Methanol-Tolerant Platinum-Palladium Catalyst Supported on Nitrogen-Doped Carbon Nanofiber for High Concentration Direct Methanol Fuel Cells

Abstract

:1. Introduction

2. Experimental Section

2.1. Preparation of Pt-Pd Catalyst

2.2. Characterization of Supporting Carbons

2.3. Characterization of the Pt-Pd Catalysts

2.4. DMFC Unit-Cell Measurements

3. Results and Discussion

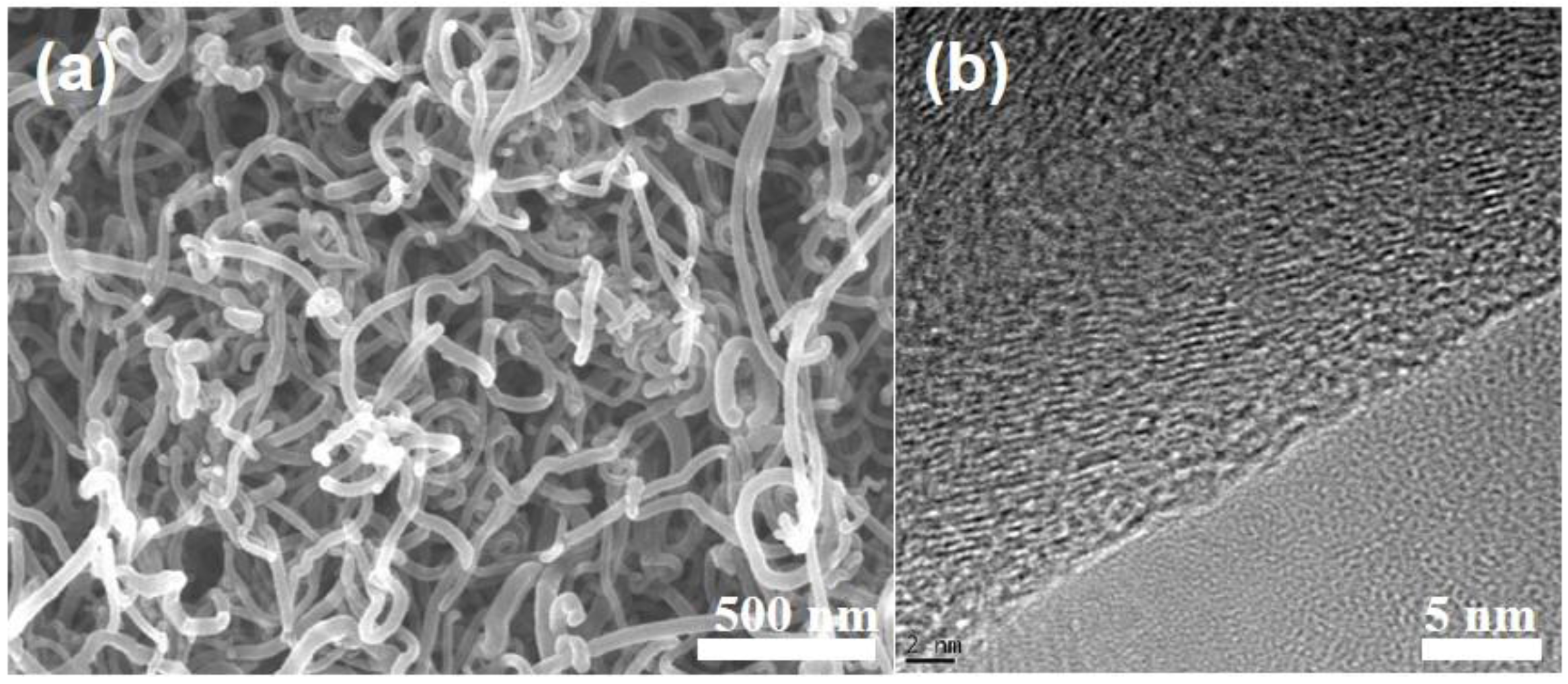

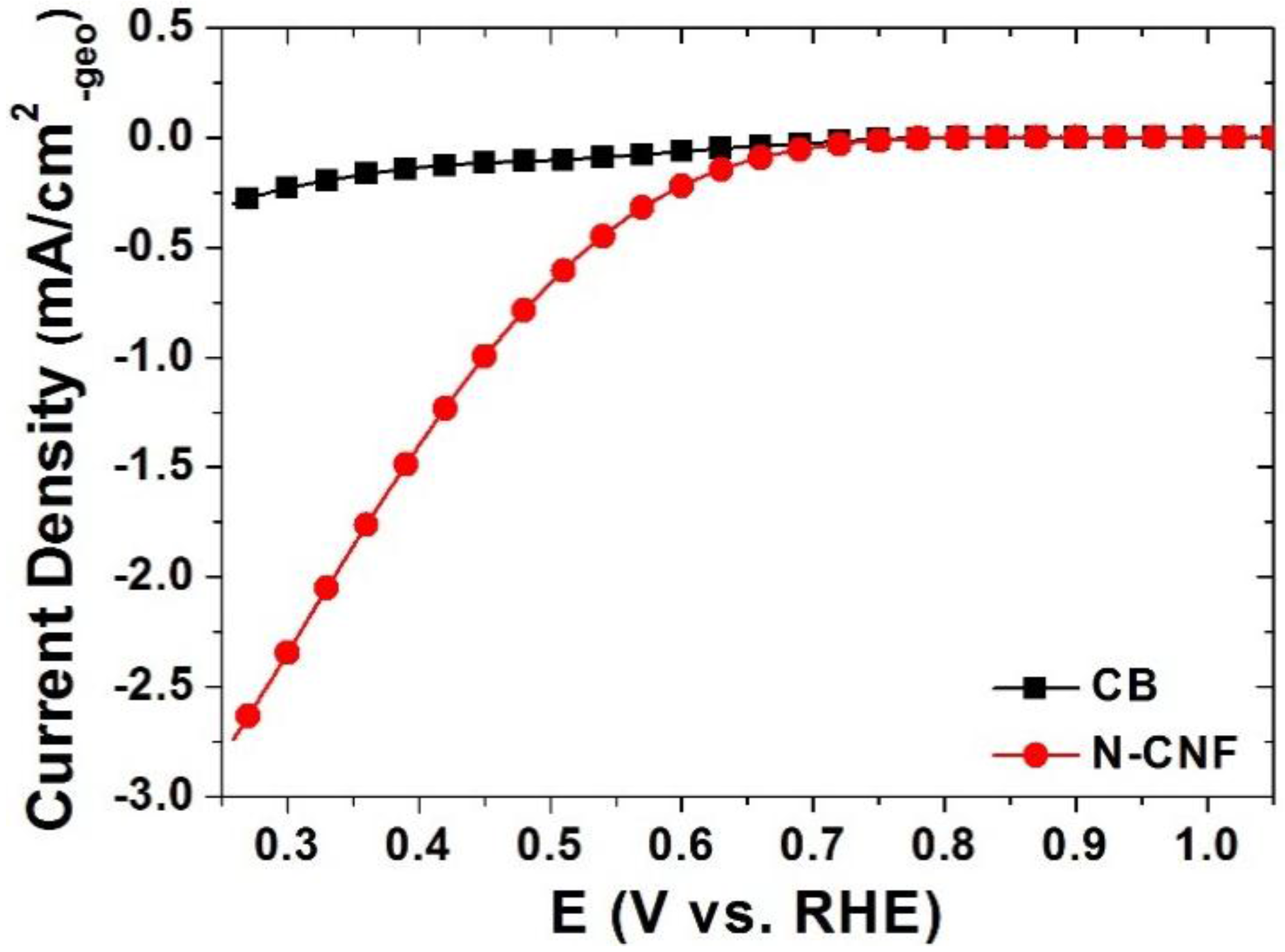

3.1. Characterization of the N-CNF

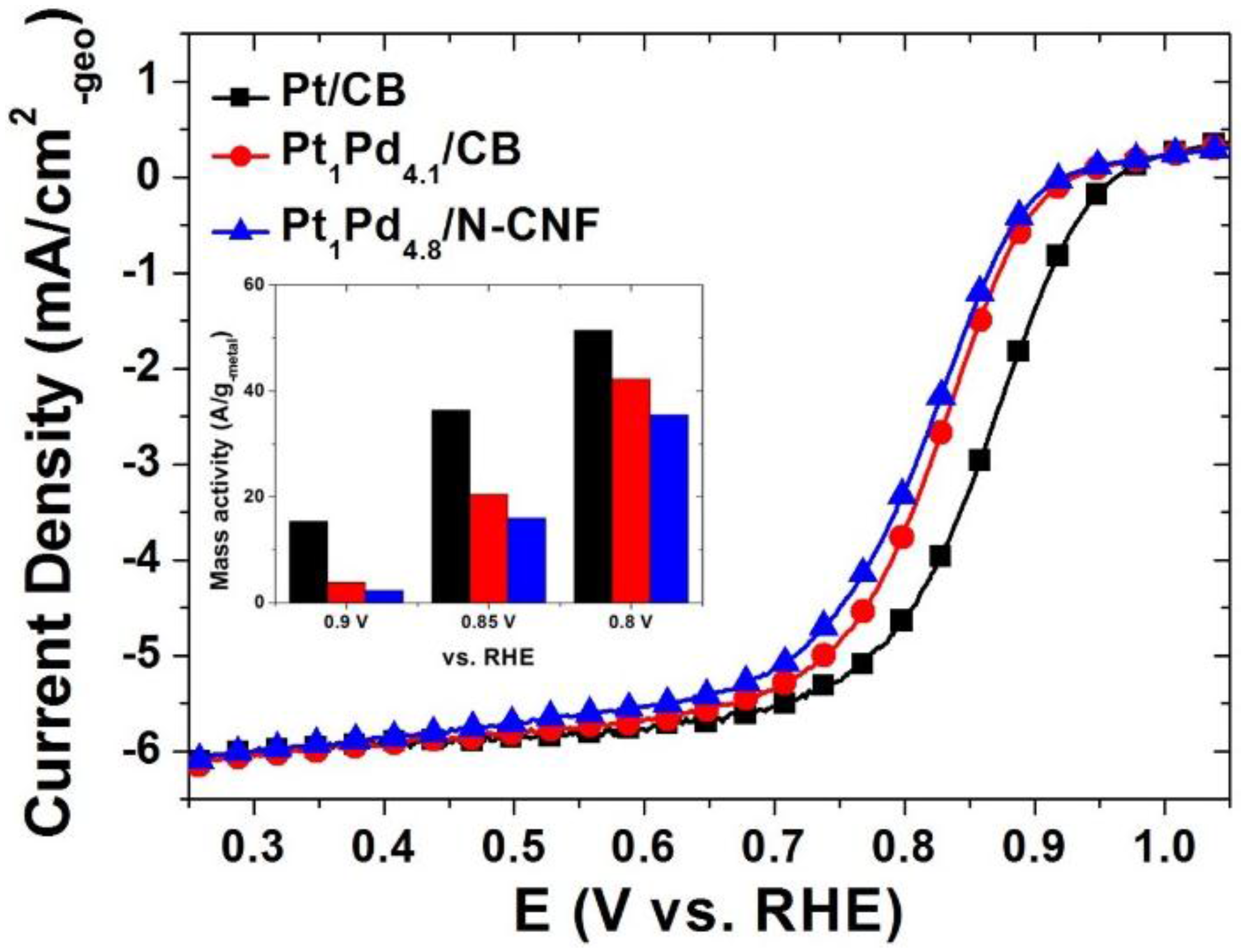

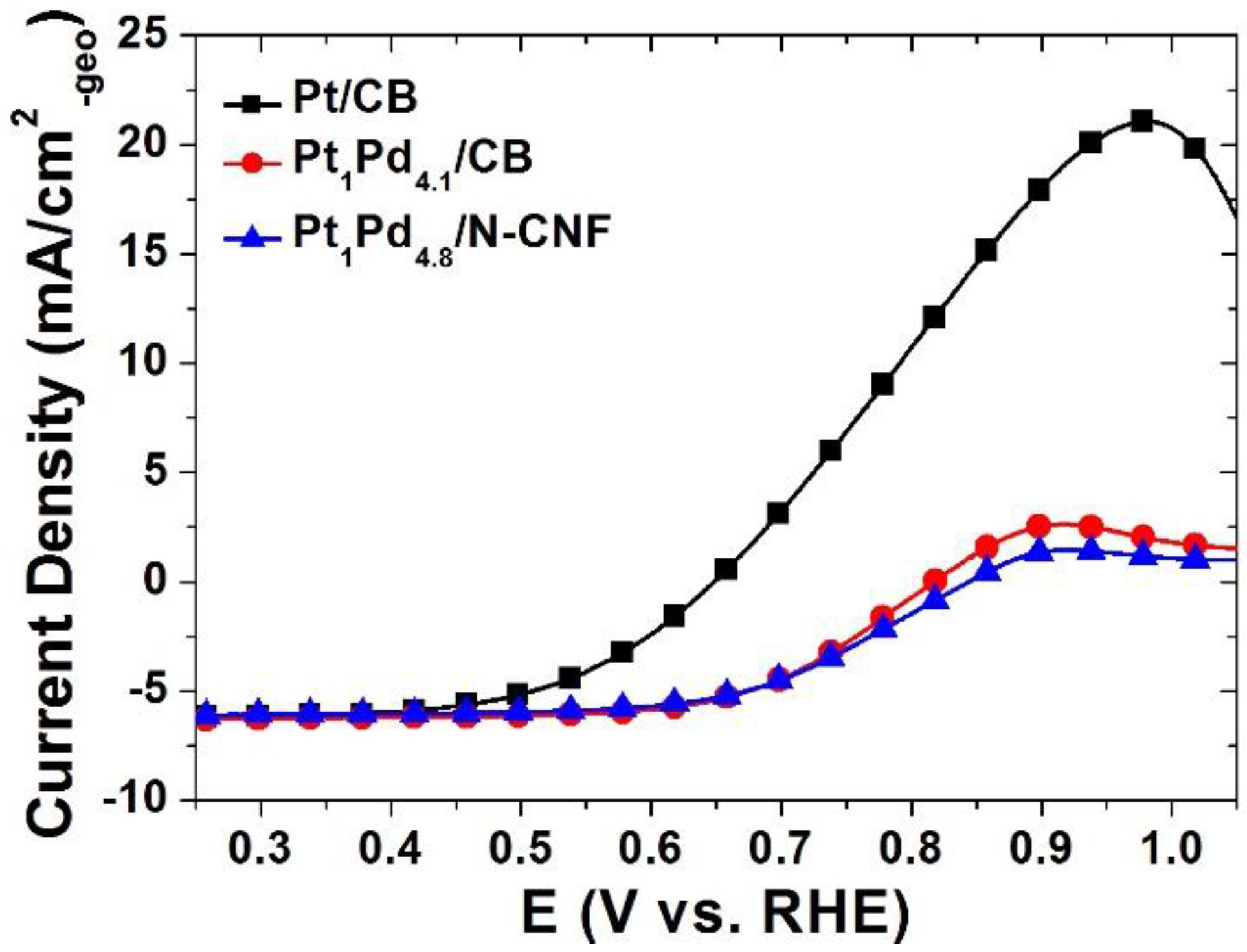

3.2. Characterization of the Pt-Pd Catalysts

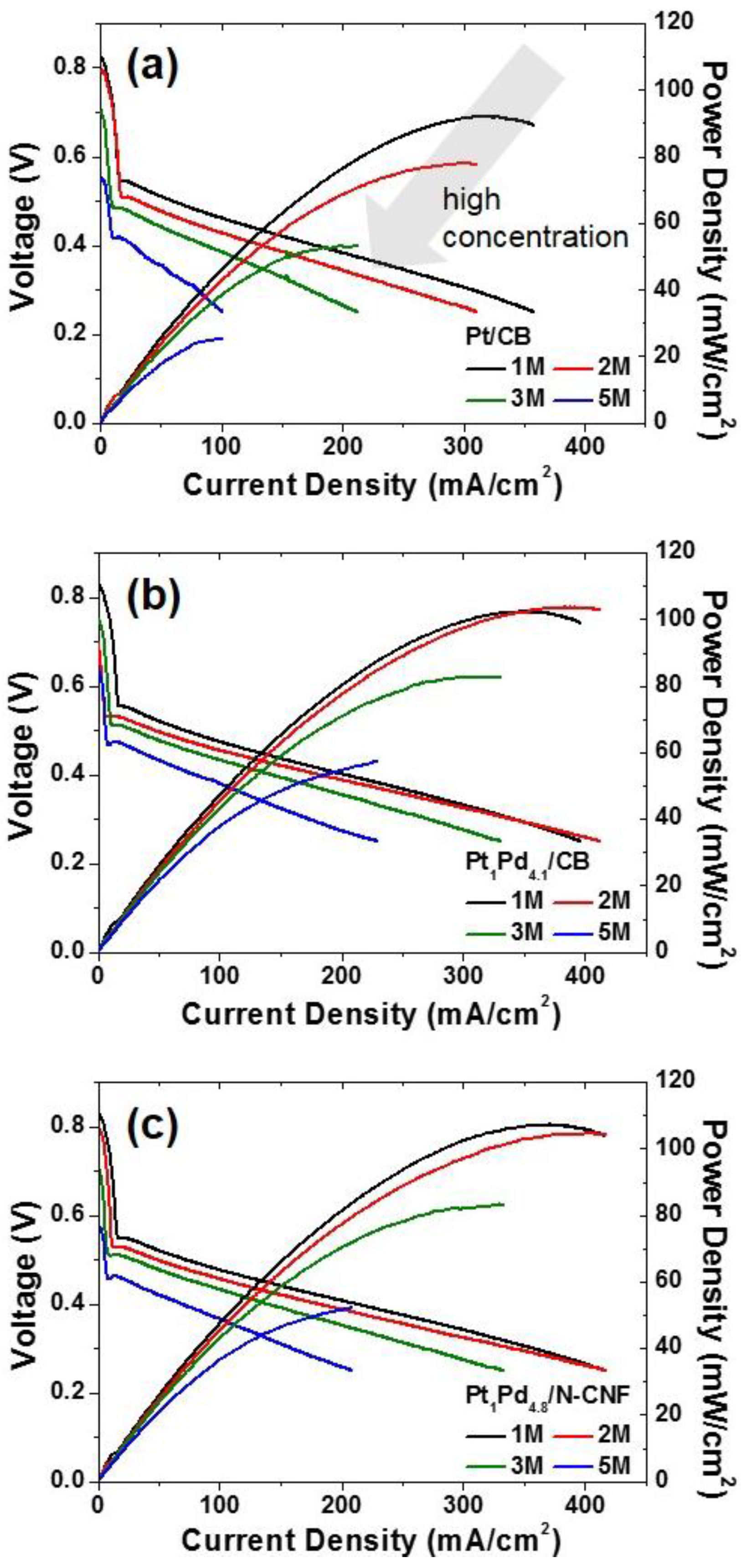

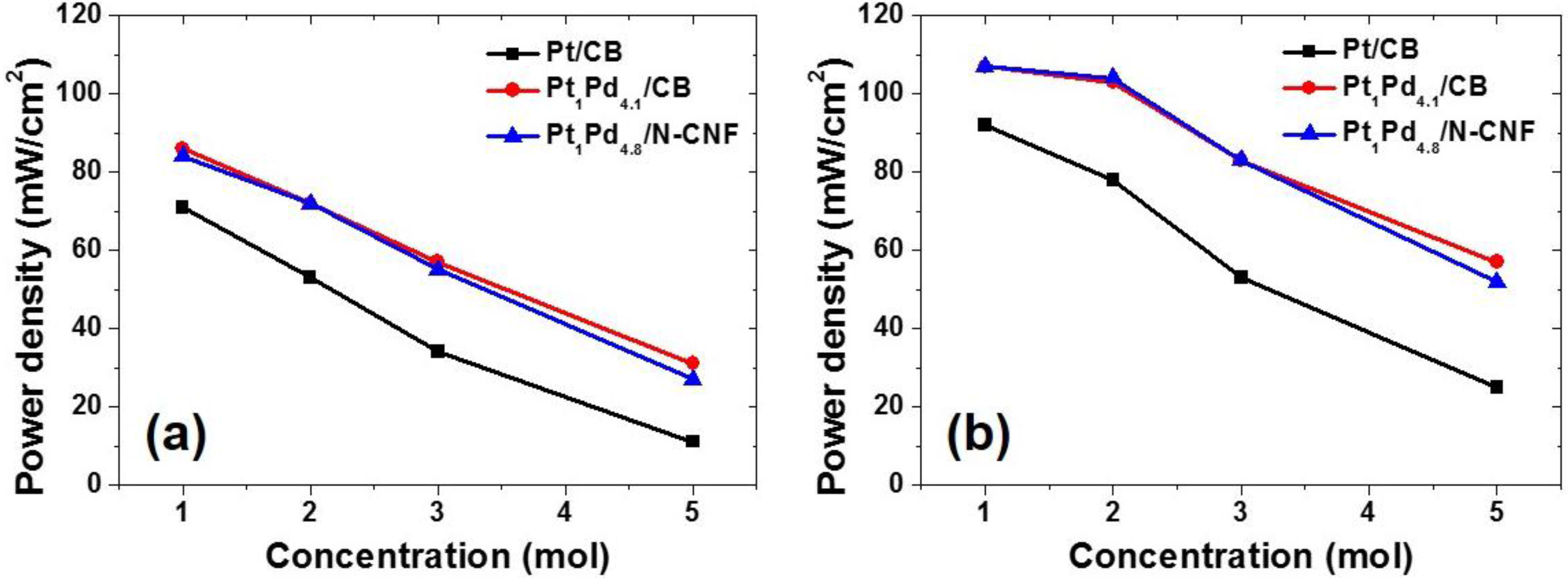

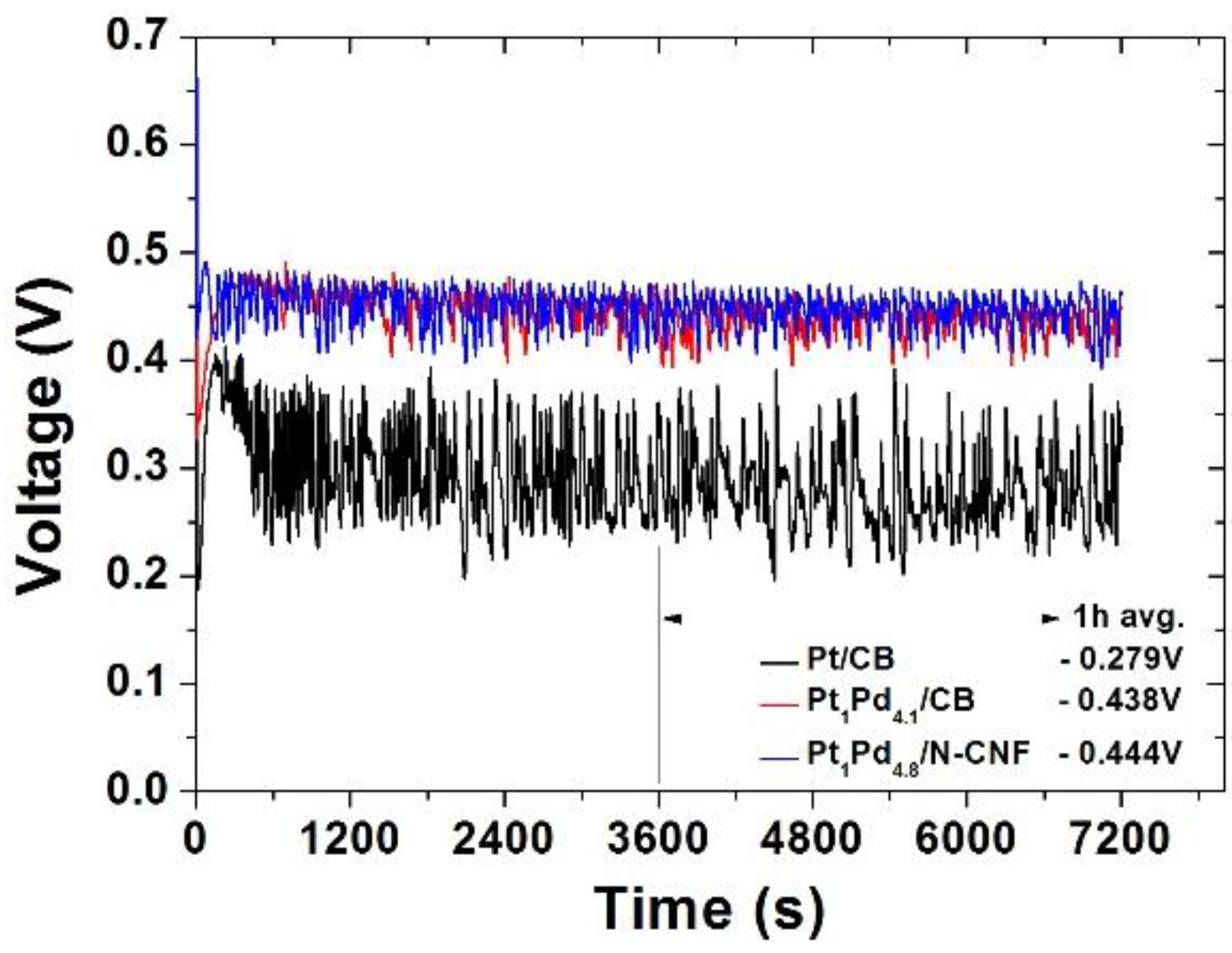

3.3. Unit-Cell Performance for DMFC

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhao, T.S.; Chen, R.; Yang, W.W.; Xu, C. Small direct methanol fuel cells with passive supply of reactants. J. Power Sources 2009, 191, 185–202. [Google Scholar] [CrossRef]

- Li, X.; Faghri, A.; Xu, C. Water management of the DMFC passively fed with a high-concentration methanol solution. Int. J. Hydrogen Energy 2010, 35, 8690–8698. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, H.-Y.; Hwang, K.-T.; Lee, J.-Y. Performance of air-breathing direct methanol fuel cell with anion-exchange membrane. Int. J. Hydrogen Energy 2010, 35, 768–773. [Google Scholar] [CrossRef]

- Yi, Q.; Huang, W.; Zhang, J.; Liu, X.; Li, L. Methanol oxidation on titanium-supported nano-scale Ni flakes. Catal. Commun. 2008, 9, 2053–2058. [Google Scholar] [CrossRef]

- Arico, A.S.; Srinivasan, S.; Antonucci, V. DMFCs: From fundamental aspects to technology development. Fuel Cells 2001, 1, 133–161. [Google Scholar] [CrossRef]

- Nam, K.-D.; Kim, T.-J.; Kim, S.-K.; Lee, B.; Peck, D.-H.; Ryu, S.-K.; Jung, D.-H. Preparation of uniform porous carbon from mesophase pitch and its characteristics of catalyst support for the direct methanol fuel cell. J. Korean Ind. Eng. Chem. 2006, 17, 223–228. [Google Scholar]

- Ahluwalia, R.K.; Wang, X. Direct hydrogen fuel cell systems for hybrid vehicles. J. Power Sources 2005, 139, 152–164. [Google Scholar] [CrossRef]

- Wu, Q.X.; Zhao, T.S.; Chen, R.; Yang, W.W. Enhancement of water retention in the membrane fuel cells operating with neat methanol. Int. J. Hydrogen Energy 2010, 35, 10547–10555. [Google Scholar] [CrossRef]

- Han, K.-I.; Lee, J.-S.; Park, S.-O.; Lee, S.-W.; Park, Y.-W.; Kim, H.-S. Studies on the anode catalysts of carbon nanotubes for DMFC. Electrochim. Acta 2004, 50, 791–794. [Google Scholar] [CrossRef]

- Liu, J.; Liu, C.T.; Zhao, L.; Wang, Z.B. Highly durable direct methanol fuel cell with double-layered catalyst cathode. J. Nanomater. 2015, 8. [Google Scholar] [CrossRef]

- Jang, J.-S.; Kim, S.-K.; Kim, J.; Peck, D.-H.; Jung, D.-H. Preparation of heat-treated iron-phthalocyanine cathode catalysts and their active sites evaluation for oxygen reduction reaction in alkaline media. Bull. Korean Chem. Soc. 2015, 36, 919–924. [Google Scholar]

- Tamaki, T.; Yamauchi, A.; Ito, T.; Ohashi, H.; Yamaguchi, T. The effect of methanol crossover on the cathode overpotential of DMFCs. Fuel Cells 2011, 11, 394–403. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Peck, D.-H.; Kim, S.-K.; Jung, D.-H.; Lim, S.; Kim, S.-H. Effects of the microstructure and powder compositions of a micro-porous layer for the anode on the performance of high concentration methanol fuel cell. Int. J. Hydrogen Energy 2013, 38, 7159–7168. [Google Scholar] [CrossRef]

- Park, Y.-C.; Kim, D.-H.; Lim, S.; Kim, S.-K.; Peck, D.-H.; Jung, D.-H. Design of a MEA with multi-layer electrodes for high concentration methanol DMFCs. Int. J. Hydrogen Energy 2012, 37, 4717–4727. [Google Scholar] [CrossRef]

- Chen, Z.; Waje, M.; Li, W.; Yan, Y. Supportless Pt and PtPd nanotubes as electrocatalysts for oxygen reduction reactions. Angew. Chem. Int. Ed. 2007, 119, 4138–4141. [Google Scholar] [CrossRef]

- Neergat, M.; Shukla, A.K.; Gandhi, K.S. Platinum-based alloys as oxygen-reduction catalysts for solid-polymer-electrolyte direct methanol fuel cells. J. Appl. Electrochem. 2001, 31, 373–378. [Google Scholar] [CrossRef]

- Savadogo, O.; Lee, K.; Oishi, K.; Mitsushima, S.; Kamiya, N.; Ota, K.-I. New palladium alloys catalyst for the oxygen reduction reaction in an acid medium. Electrochem. Commun. 2004, 6, 105–109. [Google Scholar] [CrossRef]

- Serov, A.A.; Cho, S.-Y.; Han, S.; Min, M.; Chai, G.; Nam, K.H. Modification of palladium-based catalysts by chalcogenes for direct methanol fuel cells. Electrochem. Commun. 2007, 9, 2041–2044. [Google Scholar] [CrossRef]

- Kim, J.; Lim, S.; Kim, S.-K.; Peck, D.-H.; Lee, B.; Yoon, S.-H.; Jung, D.-H. Electrochemical catalytic activity for oxygen reduction reaction of nitrogen-doped carbon nanofibers. J. Nanosci. Nanotechnol. 2011, 11, 6350–6358. [Google Scholar] [CrossRef] [PubMed]

- Hyun, M.-S.; Kim, S.-K.; Lee, B.; Peck, D.-H.; Shul, Y.; Jung, D.-H. Effect of NaBH4 concentration on the characteristics of PtRu/C catalyst for the anode of DMFC prepared by the impregnation method. Catal. Today 2008, 132, 138–145. [Google Scholar] [CrossRef]

- Kim, J.; Jang, J.-S.; Peck, D.-H.; Lee, B.; Yoon, S.-H.; Jung, D.-H. Control of nitrogen content and its effects on the electrochemical behavior of nitrogen-doped carbon nanofibers. J. Electroanal. Chem. 2016, 768, 34–40. [Google Scholar] [CrossRef]

- Zhou, Y.; Pasquarelli, R.; Holme, T.; Berry, J.; Ginley, D.; O’Hayre, R. Improving PEM fuel cell catalyst activity and durability using nitrogen-doped carbon supports: Observations from model Pt/HOPG systems. J. Mater. Chem. 2009, 19, 7830–7838. [Google Scholar] [CrossRef]

- Qu, L.; Liu, Y.; Baek, J.B.; Dai, L. Nitrogen-doped graphene as efficient metal-free electrocatalyst for oxygen reduction in fuel cells. ACS Nano 2010, 4, 1321–1326. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.; Liang, H.; Parvez, K.; Zhuang, X.; Feng, X.; Műllen, K. Nitrogen-doped carbon nanosheets with size-defined mesopores as highly efficient metal-free catalyst for the oxygen reduction reaction. Angew. Chem. Int. Ed. 2014, 126, 1596–1600. [Google Scholar] [CrossRef]

- Zhou, Y.; Neyerlin, K.; Olson, T.S.; Pylypenko, S.; Bult, J.; Dinh, H.N.; Gennett, T.; Shao, Z.; O’Hayre, R. Enhancement of Pt and Pt-alloy fuel cell catalyst activity and durability via nitrogen-modified carbon supports. Energy Environ. Sci. 2010, 3, 1437–1446. [Google Scholar] [CrossRef]

- Zhang, L.M.; Wang, Z.B.; Zhang, J.J.; Sui, X.L.; Zhao, L.; Gu, D.M. Honeycomb-like mesoporous nitrogen-doped carbon supported Pt catalyst for methanol electrooxidation. Carbon 2015, 93, 1050–1058. [Google Scholar] [CrossRef]

| Sample | Nitrogen (%) | Specific Surface Area (m2/g) | Capacitance (F/g) |

|---|---|---|---|

| CB | - | 222 | 33.6 |

| N-CNF | 8.4 | 147 | 38.1 |

| Sample | Metal (wt %) | Pt:Pd Weight Ratio | Crystallite Size (nm) |

|---|---|---|---|

| Pt/CB | 59.0 | Only Pt | 4.5 |

| Pt-Pd/CB | 57.5 | 1:4.1 | 3.7 |

| Pt-Pd/N-CNF | 60.6 | 1:4.8 | 3.4 |

| Sample | Half-Wave Potential (V) |

|---|---|

| Pt/CB | 0.862 |

| Pt1Pd4.1/CB | 0.825 |

| Pt1Pd4.8/NCNF | 0.814 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Jang, J.-S.; Peck, D.-H.; Lee, B.; Yoon, S.-H.; Jung, D.-H. Methanol-Tolerant Platinum-Palladium Catalyst Supported on Nitrogen-Doped Carbon Nanofiber for High Concentration Direct Methanol Fuel Cells. Nanomaterials 2016, 6, 148. https://doi.org/10.3390/nano6080148

Kim J, Jang J-S, Peck D-H, Lee B, Yoon S-H, Jung D-H. Methanol-Tolerant Platinum-Palladium Catalyst Supported on Nitrogen-Doped Carbon Nanofiber for High Concentration Direct Methanol Fuel Cells. Nanomaterials. 2016; 6(8):148. https://doi.org/10.3390/nano6080148

Chicago/Turabian StyleKim, Jiyoung, Jin-Sung Jang, Dong-Hyun Peck, Byungrok Lee, Seong-Ho Yoon, and Doo-Hwan Jung. 2016. "Methanol-Tolerant Platinum-Palladium Catalyst Supported on Nitrogen-Doped Carbon Nanofiber for High Concentration Direct Methanol Fuel Cells" Nanomaterials 6, no. 8: 148. https://doi.org/10.3390/nano6080148