google Scholar] [CrossRef]

- Barreca, D.; Gasparotto, A.; Tondello, E. CVD Cu2O and CuO nanosystems characterized by XPS. Surf. Sci. Spectra 2007, 14, 41–51. [Google Scholar] [CrossRef]

- Maroie, S.; Haemers, G.; Verbist, J.J. Surface oxidation of polycrystalline α(75%Cu/25%Zn) and β(53%Cu/47%Zn) brass as studied by XPS: Influence of oxygen pressure. Appl. Surf. Sci. 1984, 17, 463–467. [Google Scholar] [CrossRef]

- Grass, G.; Rensing, C.; Solioz, M. Metallic copper as an antimicrobial surface. Appl. Environ. Microb. 2011, 77, 1541–1547. [Google Scholar] [CrossRef]

- Sheng, J.; Nguyen, P.T.M.; Marquis, R.E. Multi-target antimicrobial actions of zinc against oral anaerobes. Arch. Oral Biol. 2005, 50, 747–757. [Google Scholar] [CrossRef] [PubMed]

- Sawai, J. Quantitative evaluation of antibacterial activities of metallic oxide powders (ZnO, MgO and CaO) by conductimetric assay. J. Microbiol. Meth. 2003, 54, 177–182. [Google Scholar] [CrossRef]

- Khalilpour, P.; Lampe, K.; Wagener, M.; Stigler, B.; Heiss, C.; Ulrich, M.S.; Domann, E.; Schnettler, R.; Alt, V. Ag/SiOxCy plasma polymer coating for antimicrobial protection of fracture fixation devices. J. Biomed. Mater. Res. B 2010, 94, 196–202. [Google Scholar] [CrossRef]

- Malachová, K.; Praus, P.; Rybuková, Z.; Kozák, O. Antibacterial and antifungal activities of silver, copper and zinc montmorrillinites. Appl. Clay Sci. 2011, 53, 642–645. [Google Scholar] [CrossRef]

- Karlsson, H.L.; Toprak, M.S.; Fadeel, B. Toxicity of metal and metal oxide nanoparticles. In Handbook on the Toxicology of Metals, 4th ed.; Nordberg, G.F., Fowler, B.A., Nordberg, M., Eds.; Elsevier/Academic Press: London, UK, 2015; pp. 75–112. [Google Scholar]

- Airey, P.; Verran, J. Potential use of copper as a hygienic surface; problems associated with cumulative soiling and cleaning. J. Hosp. Infect. 2007, 67, 271–277. [Google Scholar] [CrossRef]

- Wheeldon, L.J.; Worthington, T.; Lambert, P.A.; Hilton, A.C.; Lowden, C.J.; Elliott, T.S.J. Antimicrobial efficacy of copper surfaces against spores and vegetative cells of Clostridium difficile: The germination theory. J. Antimicrob. Chemoth. 2008, 62, 522–525. [Google Scholar] [CrossRef]

| Secondary Precursor | Zn(NO3)2 | Cu(NO3)2 |

|---|---|---|

| Concentration [wt.%] | 5 | 2.5 |

| Isopropanol:water volume ratio | 1:1 | 1:1 |

| Flow rate [µL/min] | 25; 50; 100 | 12.5; 25; 50 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jäger, E.; Schmidt, J.; Pfuch, A.; Spange, S.; Beier, O.; Jäger, N.; Jantschner, O.; Daniel, R.; Mitterer, C. Antibacterial Silicon Oxide Thin Films Doped with Zinc and Copper Grown by Atmospheric Pressure Plasma Chemical Vapor Deposition. Nanomaterials 2019, 9, 255. https://doi.org/10.3390/nano9020255

Jäger E, Schmidt J, Pfuch A, Spange S, Beier O, Jäger N, Jantschner O, Daniel R, Mitterer C. Antibacterial Silicon Oxide Thin Films Doped with Zinc and Copper Grown by Atmospheric Pressure Plasma Chemical Vapor Deposition. Nanomaterials. 2019; 9(2):255. https://doi.org/10.3390/nano9020255

Chicago/Turabian StyleJäger, Elisabeth, Jürgen Schmidt, Andreas Pfuch, Sebastian Spange, Oliver Beier, Nikolaus Jäger, Oliver Jantschner, Rostislav Daniel, and Christian Mitterer. 2019. "Antibacterial Silicon Oxide Thin Films Doped with Zinc and Copper Grown by Atmospheric Pressure Plasma Chemical Vapor Deposition" Nanomaterials 9, no. 2: 255. https://doi.org/10.3390/nano9020255