Feasible Route for a Large Area Few-Layer MoS2 with Magnetron Sputtering

Abstract

:1. Introduction

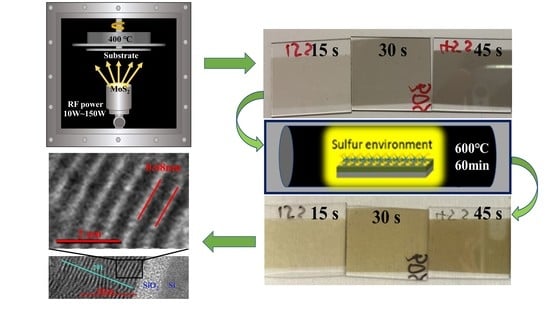

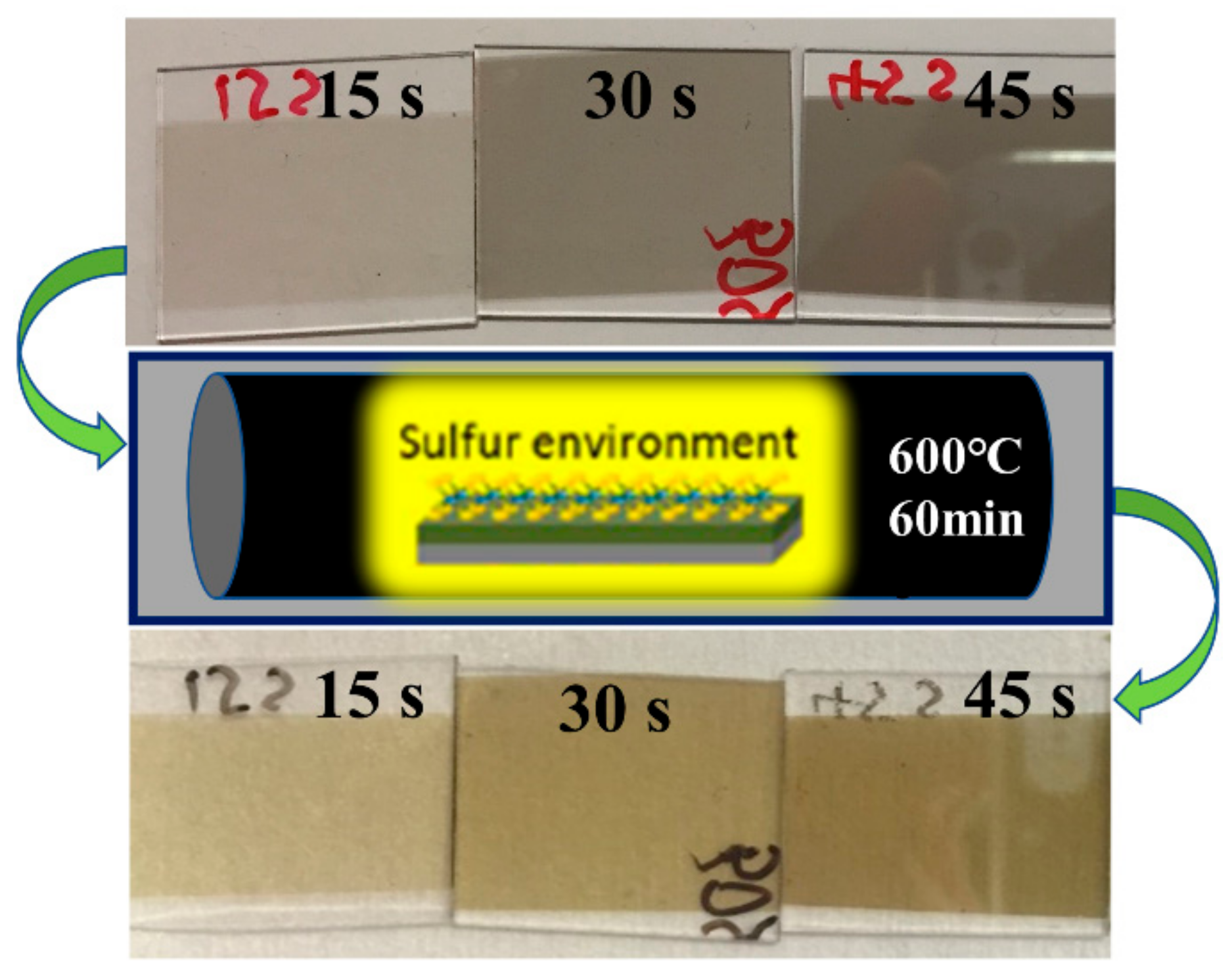

2. Materials and Methods

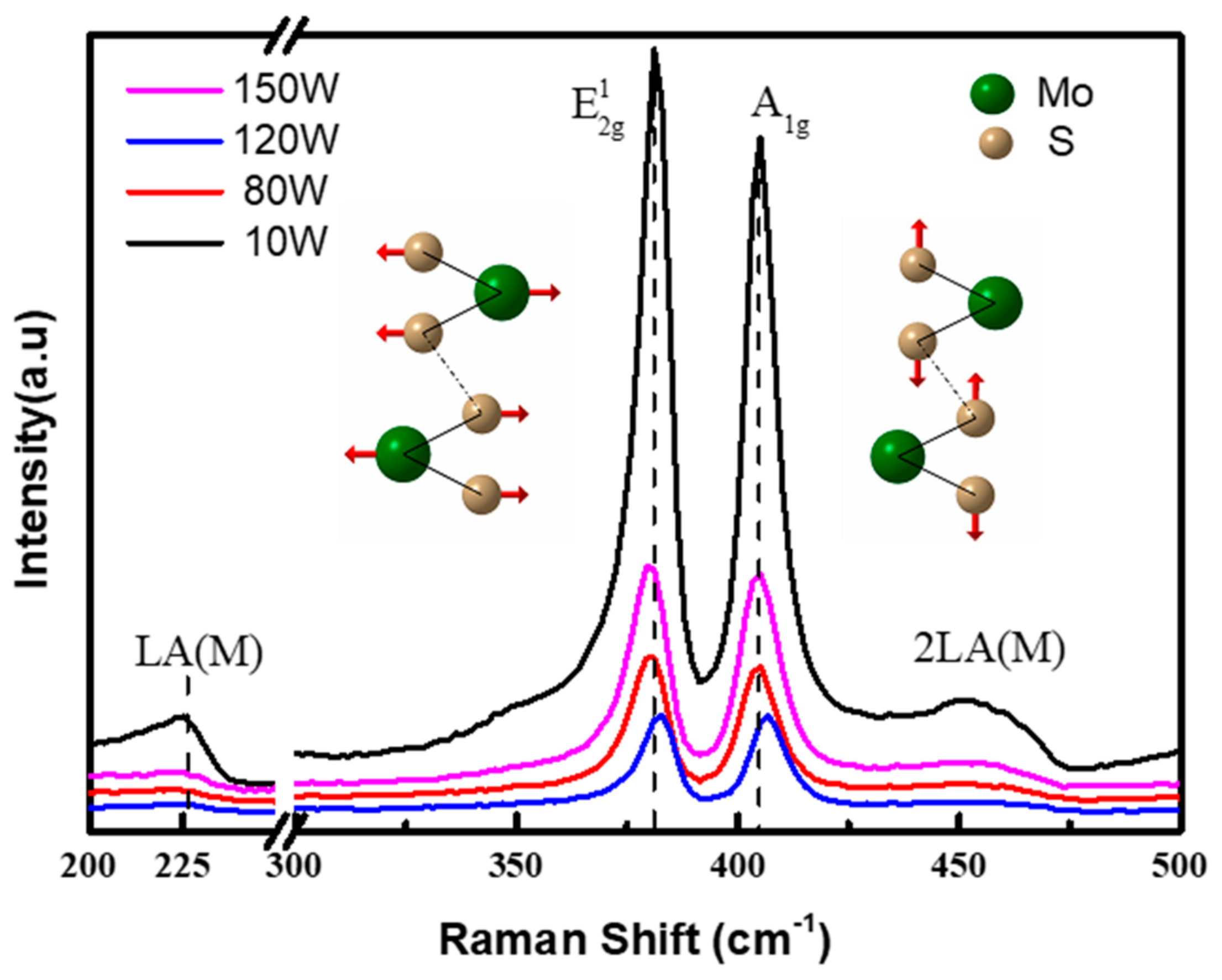

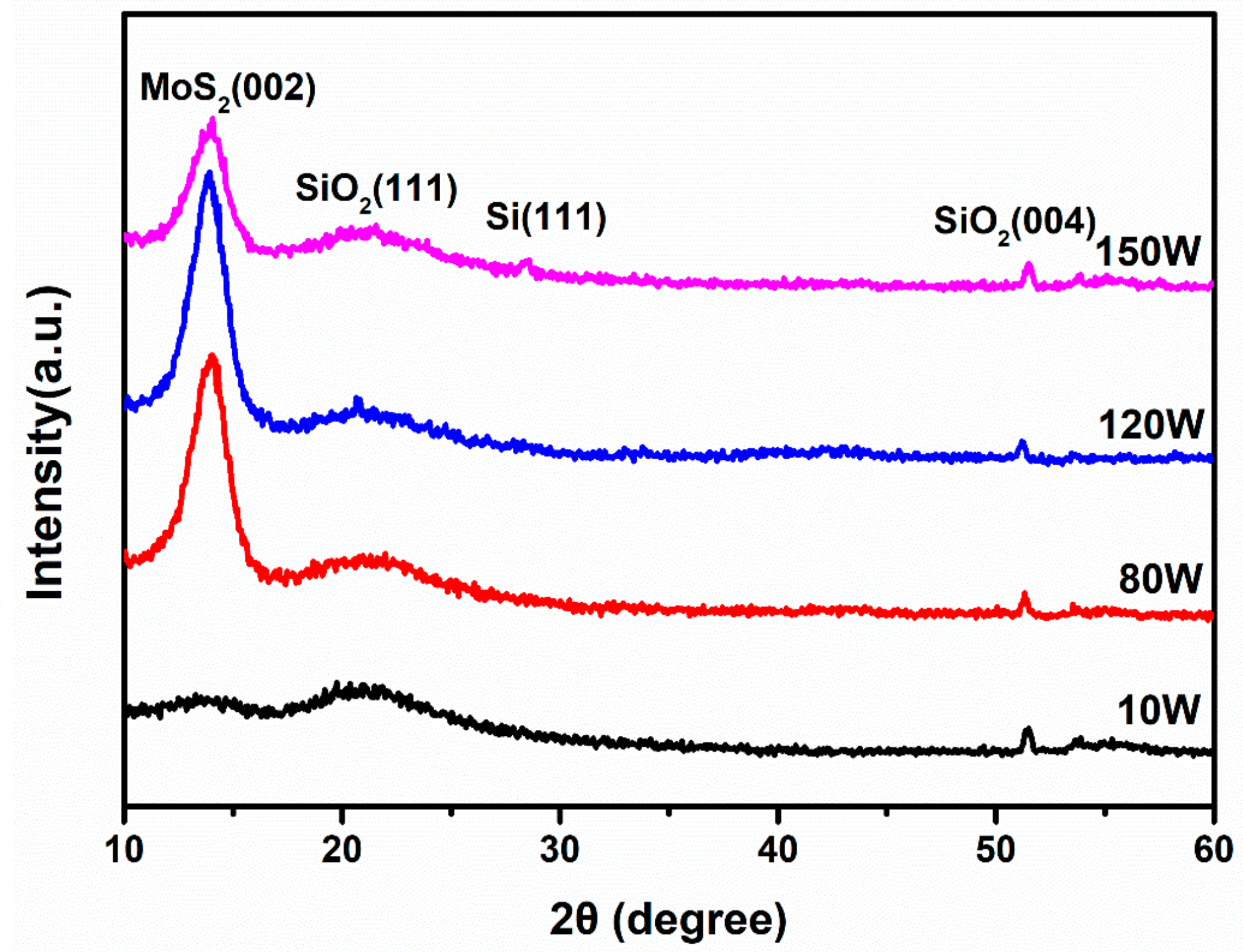

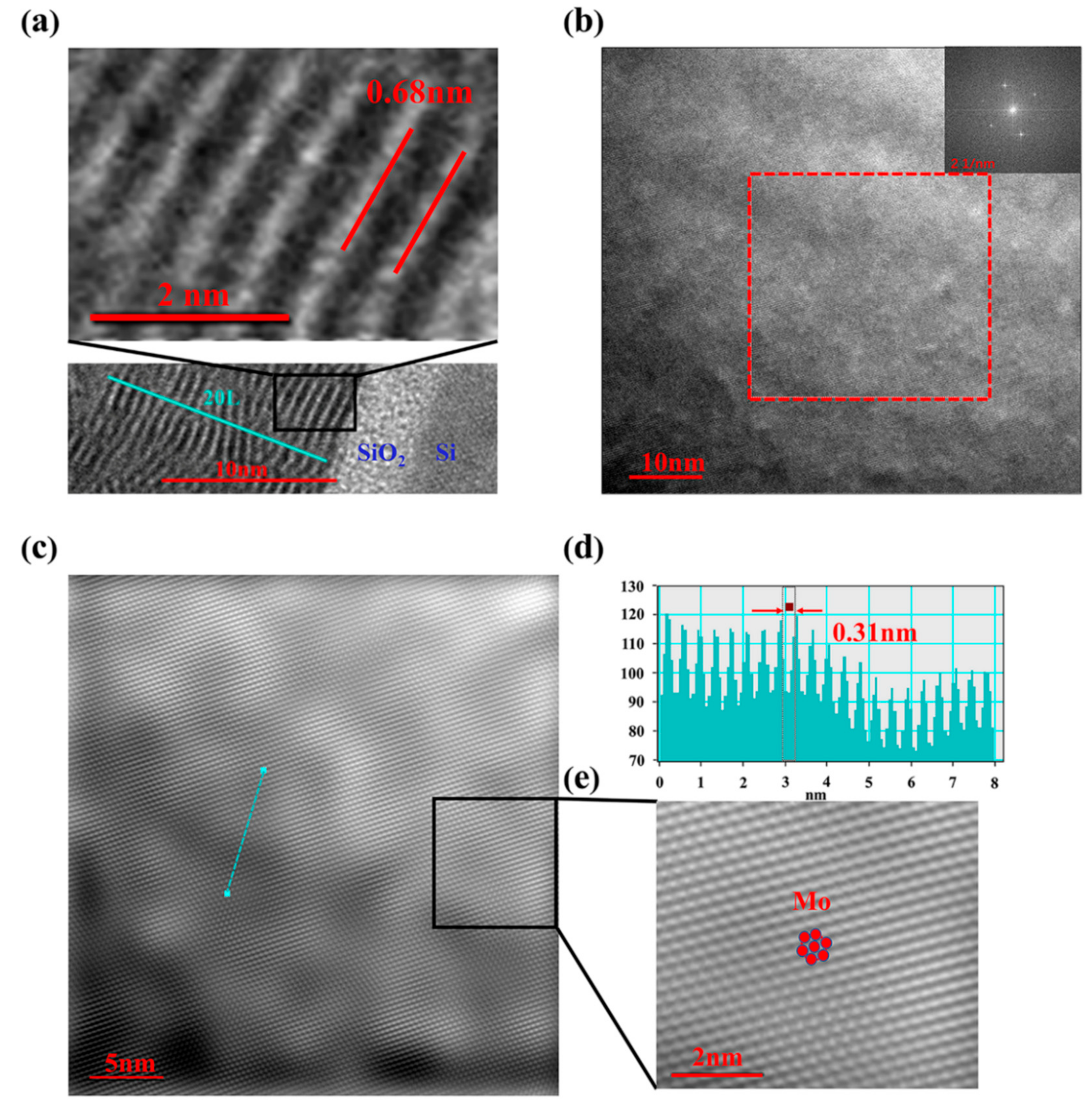

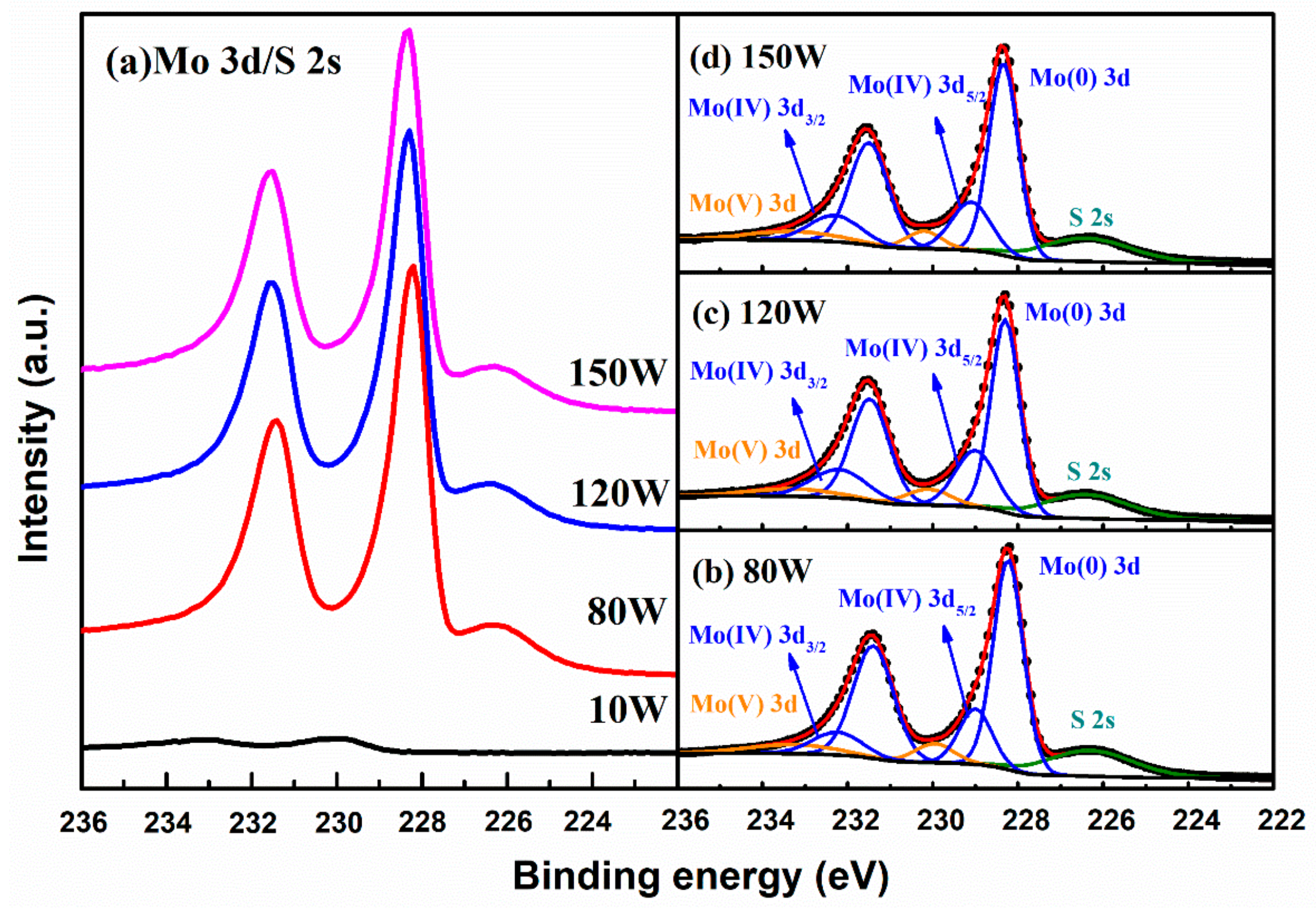

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K.; Castro Neto, A.H. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [Green Version]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Miró, P.; Audiffred, M.; Heine, T. An atlas of two-dimensional materials. Chem. Soc. Rev. 2014, 43, 6537–6554. [Google Scholar] [CrossRef] [PubMed]

- Kuc, A. Low-dimensional transition-metal dichalcogenides. In Chemical Modelling; Royal Society of Chemistry: London, UK, 2014; Volume 11, pp. 1–29. [Google Scholar]

- Fiori, G.; Bonaccorso, F.; Iannaccone, G.; Palacios, T.; Neumaier, D.; Seabaugh, A.; Banerjee, S.K.; Colombo, L. Electronics based on two-dimensional materials. Nat. Nanotechnol. 2014, 9, 768–779. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, K.; Xie, S.; Huang, L.; Han, Y.; Huang, P.Y.; Mak, K.F.; Kim, C.J.; Muller, D.; Park, J. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 2015, 520, 656–660. [Google Scholar] [CrossRef] [PubMed]

- Zeng, H.; Dai, J.; Yao, W.; Xiao, D.; Cui, X. Valley polarization in MoS2 monolayers by optical pumping. Nat. Nanotechnol. 2012, 7, 490–493. [Google Scholar] [CrossRef] [PubMed]

- Mak, K.F.; He, K.; Shan, J.; Heinz, T.F. Control of valley polarization in monolayer MoS2 by optical helicity. Nat. Nanotechnol. 2012, 7, 494–498. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Jiang, D.; Schedin, F.; Booth, T.J.; Khotkevich, V.V.; Morozov, S.V.; Geim, A.K. Two-dimensional atomic crystals. Proc. Natl. Acad. Sci. USA 2005, 102, 10451–10453. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically thin MoS2: A new direct-gap semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Mccreary, A.; Briggs, N.; Subramanian, S.; Zhang, K.; Sun, Y.; Li, X.; Borys, N.J.; Yuan, H.; Fullerton-Shirey, S.K.; et al. 2D materials advances: From large scale synthesis and controlled heterostructures to improved characterization techniques, defects and applications. 2D Mater. 2016, 3, 042001. [Google Scholar] [CrossRef]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Xu, C.Y.; Hu, P.A.; Zhen, L. Carrier Control of MoS2 Nanoflakes by Functional Self-Assembled Monolayers. ACS Nano 2013, 7, 7795–7804. [Google Scholar] [CrossRef] [PubMed]

- Sundaram, R.S.; Engel, M.; Lombardo, A.; Krupke, R.; Ferrari, A.C.; Avouris, P.; Steiner, M. Electroluminescence in single layer MoS2. Nano Lett. 2013, 13, 1416–1421. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Chen, H.Y.; Penumatcha, A.V.; Appenzeller, J. High performance multilayer MoS2 transistors with scandium contacts. Nano Lett. 2013, 13, 100–105. [Google Scholar] [CrossRef] [PubMed]

- Sik Hwang, W.; Remskar, M.; Yan, R.; Kosel, T.; Kyung Park, J.; Cho, B.J.; Haensch, W.; Grace Xing, H.; Seabaugh, A.; Jena, D. Comparative study of chemically synthesized and exfoliated multilayer MoS2 field-effect transistors. Appl. Phys. Lett. 2013, 102, 043116. [Google Scholar] [CrossRef]

- Elibol, K.; Susi, T.; M, O.B.; Bayer, B.C.; Pennycook, T.J.; Mcevoy, N.; Duesberg, G.S.; Meyer, J.C.; Kotakoski, J. Grain boundary-mediated nanopores in molybdenum disulfide grown by chemical vapor deposition. Nanoscale 2016, 9, 1591–1598. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.H.; Zhang, X.Q.; Zhang, W.; Chang, M.T.; Lin, C.T.; Chang, K.D.; Yu, Y.C.; Wang, J.T.; Chang, C.S.; Li, L.J.; et al. Synthesis of large-area MoS2 atomic layers with chemical vapor deposition. Adv. Mater. 2012, 24, 2320–2325. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Y.; Liu, Z.; Najmaei, S.; Ajayan, P.M.; Lou, J. Large Area Vapor Phase Growth and Characterization of MoS2 Atomic Layers on SiO2 Substrate. Small 2012, 8, 966–971. [Google Scholar] [CrossRef] [PubMed]

- Tao, J.; Chai, J.; Lu, X.; Wong, L.M.; Wong, T.I.; Pan, J.; Xiong, Q.; Chi, D.; Wang, S. Growth of wafer-scale MoS2 monolayer by magnetron sputtering. Nanoscale 2015, 7, 2497–2503. [Google Scholar] [CrossRef] [PubMed]

- Muratore, C.; Hu, J.J.; Wang, B.; Haque, M.A. Continuous ultra-thin MoS2 films grown by low-temperature physical vapor deposition. Appl. Phys. Lett. 2014, 104, 261604. [Google Scholar] [CrossRef]

- Kaindl, R.; Bayer, B.C.; Resel, R.; Muller, T.; Skakalova, V.; Habler, G.; Abart, R.; Cherevan, A.S.; Eder, D.; Blatter, M.; et al. Growth, structure and stability of sputter-deposited MoS2 thin films. Beilstein J. Nanotechnol. 2017, 8, 1115–1126. [Google Scholar] [CrossRef] [PubMed]

- Samassekou, H.; Alkabsh, A.; Wasala, M.; Eaton, M.; Walber, A.; Walker, A.; Pitkanen, O.; Kordas, K.; Talapatra, S.; Jayasekera, T.; et al. Viable route towards large-area 2D MoS2 using magnetron sputtering. 2D Mater. 2017, 4, 021002. [Google Scholar] [CrossRef]

- Santoni, A.; Rondino, F.; Malerba, C.; Valentini, M.; Mittiga, A. Electronic structure of Ar+ ion-sputtered thin-film MoS2: A XPS and IPES study. Appl. Surf. Sci. 2017, 392, 795–800. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Neves, B.R.A.; Medeiros-Ribeiro, G.; Enoki, T.; Kobayashi, Y.; Takai, K.; Fukui, K.; Dresselhaus, M.S.; Saito, R.; Jorio, A.; et al. Anisotropy of the Raman Spectra of Nanographite Ribbons. Phys. Rev. Lett. 2004, 93, 047403. [Google Scholar]

- Wilhelm, H.; Lelaurain, M.; Mcrae, E.; Humbert, B. Raman spectroscopic studies on well-defined carbonaceous materials of strong two-dimensional character. J. Appl. Phys. 1998, 84, 6552–6558. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1290. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, A.C.; Basko, D.M. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferrari, A.C. Raman spectroscopy of graphene and graphite: Disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Gupta, A.; Chen, G.; Joshi, P.; Tadigadapa, S.; Eklund, P.C. Raman Scattering from High-Frequency Phonons in Supported n-Graphene Layer Films. Nano Lett. 2006, 6, 2667–2673. [Google Scholar] [CrossRef] [PubMed]

- Graf, D.; Molitor, F.; Ensslin, K.; Stampfer, C.; Jungen, A.; Hierold, C.; Wirtz, L. Spatially resolved Raman spectroscopy of single- and few-layer graphene. Nano Lett. 2007, 7, 238–242. [Google Scholar] [CrossRef] [PubMed]

- Mignuzzi, S.; Pollard, A.J.; Bonini, N.; Brennan, B.; Gilmore, I.S.; Pimenta, M.A.; Richards, D.; Roy, D. Effect of disorder on Raman scattering of single-layer MoS2. Phys. Rev. B 2015, 91, 195411. [Google Scholar] [CrossRef]

- Liu, H.; Iskander, A.; Yakovlev, N.L.; Chi, D. Anomalous SiO2 layer formed on crystalline MoS2 films grown on Si by thermal vapor sulfurization of molybdenum at elevated temperatures. Mater. Lett. 2015, 160, 491–495. [Google Scholar] [CrossRef]

- Hussain, S.; Singh, J.; Vikraman, D.; Singh, A.K.; Iqbal, M.Z.; Khan, M.F.; Kumar, P.; Choi, D.C.; Song, W.; An, K.S.; et al. Large-area, continuous and high electrical performances of bilayer to few layers MoS2 fabricated by RF sputtering via post-deposition annealing method. Sci. Rep. 2016, 6, 30791. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.; Shehzad, M.A.; Vikraman, D.; Khan, M.F.; Singh, J.; Choi, D.; Seo, Y.; Eom, J.; Lee, W.; Jung, J. Synthesis and characterization of large-area and continuous MoS2 atomic layers by RF magnetron sputtering. Nanoscale 2016, 8, 4340–4347. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Zhang, Q.; Yap, C.; Tay, B.; Edwin, T.; Olivier, A.; Baillargeat, D. From Bulk to Monolayer MoS2: Evolution of Raman Scattering. Adv. Funct. Mater. 2012, 22, 1385–1390. [Google Scholar] [CrossRef]

- Liu, Y.J.; Hao, L.Z.; Gao, W.; Liu, Y.M.; Li, G.X.; Xue, Q.Z.; Guo, W.Y.; Yu, L.Q.; Wu, Z.P.; Liu, X.H.; et al. Growth and humidity-dependent electrical properties of bulk-like MoS2 thin films on Si. RSC Adv. 2015, 5, 74329–74335. [Google Scholar] [CrossRef]

- Ganatra, R.; Zhang, Q. Few-Layer MoS2: A Promising Layered Semiconductor. ACS Nano 2014, 8, 4074–4099. [Google Scholar] [CrossRef] [PubMed]

- Taylor, C.A.; Wayne, M.F.; Chiu, W.K.S. Residual stress measurement in thin carbon films by Raman spectroscopy and nanoindentation. Thin Solid Films 2003, 429, 190–200. [Google Scholar] [CrossRef]

- Piazza, A.; Giannazzo, F.; Buscarino, G.; Fisichella, G.; Magna, A.; Roccaforte, F.; Cannas, M.; Gelardi, F.M.; Agnello, S. In-situ monitoring by Raman spectroscopy of the thermal doping of graphene and MoS2 in O2-controlled atmosphere. Beilstein J. Nanotech. 2017, 8, 418–424. [Google Scholar] [CrossRef] [PubMed]

- Richter, H.; Wang, Z.P.; Ley, L. The one phonon Raman spectrum in microcrystalline silicon. Solid State Commun. 1981, 39, 625–629. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, L.; Zhou, C. Review of chemical vapor deposition of graphene and related applications. Acc. Chem. Res. 2013, 46, 2329–2339. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, B.; Matte, H.; Sood, A.; Rao, C. Layer-dependent resonant Raman scattering of a few layer MoS2. J. Raman Spectrosc. 2013, 44, 92–96. [Google Scholar] [CrossRef]

- Mercado, E.; Goodyear, A.; Moffat, J.; Cooke, M.; Sundaram, R. A Raman metrology approach to quality control of 2D MoS2 film fabrication. J. Phys. D Appl. Phys. 2017, 50, 184005. [Google Scholar] [CrossRef]

- Laskar, M.R.; Nath, D.N.; Ma, L.; Lee, E.W. p-type doping of MoS2 thin films using Nb. Appl. Phys. Lett. 2014, 104, 092104. [Google Scholar] [CrossRef]

- Mcintyre, N.S.; Spevack, P.A.; Beamson, G.; Briggs, D. Effects of argon ion bombardment on basal plane and polycrystalline MoS2. Surf. Sci. 1990, 237, L390–L397. [Google Scholar] [CrossRef]

- Wagner, C.D.; Riggs, W.M.; Davis, L.E.; Moulder, J.F.; Muilenberg, G.E. Handbook of X-ray Photoelectron Spectroscopy; Perkin-Elmer Corporation, Physical Electronics Division Press: Eden Prairie, MN, USA, 1979; p. 190. [Google Scholar]

- Al-Shihry, S.S.; Halawy, S.A. Unsupported MoO3 Fe2O3 catalysts: Characterization and activity during 2-propanol decomposition. J. Mol. Catal. A Chem. 1996, 113, 479–487. [Google Scholar] [CrossRef]

- Davis, S.M.; Carver, J.C. Oxygen chemisorption at defect sites in MoS2 and ReS2 basal plane surfaces. Appl. Surf. Sci. 1984, 20, 193–198. [Google Scholar] [CrossRef]

- Ahn, C.; Lee, J.; Kim, H.U.; Bark, H.; Jeon, M.; Ryu, G.H.; Lee, Z.; Yeom, G.Y.; Kim, K.; Jung, J.; et al. Low-Temperature Synthesis of Large-Scale Molybdenum Disulfide Thin Films Directly on a Plastic Substrate Using Plasma-Enhanced Chemical Vapor Deposition. Adv. Mater. 2015, 27, 5223–5229. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.G.; Thompson, L.T. XPS study of as-prepared and reduced molybdenum oxides. Appl. Surf. Sci. 1996, 93, 143–149. [Google Scholar] [CrossRef]

| RF Power (W) | A1g (cm−1) | (cm−1) | Δk (A1g-) (cm−1) | Full Width at Half-Maximum (cm−1) | LA(M) to A1g Peak Intensity Ration | |

|---|---|---|---|---|---|---|

| A1g | ||||||

| 10 | 405.2 ± 0.1 | 381.2 ± 0.1 | 24.0 ± 0.02 | 10.64 ± 0.46 | 10.87 ± 0.56 | 0.219 ± 0.010 |

| 80 | 405.4 ± 0.4 | 381.4 ± 0.4 | 24.0 ± 0.01 | 10.17 ± 0.34 | 10.31 ± 0.21 | 0.195 ± 0.004 |

| 120 | 407.0 ± 0.1 | 383.0 ± 0.1 | 24.0 ± 0.02 | 9.55 ± 0.02 | 9.57 ± 0.20 | 0.180 ± 0.003 |

| 150 | 403.7 ± 0.4 | 379.7 ± 0.4 | 24.0 ± 0.02 | 10.49 ± 0.13 | 10.56 ± 0.02 | 0.204 ± 0.006 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, W.; Deng, S.; Wang, K.; Li, G.; Li, G.; Chen, R.; Kwok, H.-S. Feasible Route for a Large Area Few-Layer MoS2 with Magnetron Sputtering. Nanomaterials 2018, 8, 590. https://doi.org/10.3390/nano8080590

Zhong W, Deng S, Wang K, Li G, Li G, Chen R, Kwok H-S. Feasible Route for a Large Area Few-Layer MoS2 with Magnetron Sputtering. Nanomaterials. 2018; 8(8):590. https://doi.org/10.3390/nano8080590

Chicago/Turabian StyleZhong, Wei, Sunbin Deng, Kai Wang, Guijun Li, Guoyuan Li, Rongsheng Chen, and Hoi-Sing Kwok. 2018. "Feasible Route for a Large Area Few-Layer MoS2 with Magnetron Sputtering" Nanomaterials 8, no. 8: 590. https://doi.org/10.3390/nano8080590