Remarkable Magnetic Properties in a Mn73.6Ga26.4 Alloy Produced via Out-of-Equilibrium Method

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Structural Analysis by Diffraction

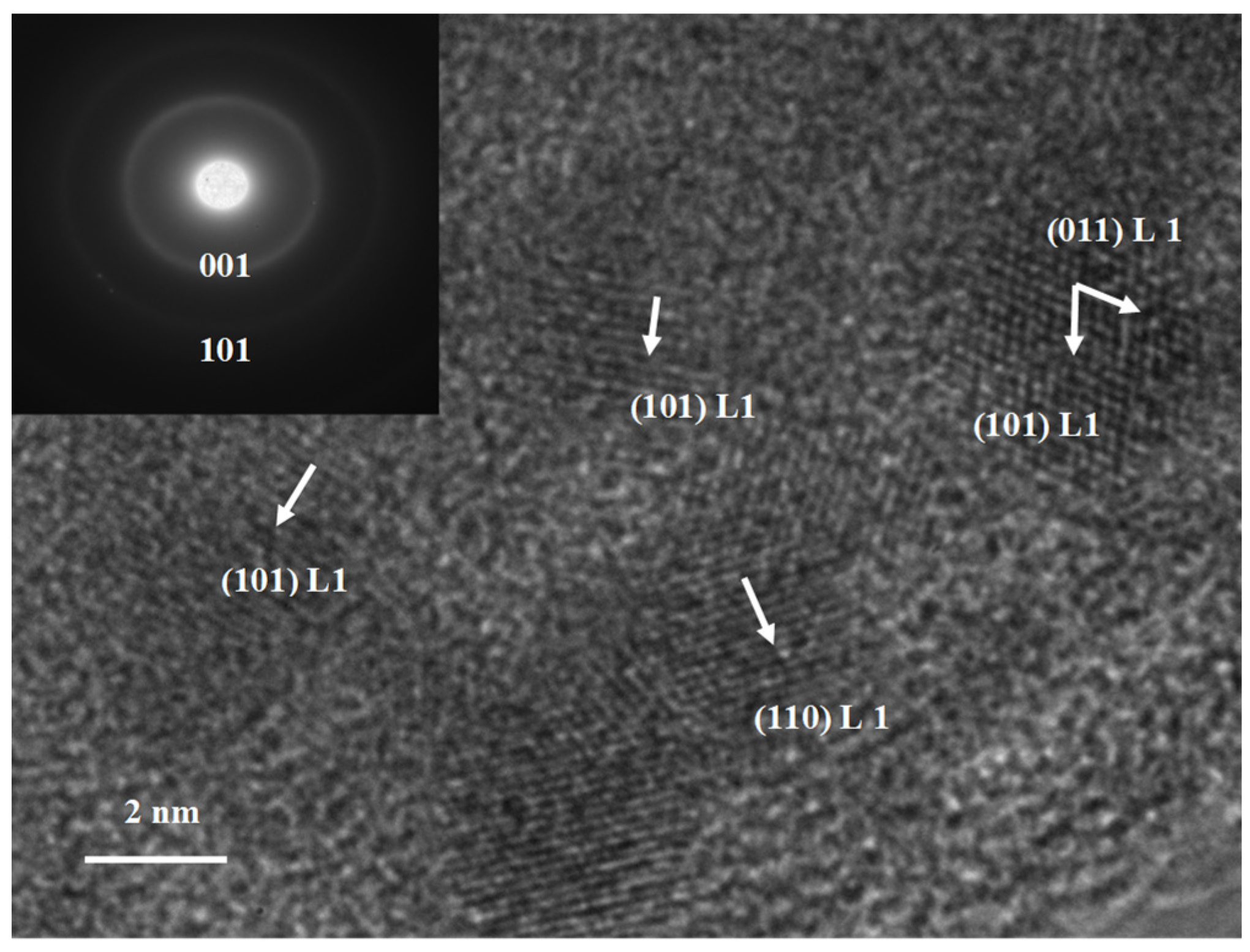

3.2. High-Resolution TEM

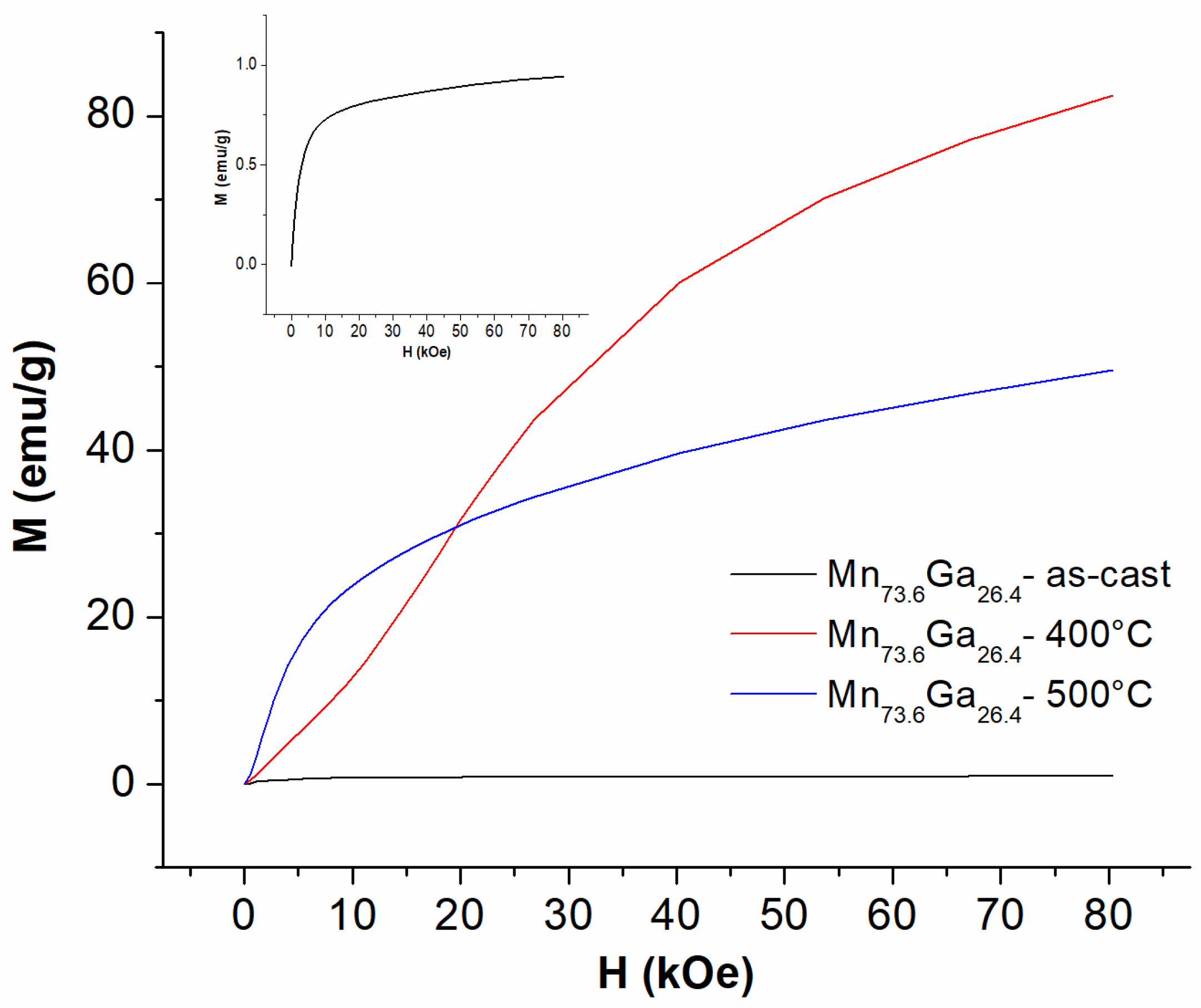

3.3. Magnetic Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Simizu, S.; Obermyer, R.T.; Zande, B.; Chandhok, V.K.; Margolin, A.; Sankar, S.G. Exchange coupling in FePt permanent magnets. J. Appl. Phys. 2003, 93, 8134–8136. [Google Scholar] [CrossRef]

- Crisan, A.D.; Vasiliu, F.; Nicula, R.; Bartha, C.; Mercioniu, I.; Crisan, O. Thermodynamic, structural and magnetic studies of phase transformations in MnAl nanocomposite alloys. Mater. Charact. 2018, 140, 1–8. [Google Scholar] [CrossRef]

- Brandt, A.; Jensen, B.A.; Tang, W.; Liu, X.B.; Nolte, A.I.; Ouyang, G.Y.; Dennis, K.W.; Cui, J. Optimizing composition in MnBi permanent magnet alloys. Acta Mater. 2019, 181, 595–602. [Google Scholar]

- Lin, J.-H.; Pan, K.-Y.; Wei, D.-H.; Chung, R.-J. FePt nanoparticles embedded-rGO nanocomposites for magnetic fluid hyperthermia. Surf. Coat. Technol. 2018, 350, 868–873. [Google Scholar] [CrossRef]

- Maenosono, S.; Suzuki, T.; Saita, S. Superparamagnetic FePt nanoparticles as excellent MRI contrast agents. J. Magn. Magn. Mater. 2008, 320, L79–L83. [Google Scholar] [CrossRef]

- Roca, A.G.; Costo, R.; Rebolledo, A.F.; Veintemillas-Verdaguer, S.; Tartaj, P.; González-Carreño, T.; Morales, M.P.; Serna, C.J. Progress in the preparation of magnetic nanoparticles for applications in biomedicine. J. Phys. D Appl. Phys. 2009, 42, 224002. [Google Scholar] [CrossRef]

- Liang, S.; Wang, F.; Zhang, Z.; Li, Y.; Cai, Y.; Ren, J.; Jiang, X. Monodisperse FePt nanoparticles as highly active electrocatalysts for methanol oxidation. RSC Adv. 2015, 5, 48569–48573. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, B.; Liu, H.; Liu, Z.; Zhang, X.; Zheng, X.; Liu, Q. FePt-Au ternary metallic nanoparticles with the enhanced peroxidase-like activity for ultrafast colorimetric detection of H2O2. Sens. Actuators B Chem. 2018, 259, 775–783. [Google Scholar] [CrossRef]

- Yang, W.; Yu, Y.; Tang, Y.; Li, K.; Zhao, Z.; Li, M.; Yin, G.; Li, H.; Sun, S. Enhancing electrochemical detection of dopamine via dumbbell-like FePt–Fe3O4 nanoparticles. Nanoscale 2017, 9, 1022–1027. [Google Scholar] [CrossRef]

- Sun, S. Recent advances in chemical synthesis, self-assembly, and applications of FePt nanoparticles. Adv. Mater. 2006, 18, 393–403. [Google Scholar] [CrossRef]

- Fukuda, K.; Fujieda, S.; Shinoda, K.; Suzuki, S.; Jeyadevan, B. Low temperature synthesis of FePt alloy nanoparticles by polyol process. J. Phys. Conf. Ser. 2012, 352, 012020. [Google Scholar] [CrossRef]

- Wiedwald, U.; Han, L.; Biskupek, J.; Kaiser, U.; Ziemann, P. Preparation and characterization of supported magnetic nanoparticles prepared by reverse micelles. Beilstein J. Nanotechnol. 2010, 1, 24–47. [Google Scholar] [CrossRef]

- Nguyen, H.L.; Howard, L.E.M.; Giblin, S.R.; Tanner, B.K.; Terry, I.; Hughes, A.K.; Ross, I.M.; Serres, A.A.; Bürckstümmer, H.; Evans, J.S.O. Synthesis of monodispersed fcc and fct FePt/FePd nanoparticles by microwave irradiation. J. Mater. Chem. 2005, 15, 5136–5143. [Google Scholar] [CrossRef]

- Wang, J.; Loh, K.P.; Zhong, Y.L.; Lin, M.; Ding, J.; Foo, Y.L. Bifunctional FePt Core−Shell and Hollow Spheres: Sonochemical Preparation and Self-Assembly. Chem. Mater. 2007, 19, 2566–2572. [Google Scholar] [CrossRef]

- Tamura, S.; Kelgenbaeva, Z.; Yamamoto, K.; Chen, L.; Mashimo, T. Preparation of FePt Nanoparticles by Pulsed Plasma in Liquid Method. Key Eng. Mater. 2017, 730, 248–252. [Google Scholar] [CrossRef]

- Liu, X.; He, S.; Qiu, J.-M.; Wang, J.-P. Nanocomposite exchange-spring magnet synthesized by gas phase method: From isotropic to anisotropic. Appl. Phys. Lett. 2011, 98, 222507. [Google Scholar] [CrossRef]

- Lyubina, J. Nanocrystalline hard magnetic FePt powders. J. Appl. Phys. 2004, 95, 7474. [Google Scholar] [CrossRef]

- Crisan, O.; Dan, I.; Palade, P.; Crisan, A.D.; Leca, A.; Pantelica, A. Magnetic Phase Coexistence and Hard–Soft Exchange Coupling in FePt Nanocomposite Magnets. Nanomaterials 2020, 10, 1618. [Google Scholar] [CrossRef]

- Crisan, A.D.; Crisan, O. Direct formation of L10 FePt in as-cast FePt-based magnetic nanocomposite ribbons without post-synthesis annealing. J. Phys. D Appl. Phys. 2011, 44, 365002. [Google Scholar] [CrossRef]

- Hao, L.Y.; Xiong, W. An evaluation of the Mn-Ga system: Phase diagram, crystal structure, magnetism and thermodynamic properties. Calphad 2020, 68, 101722. [Google Scholar] [CrossRef]

- Holguín-Momaca, J.T.; Muñoz-Carnero, C.J.; Sharma, H.; Santillán-Rodríguez, C.R.; Matutes-Aquino, J.A.; Tomy, C.V.; Olive-Méndez, S.F. Tuning the ferromagnetism of epitaxial-strained D019-Mn3Ga thin films. J. Magn. Magn. Mater. 2019, 471, 329–333. [Google Scholar] [CrossRef]

- Zhao, X.P.; Lu, J.; Mao, S.W.; Yu, Z.F.; Wei, D.H.; Zhao, J.H. Spin-orbit torque induced magnetization switching in ferrimagnetic Heusler alloy D22- Mn3Ga with large perpendicular magnetic anisotropy. Appl. Phys. Lett. 2019, 115, 142405. [Google Scholar] [CrossRef]

- Awari, N.; Kovalev, S.; Fowley, C.; Rode, K.; Gallardo, R.A.; Lau, Y.-C.; Betto, D.; Thiyagarajah, N.; Green, B.; Yildirim, O.; et al. Narrow-band tunable terahertz emission from ferrimagnetic Mn3-xGa thin films. Appl. Phys. Lett. 2016, 109, 032403. [Google Scholar] [CrossRef]

- Coey, J.M.D. New permanent magnets: Manganese compounds. J. Phys. Condens. Matter 2014, 26, 064211. [Google Scholar] [CrossRef]

- Niida, H.; Hori, T.; Onodera, H.; Yamaguchi, Y.; Nakagawa, Y. Magnetization and coercivity of Mn3−δGa alloys with a D022-type structure. J. Appl. Phys. 1996, 79, 5946–5948. [Google Scholar] [CrossRef]

- Ma, Q.L.; Mizukami, S.; Kubota, T.; Zhang, X.M.; Ando, Y.; Miyazaki, T. Abrupt Transition from Ferromagnetic to Antiferromagnetic of Interfacial Exchange in Perpendicularly Magnetized L10-MnGa/FeCo Tuned by Fermi Level Position. Phys. Rev. Lett. 2014, 112, 157202. [Google Scholar] [CrossRef]

- Oshima, D.; Tanimoto, M.; Kato, T.; Fujiwara, Y.; Nakamura, T.; Kotani, Y.; Tsunashima, S.; Iwata, S. Ion Irradiation-Induced Magnetic Transition of MnGa Alloy Films Studied by X-ray Magnetic Circular Dichroism and Low-Temperature Hysteresis Loops. IEEE Trans. Magn. 2016, 52, 3201804. [Google Scholar] [CrossRef]

- Arins, A.W.; Jurca, H.F.; Zarpellon, J.; Varalda, J.; Graff, I.L.; Schreiner, W.H.; Mosca, D.H. Structure and Magnetism of MnGa Ultra-Thin Films on GaAs(111)B. IEEE Trans. Magn. 2013, 49, 5595–5598. [Google Scholar] [CrossRef]

- Ono, A.; Suzuki, K.Z.; Ranjbar, R.; Sugihara, A.; Mizukami, S. Ultrathin films of polycrystalline MnGa alloy with perpendicular magnetic anisotropy. Appl. Phys. Express 2017, 10, 023005. [Google Scholar] [CrossRef]

- Tsunegi, S.; Mizunuma, K.; Suzuki, K.; Imamura, H.; Tamaru, S.; Yoshimura, M.; Sato, M.; Kono, Y.; Wado, H.; Fukushima, A.; et al. Spin torque diode effect of the magnetic tunnel junction with MnGa free layer. Appl. Phys. Lett. 2018, 112, 262408. [Google Scholar] [CrossRef]

- Zhu, L.J.; Zhao, J.H. Electrical Transport of Perpendicularly Magnetized L10-MnGa and MnAl Films. Spin 2017, 7, 1730001. [Google Scholar] [CrossRef]

- Wang, K.; Chinchore, A.; Lin, W.; Smith, A.; Sun, K. Delta-phase manganese gallium on gallium nitride: A magnetically tunable spintronic system. MRS Online Proc. Libr. (OPL) 2008, 1118, 606. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Nguyen, C.C.; Nguyen, T.T.; Pham, K.H. Factors on the magnetic properties of the iron nanoparticles by classical Heisenberg model. Phys. B 2018, 532, 144–148. [Google Scholar] [CrossRef]

- Sarac, U.; Nguyen, T.D.; Baykul, M.C.; Long, V.C.; Nguyen, D.T.; Lan, D.P.; Talu, S. Electrolyte pH dependence of composition, roughness parameters, particle diameter and magnetic features of nanostructured Fe-Co-Ni/ITO deposits prepared by electrochemical deposition method. J. Microsc. 2023, 290, 106–116. [Google Scholar] [CrossRef] [PubMed]

- Brown, D.R. Hard Magnetic Materials without Rare Earth Elements. Ph.D. Thesis, Florida State University, Tallahassee, FL, USA, 2016. Available online: http://purl.flvc.org/fsu/fd/FSU_2016SU_Brown_fsu_0071E_13418 (accessed on 10 November 2023).

- Zhmetko, D.N. Experimental method for determining the total demagnetizing factor of thin amorphous ribbons. J. Magn. Magn. Mater. 2011, 323, 2888–2891. [Google Scholar] [CrossRef]

- Winterlik, J.; Balke, B.; Fecher, G.H.; Felser, C.; Alves, M.C.M.; Bernardi, F.; Morais, J. Structural, electronic and magnetic properties of tetragonal Mn3-xGa: Experiments and first-principles calculations. Phys. Rev. B 2008, 77, 054406. [Google Scholar] [CrossRef]

- Kurt, H.; Rode, K.; Venkatesan, M.; Stamenov, P.; Coey, J.M.D. Mn3−xGa (0 ≤ x ≤ 1): Multifunctional thin film materials for spintronics and magnetic recording. Phys. Stat. Solidi B 2011, 248, 2338–2344. [Google Scholar] [CrossRef]

- Ren, L.Z.; Liu, L.; Shu, X.Y.; Lin, W.N.; Yang, P.; Chen, J.S.; Teo, K.L. Spin–Orbit Torque Switching of a High-Quality Perpendicularly Magnetized Ferrimagnetic Heusler Mn3Ge Film. ACS Appl. Mater. Interfaces 2021, 13, 18294–18300. [Google Scholar] [CrossRef] [PubMed]

- Sugihara, A.; Mizukami, S.; Yamada, Y.; Koike, K.; Miyazaki, T. High perpendicular magnetic anisotropy in D22-Mn3+xGe tetragonal Heusler alloy films. Appl. Phys. Lett. 2014, 104, 132404. [Google Scholar] [CrossRef]

| Sample | D022 1 | L10 1 | Abundance 2 |

|---|---|---|---|

| Mn73.6Ga26.4 annealed at 400 °C | a = 3.891 Å c = 7.072 Å | a = 3.879 Å c = 3.582 Å | D022: 58% L10: 27% |

| Mn73.6Ga26.4 annealed at 500 °C | a = 3.886 Å c = 7.064 Å | a = 3.876 Å c = 3.579 Å | D022: 72% L10: 12% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crisan, O.; Crisan, A.D. Remarkable Magnetic Properties in a Mn73.6Ga26.4 Alloy Produced via Out-of-Equilibrium Method. Nanomaterials 2023, 13, 3014. https://doi.org/10.3390/nano13233014

Crisan O, Crisan AD. Remarkable Magnetic Properties in a Mn73.6Ga26.4 Alloy Produced via Out-of-Equilibrium Method. Nanomaterials. 2023; 13(23):3014. https://doi.org/10.3390/nano13233014

Chicago/Turabian StyleCrisan, Ovidiu, and Alina Daniela Crisan. 2023. "Remarkable Magnetic Properties in a Mn73.6Ga26.4 Alloy Produced via Out-of-Equilibrium Method" Nanomaterials 13, no. 23: 3014. https://doi.org/10.3390/nano13233014