One-Pot Synthesis of Pt High Index Facets Catalysts for Electrocatalytic Oxidation of Ethanol

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis of Catalyst with PVP as Variable

2.3. Synthesis of Catalyst with Glycine as Variable

2.4. Preparation of Working Electrode

2.5. Characterization

2.6. Electrochemical Characterization

3. Results and Discussion of Catalysts with PVP as Variable

3.1. Characterization

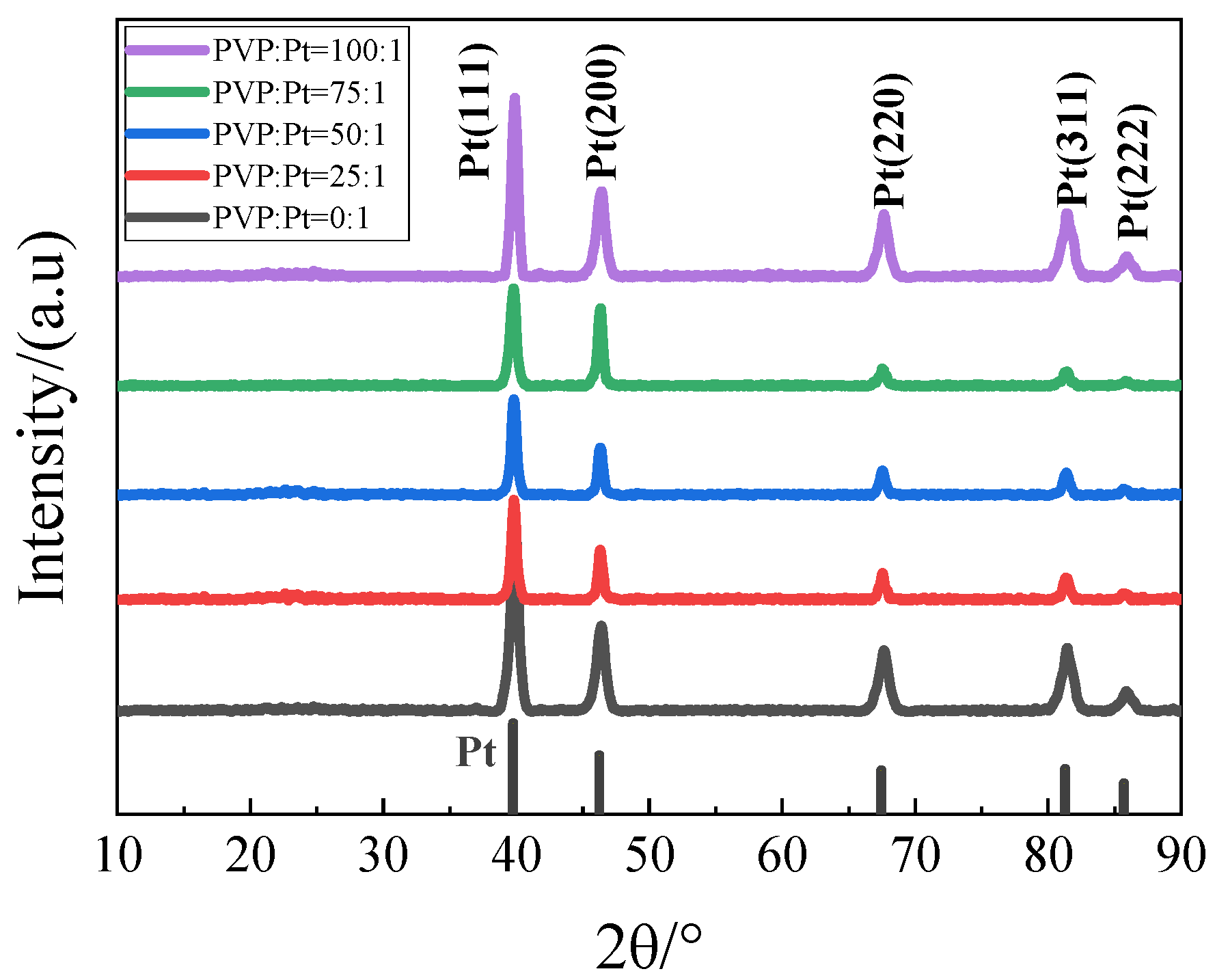

3.1.1. X-ray Diffraction (XRD) Characterization of the Catalysts

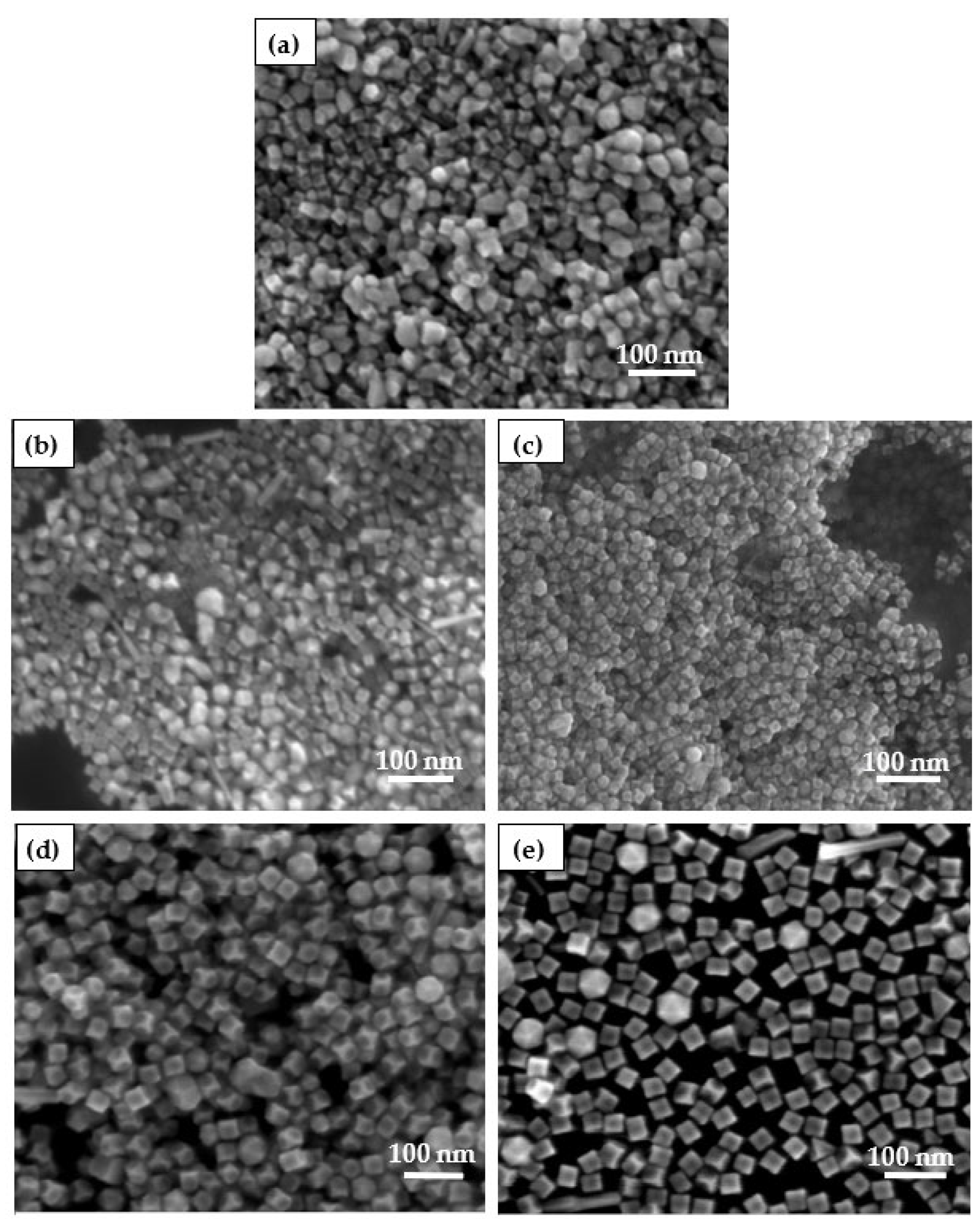

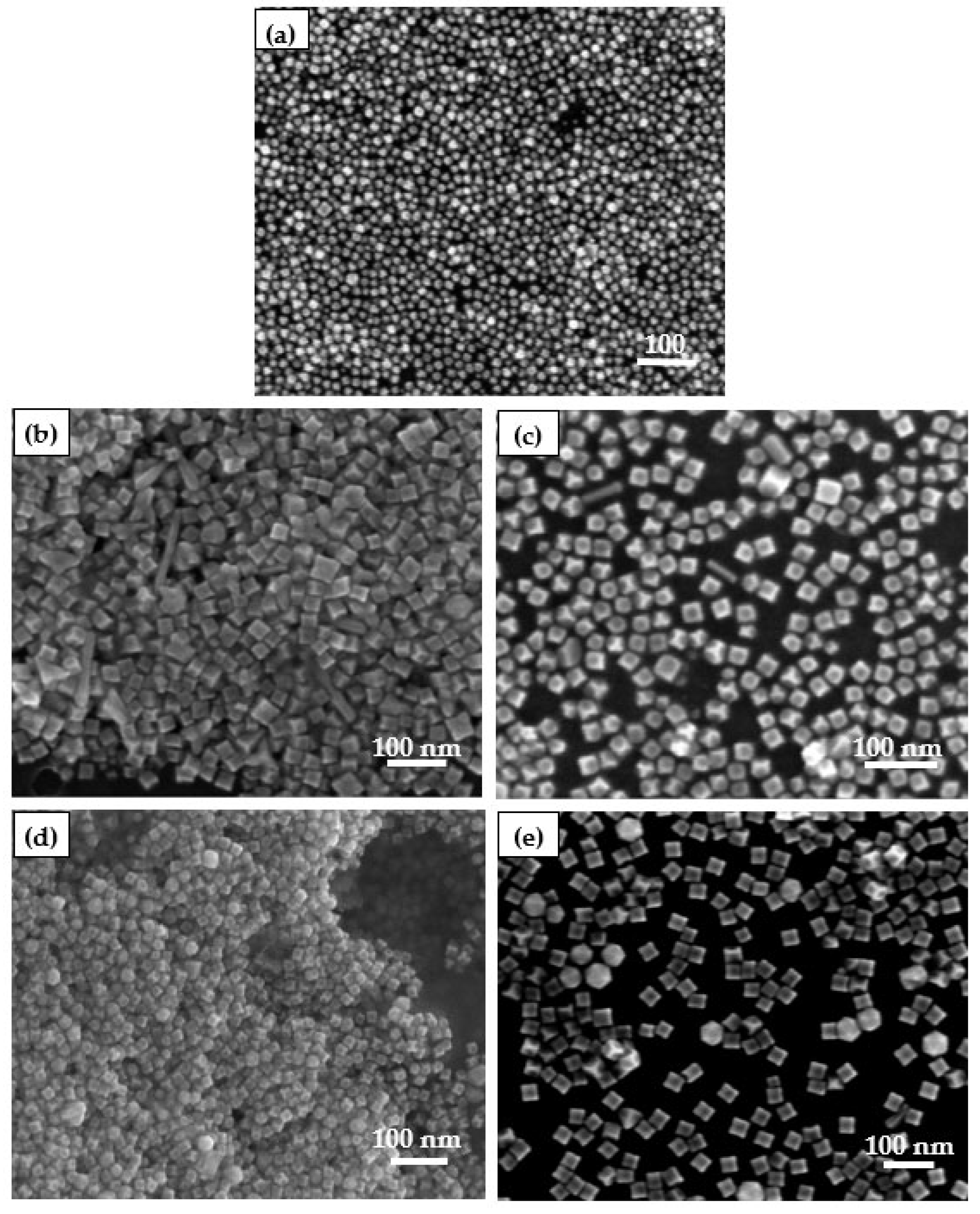

3.1.2. SEM Characterization of the Catalysts

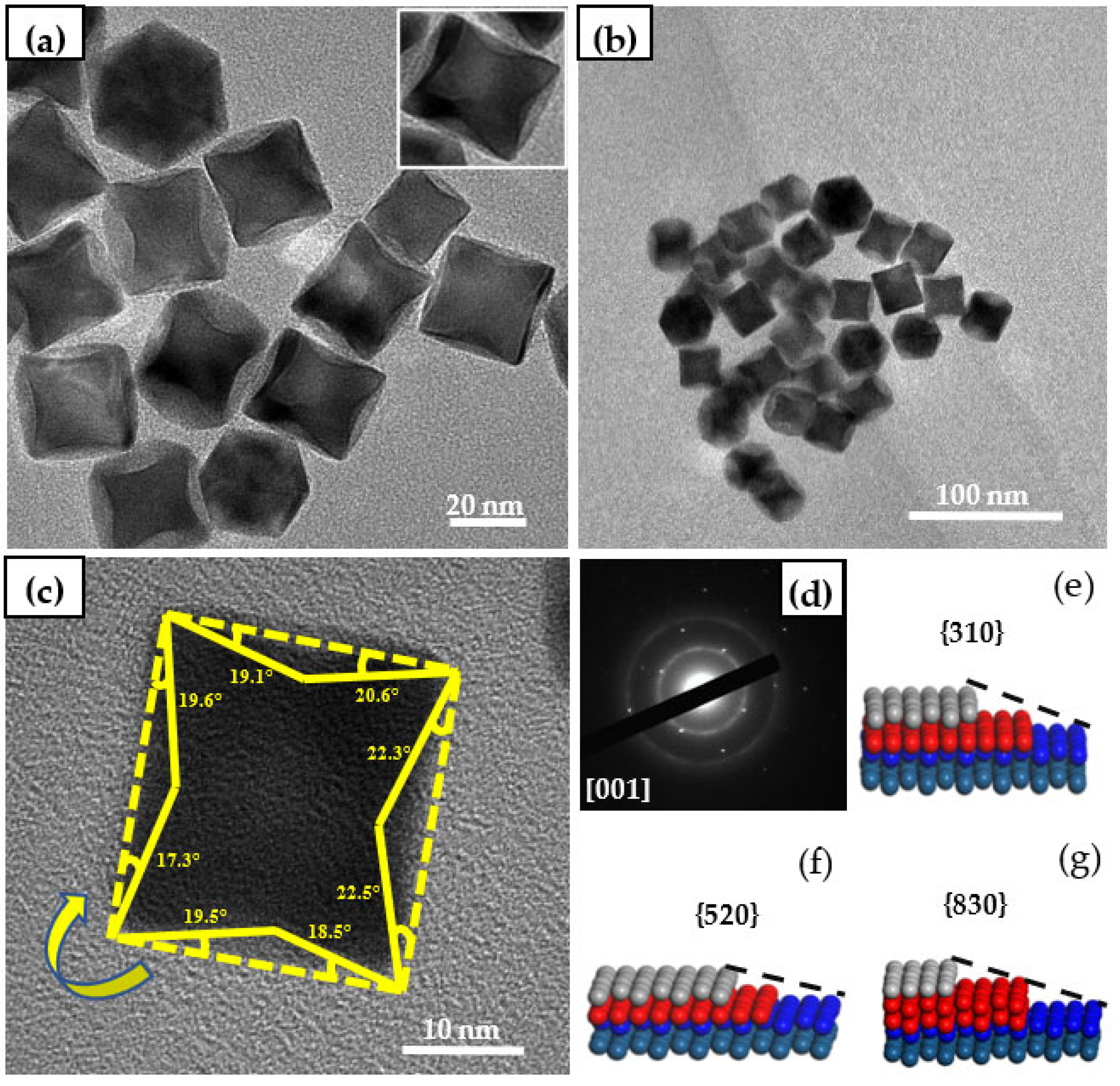

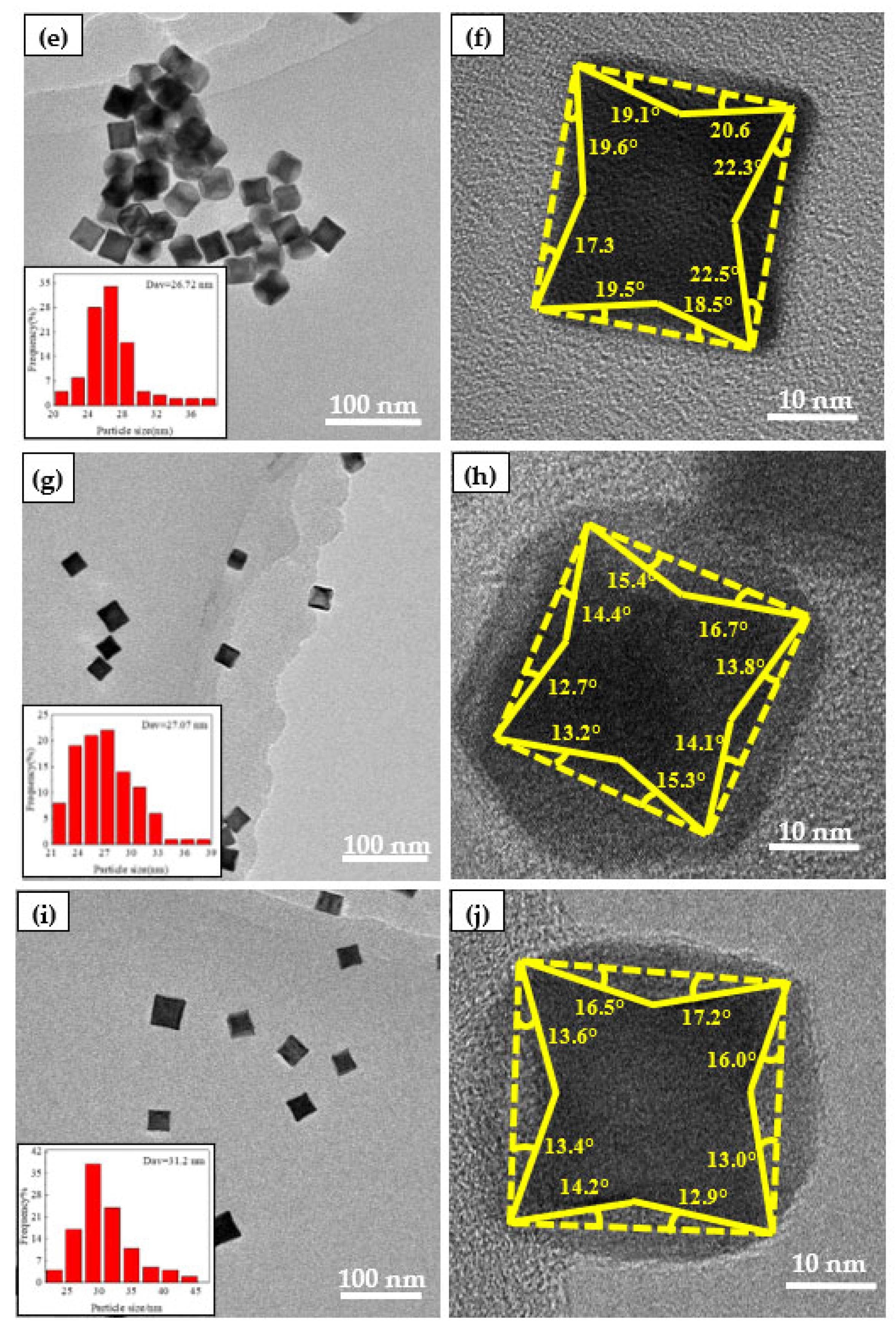

3.1.3. TEM Characterization of the Catalysts

3.2. Electrochemical Characterization

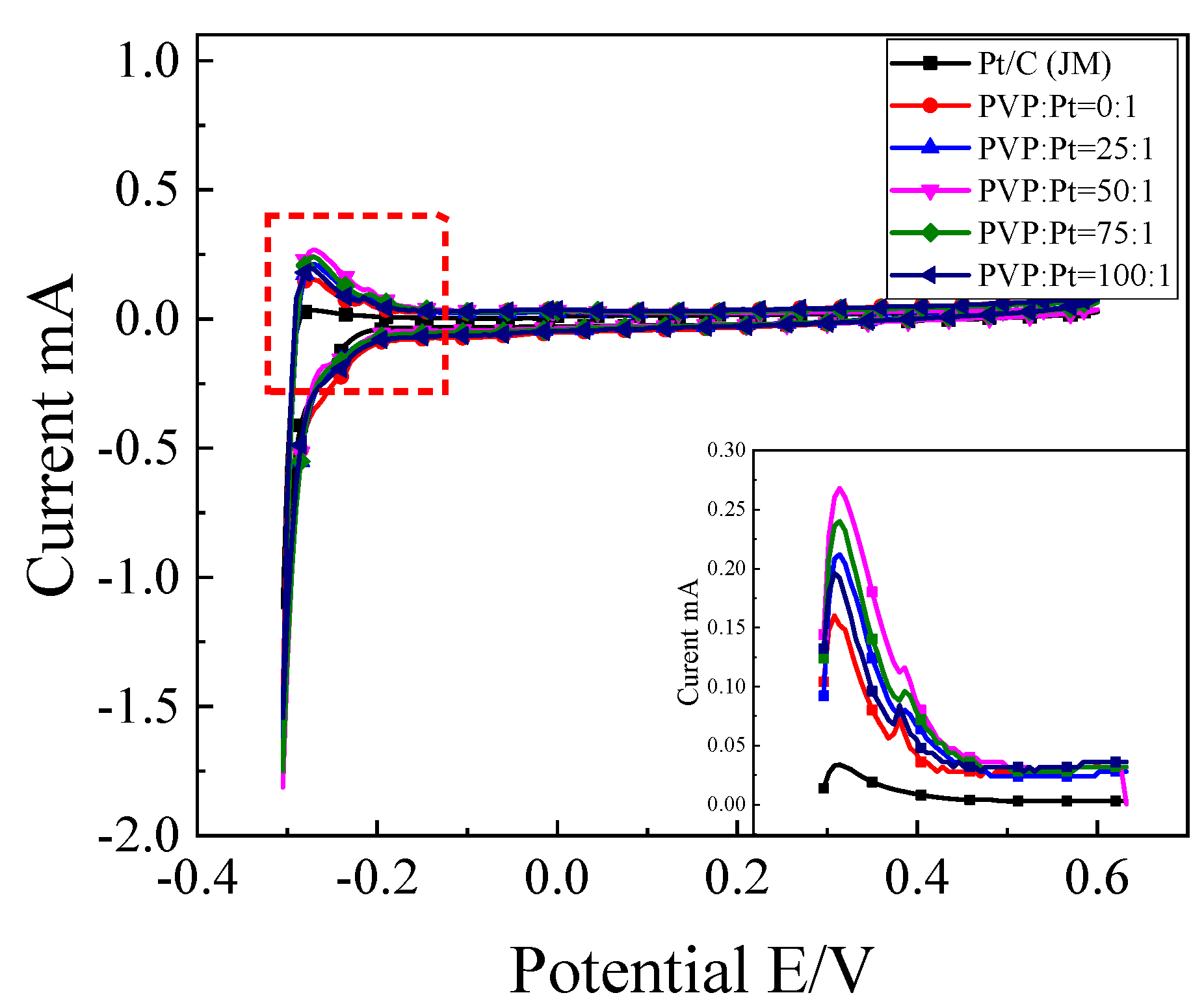

3.2.1. Electrochemical Active Surface Area of Catalyst

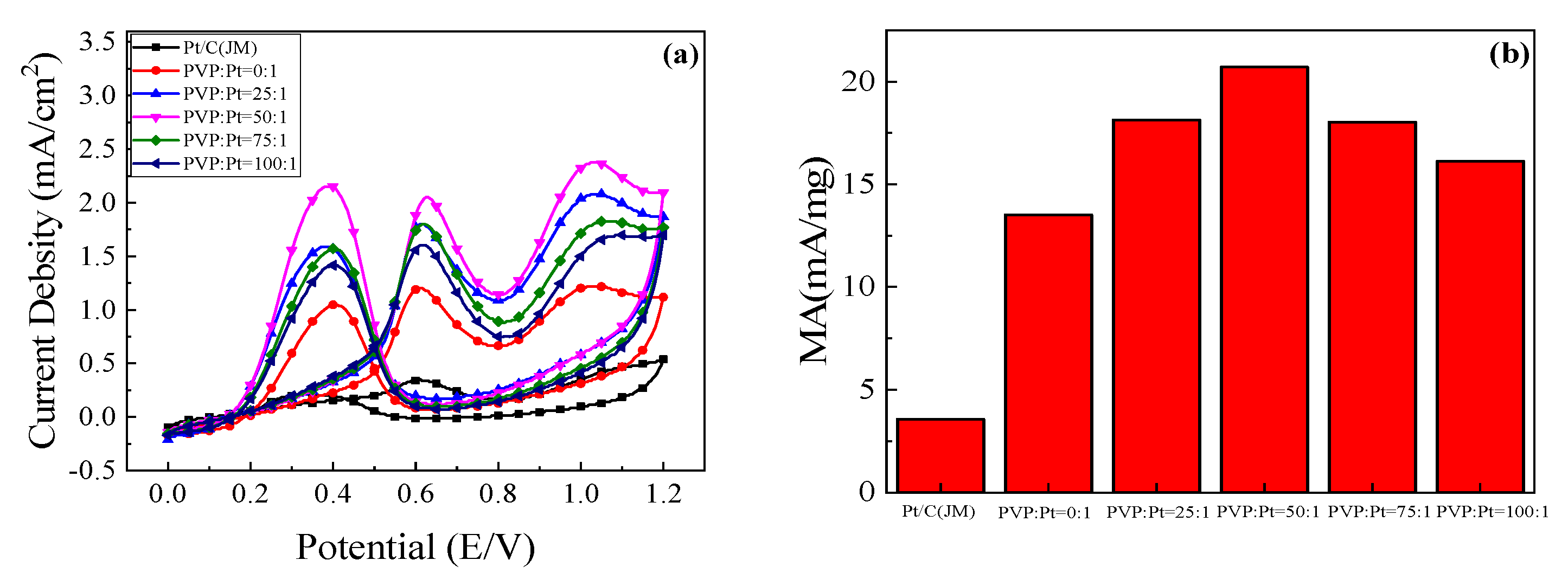

3.2.2. Cyclic Voltammetry of the Catalysts in Ethanol Oxidation

3.2.3. I–t Curves of the Catalysts

3.2.4. Anti-CO Poisoning Test of the Catalysts

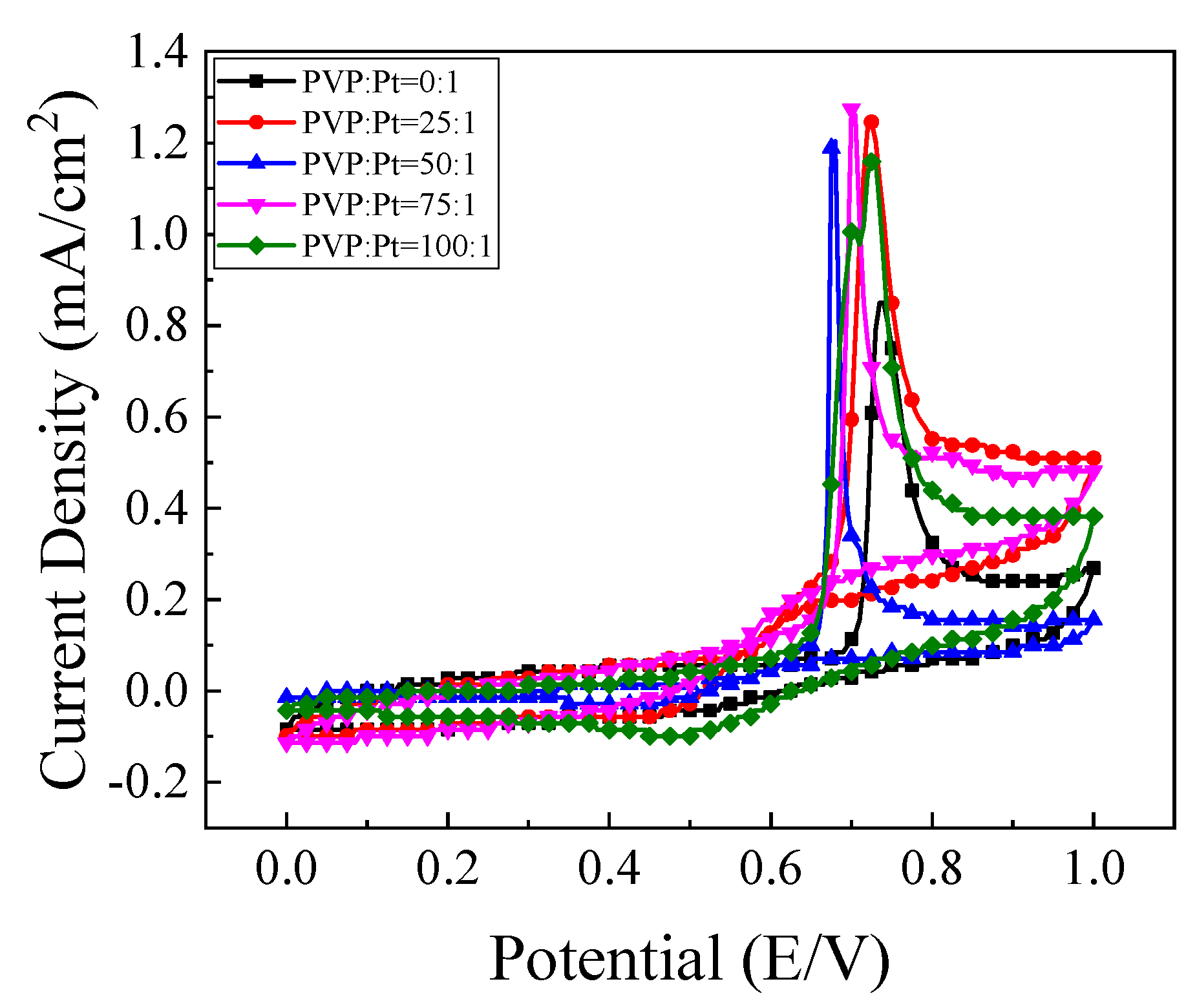

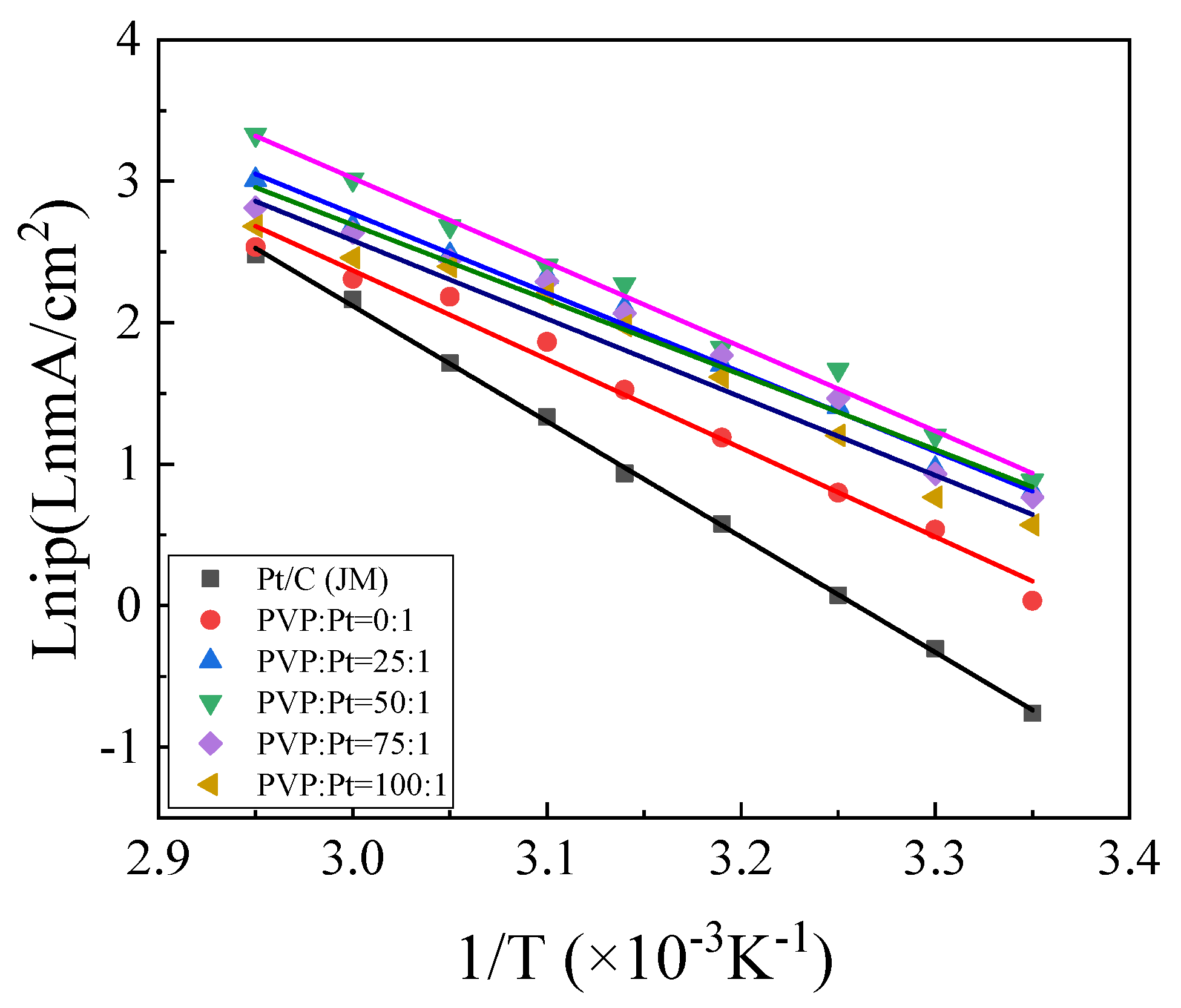

3.2.5. Variable-Temperature Cyclic Voltammetry of the Catalysts

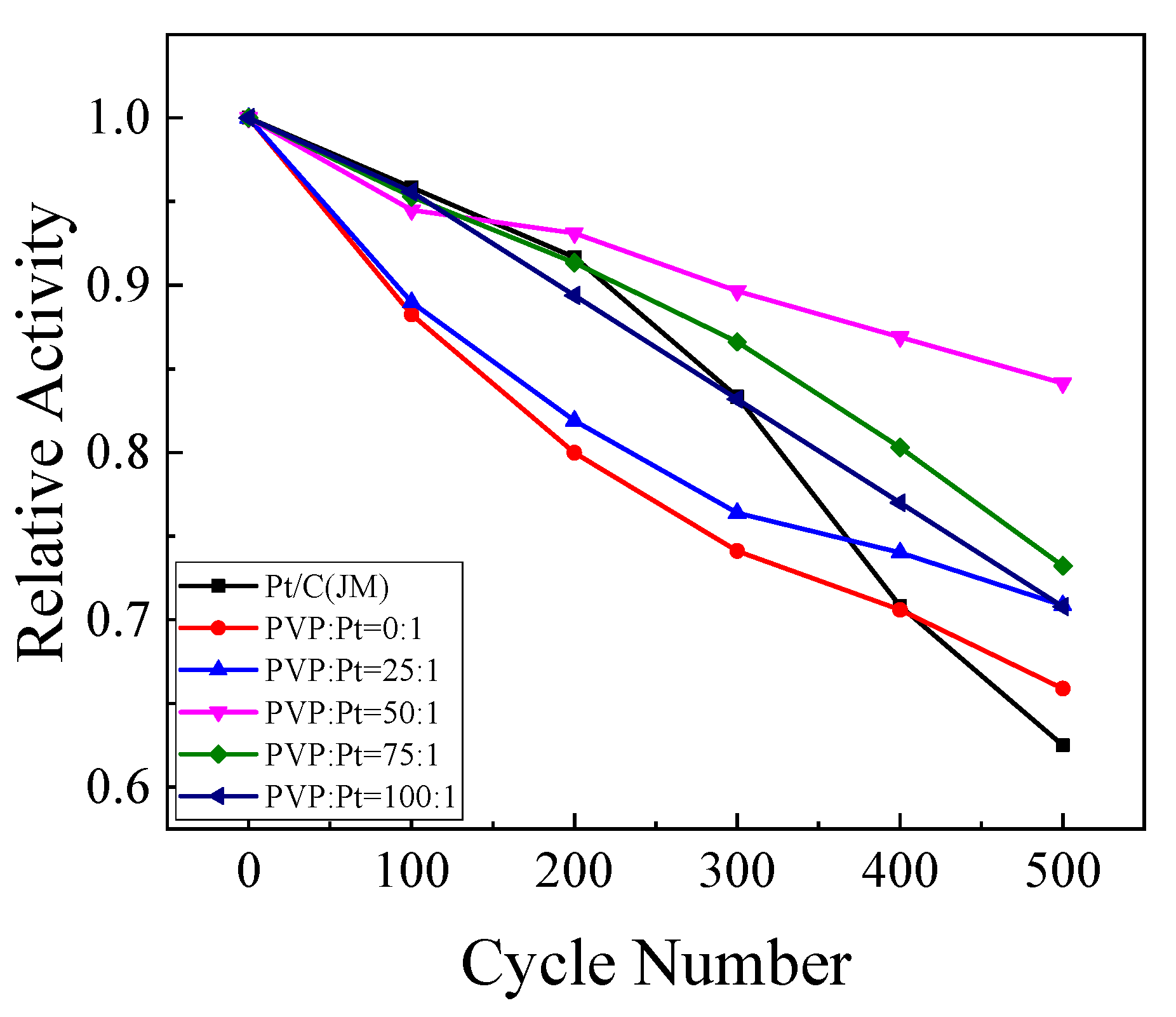

3.2.6. Cyclic Voltammetry Analysis of Degradation of the Catalysts

4. Results and Discussion of Catalysts with Glycine as Variable

4.1. Characterization

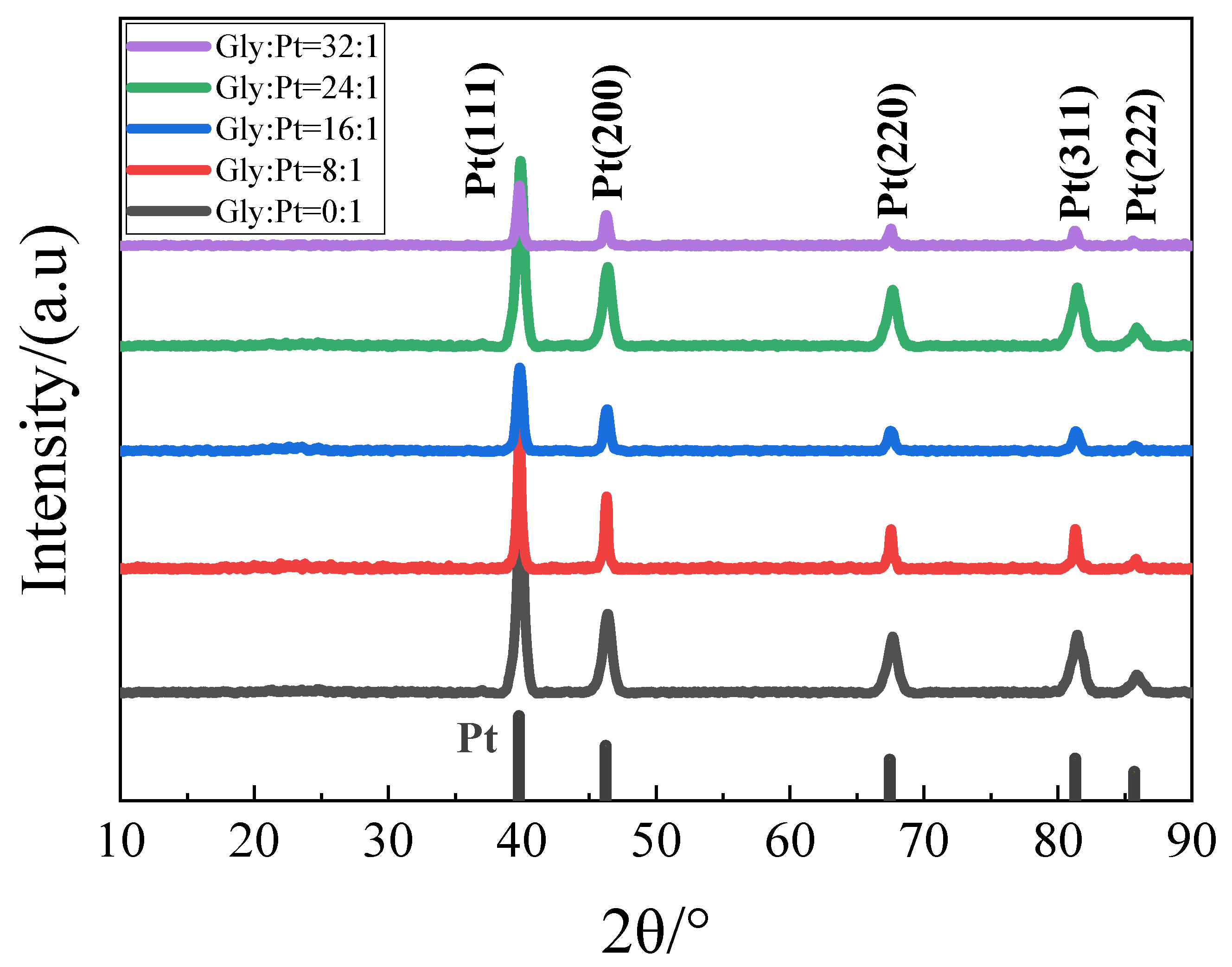

4.1.1. X-ray Diffraction (XRD) Characterization of the Catalysts

4.1.2. SEM Characterization of the Catalysts

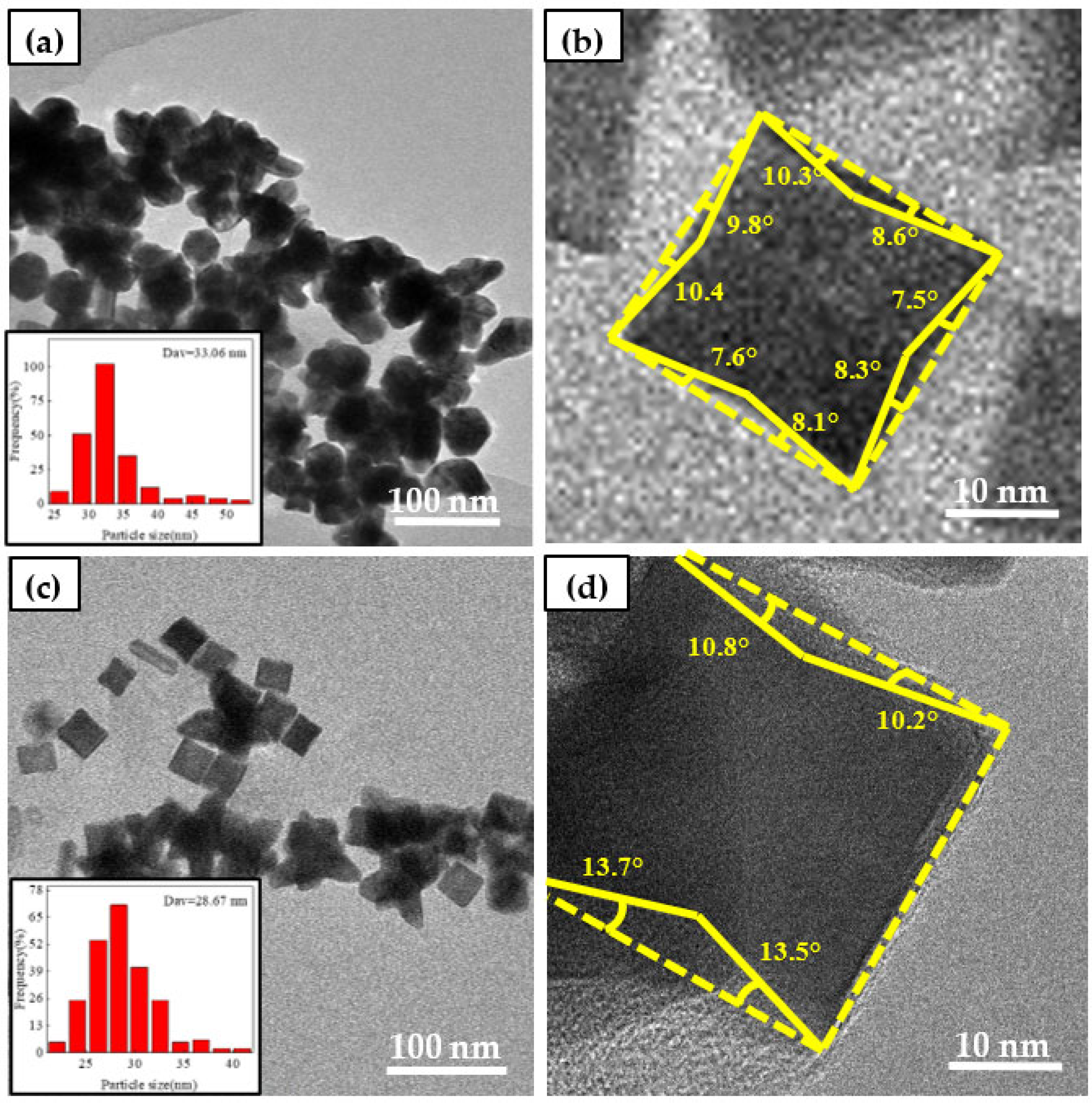

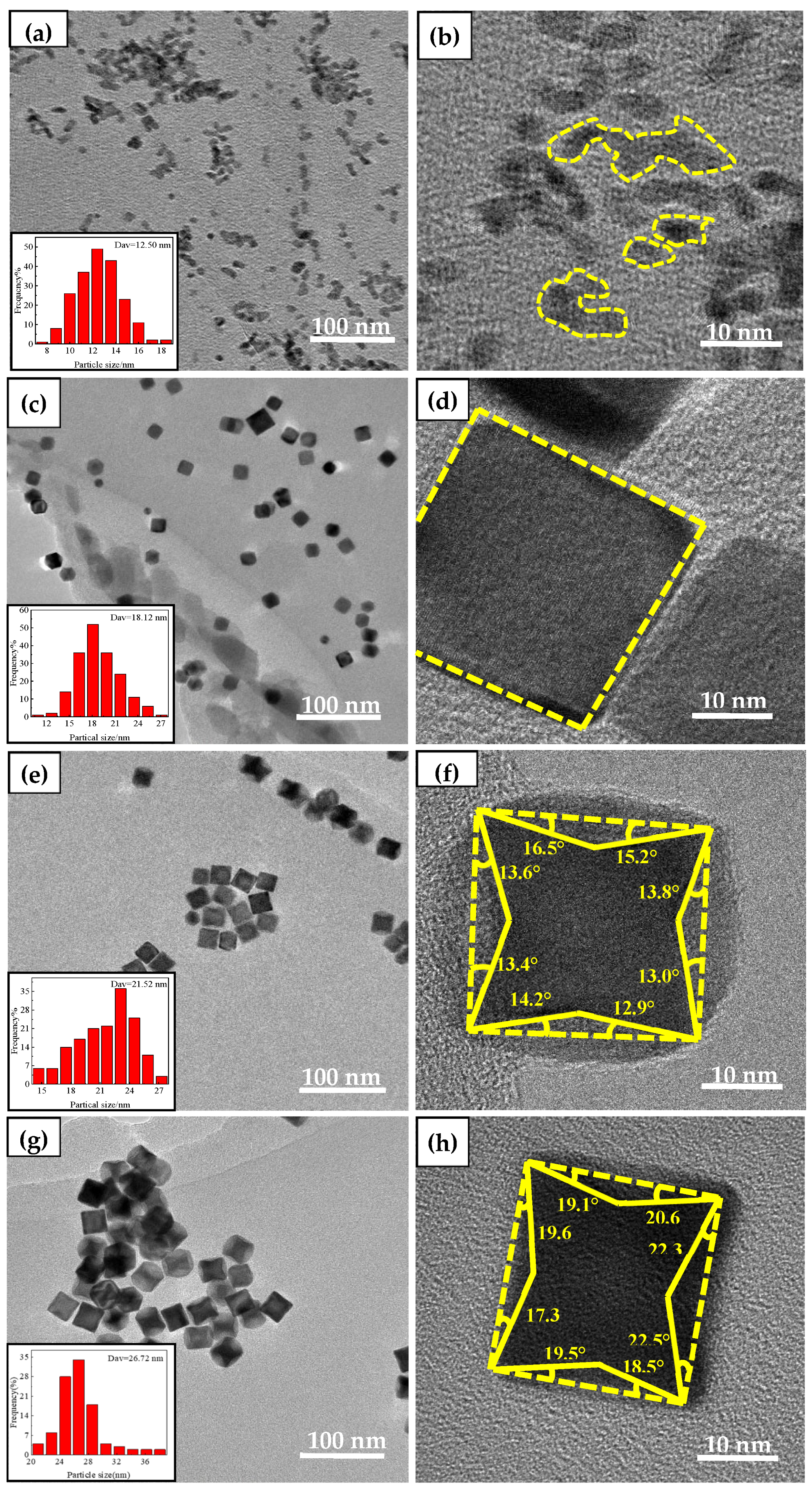

4.1.3. TEM Characterization of the Catalysts

4.2. Electrochemical Characterization

4.2.1. Electrochemical Active Surface Area of Catalyst

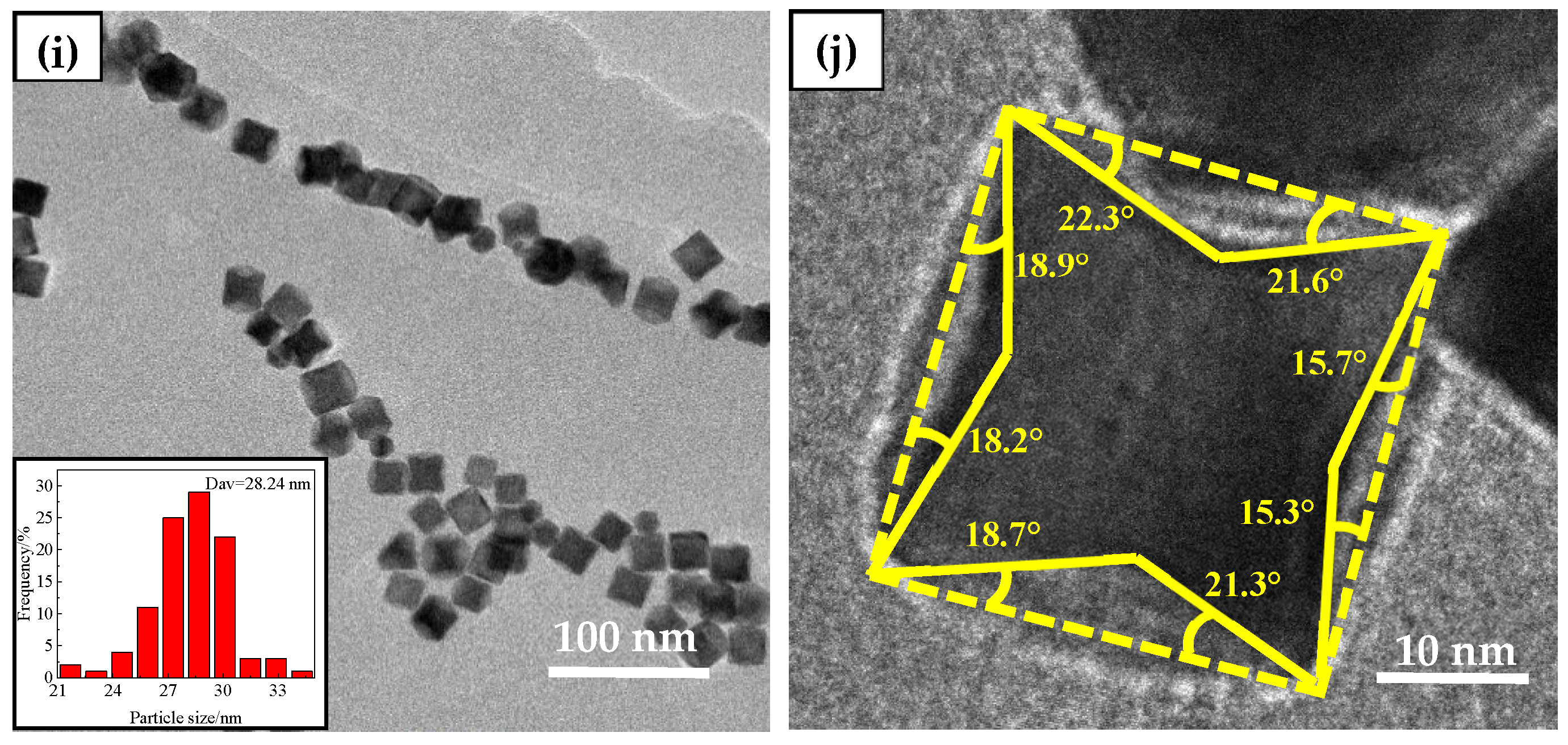

4.2.2. Cyclic Voltammetry of the Catalysts in Ethanol Oxidation

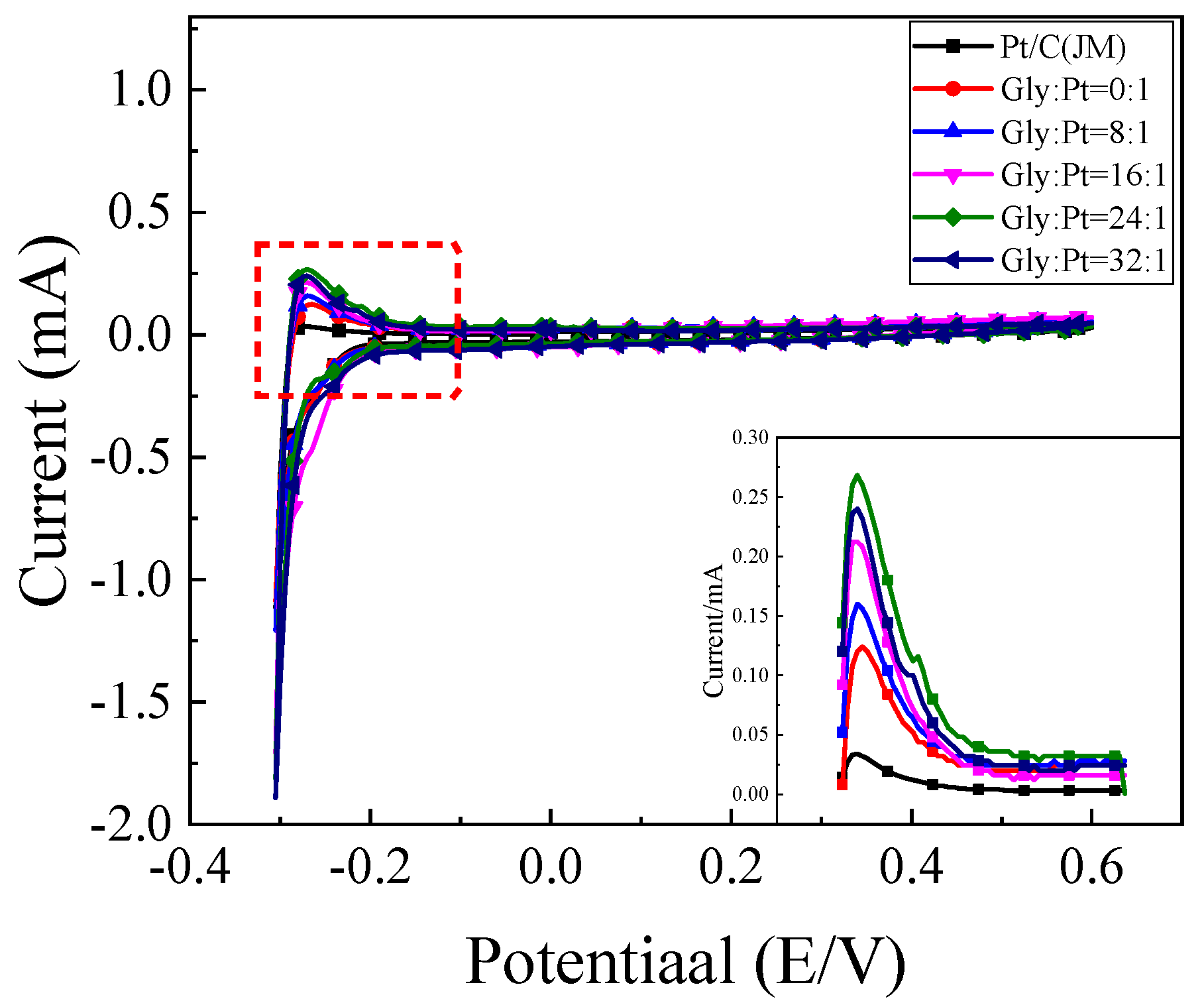

4.2.3. I–t Curves of the Catalysts

4.2.4. Anti-CO Poisoning Test of the Catalysts

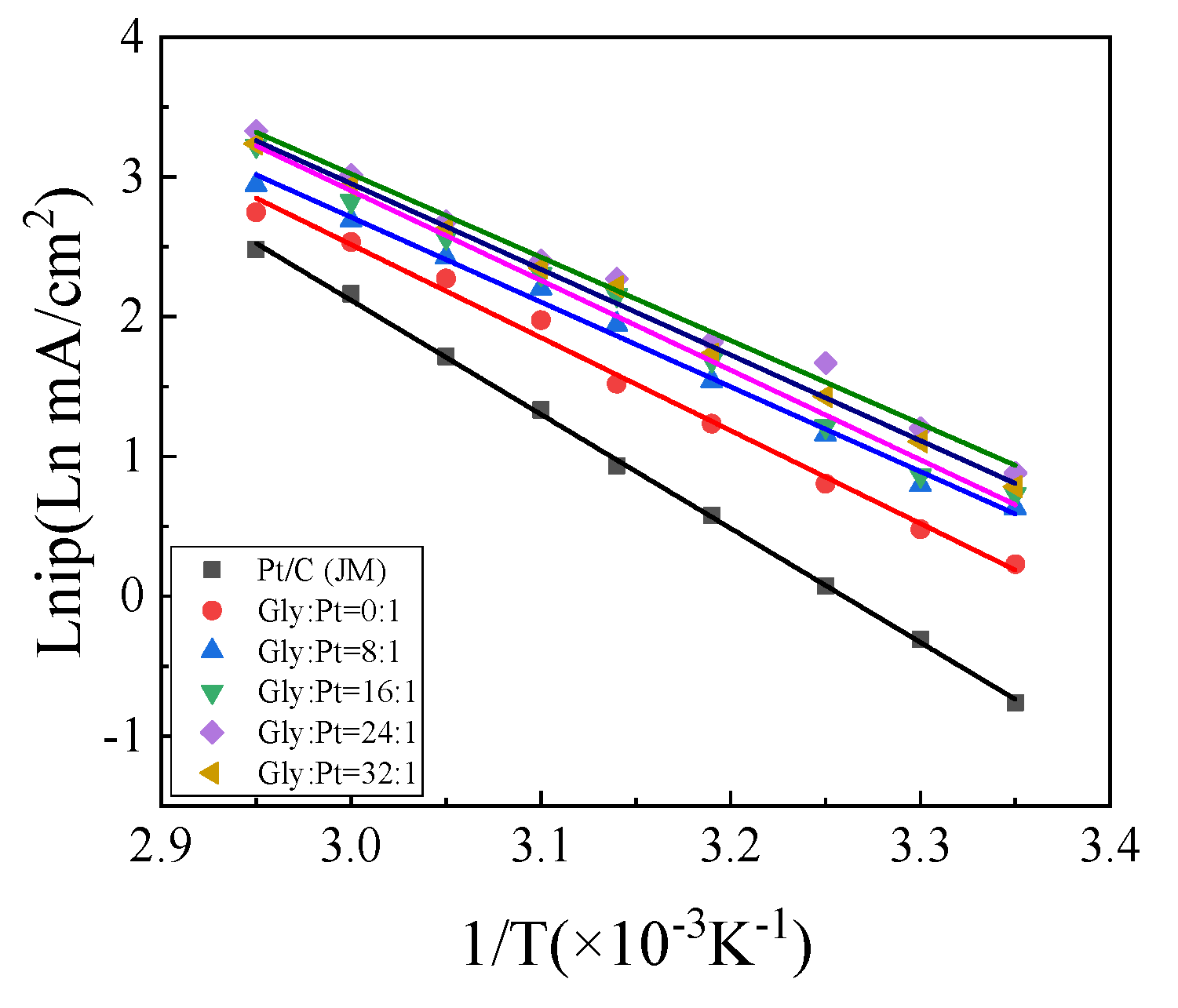

4.2.5. Variable-Temperature Cyclic Voltammetry of the Catalysts

4.2.6. Cyclic Voltammetry Analysis of Degradation of the Catalysts

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meléndez-González, P.C.; Sánchez-Castro, E.; Alonso-Lemus, I.L.; Pérez-Hernández, R.; Escobar-Morales, B.; Garay-Tapia, A.M.; Pech-Rodríguez, W.J.; Rodríguez-Varela, J. Bifunctional Pd-CeO 2 Nanorods/C Nanocatalyst with High Electrochemical Stability and Catalytic Activity for the ORR and EOR in Alkaline Media. ChemistrySelect 2020, 5, 14032–14040. [Google Scholar] [CrossRef]

- Gomes, R.S.; De Souza, M.M.; De Bortoli, L. Development of analytical and numerical solutions for direct ethanol fuel cells. Heat Mass Transf. 2019, 55, 3301–3316. [Google Scholar] [CrossRef]

- García-Rodríguez, S.; Rojas, S.; Peña, M.; Fierro, J.; Baranton, S.; Léger, J. An FTIR study of Rh-PtSn/C catalysts for ethanol electrooxidation: Effect of surface composition. Appl. Catal. B Environ. 2011, 106, 520–528. [Google Scholar] [CrossRef]

- Wang, B.; Tao, L.; Cheng, Y.; Yang, F.; Jin, Y.; Zhou, C.; Yu, H.; Yang, Y. Electrocatalytic Oxidation of Small Molecule Alcohols over Pt, Pd, and Au Catalysts: The Effect of Alcohol’s Hydrogen Bond Donation Ability and Molecular Structure Properties. Catalysts 2019, 9, 387. [Google Scholar] [CrossRef] [Green Version]

- Huang, L.; Zaman, S.; Wang, Z.T.; Niu, H.T.; You, B.; Xia, B.Y. Synthesis and Application of Platinum-Based Hollow Nanoframes for Direct Alcohol Fuel Cells. Acta Phys.-Chim. Sin. 2021, 37, 2009035. [Google Scholar] [CrossRef]

- Antolini, E. Pt-Ni and Pt-M-Ni (M = Ru, Sn) Anode Catalysts for Low-Temperature Acidic Direct Alcohol Fuel Cells: A Review. Energies 2017, 10, 42. [Google Scholar] [CrossRef] [Green Version]

- Ledendecker, M.; Calderón, S.K.; Papp, C.; Steinrück, H.-P.; Antonietti, M.; Shalom, M. The Synthesis of Nanostructured Ni5P4Films and their Use as a Non-Noble Bifunctional Electrocatalyst for Full Water Splitting. Angew. Chem. Int. Ed. 2015, 54, 12361–12365. [Google Scholar] [CrossRef]

- Hoshi, N.; Kawatani, S.; Kudo, M.; Hori, Y. Significant enhancement of the electrochemical reduction of CO2 at the kink sites on Pt(S)-[n(110)×(100)] and Pt(S)-[n(100)×(110)]. J. Electroanal. Chem. 1999, 467, 67–73. [Google Scholar] [CrossRef]

- Tian, N.; Zhou, Z.-Y.; Sun, S.-G.; Ding, Y.; Wang, Z.L. Synthesis of Tetrahexahedral Platinum Nanocrystals with High-Index Facets and High Electro-Oxidation Activity. Science 2007, 316, 732–735. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, Z.; Fan, J.; Tan, Y.; Zheng, N. Amine-Assisted Synthesis of Concave Polyhedral Platinum Nanocrystals Having {411} High-Index Facets. J. Am. Chem. Soc. 2011, 133, 4718–4721. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, J. Graphene oxide nanosheet-supported Pt concave nanocubes with high-index facets for high-performance H2O2 sensing. Anal. 2019, 144, 2436–2442. [Google Scholar] [CrossRef]

- Ming, T.; Feng, W.; Tang, Q.; Wang, F.; Sun, L.; Wang, J.; Yan, C. Growth of Tetrahexahedral Gold Nanocrystals with High-Index Facets. J. Am. Chem. Soc. 2009, 131, 16350–16351. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Langille, M.R.; Personick, M.L.; Zhang, K.; Li, S.; Mirkin, C.A. Concave Cubic Gold Nanocrystals with High-Index Facets. J. Am. Chem. Soc. 2010, 132, 14012–14014. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Zhang, Q.; Lu, X.; Lee, J.Y. Seed-Mediated Synthesis of Monodisperse Concave Trisoctahedral Gold Nanocrystals with Controllable Sizes. J. Phys. Chem. C 2010, 114, 11119–11126. [Google Scholar] [CrossRef]

- Hong, J.W.; Lee, S.-U.; Lee, Y.W.; Han, S.W. Hexoctahedral Au Nanocrystals with High-Index Facets and Their Optical and Surface-Enhanced Raman Scattering Properties. J. Am. Chem. Soc. 2012, 134, 4565–4568. [Google Scholar] [CrossRef]

- Wang, Z.L. Transmission Electron Microscopy of Shape-Controlled Nanocrystals and Their Assemblies. J. Phys. Chem. B 2000, 104, 1153–1175. [Google Scholar] [CrossRef]

- Hoppe, C.E.; Lazzari, M.; Pardiñas-Blanco, I.; López-Quintela, M.A. One-Step Synthesis of Gold and Silver Hydrosols Using Poly(N-vinyl-2-pyrrolidone) as a Reducing Agent. Langmuir 2006, 22, 7027–7034. [Google Scholar] [CrossRef]

- Van Hove, M.; Somorjai, G. A new microfacet notation for high-Miller-index surfaces of cubic materials with terrace, step and kink structures. Surf. Sci. 1980, 92, 489–518. [Google Scholar] [CrossRef] [Green Version]

- Nichols, R.; Bewick, A. SNIFTIRS with a flow cell: The identification of the reaction intermediates in methanol oxidation at Pt anodes. Electrochim. Acta 1988, 33, 1691–1694. [Google Scholar] [CrossRef]

- Zhu, C.; Yin, Z.; Lai, W.; Sun, Y.; Liu, L.; Zhang, X.; Chen, Y.; Chou, L. Fe-Ni-Mo nitride porous nanotubes for full water splitting and Zn-air batteries. Adv. Energy Mater. 2018, 8, 1802327. [Google Scholar] [CrossRef]

- Wang, L.; Cui, S.; Wang, A.Z.; Zhang, X.; Jiang, M.; Chi, L.; Fuchs, H. Multilayer Assemblies of Copolymer PSOH and PVP on the Basis of Hydrogen Bonding. Langmuir 2000, 16, 10490–10494. [Google Scholar] [CrossRef]

- Yin, A.-X.; Min, X.-Q.; Zhang, Y.-W.; Yan, C.-H. Shape-Selective Synthesis and Facet-Dependent Enhanced Electrocatalytic Activity and Durability of Monodisperse Sub-10 nm Pt−Pd Tetrahedrons and Cubes. J. Am. Chem. Soc. 2011, 133, 3816–3819. [Google Scholar] [CrossRef] [PubMed]

- Seger, B.; Kamat, P.V. Electrocatalytically Active Graphene-Platinum Nanocomposites. Role of 2-D Carbon Support in PEM Fuel Cells. J. Phys. Chem. C 2009, 113, 7990–7995. [Google Scholar] [CrossRef]

- Zhang, Z.-C.; Hui, J.-F.; Guo, Z.-G.; Yu, Q.-Y.; Xu, B.; Zhang, X.; Liu, Z.-C.; Xu, C.-M.; Gao, J.-S.; Wang, X. Solvothermal synthesis of Pt–Pd alloys with selective shapes and their enhanced electrocatalytic activities. Nanoscale 2012, 4, 2633–2639. [Google Scholar] [CrossRef]

- Jinli, Z.; Jiao, W.; Yuanyuan, L.; Ning, N.; Junjie, G.; Feng, Y.; Wei, L. High-performance lithium iron phosphate with phosphorus-doped carbon layers for lithium ion batteries. J. Mater. Chem. A 2014, 3, 2043–2049. [Google Scholar] [CrossRef]

- Guo, R.; An, N.; An, S.; Zhang, J.; Chou, K.; Guan, L.; Tian, X. One-Step Preparation of Nitrogen-Doped Platinum-Based Catalysts for Electrocatalytic Oxidation of Ethanol. Catalysts 2021, 11, 1264. [Google Scholar] [CrossRef]

- Antoniassi, R.; Silva, J.; Neto, A.O.; Spinacé, E. Synthesis of Pt+SnO2/C electrocatalysts containing Pt nanoparticles with preferential (100) orientation for direct ethanol fuel cell. Appl. Catal. B Environ. 2017, 218, 91–100. [Google Scholar] [CrossRef]

- Mai, T.P.; Chiku, M.; Higuchi, E.; Inoue, H. Structure-Controlled Rh/Sn/Pt Ternary Catalysts for Complete Oxidation Reaction of Ethanol to Carbon Dioxide. ECS Trans. 2015, 69, 675–681. [Google Scholar] [CrossRef]

- Huang, M.; Jiang, Y.; Jin, C.; Ren, J.; Zhou, Z.; Guan, L. Pt–Cu alloy with high density of surface Pt defects for efficient catalysis of breaking C–C bond in ethanol. Electrochim. Acta 2014, 125, 29–37. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Q.; Yang, W.; Han, K.; Wang, Z.; Zhu, H. Graphene–CeO2 hybrid support for Pt nanoparticles as potential electrocatalyst for direct methanol fuel cells. Electrochim. Acta 2013, 94, 245–251. [Google Scholar] [CrossRef]

- Guo, R.; Qian, F.; An, S.; Zhang, J.; Chou, K.-C.; Ye, J.; Zhou, Z. Effect of Acid Treatment on Electrocatalytic Performance of PtNi Catalyst. Chem. Res. Chin. Univ. 2020, 37, 686–695. [Google Scholar] [CrossRef]

- Liu, H.; Wang, S.; Jia, F. Conversion of commercial Pt/C to “clean” Pt-Cu/C catalyst with high activity toward methanol oxidation. Electrochim. Acta 2015, 184, 331–337. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, X.; Sun, H.; Yang, Y.; Dai, X.; Gao, J.; Li, X.; Zhang, P.; Wang, H.-H.; Yu, N.-F.; et al. Synthesis of Pt-Ni Alloy Nanocrystals with High-Index Facets and Enhanced Electrocatalytic Properties. Angew. Chem. Int. Ed. 2014, 53, 12522–12527. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Y.; Nosheen, F.; Wang, P.; Zhang, J.; Zhuang, J.; Wang, X. Fine Tuning of the Structure of Pt-Cu Alloy Nanocrystals by Glycine-Mediated Sequential Reduction Kinetics. Small 2013, 9, 3063–3069. [Google Scholar] [CrossRef] [PubMed]

- Cong, L.; He, T.; Ji, Y.; Guan, P.; Huang, Y.; Su, W. Synthesis and characterization of IT-electrolyte with perovskite structure La0.8Sr0.2Ga0.85Mg0.15O3−δ by glycine–nitrate combustion method. J. Alloy. Compd. 2003, 348, 325–331. [Google Scholar] [CrossRef]

- Shi, Y.; Ma, Z.-R.; Xiao, Y.-Y.; Yin, Y.-C.; Huang, W.-M.; Huang, Z.-C.; Zheng, Y.-Z.; Mu, F.-Y.; Huang, R.; Shi, G.-Y.; et al. Electronic metal–support interaction modulates single-atom platinum catalysis for hydrogen evolution reaction. Nat. Commun. 2021, 12, 3021. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Yao, Z.; Zhou, Q.; Zhuang, G.; Zhong, X.; Deng, S.; Li, X.; Wang, J. Optimizing Alkyne Hydrogenation Performance of Pd on Carbon in Situ Decorated with Oxygen-Deficient TiO2 by Integrating the Reaction and Diffusion. ACS Catal. 2019, 9, 10656–10667. [Google Scholar] [CrossRef]

- Chen, W.; Gao, W.; Tu, P.; Robert, T.; Ma, Y.; Shan, H.; Gu, X.; Shang, W.; Tao, P.; Song, C.; et al. Neighboring Pt Atom Sites in an Ultrathin FePt Nanosheet for the Efficient and Highly CO-Tolerant Oxygen Reduction Reaction. Nano Lett. 2018, 18, 5905–5912. [Google Scholar] [CrossRef]

| Sample | Angle/° | Crystal Facets |

|---|---|---|

| PVP:Pt = 0:1 | 8.1, 9.5 | {710};{610} |

| PVP:Pt = 25:1 | 9.5, 11.3, 14.0 | {610};{510};{410} |

| PVP:Pt = 50:1 | 18.4, 20.6, 21.8 | {310};{830};{520} |

| PVP:Pt = 75:1 | 14.0, 15.9 | {410};{720} |

| PVP:Pt = 100:1 | 14.0, 15.9 | {410};{720} |

| Sample | ESA (m2/g) | Peak Current Density (mA/cm2) | Steady Current Density (mA/cm2) |

|---|---|---|---|

| Pt/C(JM) | 0.239 | 0.354 | 0.042 |

| PVP:Pt = 0:1 | 1.203 | 1.340 | 0.098 |

| PVP:Pt = 25:1 | 1.651 | 1.797 | 0.212 |

| PVP:Pt = 50:1 | 2.194 | 2.052 | 0.241 |

| PVP:Pt = 75:1 | 1.911 | 1.786 | 0.127 |

| PVP:Pt = 100:1 | 1.641 | 1.599 | 0.099 |

| Sample | Slope k | Activation Energy W (kJ/mol) |

|---|---|---|

| Pt/C (JM) | −8.16 | 67.84 |

| PVP:Pt = 0:1 | −6.62 | 55.04 |

| PVP:Pt = 25:1 | −6.35 | 52.79 |

| PVP:Pt = 50:1 | −5.96 | 49.57 |

| PVP:Pt = 75:1 | −6.16 | 51.21 |

| PVP:Pt = 100:1 | −6.48 | 52.87 |

| Sample | 1-Cycle and 500-Cycle Peak Current Density (mA/cm2) | Current Density Retention Rate/% |

|---|---|---|

| Pt/C (JM) | 0.354/0.221 | 62.50 |

| PVP:Pt = 0:1 | 1.340/0.883 | 65.88 |

| PVP:Pt = 25:1 | 1.797/1.417 | 70.87 |

| PVP:Pt = 50:1 | 2.052/1.727 | 84.14 |

| PVP:Pt = 75:1 | 1.786/1.308 | 73.23 |

| PVP:Pt = 100:1 | 1.599/1.132 | 70.80 |

| Sample | Angle/° | Crystal Face |

|---|---|---|

| Gly:Pt = 0:1 | --- | --- |

| Gly:Pt = 8:1 | 0 | {100} |

| Gly:Pt = 16:1 | 14.0, 15.9 | {410};{720} |

| Gly:Pt = 24:1 | 18.4, 20.6, 21.8 | {310};{830};{520} |

| Gly:Pt = 32:1 | 15.9, 18.4, 21.8 | {720};{310};{830} |

| Sample | ESA (m2/g) | Peak Current Density (mA/cm2) | Steady Current Density (mA/cm2) |

|---|---|---|---|

| Pt/C(JM) | 0.239 | 0.354 | 0.042 |

| Gly:Pt = 0:1 | 1.086 | 0.906 | 0.099 |

| Gly:Pt = 8:1 | 1.352 | 1.543 | 0.142 |

| Gly:Pt = 16:1 | 1.462 | 1.741 | 0.198 |

| Gly:Pt = 24:1 | 2.194 | 2.052 | 0.241 |

| Gly:Pt = 32:1 | 1.761 | 1.868 | 0.212 |

| Sample | Slope k | Activation Energy W (kJ/mol) |

|---|---|---|

| Pt/C(JM) | −8.16 | 67.86 |

| Gly:Pt = 0:1 | −6.66 | 55.34 |

| Gly:Pt = 8:1 | −6.57 | 54.69 |

| Gly:Pt = 16:1 | −6.42 | 53.39 |

| Gly:Pt = 24:1 | −5.96 | 49.57 |

| Gly:Pt = 32:1 | −6.13 | 50.98 |

| Sample | 1-Cycle and 500-Cycle Peak Current Density (mA/cm2) | Current Density Retention rate/% |

|---|---|---|

| Pt/C(JM) | 0.354/0.221 | 62.50 |

| Gly:Pt = 0:1 | 0.906/0.595 | 65.63 |

| Gly:Pt = 8:1 | 1.543/1.090 | 70.64 |

| Gly:Pt = 16:1 | 1.741/1.359 | 78.05 |

| Gly:Pt = 24:1 | 2.052/1.727 | 84.14 |

| Gly:Pt = 32:1 | 1.868/1.373 | 73.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, R.; An, N.; Huang, Y.; Guan, L.; Zhang, G.; Zhu, G.; Liu, Z. One-Pot Synthesis of Pt High Index Facets Catalysts for Electrocatalytic Oxidation of Ethanol. Nanomaterials 2022, 12, 4451. https://doi.org/10.3390/nano12244451

Guo R, An N, Huang Y, Guan L, Zhang G, Zhu G, Liu Z. One-Pot Synthesis of Pt High Index Facets Catalysts for Electrocatalytic Oxidation of Ethanol. Nanomaterials. 2022; 12(24):4451. https://doi.org/10.3390/nano12244451

Chicago/Turabian StyleGuo, Ruihua, Na An, Yarong Huang, Lili Guan, Guofang Zhang, Guofu Zhu, and Zhaogang Liu. 2022. "One-Pot Synthesis of Pt High Index Facets Catalysts for Electrocatalytic Oxidation of Ethanol" Nanomaterials 12, no. 24: 4451. https://doi.org/10.3390/nano12244451