Cement-Induced Coagulation of Aqueous Graphene Oxide with Ultrahigh Capacity and High Rate Behavior

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

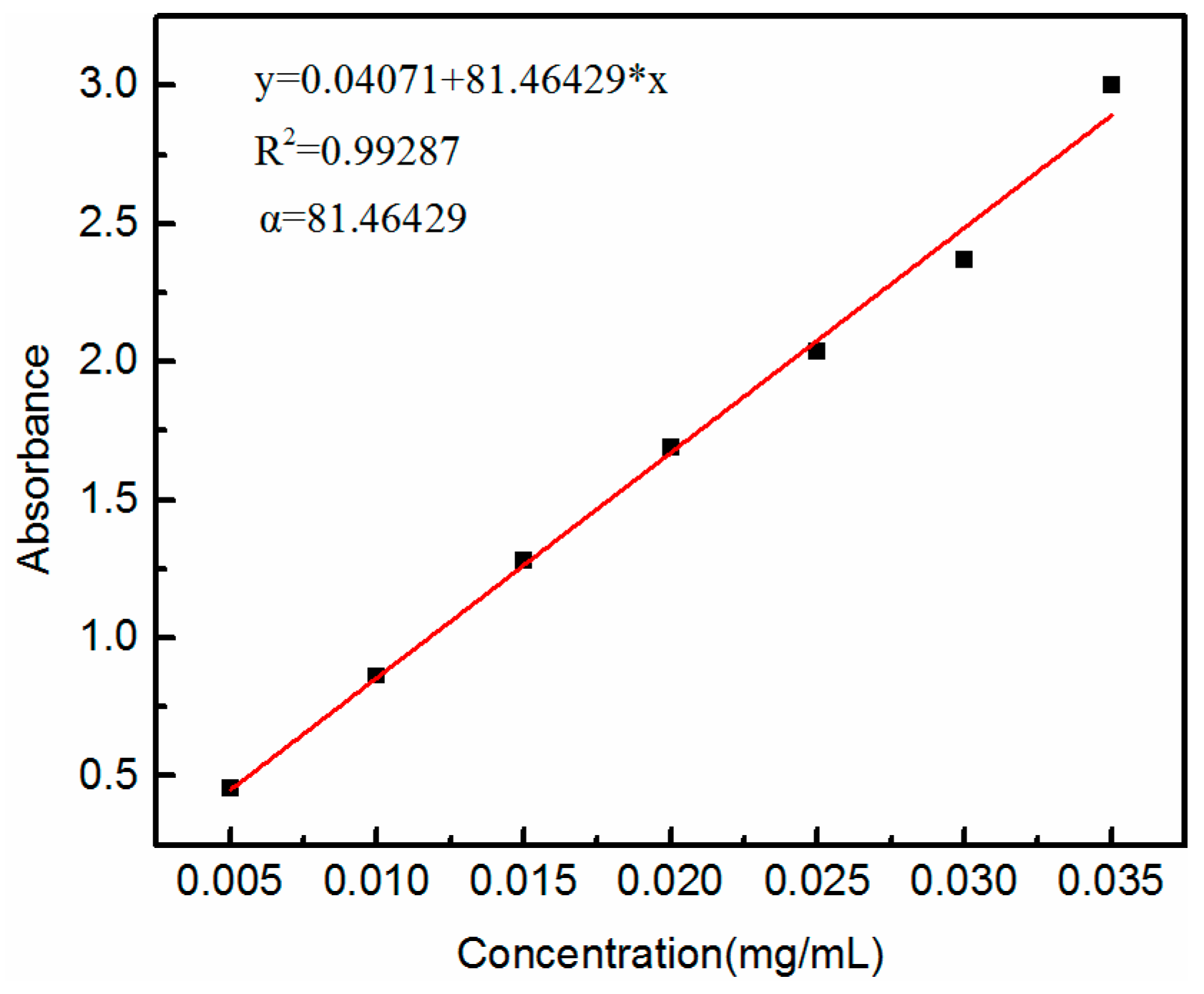

2.2. Characterization

2.3. Coagulation Tests

3. Results and Discussion

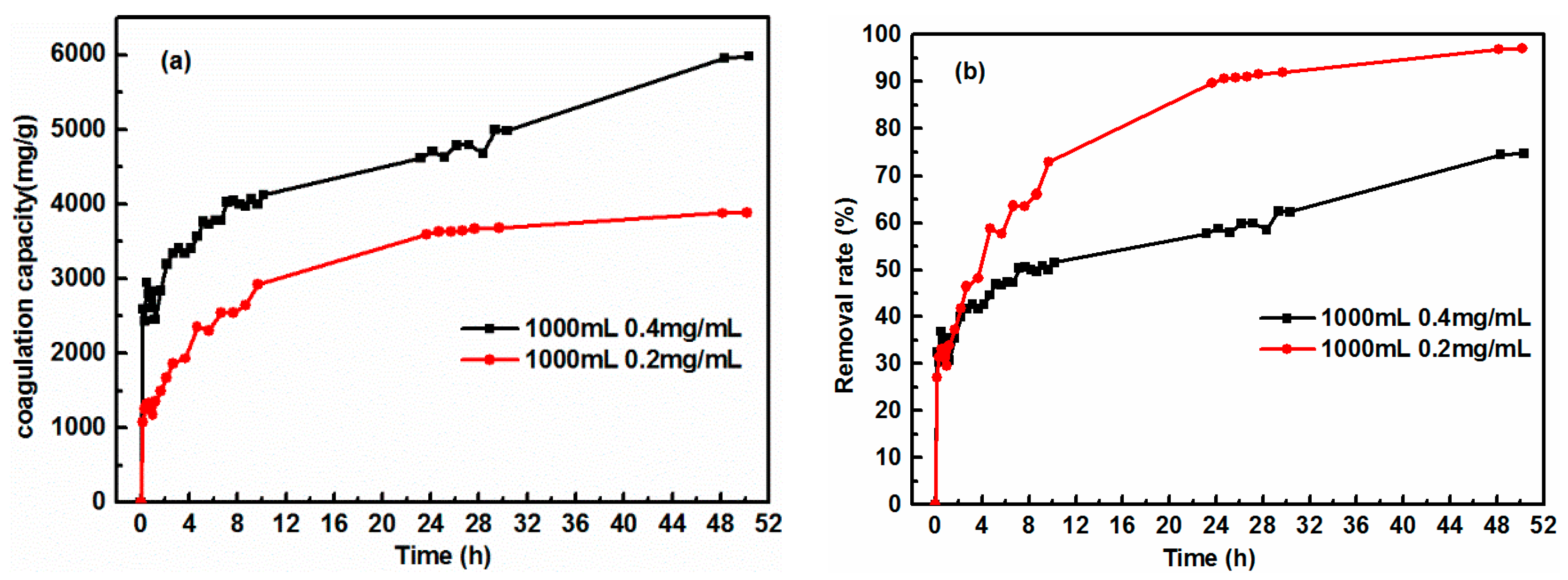

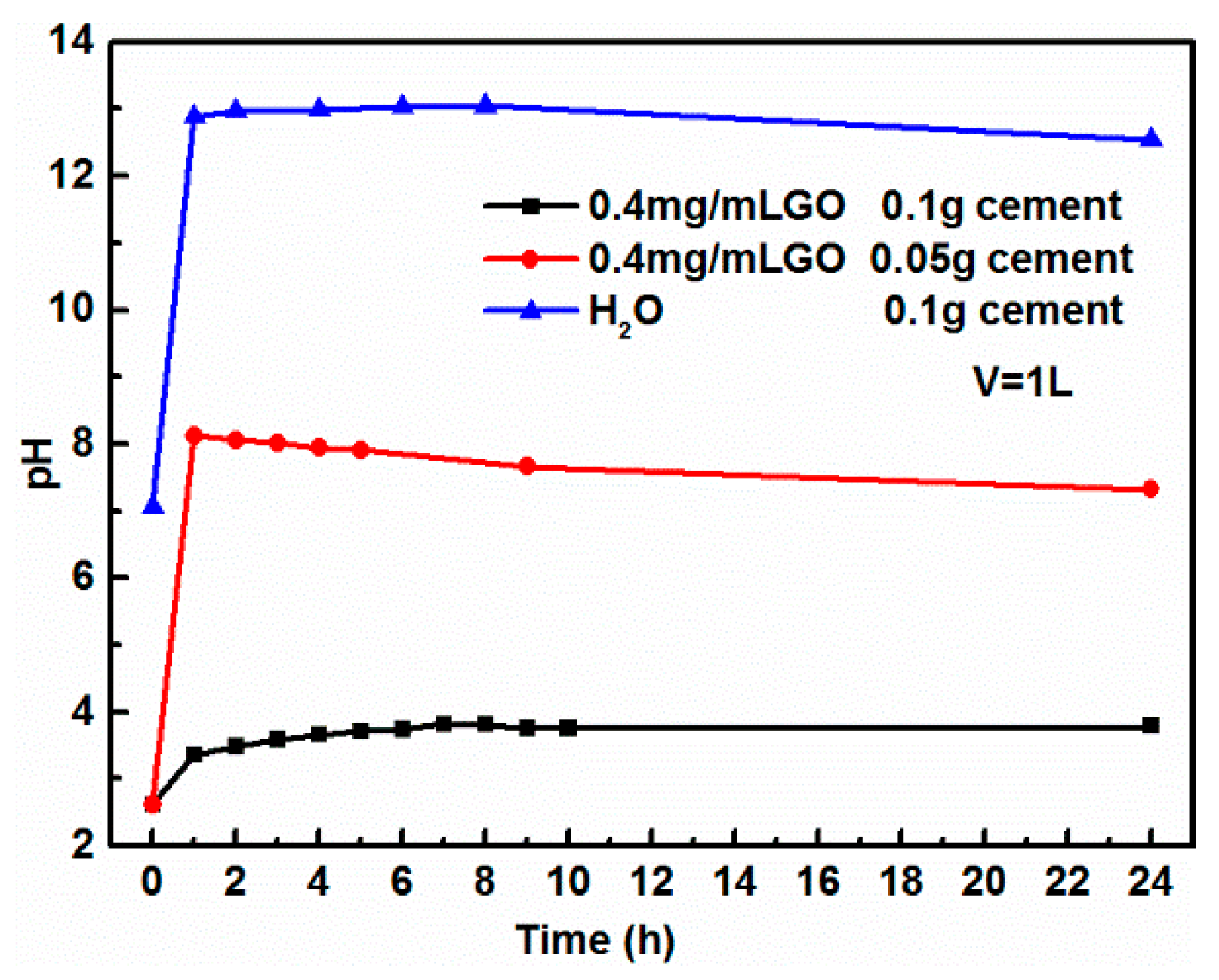

3.1. Batch Coagulation Experiments

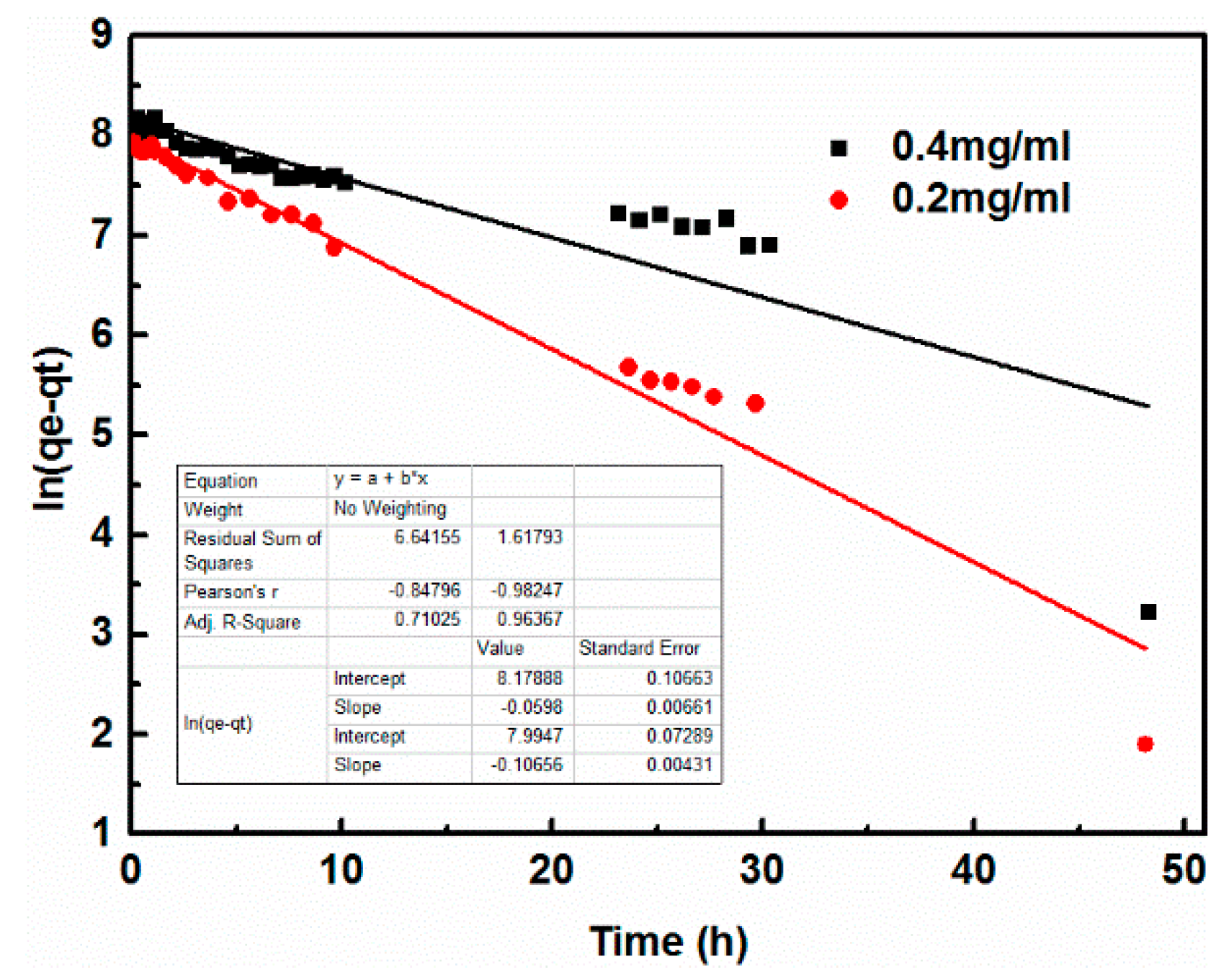

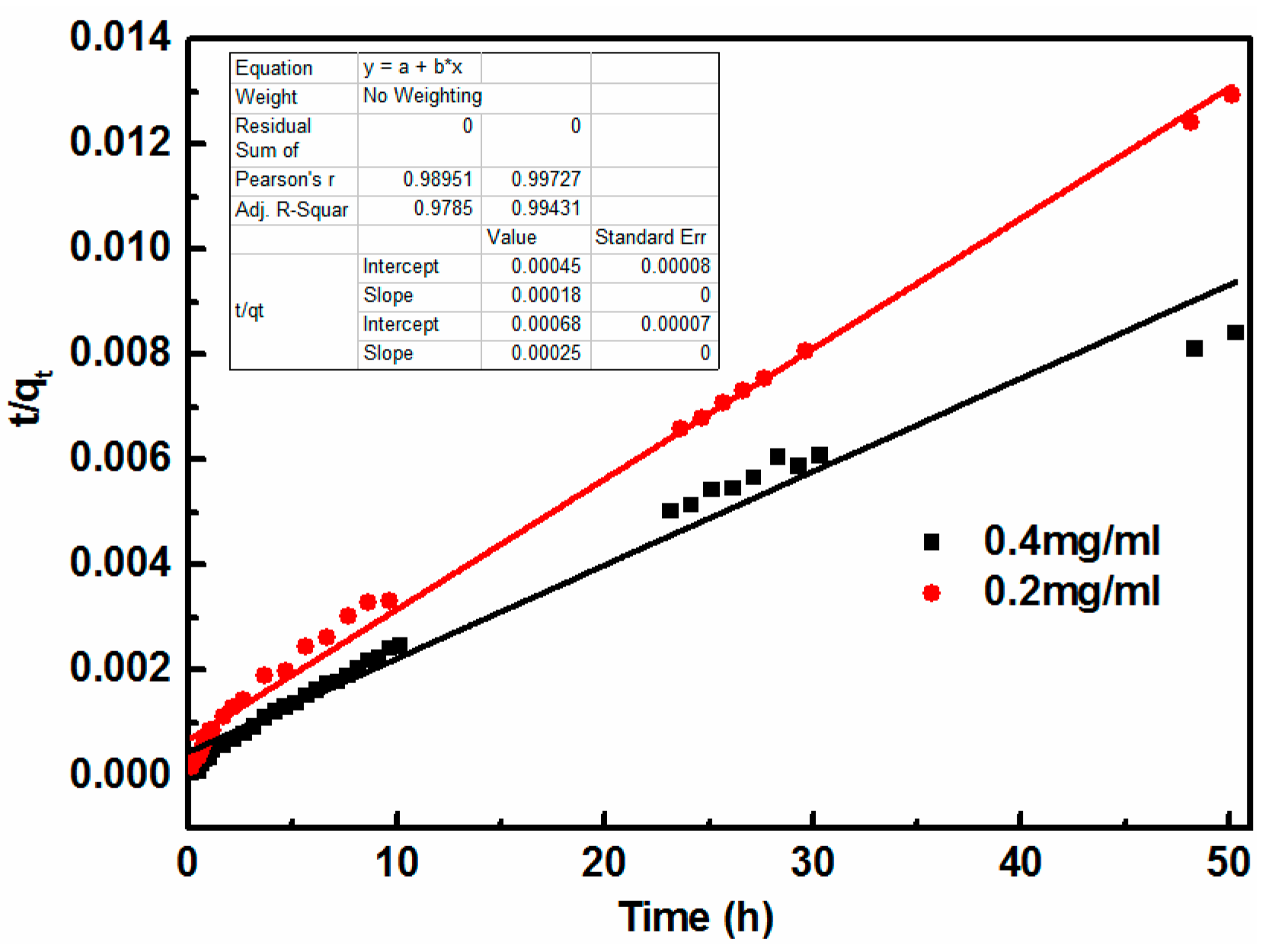

3.2. Coagulation Kinetics

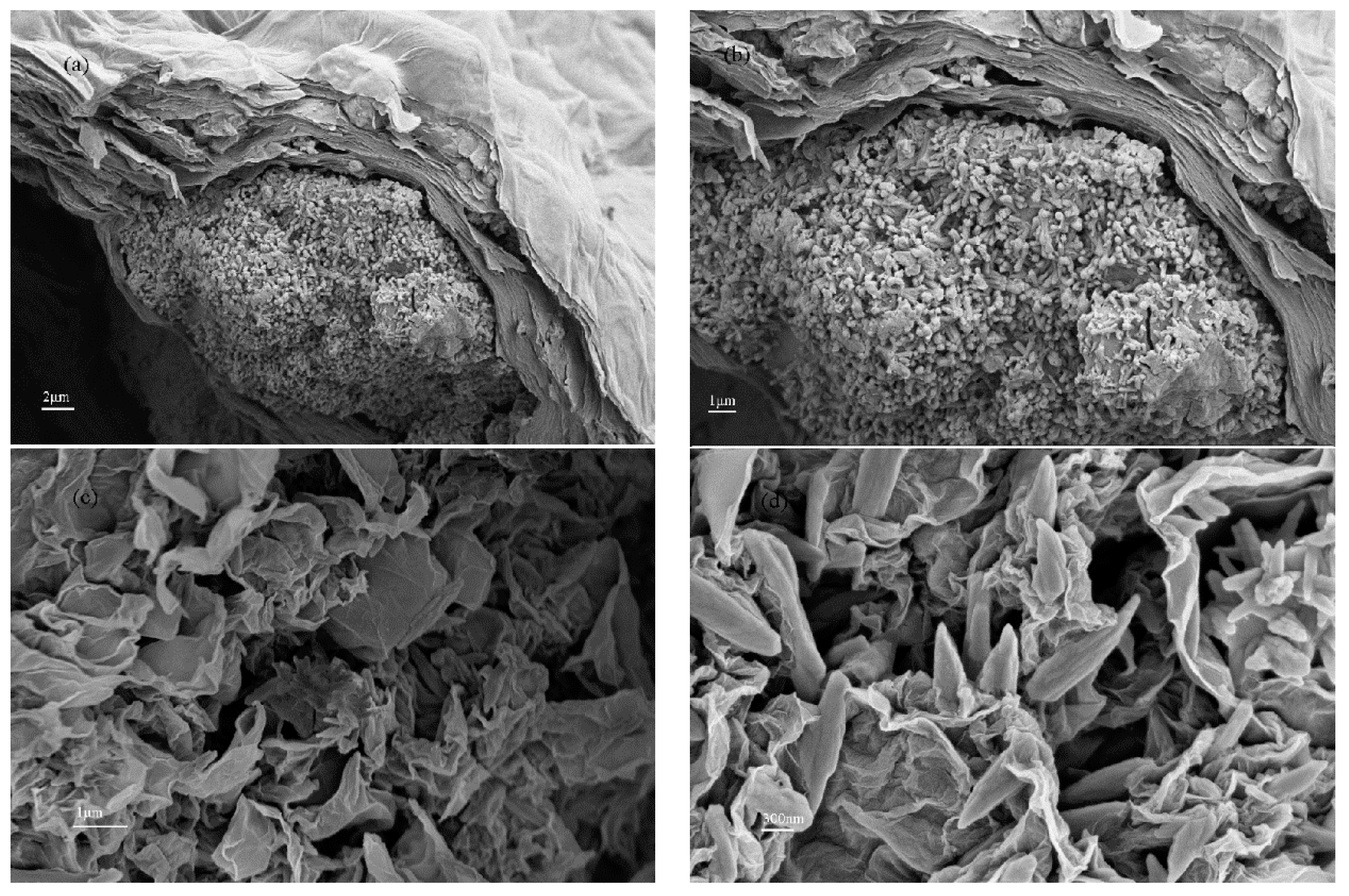

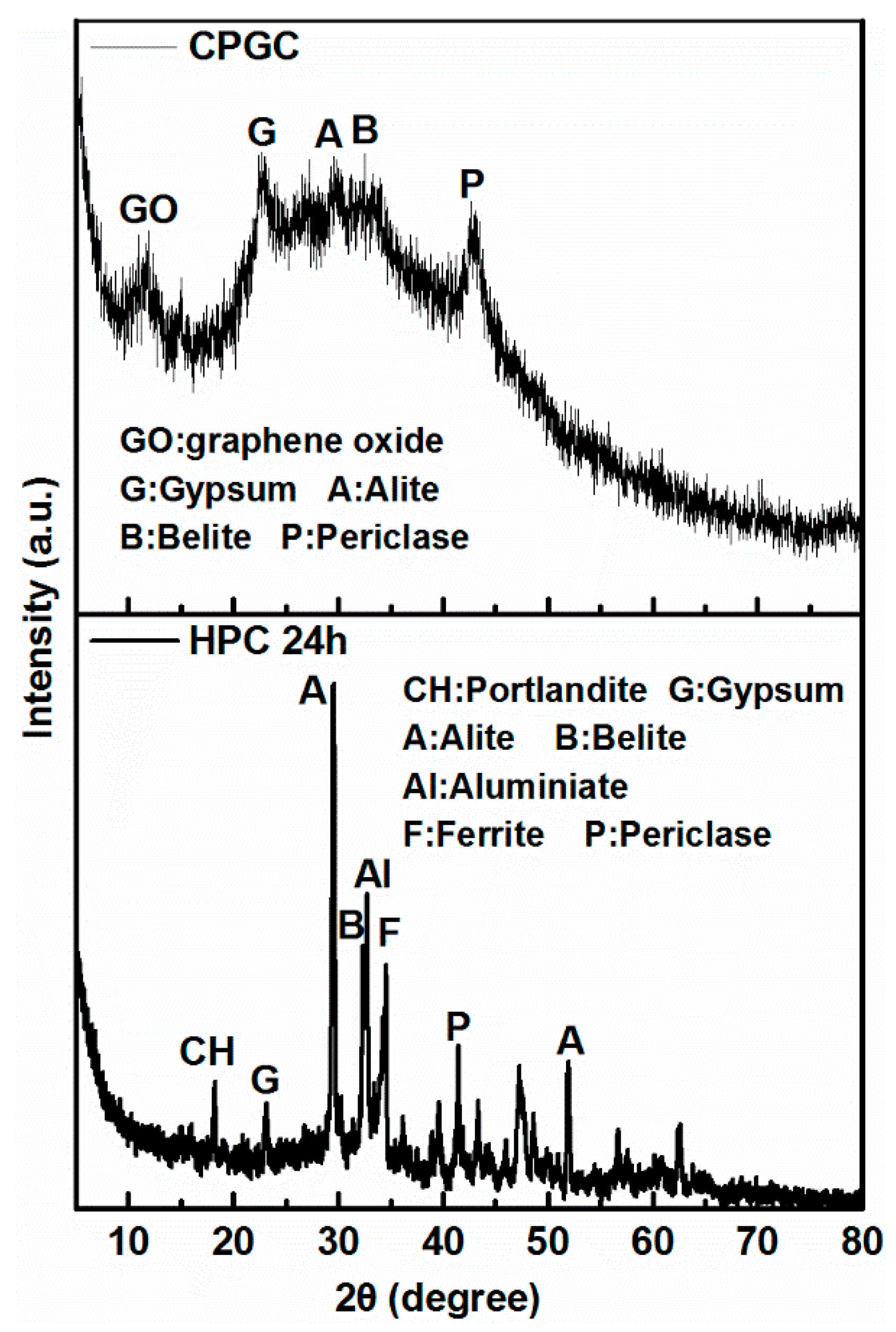

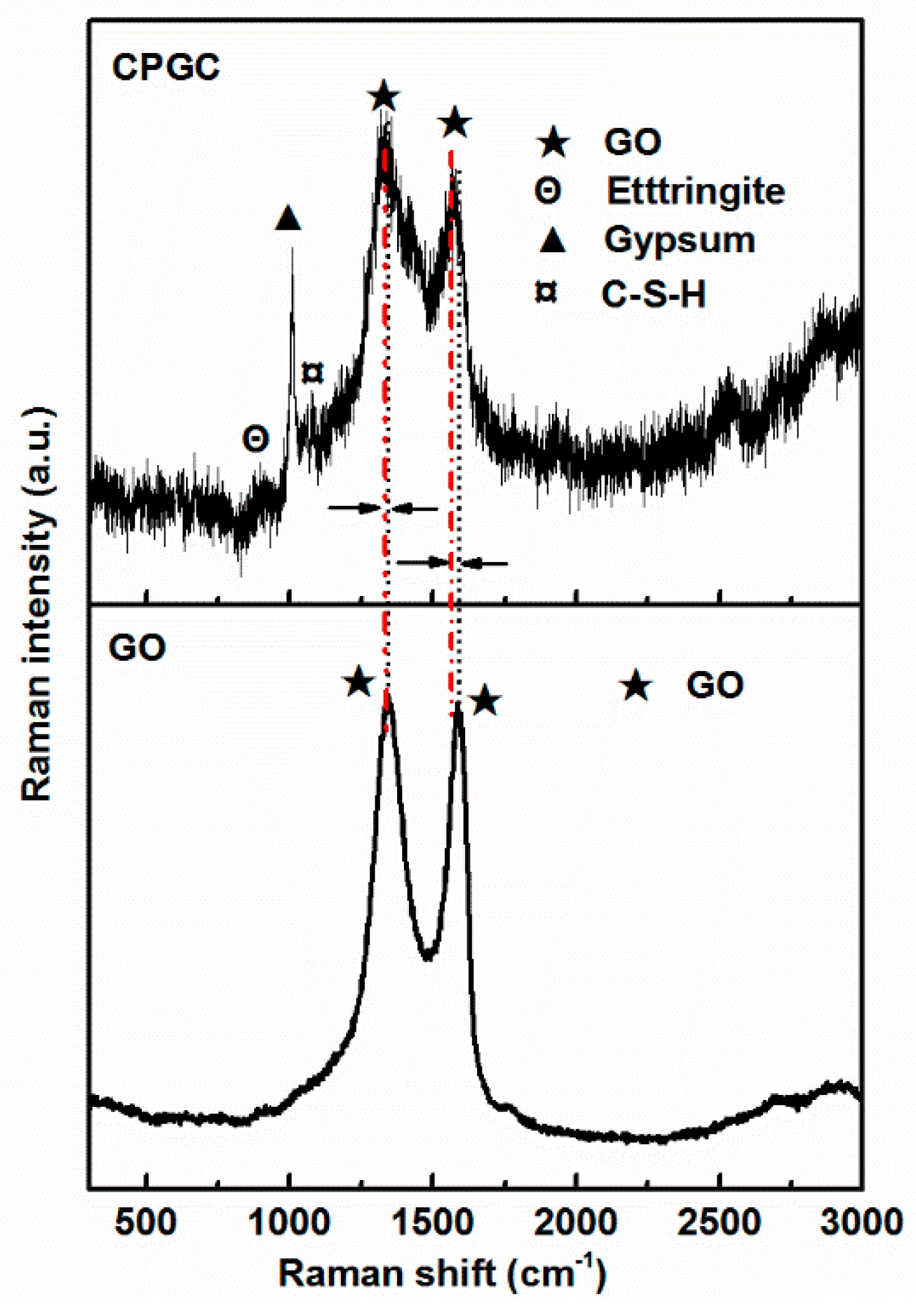

3.3. Structure Analysis of Cement-Induced GO Coagulation Products

3.4. Coagulation Mechanism

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stankovich, S.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Synthesis and exfoliation of isocyanate-treated graphene oxide nanoplatelets. Carbon 2006, 44, 3342–3347. [Google Scholar] [CrossRef]

- Qi, C.; Zhao, L.; Lin, Y.; Wu, D. Graphene oxide/chitosan sponge as a novel filtering material for the removal of dye from water. J. Colloid Interface Sci. 2018, 517, 18–27. [Google Scholar] [CrossRef] [PubMed]

- Dou, M.; Sanjay, S.T.; Dominguez, D.C.; Zhan, S.; Li, X. A paper/polymer hybrid cd-like microfluidic spinchip integrated with DNA-functionalized graphene oxide nanosensors for multiplex qlamp detection. Chem. Commun. 2017, 53, 10886–10889. [Google Scholar] [CrossRef] [PubMed]

- Ogata, C.; Kurogi, R.; Hatakeyama, K.; Taniguchi, T.; Koinuma, M.; Matsumoto, Y. All-graphene oxide device with tunable supercapacitor and battery behaviour by the working voltage. Chem. Commun. 2016, 52, 3919–3922. [Google Scholar] [CrossRef] [PubMed]

- Del Mercato, L.L.; Guerra, F.; Lazzari, G.; Nobile, C.; Bucci, C.; Rinaldi, R. Biocompatible multilayer capsules engineered with a graphene oxide derivative: Synthesis, characterization and cellular uptake. Nanoscale 2016, 8, 7501–7512. [Google Scholar] [CrossRef] [PubMed]

- Ratajczak, K.; Krazinski, B.; Kowalczyk, A.; Dworakowska, B.; Jakiela, S.; Stobiecka, M. Optical biosensing system for the detection of survivin mRNA in colorectal cancer cells using a graphene oxide carrier-bound oligonucleotide molecular beacon. Nanomaterials 2018, 8. [Google Scholar] [CrossRef] [PubMed]

- Stobiecka, M.; Dworakowska, B.; Jakiela, S.; Lukasiak, A.; Chalupa, A.; Zembrzycki, K. Sensing of survivin mrna in malignant astrocytes using graphene oxide nanocarrier-supported oligonucleotide molecular beacons. Sens. Actuators B Chem. 2016, 235, 136–145. [Google Scholar] [CrossRef]

- Yu, S.; Wang, X.; Zhang, R.; Yang, T.; Ai, Y.; Wen, T.; Huang, W.; Hayat, T.; Alsaedi, A.; Wang, X. Complex roles of solution chemistry on graphene oxide coagulation onto titanium dioxide: Batch experiments, spectroscopy analysis and theoretical calculation. Sci. Rep. 2017, 7, 39625. [Google Scholar] [CrossRef] [PubMed]

- Pecoraro, R.; D’Angelo, D.; Filice, S.; Scalese, S.; Capparucci, F.; Marino, F.; Iaria, C.; Guerriero, G.; Tibullo, D.; Scalisi, E.M.; et al. Toxicity evaluation of graphene oxide and titania loaded nafion membranes in zebrafish. Front. Physiol. 2018, 8, 1039. [Google Scholar] [CrossRef] [PubMed]

- Souza, J.P.; Venturini, F.P.; Santos, F.; Zucolotto, V. Chronic toxicity in ceriodaphnia dubia induced by graphene oxide. Chemosphere 2018, 190, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Kryuchkova, M.; Danilushkina, A.; Lvov, Y.; Fakhrullin, R. Evaluation of toxicity of nanoclays and graphene oxide in vivo: A paramecium caudatum study. Environ. Sci. Nano 2016, 3, 442–452. [Google Scholar] [CrossRef]

- Li, X.; Li, F.; Gao, Z.; Fang, L. Toxicology of graphene oxide nanosheets against paecilomyces catenlannulatus. Bull. Environ. Contam. Toxicol. 2015, 95, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Ghorbanpour, M.; Khaltabadi Farahani, A.H.; Hadian, J. Potential toxicity of nano-graphene oxide on callus cell of plantago major l. Under polyethylene glycol-induced dehydration. Ecotoxicol. Environ. Saf. 2018, 148, 910–922. [Google Scholar] [CrossRef]

- Wen, K.-P.; Chen, Y.-C.; Chuang, C.-H.; Chang, H.-Y.; Lee, C.-Y.; Tai, N.-H. Accumulation and toxicity of intravenously-injected functionalized graphene oxide in mice. J. Appl. Toxicol. 2015, 35, 1211–1218. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Yin, J.; Liang, Y.; Yuan, S.; Wang, F.; Song, M.; Wang, H. Oxidative stress and immunotoxicity induced by graphene oxide in zebrafish. Aquat. Toxicol. 2016, 174, 54–60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zou, Y.; Wang, X.; Chen, Z.; Yao, W.; Ai, Y.; Liu, Y.; Hayat, T.; Alsaedi, A.; Alharbi, N.S.; Wang, X. Superior coagulation of graphene oxides on nanoscale layered double hydroxides and layered double oxides. Environ. Pollut. 2016, 219, 107–117. [Google Scholar] [CrossRef] [PubMed]

- Zamri, M.F.M.A.; Kamaruddin, M.A.; Yusoff, M.S.; Aziz, H.A.; Foo, K.Y. Semi-aerobic stabilized landfill leachate treatment by ion exchange resin: Isotherm and kinetic study. Appl. Water Sci. 2017, 7, 581–590. [Google Scholar] [CrossRef]

- Guo, S.; Jiang, Y.; Li, L.; Huang, X.; Zhuang, Z.; Yu, Y. Thin cuox-based nanosheets for efficient phenol removal benefitting from structural memory and ion exchange of layered double oxides. J. Mater. Chem. A 2018, 6, 4167–4178. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, Y.; Wang, J.; Zhou, C.; Tang, Q.; Rao, X. Calcined graphene/MgAl-layered double hydroxides for enhanced Cr(VI) removal. Chem. Eng. J. 2013, 221, 204–213. [Google Scholar] [CrossRef]

- Yuan, X.; Niu, J.; Lv, Y.; Jing, Q.; Li, L. Ultrahigh-capacity and fast-rate removal of graphene oxide by calcined mgal layered double hydroxide. Appl. Clay Sci. 2018, 156, 61–68. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Tan, L.; Chen, Y.; Hayat, T.; Hu, J.; Alsaedi, A.; Ahmad, B.; Guo, W.; Wang, X. Performances and mechanisms of Mg/Al and Ca/Al layered double hydroxides for graphene oxide removal from aqueous solution. Chem. Eng. J. 2016, 297, 106–115. [Google Scholar] [CrossRef]

- Matlock, M.M.; Howerton, B.S.; Atwood, D.A. Chemical precipitation of lead from lead battery recycling plant wastewater. Ind. Eng. Chem. Res. 2002, 41, 1579–1582. [Google Scholar] [CrossRef]

- Ghaffar, A.; Zhang, L.; Zhu, X.; Chen, B. Porous PVdF/GO nanofibrous membranes for selective separation and recycling of charged organic dyes from water. Environ. Sci. Technol. 2018, 52, 4265–4274. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Gao, B.; Yue, Q.; Li, R. Application of enteromorpha polysaccharides as coagulant aid in the simultaneous removal of CuO nanoparticles and Cu2+: Effect of humic acid concentration. Chemosphere 2018, 204, 492–500. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Wang, X.; Ai, Y.; Liu, Y.; Li, J.; Ji, Y.; Wang, X. Coagulation behavior of graphene oxide on nanocrystallined mg/al layered double hydroxides: Batch experimental and theoretical calculation study. Environ. Sci. Technol. 2016, 50, 3658–3667. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, Y.; Chen, W.; Peng, J.; Hu, J.; Chen, Z.; Wen, T.; Lu, S.; Chen, Y.; Hayat, T.; et al. The rapid coagulation of graphene oxide on la-doped layered double hydroxides. Chem. Eng. J. 2017, 309, 445–453. [Google Scholar] [CrossRef]

- Wang, Q.; Shiyu, L.I.; Wang, J.; Pan, S.; Chunxiang, L.V.; Cui, X.; Guo, Z. Effect of graphene oxide on hydration process and main hydration products of cement. J. Chin. Ceram. Soc. 2018, 46, 163–172. [Google Scholar]

- Yao, Y.; Wang, X.; Yan, B.L.; Wang, L.; Liu, C. The research on heavy metal ions curing and its influence on the cement hydration process. Bull. Chin. Ceram. Soc. 2012, 7, e31494. [Google Scholar]

- Liu, B.; Qu, F.; Chen, W.; Liang, H.; Wang, T.; Cheng, X.; Yu, H.; Li, G.; Van der Bruggen, B. Microcystis aeruginosa-laden water treatment using enhanced coagulation by persulfate/fe(ii), ozone and permanganate: Comparison of the simultaneous and successive oxidant dosing strategy. Water Res. 2017, 125, 72–80. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Li, J.; Tan, X.; Shi, W.; Chen, C.; Shao, D.; Wen, T.; Wang, L.; Zhao, G.; Sheng, G.; et al. Impact of Al2O3 on the aggregation and deposition of graphene oxide. Environ. Sci. Technol. 2014, 48, 5493–5500. [Google Scholar] [CrossRef] [PubMed]

- Ren, R.; Liu, D.; Li, K.; Sun, J.; Zhang, C. Adsorption of quaternary ammonium compounds onto activated sludge. J. Water Resour. Prot. 2011, 3, 105–133. [Google Scholar] [CrossRef]

- Li, Z.; Sun, Y.; Xing, J.; Xing, Y.; Meng, A. One step synthesis of co/cr-codoped zno nanoparticle with superb adsorption properties for various anionic organic pollutants and its regeneration. J. Hazard. Mater. 2018, 352, 204–214. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Cao, Y.; Li, P.; Zang, X.; Sun, P.; Wang, K.; Zhong, M.; Wei, J.; Wu, D.; Kang, F.; et al. Three-dimensional porous graphene sponges assembled with the combination of surfactant and freeze-drying. Nano Res. 2014, 7, 1477–1487. [Google Scholar] [CrossRef]

- Liu, G.Y.; Fan, L.; Gao, P.F.; Jin, D.Z. Early-age hydrates and paste structure of glass powder cement paste. Bull. Chin. Ceram. Soc. 2018, 37, 86–91. [Google Scholar]

- Zhu, X.H.; Kang, X.J.; Yang, K.; Yang, C.H. Effect of graphene oxide on the mechanical properties and the formation of layered double hydroxides (ldhs) in alkali-activated slag cement. Constr. Build. Mater. 2017, 132, 290–295. [Google Scholar] [CrossRef]

- Du, S. Effect of curing conditions on properties of cement asphalt emulsion mixture. Constr. Build. Mater. 2018, 164, 84–93. [Google Scholar] [CrossRef]

- Park, S.M.; Jang, J.G. Carbonation-induced weathering effect on cesium retention of cement paste. J. Nucl. Mater. 2018, 505, 159–164. [Google Scholar] [CrossRef]

- Wen, T.; Wu, X.; Tan, X.; Wang, X.; Xu, A. One-pot synthesis of water-swellable mgÔÇôal layered double hydroxides and graphene oxide nanocomposites for efficient removal of as(v) from aqueous solutions. ACS Appl. Mater. Interfaces 2013, 5, 3304–3311. [Google Scholar] [CrossRef] [PubMed]

- López-Díaz, D.; López Holgado, M.; García-Fierro, J.L.; Velázquez, M.M. Evolution of the raman spectrum with the chemical composition of graphene oxide. J. Phys. Chem. C 2017, 121, 20489–20497. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, S.; Huo, Y.; Ning, T.; Liu, A.; Zhang, C.; He, Y.; Wang, M.; Li, C.; Man, B. 3D silver nanoparticles with multilayer graphene oxide as a spacer for surface enhanced raman spectroscopy analysis. Nanoscale 2018, 10, 5897–5905. [Google Scholar] [CrossRef] [PubMed]

- Gurunathan, S.; Han, J.W.; Dayem, A.A.; Eppakayala, V.; Kim, J.H. Oxidative stress-mediated antibacterial activity of graphene oxide and reduced graphene oxide in pseudomonas aeruginosa. Int. J. Nanomed. 2012, 7, 5901–5914. [Google Scholar] [CrossRef] [PubMed]

- Renaudin, G.; Segni, R.; Mentel, D.; Nedelec, J.-M.; Leroux, F.; Taviot-Gueho, C. A raman study of the sulfated cement hydrates: Ettringite and monosulfoaluminate. J. Adv. Concr. Technol. 2007, 5, 299–312. [Google Scholar] [CrossRef]

- Terracciano, A.; Zhang, J.; Christodoulatos, C.; Wu, F.; Meng, X. Adsorption of Ca2+ on single layer graphene oxide. J. Environ. Sci. 2017, 57, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Cash, D. Edta Titrations 2: Analysis of Calcium in a Supplement Tablet; Analysis of Magnesium in Epsom Salt; Hardness of Water; Mohawk College of Applied Arts and Technology: Hamilton, ON, Canada, 2008. [Google Scholar]

- Yang, K.; Chen, B.; Zhu, X.; Xing, B. Aggregation, adsorption, and morphological transformation of graphene oxide in aqueous solutions containing different metal cations. Environ. Sci. Technol. 2016, 50, 11066–11075. [Google Scholar] [CrossRef] [PubMed]

- Fathy, M.; Abdel Moghny, T.; Mousa, M.A.; El-Bellihi, A.-H.A.A.; Awadallah, A.E. Absorption of calcium ions on oxidized graphene sheets and study its dynamic behavior by kinetic and isothermal models. Appl. Nanosci. 2016, 6, 1105–1117. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Linglin, X.U.; Zhang, G. Hydration properties of portland cement at 0 °C to 20 °C. Mater. Rev. 2012, 27, 253–260. [Google Scholar]

- MacLaren, D.C.; White, M.A. Cement: Its chemistry and properties. J. Chem. Educ. 2003, 80, 623. [Google Scholar] [CrossRef]

- Lu, Z.; Hanif, A.; Sun, G.; Liang, R.; Parthasarathy, P.; Li, Z. Highly dispersed graphene oxide electrodeposited carbon fiber reinforced cement-based materials with enhanced mechanical properties. Cem. Concr. Compos. 2018, 87, 220–228. [Google Scholar] [CrossRef]

| Coagulants | Removal Capacity (mg/g) | References |

|---|---|---|

| Al2O3 | 0.59 | [30] |

| LDH-Cl | 57 | [25] |

| Mg/Al LDH | 79.9 | [21] |

| Ca/Al LDH | 123 | [21] |

| LDO-G1 | 448.3 | [16] |

| Ca/Al/La-MMO | 558.8 | [26] |

| Mg/Al/La-MMO | 565.8 | [26] |

| MgAl-MMO | 984.2 | [20] |

| Cement | 5981.2 | This study |

| Dosage (mg/mL) | qe,exp (mg/g) | Pseudo First-Order | Pseudo Second-Order | ||||

|---|---|---|---|---|---|---|---|

| k1 (min−1) | qe,cal (mg/g) | R2 | k2 (g/mg·g) | qe,cal (mg/g) | R2 | ||

| 0.2 | 3884.4 | 0.10656 | 2965.2 | 0.96367 | 0.0000904 | 4035.903397 | 0.9943 |

| 0.4 | 5981.2 | 0.00589 | 3564.8 | 0.71025 | 0.0000701 | 5631.011104 | 0.9785 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, X.; Niu, J.; Zeng, J.; Jing, Q. Cement-Induced Coagulation of Aqueous Graphene Oxide with Ultrahigh Capacity and High Rate Behavior. Nanomaterials 2018, 8, 574. https://doi.org/10.3390/nano8080574

Yuan X, Niu J, Zeng J, Jing Q. Cement-Induced Coagulation of Aqueous Graphene Oxide with Ultrahigh Capacity and High Rate Behavior. Nanomaterials. 2018; 8(8):574. https://doi.org/10.3390/nano8080574

Chicago/Turabian StyleYuan, Xiaoya, Jiawei Niu, Junjie Zeng, and Qiuye Jing. 2018. "Cement-Induced Coagulation of Aqueous Graphene Oxide with Ultrahigh Capacity and High Rate Behavior" Nanomaterials 8, no. 8: 574. https://doi.org/10.3390/nano8080574