Development of Bionanocomposites Based on Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/PolylActide Blends Reinforced with Cloisite 30B

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

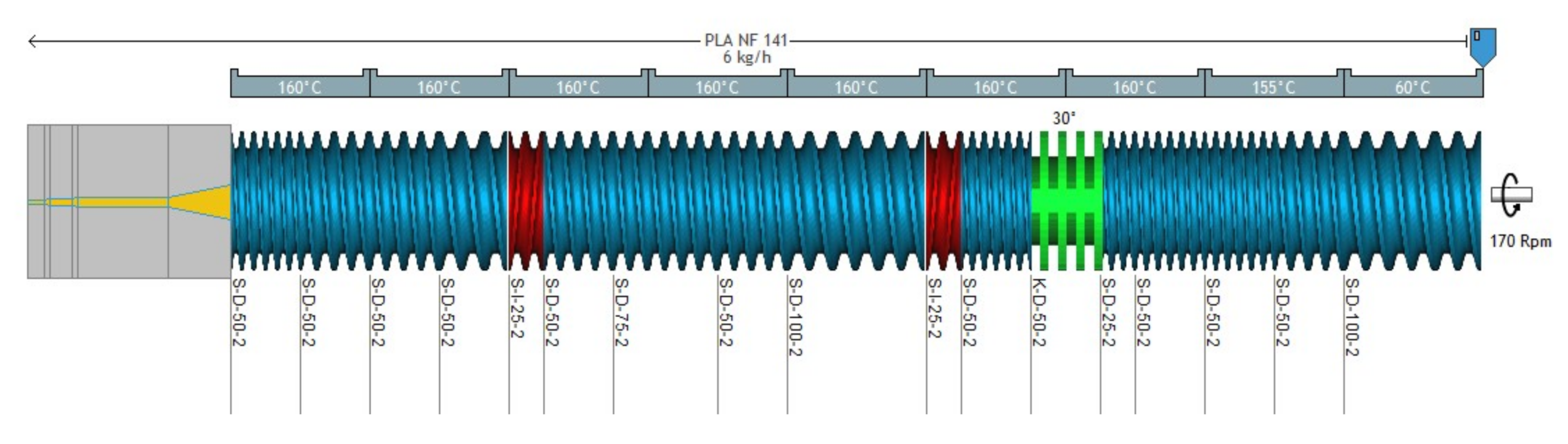

2.2. Preparation of the Blends, Films and Nanofibers

2.3. Spectral and Thermal Characterizations

2.4. Contact Angle

2.5. Tensile Tests

3. Results

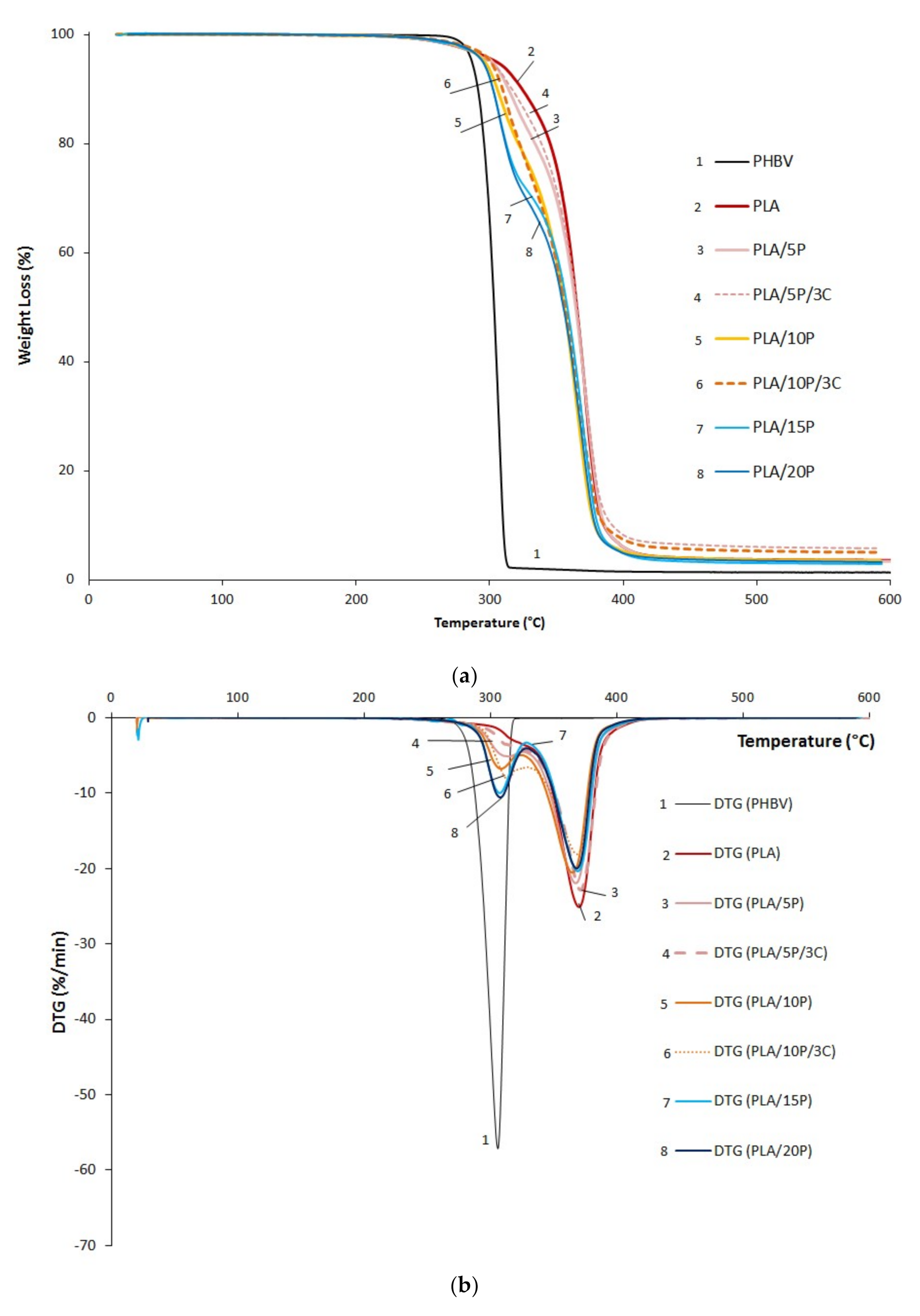

3.1. Thermal Degradation

3.2. Thermal and Crystallization Behavior of PLA/PHBV Blends

3.3. FTIR

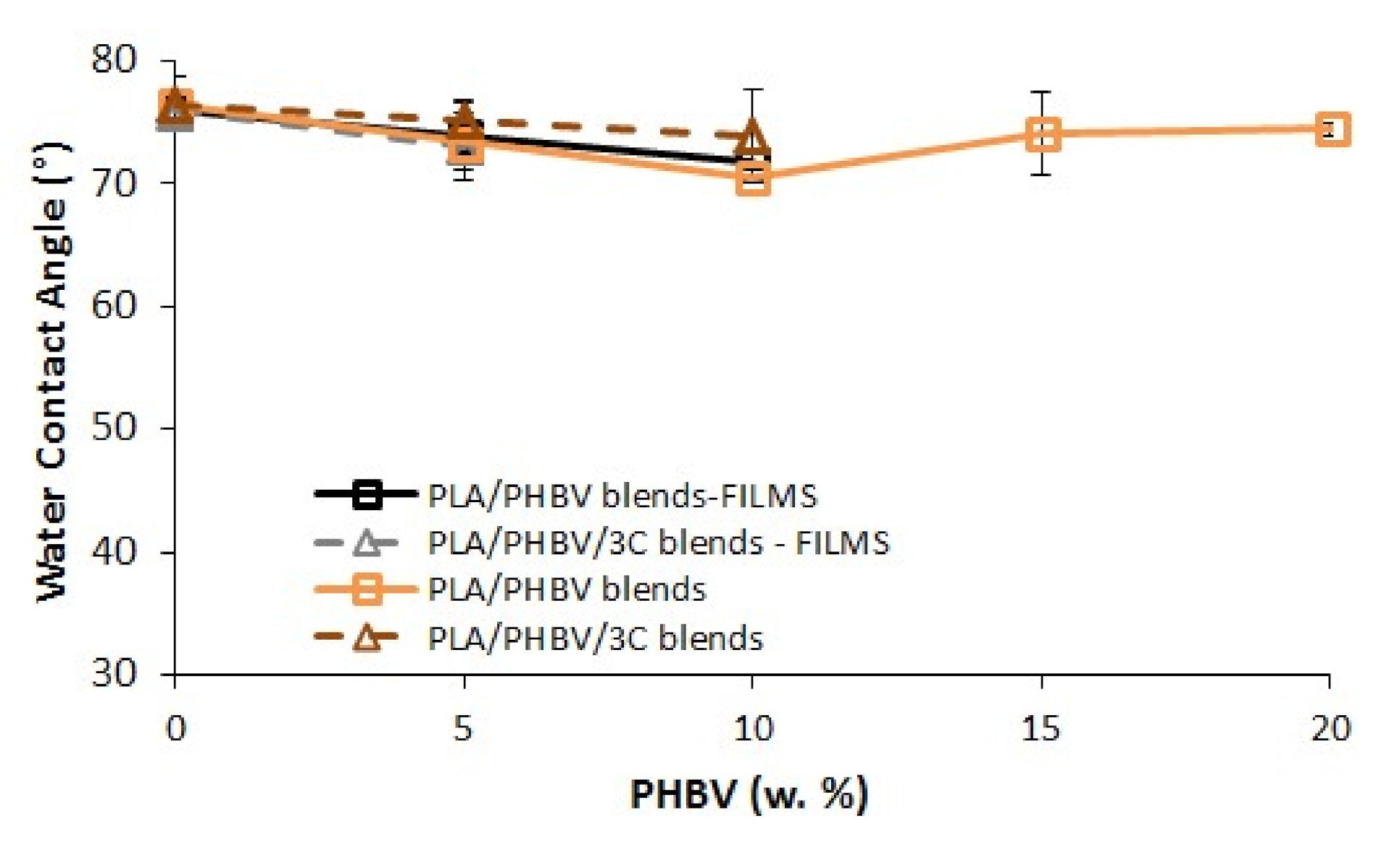

3.4. Contact Angle

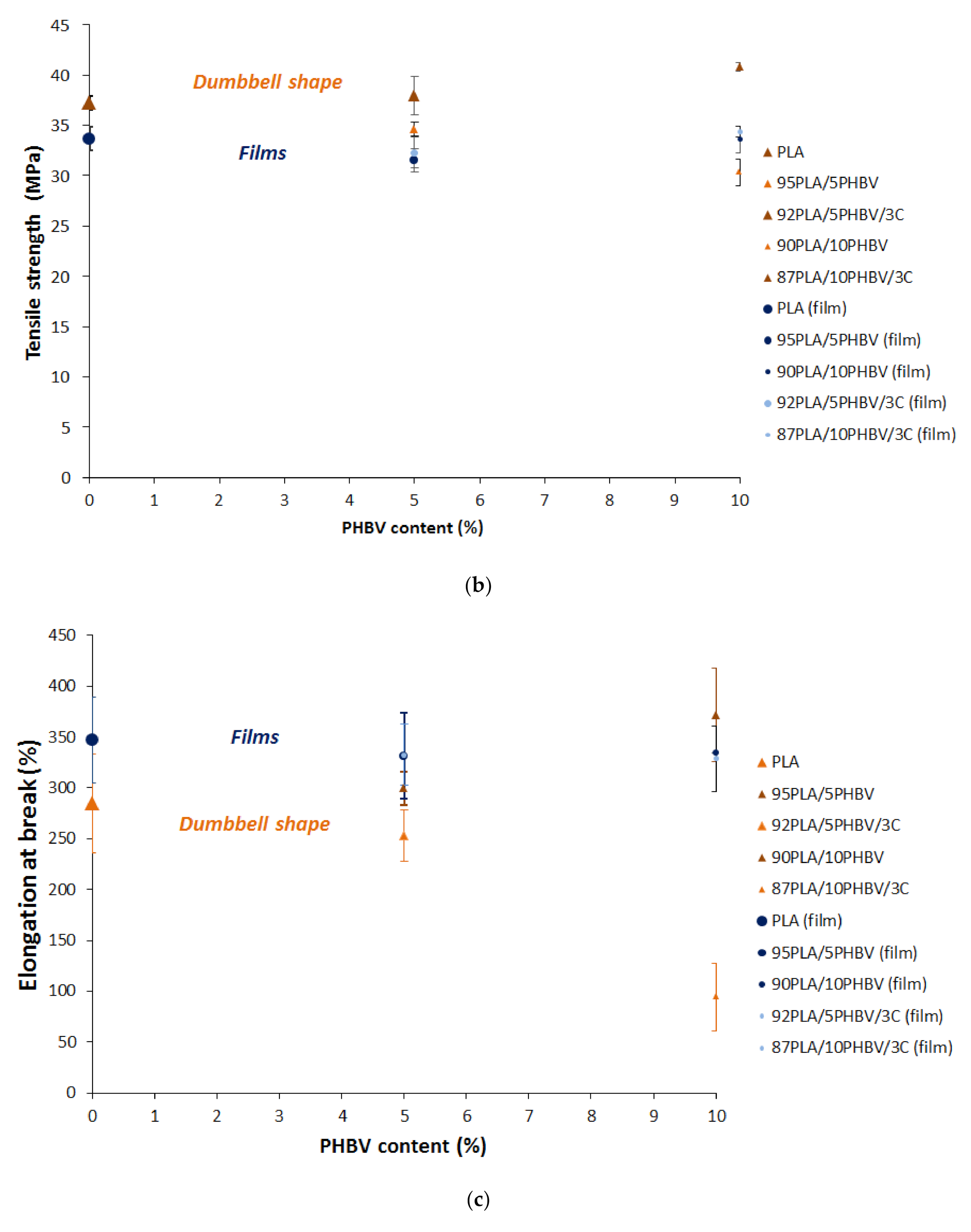

3.5. Tensile Properties

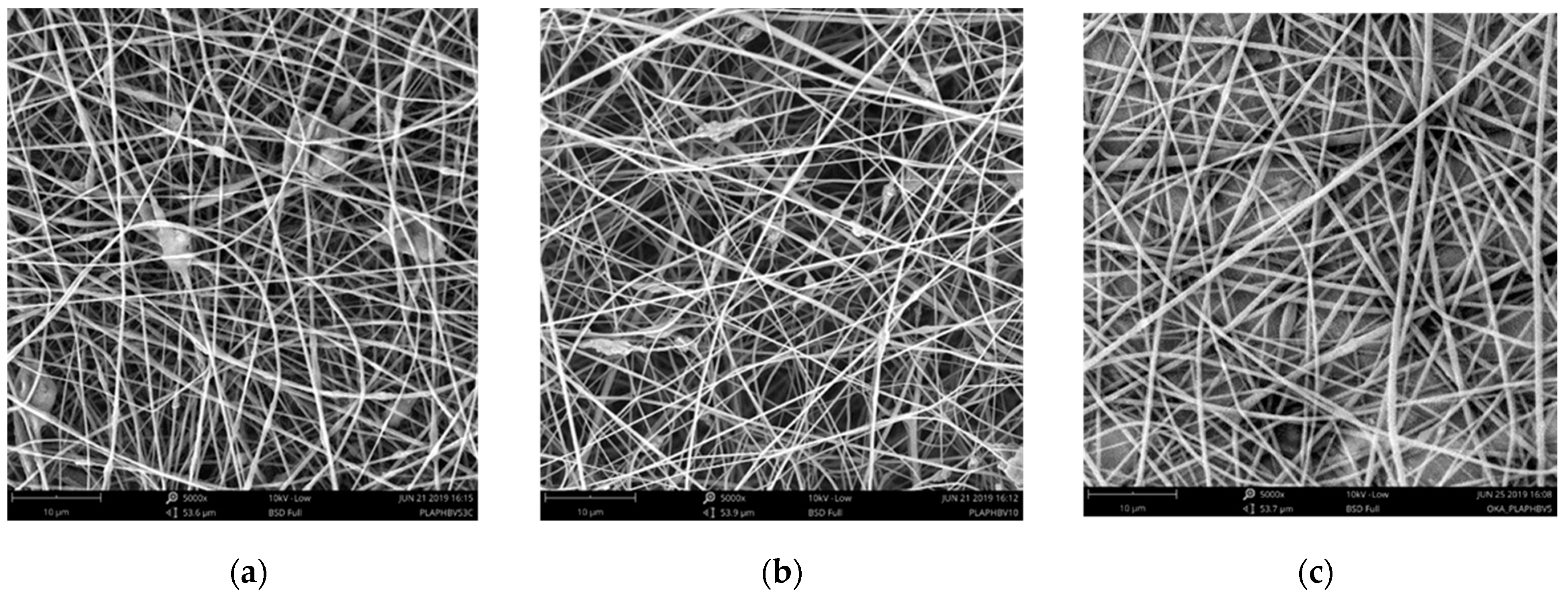

3.6. Electrospun Nanofibers

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Laycock, B.; Halley, P.; Pratt, S.; Werker, A.; Lant, P. The chemomechanical properties of microbial polyhydroxyalkanoates. Prog. Polym. Sci. 2014, 39, 397–442. [Google Scholar] [CrossRef]

- Tarrahi, R.; Fathi, Z.; Seydibeyoğlu, M.Ö.; Doustkhah, E.; Khataee, A. Polyhydroxyalkanoates (PHA): From production to nanoarchitecture. Int. J. Biol. Macromol. 2020, 146, 596–619. [Google Scholar] [PubMed]

- Zembouai, I.; Bruzaud, S.; Kaci, M.; Benhamida, A.; Corre, Y.M.; Grohens, Y.; Taguet, A.; Lopez-Cuesta, J.M. Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/Polylactide Blends: Thermal Stability, Flammability and Thermo-Mechanical Behavior. J. Polym. Environ. 2014, 22, 131–139. [Google Scholar] [CrossRef]

- Ferreira, B.M.P.; Zavaglia, C.A.C.; Duek, E.A.R. Films of PLLA/PHBV: Thermal, morphological, and mechanical characterization. J. Appl. Polym. Sci. 2002, 86, 2898–2906. [Google Scholar]

- Zembouai, I.; Kaci, M.; Bruzaud, S.; Benhamida, A.; Corre, Y.M.; Grohens, Y. A study of morphological, thermal, rheological and barrier properties of Poly(3-hydroxybutyrate-Co-3-Hydroxyvalerate)/polylactide blends prepared by melt mixing. Polym. Test. 2013, 32, 842–851. [Google Scholar]

- Yang, J.; Zhu, H.; Zhang, C.; Jiang, Q.; Zhao, Y.; Chen, P.; Wang, D. Transesterification induced mechanical properties enhancement of PLLA/PHBV bio-alloy. Polymer 2016, 83, 230–238. [Google Scholar] [CrossRef]

- Paul, M.-A.; Alexandre, M.; Degée, P.; Henrist, C.; Rulmont, A.; Dubois, P. New nanocomposite materials based on plasticized poly(L-lactide) and organo-modified montmorillonites: Thermal and morphological study. Polymer 2003, 44, 443–450. [Google Scholar] [CrossRef]

- Ozdemir, E.; Hacaloglu, J. Characterizations of PLA-PEG blends involving organically modified montmorillonite. J. Anal. Appl. Pyrolysis 2017, 127, 343–349. [Google Scholar] [CrossRef]

- Zembouai, I.; Kaci, M.; Zaidi, L.; Bruzaud, S. Combined effects of Sepiolite and Cloisite 30B on morphology and properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/polylactide blends. Polym. Degrad. Stab. 2018, 153, 47–52. [Google Scholar] [CrossRef]

- Sanhueza, C.; Acevedo, F.; Rocha, S.; Villegas, P.; Seeger, M.; Navia, R. Polyhydroxyalkanoates as biomaterial for electrospun scaffolds. Int. J. Biol. Macromol. 2019, 124, 102–110. [Google Scholar] [PubMed]

- Mutlu, G.; Calamak, S.; Ulubayram, K.; Guven, E. Curcumin-Loaded electrospun PHBV nanofibers as potential wound-dressing material. J. Drug Deliv. Sci. Technol. 2018, 43, 185–193. [Google Scholar] [CrossRef]

- Wang, S.; Ma, P.; Wang, R.; Wang, S.; Zhang, Y.; Zhang, Y. Mechanical, thermal and degradation properties of poly(d,l-lactide)/poly(hydroxybutyrate-co-hydroxyvalerate)/poly(ethylene glycol) blend. Polym. Degrad. Stab. 2008, 93, 1364–1369. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; López, D.; Kenny, J.M.; Peponi, L. Development of flexible materials based on plasticized electrospun PLA-PHB blends: Structural, thermal, mechanical and disintegration properties. Eur. Polym. J. 2015, 73, 433–446. [Google Scholar]

- Lim, S.T.; Hyun, Y.H.; Choi, H.J.; Jhon, M.S. Synthetic Biodegradable aliphatic polyester/montmorillonite nanocomposites. Chem. Mater. 2002, 14, 1839–1844. [Google Scholar] [CrossRef]

- Qiu, Z.; Ikehara, T.; Nishi, T. Miscibility and crystallization behaviour of biodegradable blends of two aliphatic polyesters. Poly(3-hydroxybutyrate-co-hydroxyvalerate) and poly(butylene succinate) blends. Polymer 2003, 44, 7519–7527. [Google Scholar] [CrossRef]

- Jiang, N.; Abe, H. Morphological changes in poly(L-lactide)/poly(3-hydroxybutyrate- co-3-hydroxyvalerate) blends induced by different miscibility. Polymer 2015, 66, 259–267. [Google Scholar] [CrossRef]

- Armentano, I.; Fortunati, E.; Burgos, N.; Dominici, F.; Luzi, F.; Fiori, S.; Jiménez, A.; Yoon, K.; Ahn, J.; Kang, S.; et al. Bio-Based PLA_PHB plasticized blend films: Processing and structural characterization. LWT Food Sci. Technol. 2015, 64, 980–988. [Google Scholar]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; López, J.; Kenny, J.M. Bionanocomposite films based on plasticized PLA-PHB/cellulose nanocrystal blends. Carbohydr. Polym. 2015, 121, 265–275. [Google Scholar] [PubMed] [Green Version]

- Noda, I.; Satkowski, M.M.; Dowrey, A.E.; Marcott, C. Polymer Alloys of Nodax Copolymers and Poly(lactic acid). Macromol. Biosci. 2004, 4, 269–275. [Google Scholar] [PubMed]

| Sample | PLA NF 141 (wt.%) | PHBV (wt.%) | C30B (wt.%) |

|---|---|---|---|

| PLA | 100 | - | - |

| PLA/5P | 95 | 5 | - |

| PLA/5P/3C | 92 | 5 | 3 |

| PLA/10P | 90 | 10 | - |

| PLA/10P/3C | 87 | 10 | 3 |

| PLA/15P | 85 | 15 | - |

| PLA/20P | 80 | 20 | - |

| Sample | T5% (°C) | T10% (°C) | T50% (°C) | Char600 °C (%) |

|---|---|---|---|---|

| PLA | 301 | 323 | 365 | 3.6 |

| PLA/5P | 302 | 314 | 364 | 3.4 |

| PLA/5P/3C | 300 | 317 | 365 | 5.8 |

| PLA/10P | 296 | 306 | 356 | 3.5 |

| PLA/10P/3C | 300 | 309 | 356 | 5.0 |

| PLA/15P | 291 | 303 | 358 | 2.9 |

| PLA/20P | 293 | 302 | 355 | 3.3 |

| PHBV | 287 | 291 | 306 | 1.3 |

| Sample | Tc (°C) | ΔHc (J.g−1) | Tm1 (°C) | ΔHm1 (J.g−1) | Tm2 (°C) | ΔHm2 (J.g−1) | Tm3 (°C) | ΔHm3 (J.g−1) |

|---|---|---|---|---|---|---|---|---|

| PLA | 89.4 | 21.0 | 145.9 | 2.5 | 156.7 | 19.4 | - | - |

| PLA/5P | 86.3 | 20.3 | 143.7 | 1.6 | 156.3 | 22.6 | - | - |

| PLA/5P/3C | 87.4 | 18.2 | 145.3 | 1.5 | 158.2 | 18.4 | 171.8 | 0.50 |

| PLA/10P | 85.7 | 15.5 | 144.1 | 1.6 | 158.1 | 17.2 | 172.1 | 0.60 |

| PLA/10P/3C | 84.0 | 17.8 | 145.5 | 0.3 | 157.9 | 15.9 | 172.3 | 3.90 |

| PLA/15P | 85.4 | 15.9 | 144.0 | 1.1 | 155.4 | 16.7 | 171.6 | 3.40 |

| PLA/20P | 85.3 | 16.1 | 145.3 | 0.5 | 157.2 | 14.6 | 173.5 | 2.50 |

| PHBV | 94.7 | 76.9 | 138.1 | 9.8 | 172.5 | 80.4 | - | - |

| Sample | Shape | C30B (%) | Tensile Strength (MPa) | Young modulus (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| PLA | film | - | 33.7 ± 0.7 | 252 ± 11 | 347 ± 49 |

| dumbbell | - | 37.3 ± 1.2 | 1981 ± 107 | 285 ± 42 | |

| 95PLA/5PHBV | film | - | 31.5 ± 1.5 | 468 ± 66 | 331 ± 27 |

| film | 3 | 32.3 ± 1.0 | 762 ± 81 | 333 ± 33 | |

| dumbbell | - | 34.7 ± 0.7 | 1888 ± 174 | 299 ± 16 | |

| dumbbell | 3 | 37.9 ± 1.9 | 3043 ± 157 | 253 ± 35 | |

| 90PLA/10PHBV | film | - | 33.6 ± 2.2 | 811 ± 87 | 334 ± 18 |

| film | 3 | 34.4 ± 0.5 | 1630 ± 41 | 329 ± 32 | |

| dumbbell | - | 30.4 ± 1.3 | 1703 ± 123 | 371 ± 46 | |

| dumbbell | 3 | 40.8 ± 0.4 | 3386 ± 97 | 95 ± 33 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lacoste, C.; Gallard, B.; Lopez-Cuesta, J.-M.; Ipek Kalaoglu-Altan, O.; De Clerck, K. Development of Bionanocomposites Based on Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/PolylActide Blends Reinforced with Cloisite 30B. J. Funct. Biomater. 2020, 11, 64. https://doi.org/10.3390/jfb11030064

Lacoste C, Gallard B, Lopez-Cuesta J-M, Ipek Kalaoglu-Altan O, De Clerck K. Development of Bionanocomposites Based on Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/PolylActide Blends Reinforced with Cloisite 30B. Journal of Functional Biomaterials. 2020; 11(3):64. https://doi.org/10.3390/jfb11030064

Chicago/Turabian StyleLacoste, Clément, Benjamin Gallard, José-Marie Lopez-Cuesta, Ozlem Ipek Kalaoglu-Altan, and Karen De Clerck. 2020. "Development of Bionanocomposites Based on Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/PolylActide Blends Reinforced with Cloisite 30B" Journal of Functional Biomaterials 11, no. 3: 64. https://doi.org/10.3390/jfb11030064